Length processing tool of round bar member

A technology of round rods and jigs, applied in the field of mechanical processing, can solve the problems of high clamping frequency, low production efficiency, and troublesome operation, and achieve the effects of reducing the number of errors, simple clamping methods, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

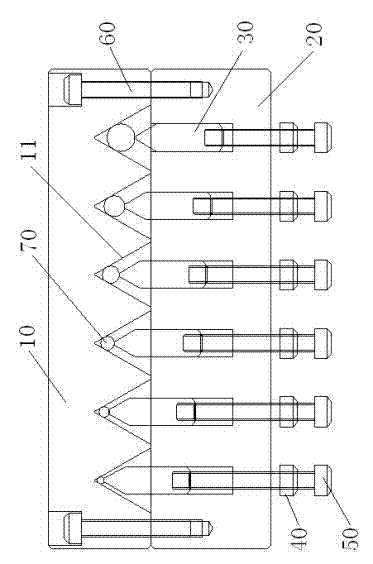

[0014] see figure 1 , the embodiment of the present invention includes:

[0015] A length processing jig for circular rods, comprising: a main body block 10, a support block 20, a clamping block 30 and a lock nut 40, the lower end of the main body block 10 is provided with a number of evenly arranged V-shaped grooves 11, The main body block 10 is docked with the support block 20 and fixed by nuts 60. The support block 20 is provided with a number of grooves corresponding to the V-shaped grooves 11 (not shown in the figure), and the clamping block 30 is set in the groove, the head of the clamping block 30 is a tapered structure, and the clamping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com