Multi-station rotary interchangeable clamp

An interchangeable, multi-station technology, applied in the direction of manufacturing tools, clamping, positioning devices, etc., can solve the problems of low product processing efficiency, low utilization rate, long standby clamping time, etc., to improve processing efficiency and save The effect of a dry run

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

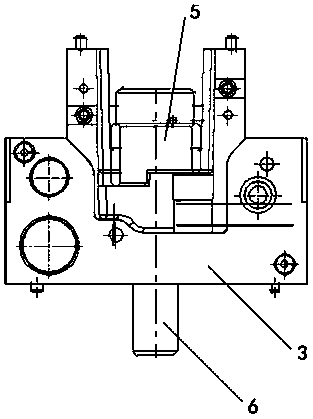

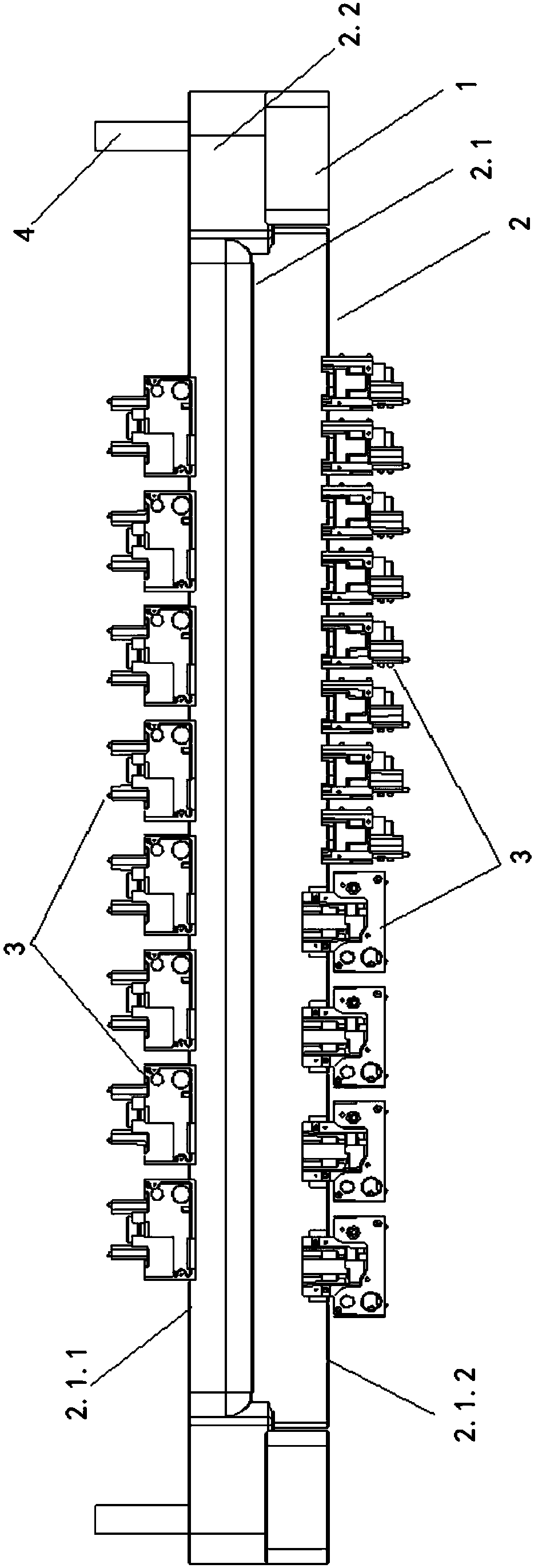

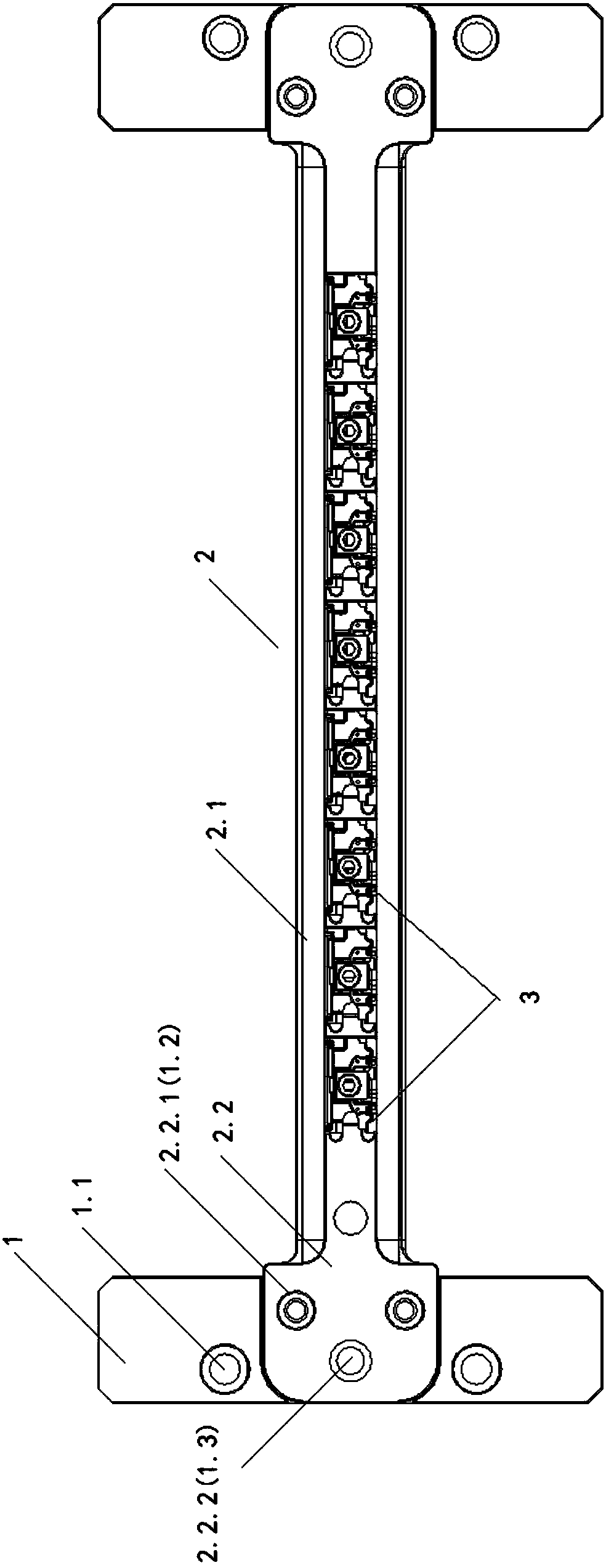

[0018] A multi-station rotary interchangeable fixture, such as Figure 1~3 As shown, it includes the base plate 1 and the bridge plate 2 of the fixture. The fixture bottom plate 1 includes two rectangular plates, and the two fixture bottom plates 1 are arranged on both sides of the bridge plate 2 . Both ends of the fixture base plate 1 are respectively provided with third fixing holes 1.1. In order to facilitate the fixed connection of the fixture bottom plate and the turntable, in this embodiment, the fixture bottom plate 1 is fixed to the turntable (not marked in the figure) through an L-shaped connecting plate (not marked in the figure). Specifically, the L-shaped connecting plate includes a transverse plate and a longitudinal plate, and the clamp bottom plate 1 is fixed to the transverse plate of the L-shaped connecting plate after the bottom plate screw passes through the third fixing hole 1.1. The longitudinal plate of the L-shaped connecting plate and the turntable ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com