Door handle assembly of a motor vehicle

A technology for car door handles and facilities, which is applied to the spherical handle of the wing leaf, the vehicle lock, and the handle of the wing leaf. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

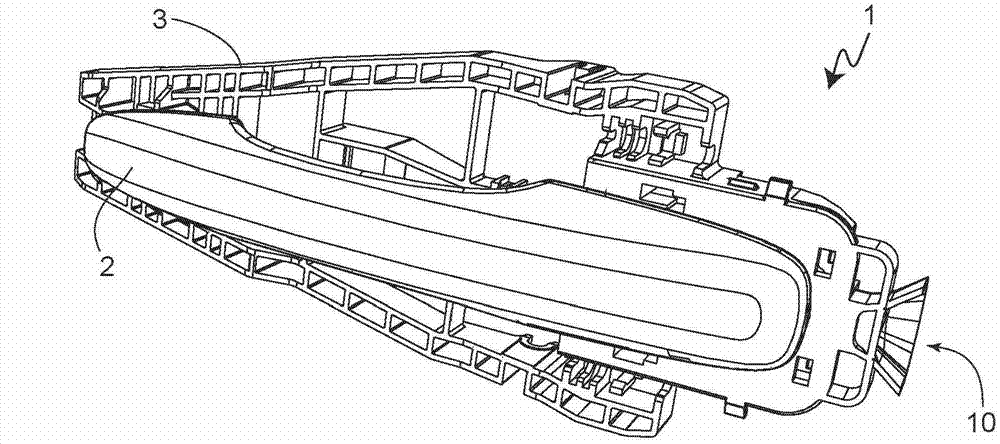

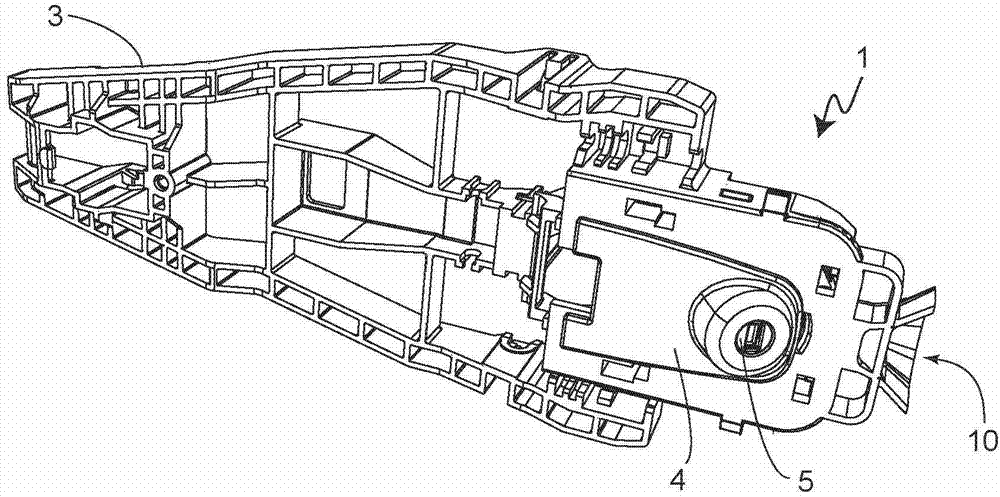

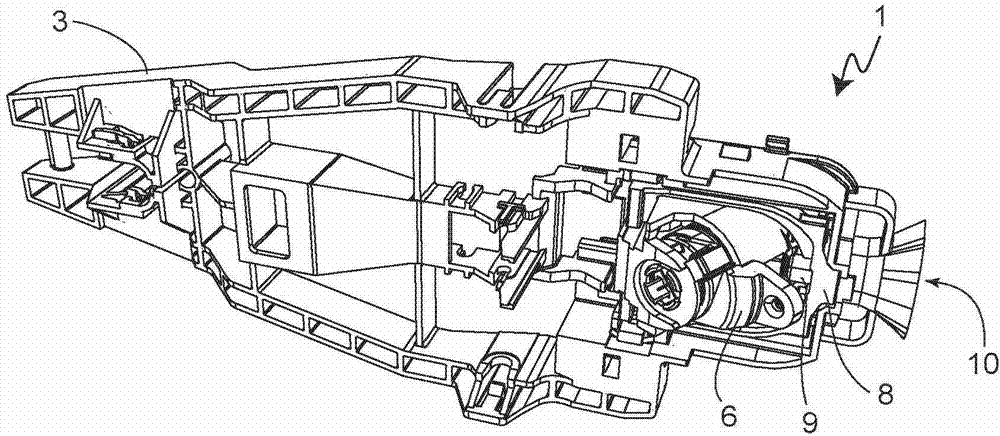

[0031] exist Figure 1 to Figure 4 A door handle arrangement 1 according to the invention of a vehicle is shown in various views, wherein figure 1 , figure 2 as well as Figure 4 shows a stereoscopic front view, conversely, in image 3 What can be seen in is the perspective rear view. The door handle arrangement 1 is fastened to a vehicle wall (not shown in the figures) and comprises a support frame 3 and a handle 2 which is rotatably mounted on the support frame 3 and which can be pivoted between a rest position and an actuating position. In addition to housing the handle 2, the support frame 3 also serves to accommodate the door handle assembly. The carrier 3 is mounted on the vehicle side and in particular on the inside behind a door panel, wherein an opening in the door panel makes it possible, for example, to attach the handle 2 from the outside. At least in its rest position, the handle 2 covers a lock cylinder housing 4 in which a lock cylinder 5 is arranged and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com