Gantry type numerical control machine tool capable of simultaneously performing tool changing and machining

A CNC machine tool and gantry type technology, which is applied in metal processing machinery parts, metal processing, metal processing equipment and other directions, and can solve the problems of low production efficiency, increased non-processing time of machine tools, and small duty cycle of machine tools.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

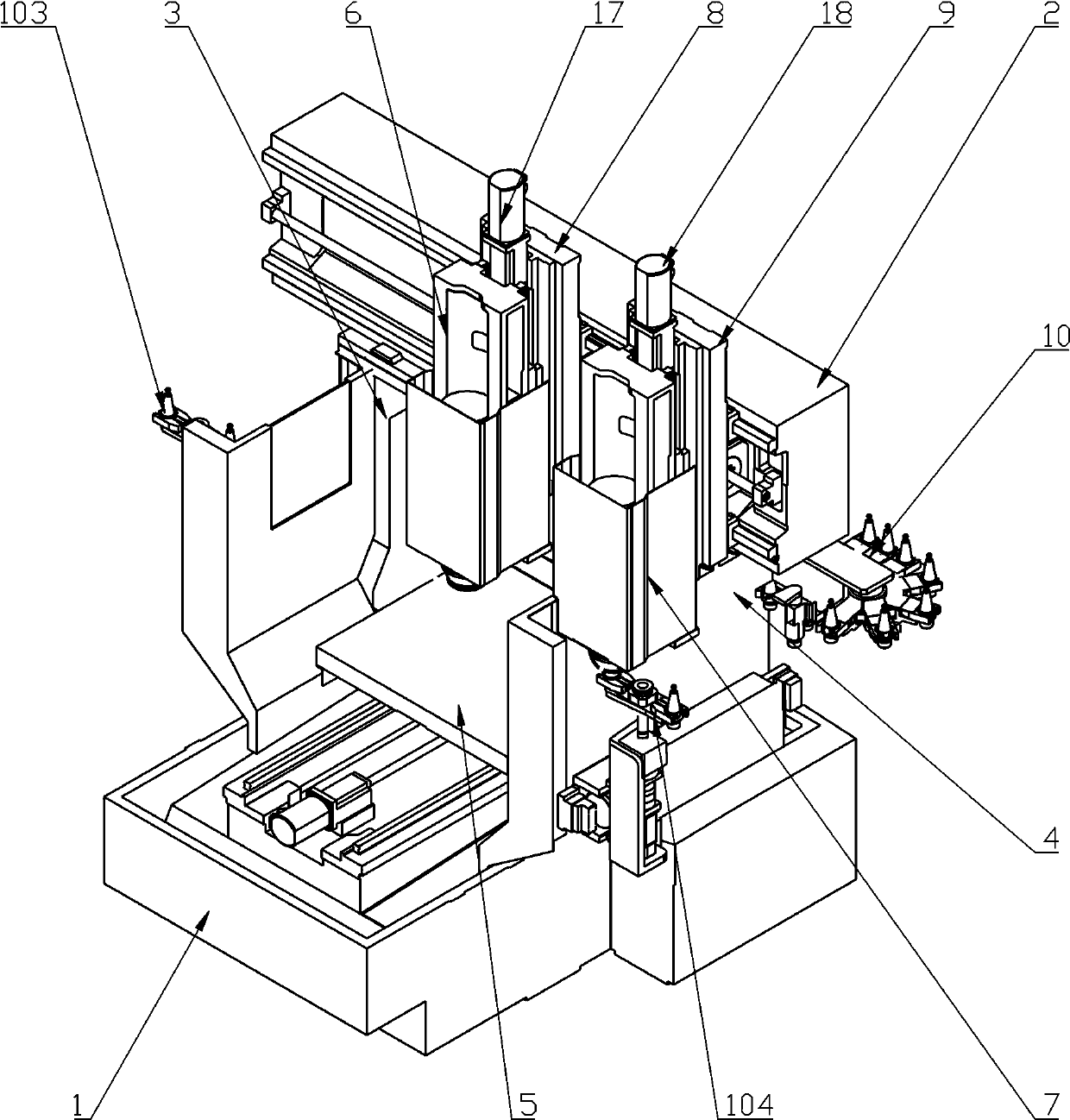

[0023] combine figure 1 , figure 2 with Figure 5 As shown, a gantry type CNC machine tool of the present invention which can carry out tool change and processing simultaneously is composed of a bed 1, a beam 2, a left column 3, a right column 4, a workbench assembly 5, a left head 6, and a right head 7. The first X sliding plate 8, the second X sliding plate 9, and the chain tool magazine 10 are composed.

[0024] The beam 2, the left column 3 and the right column 4 form a gantry structure and are fixed on the bed 1. The workbench assembly 5 is set under the beam 2 and is slidably installed on the bed 1. It can move along the Y direction under the action of the Y-axis drive assembly. reciprocating movement.

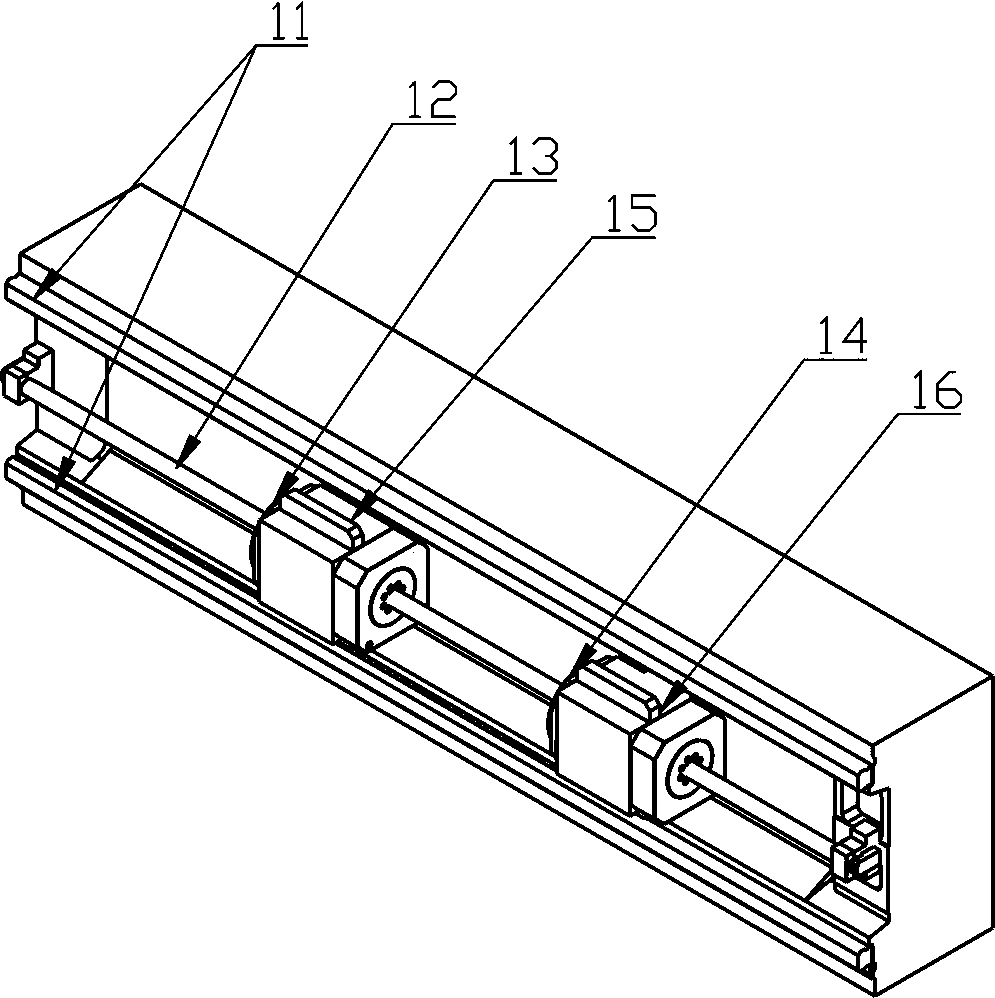

[0025] Two upper and lower guide rails 11 are arranged on the crossbeam 2 along the X direction, and a fixed lead screw 12 parallel thereto is arranged between the two guide rails 11 , and both ends of the fixed lead screw 12 are fixed on the crossbeam 2 . The fixed...

Embodiment 2

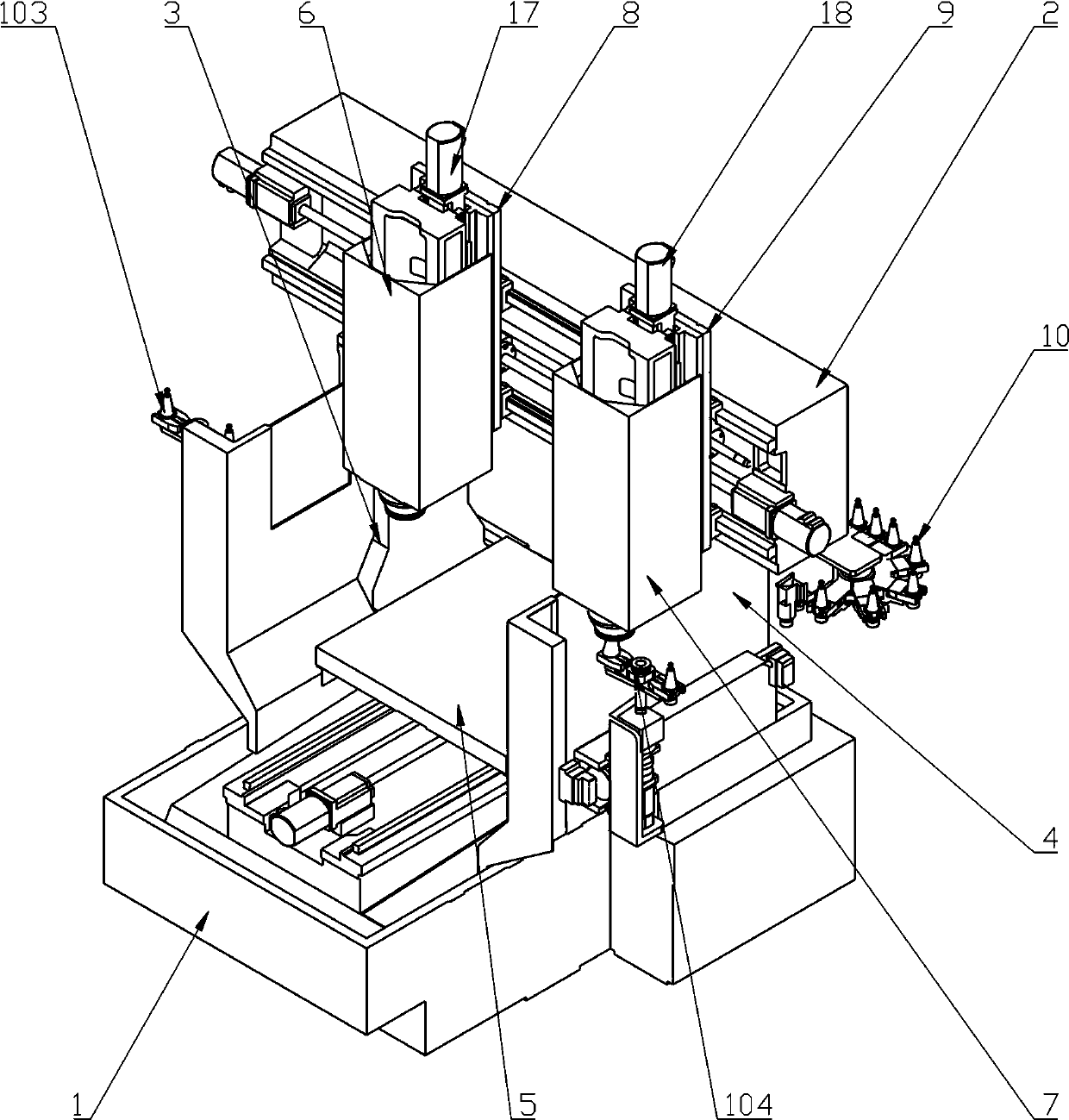

[0034] combine image 3 , Figure 4 with Figure 5 As shown, a gantry type CNC machine tool of the present invention which can carry out tool change and processing simultaneously is composed of a bed 1, a beam 2, a left column 3, a right column 4, a workbench assembly 5, a left head 6, and a right head 7. The first X sliding plate 8, the second X sliding plate 9, and the chain tool magazine 10 are composed.

[0035] The beam 2, the left column 3 and the right column 4 form a gantry structure and are fixed on the bed 1. The workbench assembly 5 is set under the beam 2 and is slidably installed on the bed 1. It can move along the Y direction under the action of the Y-axis drive assembly. reciprocating movement.

[0036] The crossbeam 2 is provided with two upper and lower guide rails 11 along the X direction, and a first rotating screw 19 and a second rotating screw 20 parallel to it are arranged between the two guide rails 11. The first rotating screw 19 and the second rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com