Pipe compression and shrinkage device for condenser manufacturing and use method of device

A condenser and shrink tube technology, which is applied in the field of condenser processing equipment, can solve the problems of complex disassembly, lower processing efficiency, and long use time, and achieve the effects of reducing waste, improving efficiency, and quickly disassembling and replacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

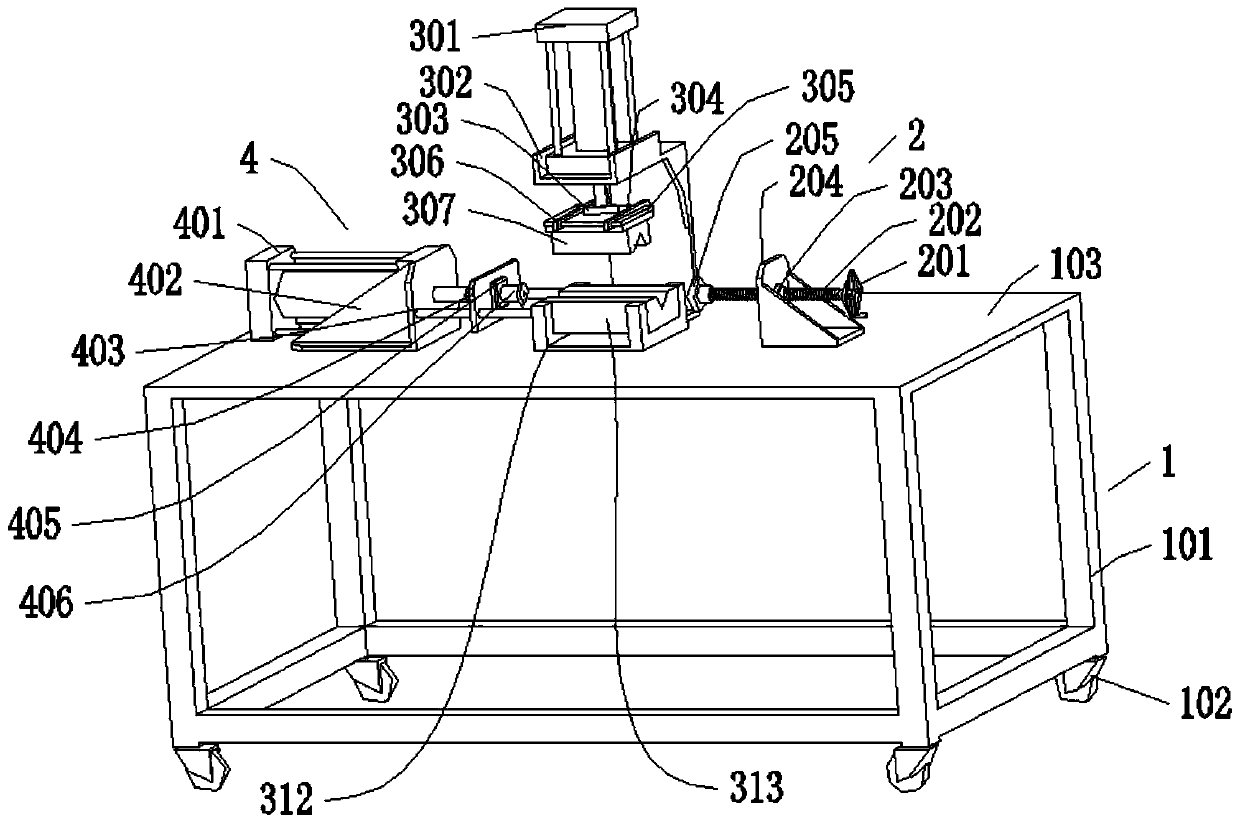

[0043] Such as figure 1 , 3 , 4, and 5, the squeeze tube device used for condenser manufacturing includes a fixing mechanism 1, and an end installed on the upper end of the fixing mechanism 1 for tightening the copper tube to be processed, so as to prevent the copper tube from being processed during the processing process. The clamping mechanism 2 for the sliding of the tube, and the shrinking mechanism 4 for providing power for the shrinking of the copper tube to be processed also include a clamping mechanism 3 for clamping the copper tube to be processed to facilitate the action of the shrinking mechanism 4, wherein , the clamping mechanism 3 , the shrinking mechanism 4 , and the top tightening mechanism 2 are all connected to the fixing mechanism 1 , and the clamping mechanism 3 is connected to the shrinking mechanism 4 .

[0044] The clamping mechanism 3 includes a first oil cylinder 301 and a first fixed frame 302, the first oil cylinder 301 is installed on the upper end...

Embodiment 2

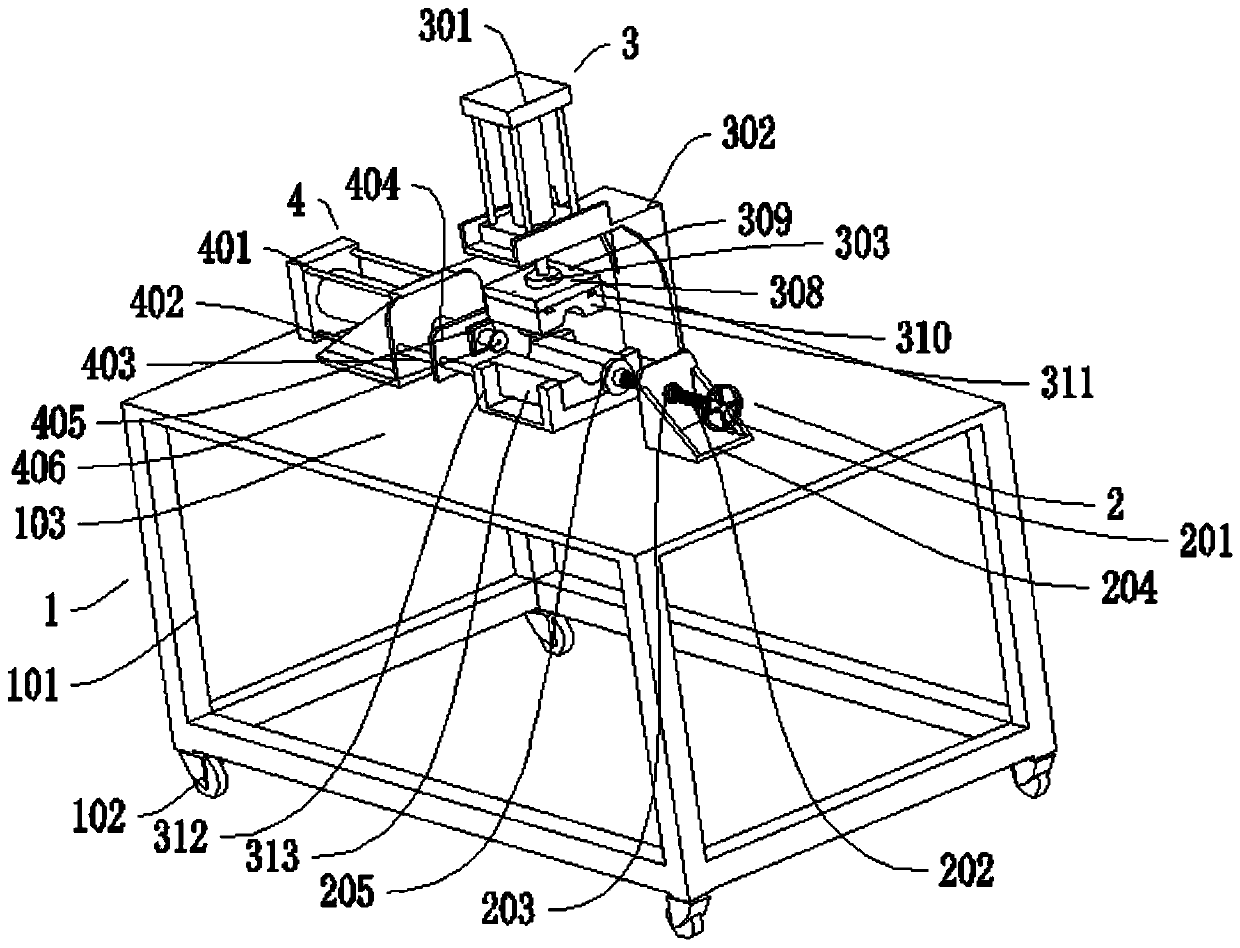

[0046] Such as figure 2 , 3 , 6, and 7, the extruded tube device for condenser manufacturing includes a fixing mechanism 1, and an end installed on the upper end of the fixing mechanism 1 for tightening the copper tube to be processed, so as to prevent the copper tube to be processed from being processed during the processing. The clamping mechanism 2 for the sliding of the tube, and the shrinking mechanism 4 for providing power for the shrinking of the copper tube to be processed also include a clamping mechanism 3 for clamping the copper tube to be processed to facilitate the action of the shrinking mechanism 4, wherein , the clamping mechanism 3 , the shrinking mechanism 4 , and the top tightening mechanism 2 are all connected to the fixing mechanism 1 , and the clamping mechanism 3 is connected to the shrinking mechanism 4 .

[0047] The clamping mechanism 3 includes a first oil cylinder 301 and a first fixed frame 302, the first oil cylinder 301 is installed on the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com