Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Reduce mechanical friction loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

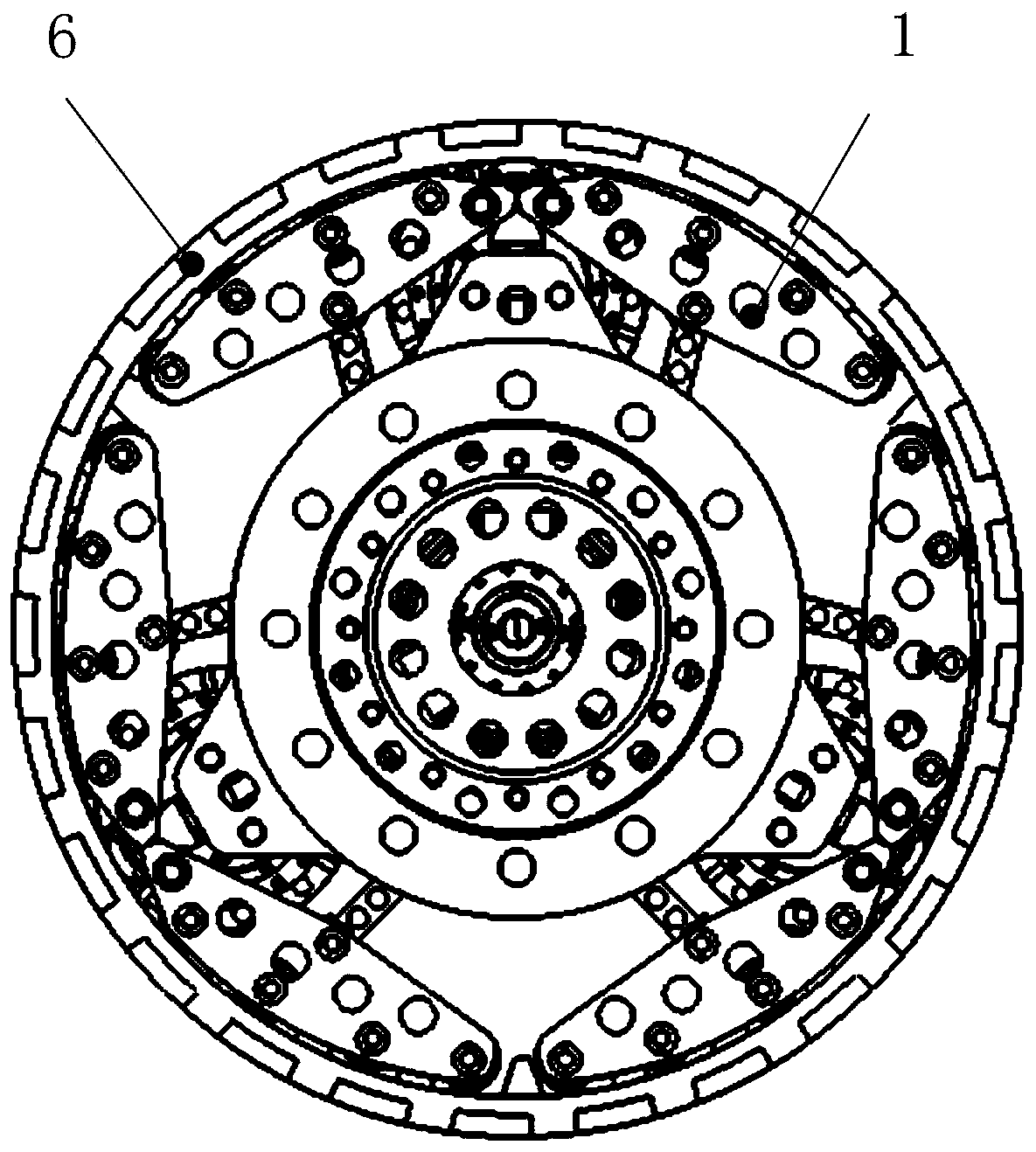

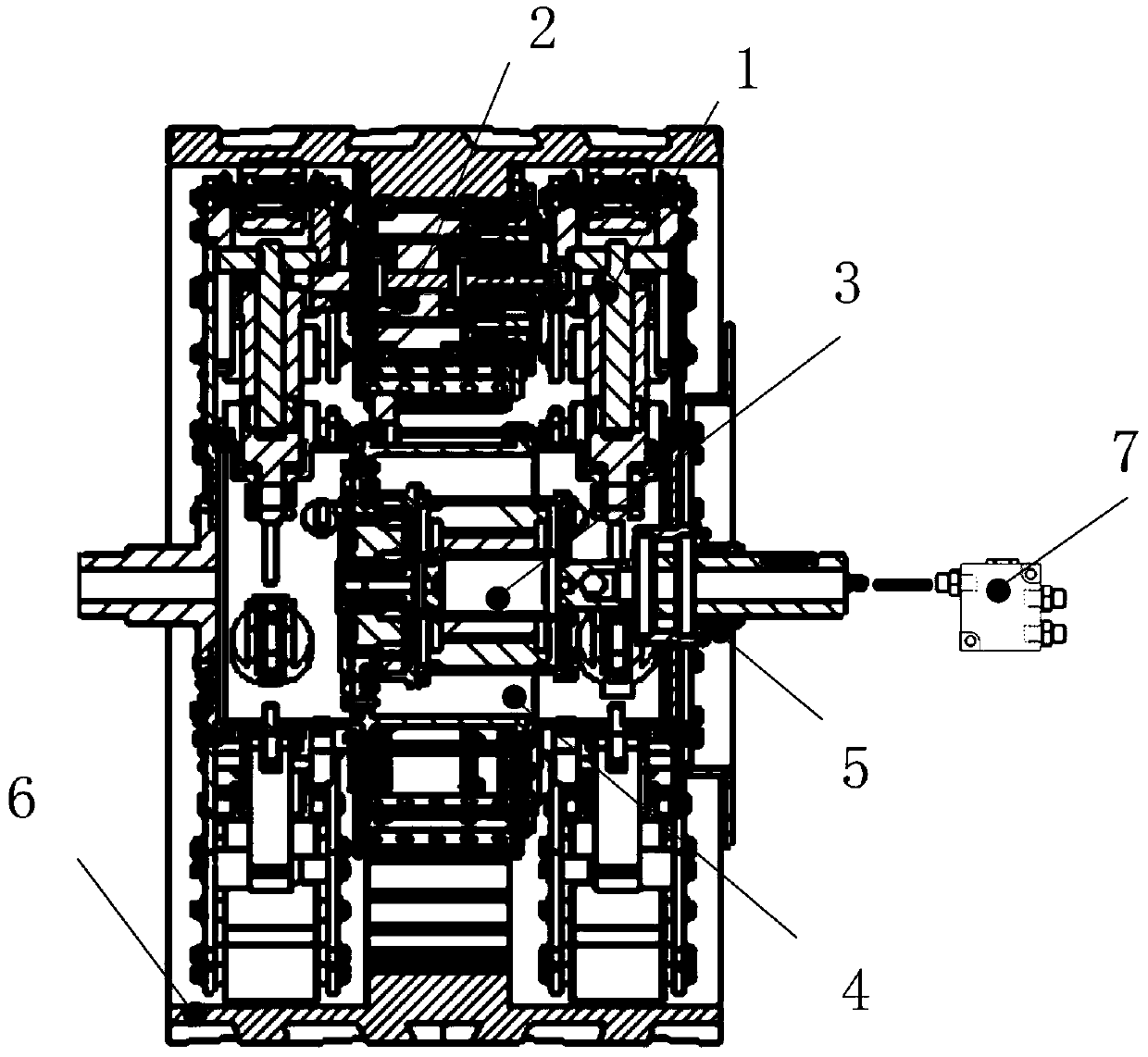

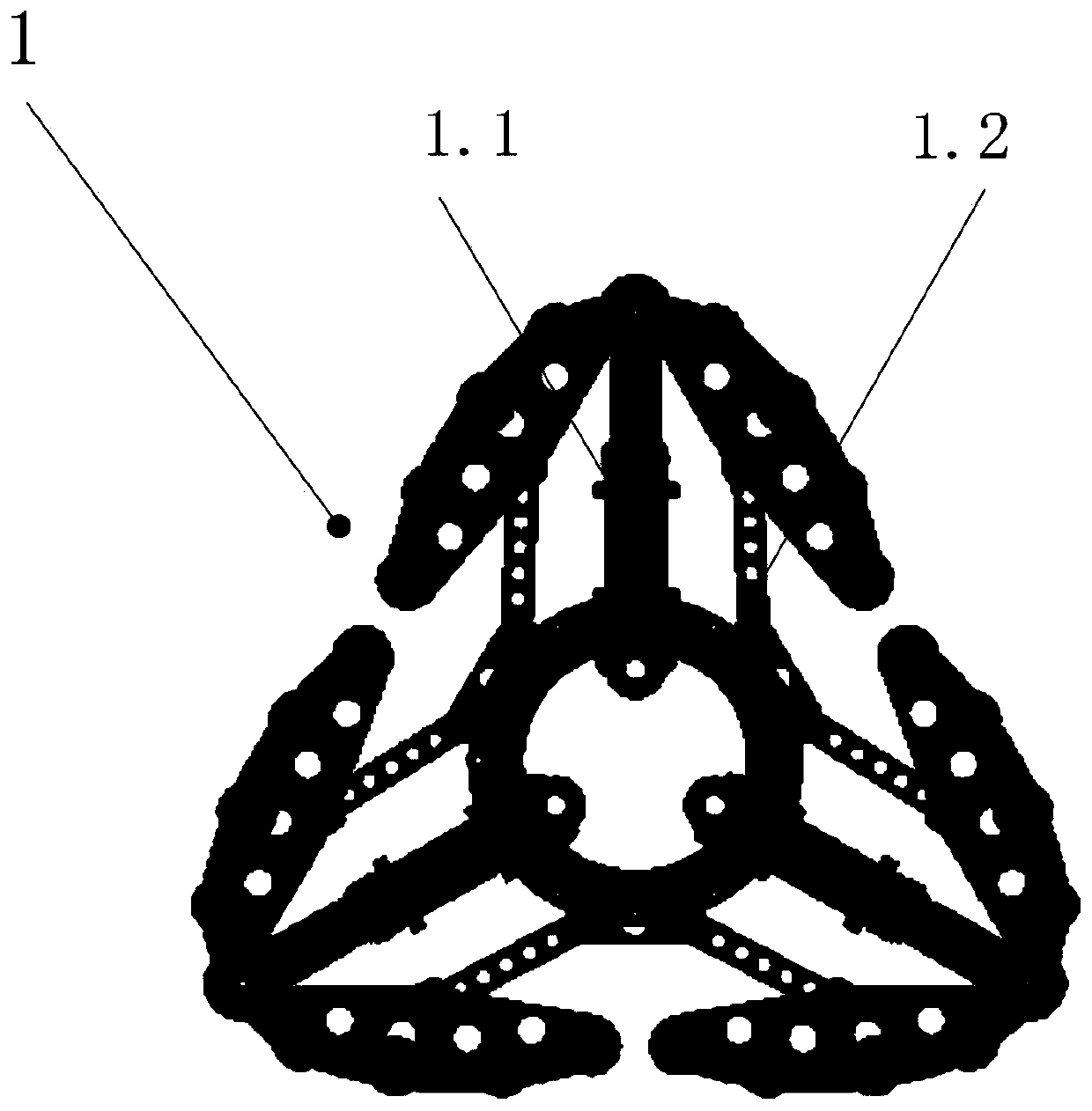

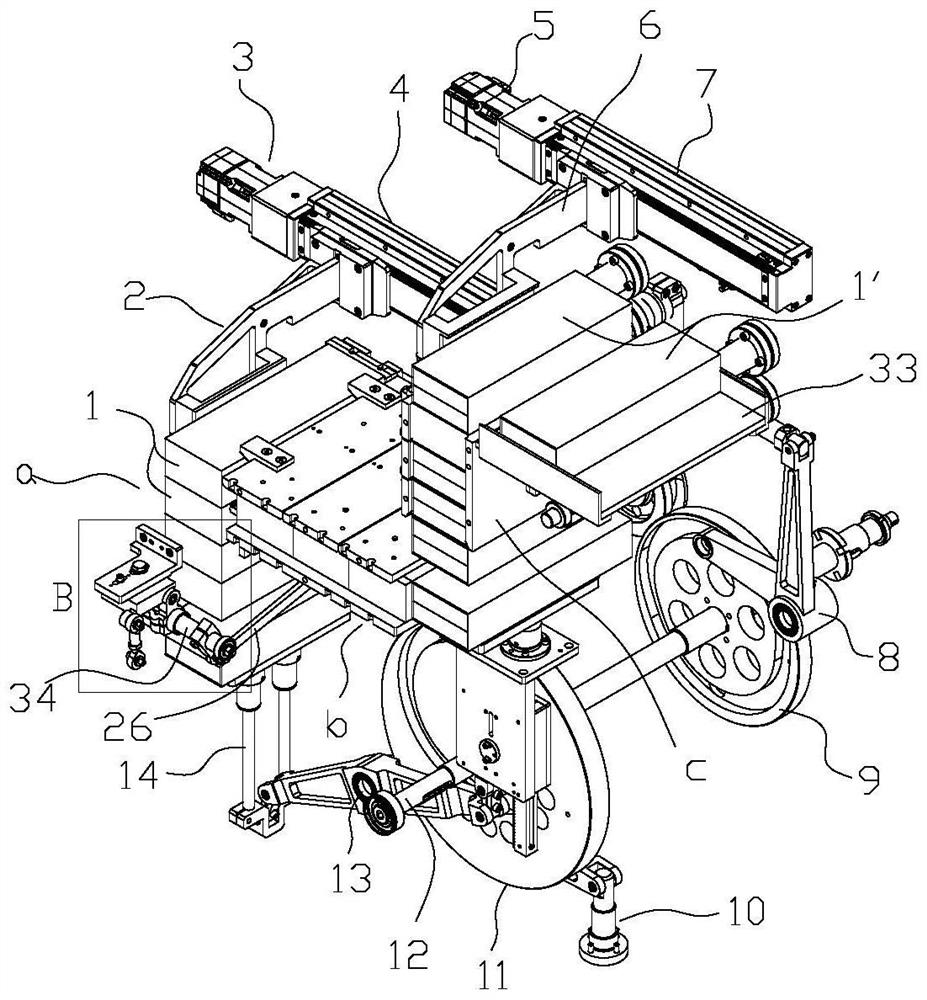

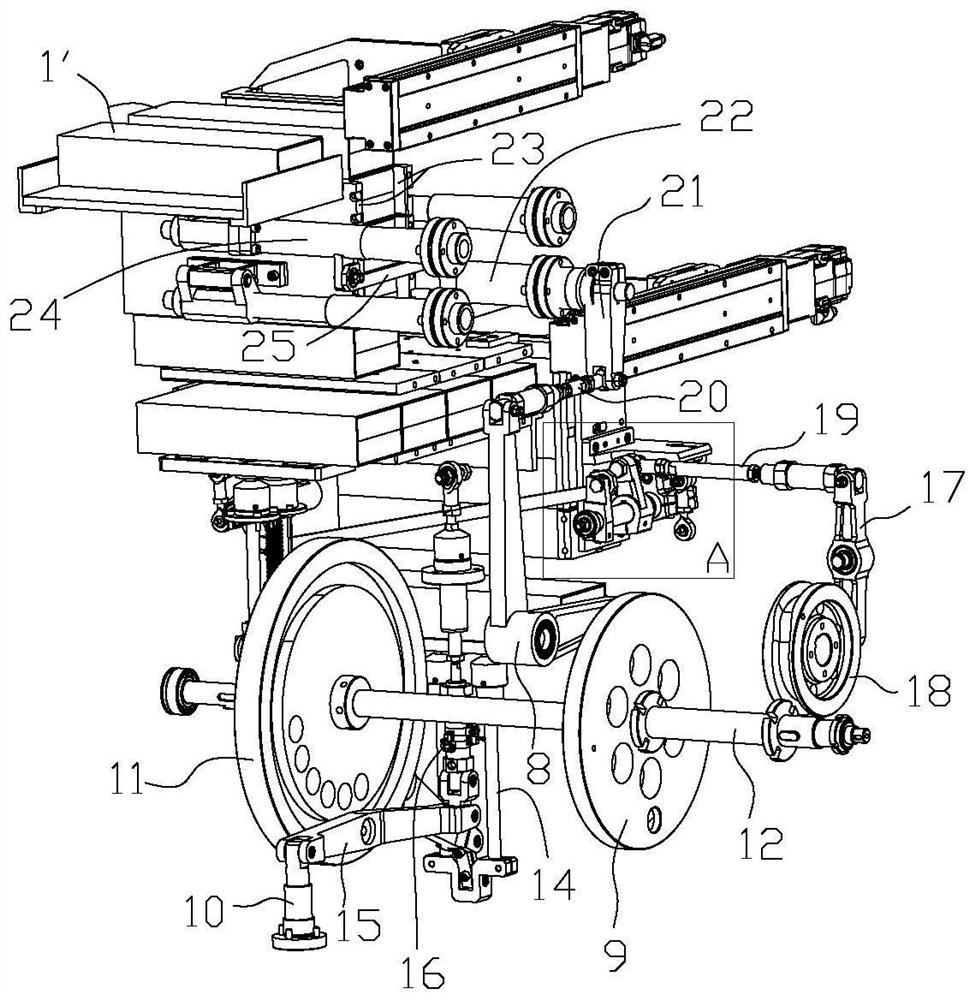

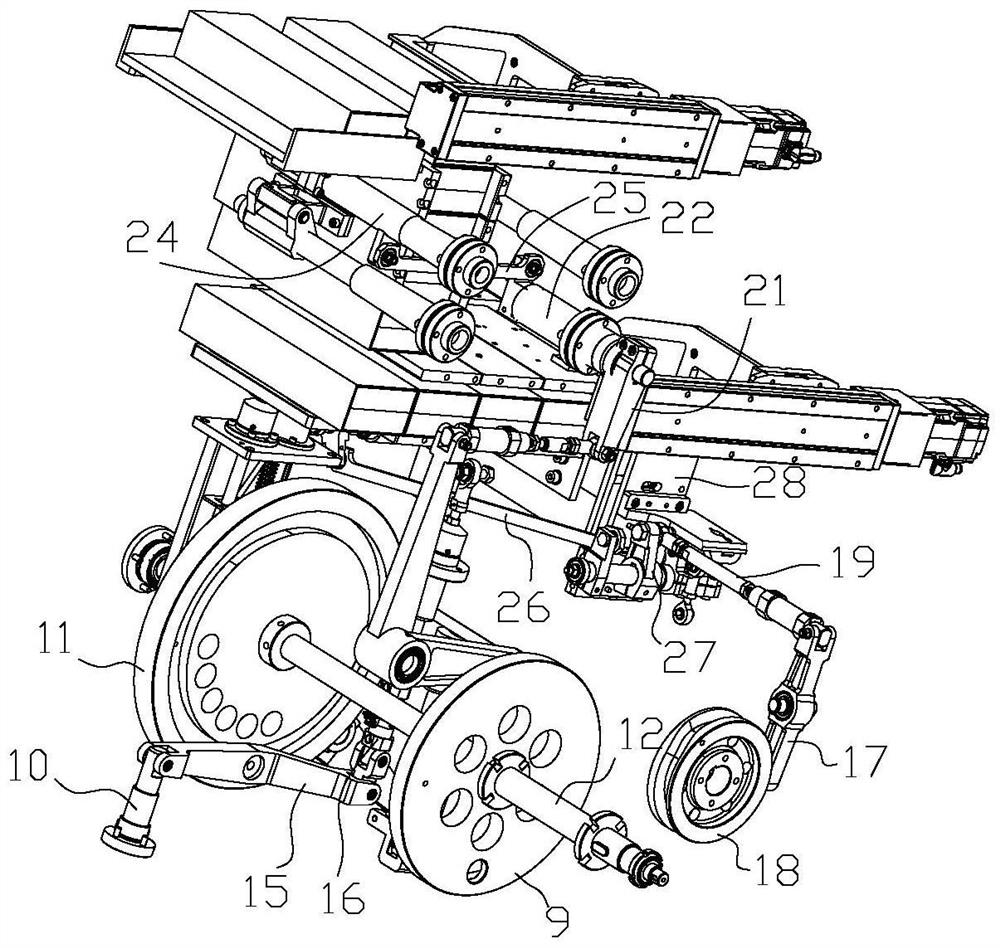

Crawler wheel walking device capable of realizing wheel-crawler conversion

ActiveCN110182269AEasy to adaptIn line with the development direction of all-electricityMotor depositionEndless track vehiclesDrivetrainEngineering

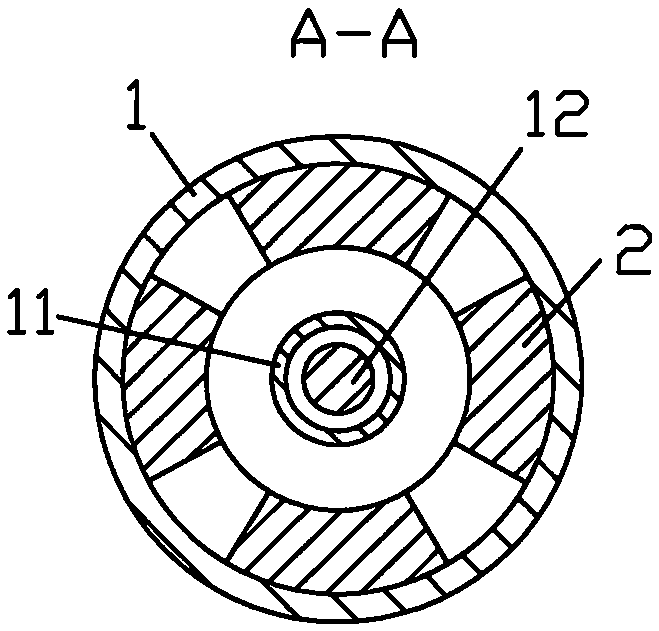

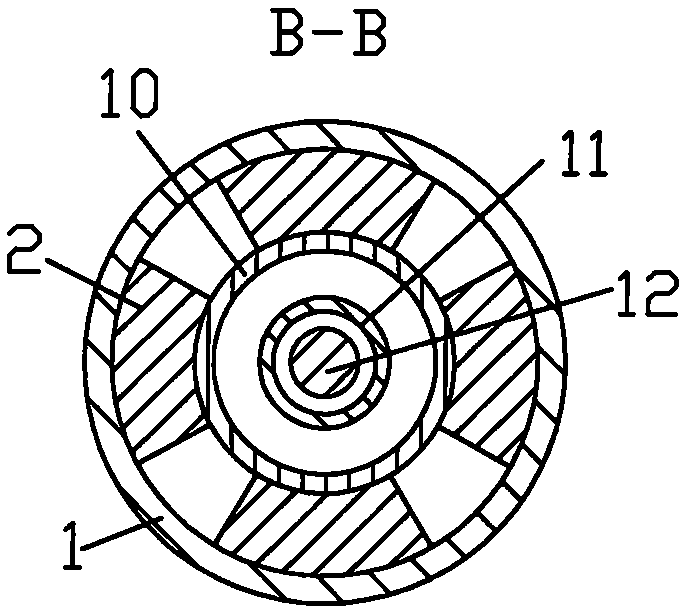

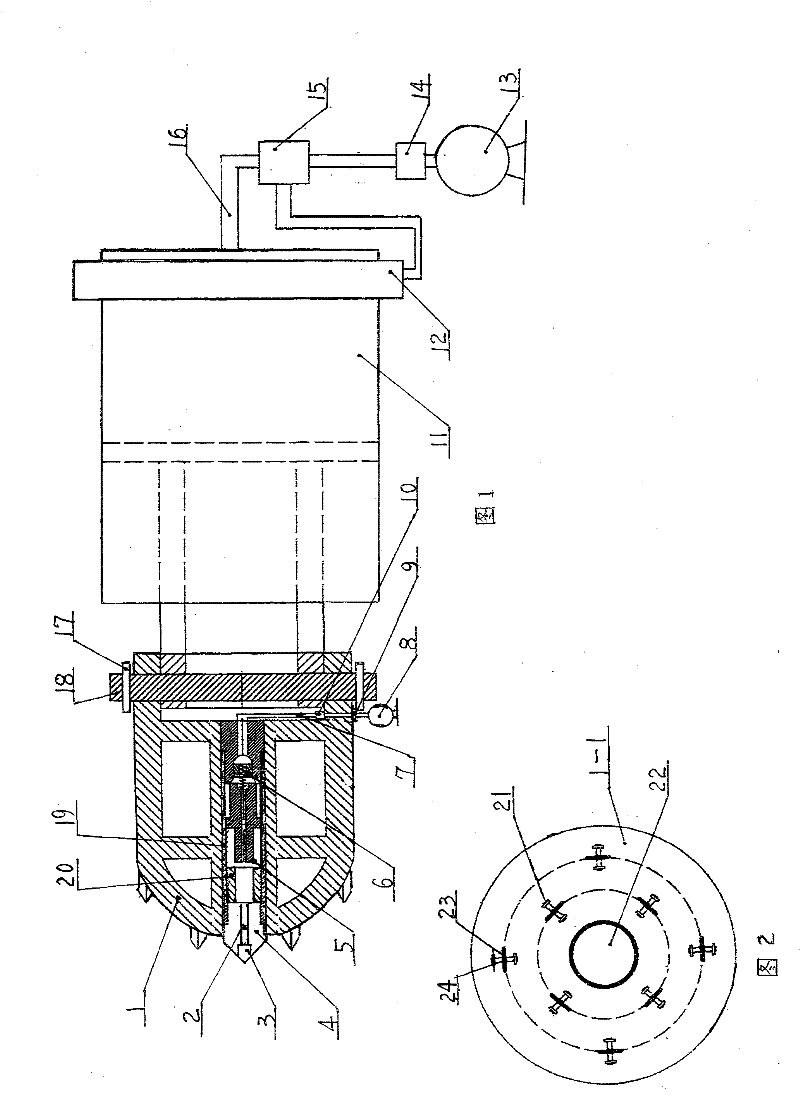

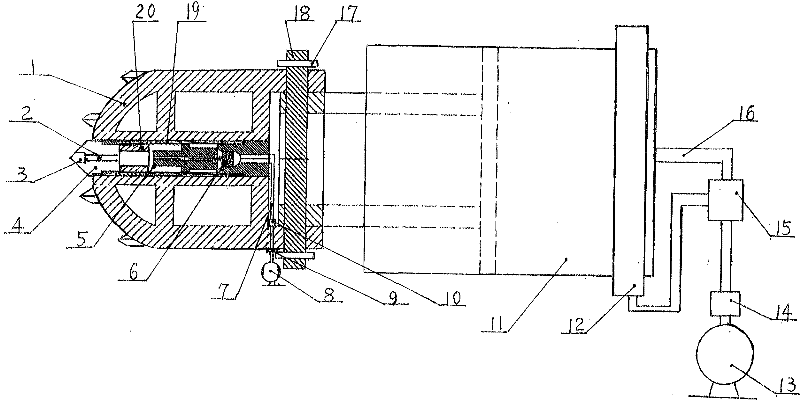

The invention provides a crawler wheel walking device capable of realizing wheel-crawler conversion. The crawler wheel walking device comprises a wheel-type drive system, a rotary high-pressure oil supply mechanism, a crawler belt drive system, a wheel-type power transmission system, a plurality of deformation adjusting mechanisms and a deformable crawler belt. The deformable crawler belt is positioned at the outermost layer of a walking device body and adopts flexible materials. The deformation adjusting mechanisms are uniformly arranged in the deformable crawler belt to control the walking device body to switch between a tire state and a crawler belt state. The rotary high-pressure oil supply mechanism provides deformation power for the deformation adjusting mechanisms, the crawler beltdrive system is located in the deformable crawler belt and is connected with teeth of the deformable crawler belt, and the wheel-type drive system is located at the axial center of the walking devicebody and is connected with the wheel-type power transmission system. The problem of poor adaptability of a traditional walking device to road conditions is solved. The designed crawler wheel walking device can switch the driving state according to different ground conditions, and thus the adaptability and trafficability of a vehicle to different ground conditions are improved.

Owner:CHINA NORTH VEHICLE RES INST

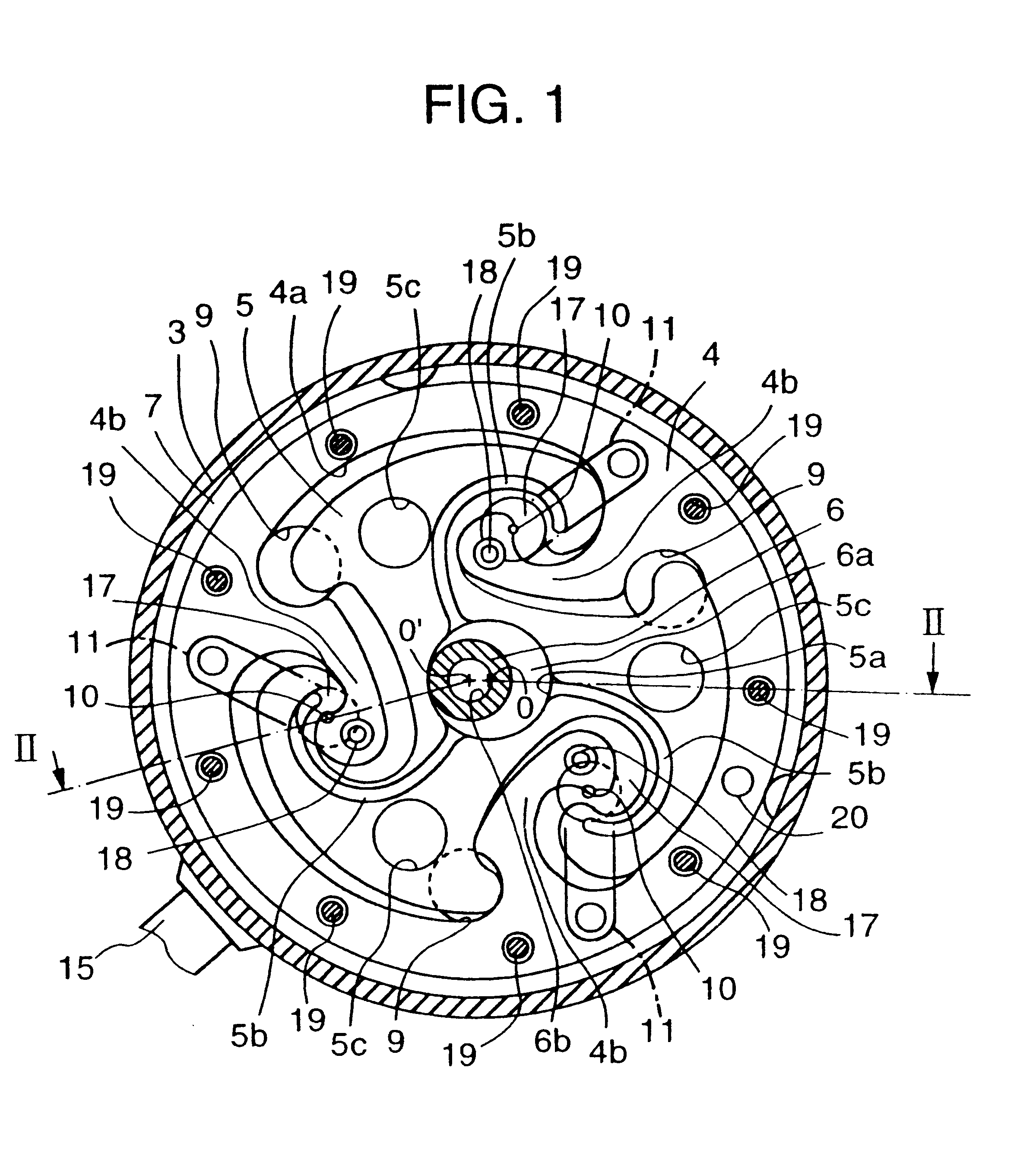

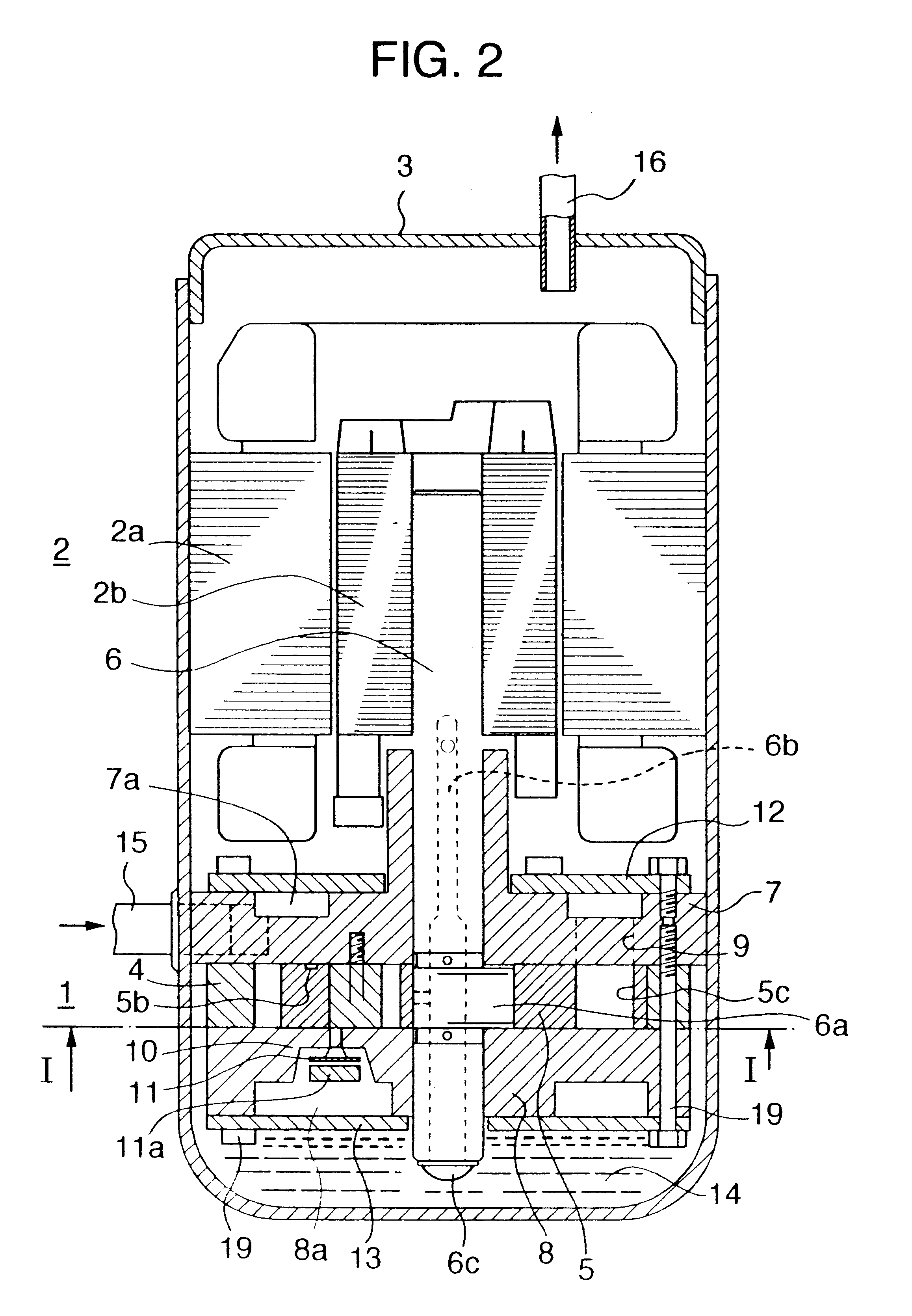

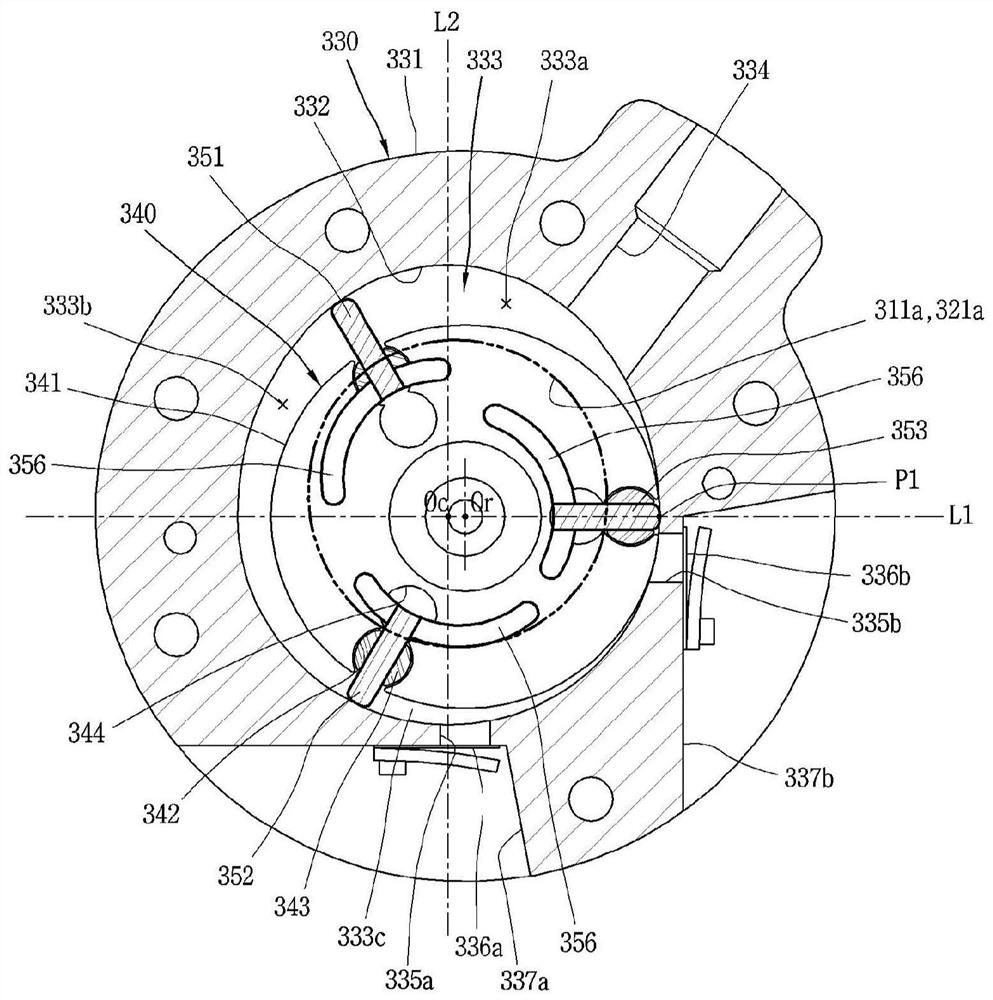

Displacement fluid machine

InactiveUS6217303B1Lower performance requirementsImprove performanceEngine of arcuate-engagement typeOscillating piston enginesWorking fluidEngineering

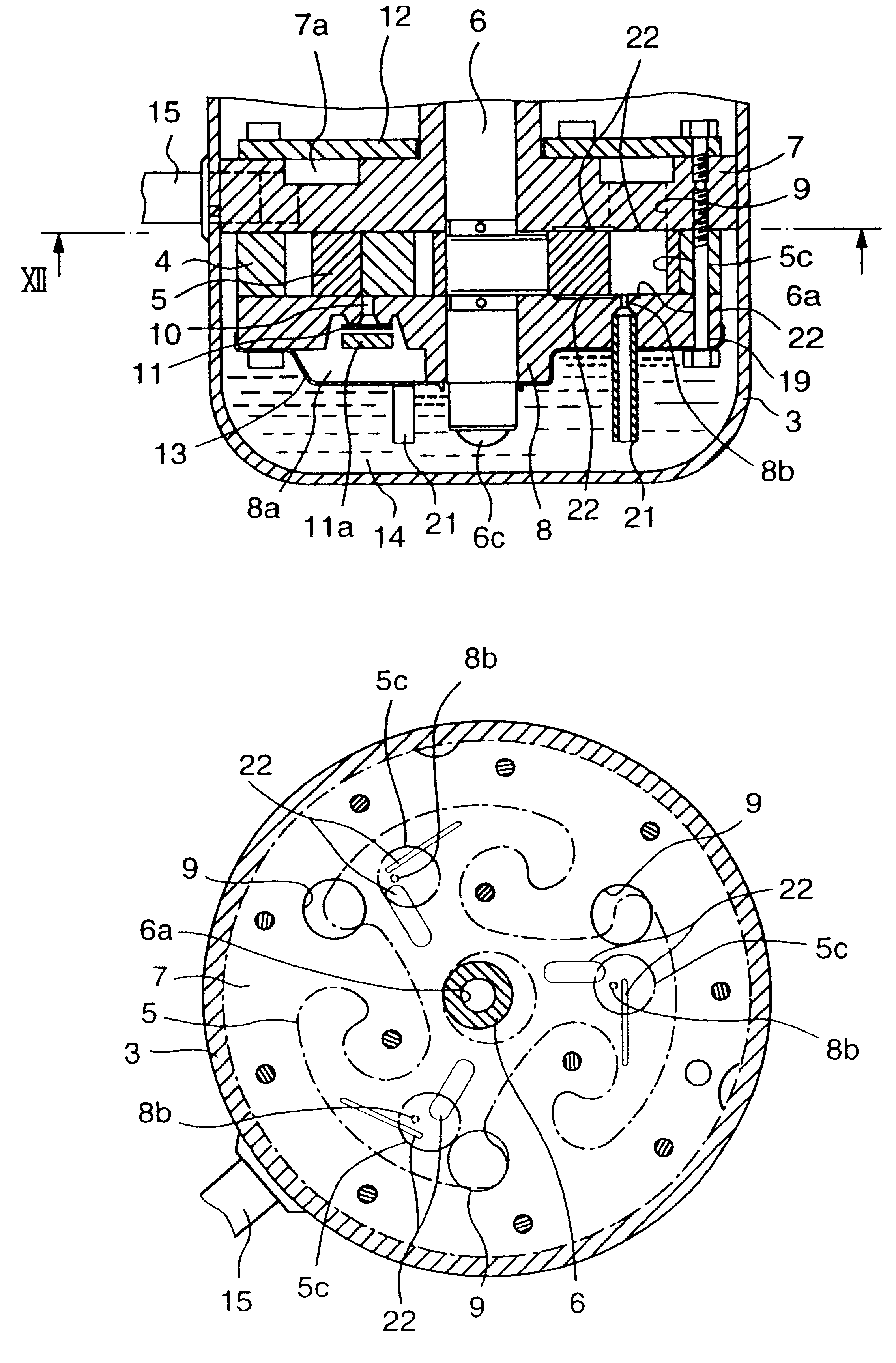

An orbiting fluid machine has a feature that the speed of sliding movement is low, while vibrations are small, its performance is lowered when the rotational speed becomes high, and this problem is resolved by the following structure. A displacement fluid machine includes a displacer making an orbital motion within a casing into which a working fluid is drawn, thereby drawing and discharging the working fluid, in which an oil retaining mechanism or a seal mechanism is provided at each of opposite end surfaces of the displacer. This results that, axial gaps at the end surfaces of the displacer are effectively sealed so as to reduce a leakage loss, thereby achieving a high performance and a high reliability.

Owner:HITACHI JOHNSON CONTROLS AIR CONDITIONING INC

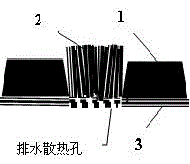

Pantograph pan with flexible electric brush

InactiveCN105459835AIncrease contactReduce contact resistancePower current collectorsCarbon fibersMetal fibers

The invention discloses a pantograph pan with a flexible electric brush. The pantograph pan is mainly composed of three parts including a rigid conductive panel, the flexible electric brush and a bottom plate. The rigid conductive panel can be a pure-carbon plate or a metal impregnation carbon plate or a powder metallurgy plate or a carbon fiber enhanced composite carbon plate. The flexible electric brush is an electric brush made of conductive fibers. The conductive fibers can be carbon fibers, graphite fibers or metal fibers or fibers achieved by blending the carbon fibers, graphite fibers and metal fibers to a scale, and are also doped with high temperature resisting aramid fibers of a certain scale. The rigid conductive panel and the flexible electric brush both adhere to the bottom plate through conductive glue. When the pantograph pan slides forwards, a contact net makes full contact with the conductive fibers on the flexible electric brush besides making contact with the rigid conductive panel, multidirectional stereoscopic friction is formed, and the purpose of current-feeding power supply is achieved; electric arcs are greatly reduced, electric abrasion to pantograph catenary is reduced, the service life of a pantograph and the pantograph pan is prolonged, and the maintenance and replacement cost are decreased; the pantograph pan is suitable for not only low-speed trains but also high-speed trains.

Owner:上海洲跃生物科技有限公司

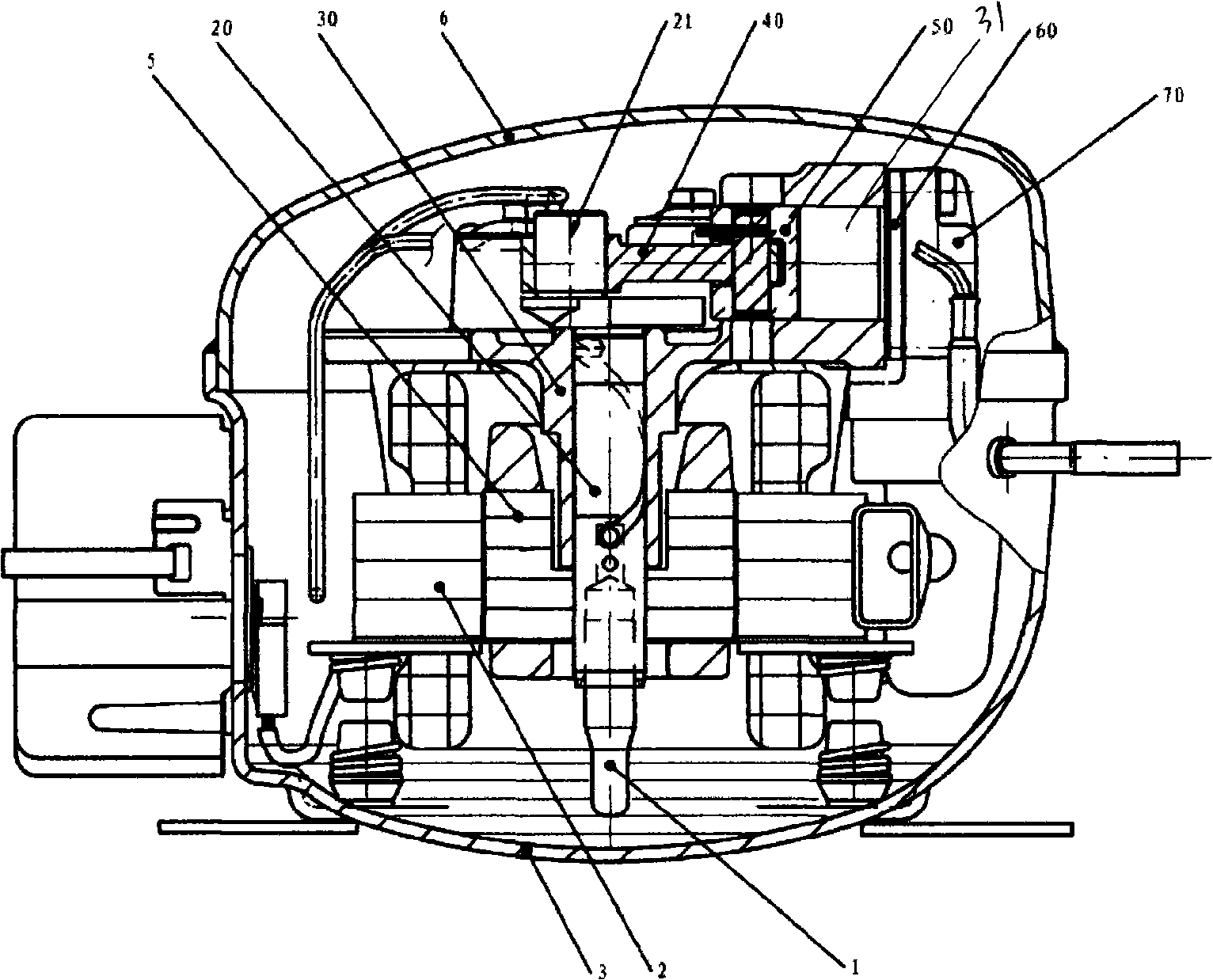

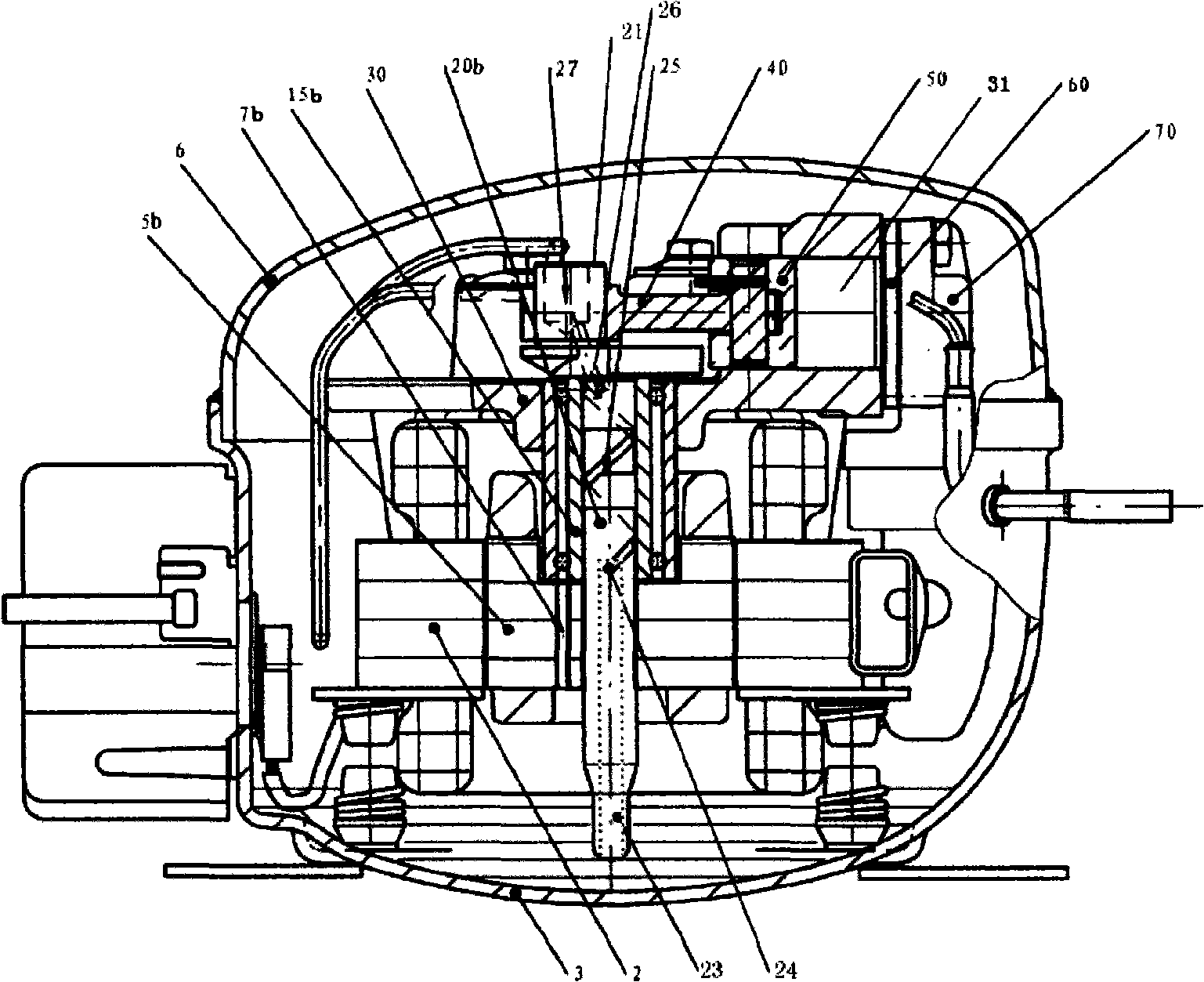

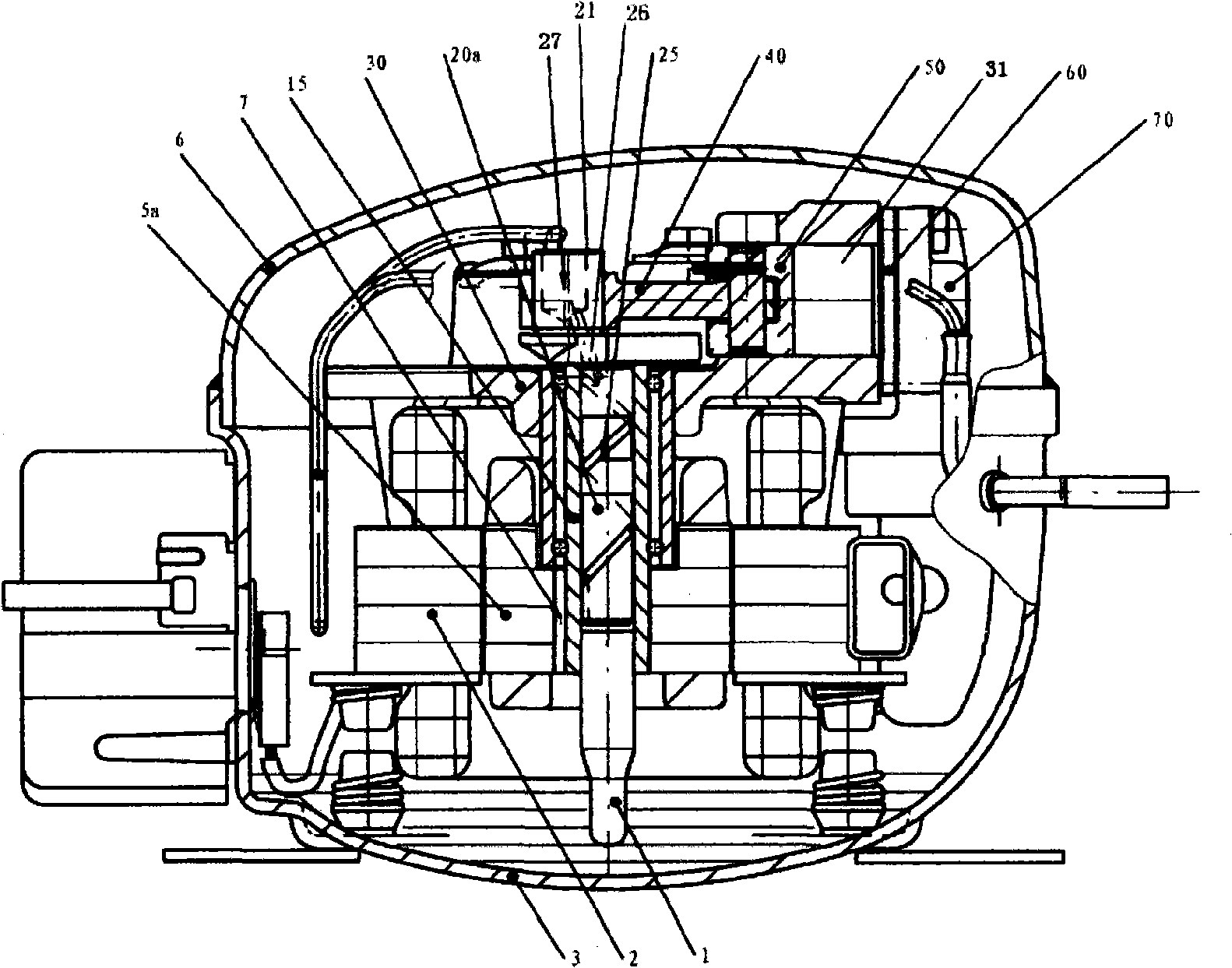

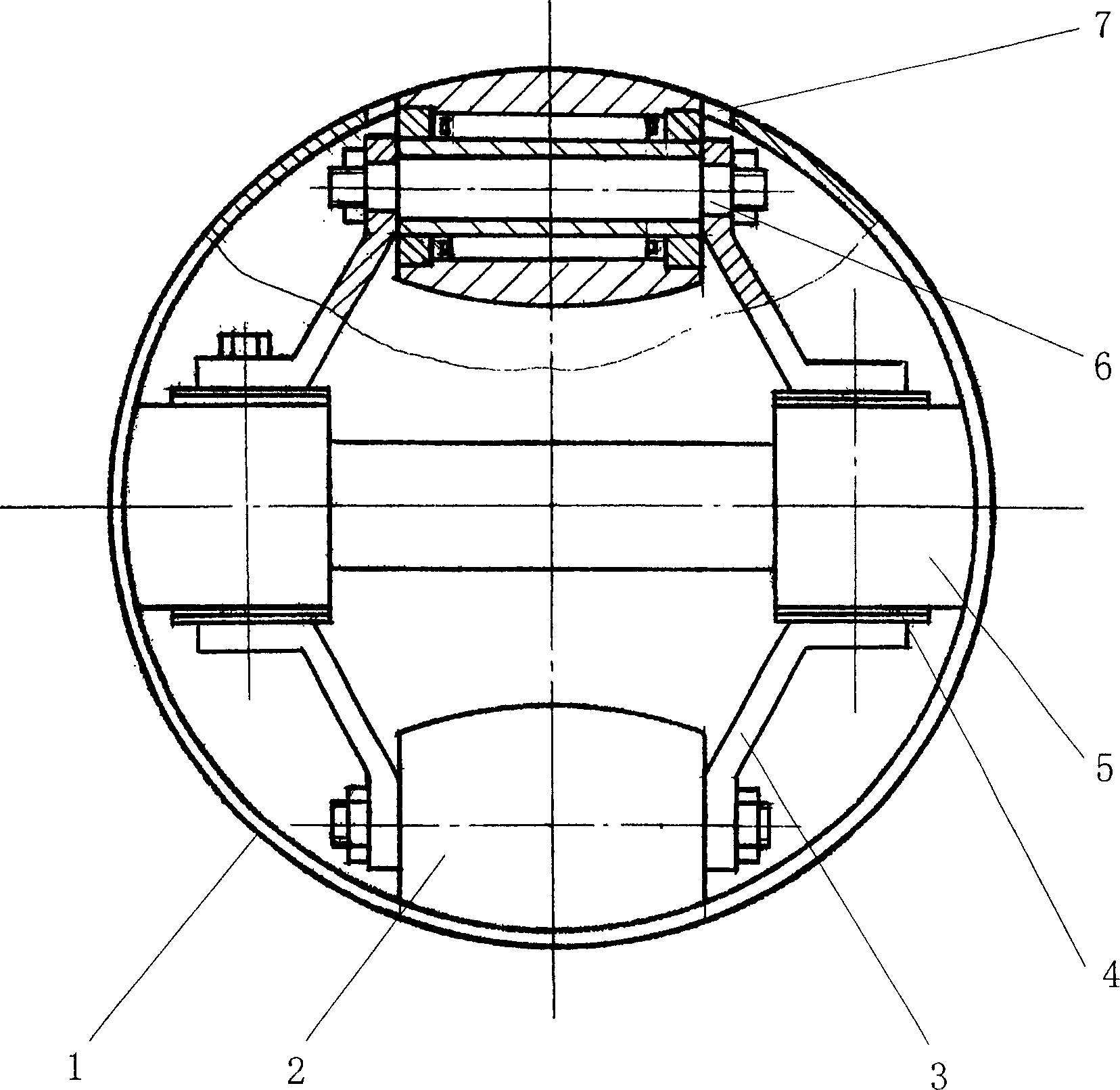

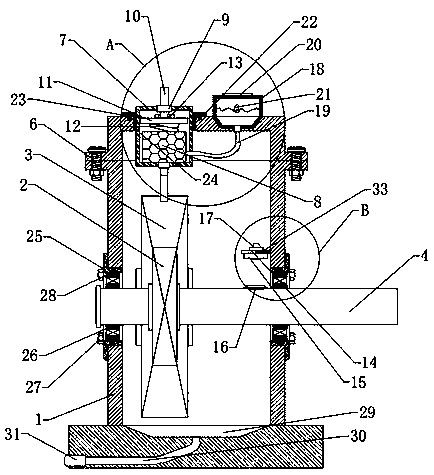

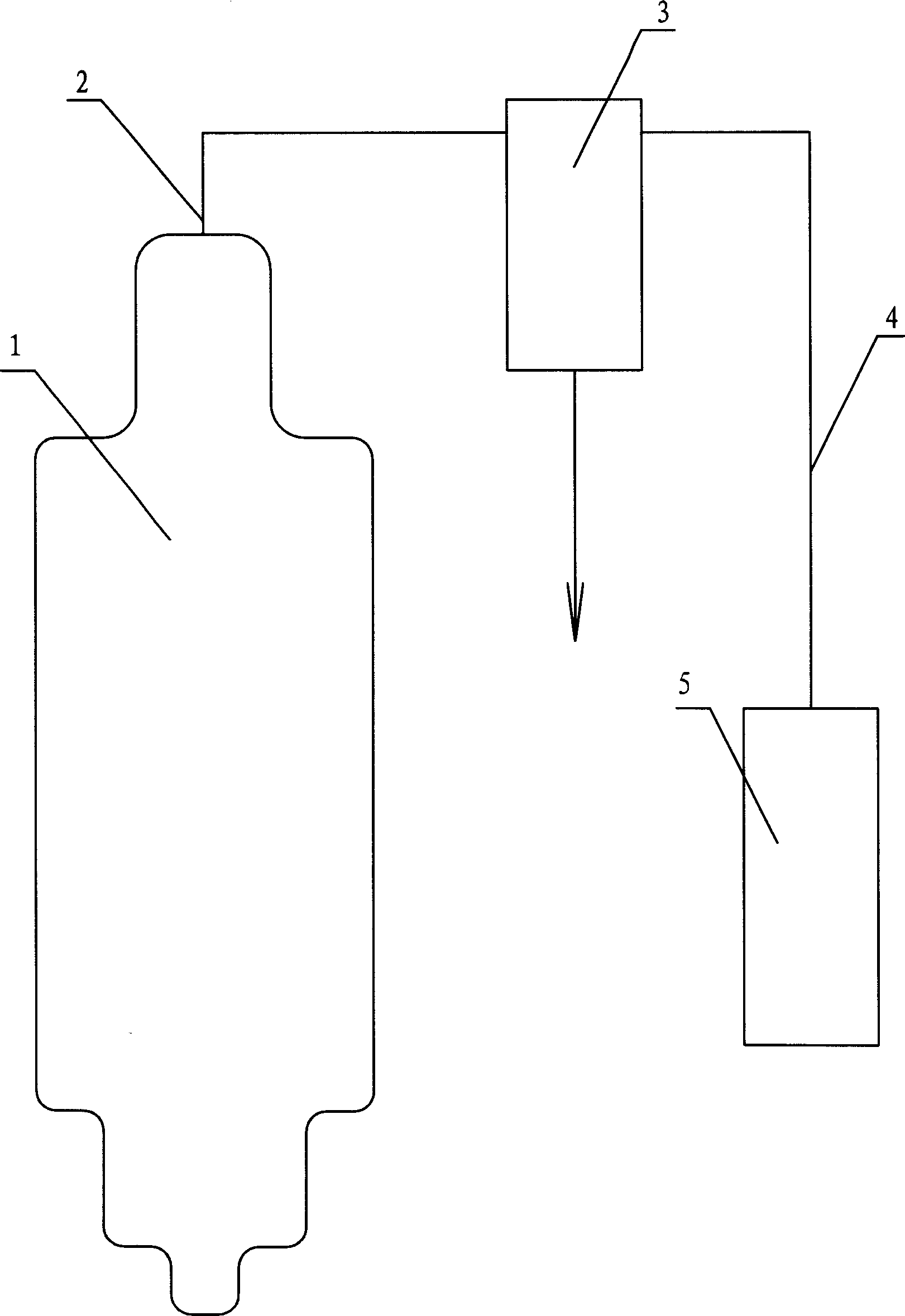

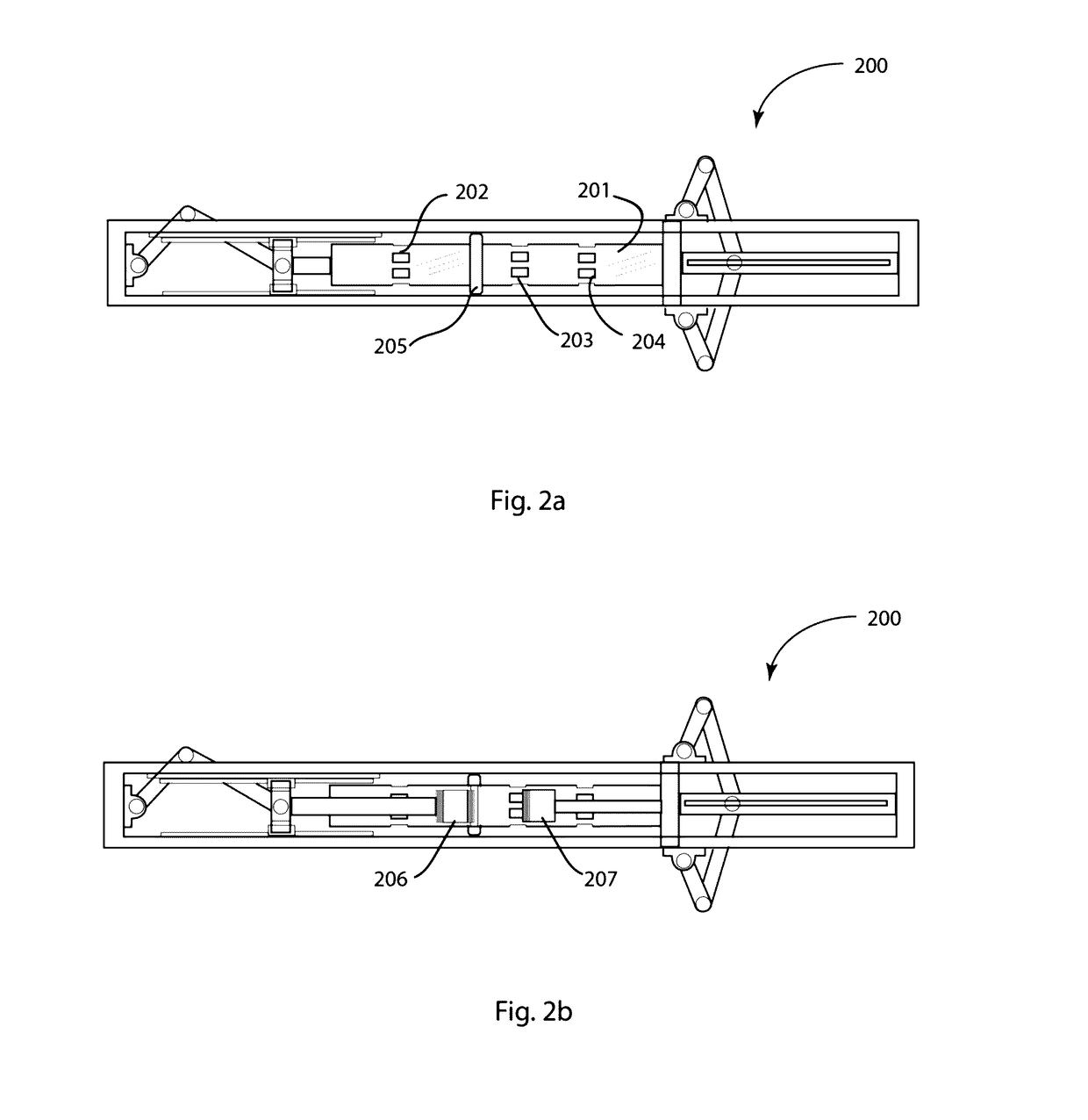

Encapsulated refrigeration compressor

InactiveCN101344081AImprove performanceReduce mechanical friction lossPositive displacement pump componentsPiston pumpsRefrigeration compressorRolling resistance

The invention provides a sealed type cold compressor which is provided with a sealed shell, an electric motor and a gas compression device are arranged in the sealed shell; the gas compression device comprises a cylinder block, a crank shaft, a cylinder, a piston and accessories, the middle part of the cylinder block is provided with a crank shaft mounting hole, one end of the crank shaft is provided with an eccentric shaft which is connected with the piston arranged in the cylinder by a piston connecting bar, and the crank shaft is provided with a lubricant supply passage; the compressor is characterized in that: the crank shaft mounting hole is internally sheathed with a double row ball bearing subassembly, the crank shaft passes through the axle hole of the double row ball bearing subassembly, and the rotor of the electric motor is sheathed in the inner ring over-long section of the crank shaft or the double row ball bearing subassembly. The double row ball bearing subassembly adopted by the invention can bear the axial load and radial load simultaneously to cause a main bearing on the crank shaft to move in a rolling friction way in the axial direction and the radial direction, thus greatly reducing the mechanical friction loss of the main bearing to improve the compressor performance; the sealed type cold compressor has the advantages of simple structure and convenient assembly, etc.

Owner:GUANGZHOU REFRIGERATION CO LTD

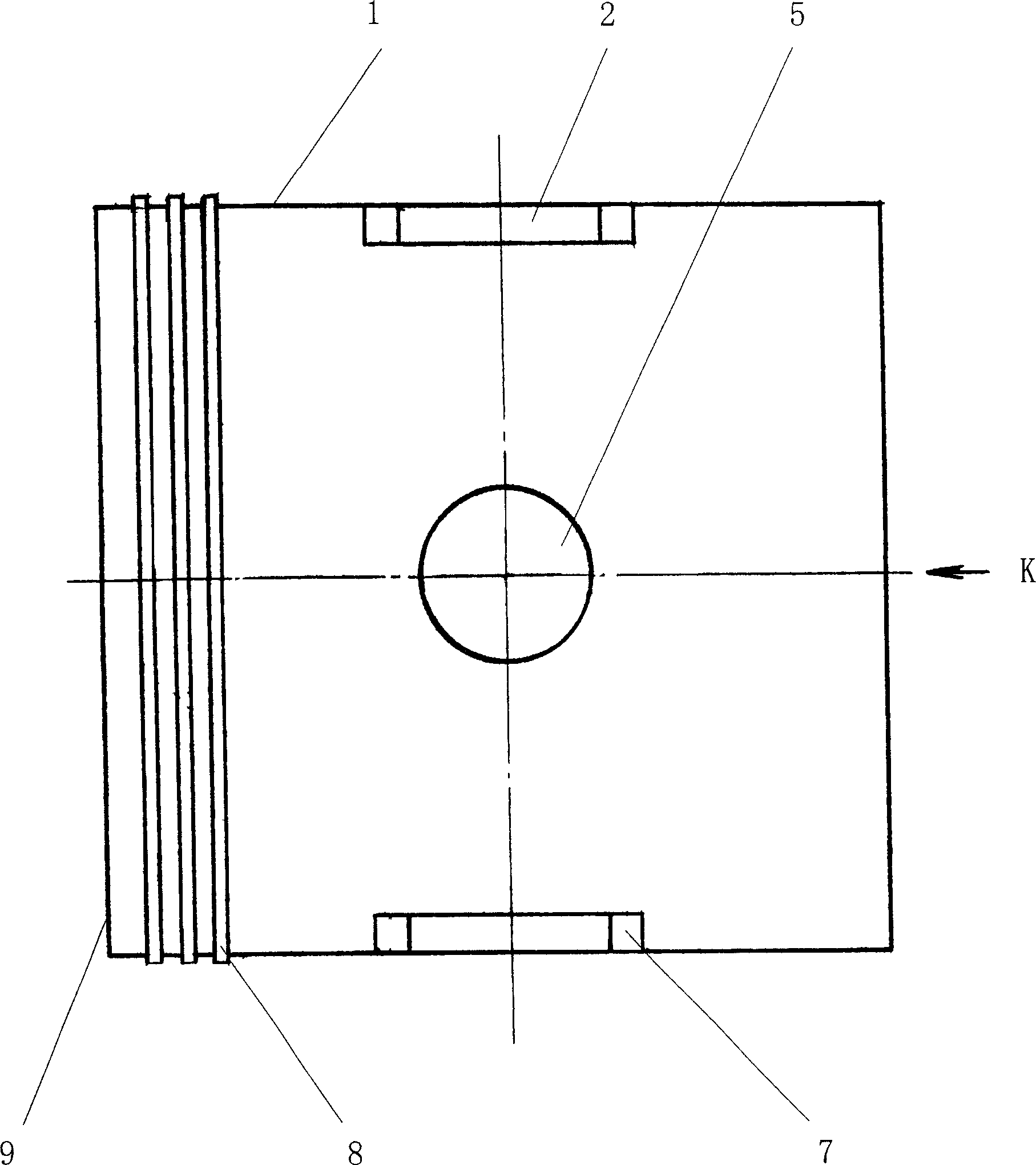

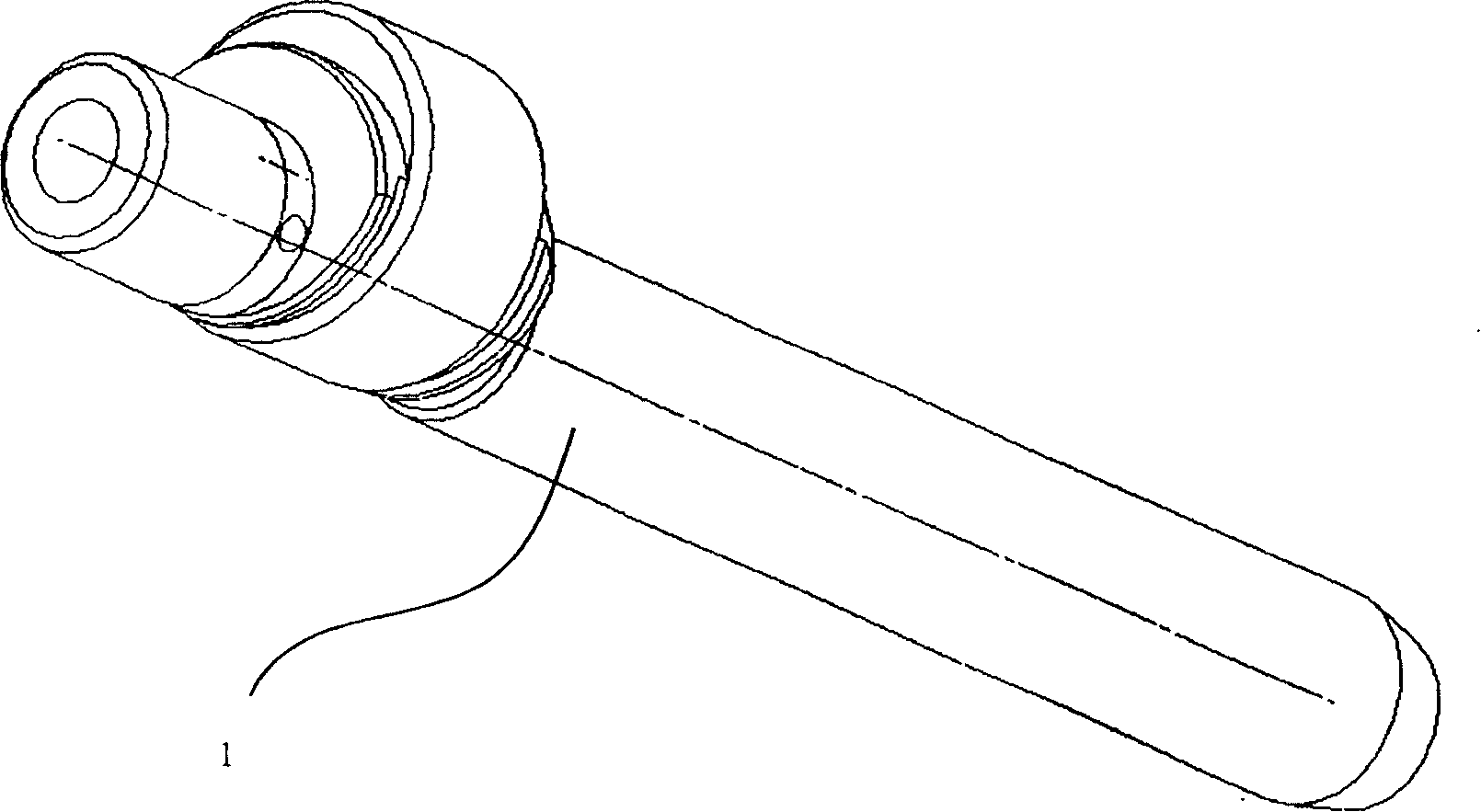

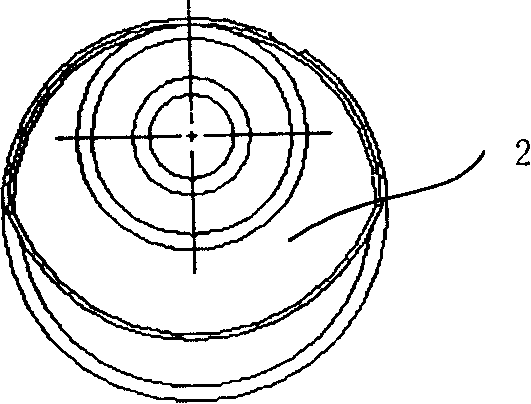

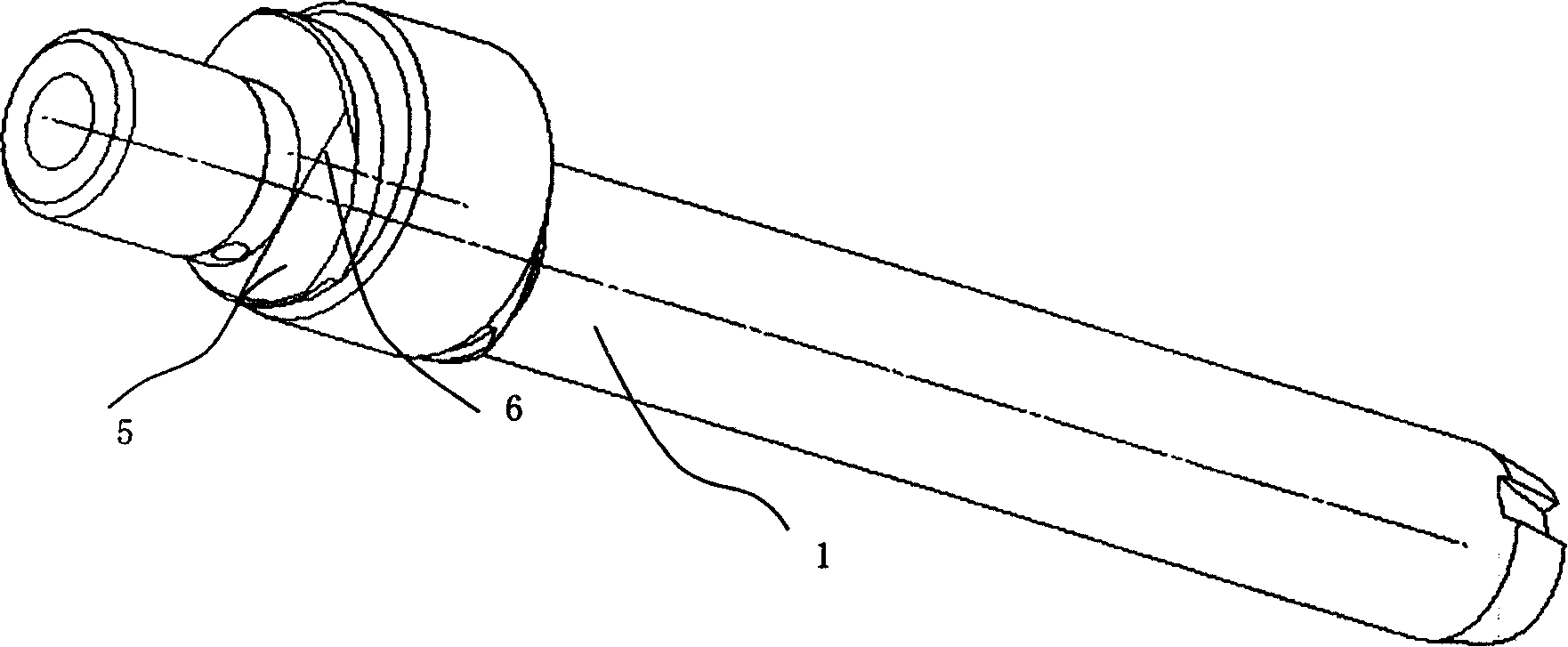

Curved surface rolling bearing type piston for internal combustion engine

InactiveCN1840884AMovement stabilityReduce noiseMachines/enginesPistonsCombustionRolling-element bearing

The invention discloses a combustion engine camber drum shaft gas piston for improving the power mechanical efficiency, which is composed of piston skirt, packing ring and piston pin hole wall, wherein there is a open on the lateral surface of the piston skirt; the camber antifriction bearing is installed in the piston skirt; the camber antifriction bearing is fixed on the inner wall of the gas piston; The invention reduces the mechanical frictional loss and wasted power, which improves the power mechanical efficiency.

Owner:柴俭

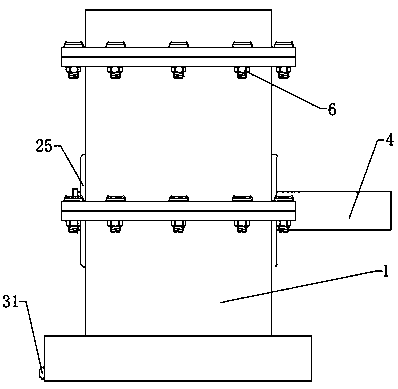

Six-surface automatic linkage beautifying system for cigarette case plastic packaging film

PendingCN114684427ASolve the problem that it is impossible to realize the beauty of the plastic packaging film of cigarette boxes onlineSmall footprintWrappers shrinkagePlastic packagingCarton

The invention relates to a six-face automatic linkage beautifying system for a cigarette carton box plastic packaging film, which comprises three continuous sections of beautifying mechanisms, namely a cigarette carton box end face beautifying mechanism, a cigarette carton box front and back face beautifying mechanism and a cigarette carton box side face beautifying mechanism in sequence, each beautifying channel comprises a pair of heating plates which are clamped oppositely, the heating plates are connected in a linkage mode, and the heating plates are controlled to be opened and closed through cams to beautify a group of opposite sides of the cigarette case. And the temperature of the heating plate is controlled to be just capable of hot ironing the plastic packaging film, so that the plastic packaging film at the corner of the cigarette case can be fitted, the surface is relatively smooth, the plastic packaging film can be neatly fitted on the surface of the cigarette case, and the appearance is attractive.

Owner:NANJING DASHU INTELLIGENT SCI & TECH CO LTD

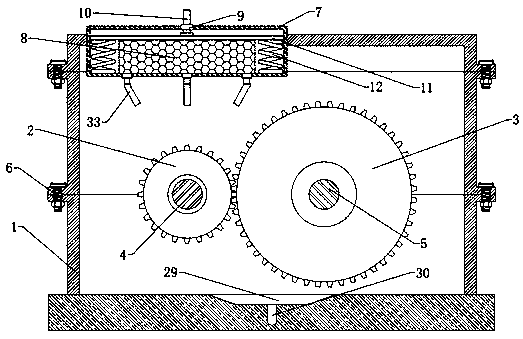

Split type mechanical variable speed equipment with automatic lubricating function

The invention discloses split type mechanical variable speed equipment with an automatic lubricating function, which includes a casing, a driving gear, a driven gear, a driving shaft and a driven shaft, wherein the casing is a steel hollow casing with a rectangular structure. The split type mechanical variable speed equipment has the following beneficial effects: the mechanical variable speed equipment is simple in structure and convenient to assemble, is convenient to replace and maintain as all the structures are independently mounted in a split manner, and after the above mechanical lubrication structure rotates for a certain rings at the driving shaft, the driving gear and the driven gear are lubricated automatically; besides, a resistance reduction structure is used for resistance reduction for the driving shaft and the driven shaft to further reduce mechanical frictional loss; a liquid leakage recycling structure is externally connected with a suction pump, so that lubricating oil during lubrication and production is recycled to avoid waste; through the structure cooperation, the variable speed device can be regularly and automatically lubricated during operation to effectively reduce the intensity of maintenance.

Owner:黄宇霖

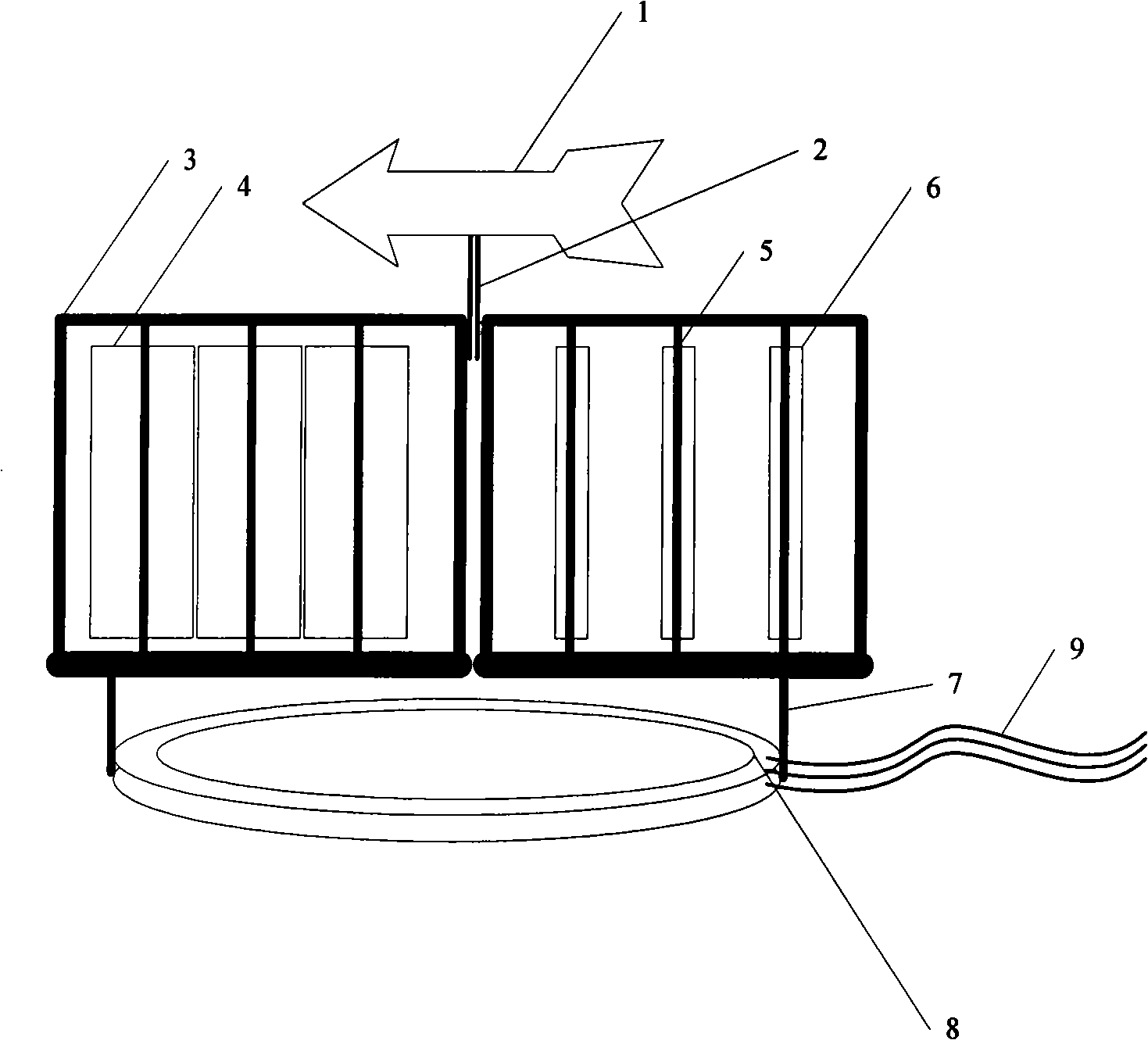

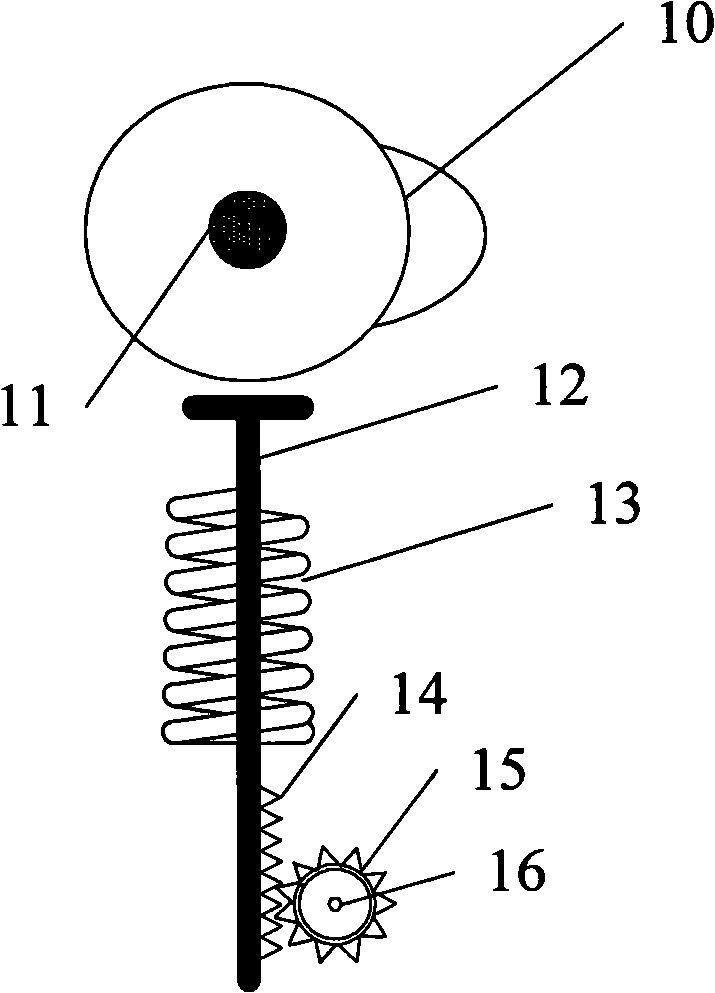

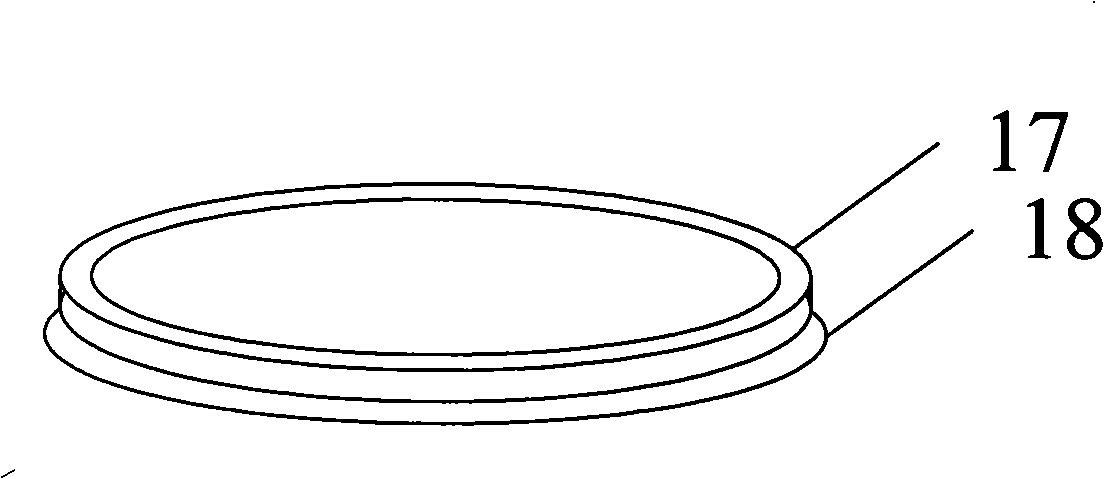

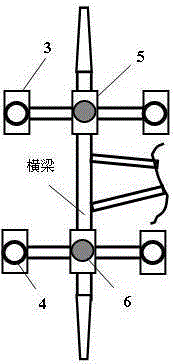

Super highly effective hollow direct drive generating plant possessing anti-gravity magnetic suspension bearing

InactiveCN101285453AReduce lossReduce stressMagnetic circuit rotating partsWind motor controlSocial benefitsAnti-gravity

The invention relates to ultra-high efficiency tubular direct driving type generating equipment provided with an antigravity magnetic suspension bearing. The generating equipment has a structure which is as follows: a non-reversed resistance wind wheel structure converts wind energy into mechanical energy; a tubular direct driving generator converts the mechanical energy into the electric energy; a controller converts and stores the electric energy generated by the generator; the upper part of a power linear overlapping wind wheel matrix is provided with a wind direction helm; a converting controller is arranged between the ultra-high efficiency tubular direct driving generator and an electric network to realize the connection of the tubular direct driving generator on a wind wheel matrix rotating shaft and the converting and storing of the electric energy generated by the generator through the controller; the wind direction helm is arranged on a fixed bracket of the wind wheel matrix by a cam rotating mechanism; the wind wheel matrix consists of the fixed bracket, a vane supporting rotating mechanism arranged inside the fixed bracket, a wind-facing vane and a wind-back vane arranged on the rotating mechanism; the wind wheel matrix is connected with the tubular direct driving generator by a connecting mechanism; and an output end of the wind wheel matrix is connected with the electric network by a cable. The ultra-high efficiency tubular direct driving type generating equipment has huge economic benefits and social benefits.

Owner:张静传

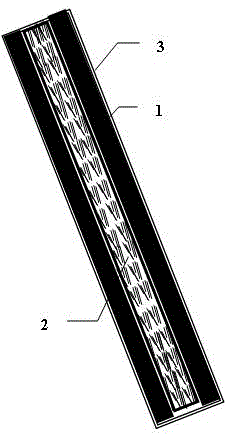

Rigidity and flexibility combined pantograph slide plate device

InactiveCN105329106AIncrease contactGood catenary contactPower current collectorsConductive materialsEngineering

The invention discloses a rigidity and flexibility combined pantograph slide plate device. The rigidity and flexibility combined pantograph slide plate device is formed by adding a flexible slide plate on the basis of a traditional rigid slide plate. The traditional rigid slide plate and the flexible slide plate are assembled on the same pantograph head. The flexible slide plate is made from a flexible conductive material. Good contact between the flexible slide plate and a contact net can be achieved under small contact force, and therefore the contact resistance of the slide plates is reduced, and electric heating ablation caused when local temperature is too high can be reduced. Contact between the flexible slide plate and the contact net can be kept at any time even in oscillation caused by a pantograph net, the offline possibility is reduced, and therefore electric arcs can be greatly reduced, and electric abrasion between the slide plates and the contact net is reduced. Meanwhile, the number of conductive spots is greatly increased due to the concave contact face of the flexible slide plate, the pressure of contact between the flexible slide plate and the pantograph net can be remarkably reduced compared with the traditional rigid slide plate, and therefore mechanical friction and loss of the rigid slide plate are reduced, the service life of the slide plates can be greatly prolonged, and maintenance and replacement cost is reduced. The rigidity and flexibility combined pantograph slide plate device is suitable for subways, light rails and other low-speed electric automobiles and is also suitable for high-speed trains.

Owner:上海洲跃生物科技有限公司

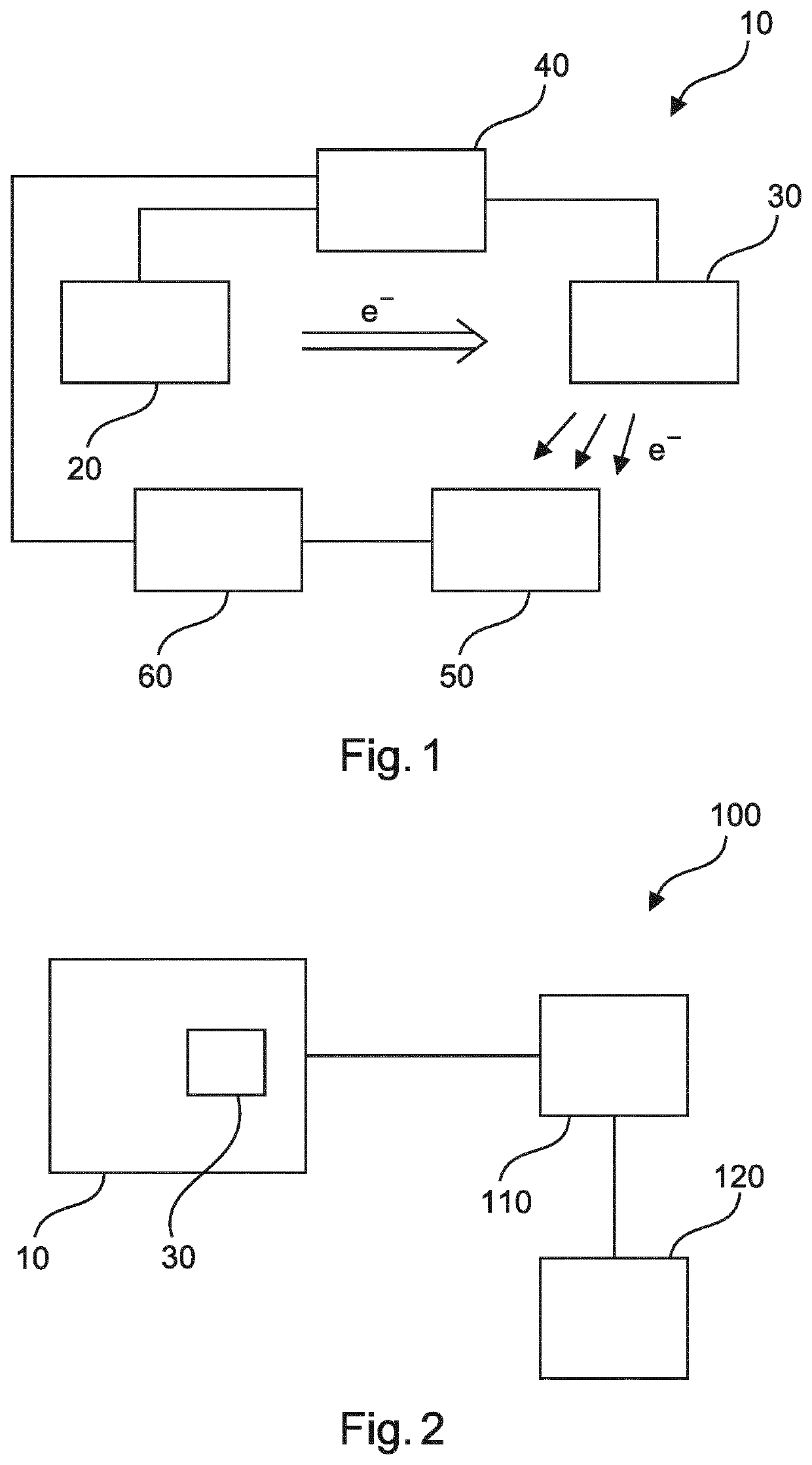

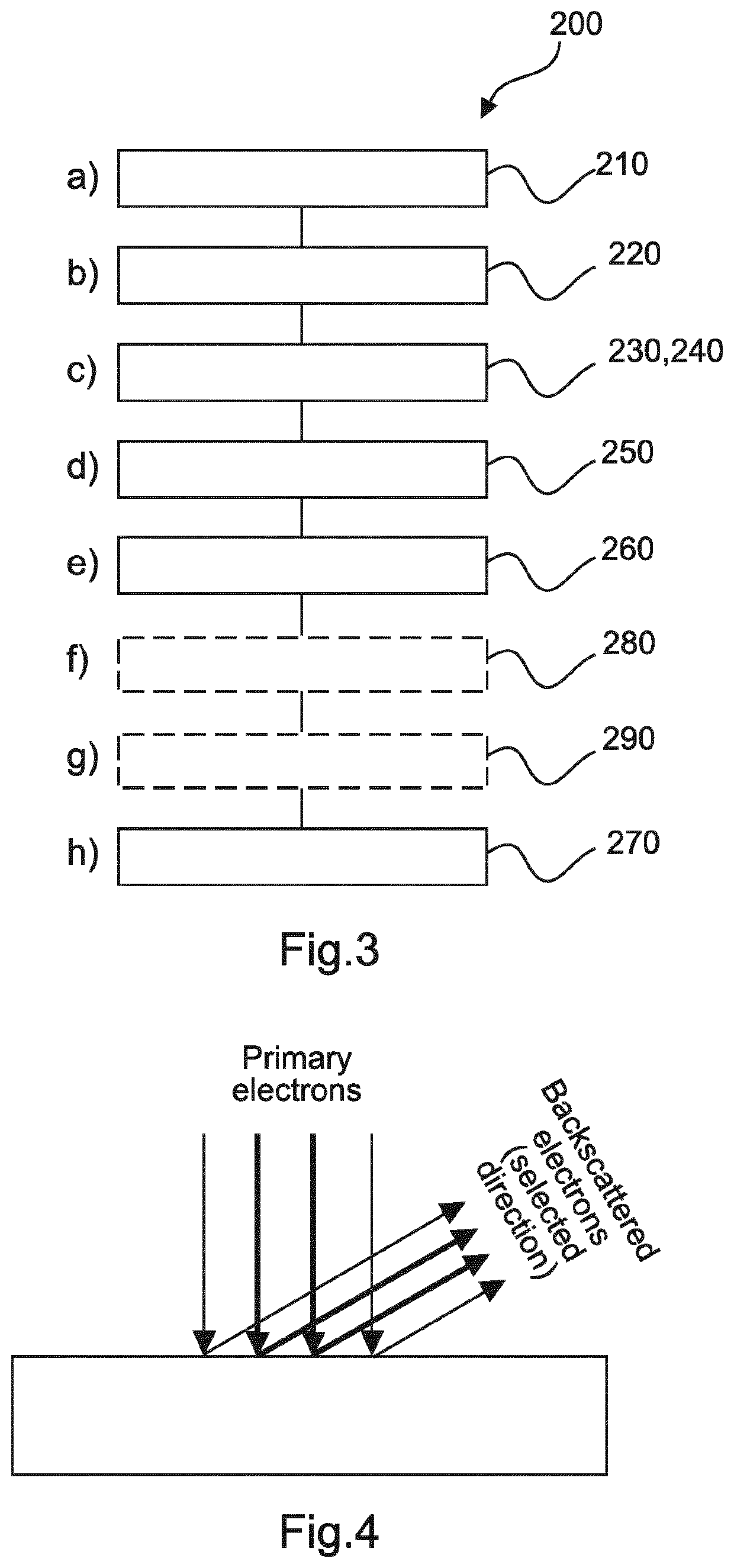

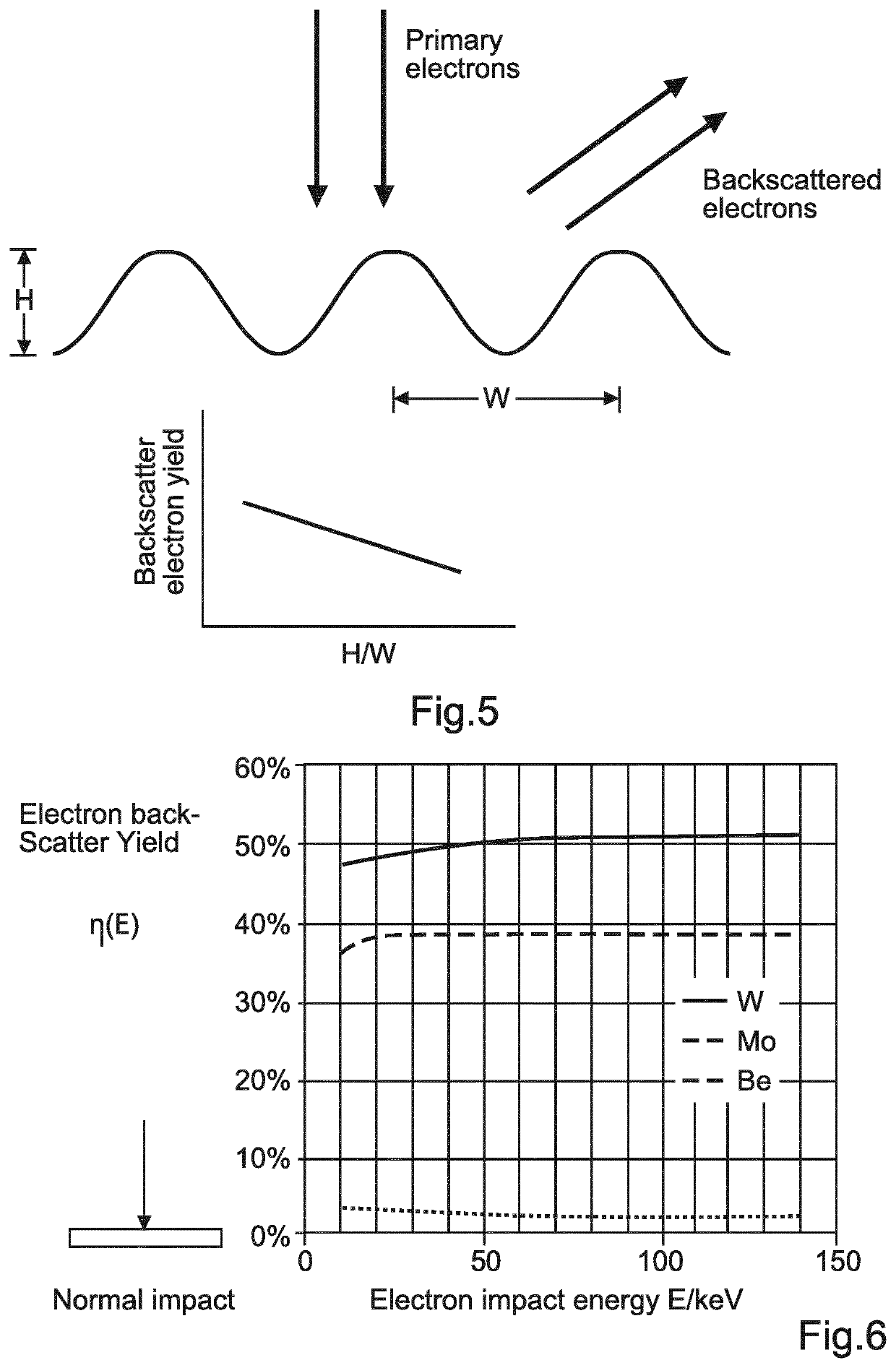

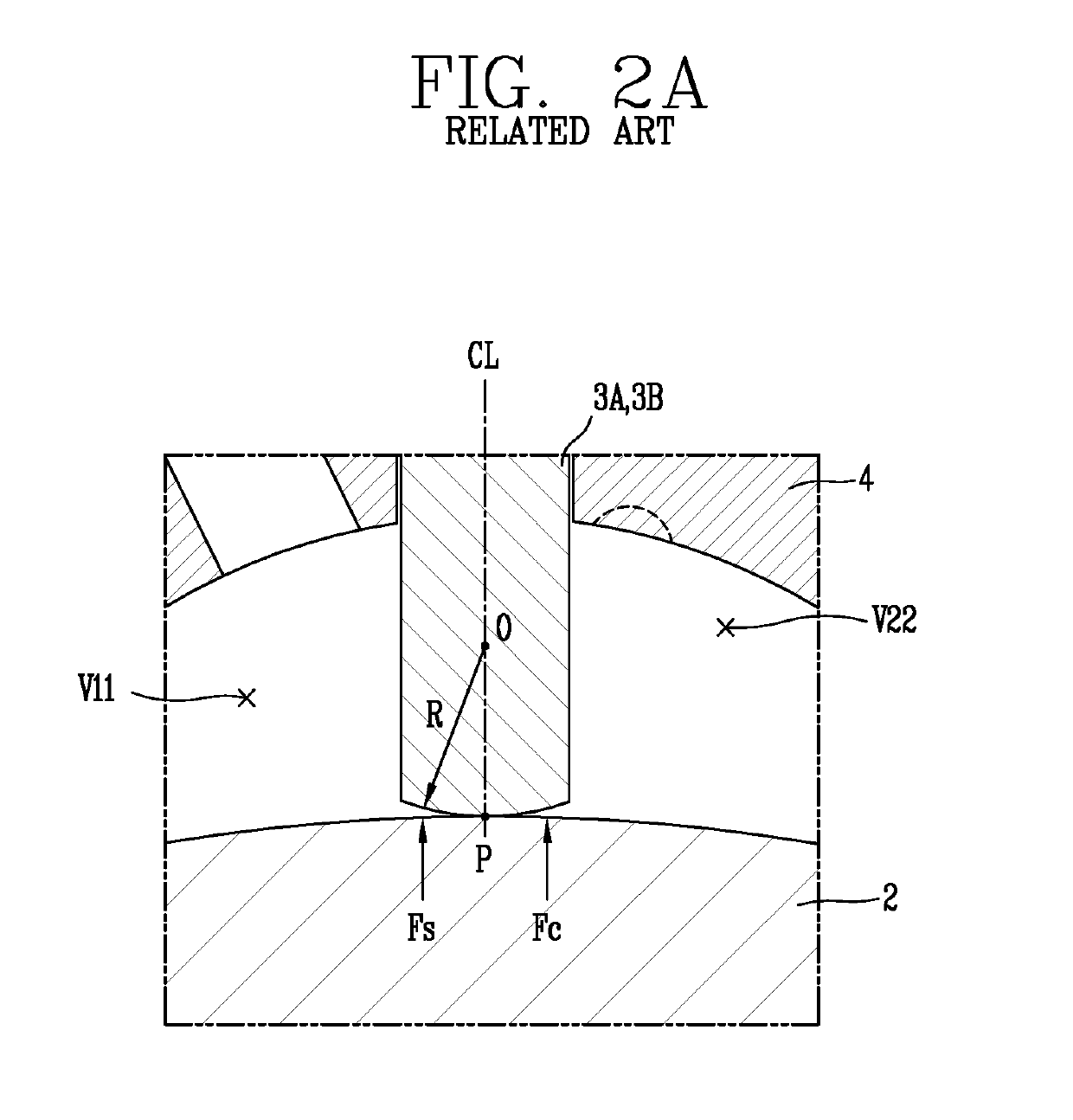

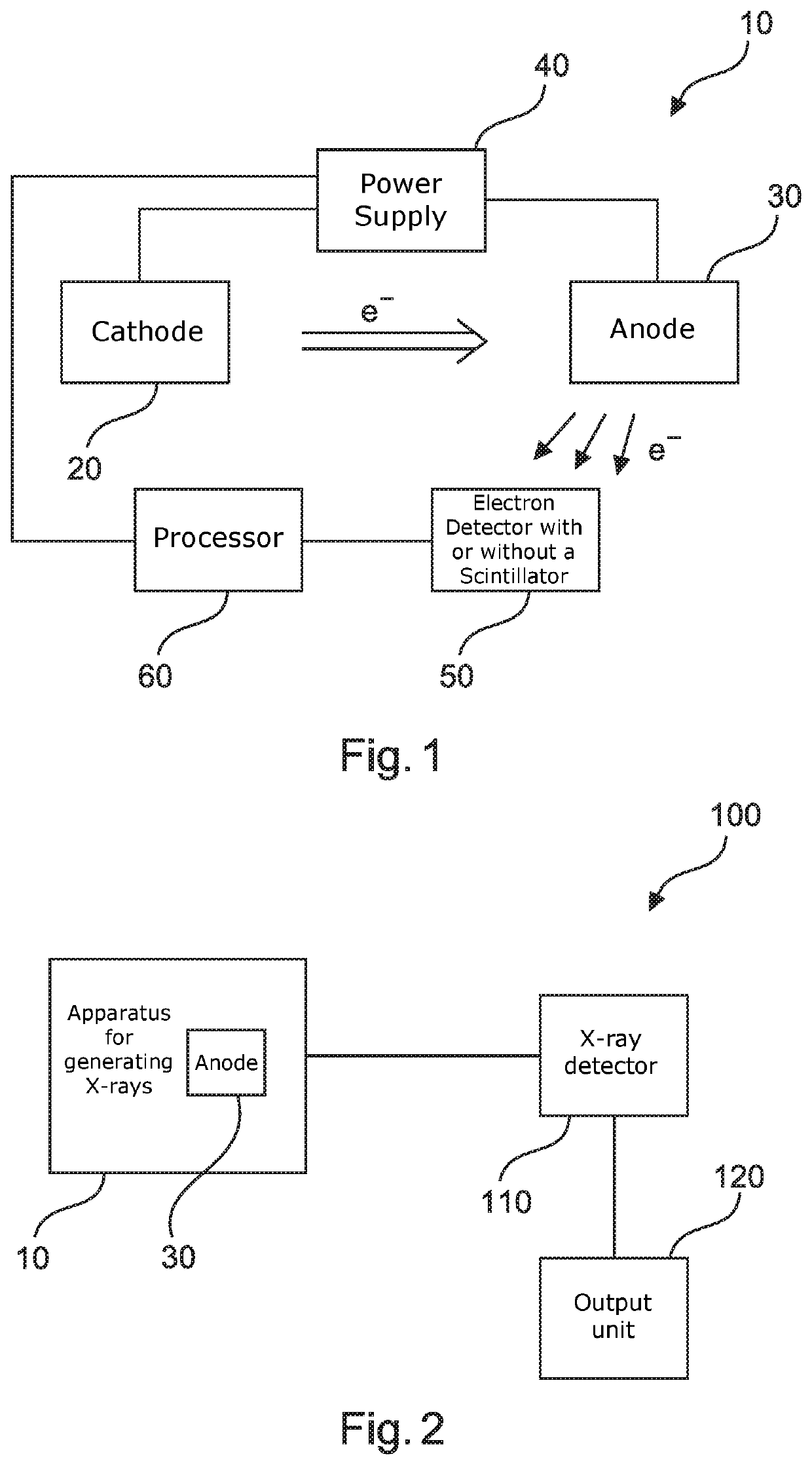

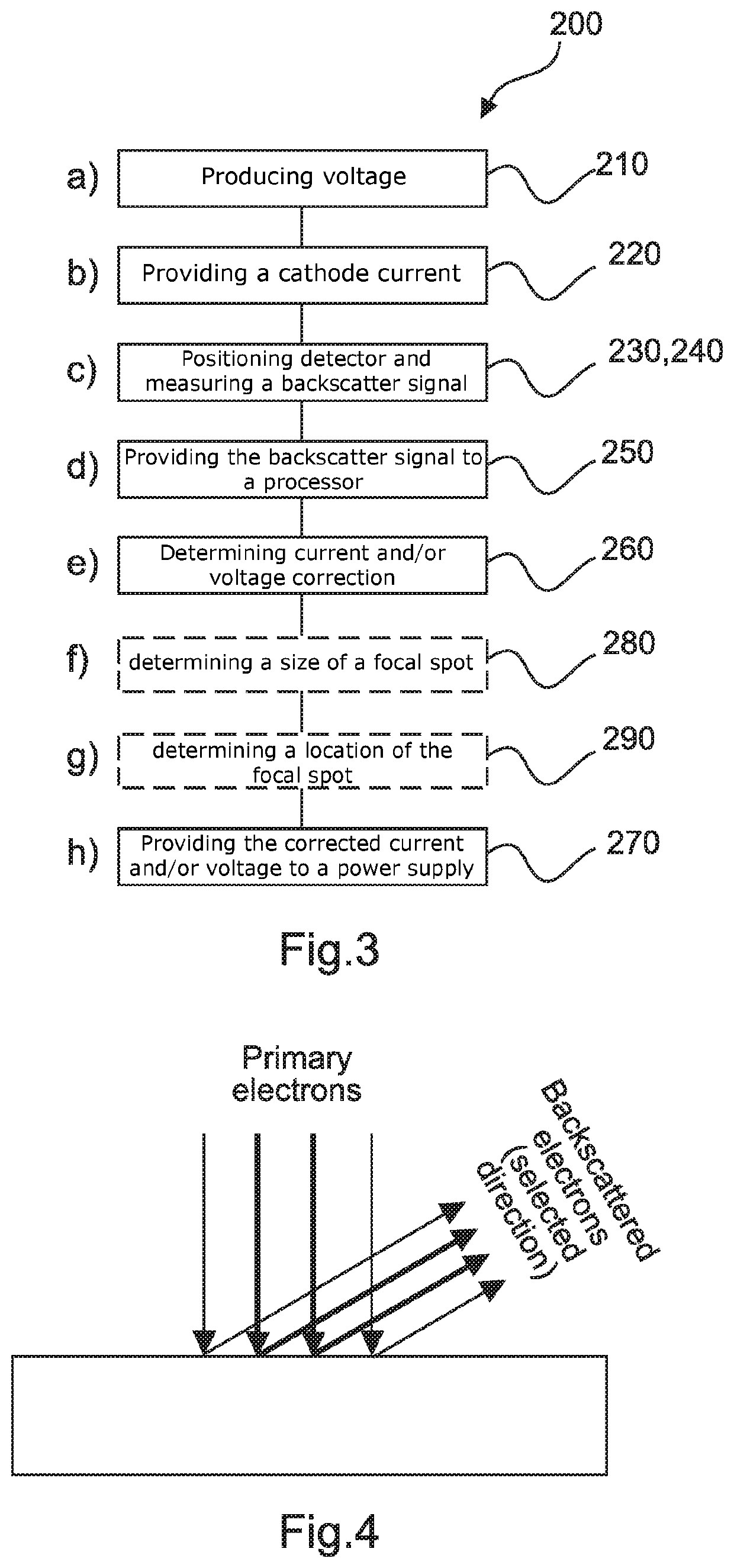

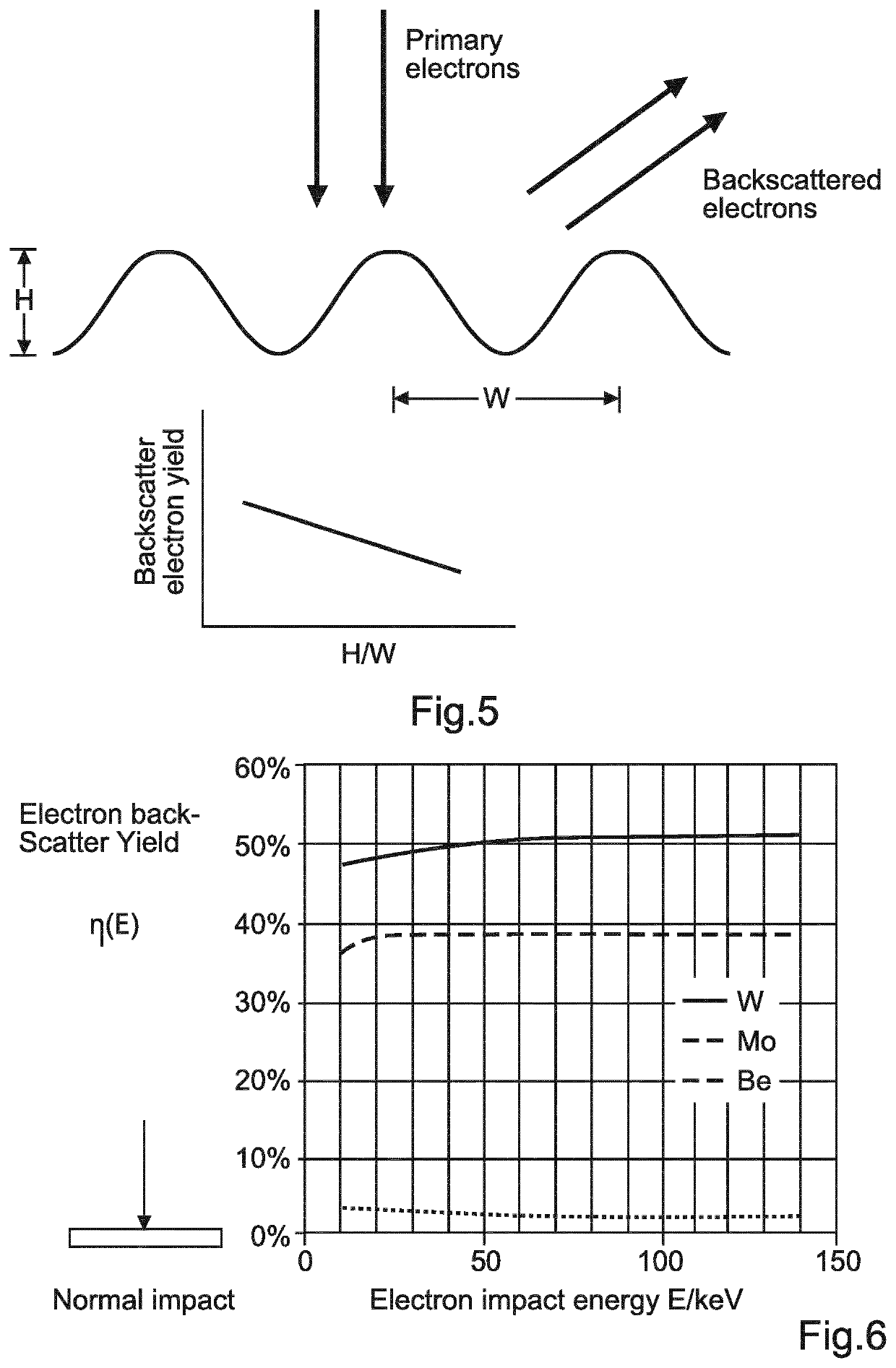

Apparatus for generating x-rays

ActiveUS20200154553A1Low costMaximize sizeRadiation diagnostics testing/calibrationX-ray tube electrodesParticle physicsQuantum electrodynamics

The present invention relates to an apparatus (10) for generating X-rays. It is described to produce (210) with at least one power supply (40) a voltage between a cathode (20) and an anode (30). The cathode is positioned relative to the anode, and the cathode and anode are operable such that electrons emitted from the cathode interact with the anode with energies corresponding to the voltage, and wherein the electrons interact with the anode at a focal spot to generate X-rays. The at least one power supply provides (220) the cathode with a cathode current. An electron detector (50) is positioned (230) relative to the anode, and a backscatter electron signal is measured (240) from the anode. The measured backscatter electron signal is provided (250) to a processing unit (60). The processing unit determines (260) a cathode current correction and / or a correction to the voltage between the cathode and the anode, wherein the determination comprises utilization of the measured backscatter electron signal and a correlation between anode surface roughness and backscatter electron emission. The cathode current correction and / or the correction to the voltage between the cathode and the anode is provided (270) to the at least one power supply.

Owner:KONINKLJIJKE PHILIPS NV

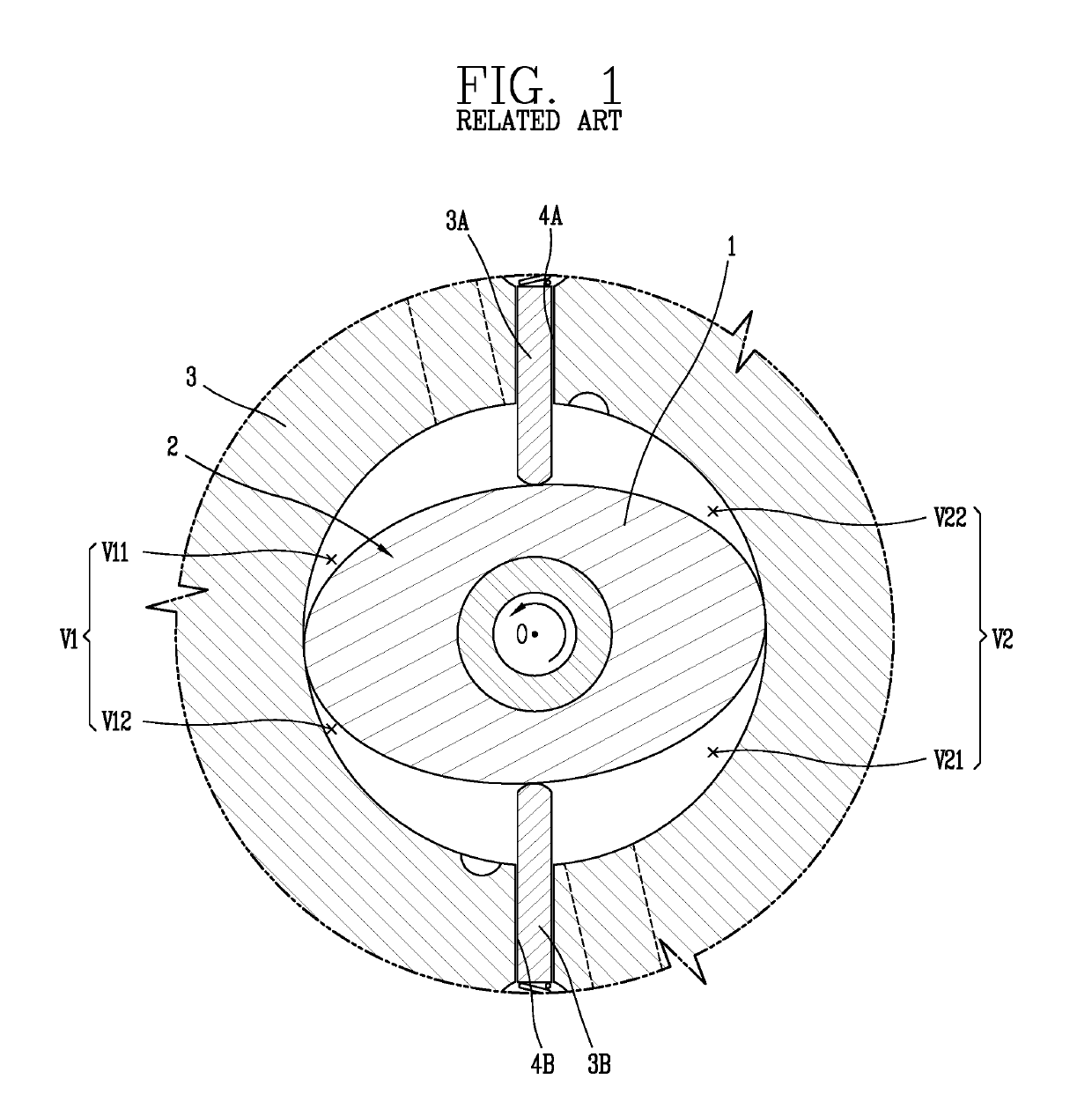

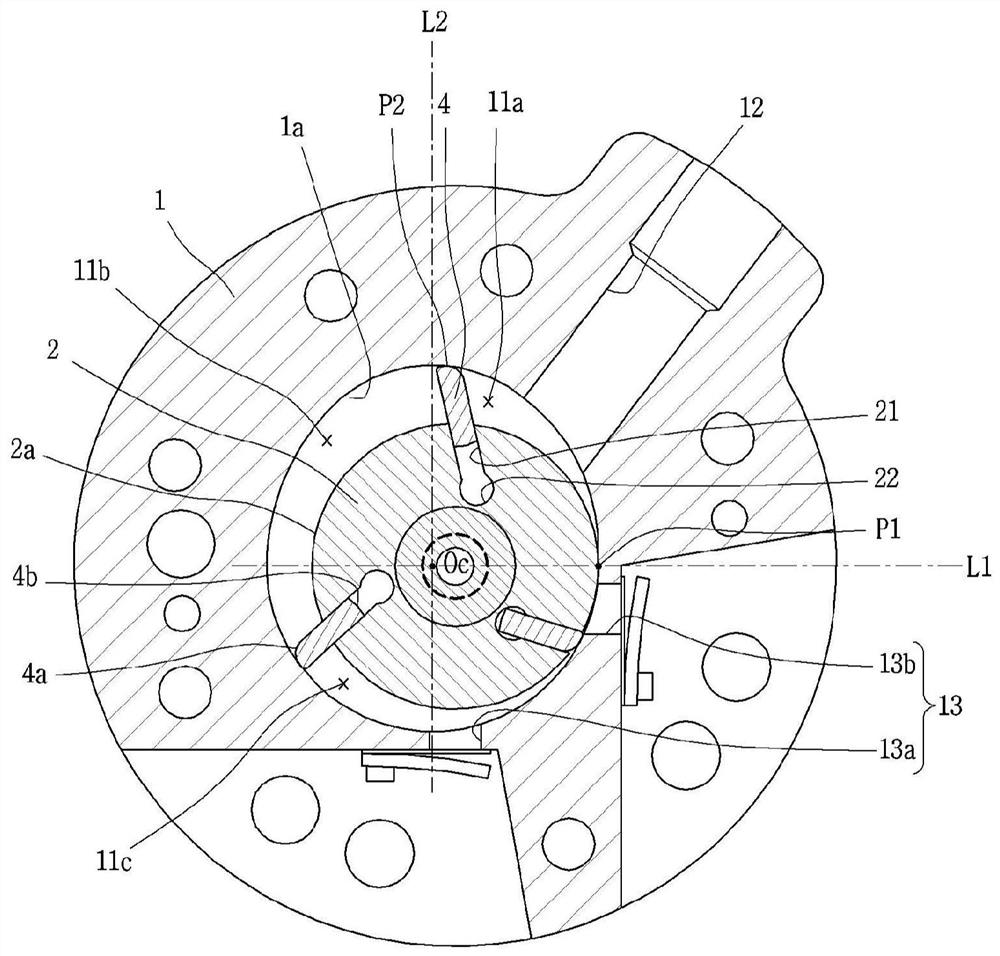

Rotary compressor having fluid passage between sliding vane and vane slot

ActiveUS10473102B2Reduce contact forceReduce mechanical friction lossRotary/oscillating piston combinations for elastic fluidsSealing arrangement for pumpsDischarge pressureEngineering

A compressor is provided in which an outer circumferential side cross-sectional area of a vane slot is formed smaller than an inner circumferential side cross-sectional area thereof to decrease an area receiving a force in a roller direction by a vane to reduce a contact force between the roller and the vane, and a gas accommodation portion selectively forming a suction pressure and an intermediate pressure is formed between the vane and the vane slot to control the contact force. A contact surface of the vane facing the roller is formed at a side of a compression chamber to reduce the contact force, and a space forming a discharge pressure is formed at at least either one side of a side surface of the vane and a cylinder to decrease a side directional reaction force applied to the vane, thereby reducing a friction between the vane and the cylinder.

Owner:LG ELECTRONICS INC

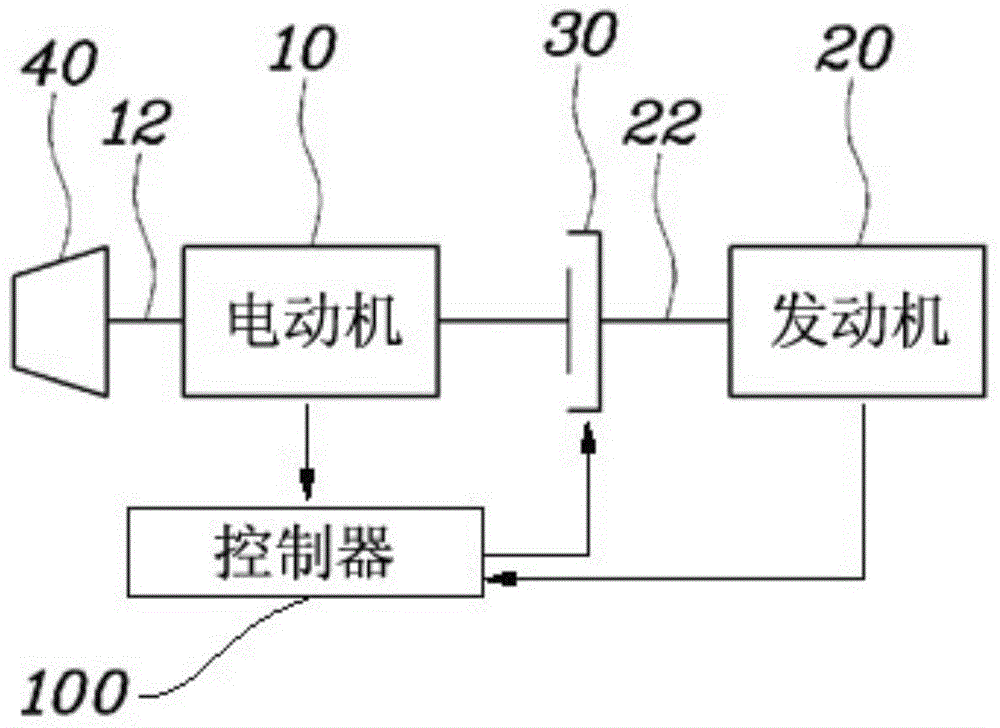

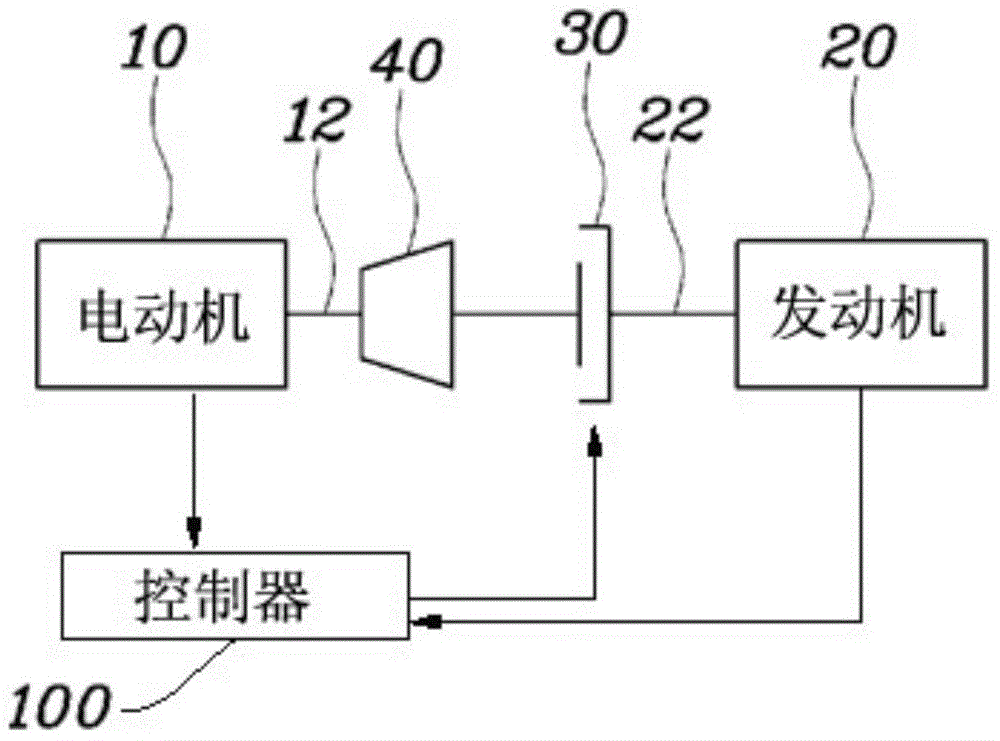

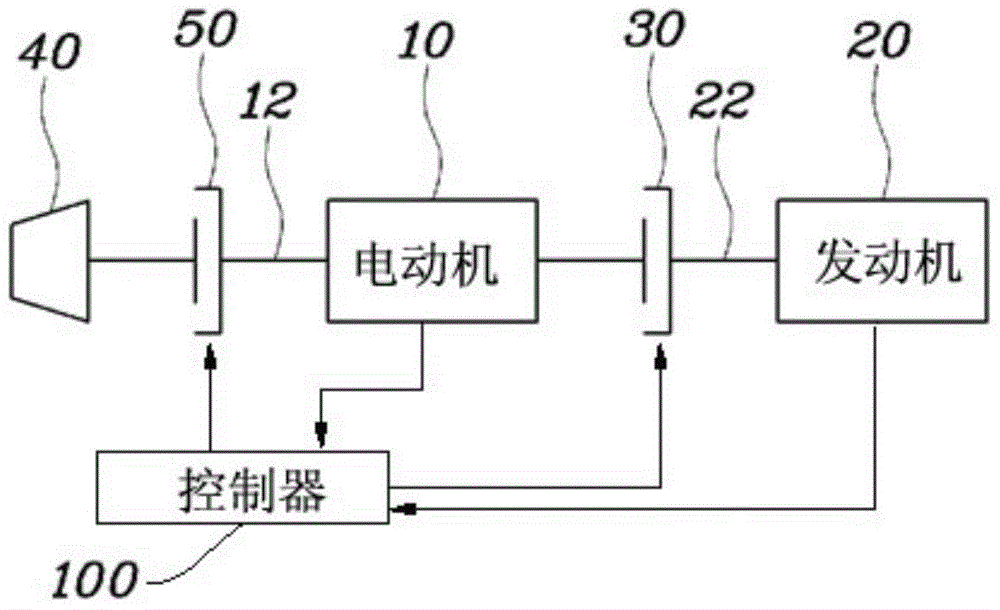

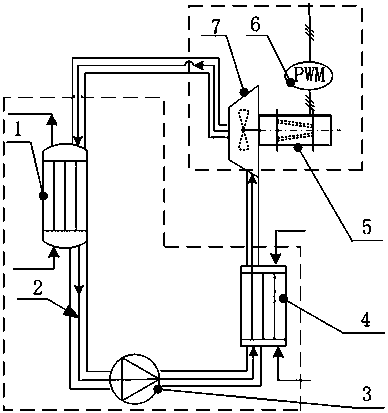

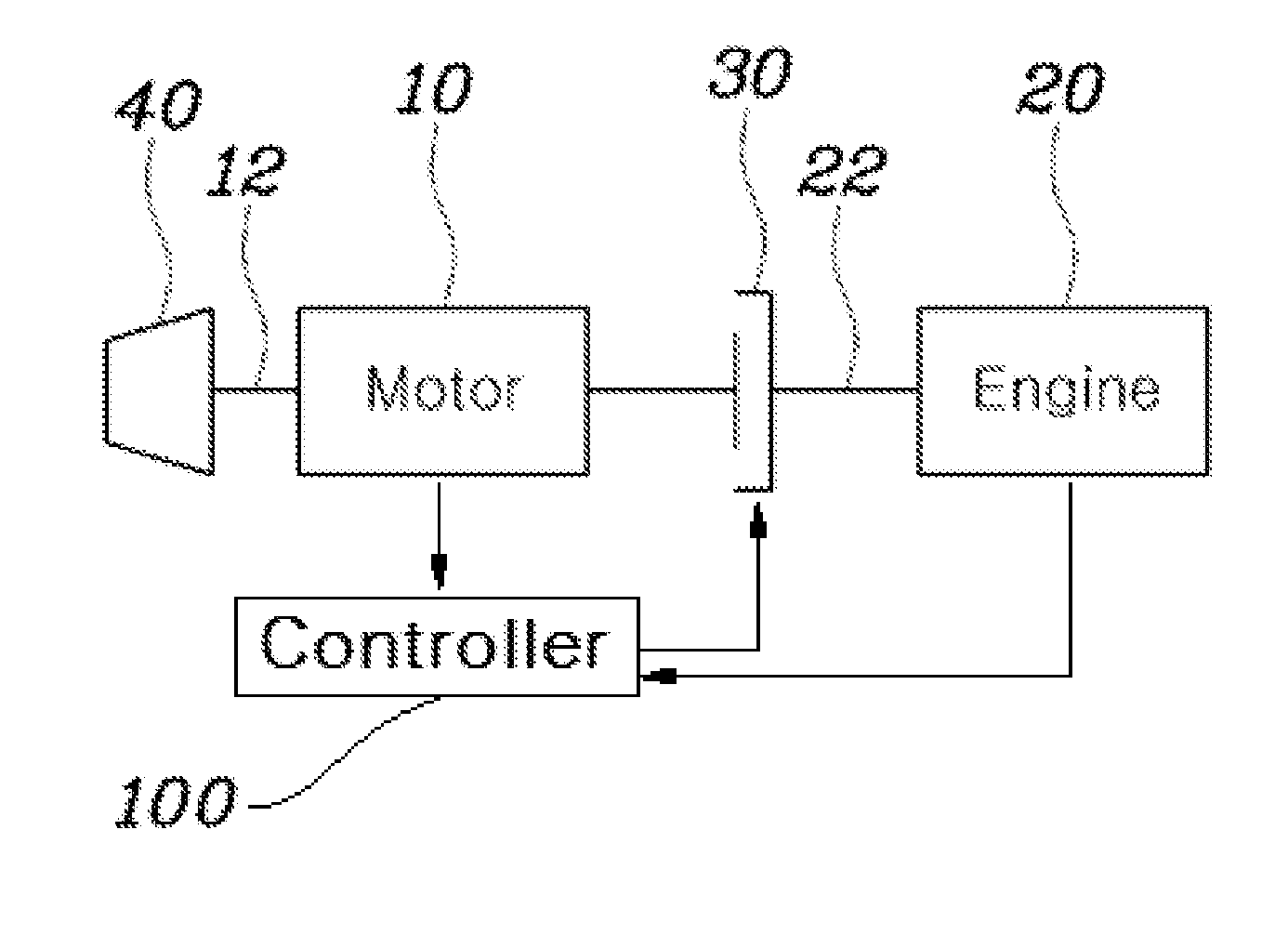

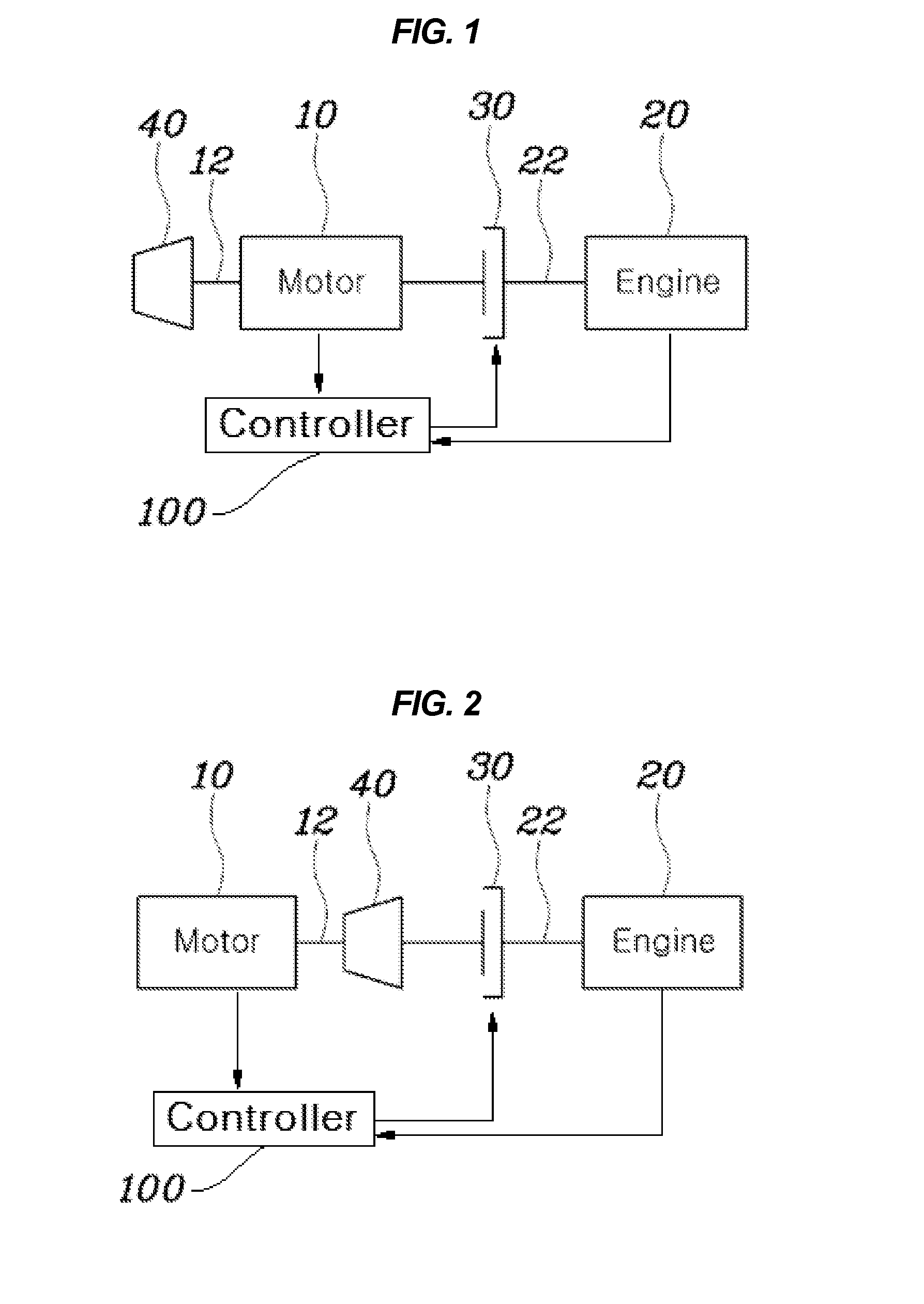

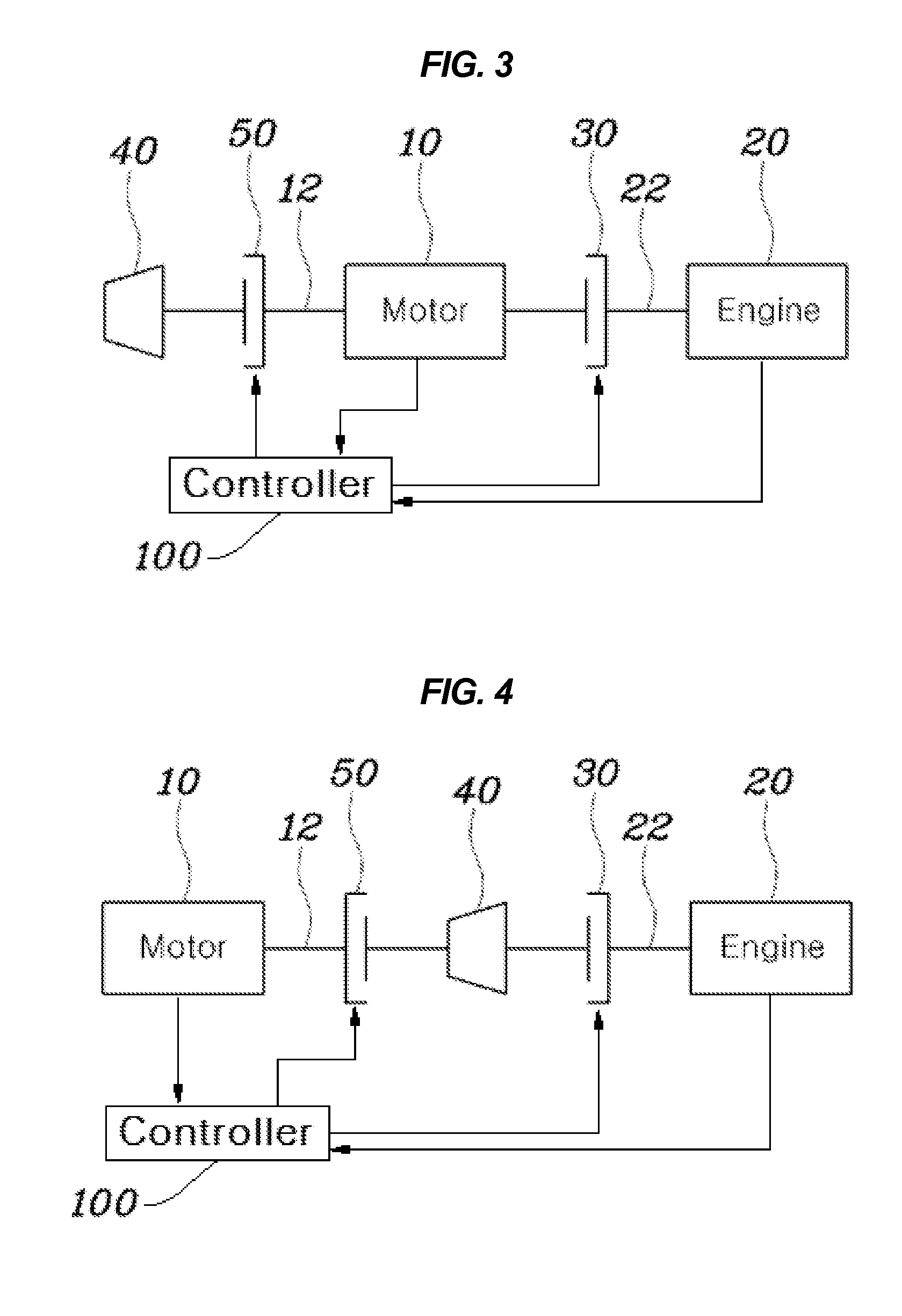

Hybrid Oil Pump System and Method of Controlling the Same

ActiveCN105422409AImprove fuel efficiencyReduce manufacturing costHybrid vehiclesMechanical actuated clutchesClutchElectric motor

A hybrid oil pump system may include a motor connected to an oil pump and supplying torque, an engine disposed to supply torque to the oil pump, and a first one-way clutch disposed in a line through which the torque from the engine may be supplied to the oil pump, and selectively supplying the torque from the engine to the oil pump in accordance with a difference in RPM between the engine and the motor.

Owner:HYUNDAI MOTOR CO LTD

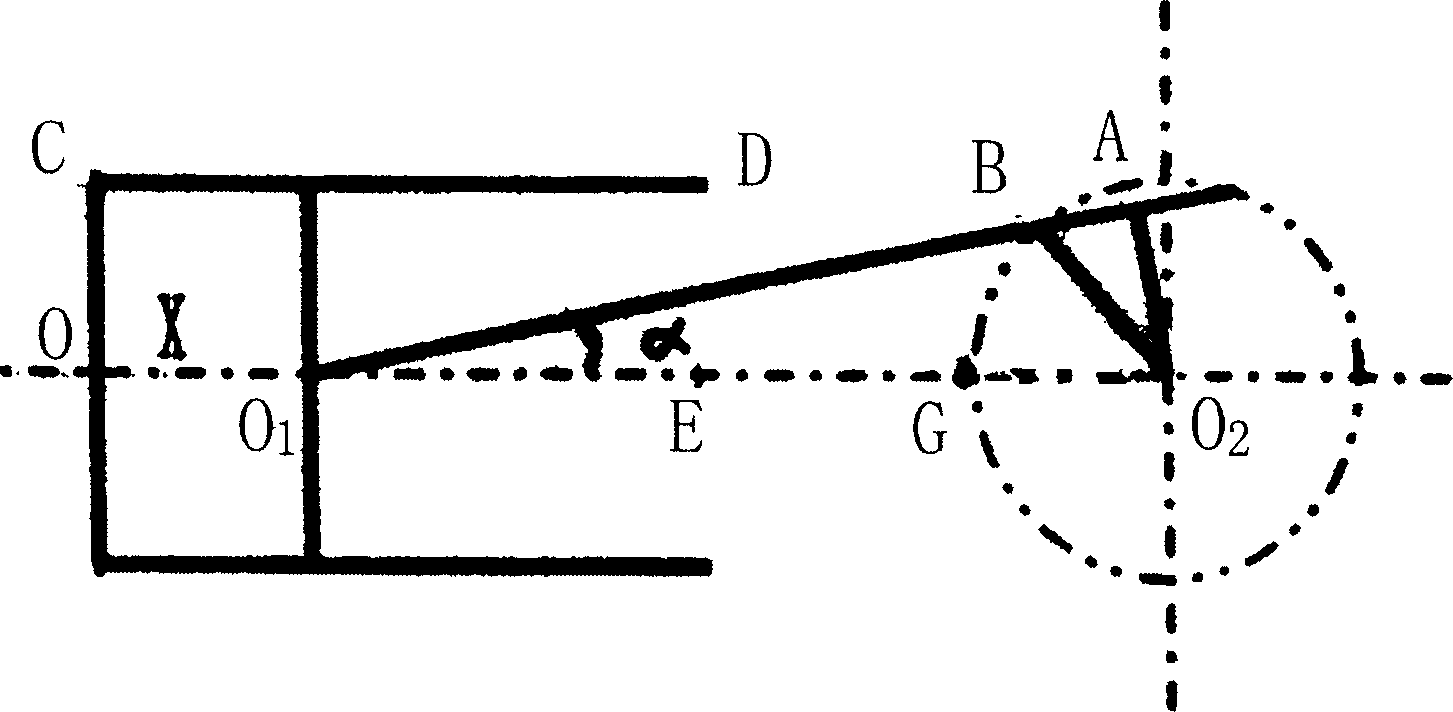

Rotor type compressor crankshaft TH face structure

InactiveCN101178092AReduce mechanical friction lossImprove lubrication conditionsCrankshaftsMilling equipment detailsEngineeringCrankshaft

The invention provides a rotor-typed compressor crankshaft TH surface structure; the TH surface of the invention is tangentially provided with a bevel; the bevel and the TH surface have an angle ranging from 0 DEG to 5 DEG; the distance from the intersection of the bevel and the TH surface to the external edge of a lower bearing is more than 0.5mm; the angle between the intersection and the symmetrical line of the TH surface is ranging from 0 DEG to 90 DEG; the friction force between the TH surface and the lower bearing is reduced, the mechanical efficiency of the compressor is improved, and the energy is saved.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Vacuum assembly for decompression device

InactiveCN1621120AIncrease pumping rateReduce driving timeVacuum distillation separationVacuum distillationVacuum pumpingSeparation technology

The present invention belongs to the field of separation technology, and is especially vacuum pumping unit for decompression distilling apparatus. The vacuum pumping unit includes condenser with hot medium inlet connected to the outlet pipe of the decompression distilling tower and Roots-water ring vacuum set or Roots-reciprocating vacuum set in the outlet pipeline of hot medium outlet of the condenser. Adopting vacuum set to provide negative pressure source for the decompression apparatus makes the present invention has high pumping rate, fast starting, powerful adaptability, shortened operation time, stable operation state and other advantages. The present invention may be used widely in atmospherical and vacuum unit of petrochemical industry.

Owner:淄博华中真空设备有限公司

Rotor system and micro gas turbine generator unit

PendingCN111042925ACompact structureAxial dimension shortTurbine/propulsion engine coolingGas turbine plantsRotational axisGas compressor

The invention provides a rotor system and a micro gas turbine generator unit. The rotor system comprises a rotating shaft, a thrust bearing, a first radial bearing, a motor, a second radial bearing, agas compressor and a turbine, wherein the rotating shaft is of an integrally-formed structure, and the thrust bearing, the first radial bearing, the motor, the second radial bearing, the gas compressor and the turbine are sequentially arranged on the rotating shaft. The rotating shaft rotates in a stator of the thrust bearing, the first radial bearing, a motor stator and the second radial bearing, and the rotating shaft is fixedly connected with a thrust disc of the thrust bearing, a worm wheel of the turbine and a compression wheel of the gas compressor. The integral rotating shaft is adopted for connecting a micro gas turbine rotor and a generator rotor, the thrust bearing is arranged at the end with a generator, and the technical problem that the arrangement position of the thrust bearing is limited in the prior art is solved.

Owner:TECH XANADU OF RESONATORY SOLAR SYSTD CO LTD +1

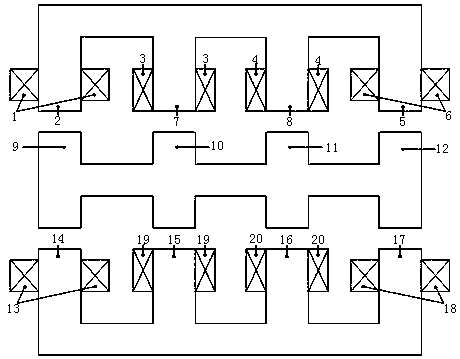

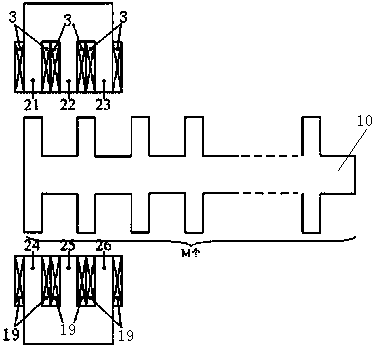

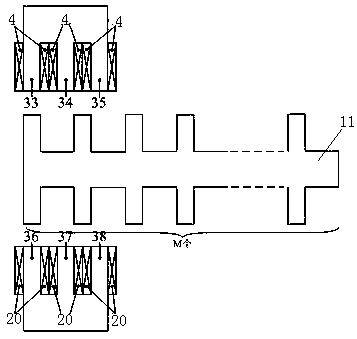

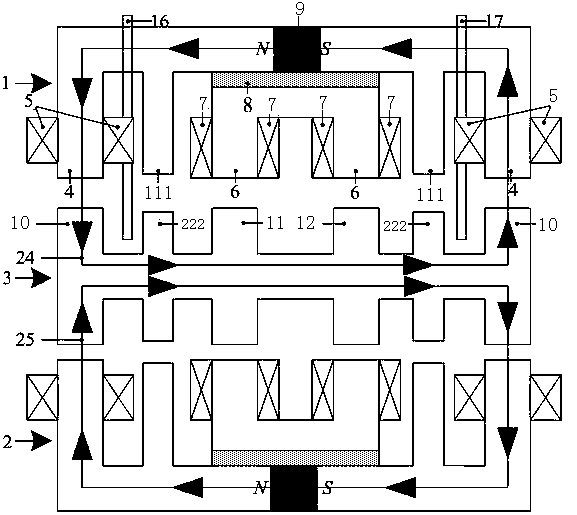

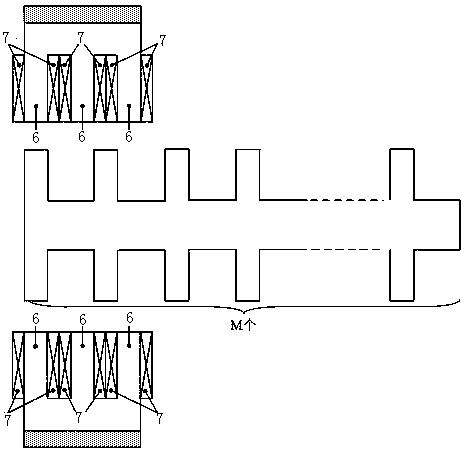

Reluctance magnetic suspension linear motor

InactiveCN108599522ANo contact transmission forceEasy to controlStructural associationPropulsion systemsFriction lossEngineering

The invention discloses a reluctance magnetic suspension linear motor, comprising an upper stator, a lower stator and a rotor. Side-looking projections of an upper left suspension iron core and an upper right suspension iron core are U-shaped structures. First suspension windings and sixth suspension windings are respectively wound on U-shaped teeth of the upper left suspension iron core and the upper right suspension iron core. The side-looking projections of an upper left control iron core and an upper right control iron core are E-shaped structures. Third axial control windings and fourth axial control windings are respectively wound on E-shaped teeth of the upper left control iron core and the upper right control iron core. The rotor comprises a left suction disk, a right suction disk,M axially arranged left rotor teeth, and M axially arranged right rotor teeth. The rotor contactless suspension support is realized, and the sensitivity, rapidity and servo performance of a system are greatly improved. The contactless transmitting ability of the magnetic suspension linear motor is realized, the mechanical friction loss is almost zero, all faults are few, the maintenance is avoided, the work is safe and reliable, and the service life is long.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

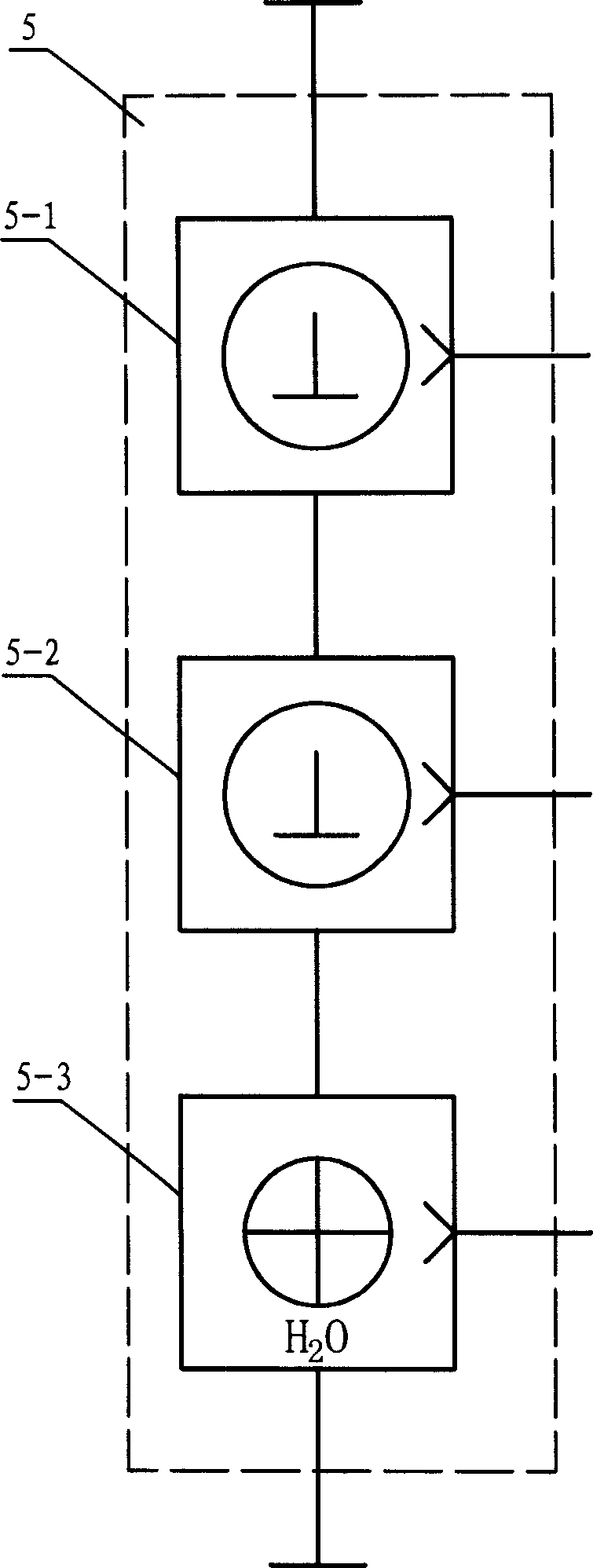

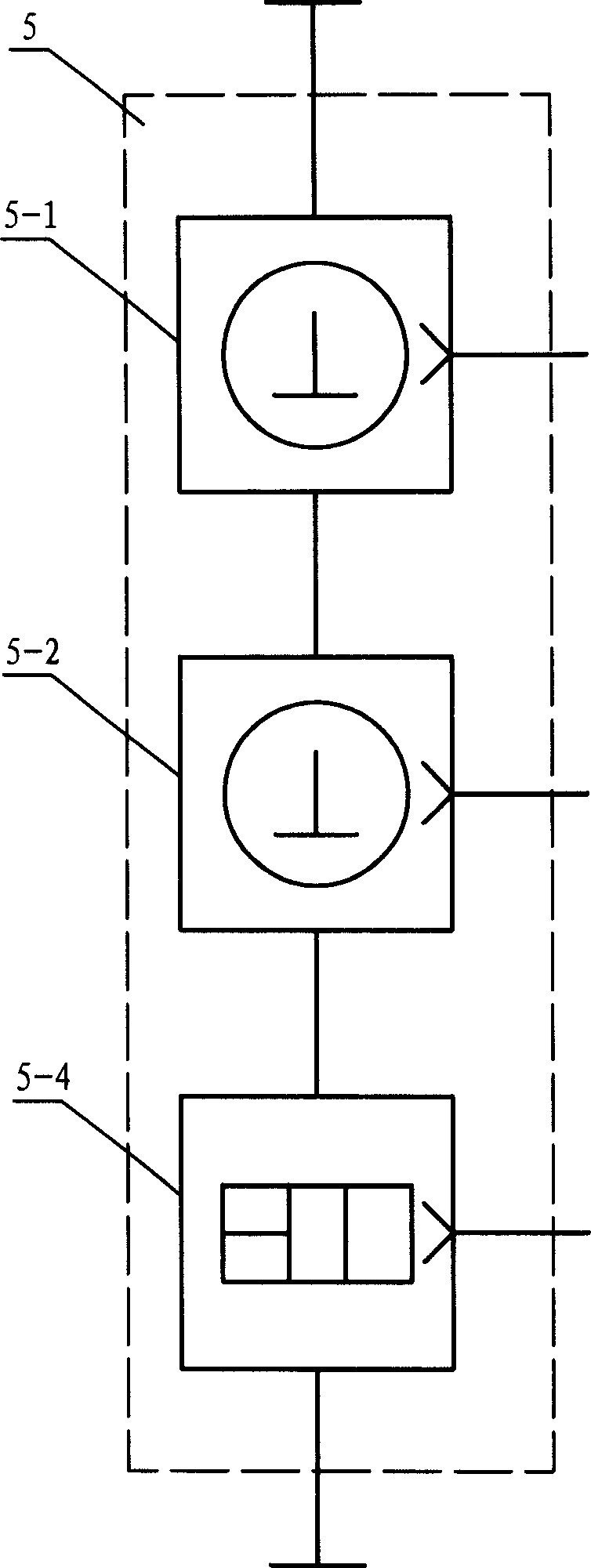

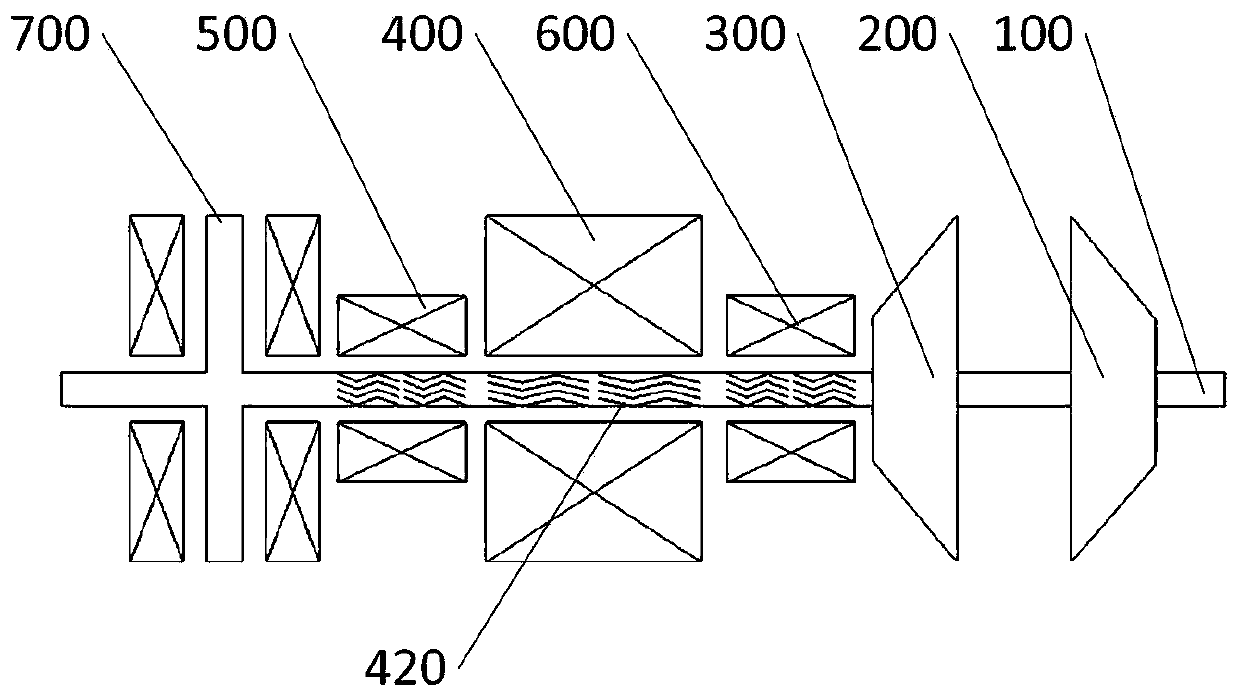

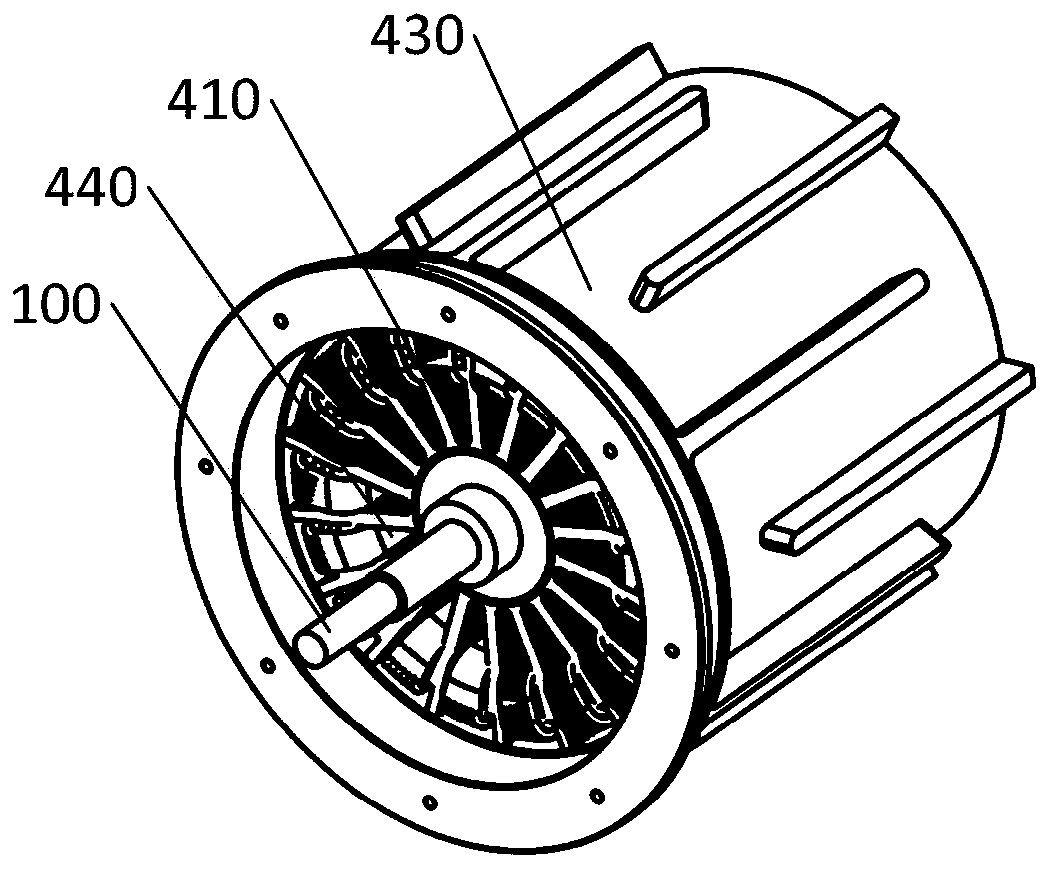

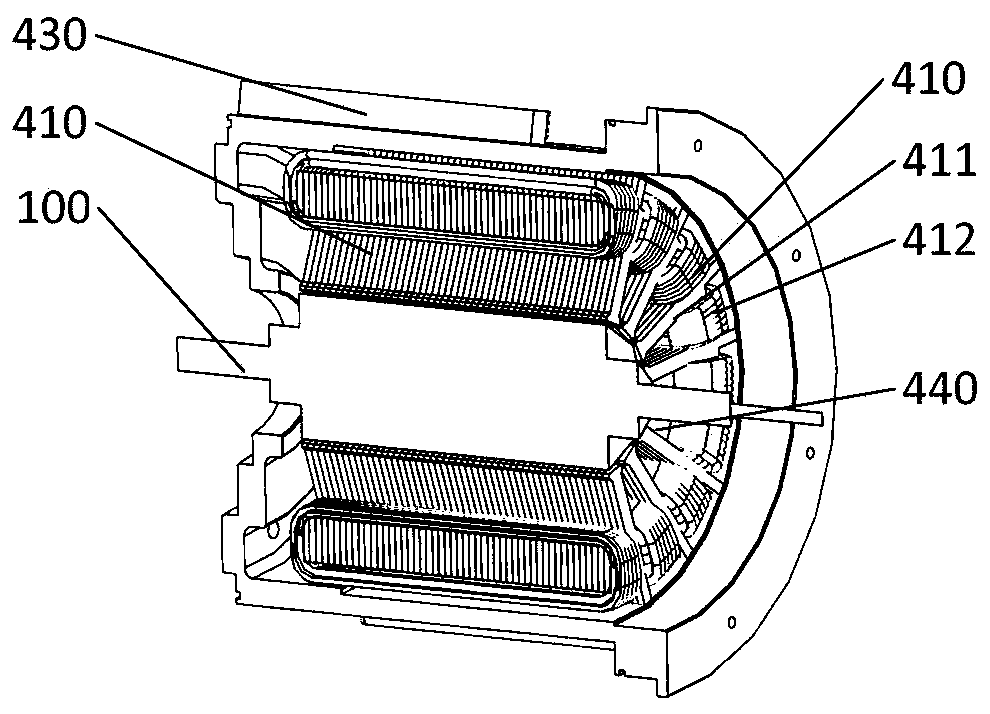

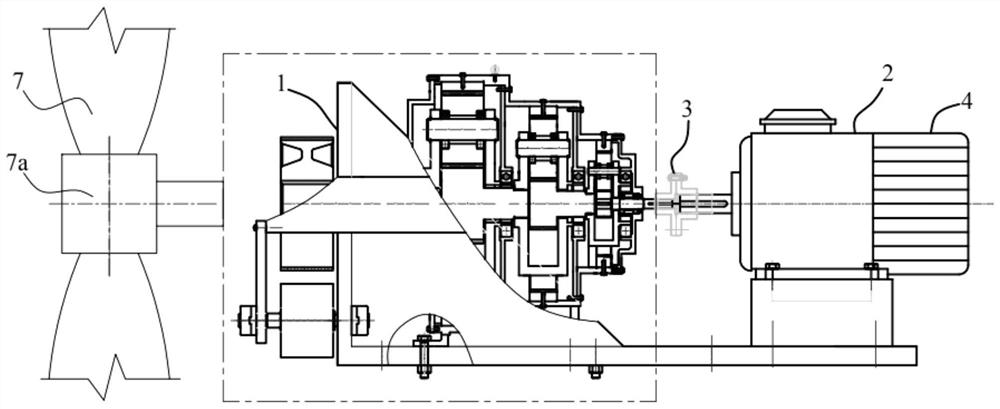

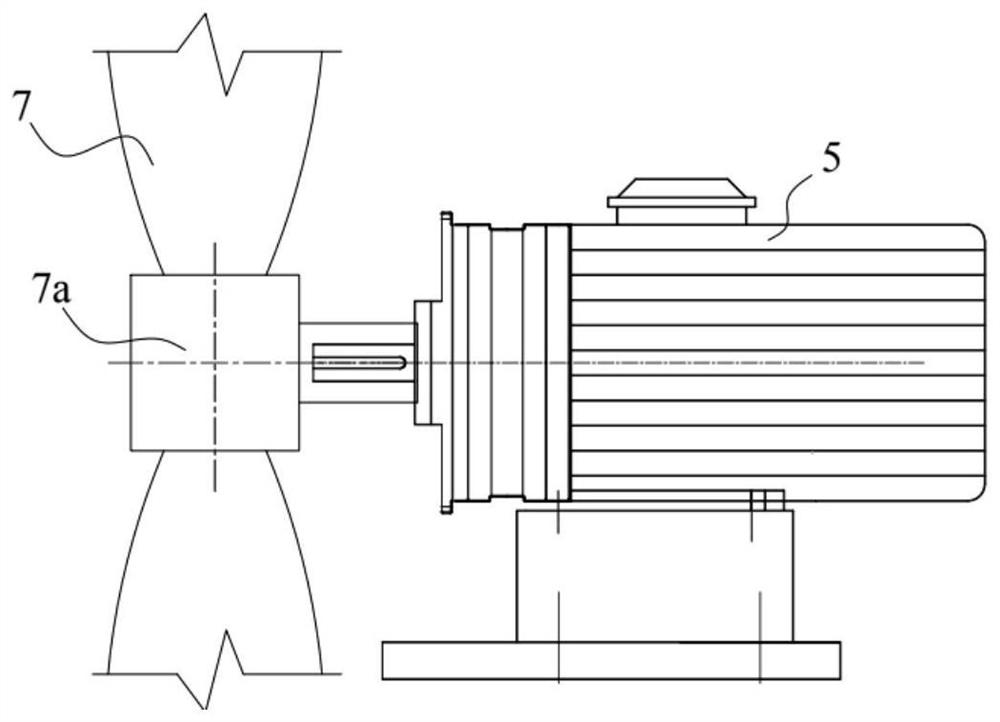

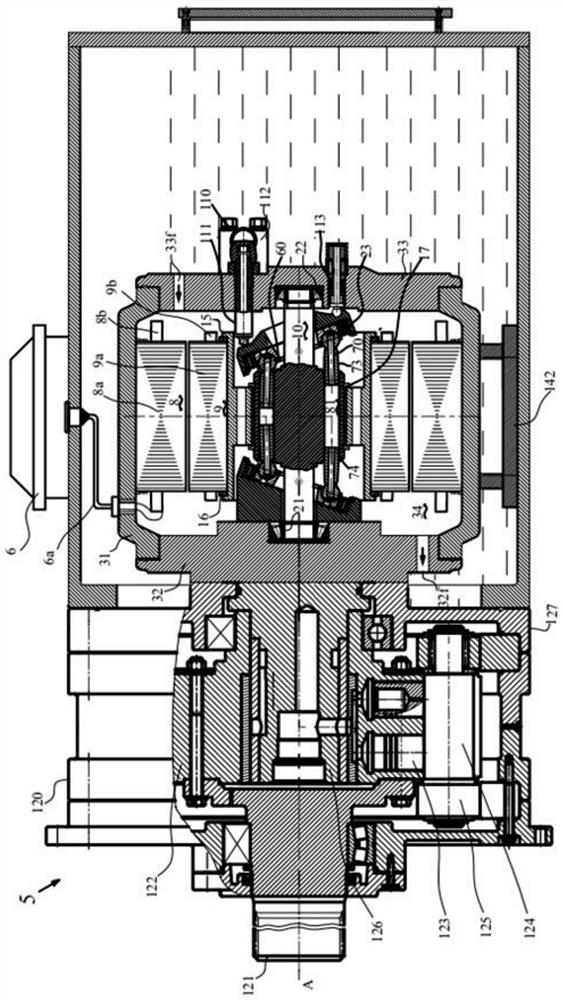

High-power compact electro-hydraulic wind generating set assembly

PendingCN114810981AReduce overall weightCabin weight reductionServomotor componentsEngine fuctionsImpellerCooling power

The invention discloses a high-power compact electro-hydraulic wind generating set assembly which comprises an impeller assembly, a hydraulic pump assembly, an oil tank and an electro-hydraulic all-in-one machine assembly contained in a cavity of an oil tank shell. The electro-hydraulic all-in-one machine assembly comprises a generator shell assembly, a rotor assembly, a stator assembly and a hydraulic motor assembly, the rotor assembly, the stator assembly and the hydraulic motor assembly are contained in a shell cavity of the generator shell assembly, the hydraulic pump assembly sucks oil from an oil tank shell cavity and / or a generator shell cavity, and the impeller assembly is connected with the hydraulic pump assembly. The hydraulic pump assembly outputs high-pressure oil to drive a hydraulic motor assembly and a rotor assembly in the electro-hydraulic all-in-one machine assembly to rotate, and power generation is achieved. The wind generating set disclosed by the invention is high in electro-hydraulic fusion, and has the characteristics of high power, compact structure, small volume, light weight, low noise, high efficiency, energy conservation, self-cooling, high power density, high reliability, long service life and the like.

Owner:钟彪

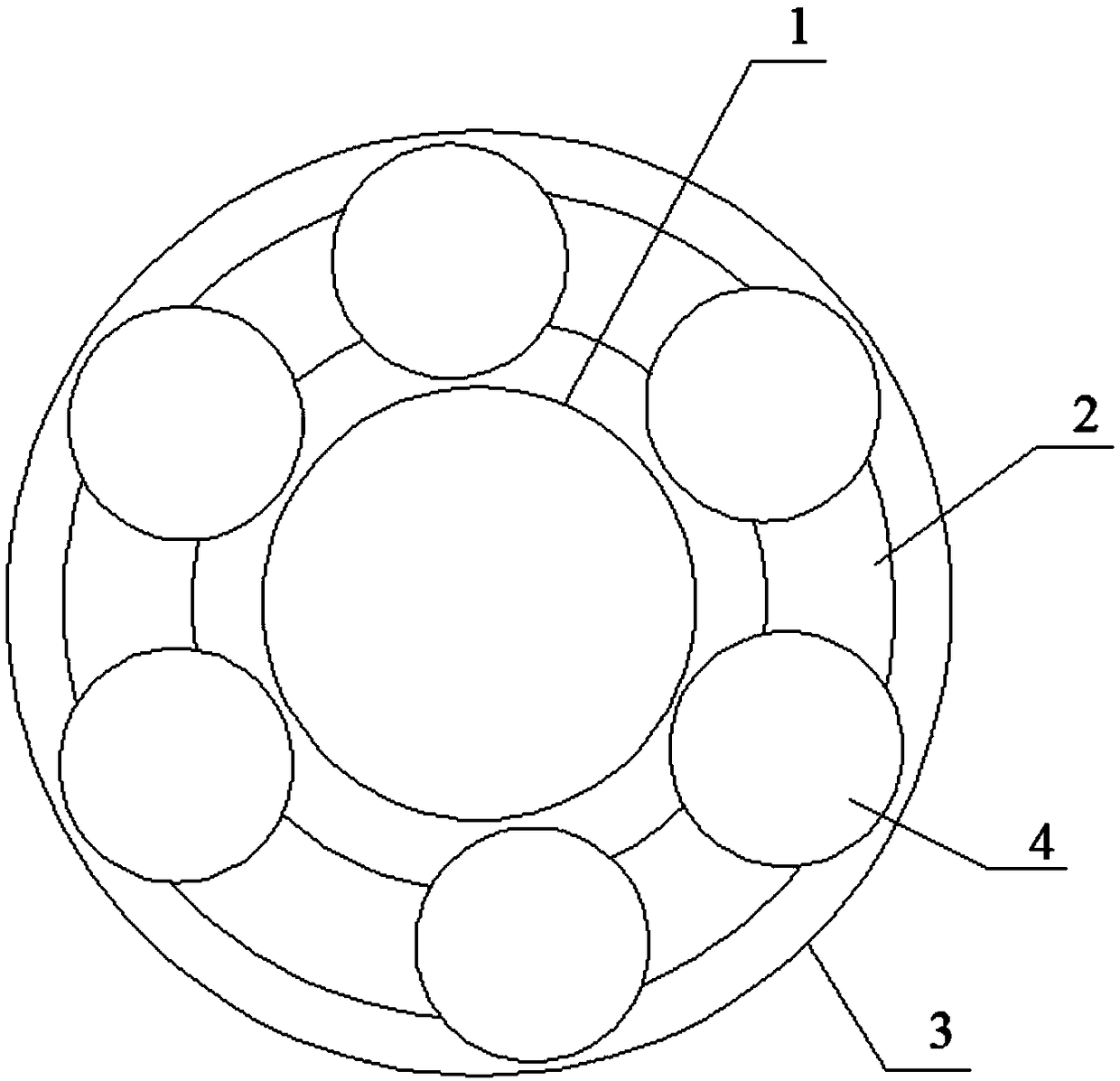

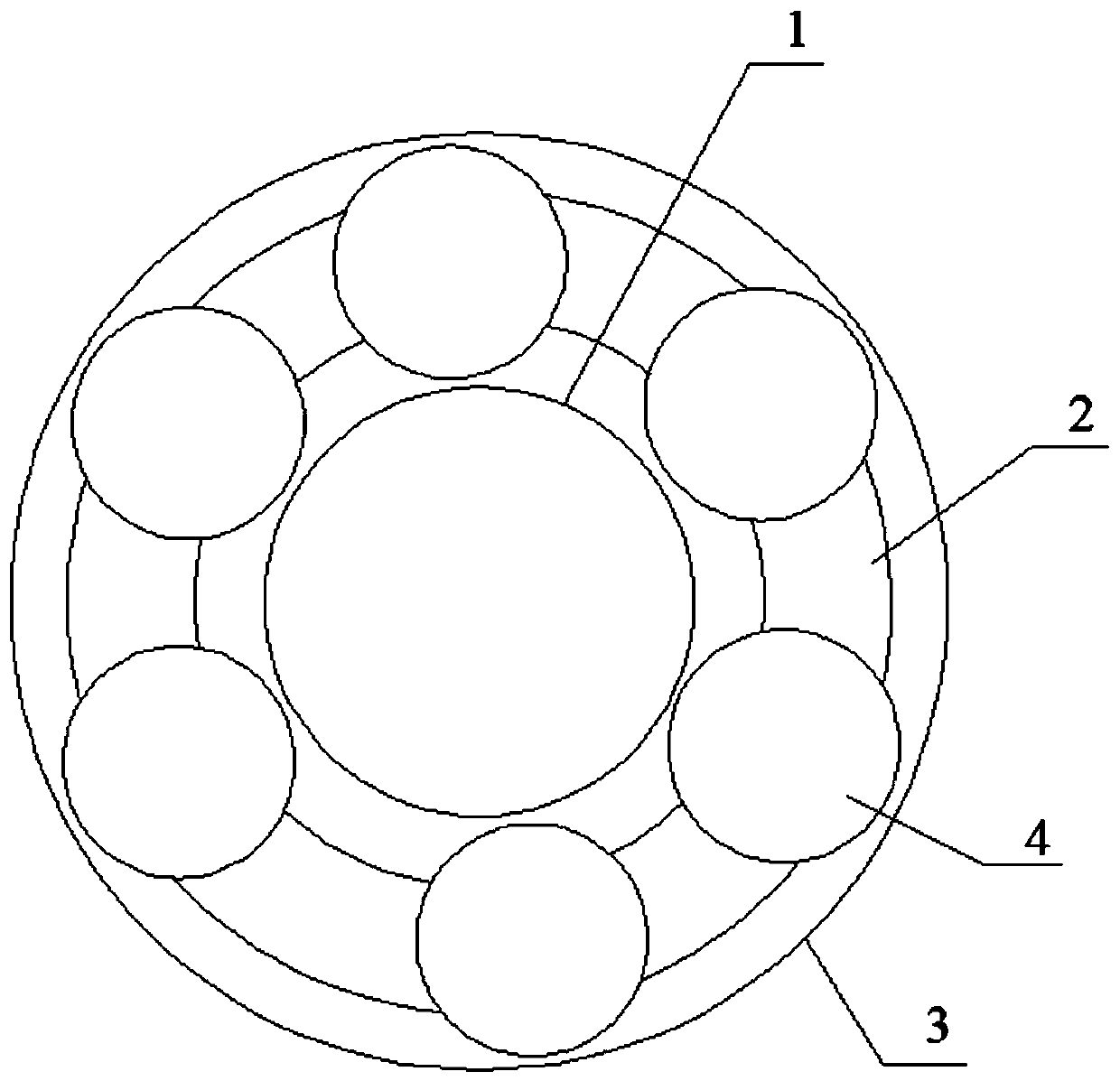

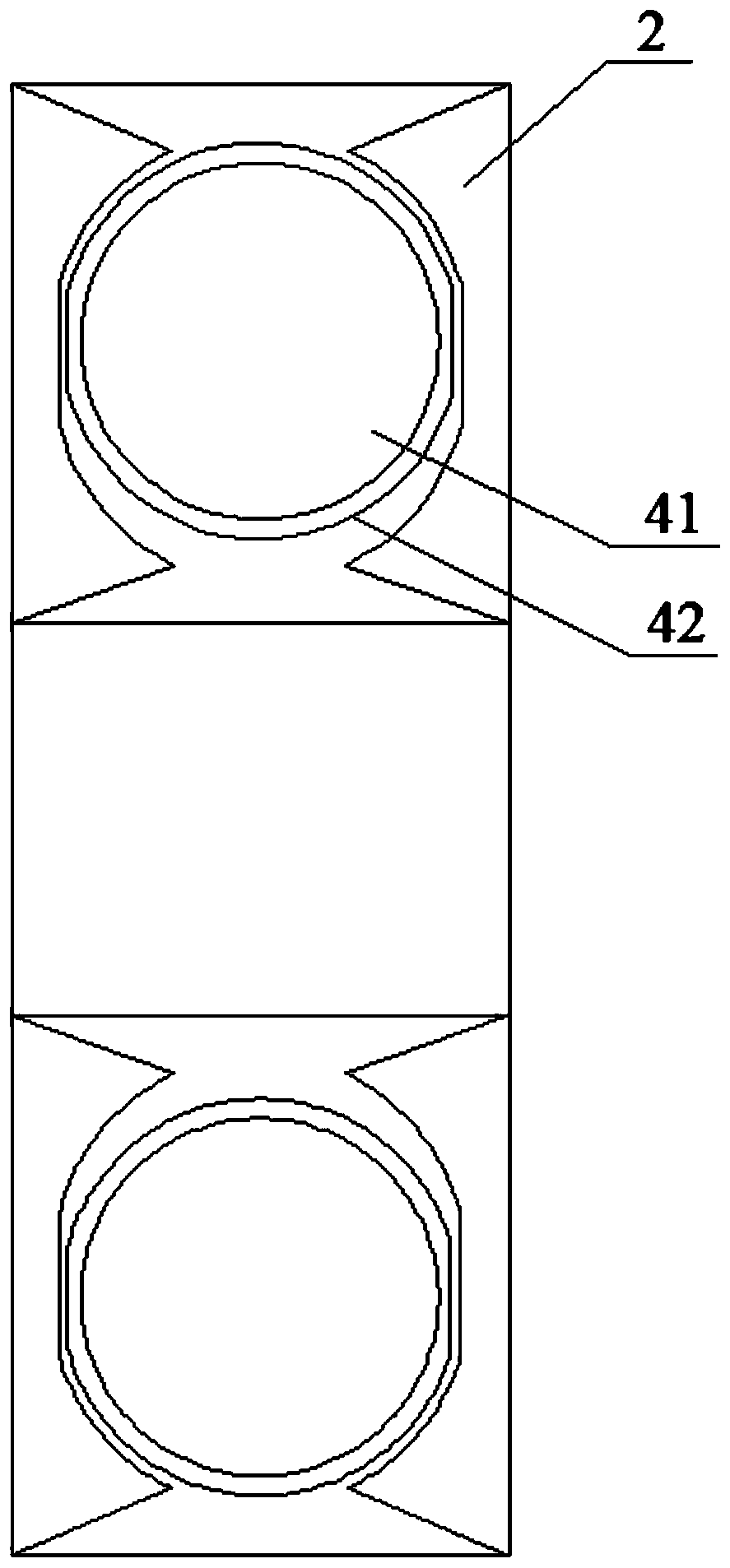

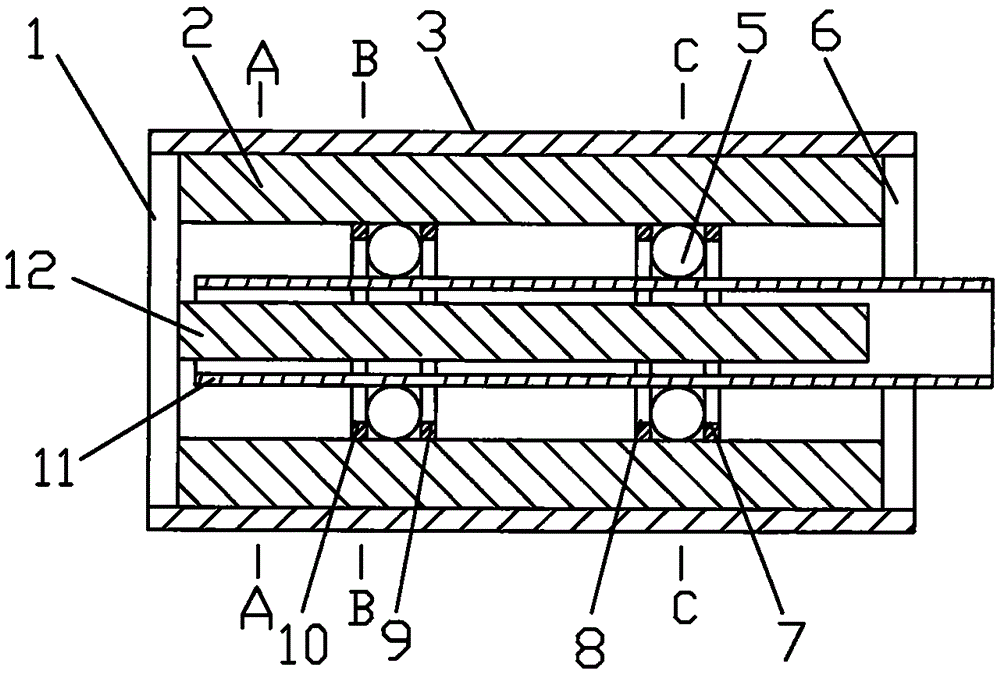

Porous metal matrix composite material bearing based on elastohydrodynamic lubrication

ActiveCN109253167AImprove plasticityGood molding effectRolling contact bearingsShaftsHigh-pressure areaFriction loss

The invention belongs to the technical field of bearings and particularly relates to a porous metal matrix composite material bearing based on elastohydrodynamic lubrication. The porous metal matrix composite material bearing comprises a bearing inner ring, a rolling ball retainer and a bearing outer ring which are sequentially arranged from inside to outside, wherein the rolling ball retainer isinternally provided with a plurality of rolling balls which are uniformly distributed around the bearing inner ring; in addition, each rolling ball comprises a spherical matrix with a porous surface;an elastic reinforcement layer wraps the outer surface of each spherical matrix. According to the porous metal matrix composite material bearing disclosed by the invention, a high-pressure area is formed on micro contact area by adopting the spherical matrixes with the porous surface and the elastic reinforcement layers and an elastohydrodynamic lubrication principle; by adding a lubricating area,mechanical friction loss between the surfaces of rigid parts is reduced, and bearing capacity of the bearing is improved.

Owner:NANCHANG INST OF TECH

Apparatus and system configured to correct a cathode current and a voltage between a cathode and an anode for generating X-rays

ActiveUS11064600B2Low costMaximize sizeRadiation diagnostics testing/calibrationRadiation diagnostic device controlParticle physicsQuantum electrodynamics

At least one power supply produces a voltage between a cathode and an anode. The cathode and anode are operable such that electrons emitted from the cathode interact with the anode with energies corresponding to the voltage. The electrons interact with the anode at a focal spot to generate X-rays. The power supply provides the cathode with a cathode current. An electron detector is positioned relative to the anode, and a backscatter electron signal is measured from the anode. The measured backscatter electron signal is provided to a processing unit, which determines a cathode current correction and / or a correction to the voltage between the cathode and the anode using the measured backscatter electron signal and a correlation between anode surface roughness and backscatter electron emission.

Owner:KONINKLJIJKE PHILIPS NV

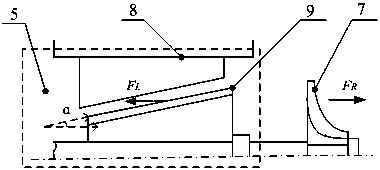

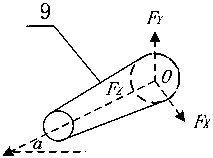

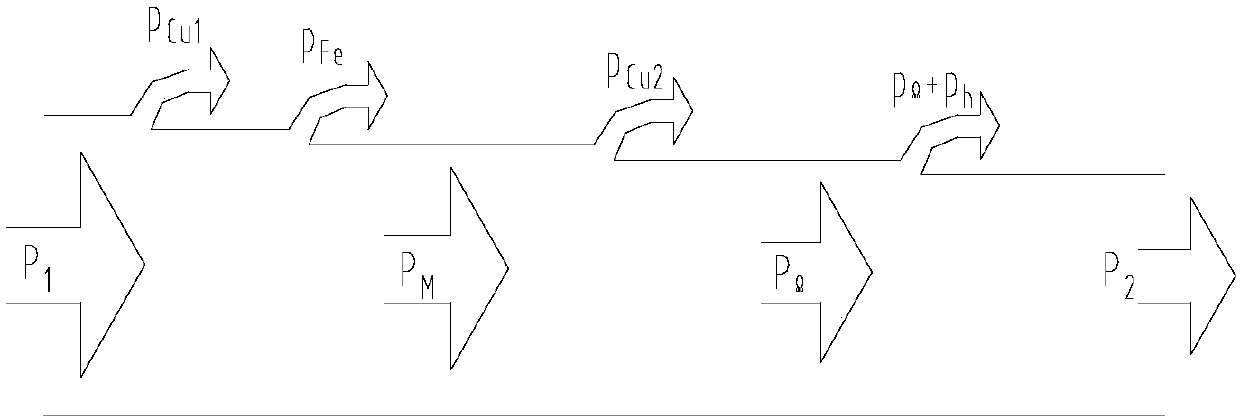

A Waste Heat Power Generation System with Conical Rotor Generator

ActiveCN106801632BReduce mechanical friction lossImprove efficiencyMechanical energy handlingSteam engine plantsAxial forceEngineering

Owner:HUNAN UNIV

Hybrid Oil Pump System and Method of Controlling the Same

InactiveUS20160084124A1Improve fuel efficiencyMinimizing friction of engineHybrid vehiclesLubrication of auxillariesEngineeringClutch

A hybrid oil pump system may include a motor connected to an oil pump and supplying torque, an engine disposed to supply torque to the oil pump, and a first one-way clutch disposed in a line through which the torque from the engine may be supplied to the oil pump, and selectively supplying the torque from the engine to the oil pump in accordance with a difference in RPM between the engine and the motor.

Owner:HYUNDAI MOTOR CO LTD

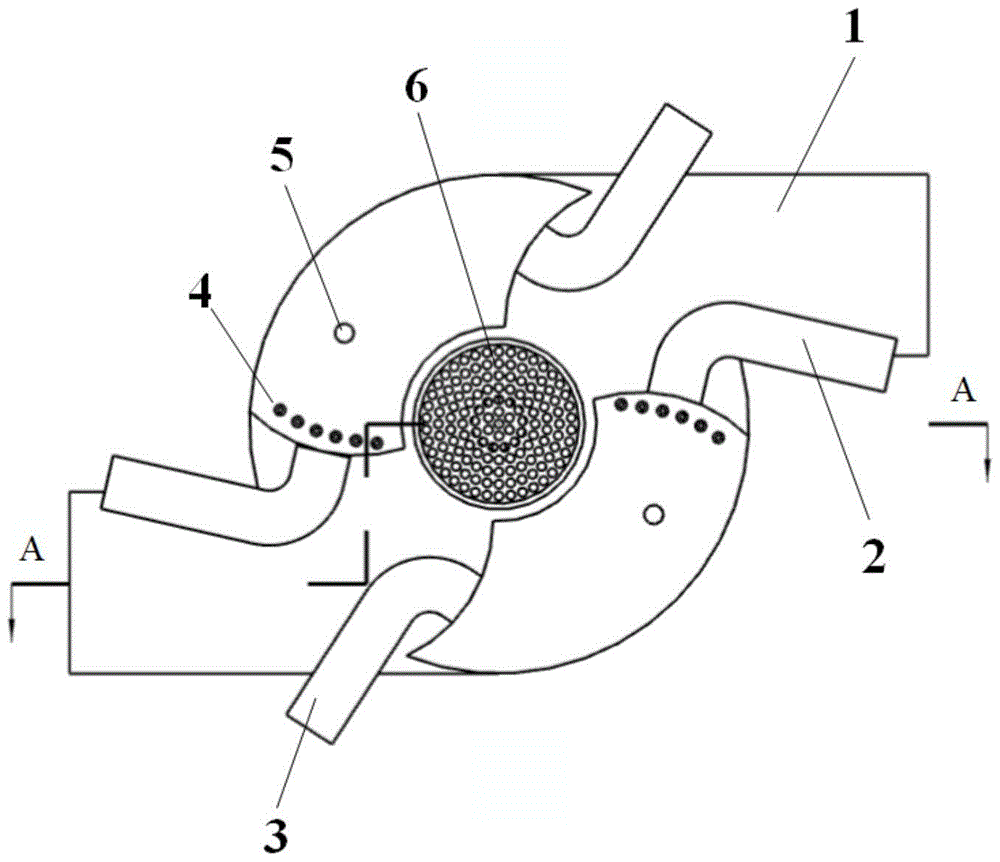

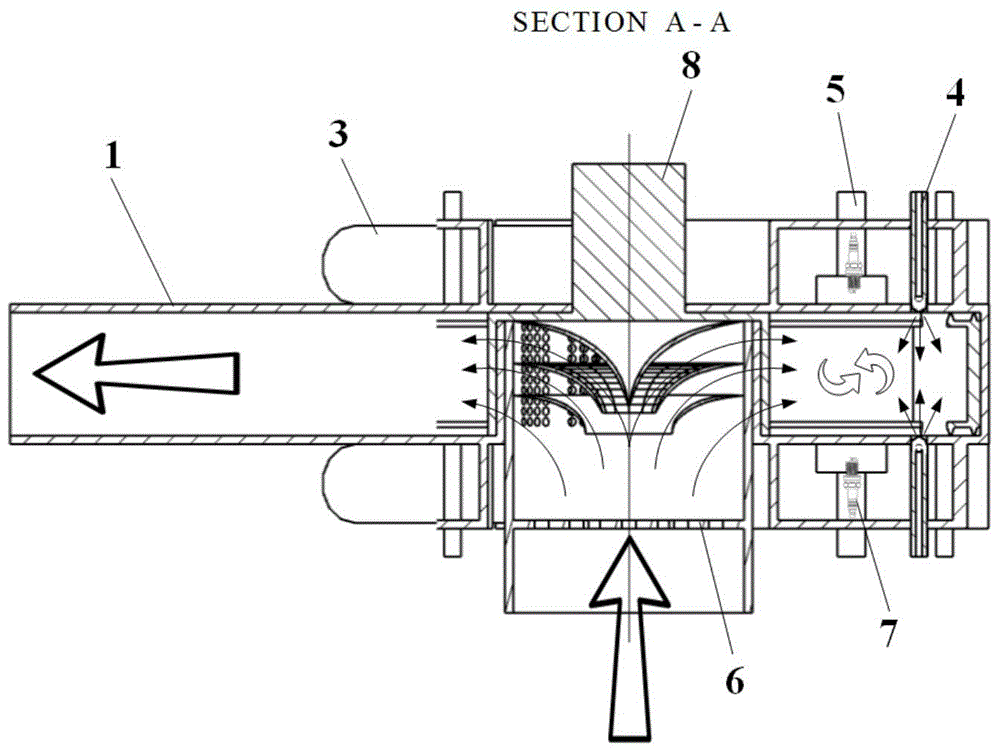

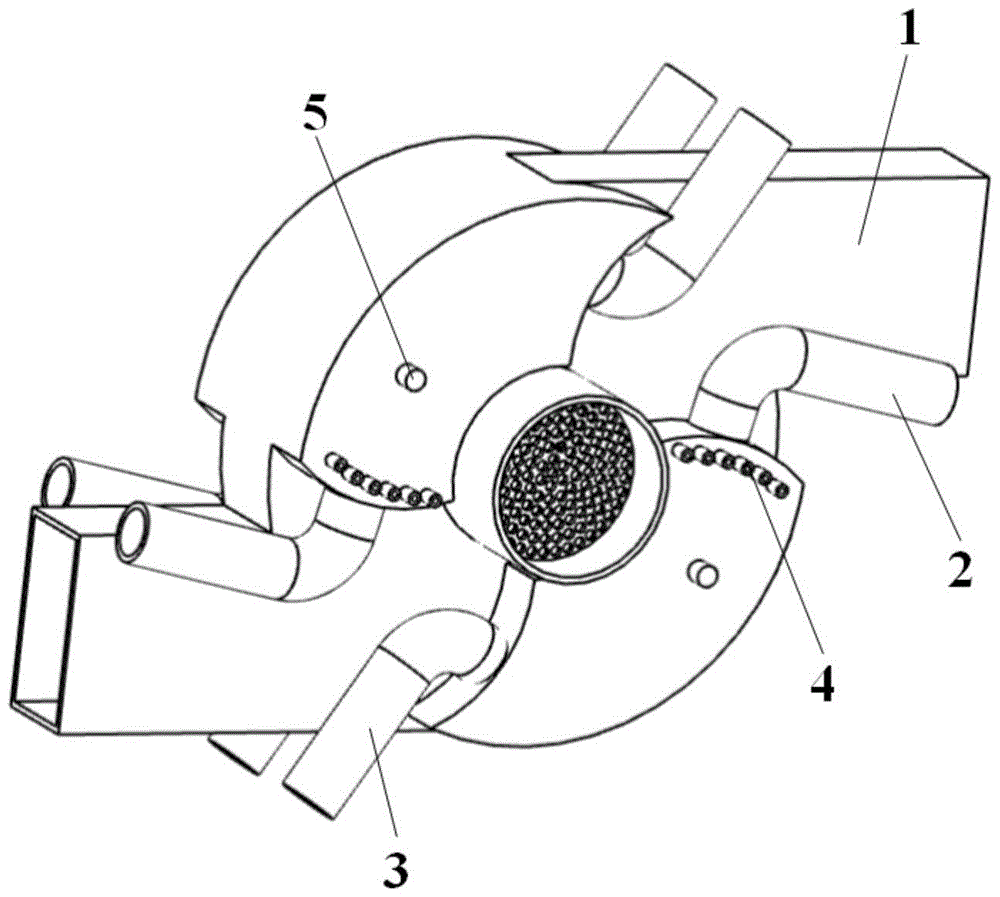

A rotary isovolume supercharged combustion chamber

InactiveCN105066175BImprove air intake efficiencyImprove exhaust efficiencyContinuous combustion chamberThermal energyCombustion chamber

The invention discloses a rotary constant-volume pressurizing combustion chamber. The rotary constant-volume pressurizing combustion chamber comprises multiple independent constant-volume combustion chamber bodies, a fuel inlet tube, a fuel outlet tube, fuel nozzles, a spark plug mounting base, an air feeding structure, a spark plug and the like. The rotary constant-volume pressurizing combustion chamber is simple in structure. The air feeding structure can send air and fuel into the combustion chamber bodies uninterruptedly, an exhaust structure can exhaust high-temperature and high-pressure gas continuously after combustion in the independent constant-volume combustion chamber bodies, and continuous air feeding and exhaust of the combustion chamber bodies are achieved; accordingly the air feeding and exhaust efficiency of the combustion chamber bodies is improved, and the fuel and air filling speed of the combustion chamber bodies is improved at the same time. The rotary constant-volume pressurizing combustion chamber is free of a piston compression structure, upper and lower dead centers are absent, and the effective volume can be equal to the volume of the combustion chamber, accordingly the space use rate of the combustion chamber bodies is improved; meanwhile, according to the combustion chamber bodies, friction between pistons and combustion chamber body walls is prevented, so that the mechanical friction loss is small, and the fuel heat use rate of the combustion chamber bodies can be improved.

Owner:HUANENG POWER INT INC +1

A Porous Metal Matrix Composite Bearing Based on Elastohydrodynamic Lubrication

ActiveCN109253167BImprove plasticityGood molding effectRolling contact bearingsShaftsFriction lossLubrication

Owner:NANCHANG INST OF TECH

hermetic compressor

ActiveCN110268163BImprove efficiencyReduce mechanical friction lossRotary/oscillating piston combinations for elastic fluidsPositive displacement pump componentsFriction lossCylinder block

A hermetic compressor including blades inserted into rollers, rotated together with the rollers, and pushed toward the inner peripheral portion of the cylinder by the rotation of the rollers to divide a compression chamber into a plurality of spaces, The vane includes: a body portion having a sealing surface in contact with the inner peripheral portion of the cylinder and inserted into the roller; and a guide portion crossing from an axial end of the body portion in a direction in which the vane slides out direction, and it can be slidably inserted into a guide groove formed on at least one of the first bearing and the second bearing to limit the vane toward the inner periphery of the cylinder in at least some part of the circumference of the cylinder part slides off the roller. Thereby, the mechanical friction loss of a blade can be reduced.

Owner:LG ELECTRONICS INC

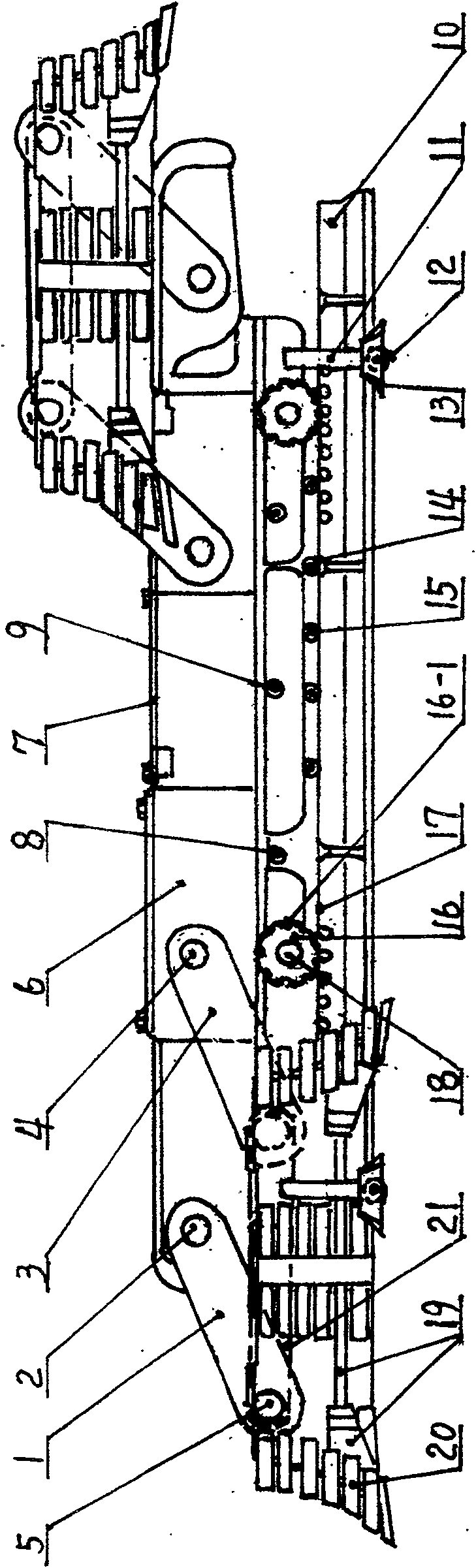

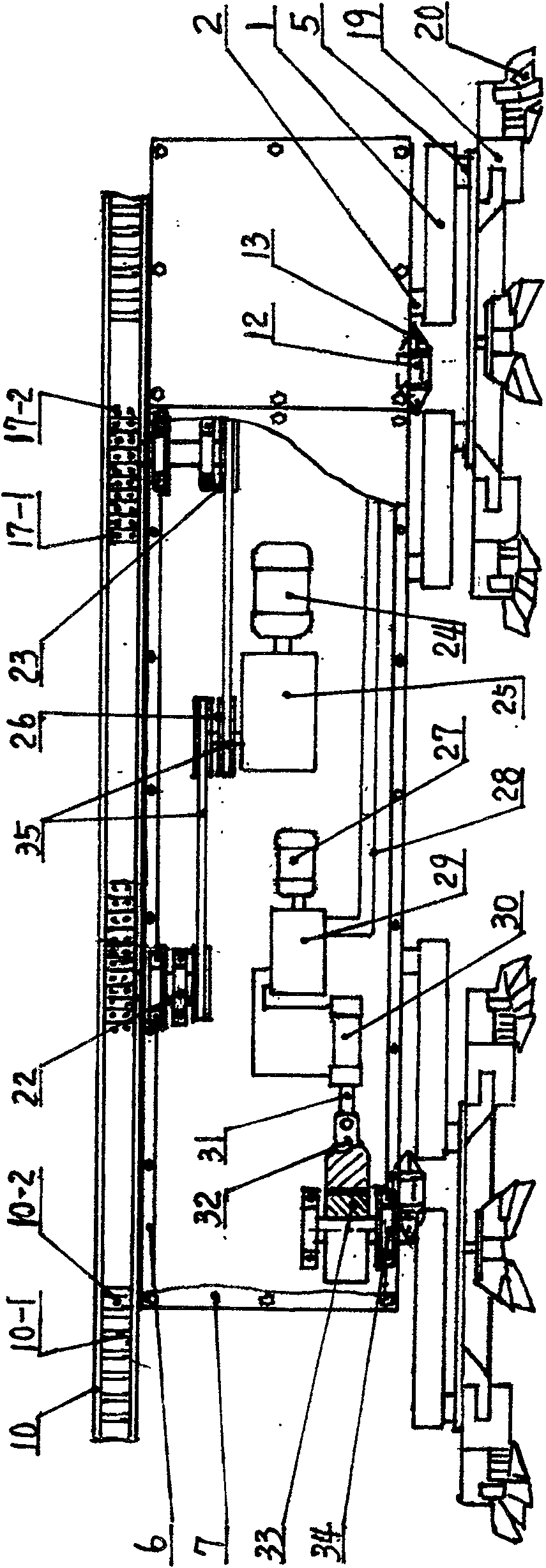

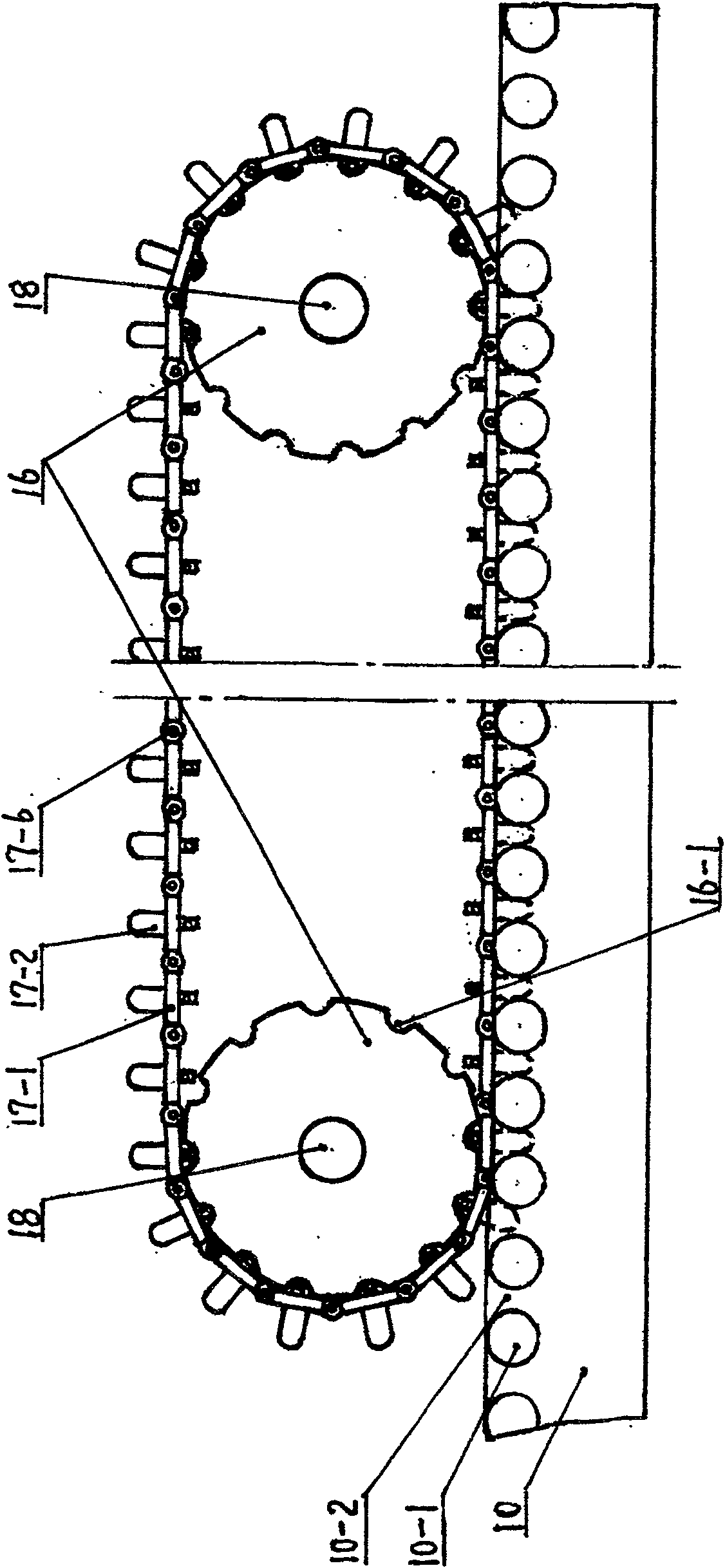

Coal mining and digging machine

The invention belongs to coal mining machinery, in particular to a coal mining planer with few power sources, simple structure, wide application range and high production efficiency. , speed reducer (25), hydraulic system motor (27), hydraulic pump station (29), oil cylinder (30), planer head (19) and planer (20), two fixed on the output shaft of speed reducer (25) A driving sprocket (26), is connected with the driven sprocket (23) transmission that is fixed on two driving shafts (18) with two transmission chains (35), and the driving shaft (18) outer end is fixed on a circle evenly Traction wheels (16) with several U-shaped grooves (16-1) are distributed; transmission crawlers (17) are movable between the two traction wheels (16); the coal mining planer is simple in structure and light in weight. Low cost; save energy consumption; low failure rate, high start-up rate, simple maintenance, small maintenance and low cost.

Owner:LIAONING TECHNICAL UNIVERSITY

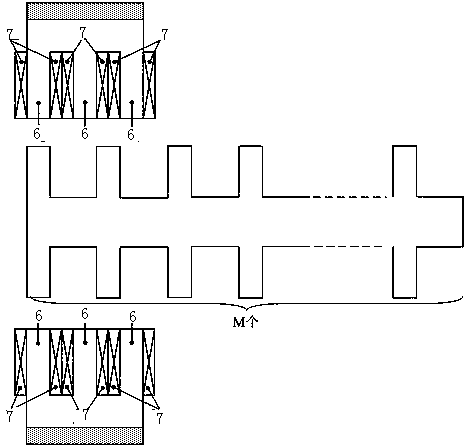

A square double stator hybrid reluctance type magnetic levitation linear motor

ActiveCN108832795BSuspension stabilityReduce power consumptionPropulsion systemsMagnetic holding devicesElectric machineMagnetic reluctance

The invention discloses a square dual-stator hybrid reluctance type magnetic levitation linear motor, which comprises an upper stator, a lower stator and a mover. Pressed, each sheet stator from left to right is: left suspension core, left stator bypass core, left axial control core, right axial control core, right stator bypass core, right suspension core, left and right suspension The iron core, the left and right bypass iron cores are connected as a whole through an axially magnetized permanent magnet block, and then connected with the left and right axial control iron cores through a magnetic isolation aluminum block. The positioning is accurate and the action is fast. When the mover is in the equilibrium position , the mover is kept in stable suspension by the bias magnetic flux, and the power consumption of the motor is low.

Owner:东莞市高工智能传动股份有限公司

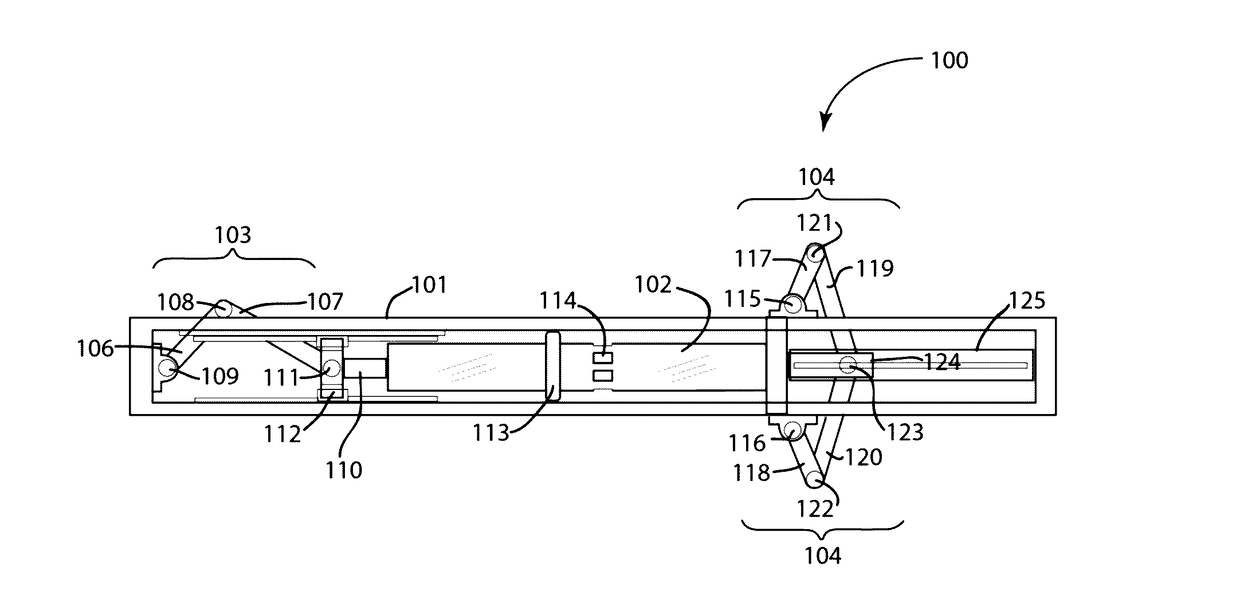

Crank mechanisms for asymmetrical non-sinusoidal piston motion profiles in opposed piston internal combustion engines

InactiveUS9664108B1Increases power output (density)More power strokeInternal combustion piston enginesGearingCombustion chamberReciprocating motion

A dual crank mechanism is introduced for controlling and optimizing asymmetry in the motion profile of at least one piston of an opposed piston internal combustion (OPIC) engine piston pair. The dual crank mechanism produces a substantially asymmetrical non-sinusoidal, but periodic, reciprocating motion profile of the right-hand piston. A single crank mechanism is also introduced for controlling non-sinusoidal, but mostly symmetric, piston motion profile for one or both pistons of an opposed piston pair. The two novel crank mechanisms may be advantageously used exclusively or in combination in order to optimize the piston motion in a novel high efficiency OPIC engine having an externally mounted combustion chamber, an external compressing means for injecting compressed fuel mixtures directly into the external combustion chamber, and reducing cylinder porting to a single exhaust port per cylinder due to improved scavenging resulting from the asymmetric non-sinusoidal piston profiles produced by the novel crank mechanisms.

Owner:SNELL WILLIAM +1

Direct current brushless motor

InactiveCN105553215ARealize power outputBrushlessDynamo-electric machinesBrushless motorsFriction loss

The invention discloses a direct current brushless motor, comprising a motor shell; a left end cover and a right end cover are fixedly connected to two ends of the motor shell; four peripheral magnets are evenly and fixedly connected to the inner surface of the motor shell; a first rail, a second rail, a third rail and a fourth rail are fixedly connected to the inner surface of the peripheral magnets; the peripheral face of a roll sphere is in rolling connection between the first rail and the second rail and is also in rolling connection between the third rail and the fourth rail; a central roller is in rolling connection with the inner circumference face of the roll sphere; a central magnet is sleeved in the central roller; one end of the central magnet is fixedly connected with the left end cover; the magnetic pole of the central magnet is opposite to those of the peripheral magnets; the first rail and the fourth rail are connected with the positive pole of a power supply; the second rail and the third rail are connected with the negative pole of the power supply. The motor has no brush; the mechanical friction loss is little; the efficiency is high; the noise is low; and no spark is generated.

Owner:陈卓

Adaptive hard-rock impact rotary crushing system

InactiveCN102042016BImprove abilitiesQuality improvementTesting machinesSlitting machinesFailure rateHydraulic motor

The invention belongs to coal mine tunneling and crushing machinery, in particular to an adaptive hard-rock impact rotary crushing system. The system comprises a hydraulic pump (13), a hydraulic control module (14), a hydraulic control valve (15), a hydraulic pipeline (16), a hydraulic motor (12) and a thrust hydraulic main cylinder (11); a rotating knife rest (1) is sleeved at the left end of the thrust hydraulic main cylinder (11); the thrust hydraulic main cylinder (11) and the rotating knife rest (1) are connected through a supporting pin (18); two ends of the supporting pin (18) are fixedly limited by a locking pin (17) respectively; a hob head supporting surface (1-1) and a central hole are formed on a front end face of the rotating knife rest (1); and a plurality of angle adjustable disc-shaped hobs (23) are uniformly and fixedly arranged on the hob head supporting surface (1-1) and are supported by a hob supporting bearing (21). The adaptive hard-rock impact rotary crushing system has a simple structure, light weight, low failure rate and low maintenance, and is low in cost, easy to repair and low in maintenance expense.

Owner:LIAONING TECHNICAL UNIVERSITY

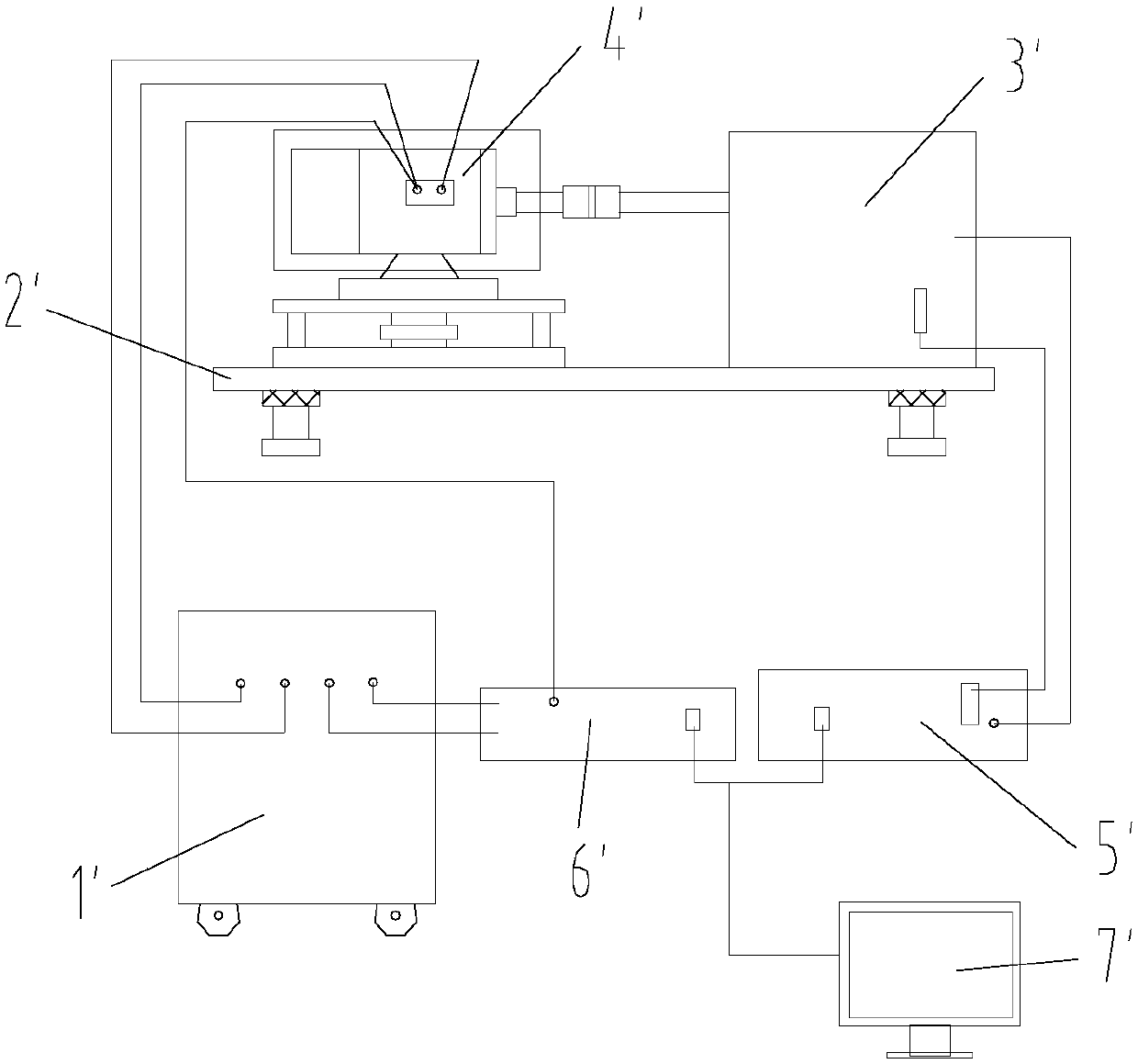

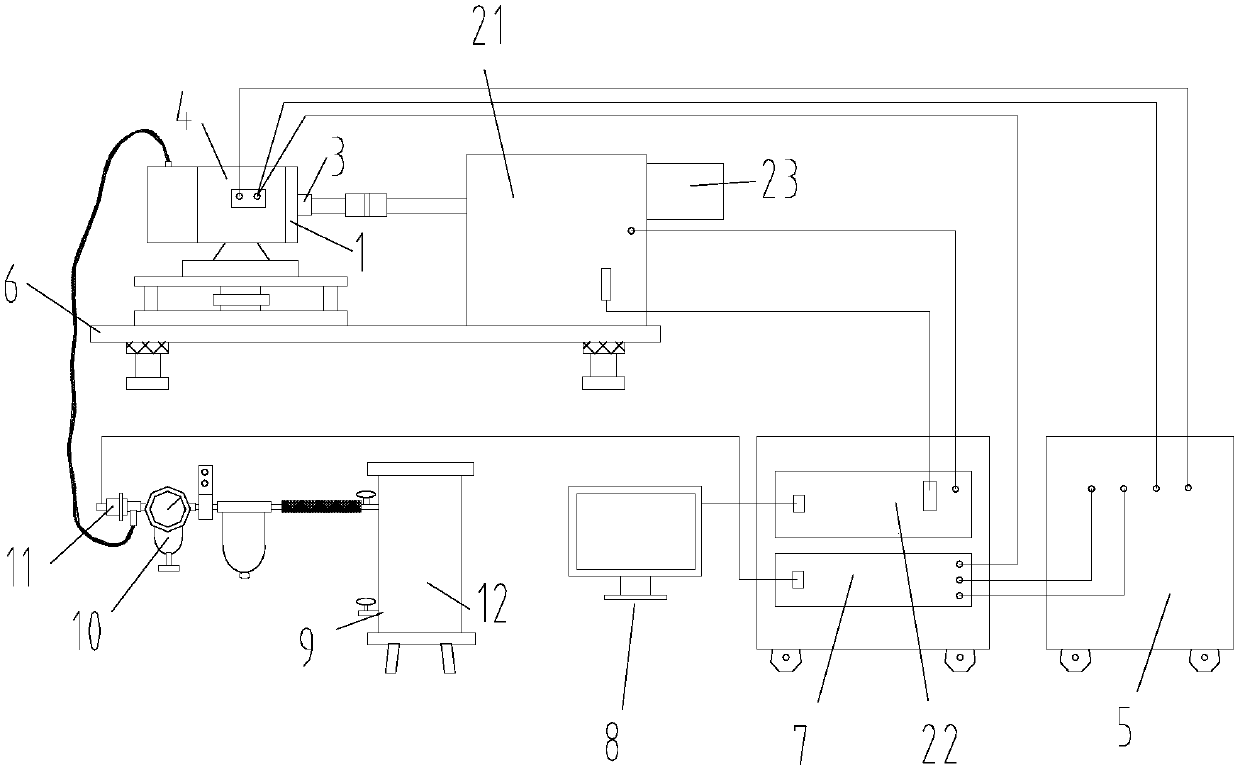

Motor test system and method

PendingCN107907829AImprove stabilityImprove consistencyDynamo-electric machine testingMotor testingFriction loss

The invention provides a motor test system and method. The motor test system comprises a clamp for clamping a to-be-tested motor stator, a dynamometer for testing the power of the to-be-tested motor,a connection shaft connected with an extending shaft of the dynamometer and a bearing, wherein the bearing comprises a main shaft connected with the connection shaft and a shaft sleeve sleeving the main shaft; the shaft sleeve and the clamp are fixedly arranged; and the main shaft is suspended in the shaft sleeve. According to the motor test system and method provided in the invention, through suspending the main shaft connected with the rotor of the to-be-tested motor in the shaft sleeve, direct contact with the inner wall of the shaft sleeve in the case of rotating of the main shaft is avoided, the mechanical friction loss of the motor test system is reduced, and the stability and the consistency in the case of motor test can be improved.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com