Laser cutting device for saw web base body

A laser cutting and matrix technology, which is applied in the tool manufacturing of sawing machines, auxiliary devices, metal sawing equipment, etc. wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

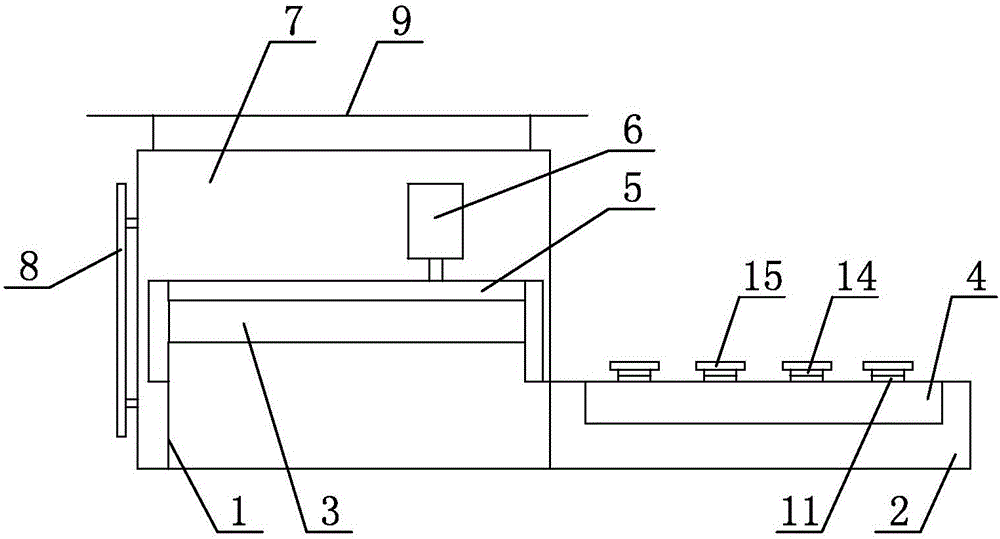

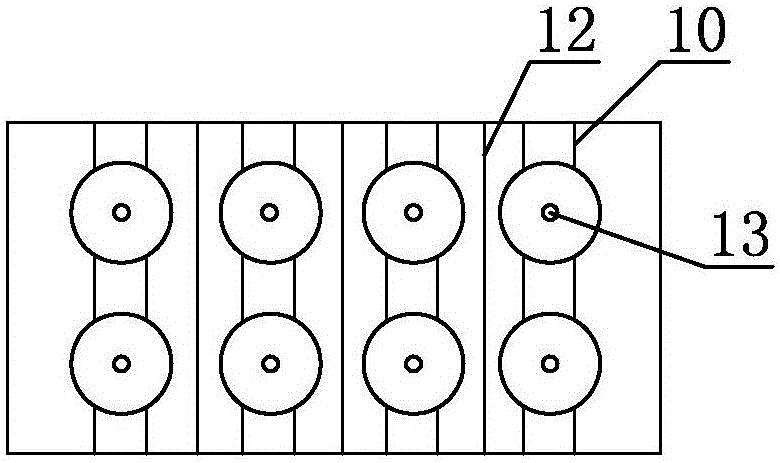

[0017] Such as figure 1 and figure 2 As shown, the present invention is provided with a first base 1 and a second base 2, and the first base 1 and the second base 2 are adjacent. The first base 1 is provided with a first workbench 3 , and the second base 2 is provided with a second workbench 4 . A dustproof cover 5 is also provided on the first base 1 , and the dustproof cover 5 is arranged above the first workbench 3 . A laser cutting machine 6 is also provided on the first base 1 , and the laser cutting machine 6 cuts the circular plate on the first workbench 3 through the dust cover 5 .

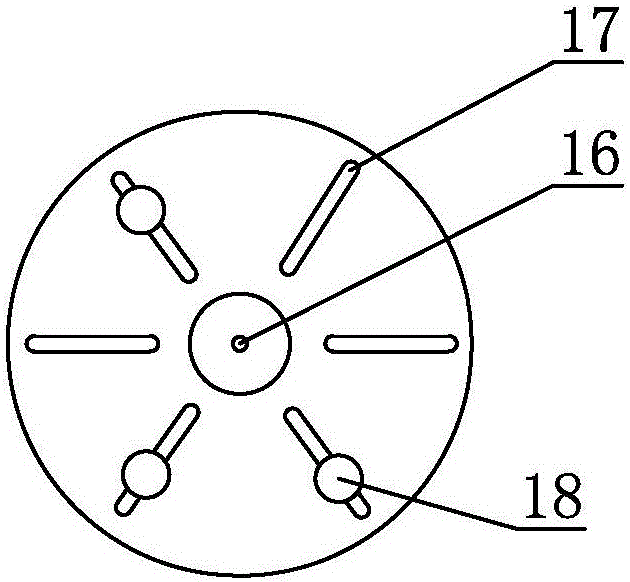

[0018] The outer periphery of the first base 1 is provided with a dust-proof house 7 , and the cutting of the circular plate by the laser cutting machine 6 is carried out in the dust-proof house 7 . One side of the dust-proof house 7 is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com