Five-axis multi-head polishing machine

A processing machine, multi-head technology, applied in surface polishing machine tools, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of space waste, affecting work efficiency, etc., to improve production capacity, optimize occupied space, and reduce occupancy effect of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] specific implementation plan

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

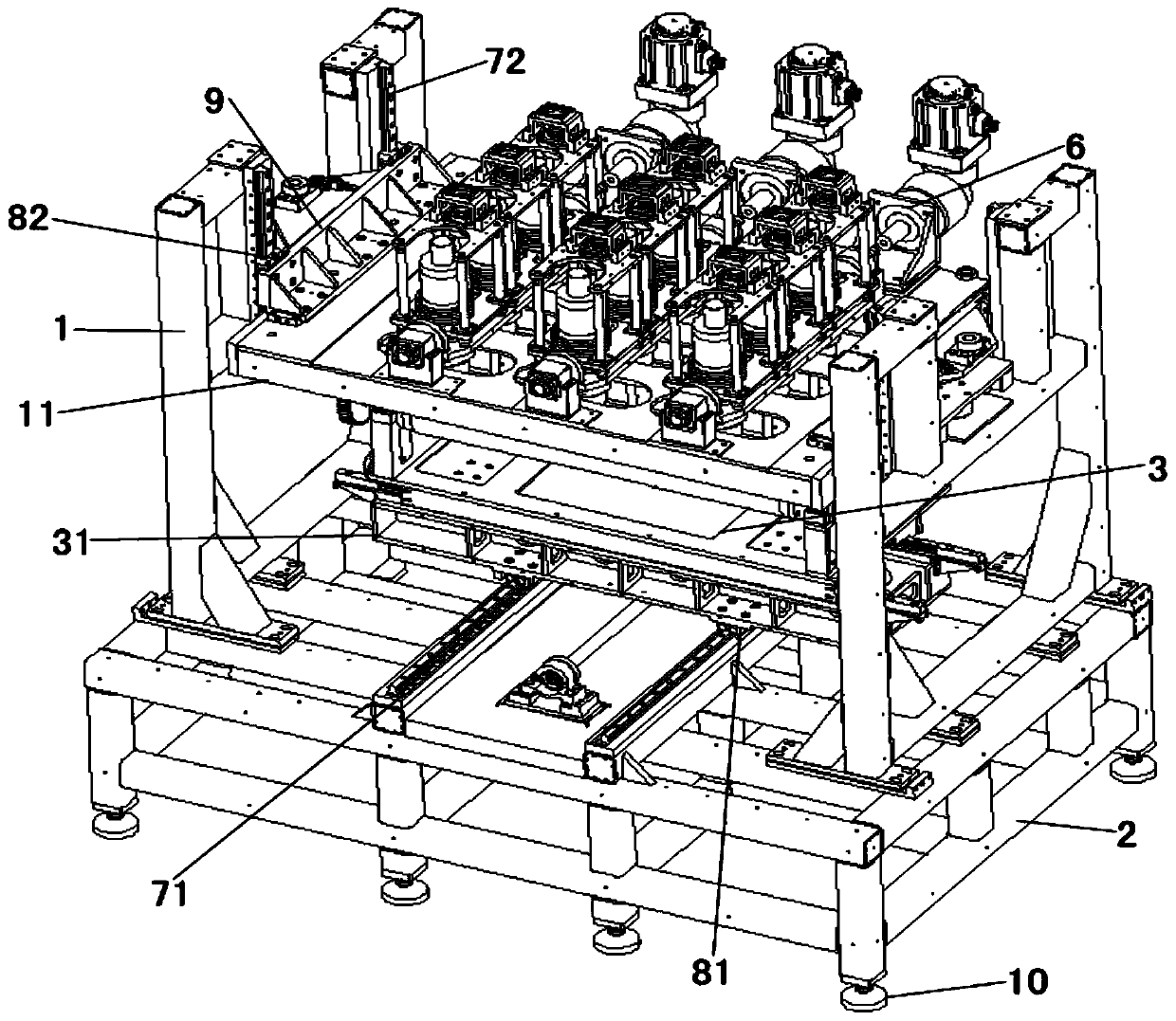

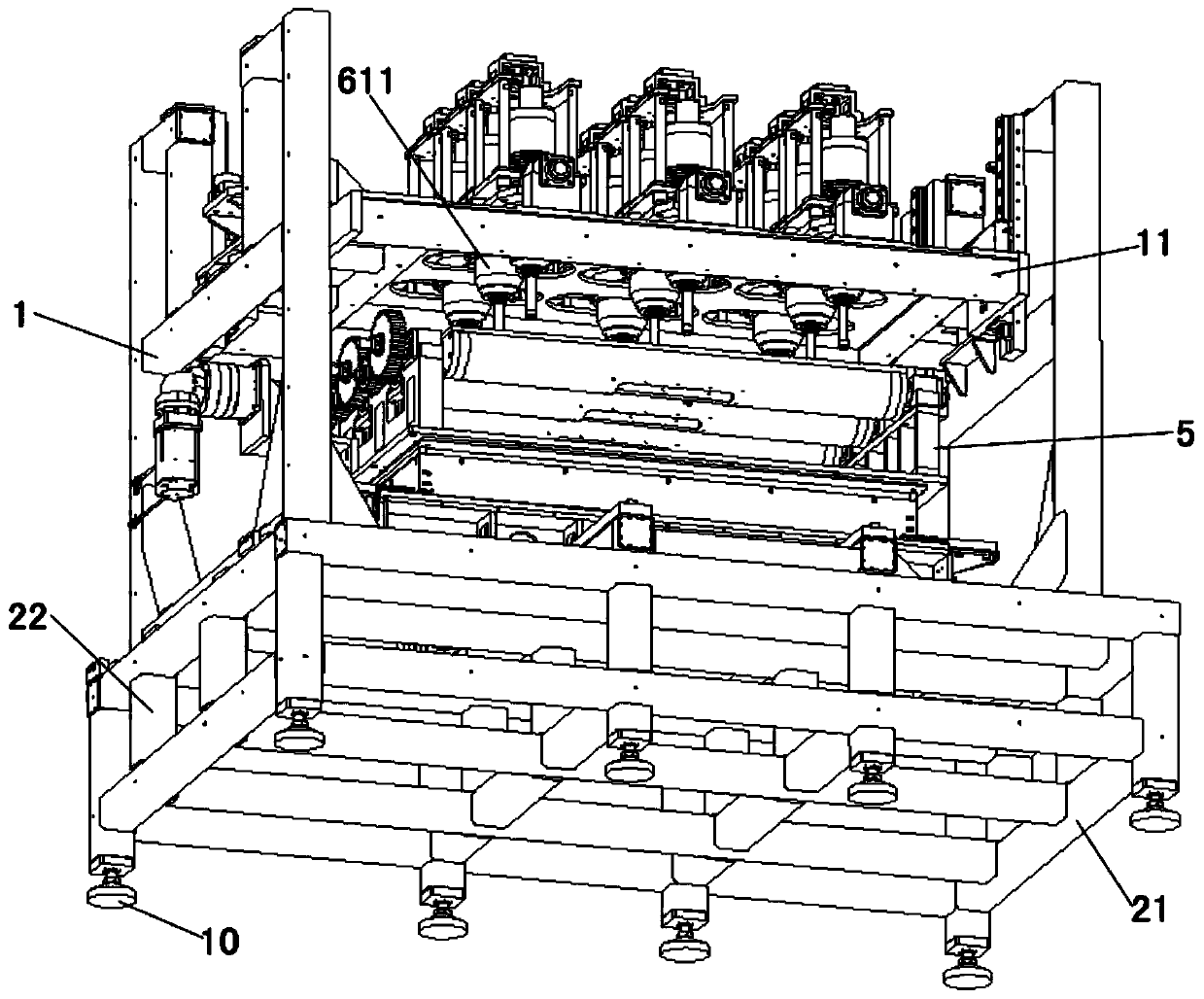

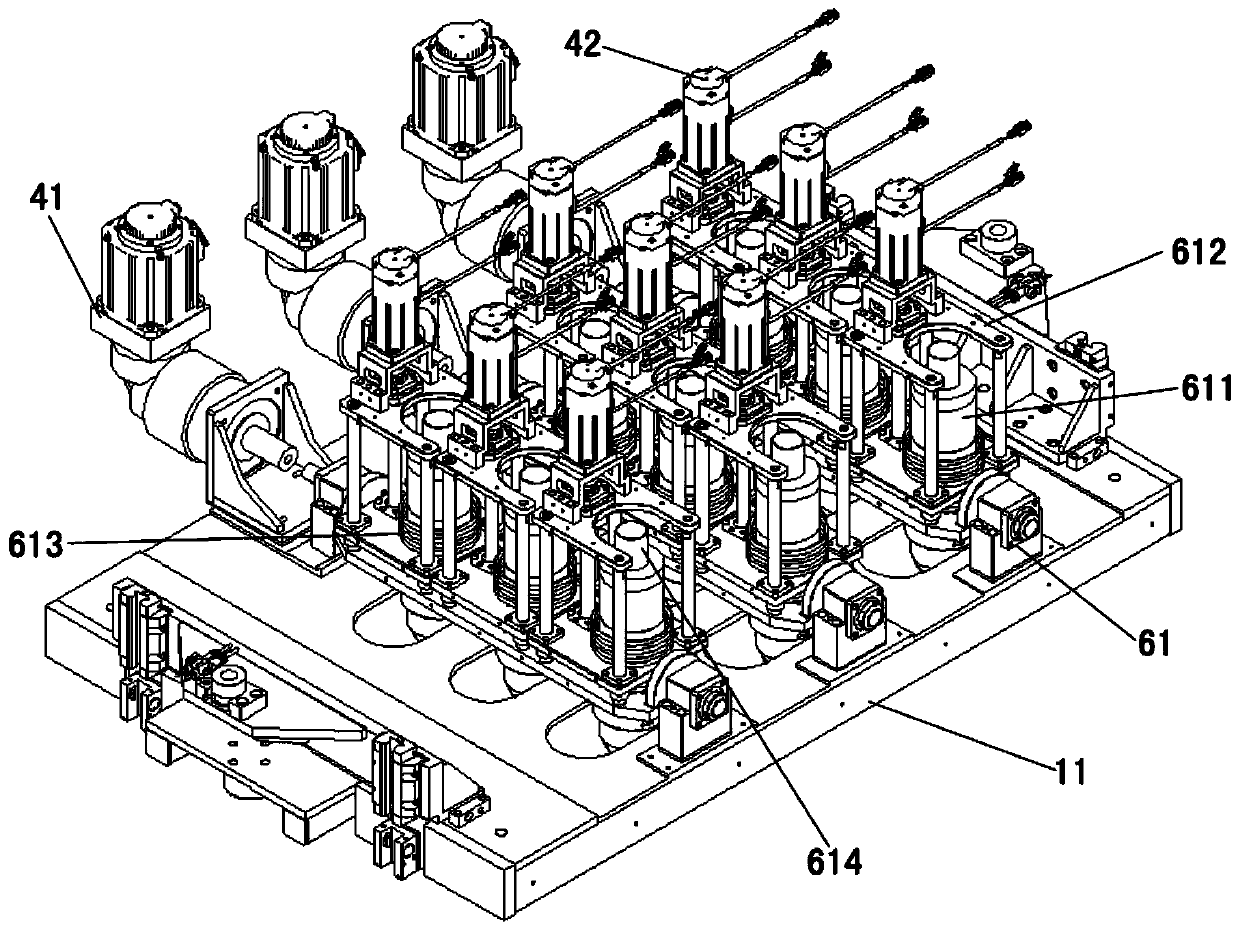

[0018] Such as figure 1 with 2 , a five-axis multi-head polishing machine, including a main frame 1, a base frame 2 and a workbench 3, the base frame 2 is fixedly connected below the main frame 1, and a balance beam frame 11 is arranged on the upper part of the main frame 1, so The upper part of the balance beam frame 11 is fixedly connected with the B-axis rotation module 6, the side of the B-axis rotation module 6 is provided with a servo motor 41, the workbench 3 is arranged in the middle of the main frame 1, and the workbench 3 is arranged at intervals above There is an A-axis rotation module 5, a servo motor 41 is connected to the side of the A-axis rotation module 5, a sliding seat 31 is provided on the bottom surface of the workbench 3, a line rail slider 1 71 is provided on the bottom of the main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com