Soybean screening device for soybean product processing

A screening device and soybean product technology, which is applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of cumbersome loading and unloading of soybeans, labor-intensive and other problems, and achieve the effect of convenient screening, convenient unloading, and good screening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

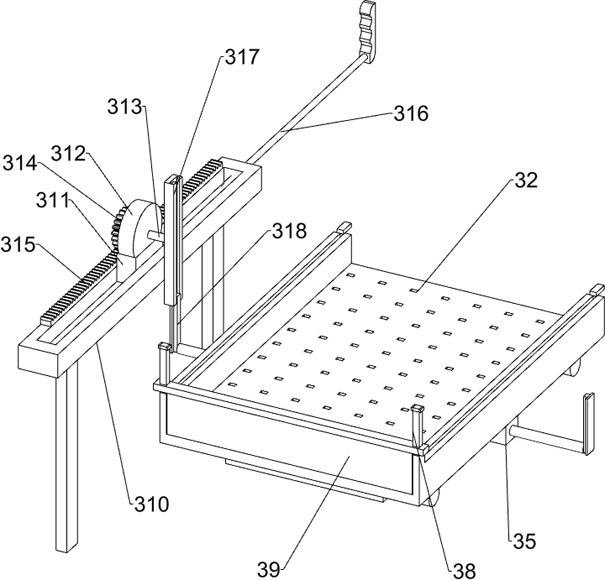

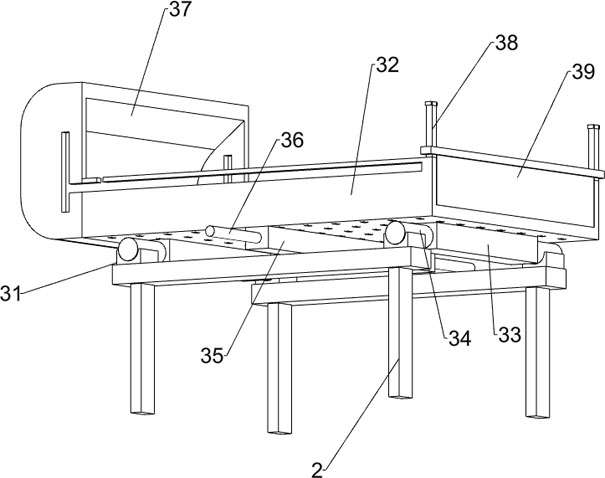

[0023] Such as Figure 1-4 As shown, a soybean screening device for soybean product processing includes a base 1, a placement frame 2, a flipping screening device 3, a fixed frame 4 and a discharge device 5, and the top of the base 1 is symmetrically arranged with a placement frame 2 and a placement frame 2 The top is provided with a turning and screening device 3 , and the left side of the top of the base 1 is provided with a fixed frame 4 .

[0024] Turning over screening device 3 includes arc-shaped deck 31, screening frame 32, square seat 33, clamping shaft 34, cross bar 35, slide shaft 36, arc-shaped bucket 37, guide post 38, chamber door 39, straight slide rail 310, Straight slide block 311, bearing seat 312, rotating shaft 313, gear 314, tooth bar 315, push rod 316, straight slide rail 317 and slide bar 318, two placing racks 2 tops are all left and right symmetrically provided with arc-shaped deck 31, screening The bottom of the frame 32 is symmetrically arranged with...

Embodiment 2

[0028] On the basis of Example 1, such as Figure 5-6 As shown, it also includes a second elastic member 7, a movable rod 8, a sliding frame 11, a toggle brush 12 and a pull bar 13, and the front and rear sides of the arc bucket 37 are symmetrically provided with vertical chute 6, and the arc bucket 37 The vertical chute 6 on the side wall is provided with the second elastic part 7, and the second elastic part 7 is a compression spring, and a movable rod 8 is arranged between the tops of the two second elastic parts 7, and the front and rear side walls of the screening frame 32 are opened symmetrically. There is a horizontal chute 9, and the horizontal chute 9 communicates with the vertical chute 6, and the left side of the screening frame 32 is symmetrically opened with a broken groove 10 connected with the horizontal chute 9, and the horizontal chute 9 is slidingly provided with a sliding frame 11 , the bottom of the sliding frame 11 is uniformly provided with a toggle brush 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com