Vacuum assembly for decompression device

A technology of vacuum unit and decompression device, applied in the field of separation, can solve the problems of large equipment area, large maintenance workload, low energy utilization rate of steam jet pump, etc. The effect of low operation and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

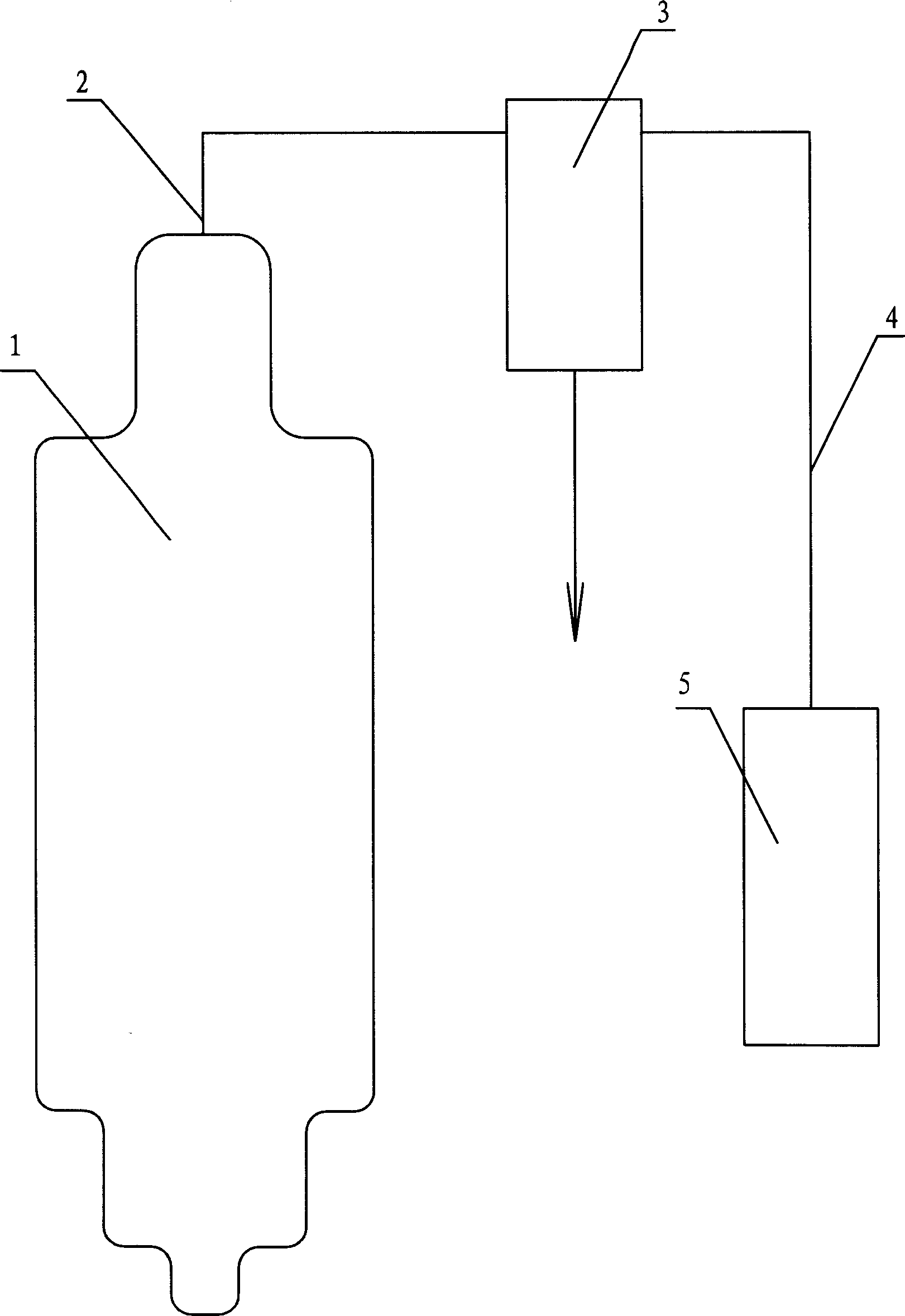

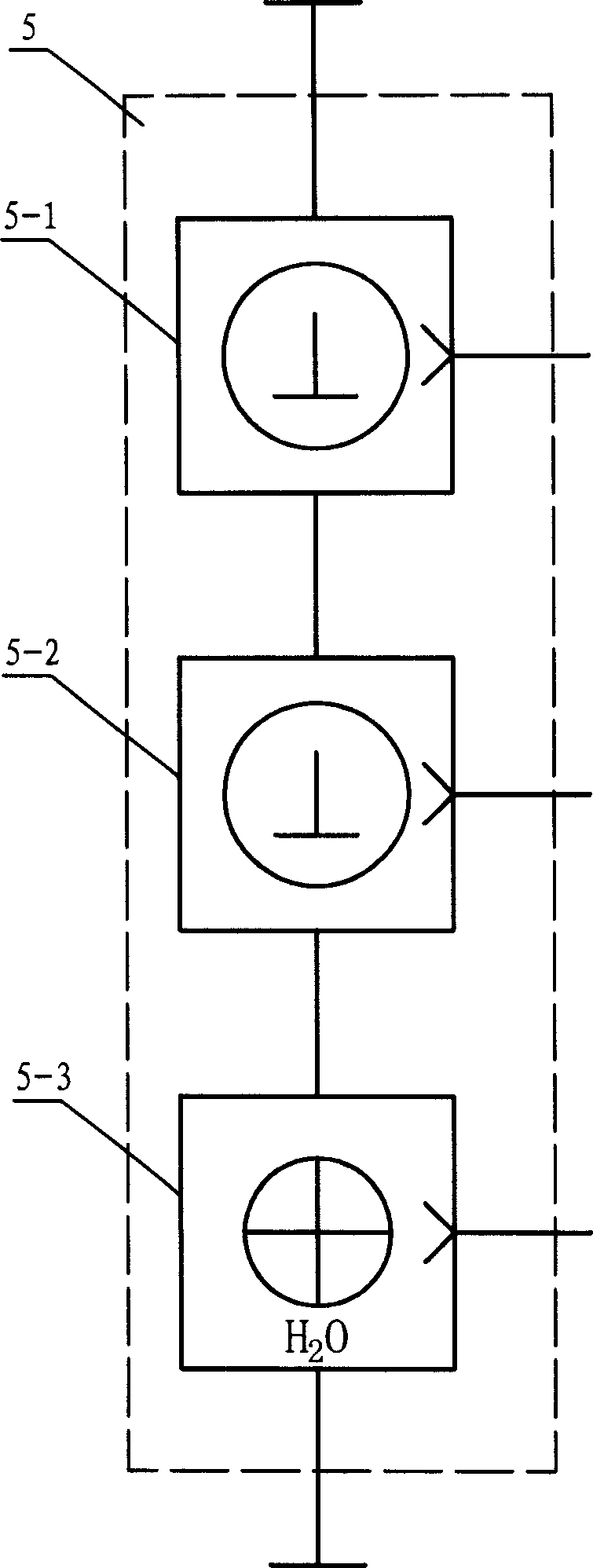

[0033] The Roots-water ring vacuum unit is used as the vacuum device for the vacuum distillation tower:

[0034] figure 2 Among them, the Roots vacuum unit includes two Roots vacuum pumps, a water ring vacuum pump and its corresponding control device (not shown in the figure), wherein, the Roots vacuum pumps 5-1, 5-2 and the water ring vacuum pump 5-3 are sequentially connected in series to form a Roots-Roots-water ring vacuum unit.

[0035] The above-mentioned control device is the operation control circuit of each vacuum pump motor and the open / close control circuit of the pipeline of the vacuum unit and the valve of the oil circuit.

[0036] Since the start / stop operation control circuit of the motor and the open / close control circuit of the valve are all existing technologies, they will not be described in detail here.

[0037] The function of setting the water ring vacuum pump is to cause the preliminary vacuum required by the Roots pump and act as its backing pump.

...

Embodiment 2

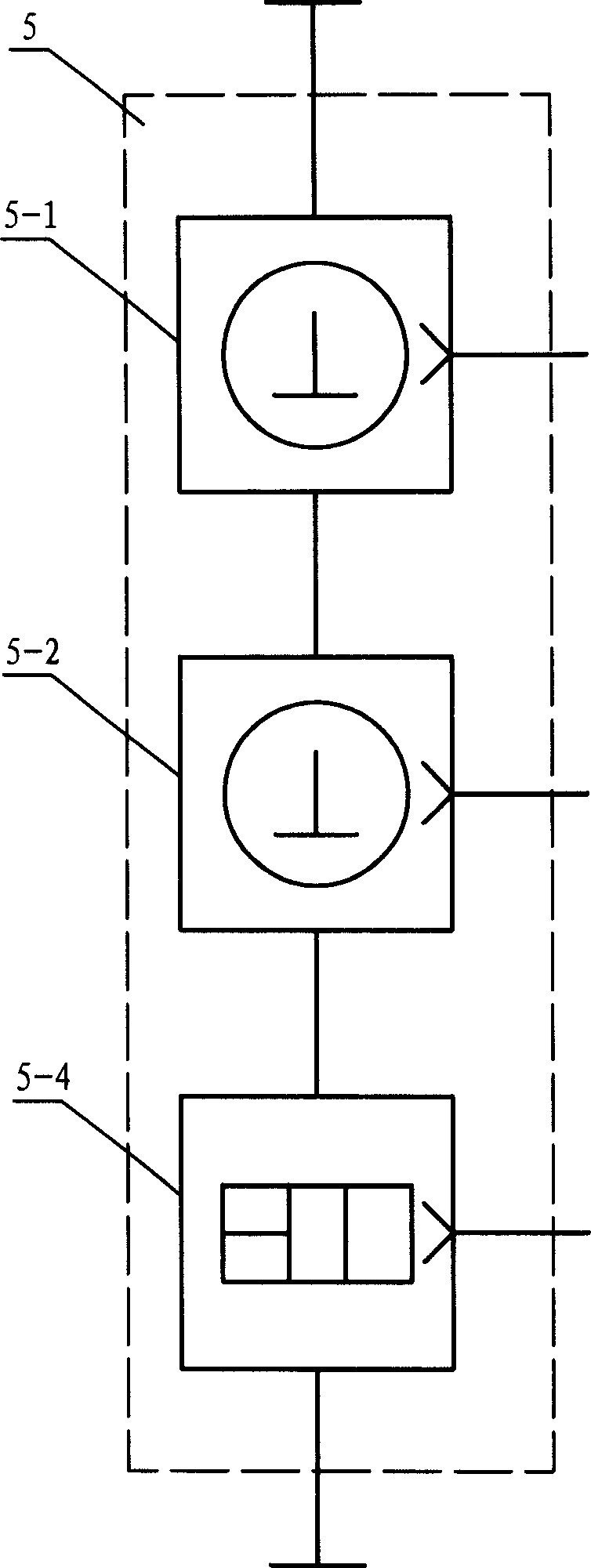

[0041] The Roots-reciprocating vacuum unit is used as the vacuuming device for the vacuum distillation tower:

[0042] image 3 Among them, the Roots vacuum unit includes two Roots vacuum pumps, a reciprocating vacuum pump and its corresponding control device (not shown in the figure), wherein the Roots vacuum pumps 5-1, 5-2 and the reciprocating vacuum pump 5-4 Connected in series to form a Roots-Roots-reciprocating vacuum unit.

[0043] The effect of setting the reciprocating vacuum pump is the same as Example 1.

[0044] All the other are with embodiment 1.

[0045] Since the present invention uses a vacuum unit to provide a negative pressure source for the decompression device, it has high pumping rate, quick start-up of the device, and strong adaptability, which is beneficial to shortening the start-up time of the entire vacuum distillation system and stabilizing the operating conditions of the vacuum distillation tower. It has the advantages of compact structure, smal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com