Gas-switching ironmaking device

A technology of gas and furnace body, which is applied in the direction of fluidized bed furnace, etc., can solve the problems of wasting and exhausting heat, trouble, labor, etc., and achieve the effect of full utilization and sufficient heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

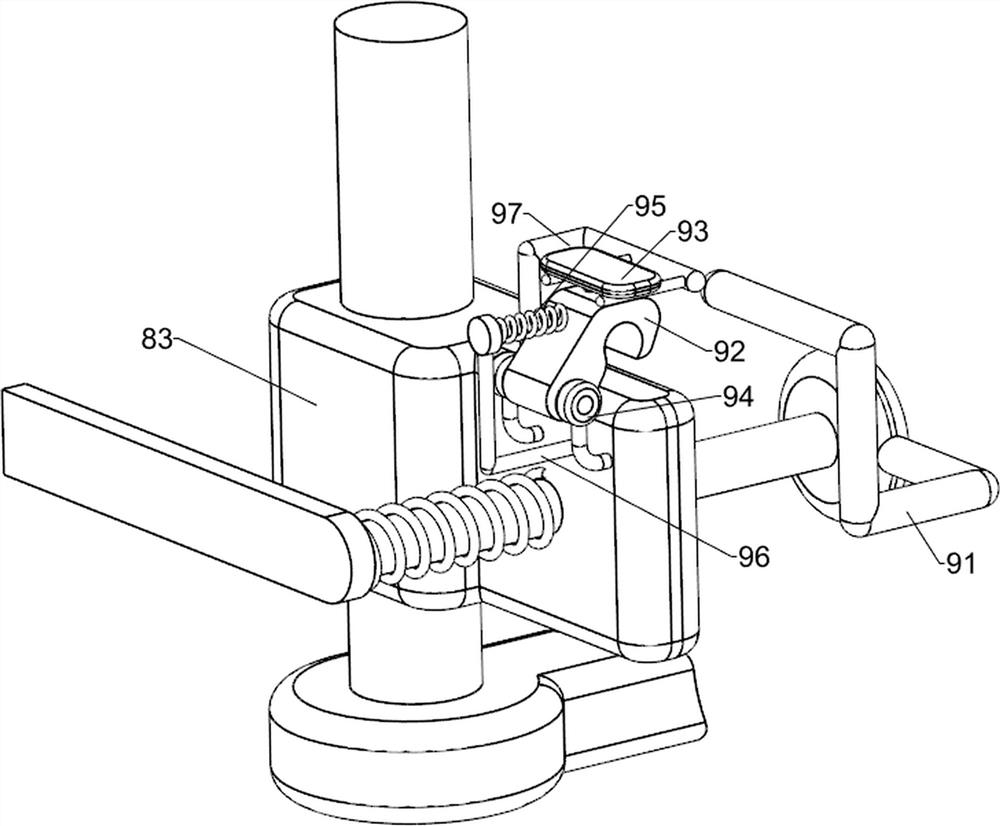

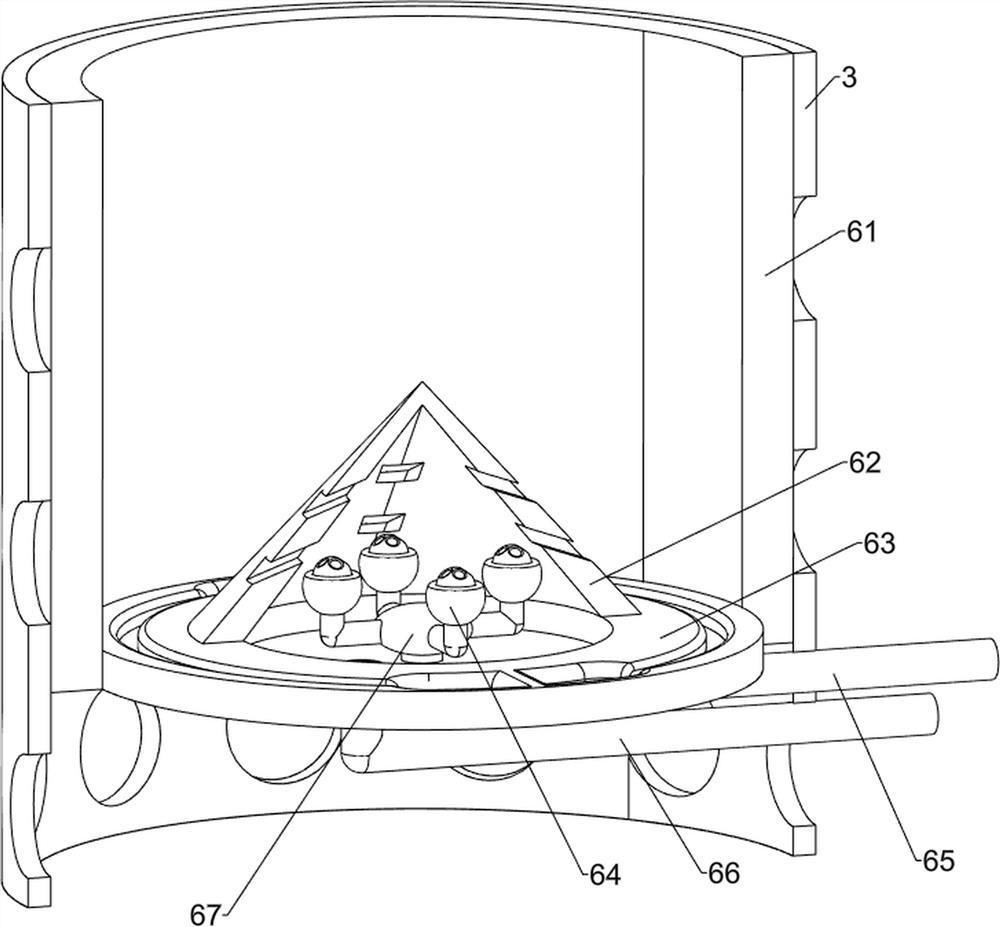

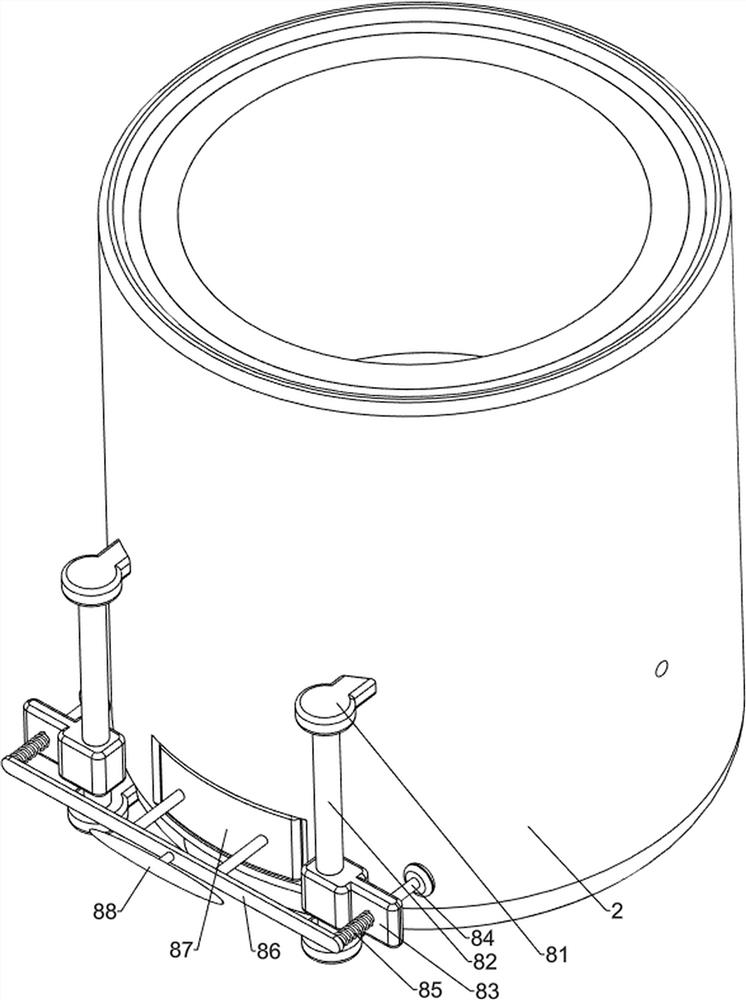

[0030] An ironmaking plant that converts gases, such as figure 1 , figure 2 , image 3 and Figure 4 As shown, it includes a base 1, a feed box 11, a furnace body 2, a heat shield 3, a filter plate 4, a feeding mechanism 5 and a combustion mechanism 6, the upper left side of the base 1 is connected with a feed box 11, and the base 1 The furnace body 2 is connected in the middle on the right side of the upper part, and the inside of the furnace body 2 is connected with a heat insulation board 3, and the inner lower side of the furnace body 2 is connected with a filter plate 4, and the filter plate 4 is located at the lower side of the heat insulation board 3, and the feed box 11 is equipped with a There is a feeding mechanism 5, and a combustion mechanism 6 is arranged inside the heat shield 3.

[0031] The feeding mechanism 5 includes a material pipe 51, a discharge port 52, a first motor 53, a rotating shaft 54, and a coil 55. The feed box 11 is connected with a material ...

Embodiment 2

[0035] On the basis of Example 1, such as figure 1 , figure 2 , Figure 5 , Figure 6 , Figure 7 and Figure 8 As shown, a preheating assembly 7 is also included, and the preheating assembly 7 includes a second motor 71, a fan blade 72, a support frame 73, an air box 74, a suction hood 75 and a delivery pipe 76, and the upper part of the rear side of the furnace body 2 is connected in the middle There is a support frame 73, the upper part of the rear side of the support frame 73 is connected with a bellows 74, the right side of the upper part of the bellows 74 is equipped with a second motor 71, the left side of the output shaft of the second motor 71 is connected with a fan blade 72, the output shaft of the second motor 71 is connected with the bellows 74 rotary connection, the fan blade 72 is located inside the bellows 74, the front side of the bellows 74 is connected with a suction cover 75 in the middle, the suction cover 75 is located on the upper side of the furnac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com