Rotary sheet feeding manipulator

A manipulator and rotary technology, applied in manipulators, program-controlled manipulators, chucks, etc., can solve the problems of large floor space and large space required for work, so as to facilitate installation and layout, reduce non-processing time, and reduce floor space. and the effect of the space required for work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

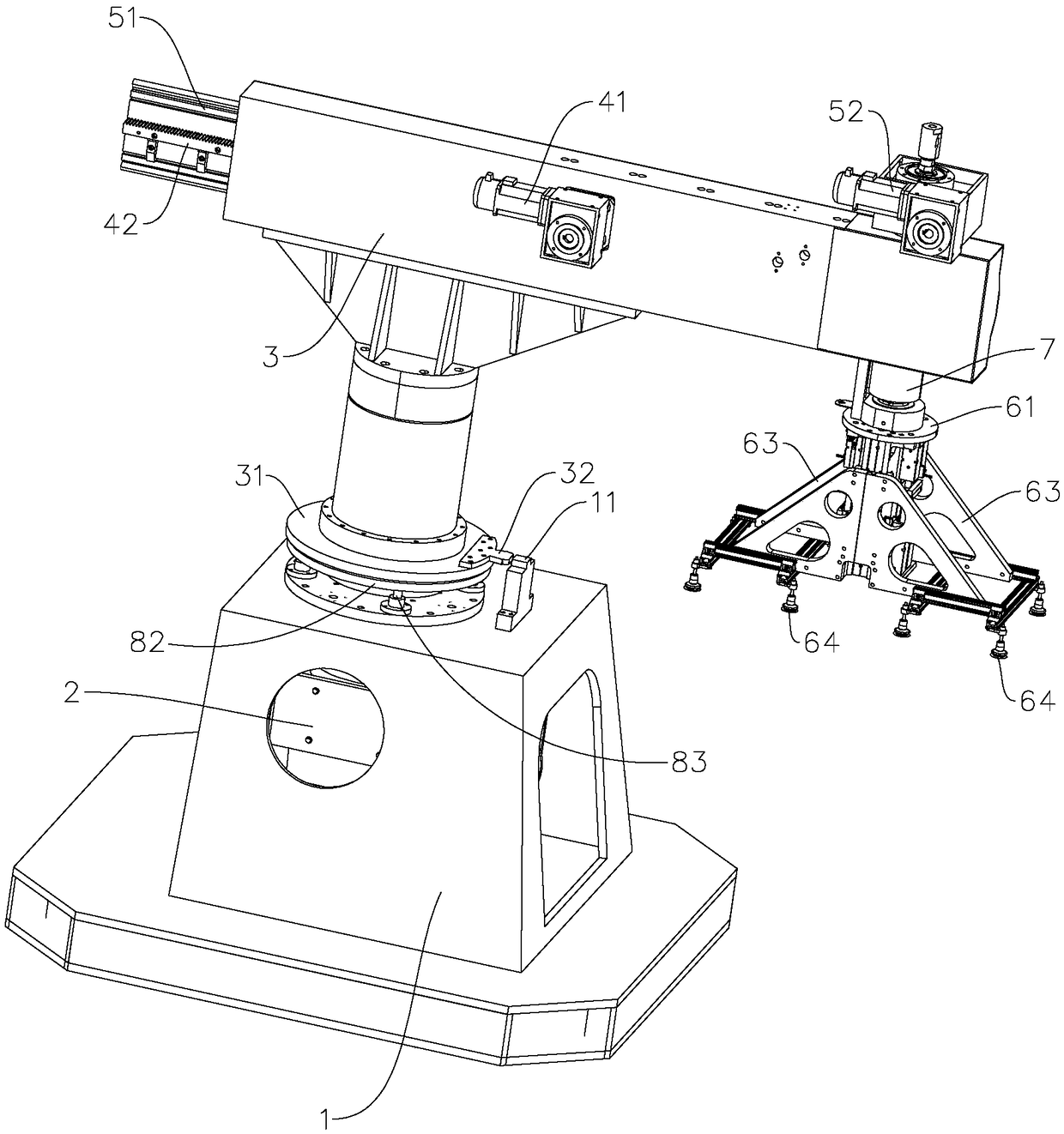

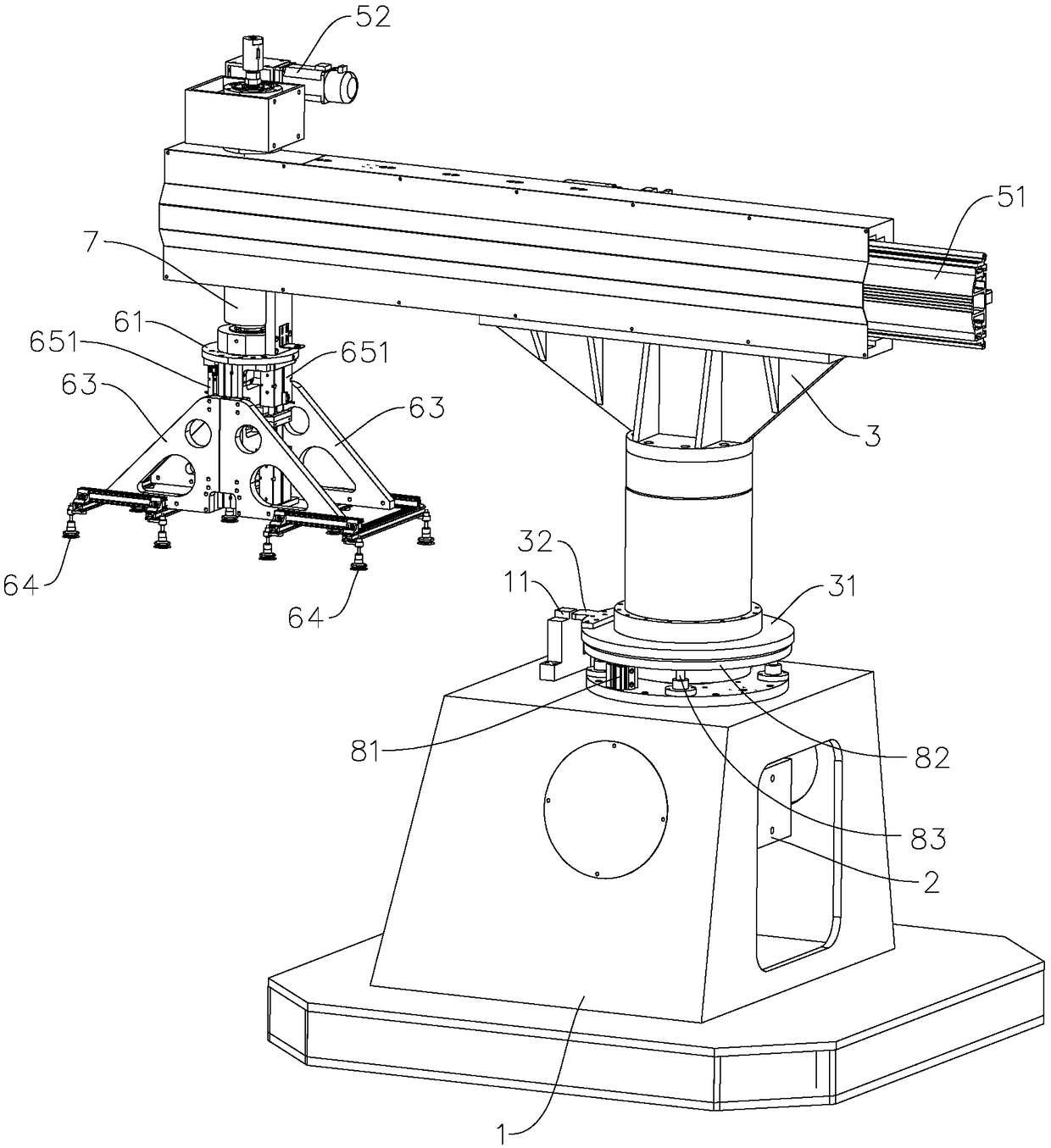

[0025] refer to Figure 1 ~ Figure 4 , the present invention is a rotary loading manipulator, which includes a control device, a base 1, a first rotary frame 3, a traverse bracket 51 and a grabbing device 6, and a first rotary drive device 2 is arranged on the base 1. The first slewing frame 3 is connected with the output shaft of the first rotary driving device 2 . The traversing support 51 is movably arranged on the first revolving frame 3, and the traversing support 51 is connected with a traversing drive device arranged on the first revolving frame 3, and the traversing drive device can drive the traversing support 51 along the The first slewing frame 3 moves laterally. The grabbing device 6 is pivotally arranged on the traversing bracket 51 , and the grabbing device 6 is connected with the second rotation driving device 52 arranged on the traversing bracket 51 .

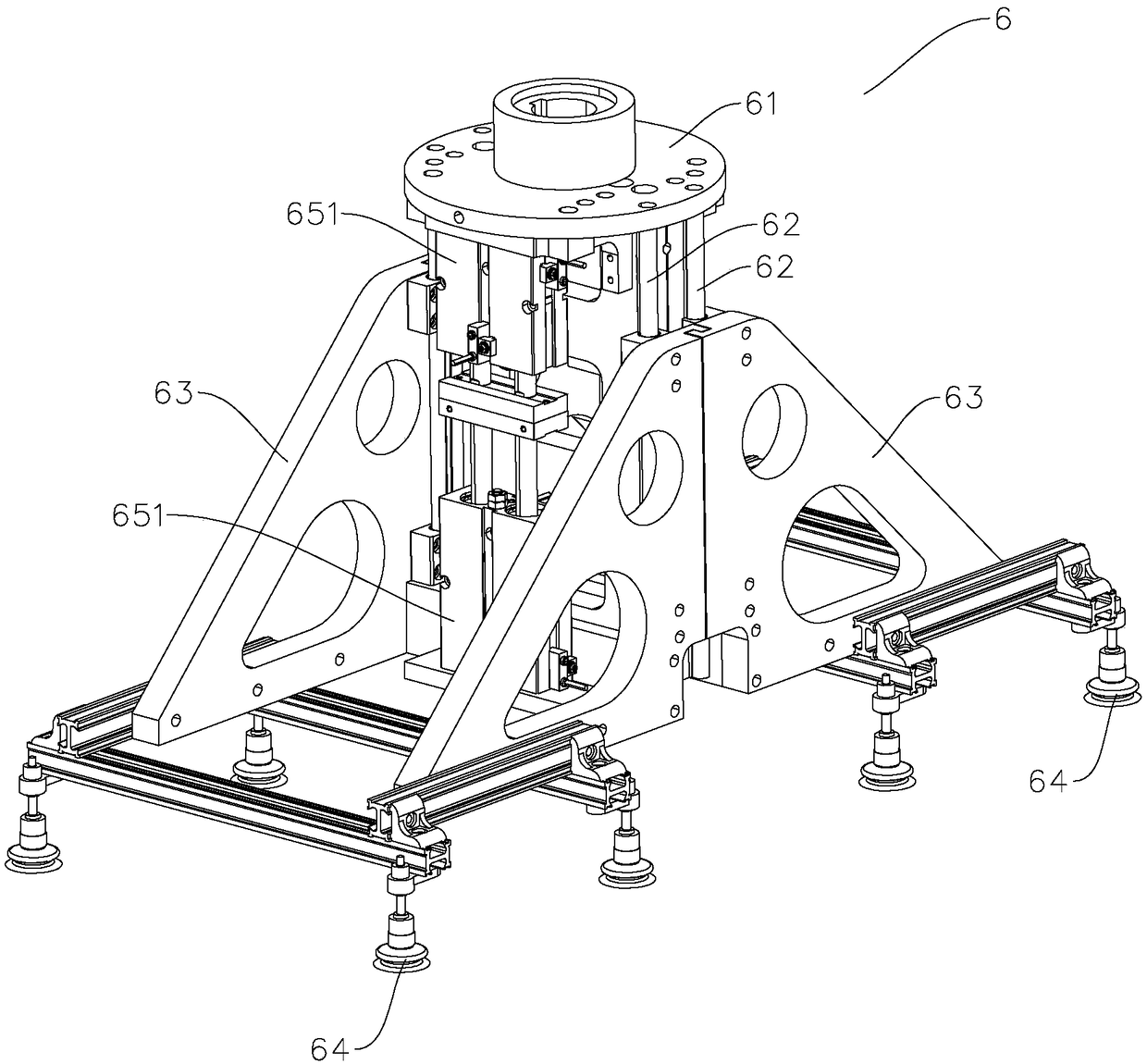

[0026] Specifically, the grabbing device 6 includes a second revolving frame 61 , a retrieving frame 63 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com