Milling machine fixture for machining internal chute of ring part and processing method

A technology for ring parts and milling machine fixtures, applied in milling machine equipment, manufacturing tools, details of milling machine equipment, etc., can solve problems such as large equipment limitations, and achieve the effects of low production cost, convenient clamping and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

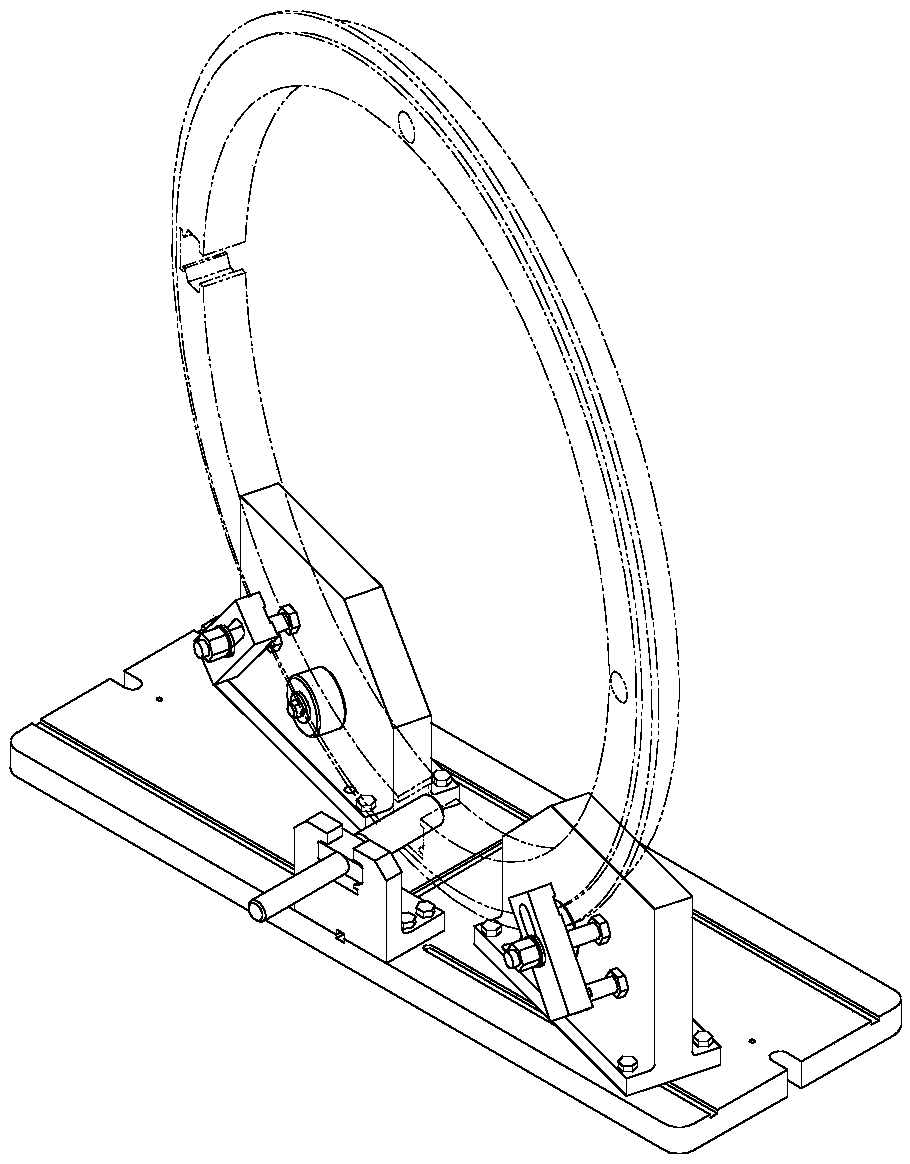

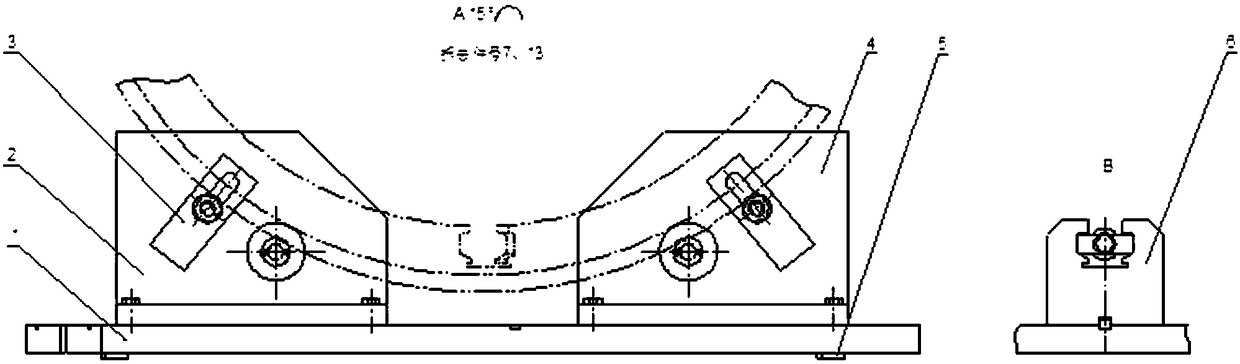

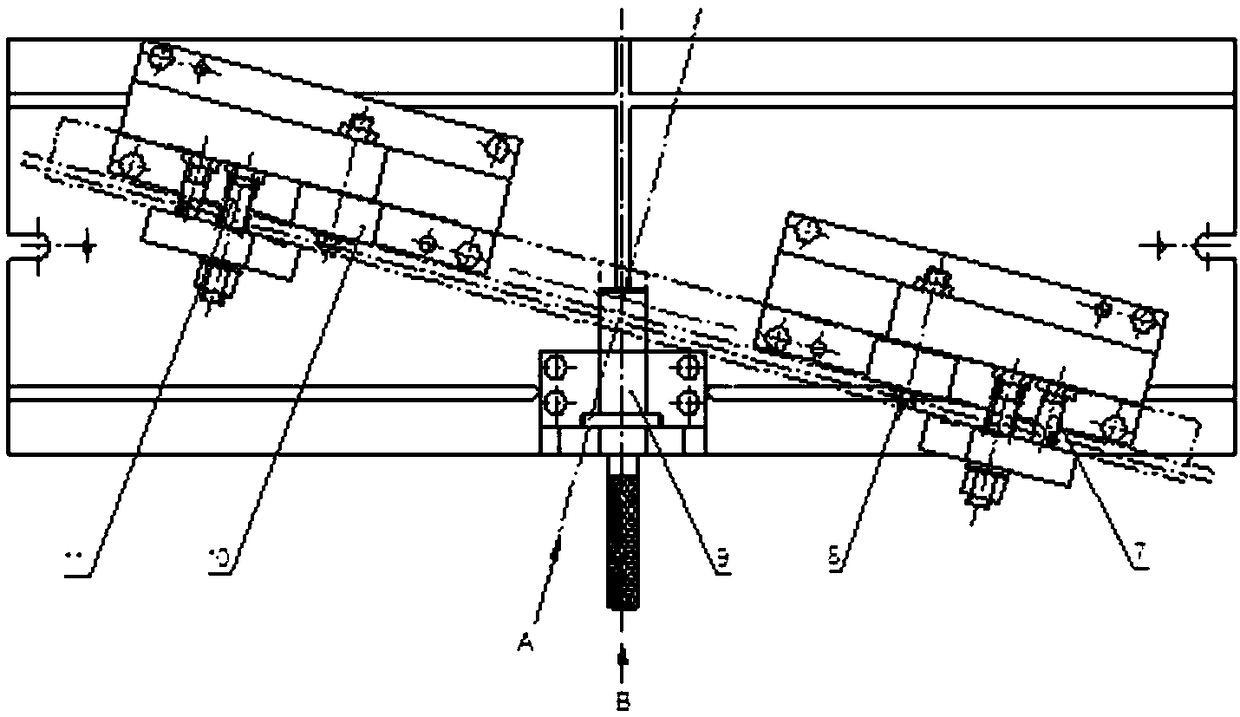

[0039] see figure 1 — Figure 13, the milling machine fixture for processing the internal chute of ring parts according to the present invention is especially suitable for milling the internal chute of medium-sized ring parts. Positioning key 5, tool setting block 6, adjustment support 7, roller shaft 8, positioning pin 9, roller 10. The combination of the first support 2 and the second support 4 forms the clamping body, which are respectively fixed on the two ends of the bottom plate 1 along a straight line according to the angle requirements of the part processing, and are connected with the bottom plate 1 using the hexagon head bolt M10 and the cylindrical pin Φ10; The block 6 is fixed at the middle position of the lower part of the base plate 1 with a hexagon head bolt M10, and the position between the tool setting block 6 and the base plate 1 is positioned by the positioning key 5, and the positioning key 5 is fixed in the rectangular keyway on the lower surface of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com