A Control Method for Realizing Efficient Dry Running in Numerical Control System

A control method and numerical control system technology, applied in the direction of digital control, electrical program control, etc., can solve the problems of low actual utilization rate of equipment and long non-processing time, and achieve the goals of reducing non-processing time, safe operation and improving use efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

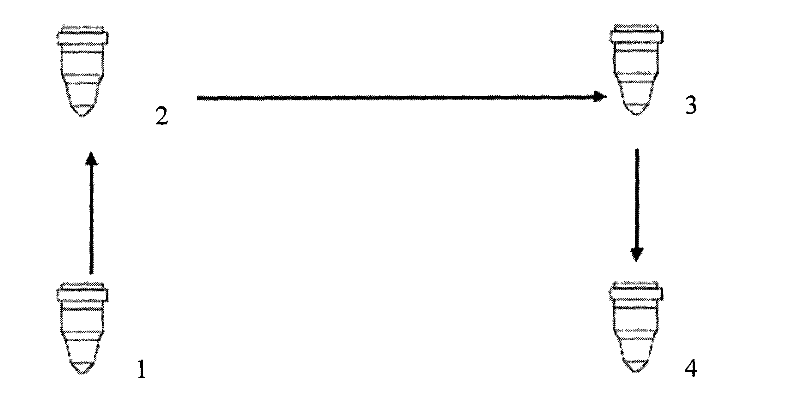

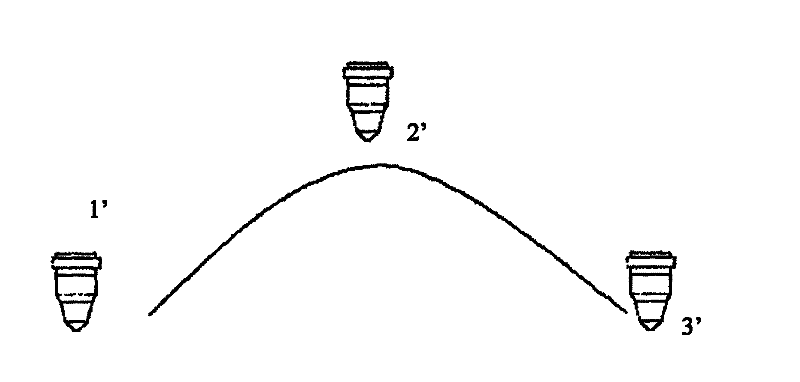

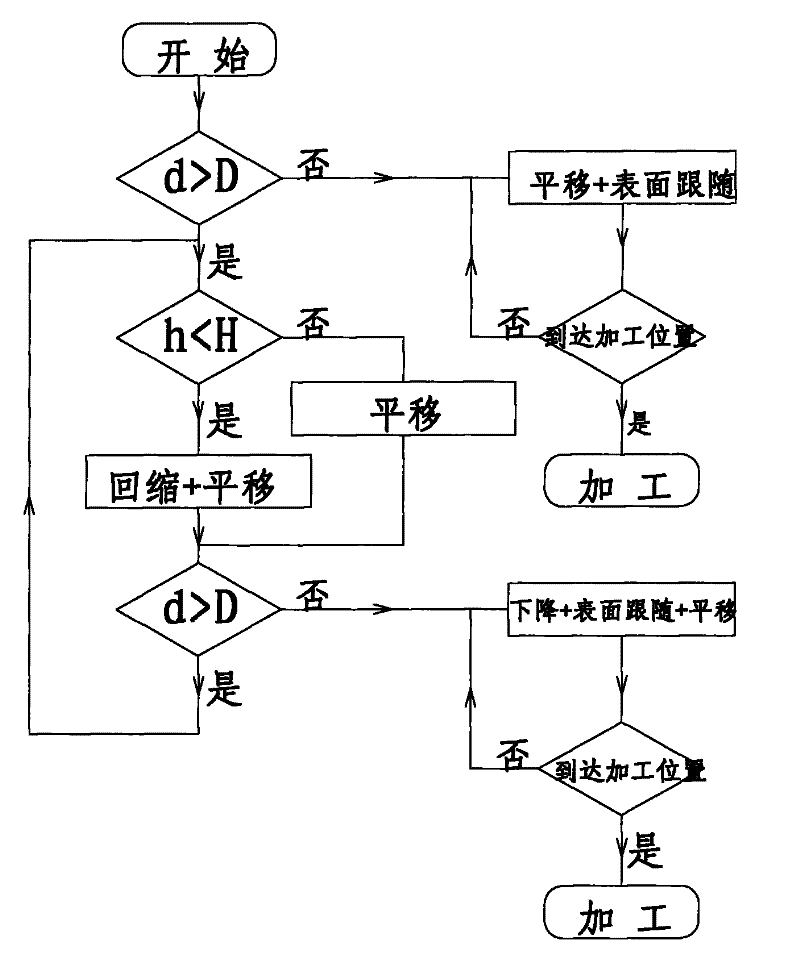

[0021] refer to image 3 , the working flowchart of the control method for realizing high-efficiency dry running in the numerical control system of the present invention.

[0022] Taking CNC laser cutting in laser processing as an example, the embodiment of the present invention can be applied to a CNC laser cutting machine based on the automatic height tracking function, which automatically detects, calculates and synchronizes automatic retraction and head-down tracking when the CNC servo axis is running dry. automatic control method. The control method includes setting a retraction predetermined height H, and a predetermined distance D before the end of the dry run, including the following steps,

[0023] (1) Execution of a processing program is completed;

[0024] (2) Determine whether the actual distance d between the processing head and the next processing point is greater than the predetermined distance D, if yes, perform step (3), otherwise, perform step (4);

[0025...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com