Treatment method for inferior heavy oil and residual oil

A treatment method and technology for residual oil, which are applied in the treatment of hydrocarbon oil, hydrotreating process, petroleum industry, etc., can solve the problems of difficulty in becoming asphalt products, increased pressure drop in the bed, and can only be used as a product, so as to reduce production operations. The effect of cost, coke suppression, and extension of the start-up period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

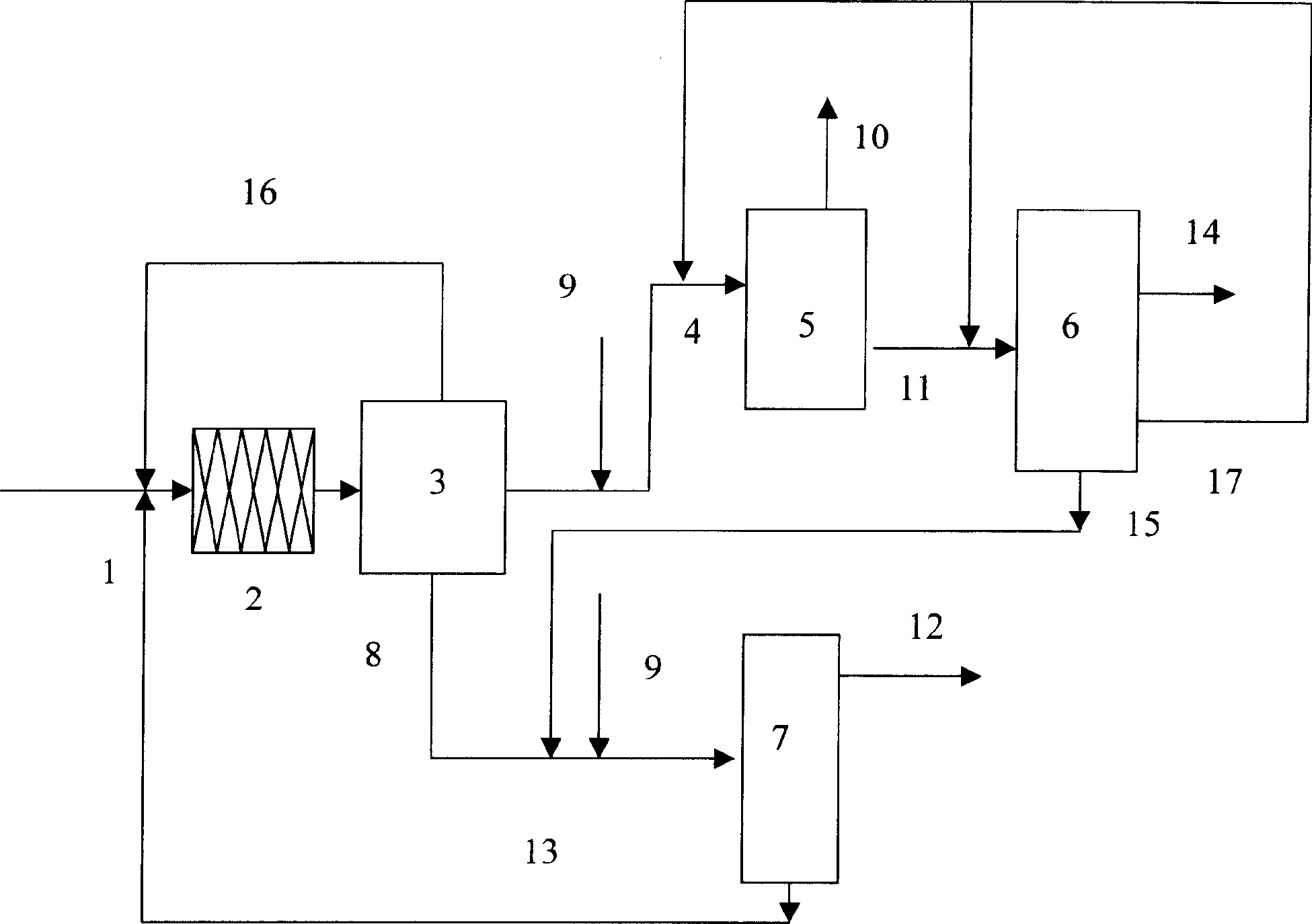

Image

Examples

Embodiment 1 and comparative example 1

[0041] This experiment investigates the property change of deasphalted oil after solvent extraction when adding or not adding suspended bed hydrogenation tail oil to residual oil raw material.

[0042] project

Embodiment 2 and comparative example 2

[0044] This experiment illustrates the situation that the DAO obtained in Example 1 and Comparative Example 1 is subjected to fixed-bed hydroprocessing.

[0045] The fixed-bed hydrogenation catalysts used in the test are CEN, FZC series hydrodemetallization catalysts produced by the pilot base of Fushun Petrochemical Research Institute, ZTN, ZTS series hydrodenitrogenation, ZTS series produced by Qilu Petrochemical Company No. Hydrodesulfurization catalyst. The sequence of catalyst loading is hydrodemetallization, hydrodesulfurization and hydrodenitrogenation catalysts. The hydrodemetallization catalysts used in this test are CEN-5, CEN-6; the protective agents are CEN-2, CEN-4, FZC-16 (transitional protective agent); the hydrodesulfurization catalysts ZTS-01, ZTS-02 , ZTS-03; Hydrodenitrogenation catalyst ZTN-01. The packing volume ratio between each catalyst is:

[0046] CEN-2: FZC-16: CEN-4: CEN-5: CEN-6: ZTS-01: ZTS-02: ZTS-03: ZTN-01 = 1: 1.25: 1.5: 2.62: 7.8: 6.63: 0....

Embodiment 3 and comparative example 3

[0051] This test illustrates the situation that the hydrogenated tail oil of embodiment 2 and comparative example 2 carries out the FCC test on the small-scale riser catalytic cracking unit, because the hydrogenated tail oil properties of embodiment 2 and comparative example 2 are not much different, so only use The hydrogenated tail oil in Example 2 was taken as an example for FCC treatment. The FCC test device has a processing capacity of 1kg / h and adopts a cycle reaction-regeneration working mode. The catalytic cracking catalyst is CHV-1 catalyst produced by Changling Refinery and Chemical Zongshi Catalyst Factory.

[0052] Numbering

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com