Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Reduce production operating costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

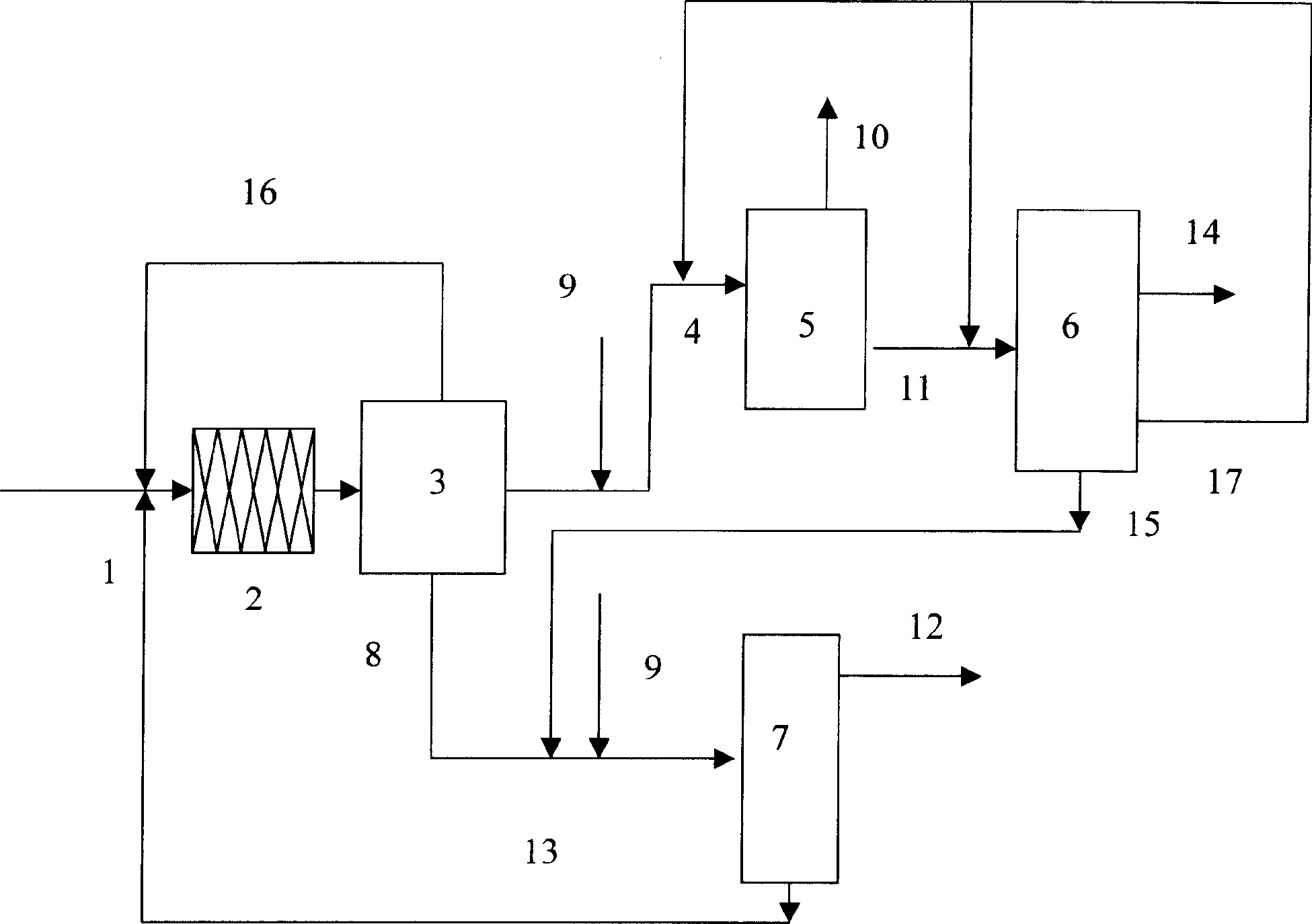

Treatment method for inferior heavy oil and residual oil

ActiveCN1766059ABroaden sources of raw materialsReduce production operating costsTreatment with hydrotreatment processesSolventChemistry

The invention discloses a process for treating inferior heavy oil and residual oil comprising the following steps: loading heavy oil and petroleum residue into a solvent extraction apparatus, charging the obtained deasphalted oil into a fixed bed for hydrotreatment, entering the obtained tail oil into a catalytic cracking device, loading part or total slurry oil and de-oiled asphalt into a floating bed hydrogenation unit, separating the outcome yield to obtain lightweight fraction and untransformed tail oil, which is circulated to the solvent extraction device.

Owner:CHINA PETROLEUM & CHEM CORP +1

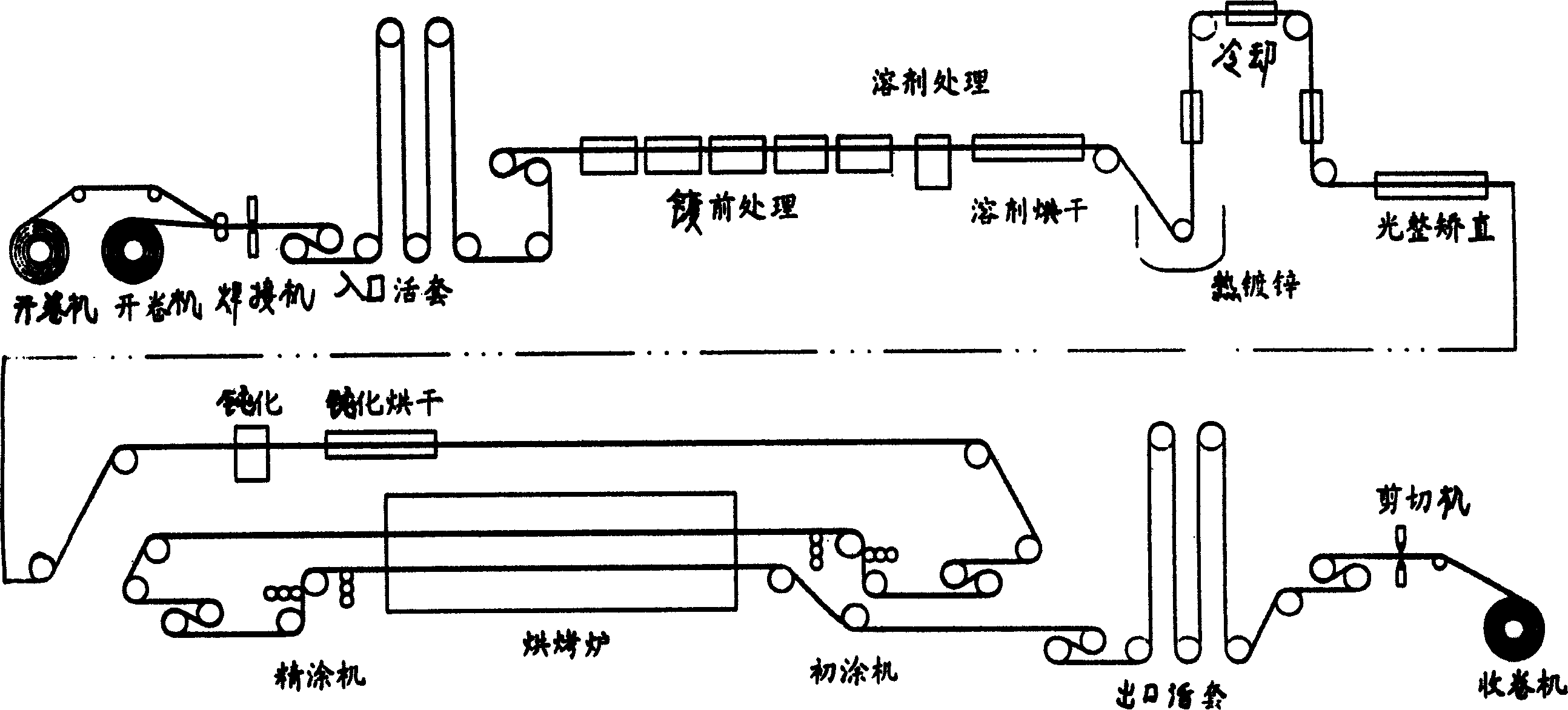

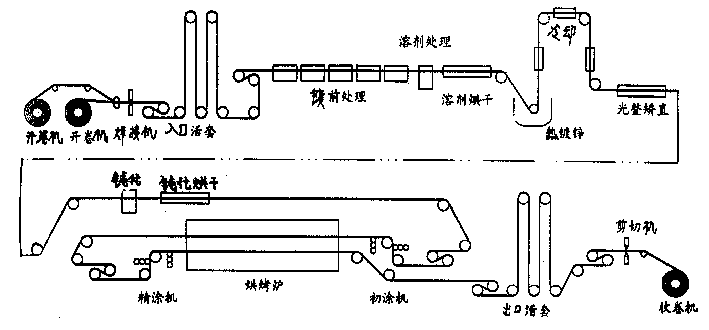

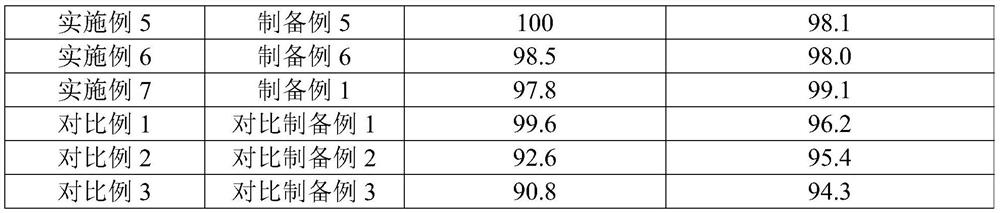

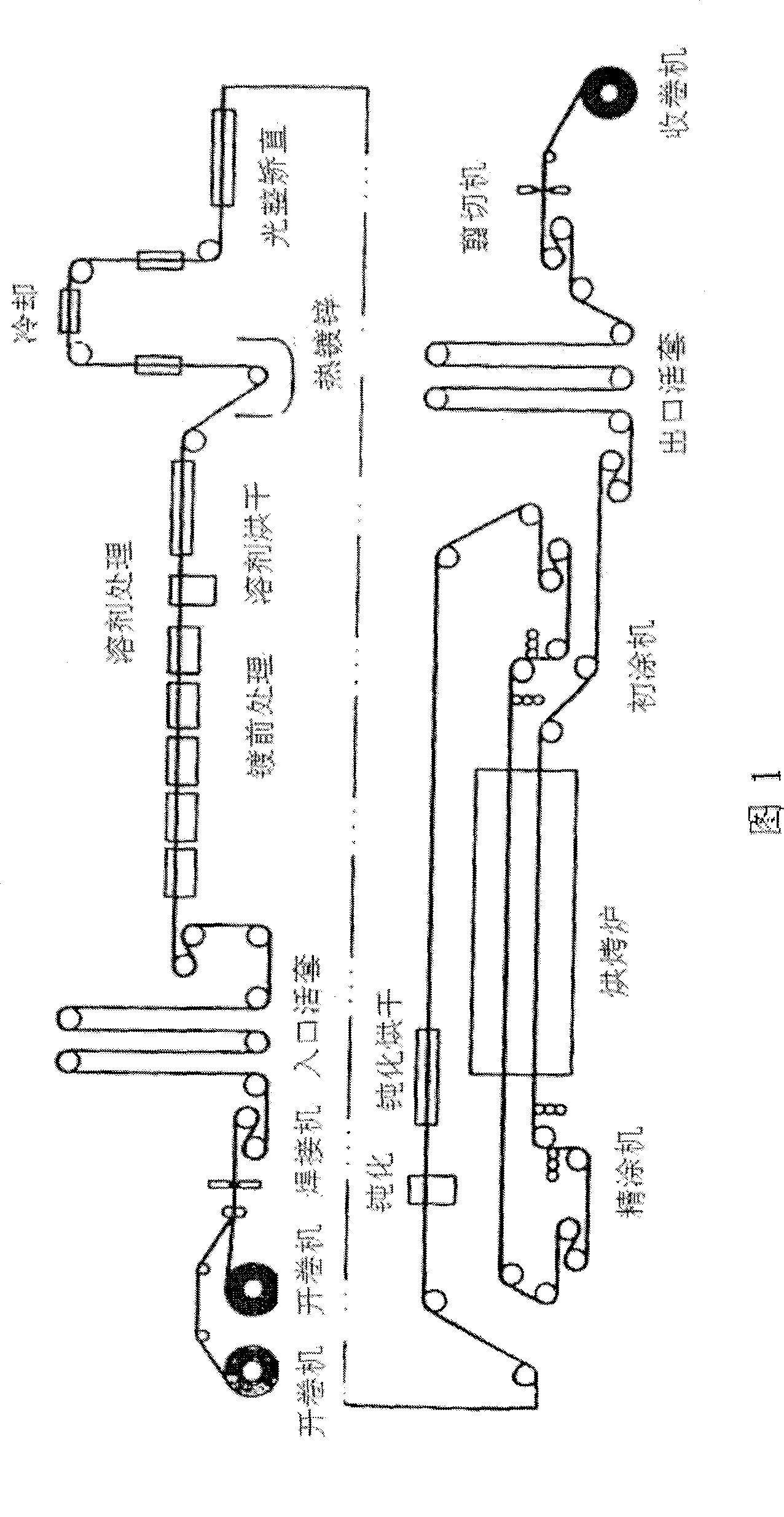

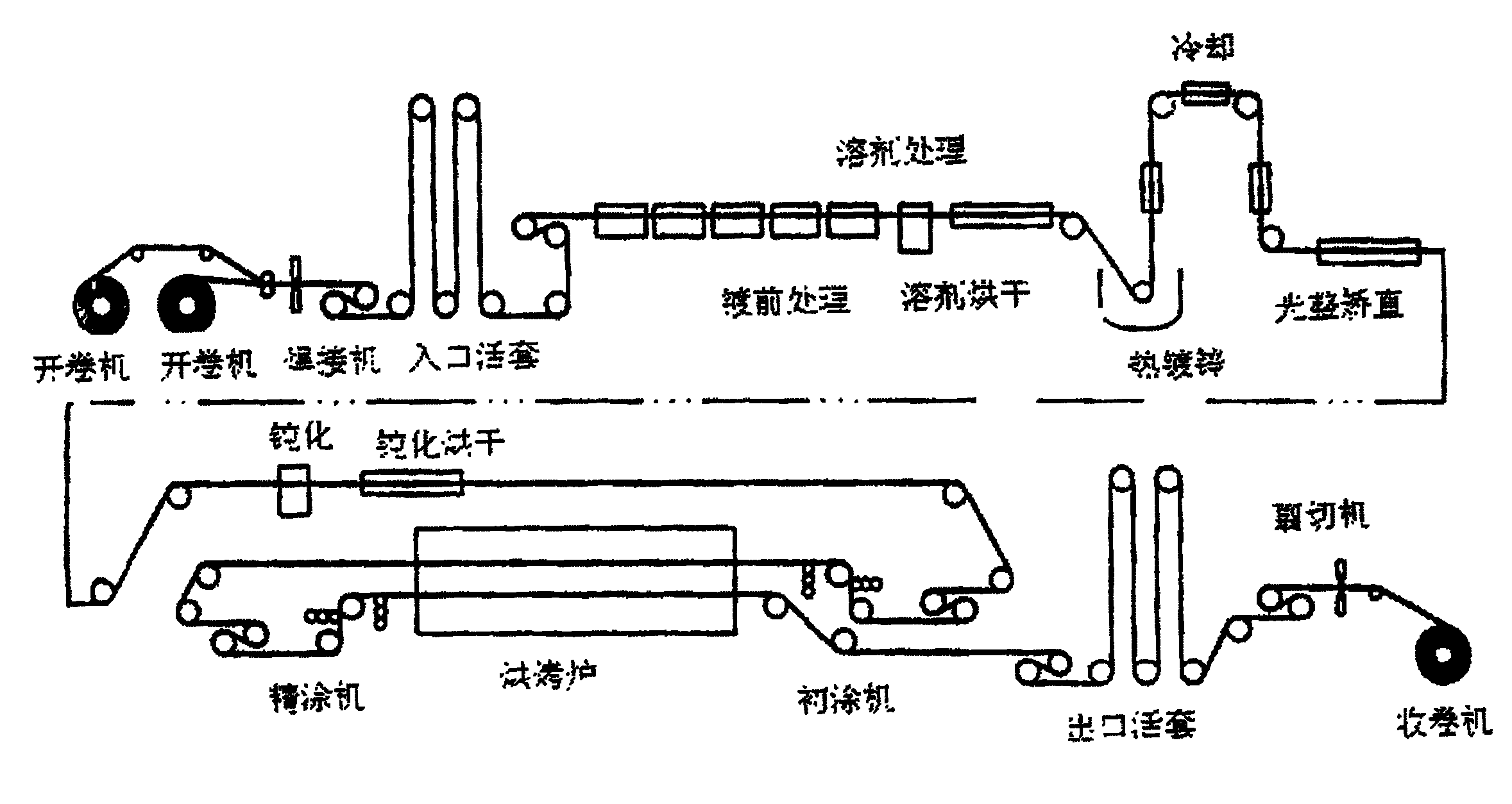

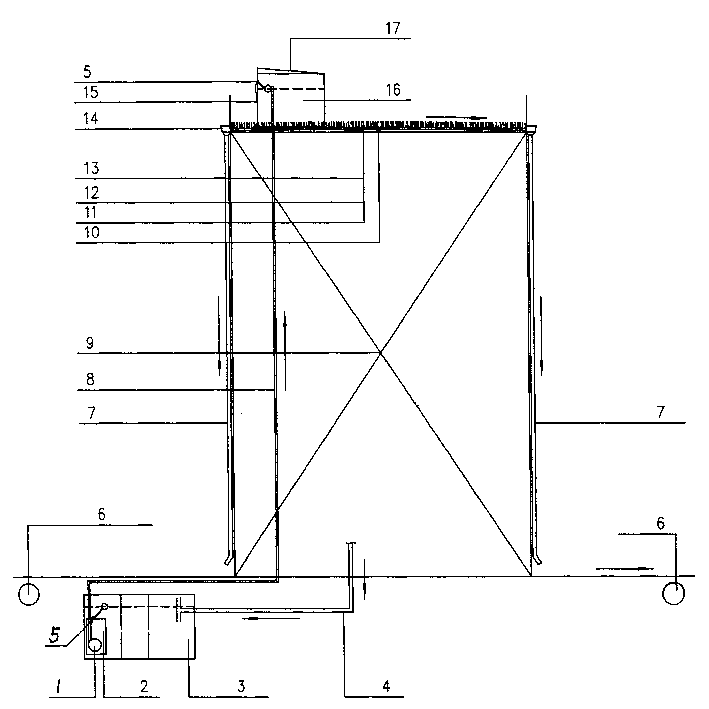

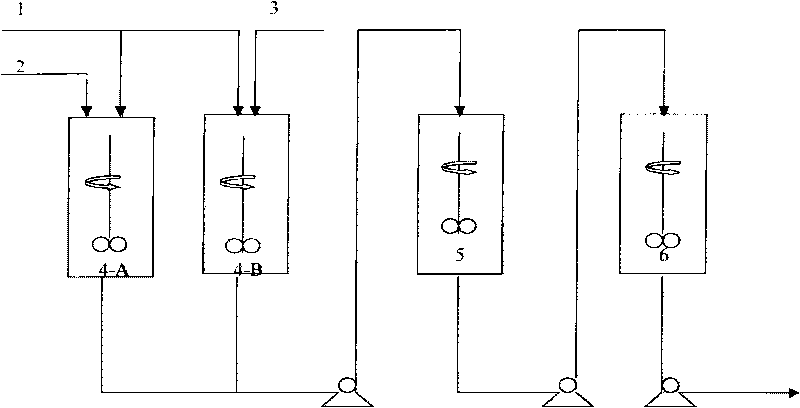

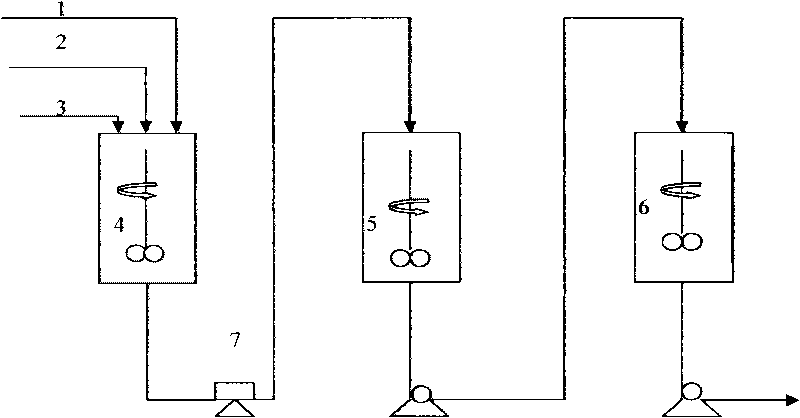

Method for continuous production of hot galvanizing color-painted steel strip

InactiveCN1594655ALow investment costSmall footprintHot-dipping/immersion processesLiquid surface applicatorsProduction lineSheet steel

The invention discloses a continuous hot galvanizing colorful coating steel plate production method, which combines the hot galvanizing and color coating into one assembly line. The inventive continuous hot galvanizing colorful coating steel plate production method can cut down auxiliary apparatus, reduce the assembly line investment cost by 30-40%, reduce the accommodation area by 50-60%. The inventive method has no need for oiling after hot galvanizing, also has no need for treatment before color coating, so diminish the damage to steel plate shape. The inventive method has no need for the unstable operation of galvanizing plate welding, can effectively save the steel strip.

Owner:ZHONGSHAN CHUANGZHI BUILDING MATERIALS TECHCO

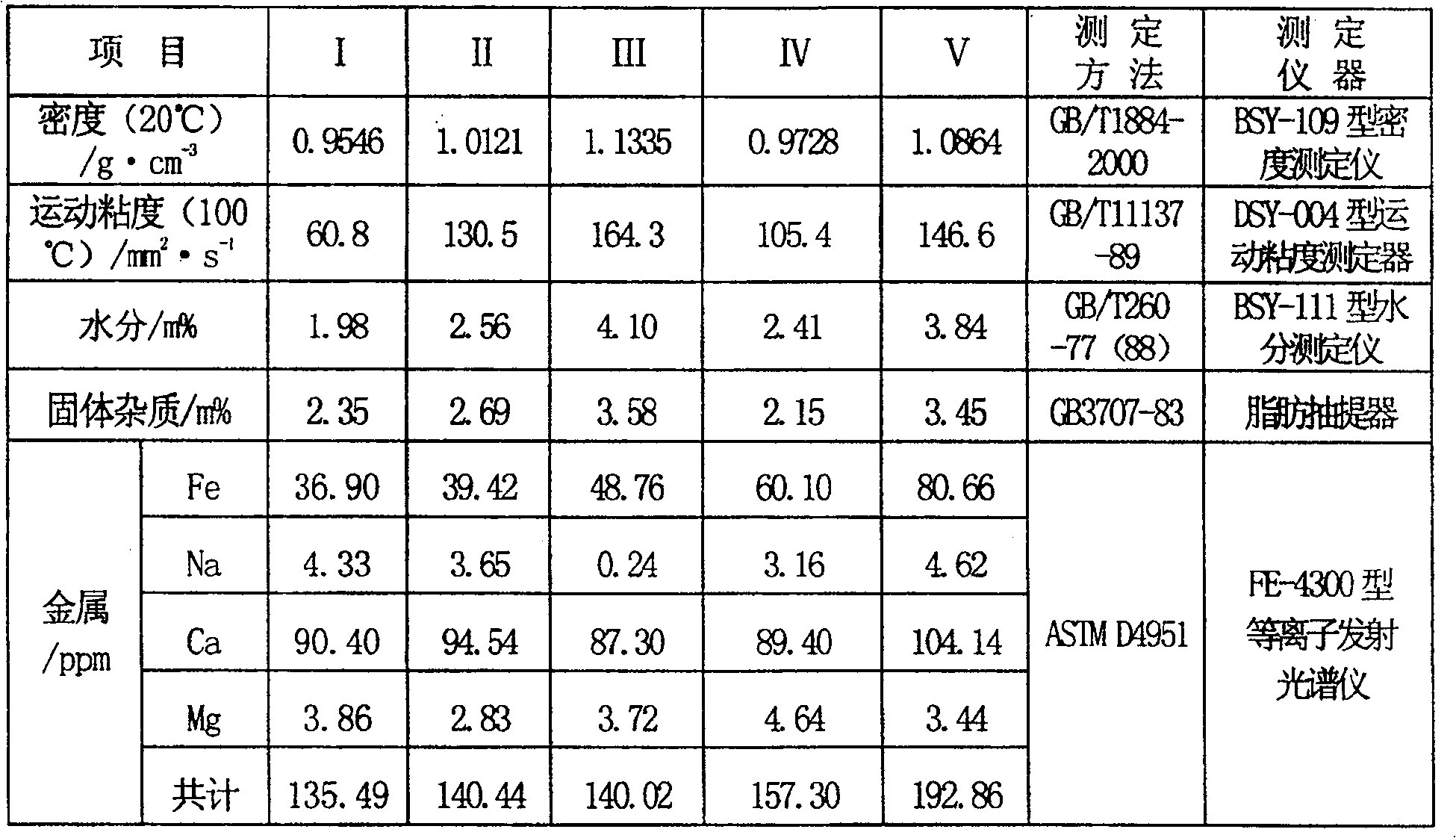

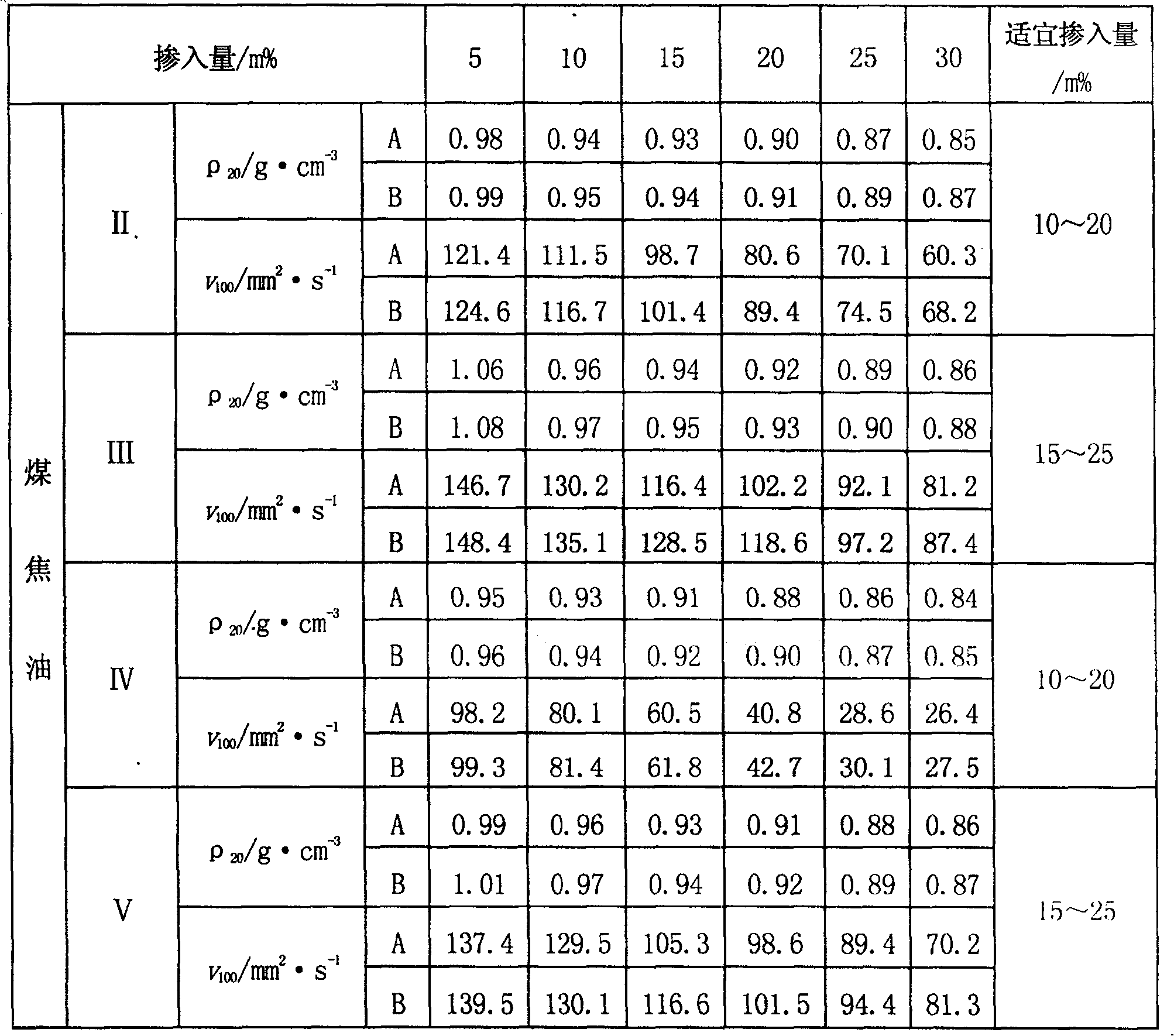

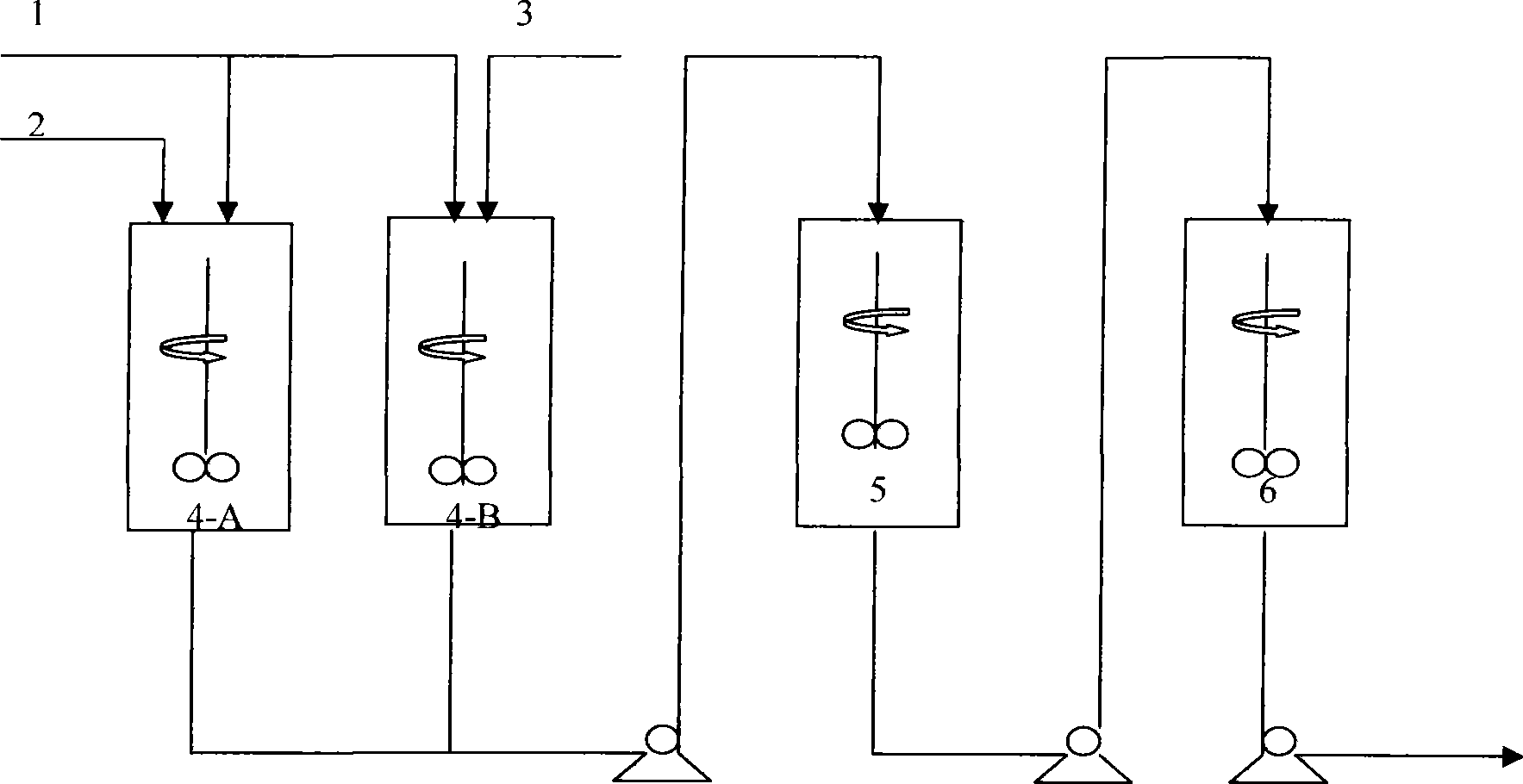

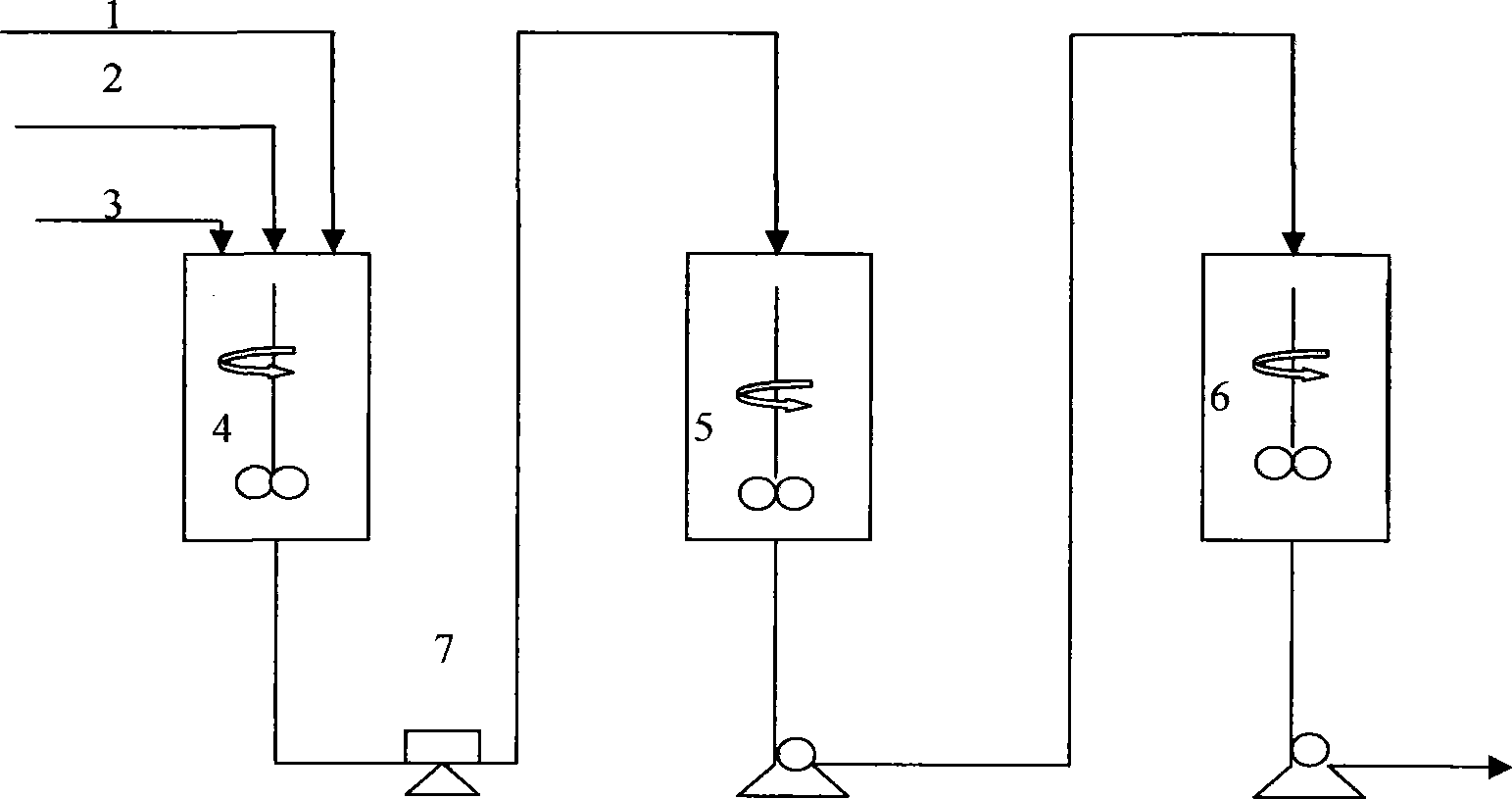

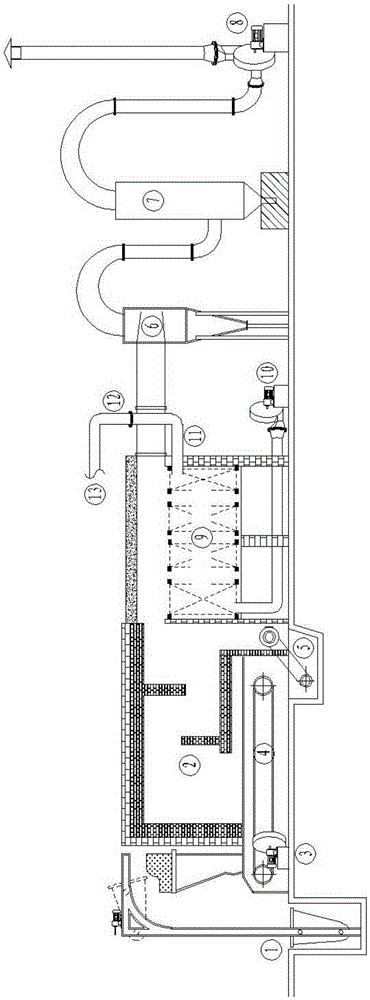

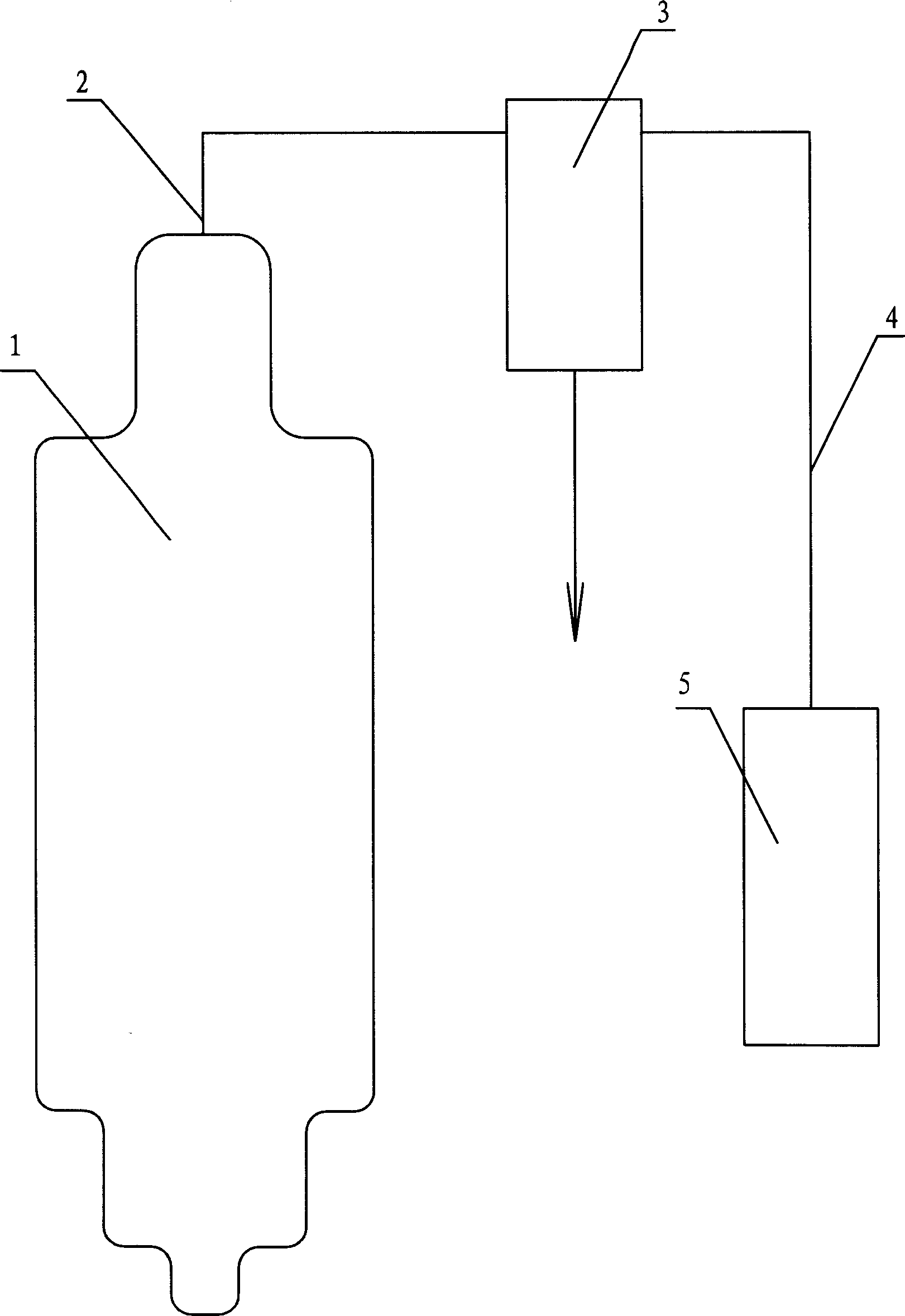

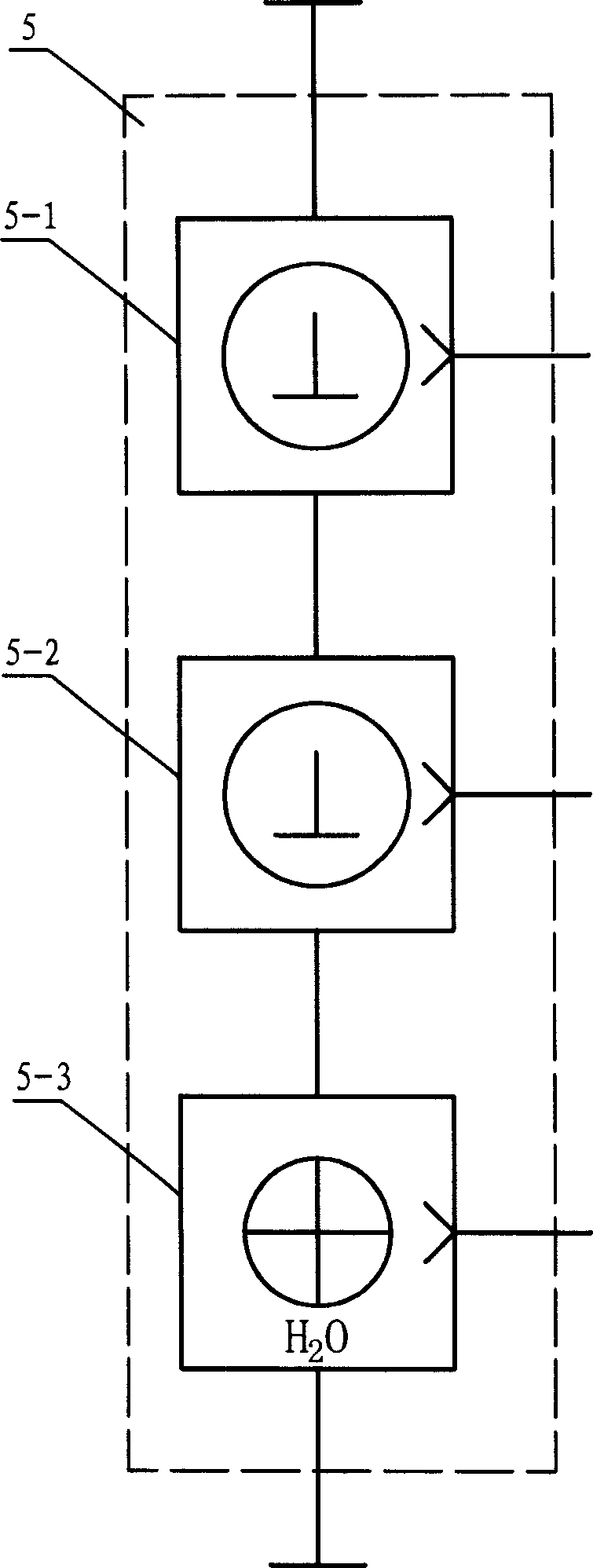

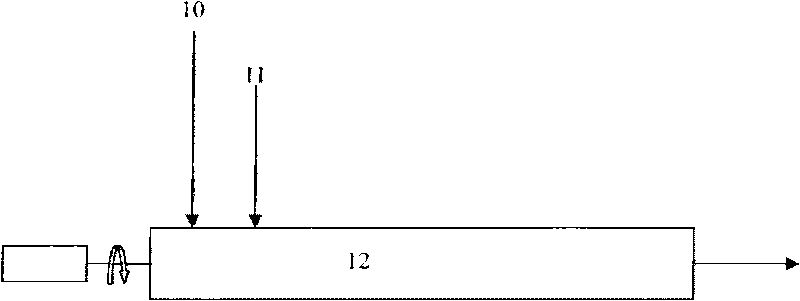

Electric field purifying process of coal-tar oil

ActiveCN100999675AAvoid poisoningAvoid cloggingWorking-up tarRefining by electric/magnetic meansPtru catalystGasoline

The electric field coal tar purifying process includes the technological steps of preparing mixed oil, the first stage of electric purifying, the second stage of electric purifying, the third stage of electric purifying, draining waste water, etc. The experiments show that the coal tar purifying process of the present invention is superior to available coal tar purifying process, and has the advantages of simple technological process, low running cost, high purifying rate, etc. The present invention can reach coal tar purifying rate over 95 %, and the purified coal tar may be used in producing gasoline and diesel oil through hydromodification with no corrosion to the production apparatus, no catalyst poisoning, no blocking of the reactor bed layer and long production apparatus running period.

Owner:SHENMUFUYOU ENERGY TECH

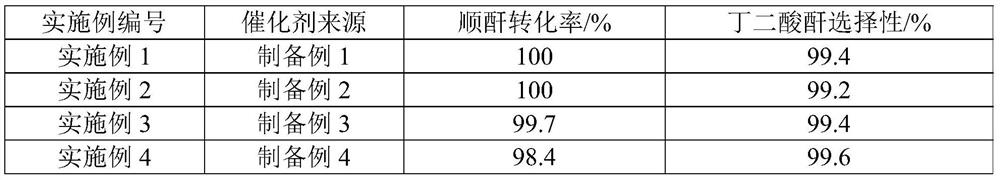

Hydrogenation catalyst, preparation method and application thereof, and method for preparing succinic anhydride through maleic anhydride hydrogenation

PendingCN114433100AHigh activityHigh selectivityOrganic chemistryHeterogenous catalyst chemical elementsPolymer sciencePtru catalyst

The invention relates to the technical field of catalysts, in particular to a hydrogenation catalyst, a preparation method and application thereof and a method for preparing succinic anhydride through maleic anhydride hydrogenation, the catalyst comprises a carrier and active components loaded on the carrier, the active components contain Ni elements, Cu elements and Ce elements, and the carrier contains SiO2; in the catalyst, on the basis of the total weight of the catalyst and in terms of oxide, the content of the Ni element is 10-40 wt%, the content of the Cu element is 1-5 wt%, the content of the Ce element is 1-8 wt%, and the content of the carrier is 47-88 wt%. The catalyst provided by the invention has excellent catalytic activity and succinic anhydride selectivity, is low in cost and simple in process, and can be applied to continuous large-scale production.

Owner:CHINA PETROLEUM & CHEM CORP +1

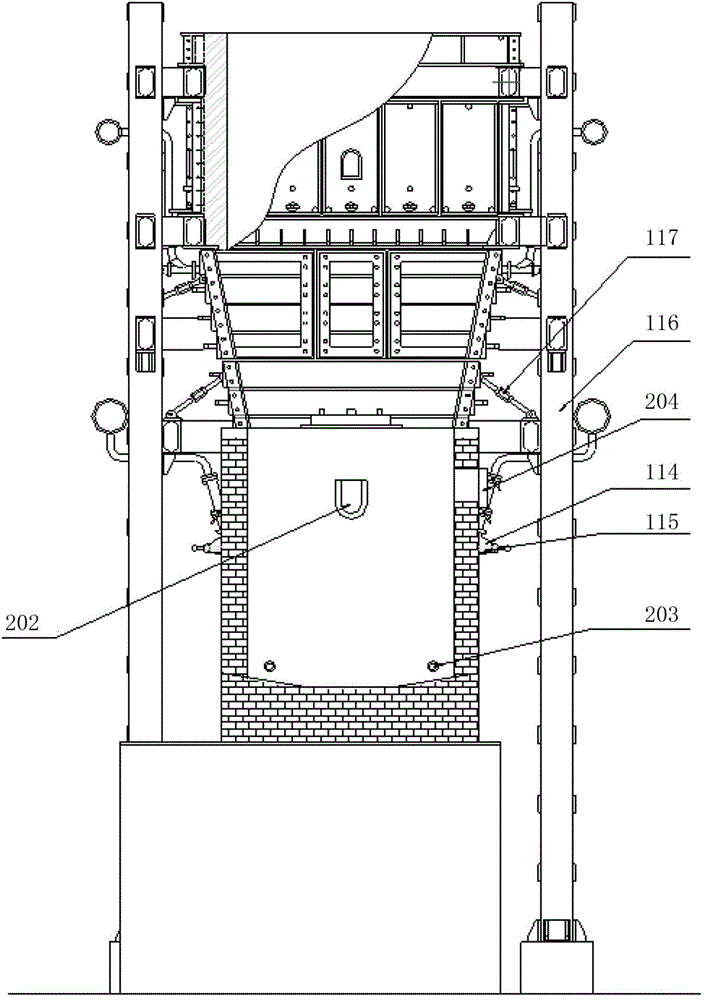

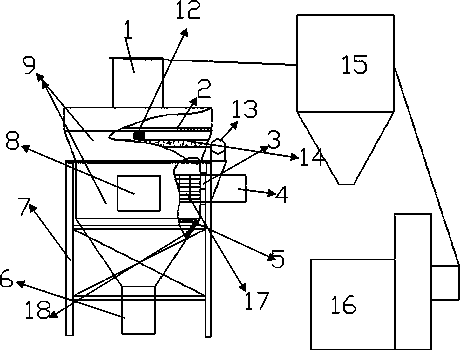

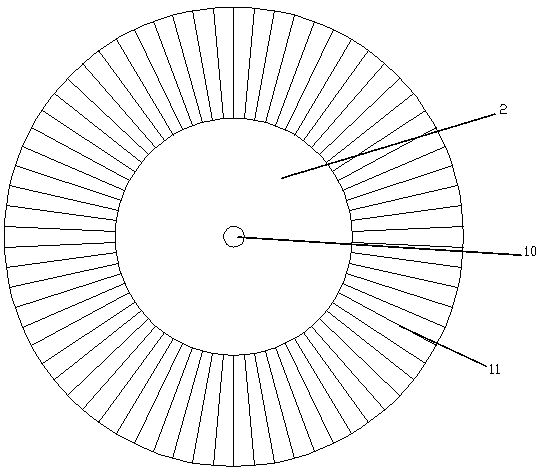

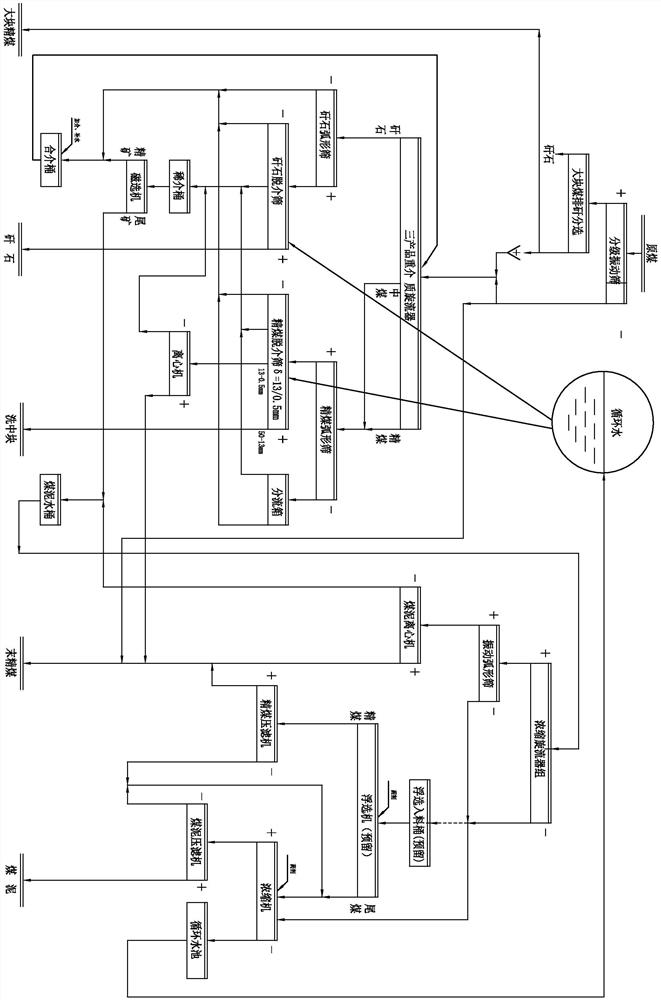

Copper smelting device with high-oxygen-enrichment double-side-blowing melting bat and operation method of copper smelting device

ActiveCN104593617AIncrease useful gas contentReduce take awayRotary drum furnacesCrucible furnacesMelting tankSlag

The invention relates to a copper smelting device with a high-oxygen-enrichment double-side-blowing melting bat and an operation method of the copper smelting device and belongs to the technical field of copper smelting devices and processes. According to the method, a large-volume hearth is used, the continuous production is performed, a single furnace is adopted so as to meet the periodic production of a PS converter, smelting slag continuously overflows from a smelting slag outlet and matte is directly discharged from a matte outlet formed in the bottom end of the hearth. During the smelting slag is discharged, the flowing direction of the smelting slag is controlled by virtue of a switching chute so that the smelting slag can be continuously discharged; the ratio of Fe to SiO2 in the smelting slag is controlled at 1.6-1.8, the ratio of a fuel to input materials is controlled at 2-2.5% and the content of copper in the smelting slag is less than or equal to 0.65%. The method has the characteristics of small construction investment, low production cost, good working environment, high degree of automation, high utilization rate of plant building and the like.

Owner:CHIFENG FUBANG COPPER

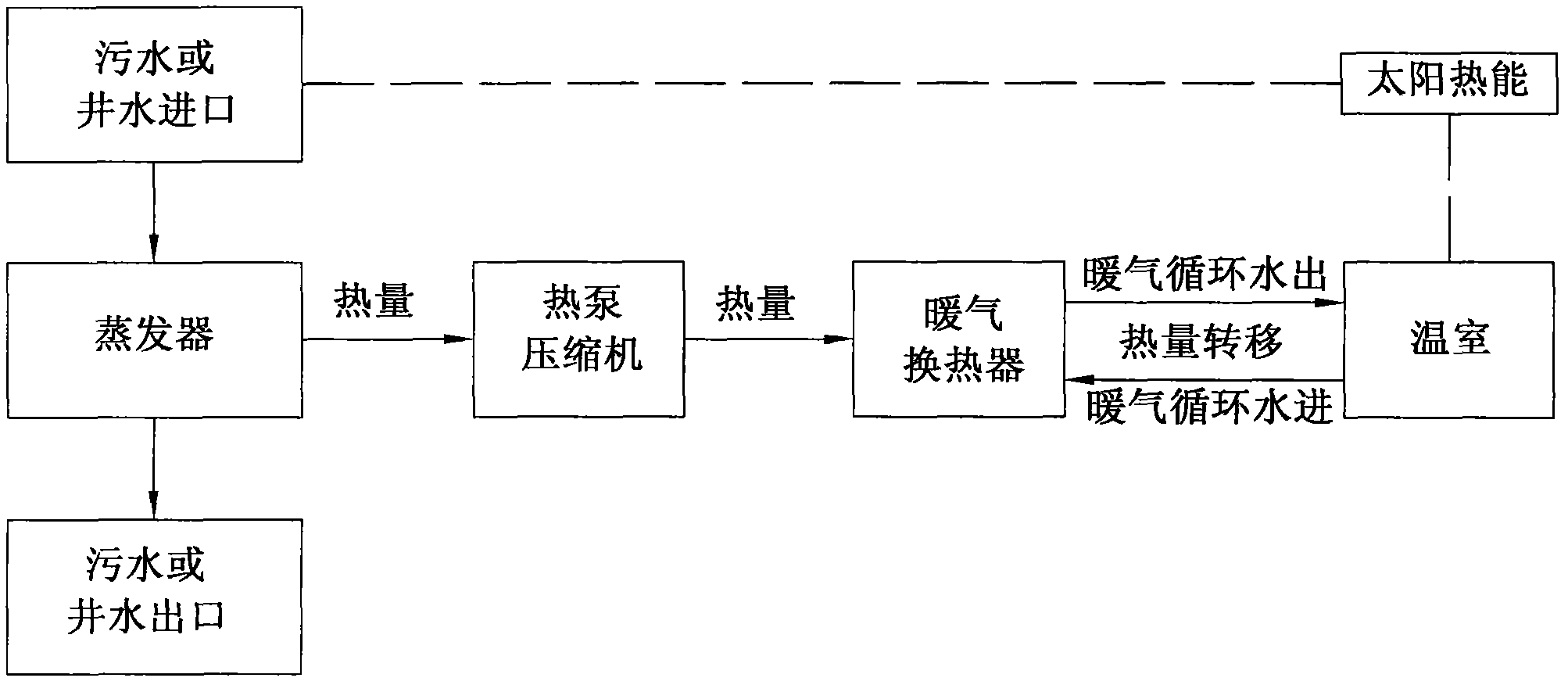

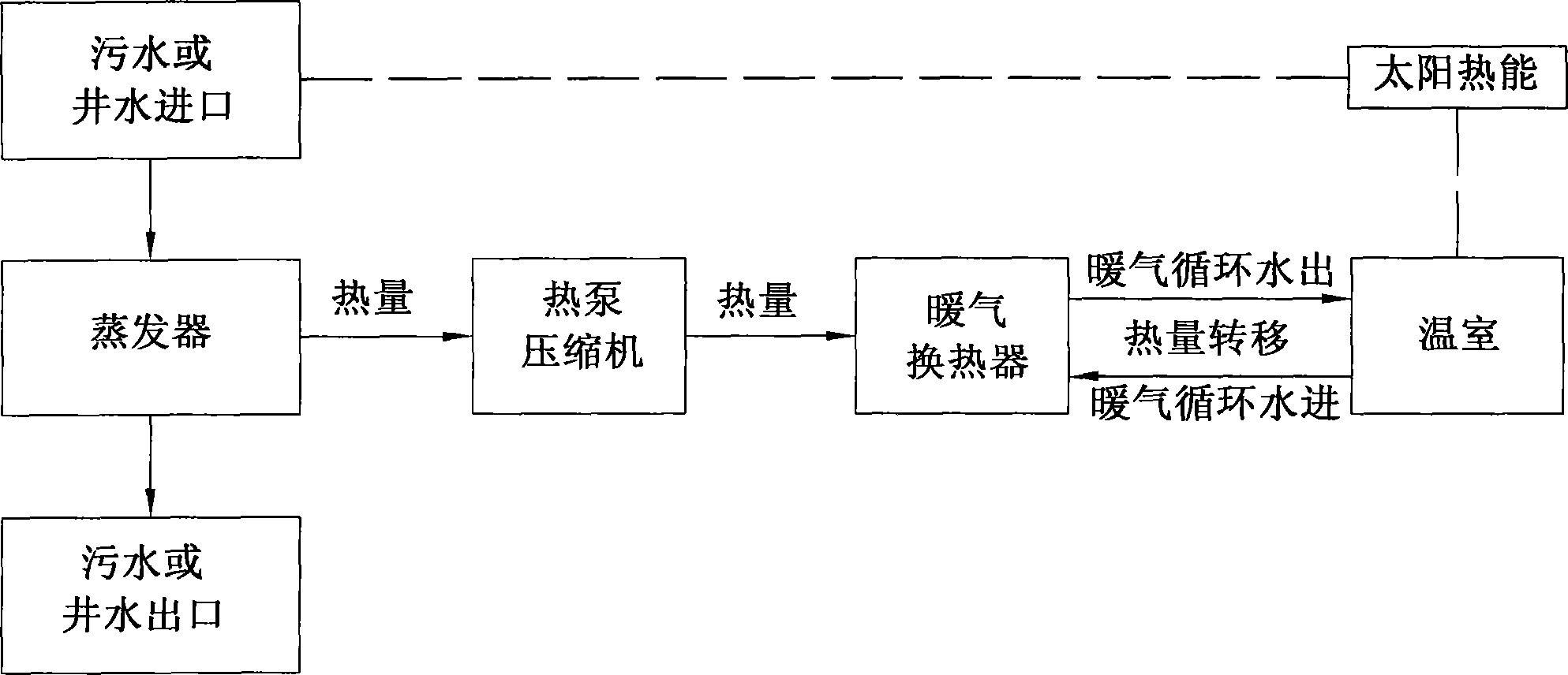

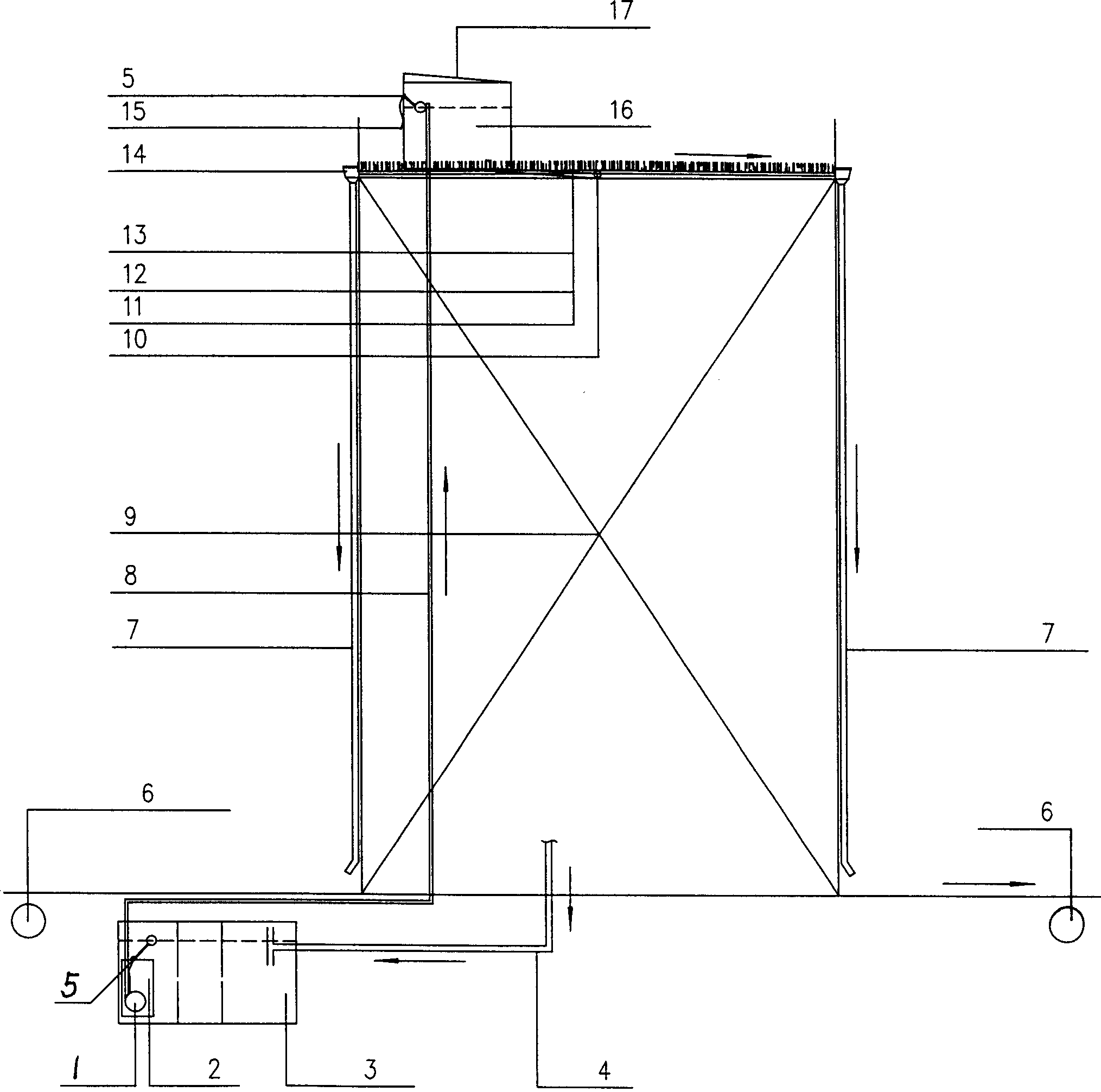

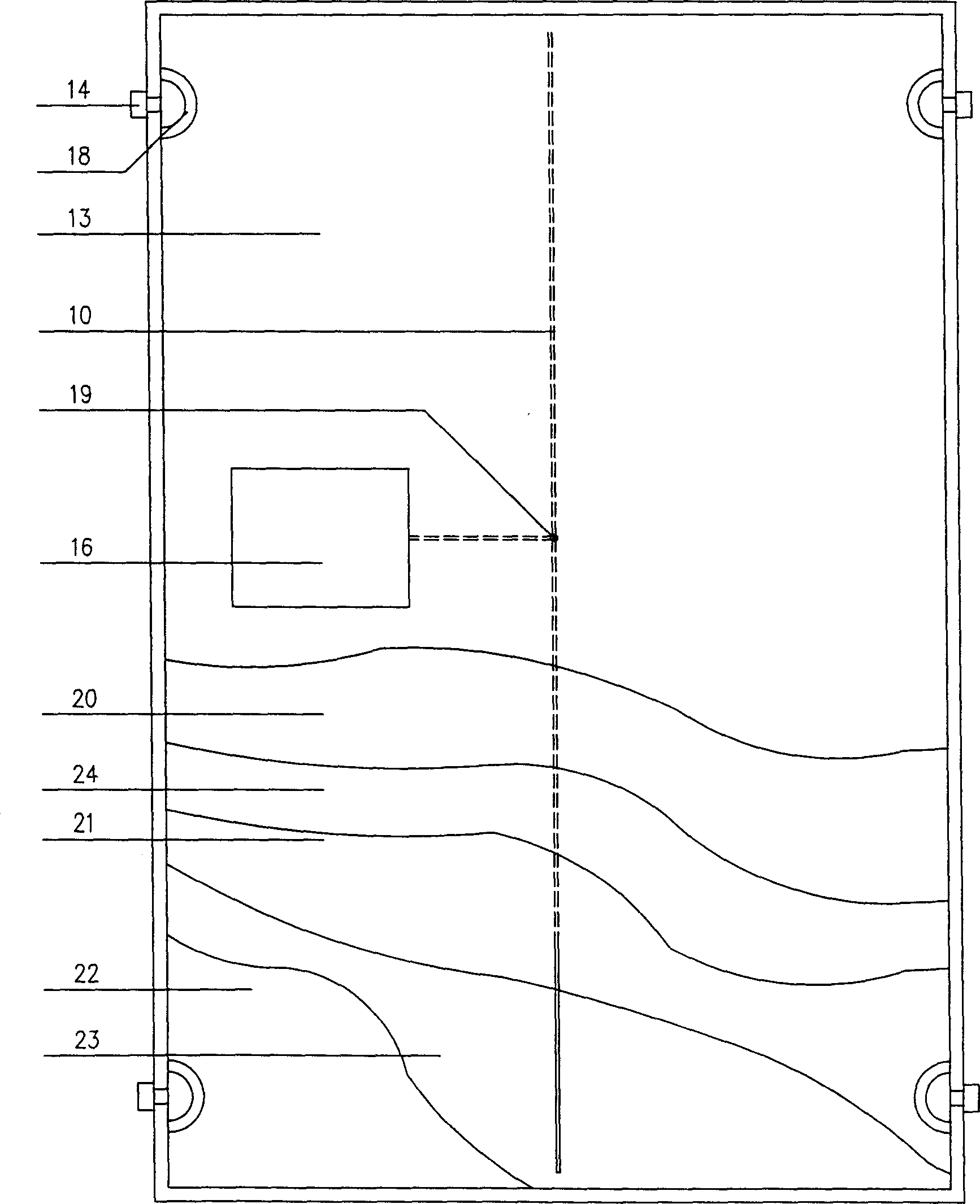

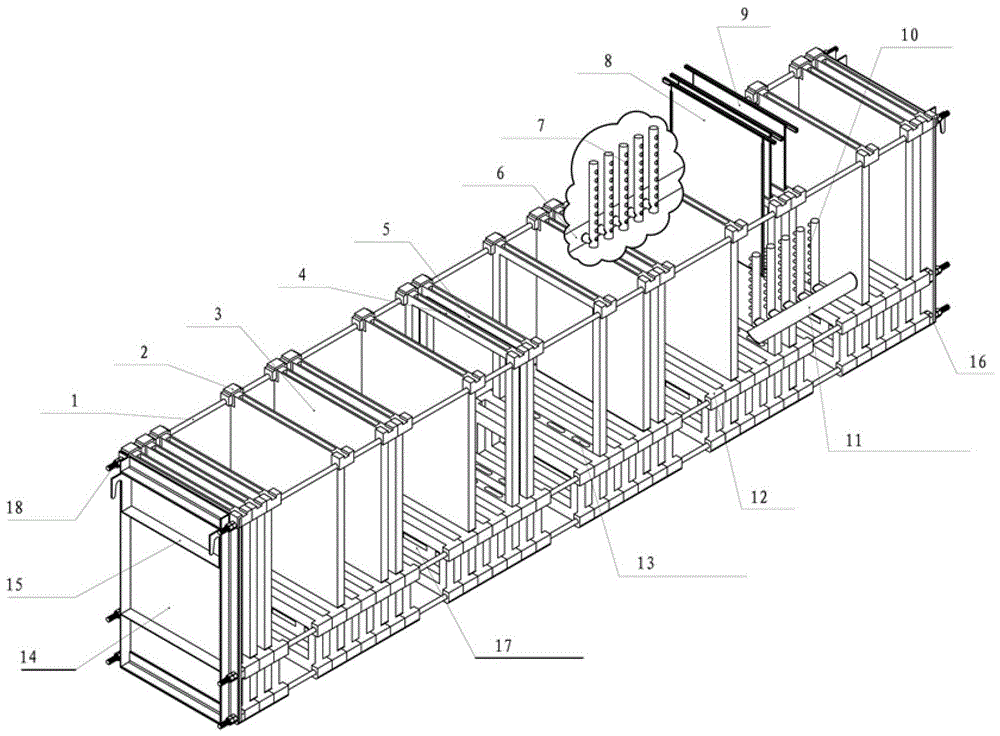

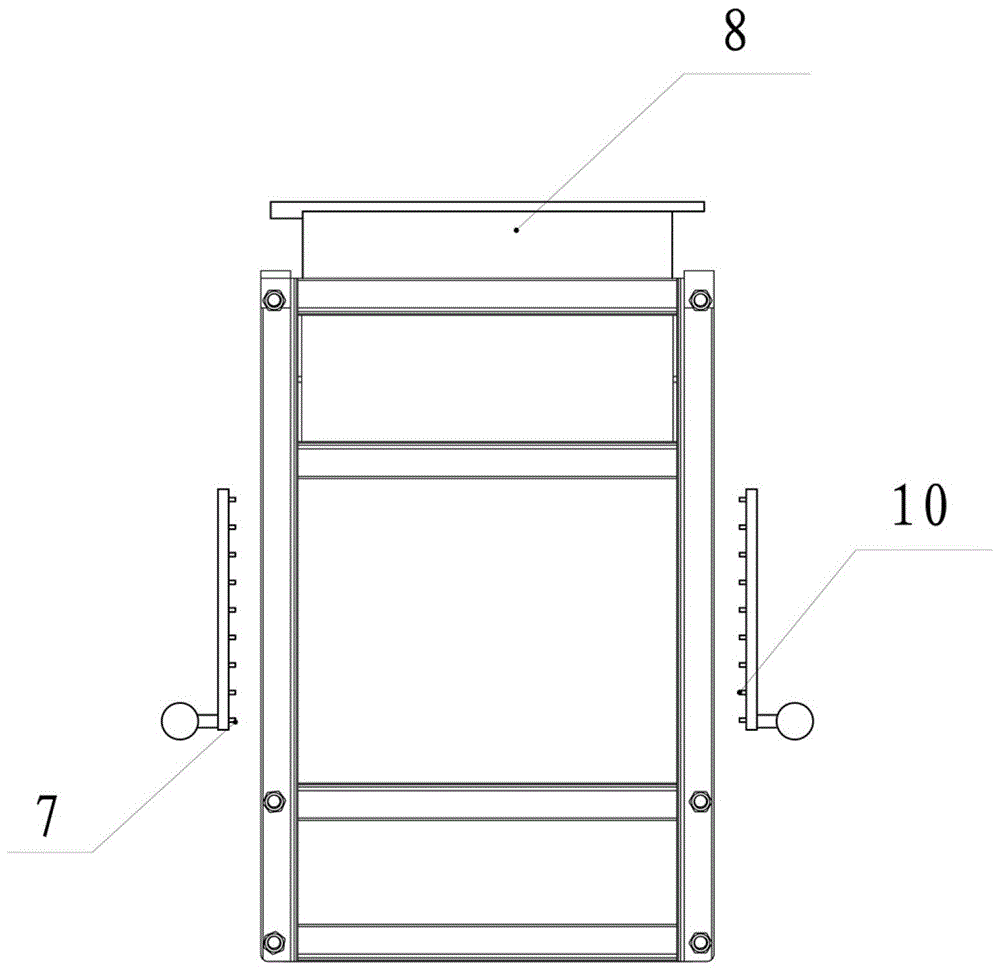

Heat pump greenhouse

InactiveCN102657048AReduce production operating costsInexpensive and sufficient heat supplyHeat recovery systemsClimate change adaptationThermal energyWater source

The invention discloses a heat pump greenhouse, comprising an evaporator, wherein an inlet is communicated with a hot water source by a pipeline, an outlet is communicated with a wastewater outlet, and the hot water enters the evaporator through the inlet and is discharged from the outlet after emitting the heat; and a heat pump compressor, wherein a inhalation end is connected with the evaporator and an exhaust end is connected with a heat exchanger, and the heat pump compressor, from the evaporator, absorbs the heat emitted by the hot water in the evaporator, and transmits the heat to the heat exchanger by a working medium. The heat exchanger is connected with the greenhouse by a water circulation system by which the heat exchange is realized between the heat exchanger and the greenhouse. The hot water source is a geothermal well or a sewer line. The heat pump greenhouse, using heat sources such as underground water in planting area, industrial or domestic sewage, exhaust gas, etc., extracts the heat with the heat pump technology for heating so that an energy-saving, environmental and low-carbon production mode is realized, a cheap and sufficient heat supply is provided to the greenhouse of agricultural productions, and the production operating cost of the greenhouse is reduced.

Owner:新疆麦立德保鲜技术开发有限责任公司

Electric field purifying process of coal-tar oil

ActiveCN100569910CAvoid poisoningAvoid cloggingWorking-up tarRefining by electric/magnetic meansPurification methodsDesorption

An electric field purification method for coal tar comprises the process steps of preparing mixed oil, first-stage electric detachment, second-stage electric detachment, third-stage electric detachment, and sewage discharge. The present invention has gone through the intermediate scale-up test after the laboratory research test. Compared with the existing coal tar purification method, the present invention has the advantages of relatively simple process, low production and operation costs, and high purification rate, and the purification rate can reach more than 95%. , the purified coal tar can prevent corrosion of equipment, prevent catalyst poisoning, avoid blockage of reactor bed, and prolong the operation period of production equipment in the process of hydrogenation and upgrading to produce gasoline and diesel oil.

Owner:SHENMUFUYOU ENERGY TECH

Method for continuous production of hot galvanizing color-painted steel strip

InactiveCN100497737CLow investment costSmall footprintHot-dipping/immersion processesLiquid surface applicatorsProduction lineSheet steel

The invention discloses a continuous hot galvanizing colorful coating steel plate production method, which combines the hot galvanizing and color coating into one assembly line. The inventive continuous hot galvanizing colorful coating steel plate production method can cut down auxiliary apparatus, reduce the assembly line investment cost by 30-40%, reduce the accommodation area by 50-60%. The inventive method has no need for oiling after hot galvanizing, also has no need for treatment before color coating, so diminish the damage to steel plate shape. The inventive method has no need for the unstable operation of galvanizing plate welding, can effectively save the steel strip.

Owner:ZHONGSHAN CHUANGZHI BUILDING MATERIALS TECHCO

Preparation method of granular color cementing agent

The invention discloses a method for preparing granular color cementing agent which is used for paving and constructing color concrete pavement. The method uses a double screw extruder or a single screw extruder, and the raw materials of the color cementing agent are added into a feeding port of the extruder and extruded into strips after cutting and mixing by the screw in the extruder, and then the color strips of the color paving cementing agent enters a granulator to be cut into grains after water bath cooling, thus obtaining the granular color cementing agent product. The method can obtain the following effects of: (1) continuous production, short production cycle and high production efficiency; (2) less required production equipment and small occupied area; (3) little equipment investment and low production and running costs; and (4) granular product and convenient storage, transportation and use.

Owner:CHINA PETROLEUM & CHEM CORP +1

Water purifying plant for buildings

InactiveCN1415560AEasy to useReduce production operating costsEnergy based wastewater treatmentBiological water/sewage treatmentReclaimed waterSewage

A water cleaning facility for building is composed of separating unit, water regulating unit, diffusing unit, cleaning unit and water collecting unit for drainging the reclaimed water. The septic tank, immersible pump, water supply pipe, sewage tank, diffusing pipe and roof region for planting are included.

Owner:孙王虎

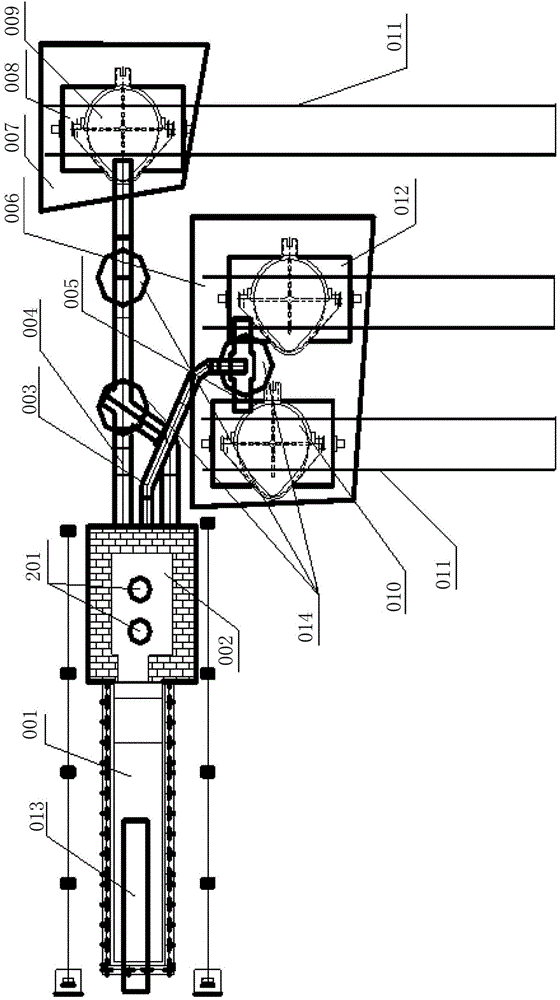

Coal fired chain grate hot-blast stove and application thereof

InactiveCN105423549ASimple structureEasy to operateDrying gas arrangementsAir heatersCombustion chamberCyclonic spray scrubber

The invention provides a coal fired chain grate hot-blast stove. The coal fired chain grate hot-blast stove comprises a combustion chamber, a chain grate and a heat exchanger. The hot-blast stove is a horizontal stove; a combustion fan is arranged below one fuel adding end of the chain grate; a deslagging machine is mounted below the other end of the chain grate; the heat exchanger is a tube type clean air heat exchanger; a tube pass of the heat exchanger is a clean air channel; a smoke outlet and a clean air outlet are formed in the stove wall of the same side of the hot-blast stove; the smoke outlet is sequentially connected with a cyclone dust collector, a water dust scrubber, a smoke guiding fan and a chimney through pipelines. The coal fired chain grate hot-blast stove is simple in structure and convenient to operate by workers, the combustion chamber temperature is easy to control, and temperature fluctuation of hot air generated by the clean air heat exchanger is stable.

Owner:安徽泰格生物技术股份有限公司

Horizontal screw centrifuge

PendingCN112387427ARotate synchronouslyPrevent flow rejectionRotary centrifugesSpiral bladeEngineering

The invention discloses a horizontal screw centrifuge. A spiral conveyor is located in a rotary drum shell, a feeding pipe is in communication with an inner pipe of the spiral conveyor, a dischargingport is formed in the inner pipe, spiral blades are fixed to the periphery of the inner pipe, a light phase outlet is located in an end cover on one side of the rotary drum shell, an isolation disc ofa disc system is arranged between the spiral blade at the tail end of the spiral conveyor and the light phase outlet, the isolation disc is fixed to the spiral conveyor, a flow channel is formed in the side, close to the inner pipe, of the isolation disc, and a solid phase channel is formed between the isolation disc and the inner wall of the rotary drum; and the disc system is positioned betweenthe isolation disc and the light phase outlet, and is fixed with the rotary drum. The disc system is additionally arranged between the rotary drum shell close to the light phase outlet and the innerpipe, tiny solid particles are rapidly separated from a liquid phase, the content of the tiny solid particles in a liquid is greatly reduced, and therefore final clear liquid with higher purity can beobtained, filtering treatment of the tiny solid particles does not need to be carried out in the later procedure, and the centrifuge capability of the centrifuge is increased.

Owner:JIANGSU JUNENG MASCH CO LTD

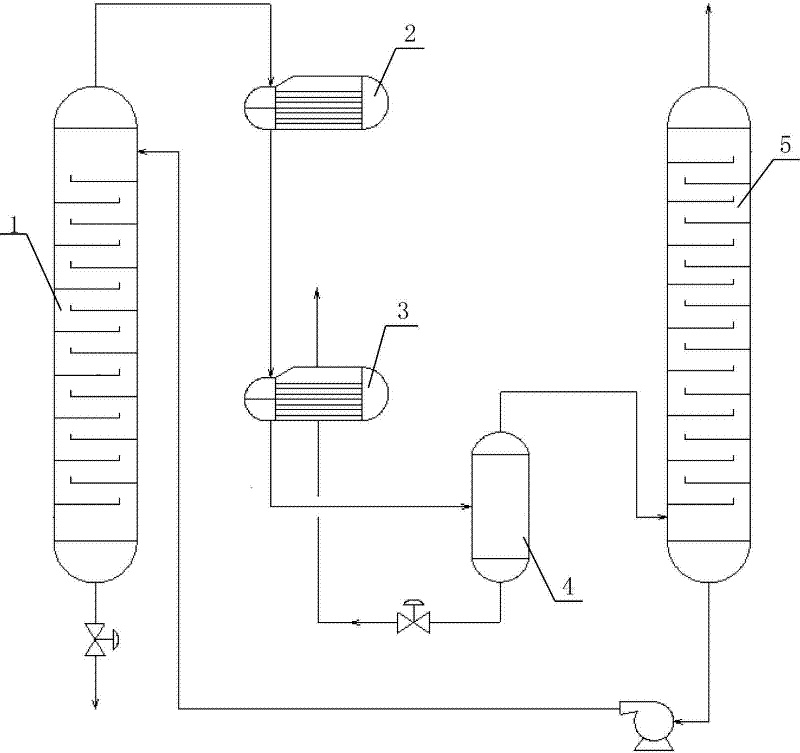

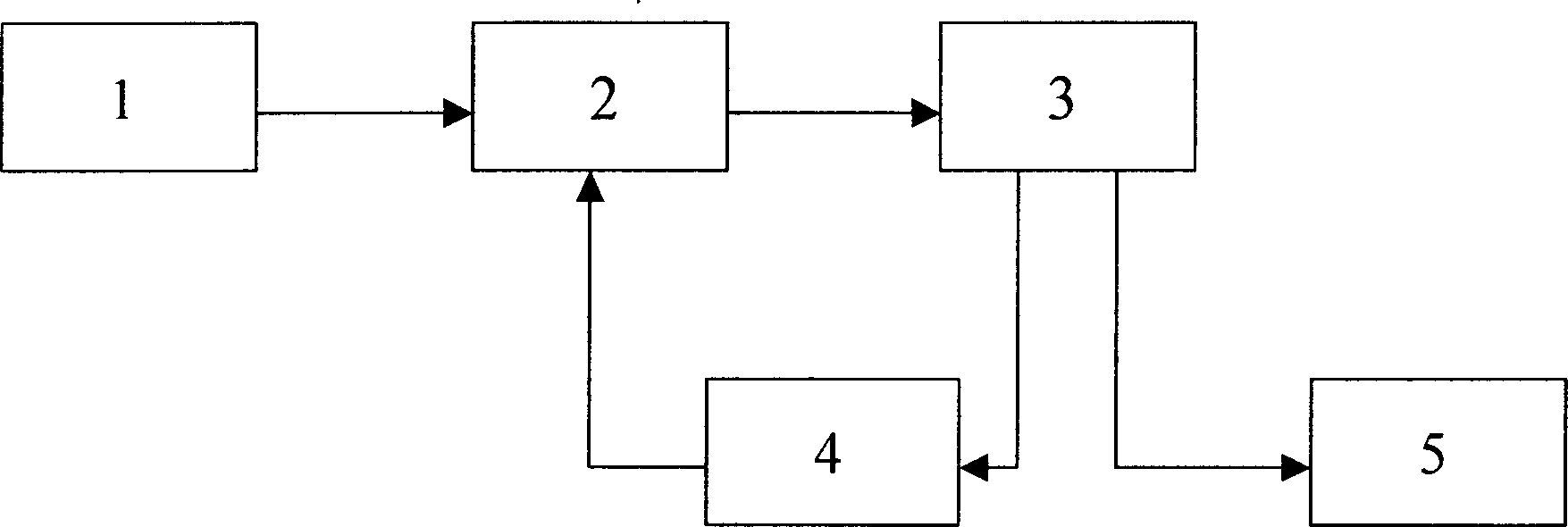

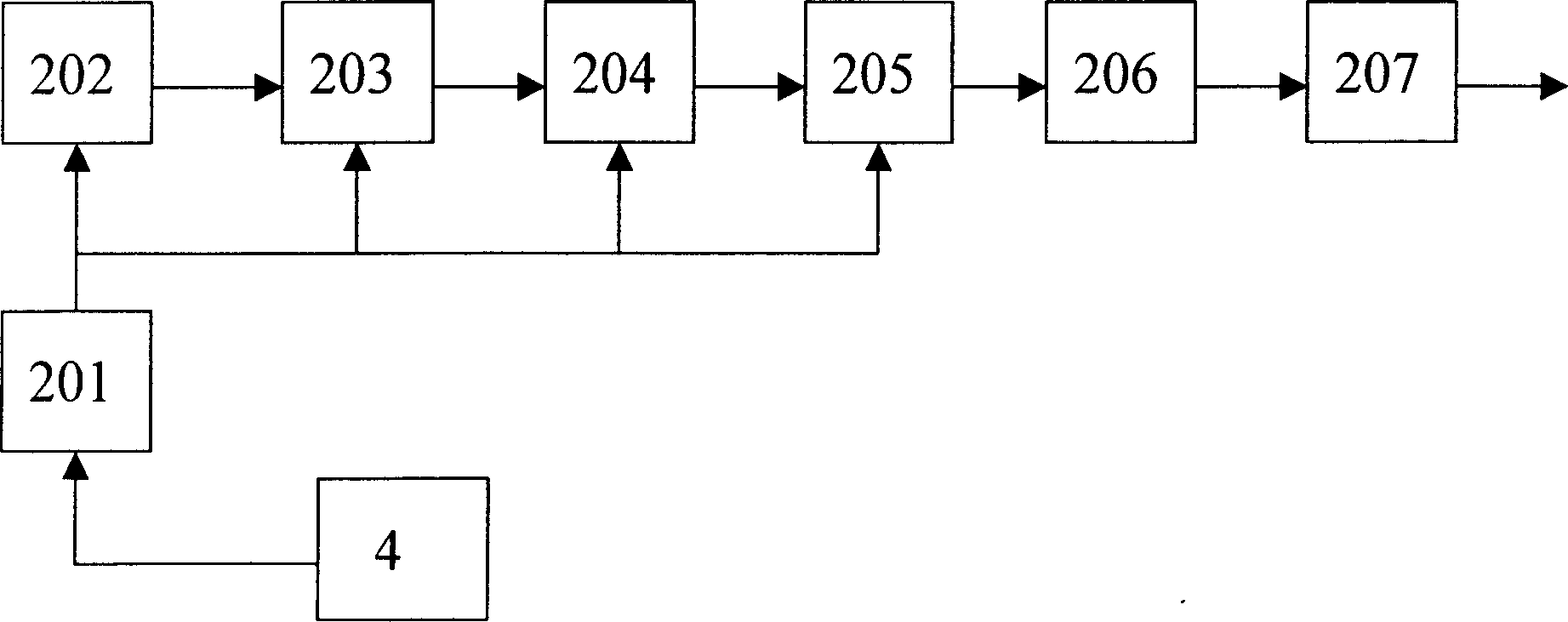

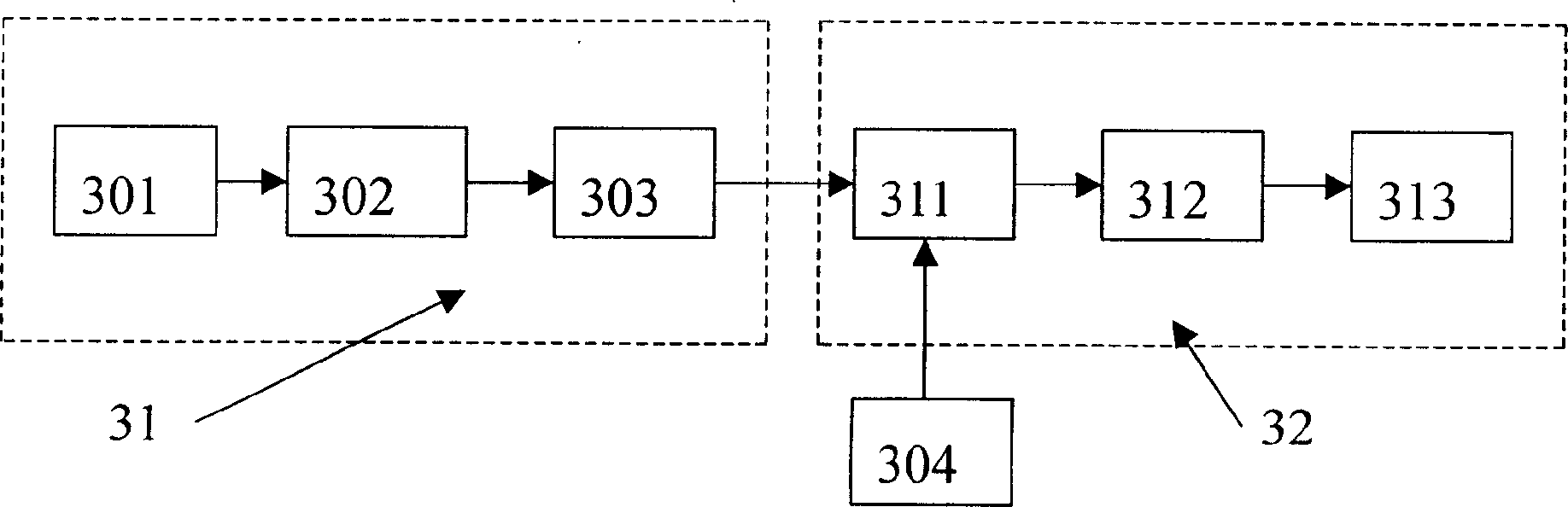

Vacuum assembly for decompression device

InactiveCN1621120AIncrease pumping rateReduce driving timeVacuum distillation separationVacuum distillationVacuum pumpingSeparation technology

The present invention belongs to the field of separation technology, and is especially vacuum pumping unit for decompression distilling apparatus. The vacuum pumping unit includes condenser with hot medium inlet connected to the outlet pipe of the decompression distilling tower and Roots-water ring vacuum set or Roots-reciprocating vacuum set in the outlet pipeline of hot medium outlet of the condenser. Adopting vacuum set to provide negative pressure source for the decompression apparatus makes the present invention has high pumping rate, fast starting, powerful adaptability, shortened operation time, stable operation state and other advantages. The present invention may be used widely in atmospherical and vacuum unit of petrochemical industry.

Owner:淄博华中真空设备有限公司

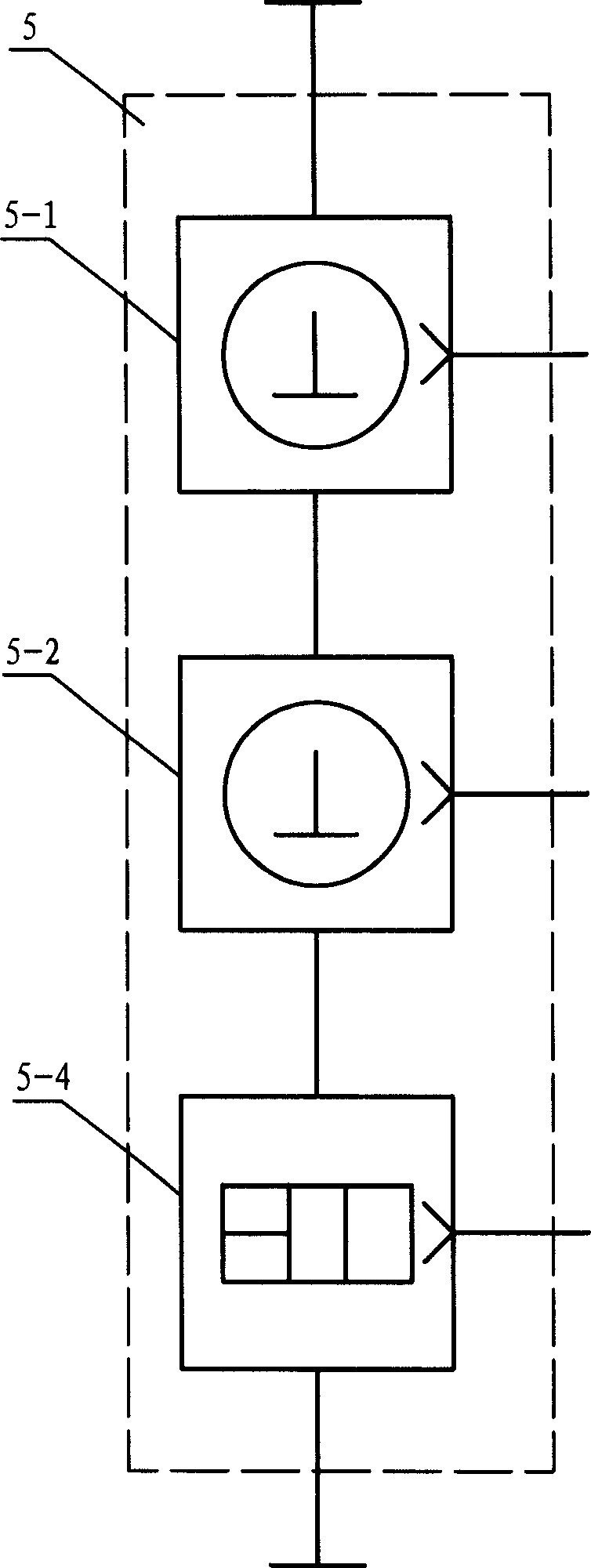

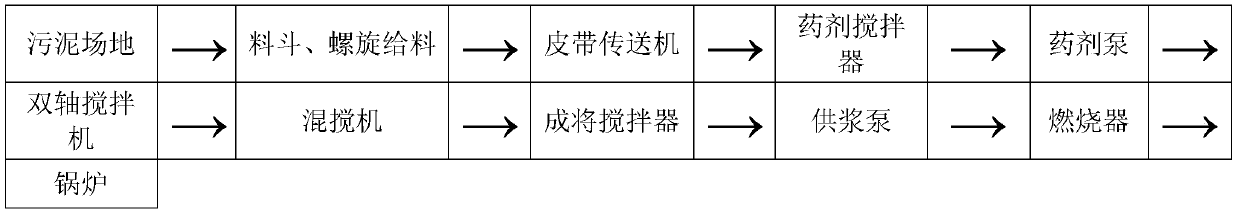

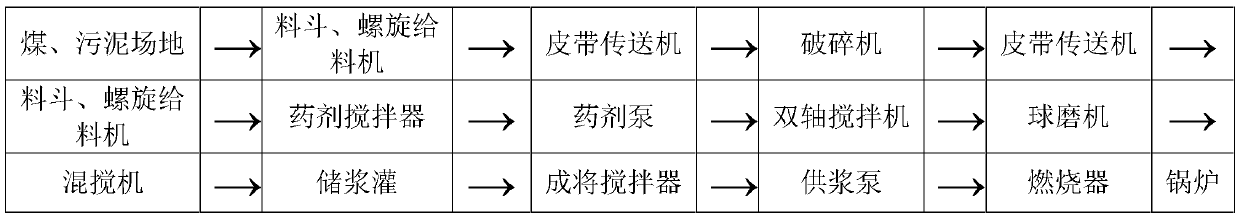

Sludge incineration treatment method

InactiveCN110030561ASolve efficiency problemsSolve the costIncinerator apparatusSocial benefitsCombustion

The embodiment of the invention provides a sludge incineration treatment method. The sludge incineration treatment method comprises a sewage slurry associated burning incineration method and a synthetic sewage slurry atomization combustion method. The beneficial technical effects of the sludge incineration treatment method are embodied in: superiority: (1). simple slurry preparation process; (2).less slurry preparation equipment; (3). small floor space; (4). simple and convenient operation of the equipment; (5). reduction of production and operation cost; and (6) low requirements of fluidizedcombustion on quality standard of sewage slurry; efficiency: reducing cost and improving efficiency by stokehold slurry preparation, off-site slurry preparation reduction, storage, transportation andother processes; effectiveness: environmental protection technological process, win-win economic benefits, environmental benefits and social benefits; environmental protection: no wastewater discharge, no odor emission, and zero emission in production process; and advantage: respond to national environmental protection policy.

Owner:青岛振华绿能能源科技有限公司

Non-halogen flame-resistant sandwich materials with polyethylene for fire-proof aluminium plastic plate and production thereof

ActiveCN100341813CImprove mechanical propertiesImprove toughnessFire proofingLow-density polyethyleneHalogen

A non-halogen and fire-retardant polythene sandwich layer material for fireproof aluminum plate and its production are disclosed. The sandwich layer consists of low-density polythene 15-30 proportion, linear low-density polythene 15-20 proportion, polythene and octylene multi-polymer 3-15 proportion, aluminum hydrate 30-45 proportion, magnesium hydrate 10-15 proportion, fire-retardant synergist 2-25 proportion and coupler 0.5-5 proportion. The process is carried out by mixing aluminum hydrate and magnesium hydrate with coupler separately, mixing at 80-120 DEG C for 15-25mins by high-speed kneader, extruding out into strips by double-screw extruder, granulating by thermal cutting at 100-179 degrees C or cooling and granulating by dicing cutter to obtain final product. It has better machining fluidity, fire-retardant effect and mechanical performance.

Owner:南通金威复合材料有限公司

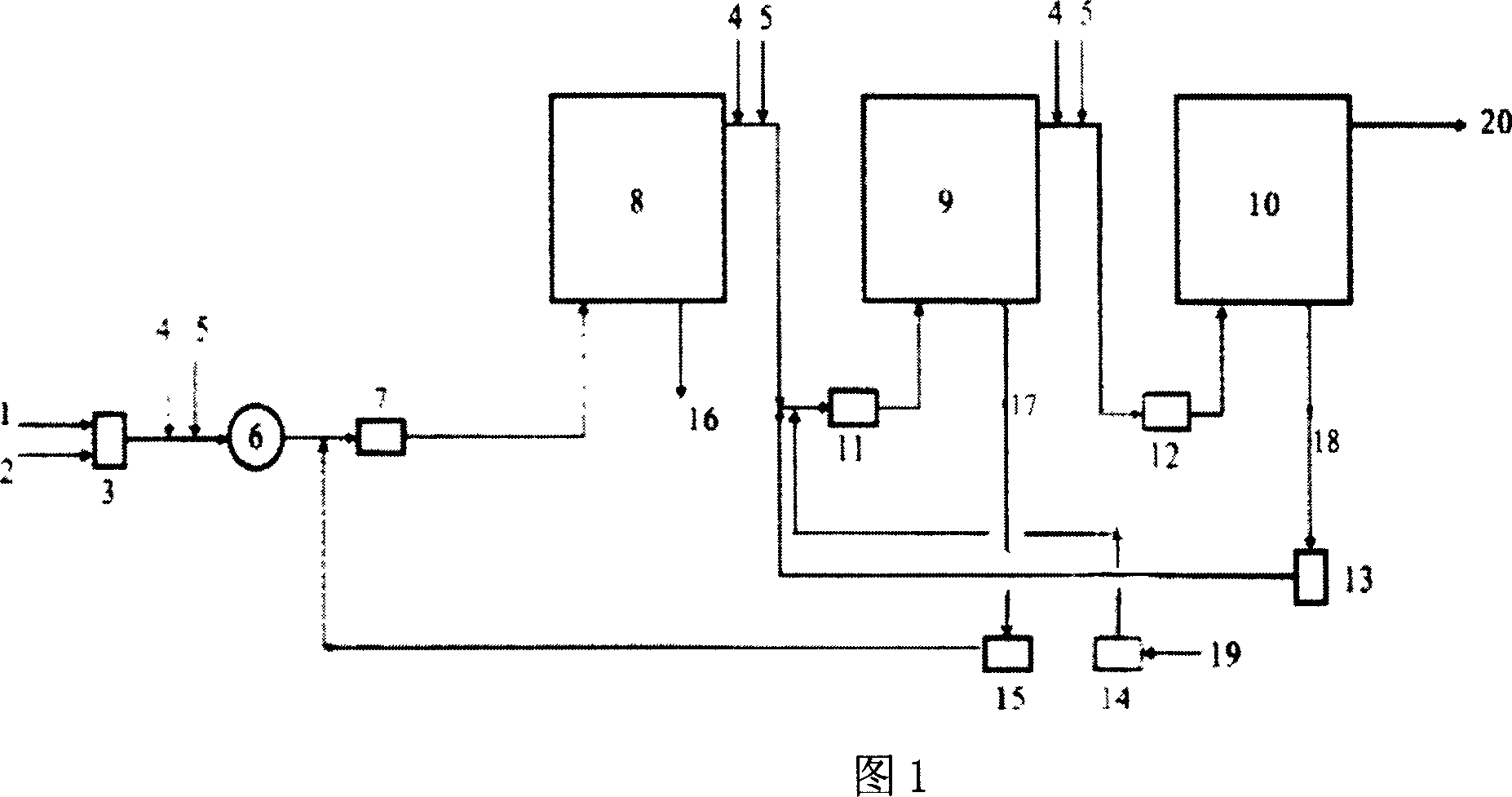

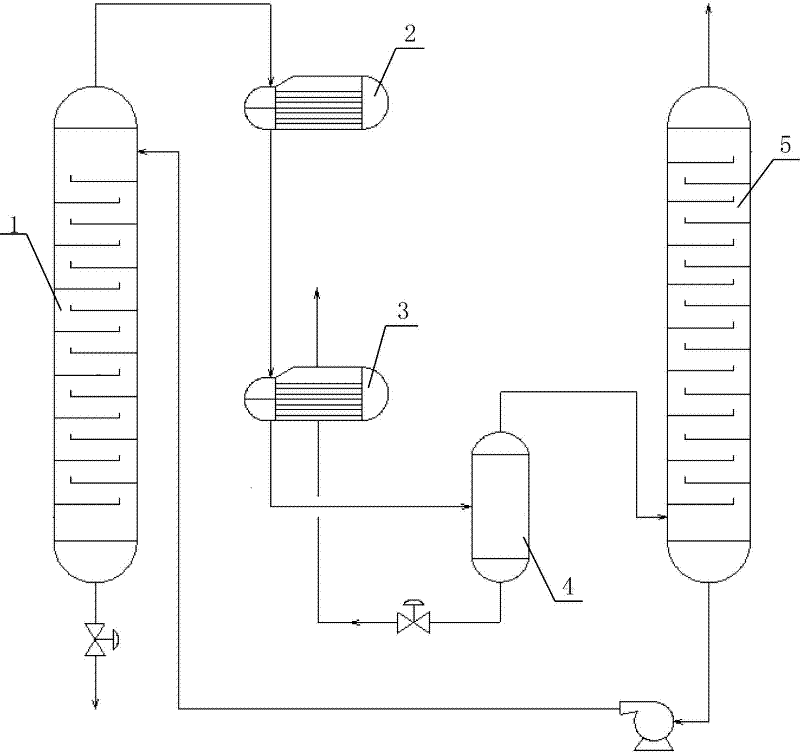

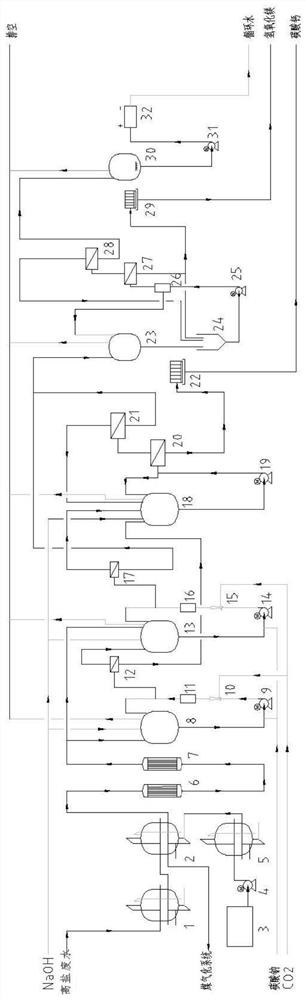

Improved low-temperature rectisol and improved low-temperature rectisol device

InactiveCN102517097ALower carbon dioxide levelsReduced Methanol RecycleCarbon compoundsGas purification by non-gaseous materials condensationCo2 absorptionNitrogen

Provided are an improved low-temperature rectisol method and an improved low-temperature rectisol device. Hydrogen sulfide and carbon dioxide in process gas are removed respectively in two absorbing towers, and the process gas is cooled between two towers so that part of carbon dioxide is liquefied and separated. The two towers absorb hydrogen sulfide and carbon dioxide respectively. Part of carbon dioxide is liquefied and separated by cooling the process gas after hydrogen sulfide is removed through the hydrogen sulfide absorbing tower so that content of carbon dioxide in the process gas is reduced, and content of carbon dioxide in the process gas entering the carbon dioxide absorbing tower is correspondingly reduced. The method can effectively reduce dimensions of a low-temperature rectisol pipeline and equipment, reduces methanol circulating quantity, equipment investment and production running costs are reduced, air-lift nitrogen dosage is reduced, and more pure-state carbon dioxide facilitating application and treatment is obtained.

Owner:李德全 +1

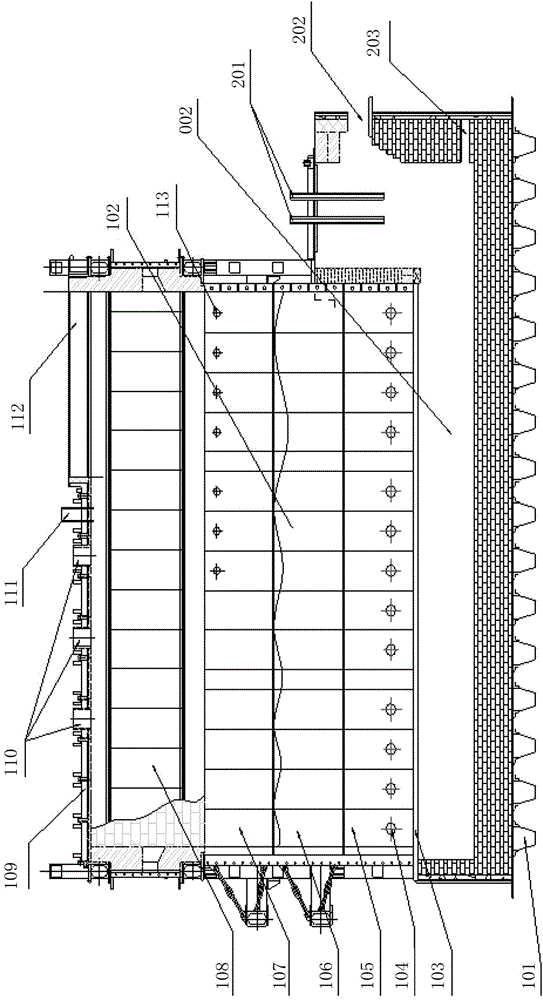

Quick cleaning pulping production equipment

InactiveCN1796653AReasonable structureLess investmentPulp liquor regenerationFibrous raw materialsPulp and paper industryWater treatment

A device of preparing pulp quickly and cleanly is prepared as connecting raw material unit to catalytic copolymerization unit, connecting catalytic copolymerization unit separately to separation unit of pulp washing and pulp bleaching as well as online recovery unit of catalyst, connecting separation unit of pulp washing and pulp bleaching to waste water recovering unit.

Owner:程相武

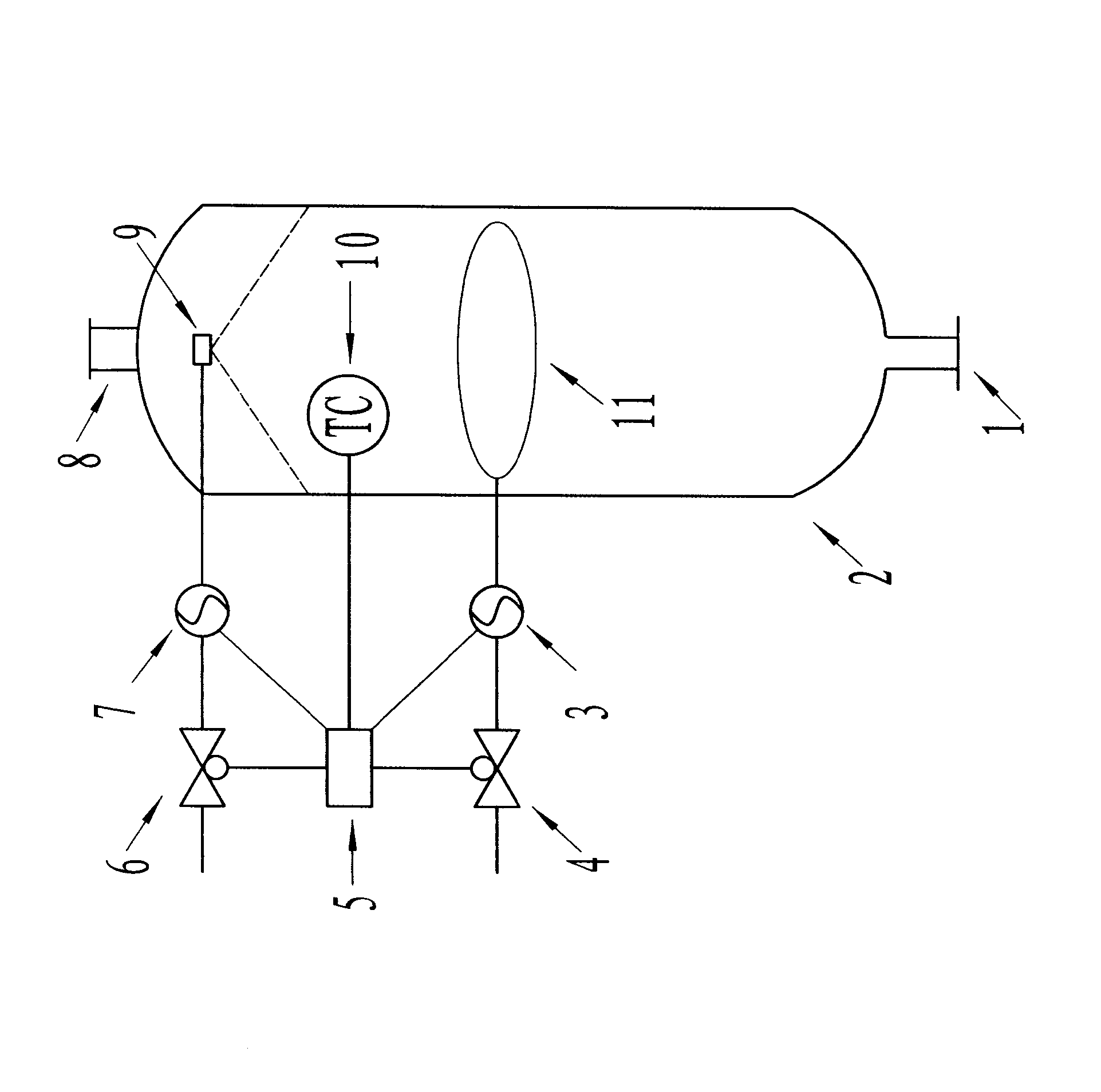

Method for producing ammonium nitrate solid

InactiveCN102583441BShort stayReduce investmentAmmonium nitratesReaction temperatureAmmonium nitrate

The invention relates to a method for producing ammonium nitrate solid. Concentrated nitric acid and ammonia gas are introduced into a reaction tower of a tower reactor, with the weight flow ratio being 3.7-5.3:1, specifically, concentrated nitric acid is introduced into a spraying device arranged at the top of the reaction tower, ammonia gas is introduced to the reaction tower through an annulardistributor in the middle of the reaction tower, the spraying device is adjusted to enable concentrated nitric acid to be sprayed into fine concentrated nitric acid drops at the top of the reaction tower through the spraying device, the concentrated nitric acid drops contact the ascending normal-pressure ammonia gas in the reaction tower during the falling process to react and generate ammonium nitrate solution fine droplets, the reaction temperature is controlled between 150 to 190 DEG C, moisture in the ammonium nitrate solution is vaporized through heat generated by reaction, vapor-solid separation can be achieved in the reaction tower, and the ammonium nitrate particles, namely the ammonium nitrate solid can be directly prepared. According to the method, reaction flow and reaction time can be reduced, the time of materials retaining in a system can be reduced, the energy is saved and the operating steps are simple and safe.

Owner:杨勇 +2

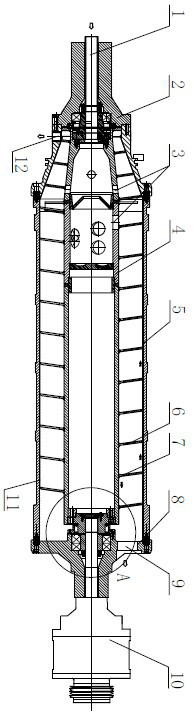

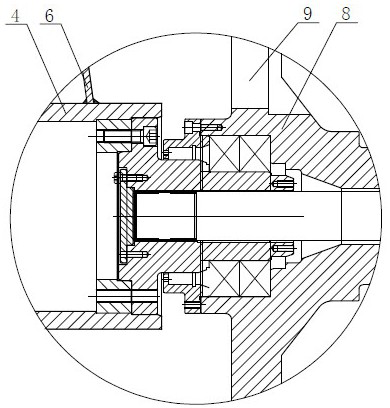

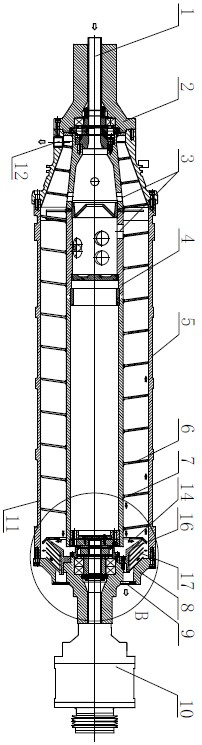

A High Current Density Circulating Flow Anode Diaphragm Electrolyzer

ActiveCN102851709BIncrease circulation flowImprove migration speedElectrolysis componentsHigh current densityElectrolysis

The invention relates to a high current density circulating flow anode diaphragm electrolyzer. Anode frames are fixed on an upper fastening pull rod; cathode frames are fixed on a lower fastening pull rod; diaphragm bags are sleeved outside the anode frames; anode plates are fixed on the anode frames; anode plate regions are formed in the anode frames; cathode plates are fixed on the cathode frames; cathode plate regions are formed outside the anode frames; electrolytic tank walls at one sides of the cathode regions are provided with catholyte circulating spraying devices; and the other sides of the cathode regions are provided with catholyte circulating return devices. The high current density circulating flow anode diaphragm electrolyzer has the beneficial effect that the anode frames are sleeved in the diaphragm bags and a circulating flow device is arranged, so that the catholyte circulating flow is improved, the migration rate of metal cations is improved, the high cathode current efficiency and a high-quality cathode product under the condition of the cathode high current density are implemented, the aims of greatly improving the current density and obviously improving the unit production capacity of the electrolyzer are fulfilled and the production operation cost is effectively reduced.

Owner:杭州贝德环保工程有限公司

Screening pavement method of multi-layer structure wood-based panels

InactiveCN101628442BSimplify paving equipmentSmall footprintWood working apparatusFlat articlesProduction lineAdhesive

The invention belongs to the manufacture of wood-based panels. A sieving-type paving method for multi-layered wood-based panels, characterized in that the raw materials mixed with sieveable adhesive are divided into two by a splitter to form a two-layer structure with one at the front and one at the back according to the direction of the production line. The two descending material streams respectively fall on the multi-layer vibrating screen inclined from the front and back to the middle opening, and the materials are layered through sieves with different apertures during the process of moving down the middle opening along the screen surface under high-frequency vibration. After screening, it converges and descends toward the middle opening, and the width of the middle opening of each layer of sieve increases gradually from top to bottom. Finally, the material forms a vertically falling material flow at the opening according to fine-coarse-fine layer arrangement. After being in contact with the forward moving slab, turn to 90° and lay flat on the slab to form a layered slab. The invention solves the technical problem of forming a material flow of fine-coarse-fine layers after sieving the raw materials mixed with glue during the conveying process.

Owner:黑龙江省双领秸秆板业有限公司

Multi-layered structural artificial board screening paving method

InactiveCN101628442ASimplify paving equipmentSmall footprintWood working apparatusFlat articlesAdhesiveMixed materials

The invention belongs to the manufacture of artificial boards, in particular to a multi-layered structural artificial board screening paving method; the invention is characterized in that a depiler is used for dividing raw materials mixed with screenable adhesive into two parts, to form two descending material streams with one in front and one at rear according to production assembly direction, the two descending material streams respectively fall on a multi-layered vibrating screen with the front and rear parts inclined to a middle opening, the material converges to the middle opening and fall after passing through layered screening of screens with different apertures in the process of descending along the screen surface towards the middle opening under high frequency vibration, the middle openings of the layers are gradually wider from up to down, and finally the material forms a material stream falling vertically in the arrangement of narrow-wide-narrow, the material contacts with a blank plate moving forwards and turns 90 degrees to lay horizontally on the blank plate to form a layered paving board blank. The invention can solve the technical problem that the glue-mixed material forms a narrow-wide-narrow layered material stream after screening in the process of conveying.

Owner:黑龙江省双领秸秆板业有限公司

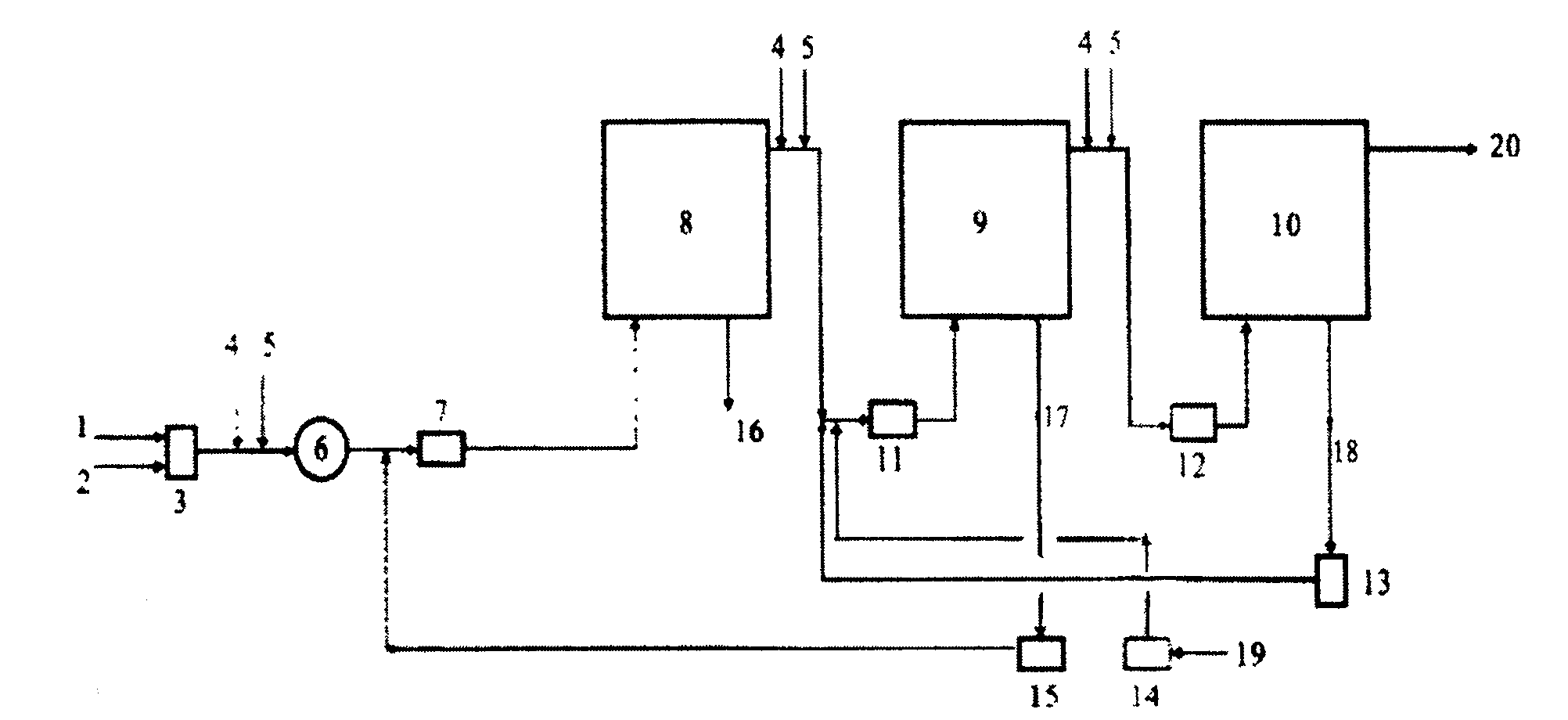

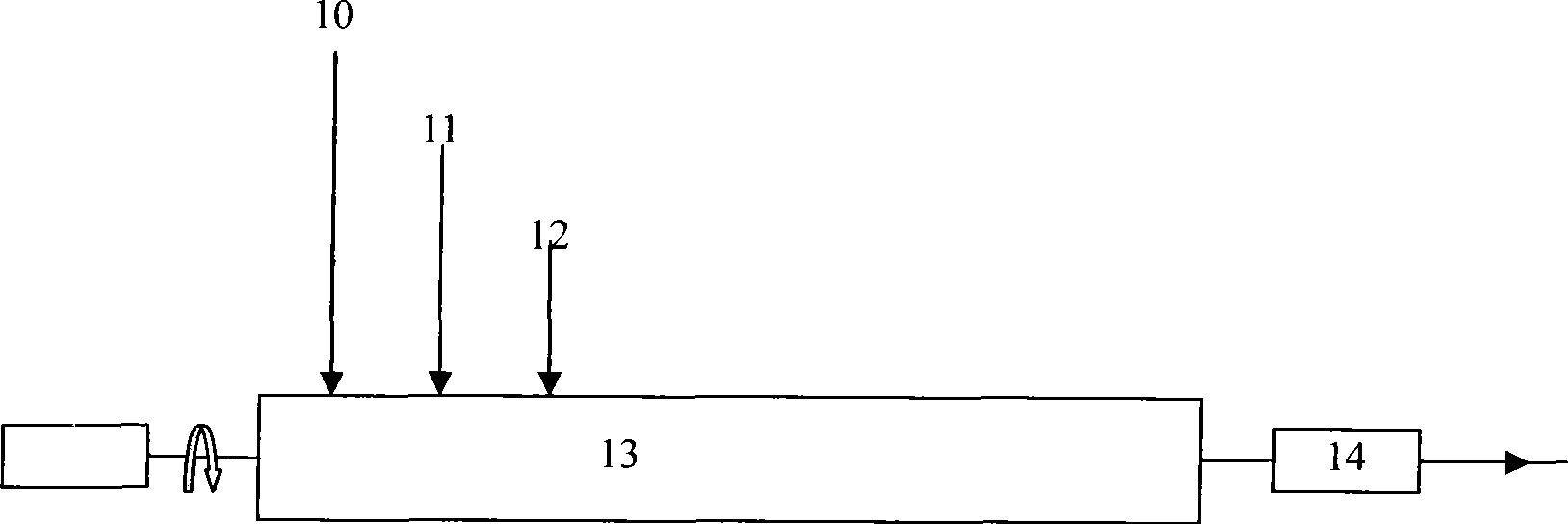

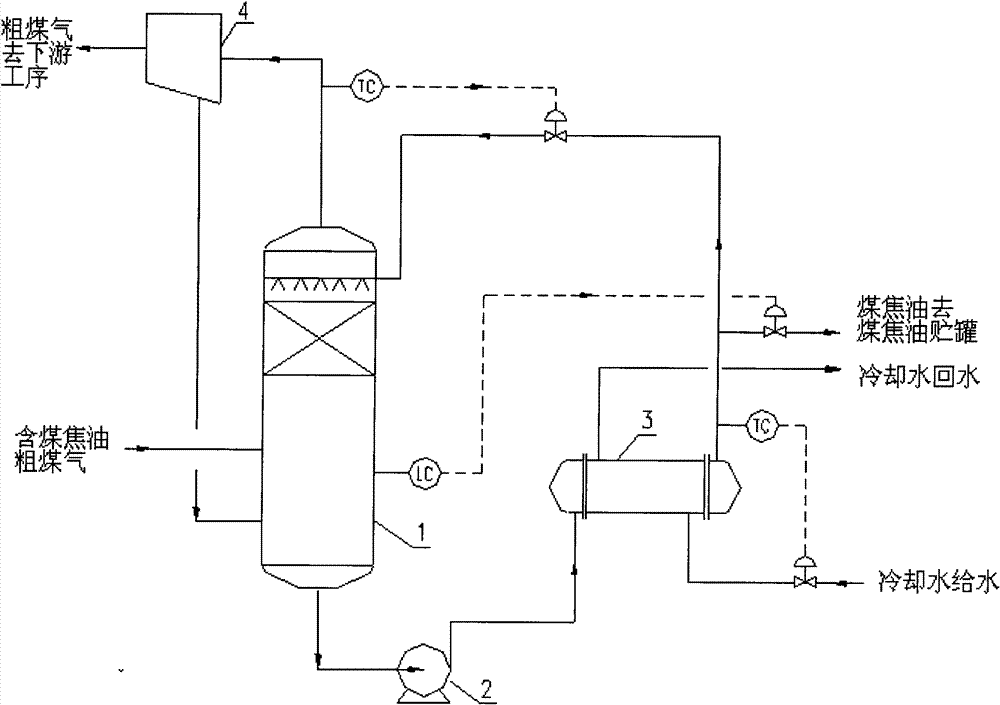

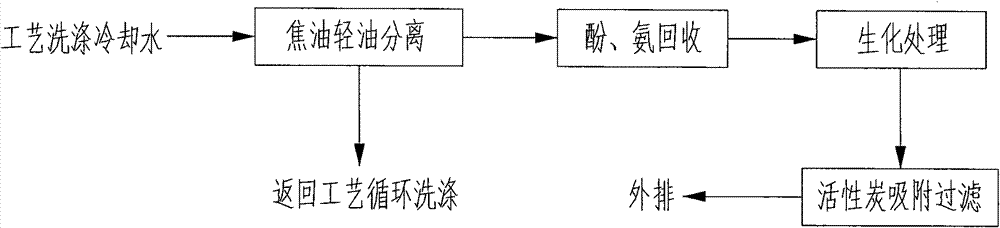

Technology for removing tar from raw gas containing coal tar

ActiveCN101724472BEfficient removalCoal tar content is smallDispersed particle separationCombustible gas purificationEngineeringCurrent technology

Owner:WUHUAN ENG

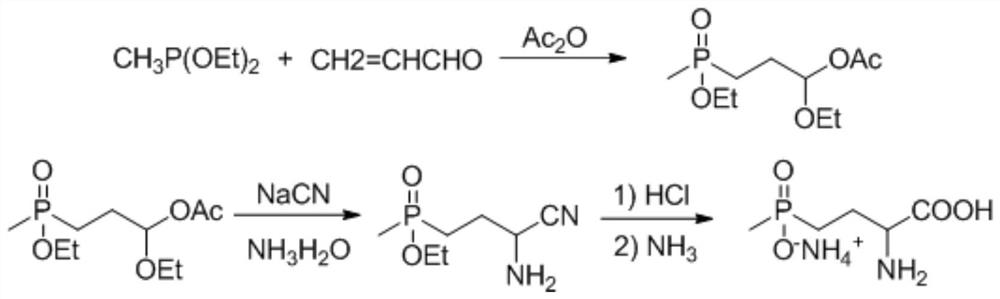

Method for producing glufosinate-ammonium with low energy consumption

ActiveCN110003269BLower gas phase vapor pressureChanging the relative volatilityGroup 5/15 element organic compoundsTriethylphosphitePhosphorous chloride

A method for producing glufosinate-ammonium with low energy consumption. A trapping agent is used to trap methane and phosphorus trichloride high-temperature cracking materials, and the obtained trapping liquid is rectified to separate most of the phosphorous trichloride, and then React with ethanol to obtain a diethyl methylphosphonite collector solution containing a small amount of triethyl phosphite, rectify and separate the heavy component triethyl phosphite, then react with acrolein to prepare acetal, and finally pass through cyanamide glufosinate-ammonium through chemical reaction and hydrolysis.

Owner:LIER CHEM CO LTD +1

Layout method of decomposing and grading system and corresponding water circulating system in aluminium plant

InactiveCN1974393BReduce transportation energy consumptionReduce distanceAluminium compoundsEngineeringGrade system

The layout method of decomposing and grading systems and corresponding water circulating systems in aluminum plant includes setting two corresponding water circulating systems in every two decomposing and grading systems within the same production area. The present invention has shortened water circulating pipeline, reduced underwater pipeline, simplified construction, lowered power consumption and production cost and other advantages.

Owner:GUIYANG AL-MG DESIGN & RES INST

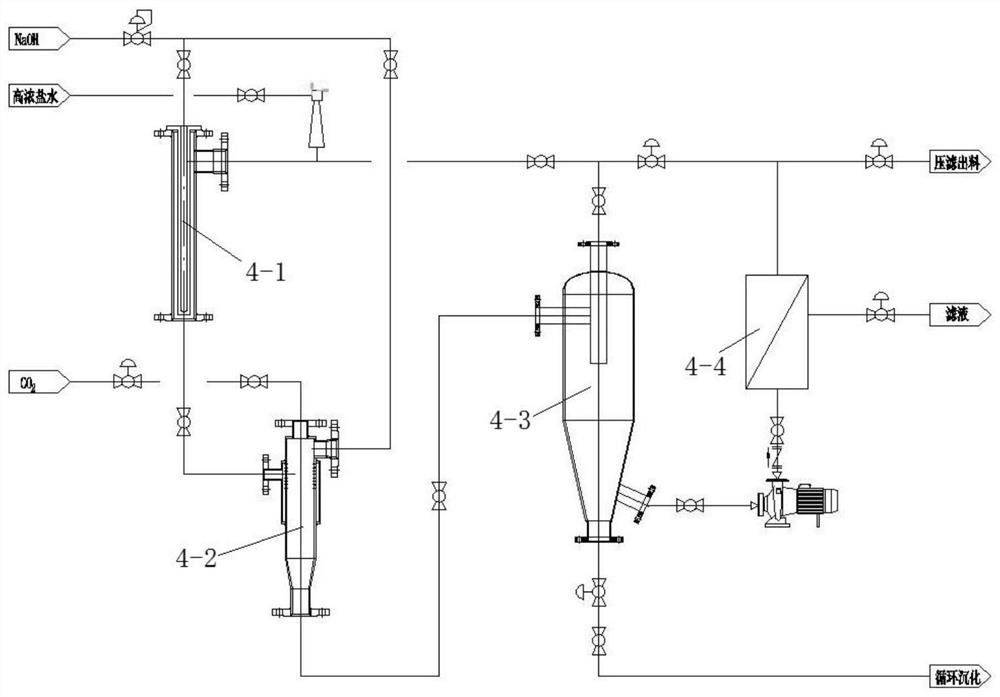

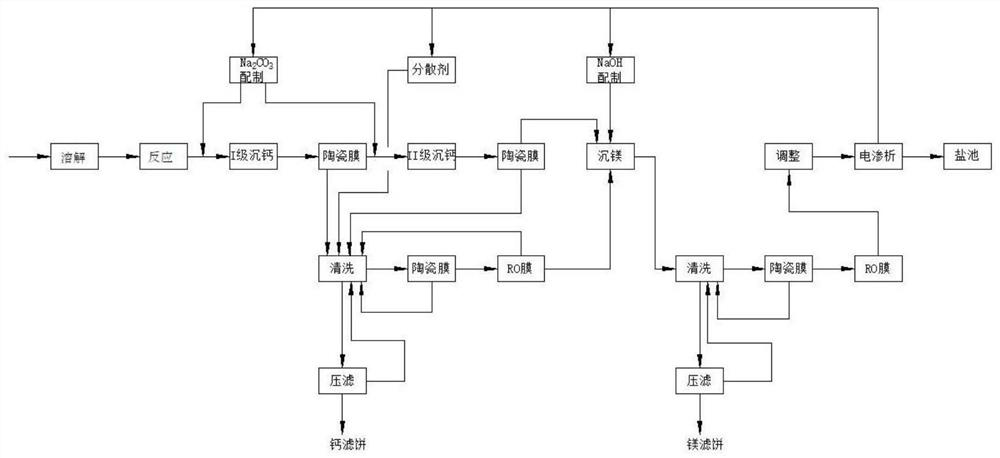

A zero-discharge process for coal chemical high-salt wastewater

ActiveCN112694201BAchieve recyclingAvoid badCalcium/strontium/barium carbonatesSpecific water treatment objectivesProcess engineeringPre treatment

The invention discloses a coal chemical industry high-salt wastewater zero-discharge process, comprising: the wastewater in the coal chemical industry wastewater settling tank is pumped into a pretreatment tank by a raw water pump, and after pretreatment, its produced water enters an adsorption tank; After the adsorber is saturated with adsorption, the system is automatically cut off, and the analysis tank is used for analysis; the analysis waste liquid generated after the analysis of the adsorber by the analysis tank is sent to the calcium recovery device through the first-stage heat exchanger and the second-stage heat exchanger. Processing, using a dispersant to produce nano-scale calcium carbonate, which is separated and solidified in a calcium-precipitated ceramic membrane and a calcium filter press to produce a nano-calcium carbonate product; after being separated by a class II ceramic membrane, the clear liquid enters the magnesium recovery device and passes through the magnesium-precipitated ceramic membrane. Magnesium products are produced after separation from magnesium and magnesium filter presses, and the clear liquid is recovered and reused as analytical liquid to achieve zero discharge and resource utilization of waste liquid. According to the characteristics of water quality, this application designs a process plan to realize standardization and resource utilization, to make waste from waste, to realize waste water recycling and zero discharge of waste water.

Owner:大连东道尔膜技术有限公司

Method for preparing colored cementitious material

The invention discloses a method for preparing a colored cementitious material, which is needed by the paving construction of a colored concrete road surface. A double-screw extruder or a single screw extruder is utilized, various raw materials of the colored cementitious material are added to the feed inlet of the extruder, sheared and mixed through the screw in the extruder and extruded to finally obtain a colored cementitious material product. The invention has the advantages of continuous production, short making cycle, high production efficiency, few needed production facility, less occupying area, less equipment investment and low production and operation cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

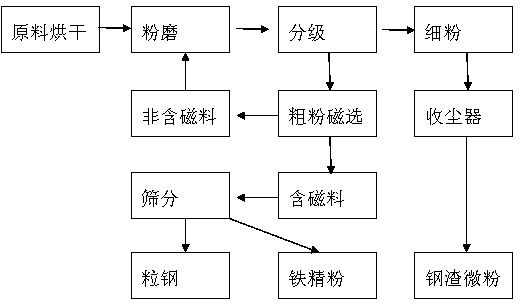

Dry processing technique for iron-containing steel slag

InactiveCN103045777BImprove the useful work of grindingImprove grinding efficiencyRecycling and recovery technologiesLand resourcesSlag

Owner:王新军

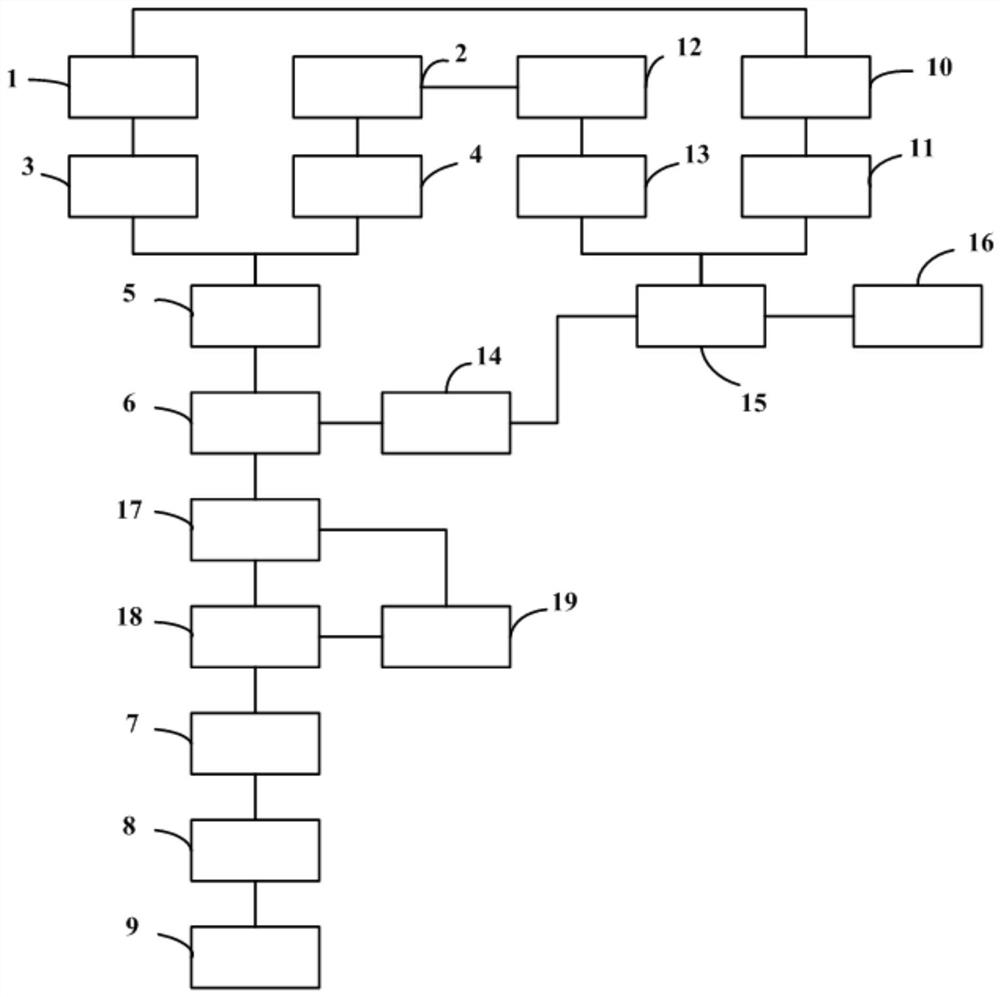

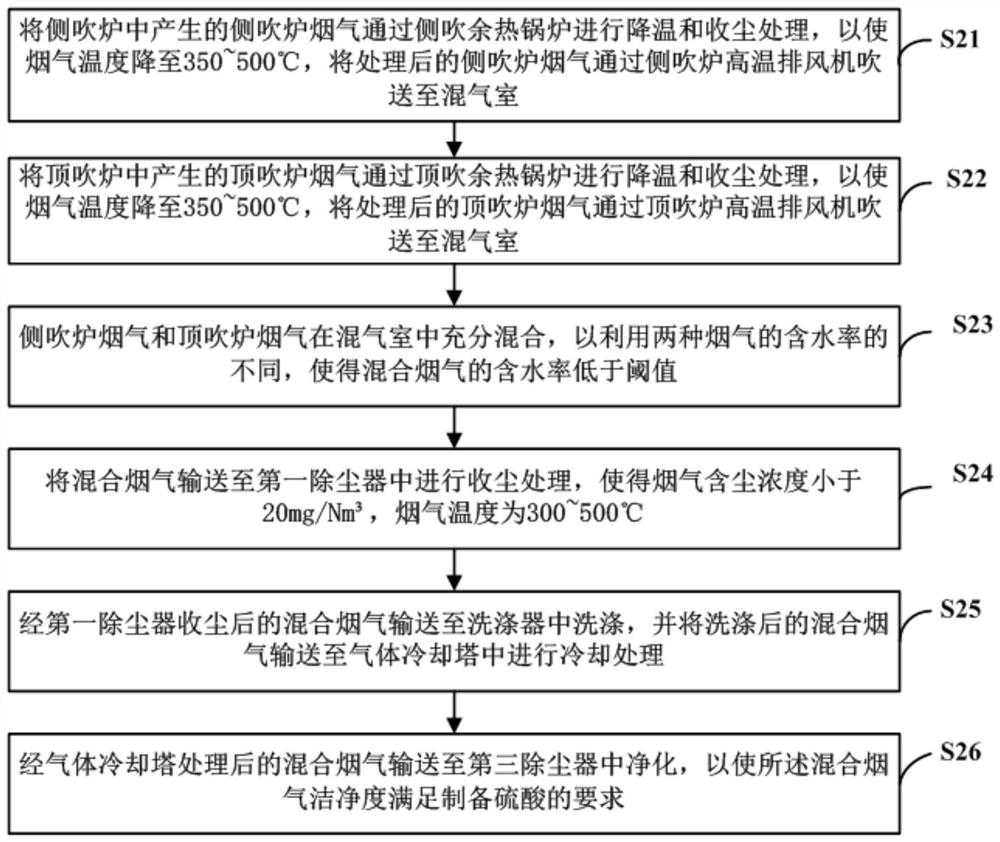

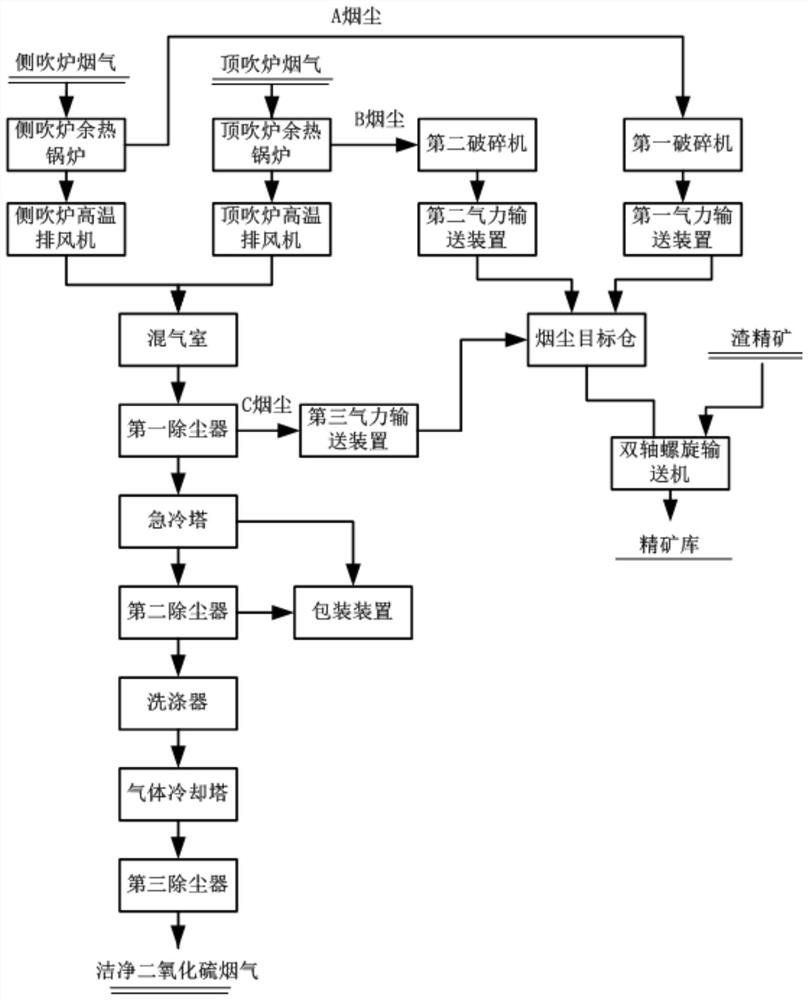

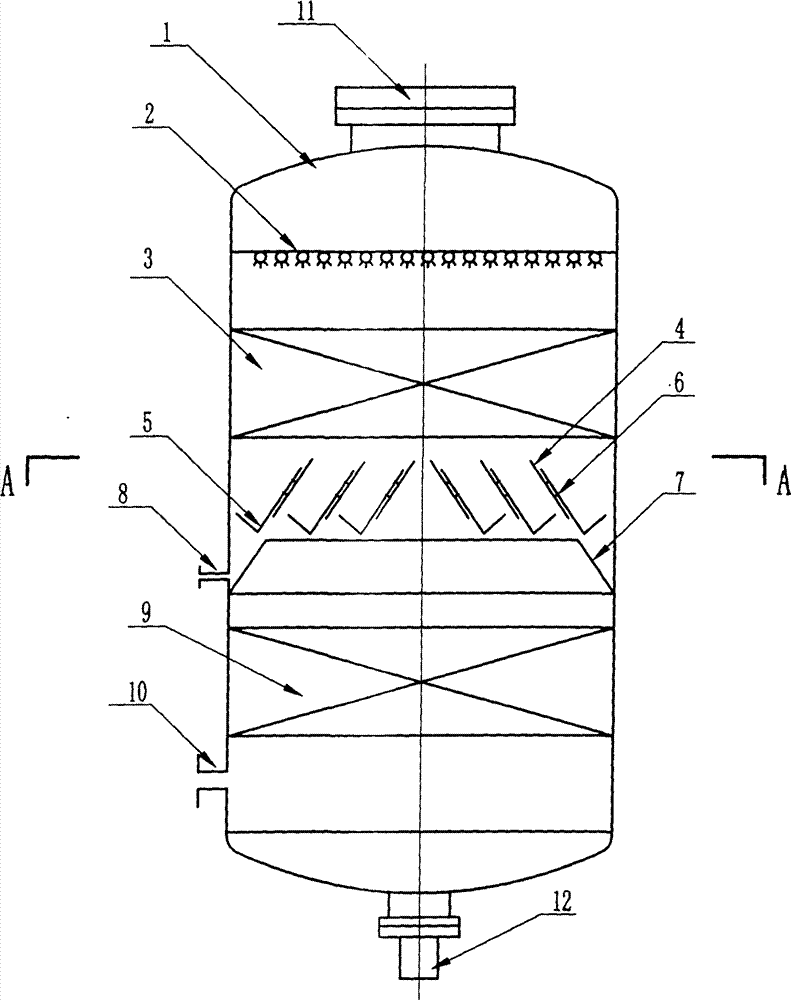

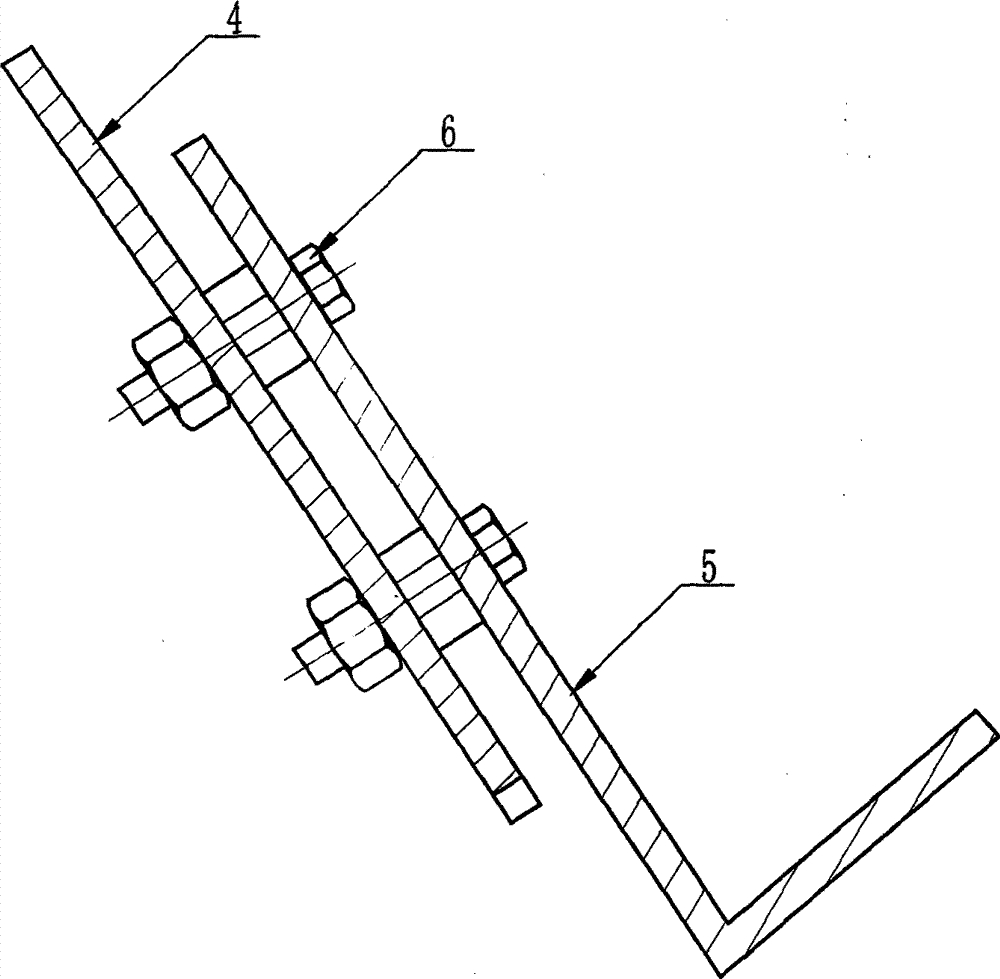

Flue gas treatment system and method

PendingCN112755774AEasy to handleEfficient removalCombination devicesGas treatmentCooling towerGas cooling

The invention discloses a flue gas treatment system and method, and the system comprises: a side-blown furnace waste heat boiler, wherein a feed port of the side-blown furnace waste heat boiler is connected with a side-blown furnace; a top-blown furnace waste heat boiler, wherein a feed port of the top-blown furnace waste heat boiler is connected with the top-blown furnace; a gas mixing chamber; a side-blown furnace high-temperature exhaust fan which is connected between the gas mixing chamber and the side-blown furnace waste heat boiler; a top-blown furnace high-temperature exhaust fan which is connected between the gas mixing chamber and the top-blown furnace waste heat boiler; a first dust remover which is connected with the discharge hole of the gas mixing chamber; a washer which is connected with the first dust remover; a gas cooling tower which is connected with the washer; and a third dust remover which is connected with the gas cooling tower. By utilizing the system, the sulfur dioxide-containing flue gas can be efficiently treated, valuable metals in the flue gas can be recovered, harmful elements can be effectively removed, the process flow is simplified, the stability of the production system is improved, and the production operation cost is reduced.

Owner:CHINA NERIN ENG

A Simplified Separation Process for Full-grade Anthracite Selection

A whole-level simplified separation process for anthracite, which adopts dry screening with large sieve holes, pre-discharging gangue by non-dense medium separation process for lump coal, and a set of low-density control system for dense medium process. The specific operation steps are: The raw coal is pre-screened with a grading sieve, and the gangue discharge and separation process system is used to discharge the lump coal, and the three-product dense medium cyclone is used for separation: the clean coal and medium coal are used as a product alone or mixed as a clean coal product, and enter the degassing process. Qualified products are obtained after mediation and dehydration equipment; media circulation, recycling, and additional media are carried out after the product is removed from media and dehydrated. Then the coal slime is concentrated and classified, and the fine coal slime is recovered. This sorting process system is simple, high sorting efficiency, flexible product structure, low production and operation costs, easy to maximize the yield of clean coal, and reduce infrastructure investment. A highly efficient anthracite full-grade selection simplified sorting process to adapt to construction Efficient and integrated to meet the needs of coal preparation plants for anthracite separation.

Owner:TANGSHAN BRANCH COAL SCI ACAD

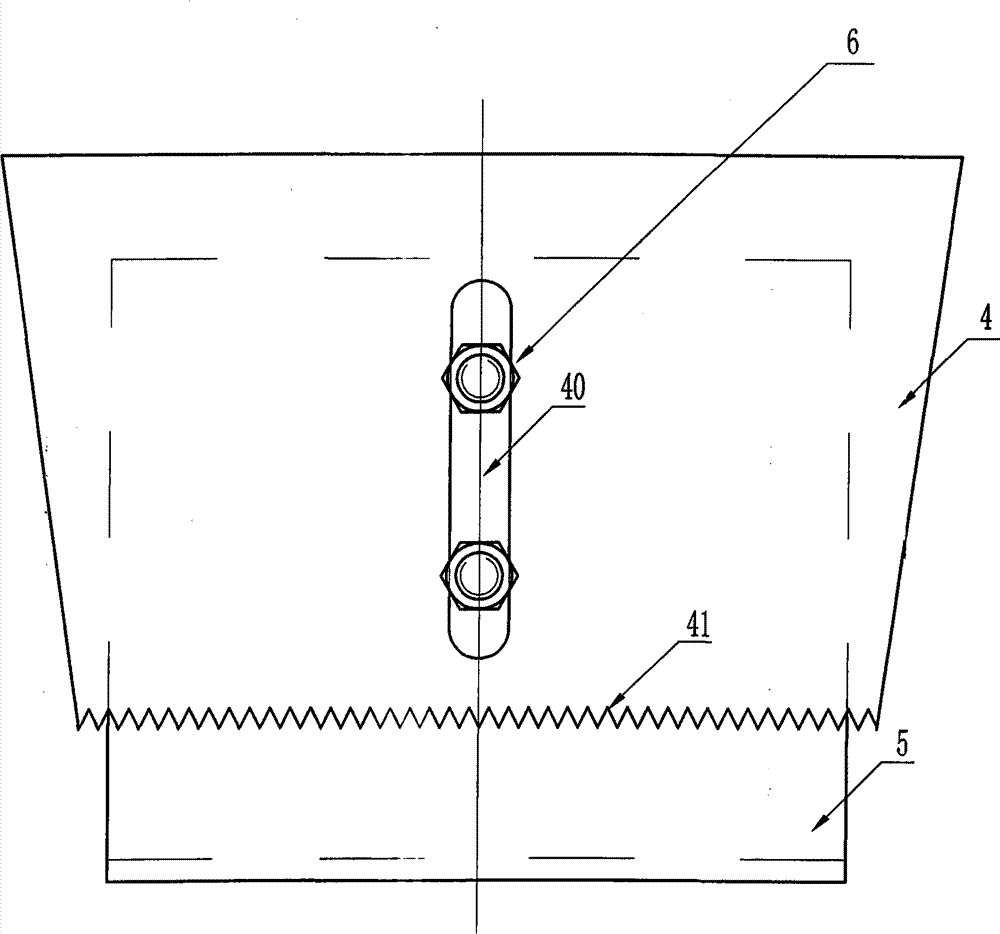

Reflux oil distribution device in washing section of distillation tower

ActiveCN104096373BSelf-supplyLess investmentVacuum distillation separationOn boardFractionating column

The invention discloses a distillating tower washing section return oil distributor, which comprises a return oil distributor, a filler condensation section, a distribution board, an L-shaped long board, a ring-shaped collection tank, an oil outlet and a filler washing section, wherein the filler condensation section is arranged below the return oil distributor; a distribution board is arranged under the filler condensation section; the L-shaped long board is fixed on the distribution board via bolts, and the ring-shaped liquid collection tank is arranged under the L-shaped long board; the oil outlet is formed in the ring-shaped liquid collection tank; the filler washing section is arranged under the ring-shaped liquid collection tank. According to the invention, the filler washing section return oil can be supplied in the tower, and a set of return oil feeding system is not needed to be additionally arranged, so that the equipment investment is lowered; the height difference between the distribution board and the L-shaped long board can be regulated, and the flux of the return oil can be regulated; a sawtooth shaped lower end surface is arranged on the distribution board, as a result, the filler washing section return oil is uniformly distrusted, and the washing effect is improved; the filler washing section has the effects of washing and rectifying, and improves the rectifying efficiency.

Owner:安徽国孚环境科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com