Differential case vehicle inner spherical surface two-side pressing clamp

A kind of differential shell car and fixture technology, applied in the direction of clamping, clamping device, manufacturing tool, etc., can solve the problems of large overall structure of the fixture, low clamping efficiency, and the center of gravity and the center of gravity are not coincident, so as to avoid excessive centrifugal force. , accurate positioning, fast clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

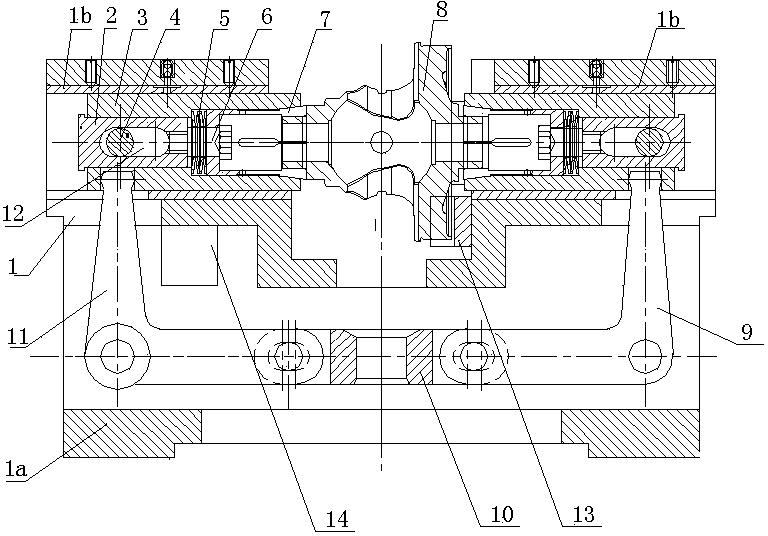

[0014] Such as figure 1 The shown one kind of double-sided compression fixture of the differential shell car ball includes a fixture body 1, and the rear end of the fixture body 1 is provided with a connecting flange part 1a (during installation, it is installed on the main shaft of the lathe through the connecting flange part 1a), The front end of the clamp body is symmetrically provided with a boss 1b, and an elastic sleeve clamping mechanism is symmetrically arranged on the boss 1b;

[0015] The structure of the elastic sleeve clamping mechanism: the mounting hole of the boss 1b is slidably connected with the pressure sleeve 3, and the pressure sleeve 3 is provided with a stepped hole, and the stepped hole is composed of the elastic sleeve installation cavity at the inner end and the connecting column installation cavity at the outer end. The elastic sleeve 7 is installed in the installation cavity of the elastic sleeve, the connecting column 2 is installed in the installat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com