Method for preparing metal or metallic oxide/carbon composite material

A technology of carbon composite materials and oxides, applied in metal/metal oxide/metal hydroxide catalysts, catalyst activation/preparation, chemical instruments and methods, etc. diameter, harsh reaction conditions, complex process, etc., to achieve the effect of simple and easy operation, controllable output, and simple preparation process route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

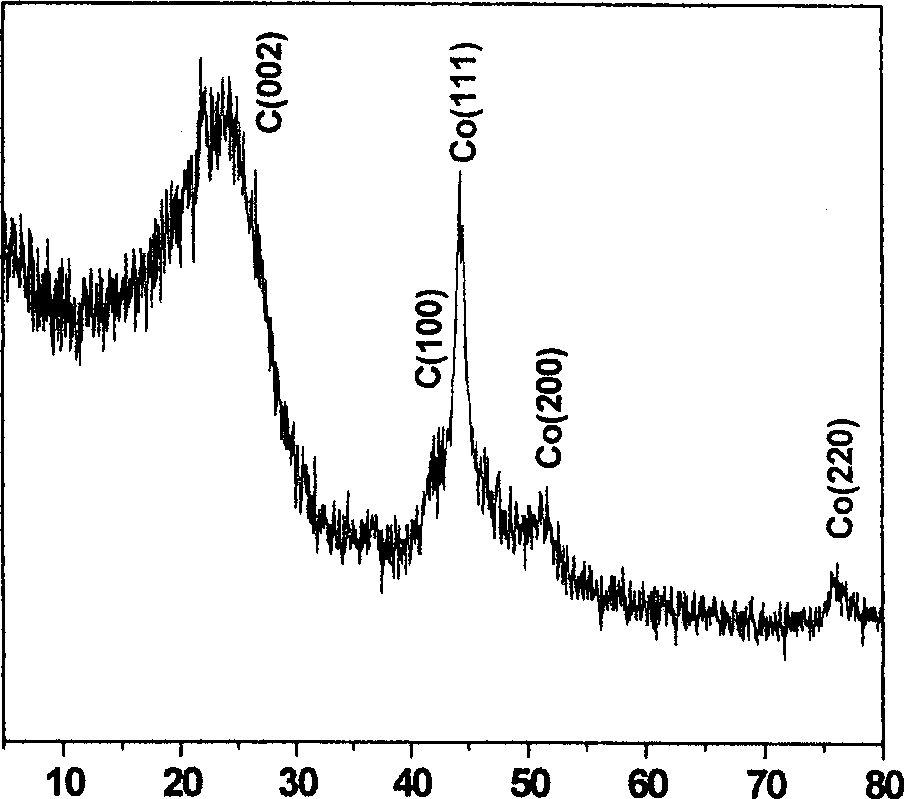

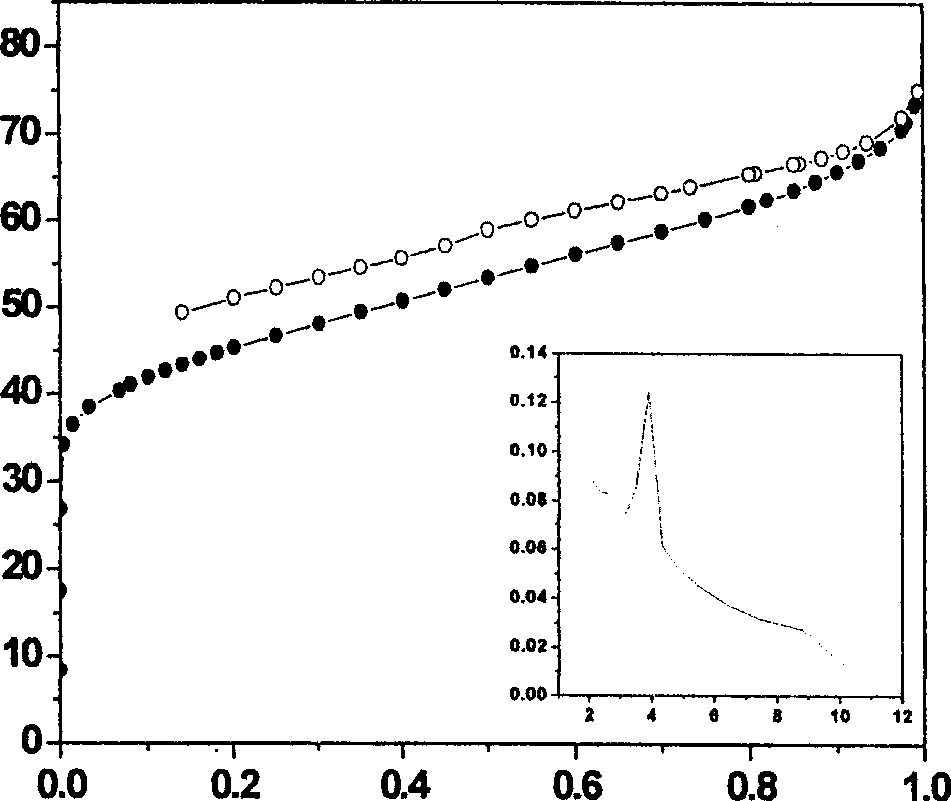

Embodiment 1

[0033] Cobalt / carbon composites were prepared using asphaltenes in coal direct liquefaction residue as carbon source, polyethylene glycol as porogen, and cobalt nitrate as metal precursor. The specific steps are as follows: 1. Weigh 50g of coal direct liquefaction residue without any treatment, crush it and pass through an 80-mesh sieve. The residue powder is Soxhlet extracted with n-hexane at 92°C for 50 hours, and the obtained insoluble matter is dried and ground through 80 mesh. Mesh sieve, extracted with toluene at 140°C for 50h, the toluene soluble matter was evaporated under reduced pressure at 80°C by a rotary evaporator to remove the toluene solvent, and the obtained solid was asphaltene. 2. Raise the asphaltene from room temperature to 300°C at a rate of 1°C / min in the air, and keep it at this temperature for 4 hours for pre-oxidation treatment. 3. Mix and grind the pre-oxidized asphaltenes, polyethylene glycol (molecular weight 6000) and cobalt nitrate ground through...

Embodiment 2

[0035] Cobalt / carbon composites were prepared using pre-asphaltenes in coal direct liquefaction residue as carbon source, polyethylene glycol as porogen, and cobalt nitrate as metal precursor. The specific steps are as follows: 1. Weigh 50g of coal direct liquefaction residue without any treatment, crush it and pass through an 80-mesh sieve. The residue powder is Soxhlet extracted with n-hexane at 92°C for 50 hours, and the obtained insoluble matter is dried and ground through 80 mesh. Mesh sieve, extracted with toluene at 140°C for 50h, the extracted insoluble matter was dried, ground into powder and passed through a 80 mesh sieve, after THF was extracted at 92°C for 50h, the obtained THF soluble matter was extracted with a rotary evaporator The solid substance obtained after removing the tetrahydrofuran solvent by evaporating under reduced pressure at 50°C is pre-asphaltene. 2. Mix and grind the pre-asphaltenes, polyethylene glycol (molecular weight 6000) and cobalt nitrate ...

Embodiment 3

[0037] Cobalt oxide / carbon composites were prepared using asphaltenes in coal direct liquefaction residues as carbon source, polyethylene glycol as porogen, and cobalt nitrate as metal precursor. The specific steps are as follows: 1. Weigh 40g of coal direct liquefaction residue without any treatment, crush it and pass through an 80-mesh sieve. The residue powder is Soxhlet extracted with n-hexane at 92°C for 50 hours, and the obtained insoluble matter is dried and ground through 80-mesh sieve. Mesh sieve, extracted with toluene at 140°C for 50h, the toluene soluble matter was evaporated under reduced pressure at 80°C by a rotary evaporator to remove the toluene solvent, and the obtained solid was asphaltene. 2. Raise the asphaltene from room temperature to 300°C at a rate of 1°C / min in the air, and keep it at this temperature for 4 hours for pre-oxidation treatment. 3. Mix and grind the pre-oxidized asphaltenes, polyethylene glycol (molecular weight 6000) and cobalt nitrate g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com