PCB welding table based on independent cooling technology

A PCB board, independent cooling technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of difficult to meet the needs of the PCB board, unable to cool the PCB board, prolonged non-processing time, etc., to shorten the time The effect of non-processing time, avoiding welding slag scattering, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

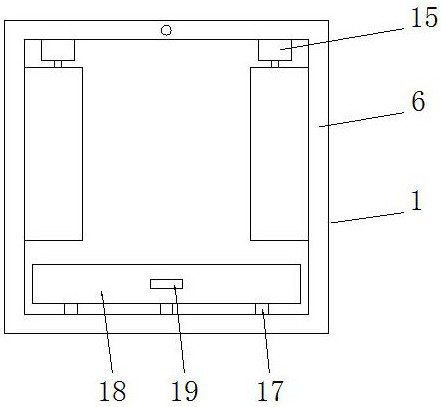

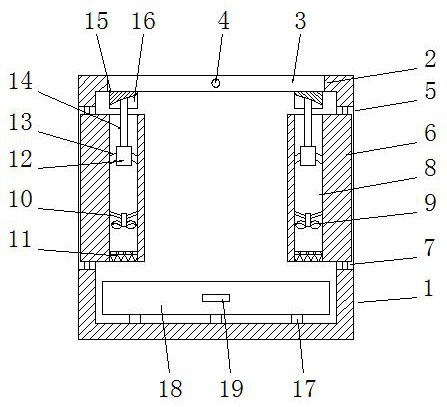

[0030] See Figure 1-2 , a PCB board welding station based on independent cooling technology, including a stand 1, the stand 1 is a rectangular ring frame structure, the top of the stand 1 is connected to a turning chamber 2, and a welding station is arranged in the turning chamber 2 plate 3, the welding platen 3 is rotatably connected to the inner cavity wall of the turning chamber 2 through the turning shaft 4, and the left and right sides of the platform 1 are symmetrically provided with side support chambers 5, and the inside of the side support chambers 5 A support column 6 is provided, and the support column 6 is rotatably connected to the side support cavity 5 through a rotating shaft 7. The lateral surface of the support column 6 is a semicircular structure, and the support column 6 is provided with an air cooling hole 8, and the air cooling hole 8 is arranged inside the support column 6. The cooling hole 8 connects the upper and lower end faces of the support column 6...

Embodiment 2

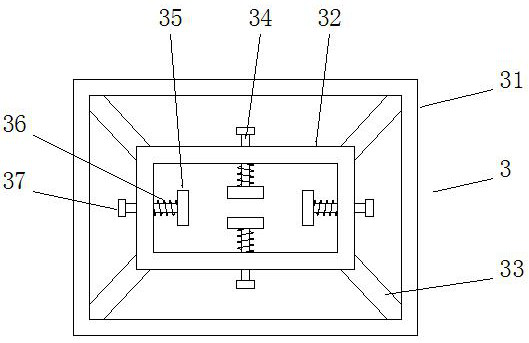

[0034] See image 3 The difference from Embodiment 1 is that the welding table 3 includes an outer frame 31 and an inner frame 32, the outer frame 31 is a rectangular ring frame structure, and the inner cavity of the outer frame 31 is provided with an inner plate frame 32, the inner frame 32 is a rectangular ring structure, the four corners of the inner frame 32 are fixedly connected to the inner cavity wall of the outer frame 31 through connecting rods 33, and the side walls of the inner frame 32 are embedded with Clamping rod 34, which is slidingly connected between the clamping rod 34 and the inner plate frame 32, one end of the clamping rod 34 is fixedly connected to the control panel 37, the other end of the clamping rod 34 is fixedly connected to the movable clamp 35, and the outer side of the clamping rod 34 is sleeved There is a pre-tension spring 36 matched with the movable clamp 35, the end of the pre-tension spring 36 is fixedly connected to the inner cavity wall of...

Embodiment 3

[0036] See Figure 4-5 The difference from Embodiment 1 is that the welding slag pumping box 18 includes a box body 181, and the two handles 19 are symmetrically arranged at the front and rear ends of the box body 181, and the middle part of the top of the box body 181 is provided with a welding slag Cavity 182, described welding slag cavity 182 corresponds to welding platen 3 on the vertical direction, is provided with isolation cavity 185 in the side wall of welding slag cavity 182, and described isolation cavity 185 is annular cavity, and the front and back of isolation cavity 185 The side ends are symmetrically connected to the air intake pipe 186, and the inner cavity of the air intake pipe 186 is provided with an air blowing fan 188 and a second protective net 187 in turn from the inside to the outside, and the air blowing fan 188 is fixedly connected to the air intake pipe 188 through a third fixed rod 189 On the inner cavity wall of the air intake pipe 186, the left an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com