Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

155results about How to "Reduce contact force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

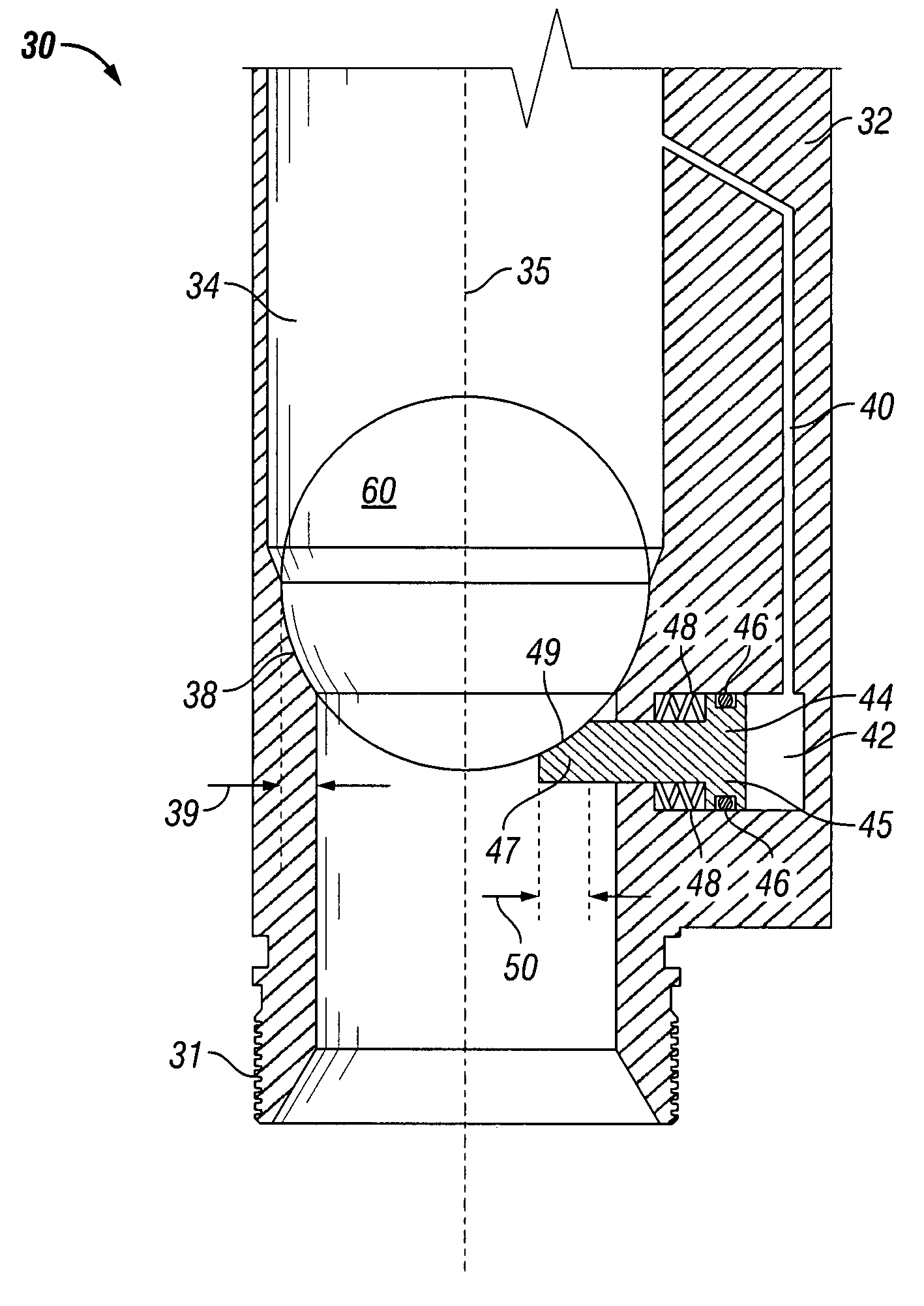

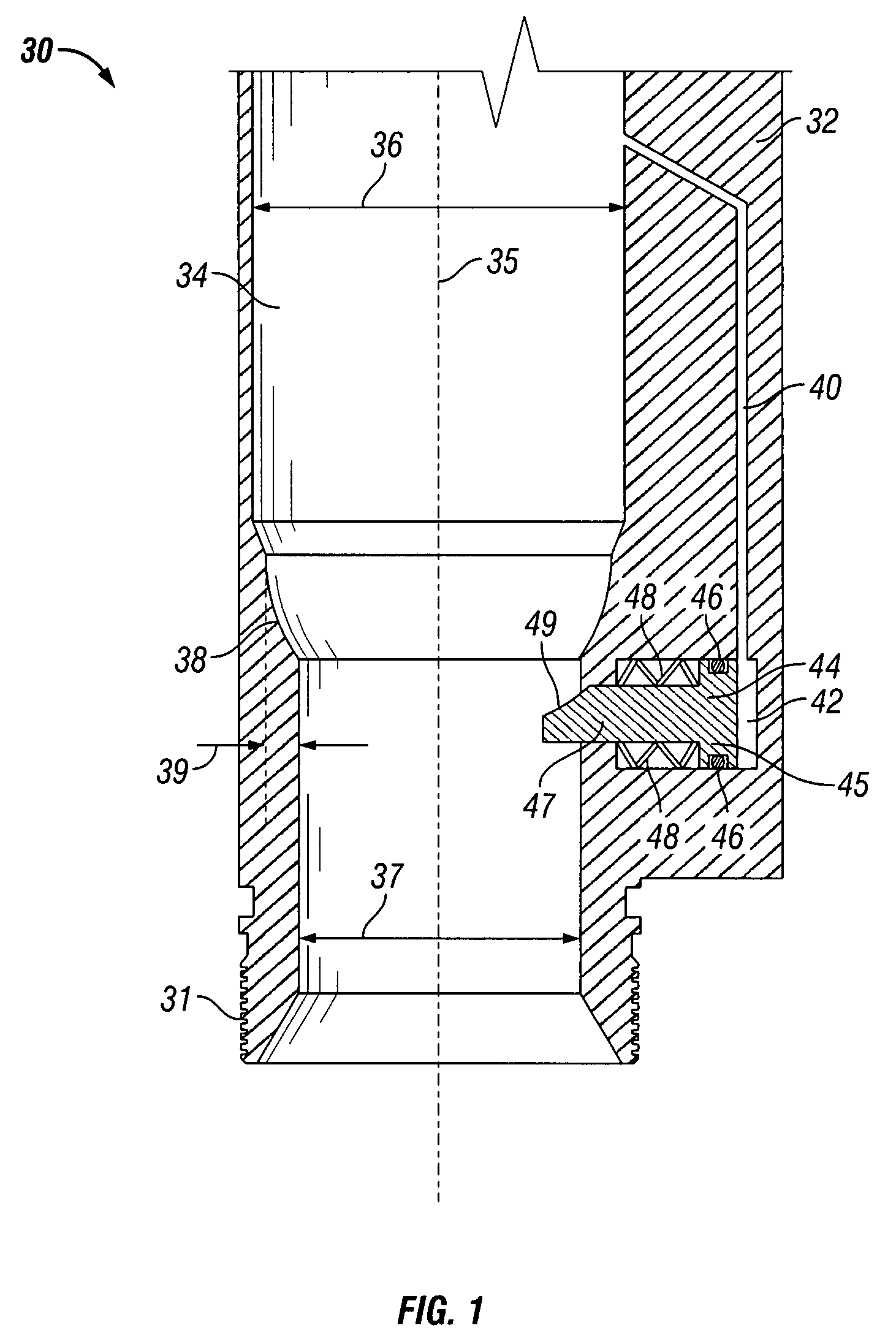

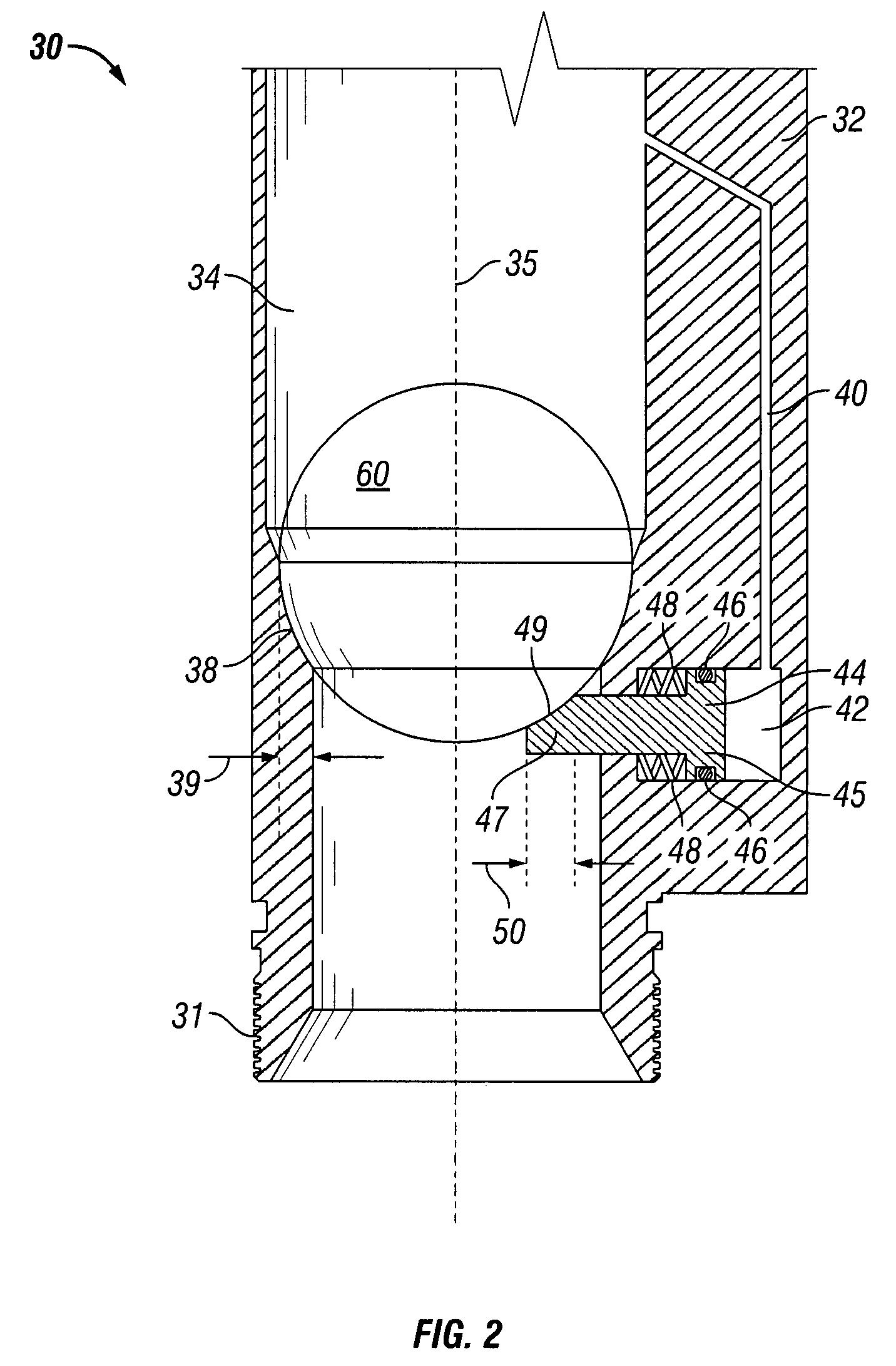

Ball seat having fluid activated ball support

ActiveUS7637323B2Reduce the possibilityReduce contact forceCheck valvesFluid removalEngineeringPiston

Apparatuses for closing a well conduit comprise a housing having a longitudinal bore and a seat disposed within the bore. A chamber is disposed within the housing and includes a plug element support member, such as ram or piston, operatively associated within the chamber. The plug element support member has a retracted position and an extended position. A passageway is in fluid communication with the bore and the chamber. A plug element such as a ball or drop plug, is adapted to be disposed into the bore and landed on the seat to restrict fluid flow through the bore and the well conduit. Landing the plug element causes and allowing fluid pressure to build causes the plug element support member to move from the retracted position to the extended position to provide support to the plug element landed on the seat.

Owner:BAKER HUGHES INC

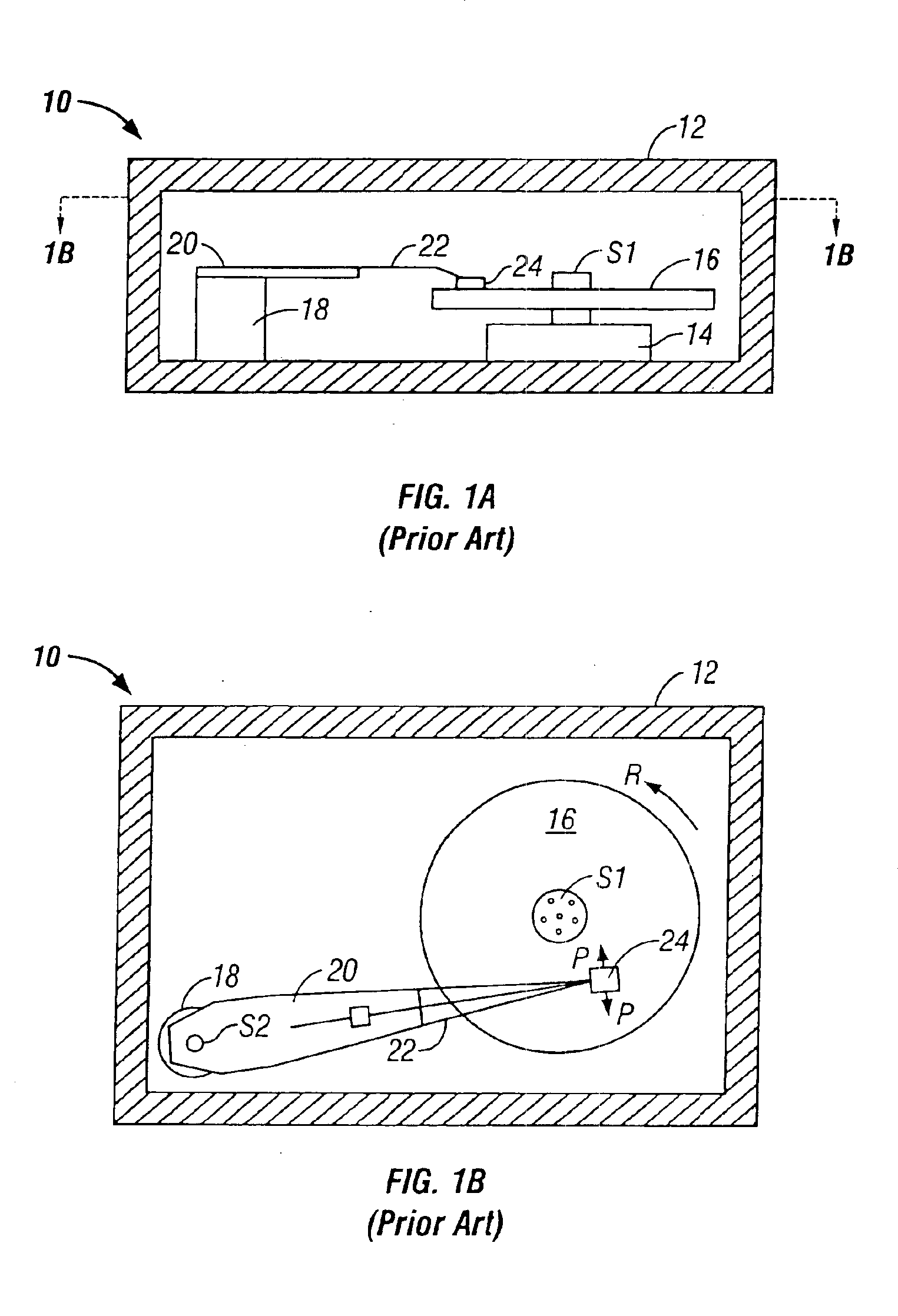

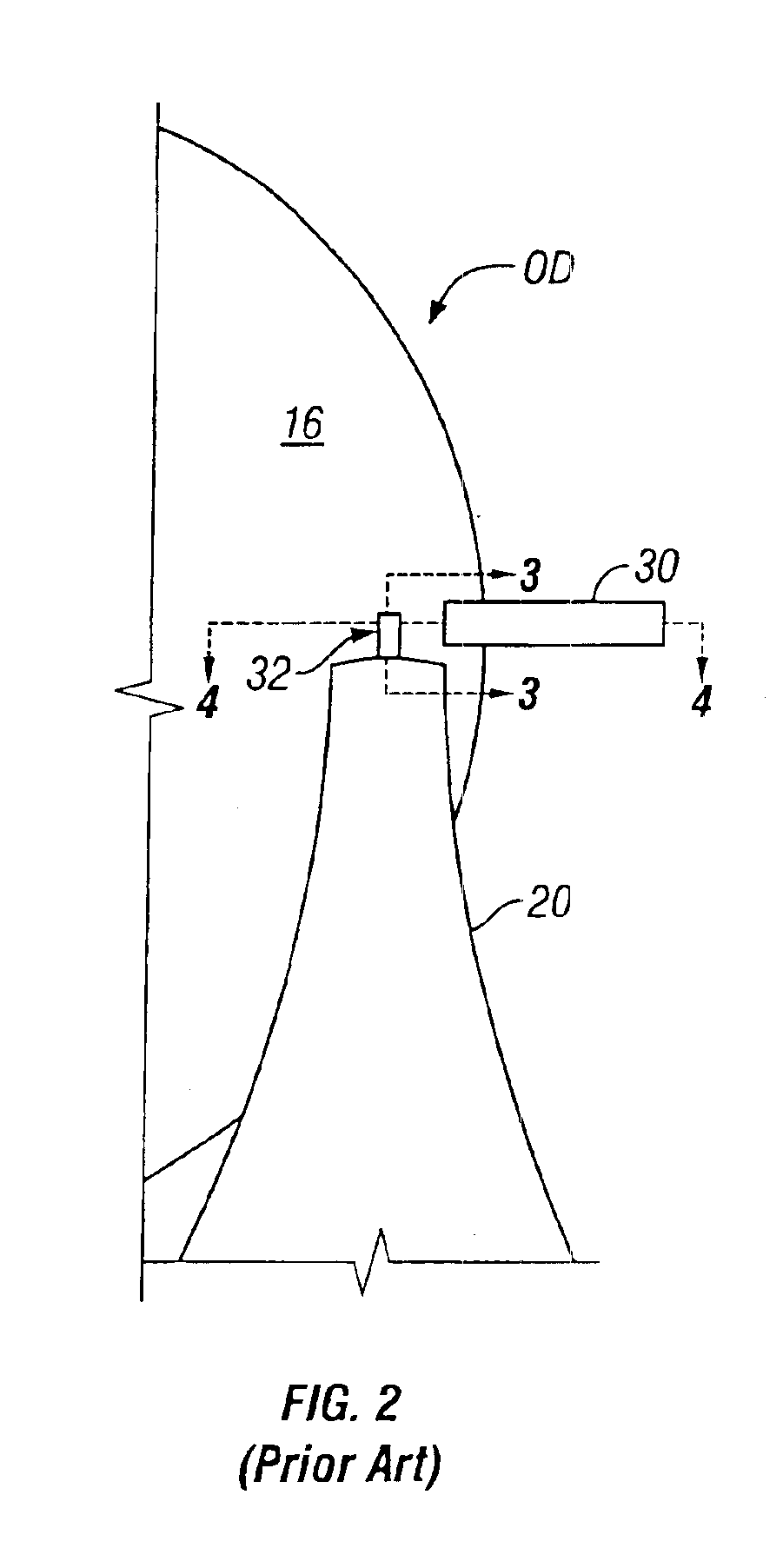

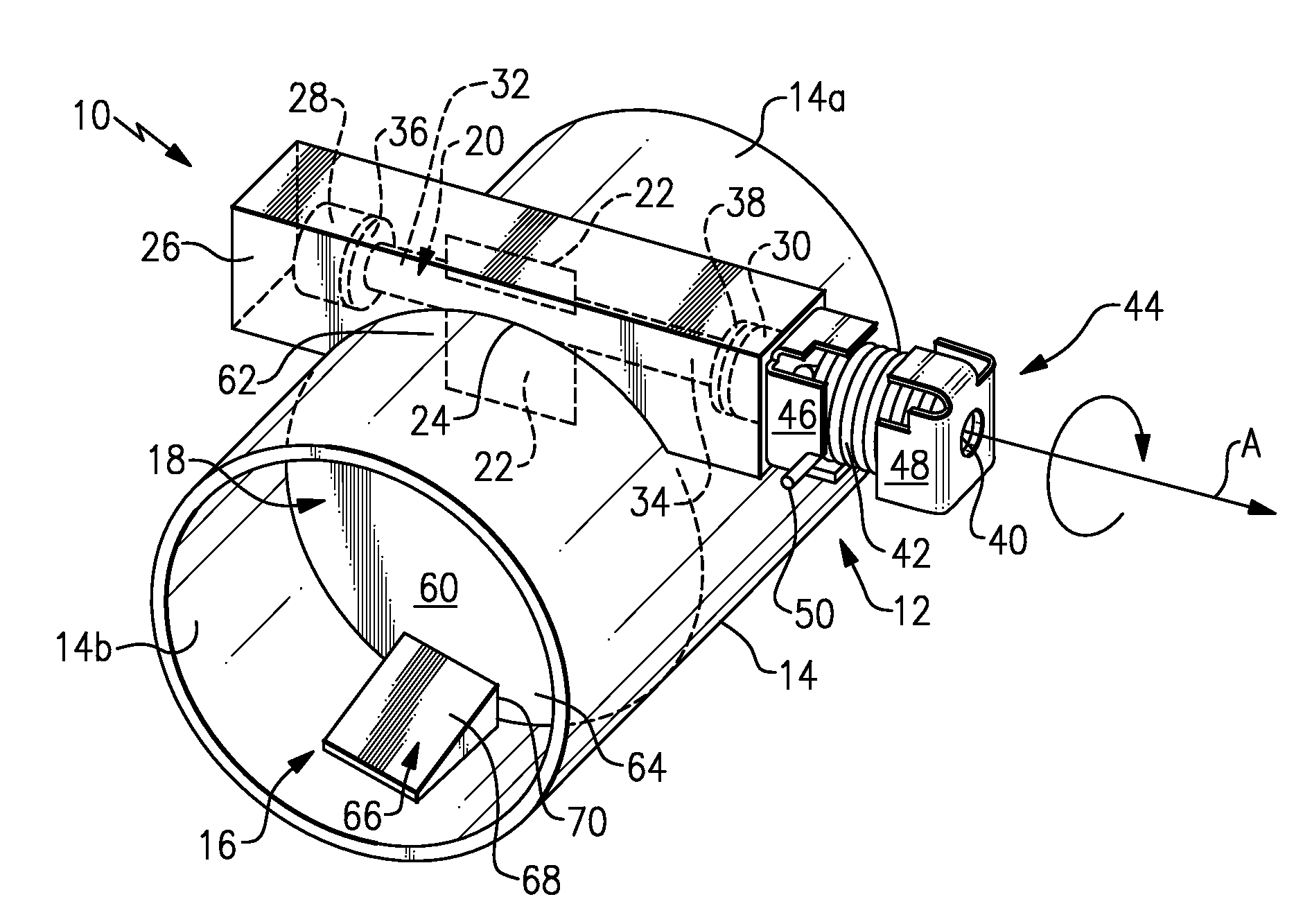

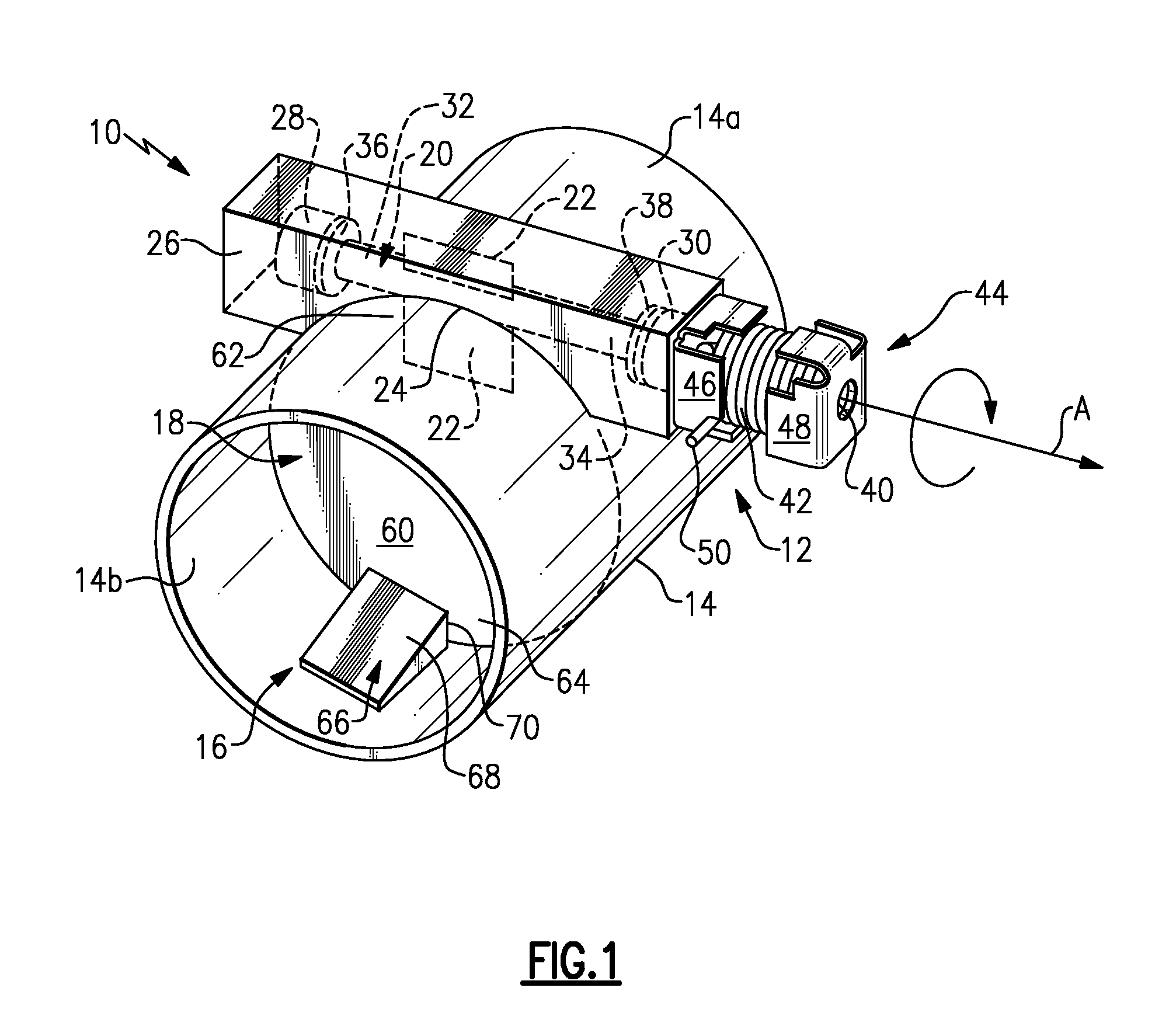

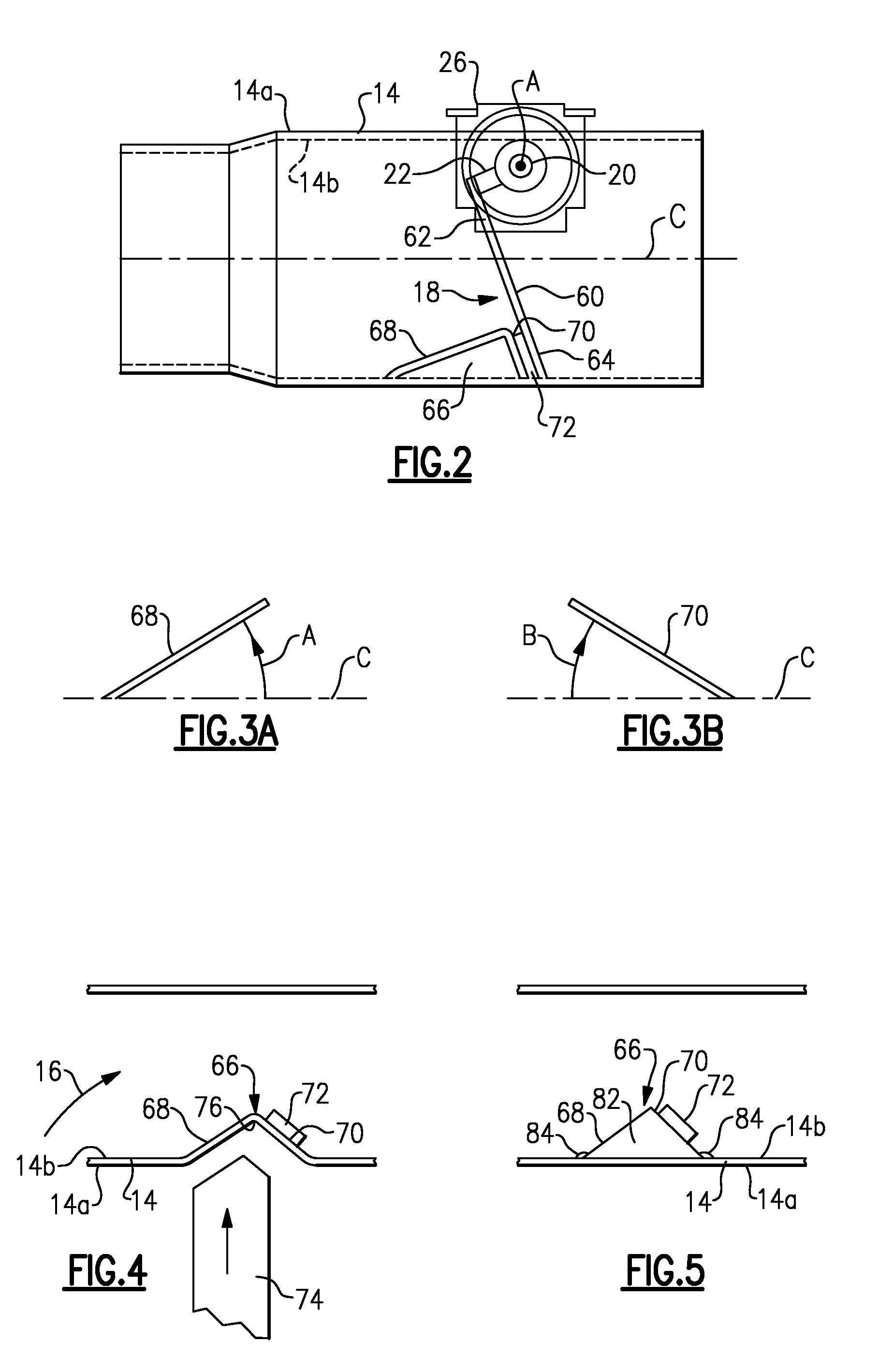

Airflow assisted ramp loading and unloading of sliders in hard disk drives

InactiveUS6856489B2Assist in loadReduce rotationDriving/moving recording headsRecord information storageHard disc driveEngineering

Windage proximate to a spinning disk within a disk drive is directed through a plurality of apertures in a ramp situated near the outside diameter of the disk. A tab extending from a load beam that supports a slider rests on the ramp when the drive is not in use. When the drive is started the disk begins to spin and an actuator moves the load beam to bring the slider over the surface of the disk. As the load beam moves, the tab is guided along the ramp and cushioned by the air flow emerging from apertures in the ramp beneath it. When the drive is stopped the actuator brings the load beam back so that the tab engages the ramp. A cushion of air is again provided as the tab is moved along the ramp as the tab is returned to a parked position.

Owner:WESTERN DIGITAL TECH INC

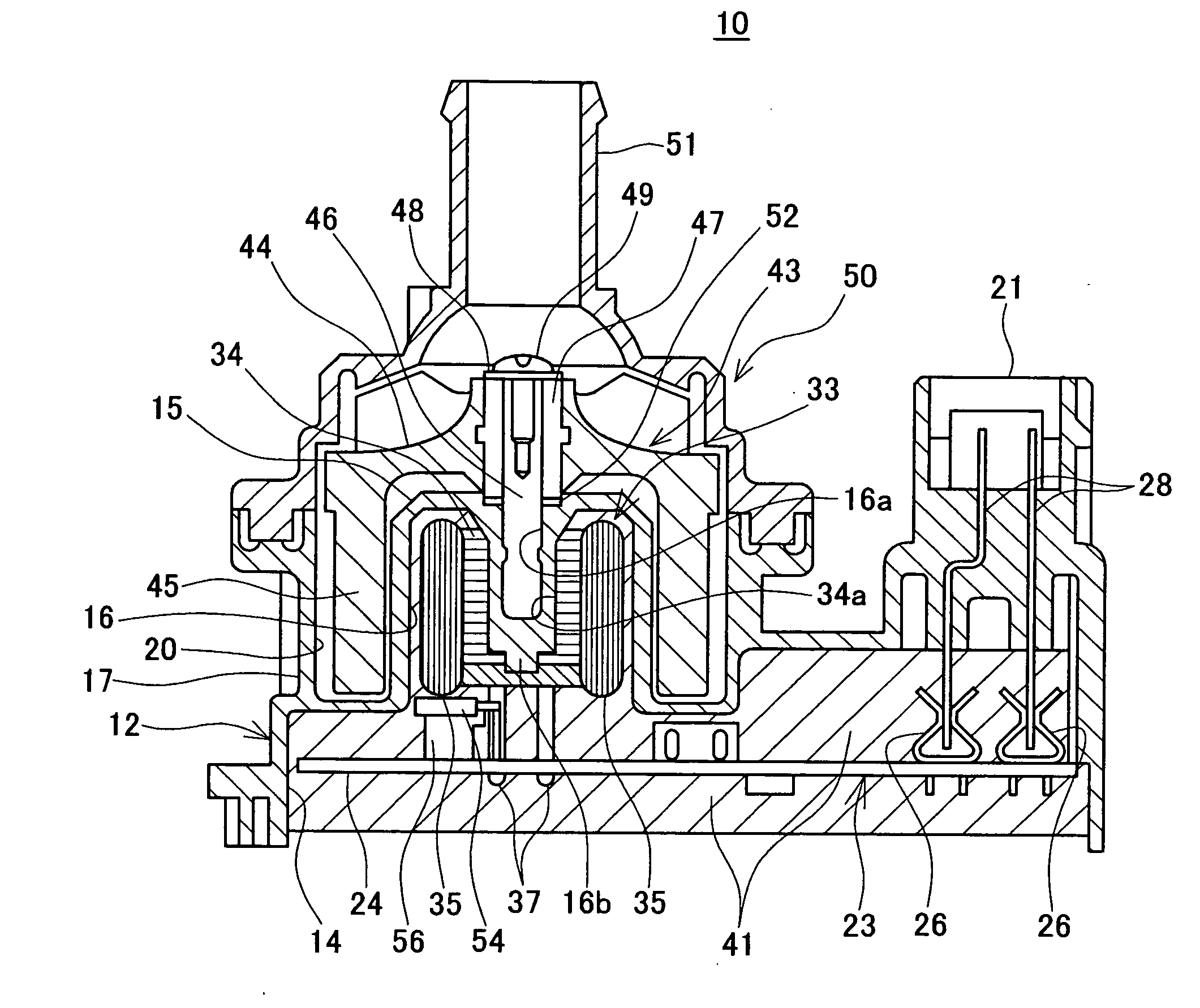

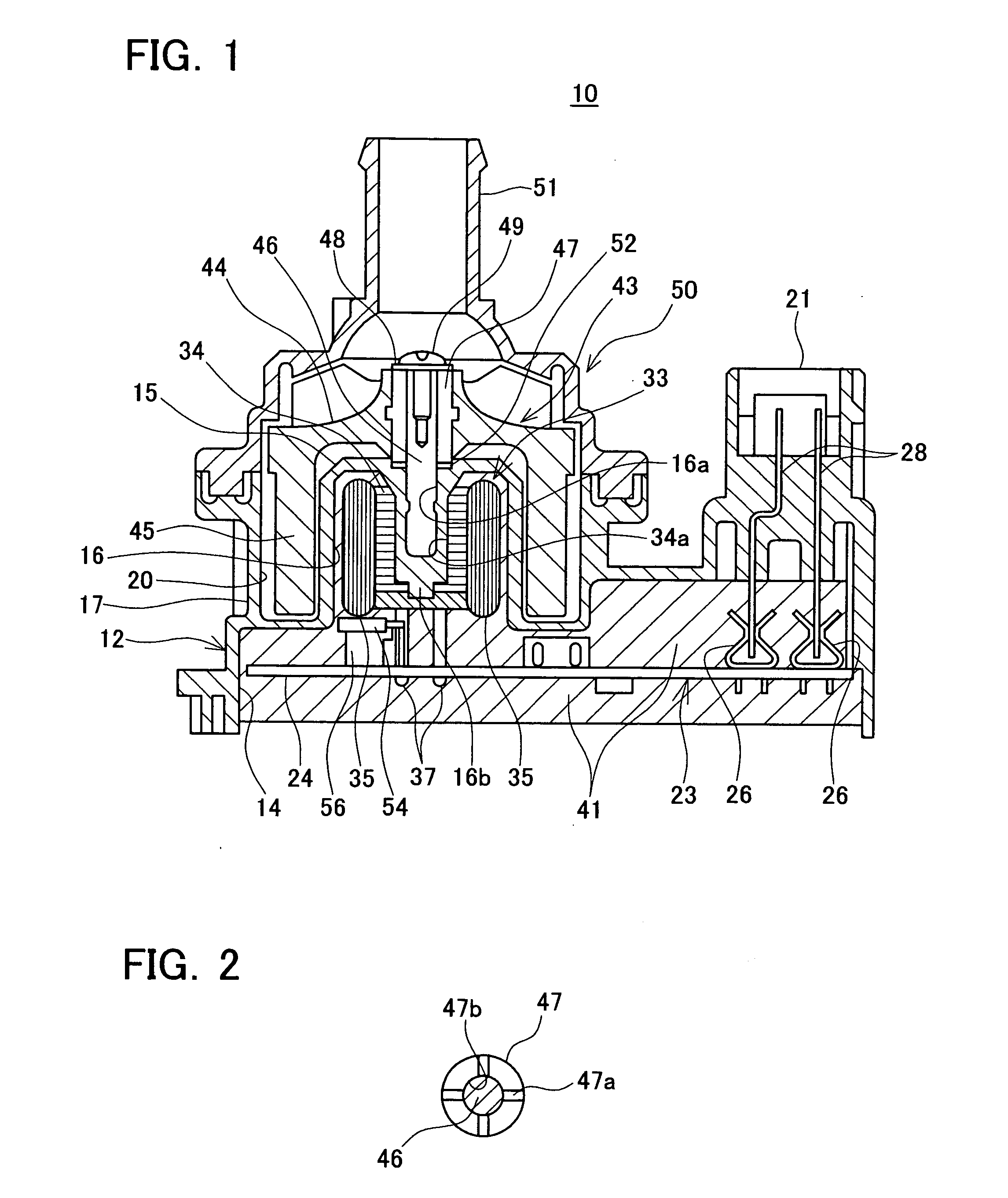

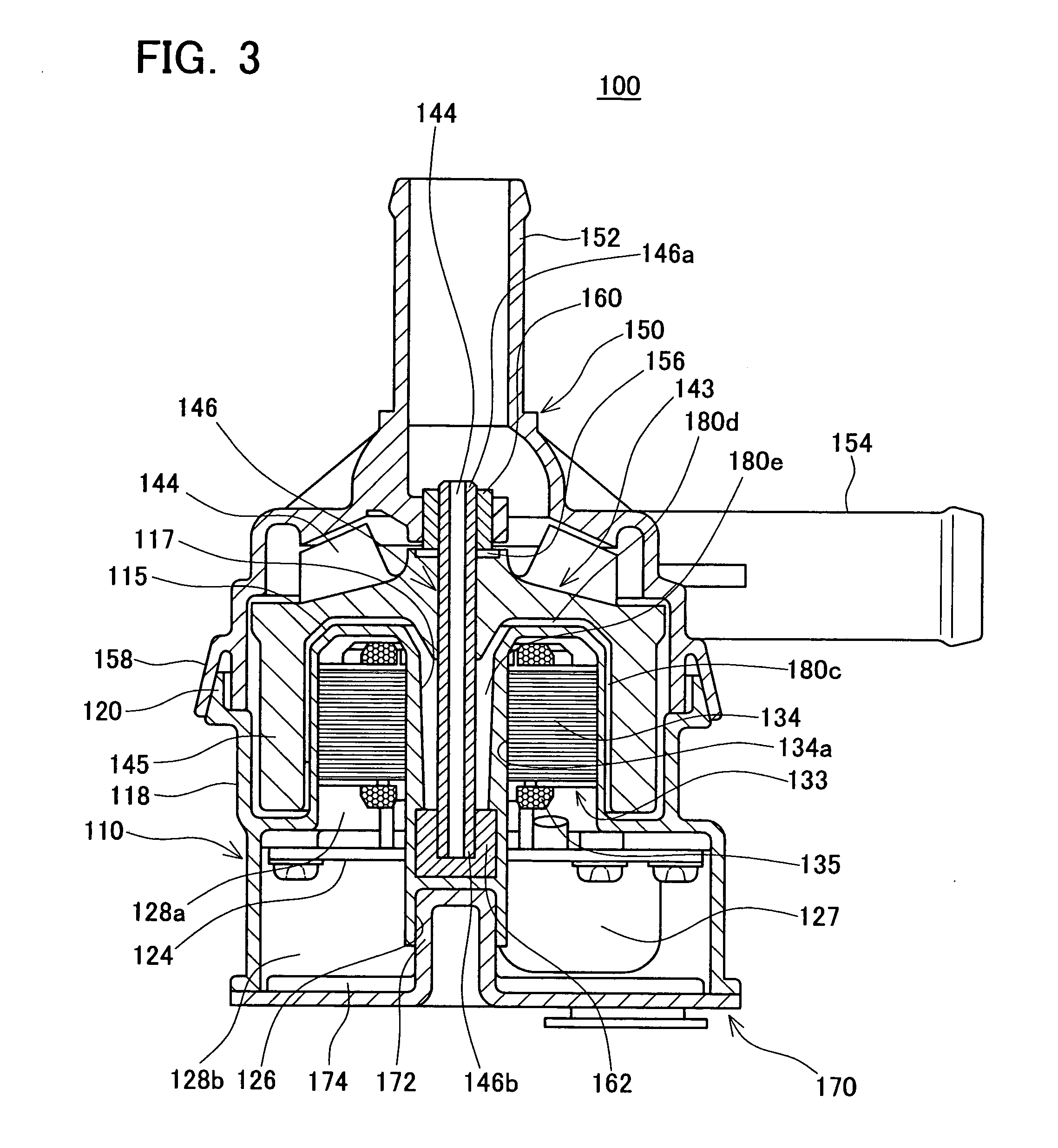

Electric pump

An electric pump may comprise a pump case (110, 150) having a pump chamber. An impeller 143 may be rotatably disposed within the pump chamber. The impeller 143 may include a magnetized cylindrical portion 145. A stator 133 may be disposed opposite to the cylindrical portion 145 of the impeller 143. The stator 133 may drive the impeller 143 by applying magnetic forces to the cylindrical portion 145 of the impeller 143. A shaft 146 may be formed integrally with the impeller 143. One end of the shaft 143 may be rotatably supported with respect to the pump case.

Owner:AISAN IND CO LTD

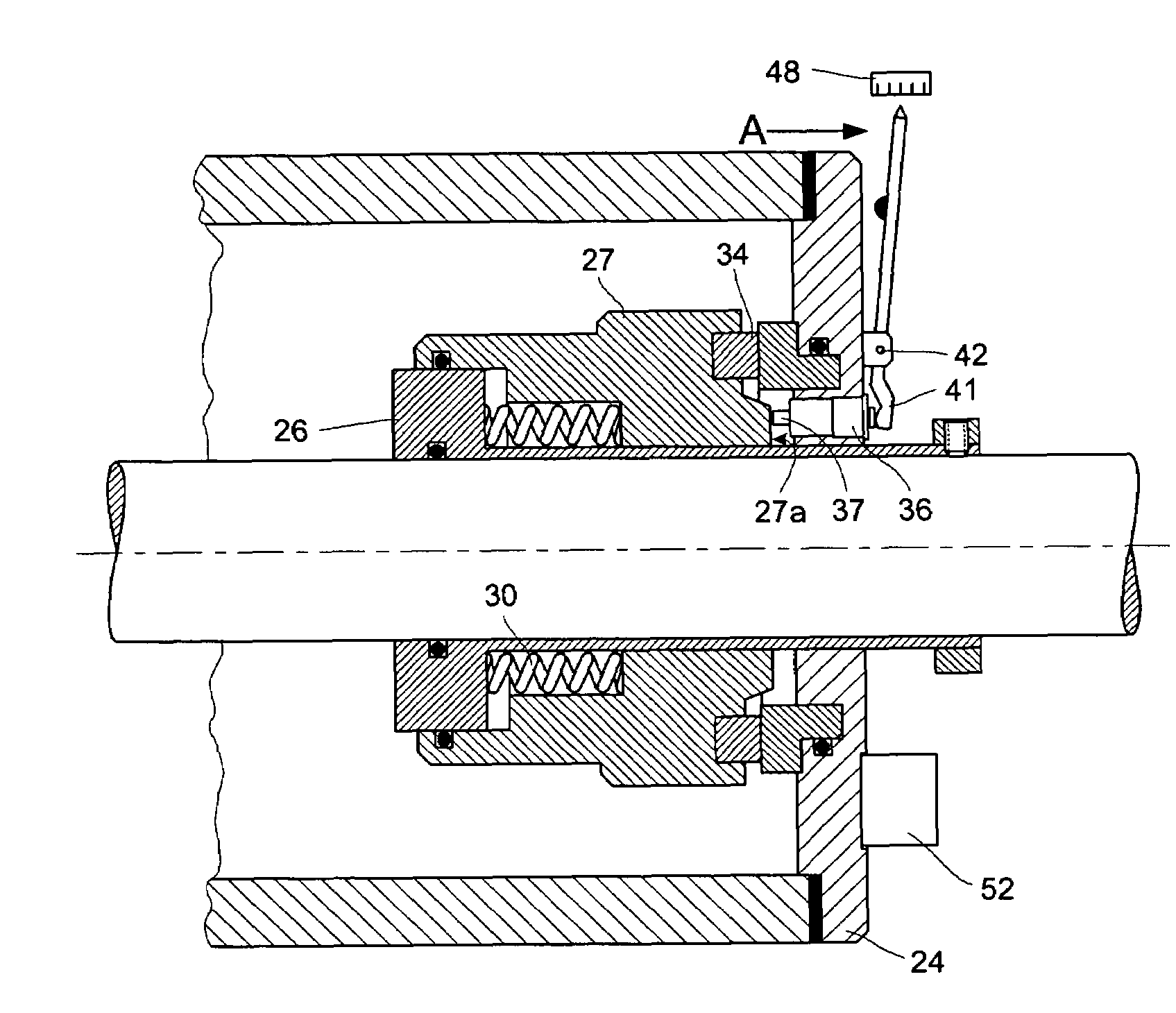

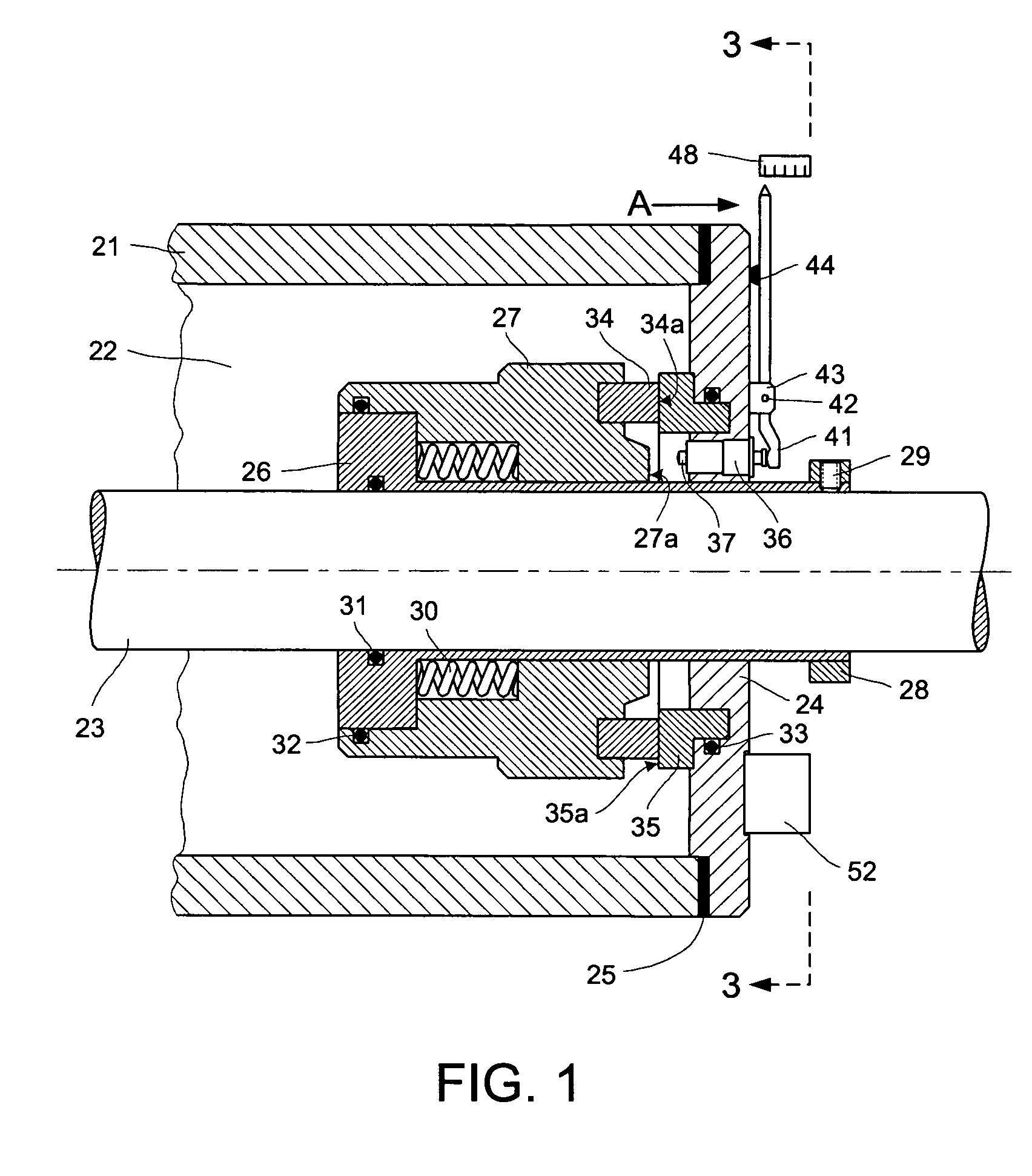

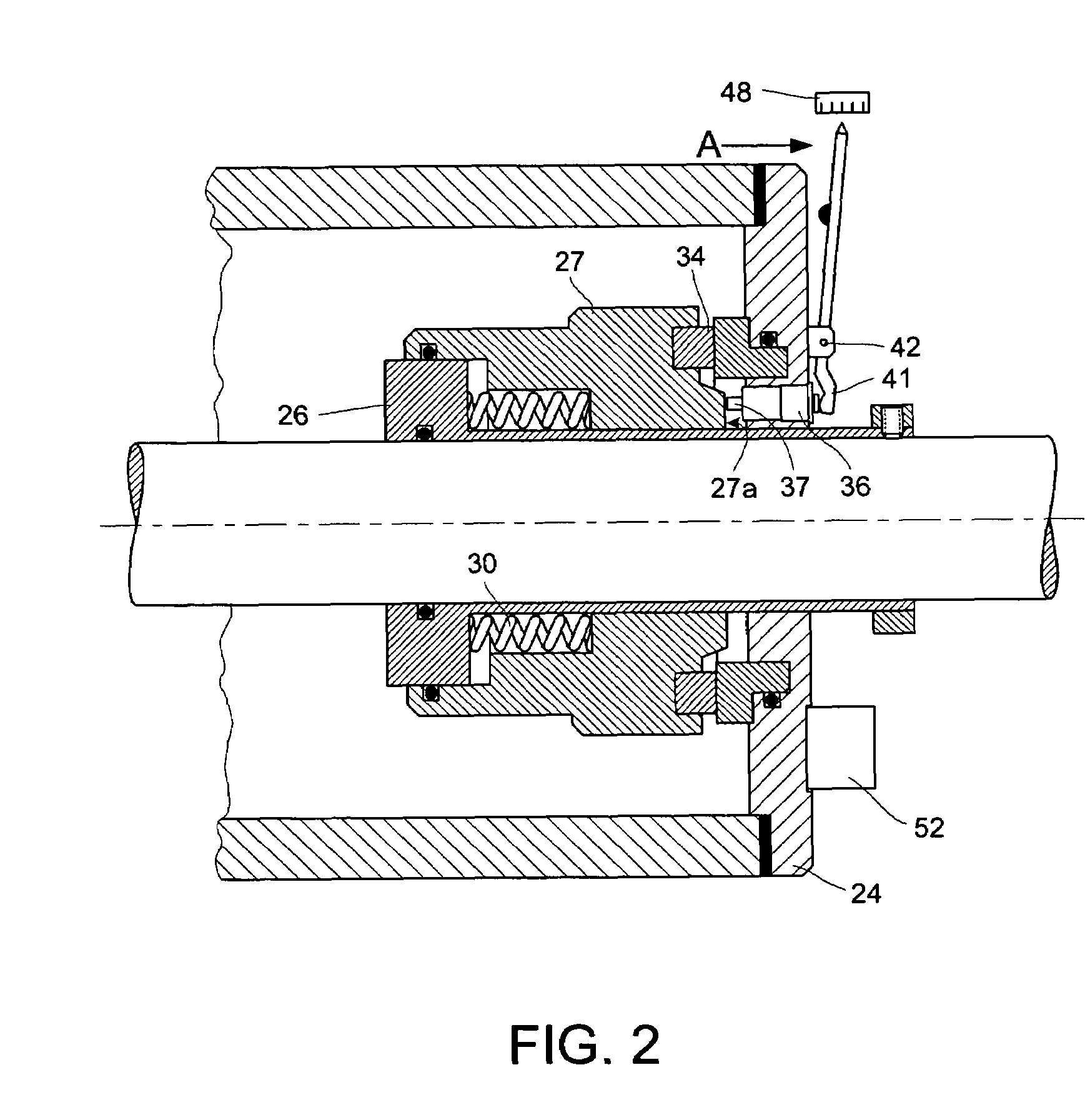

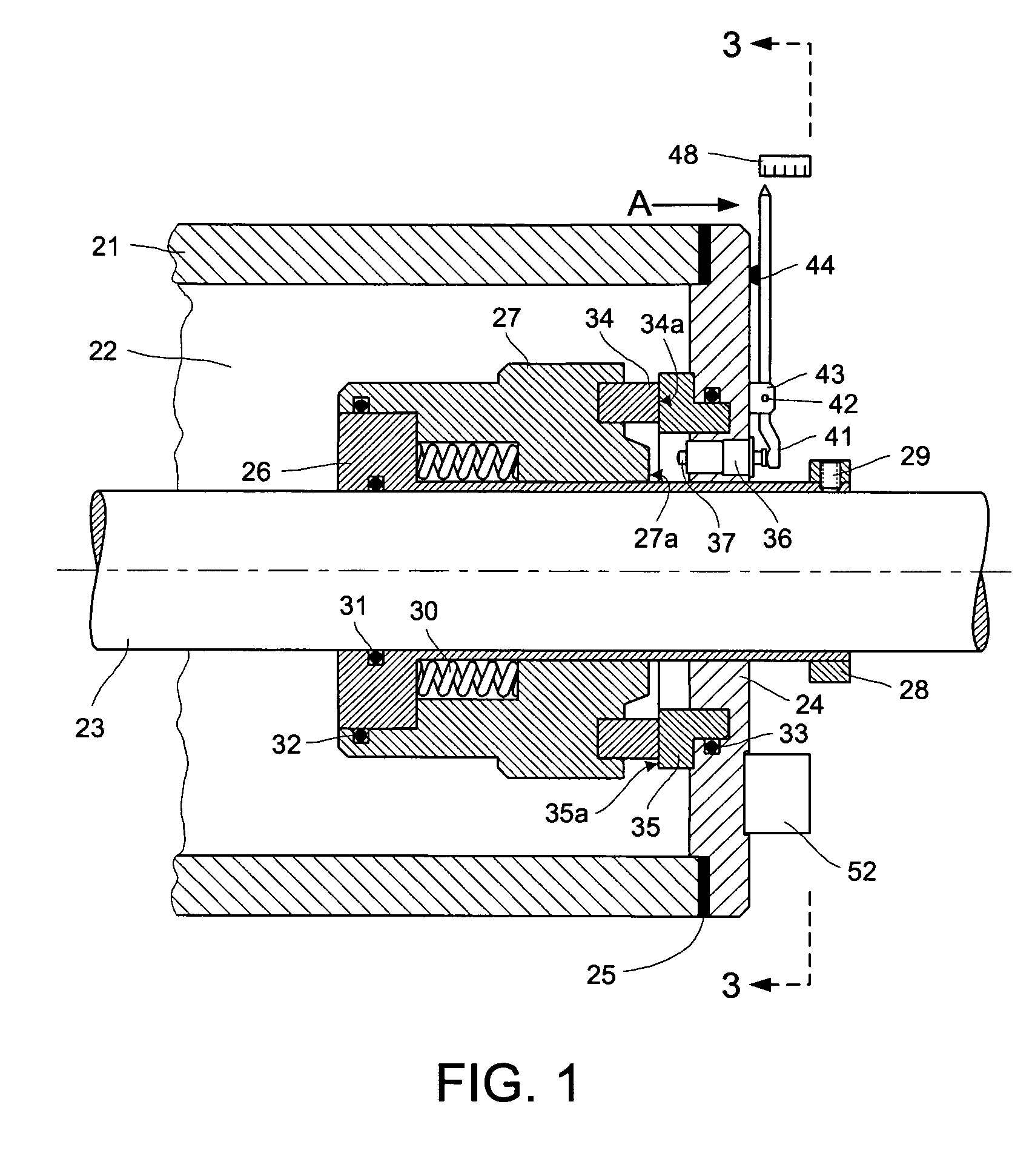

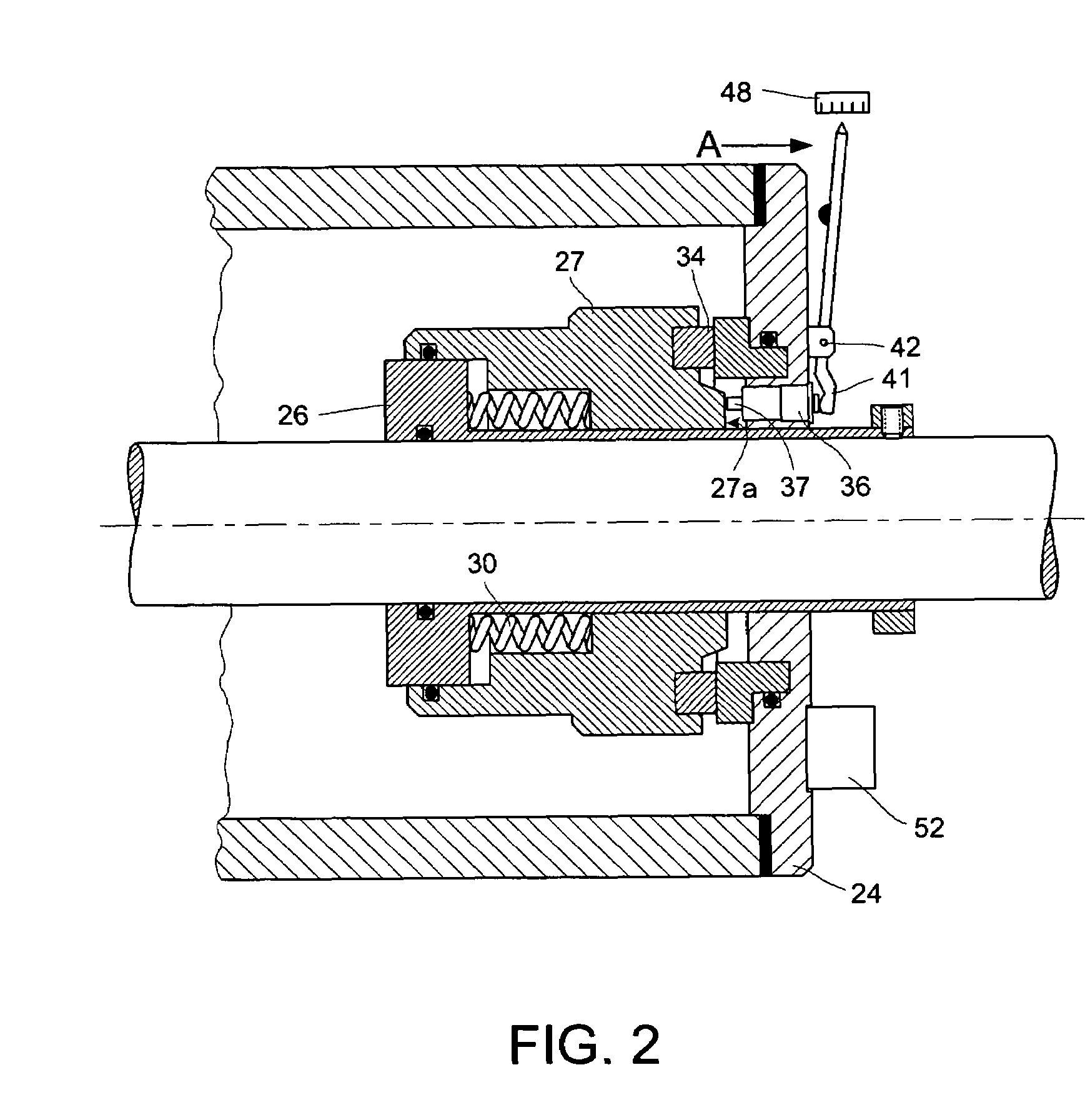

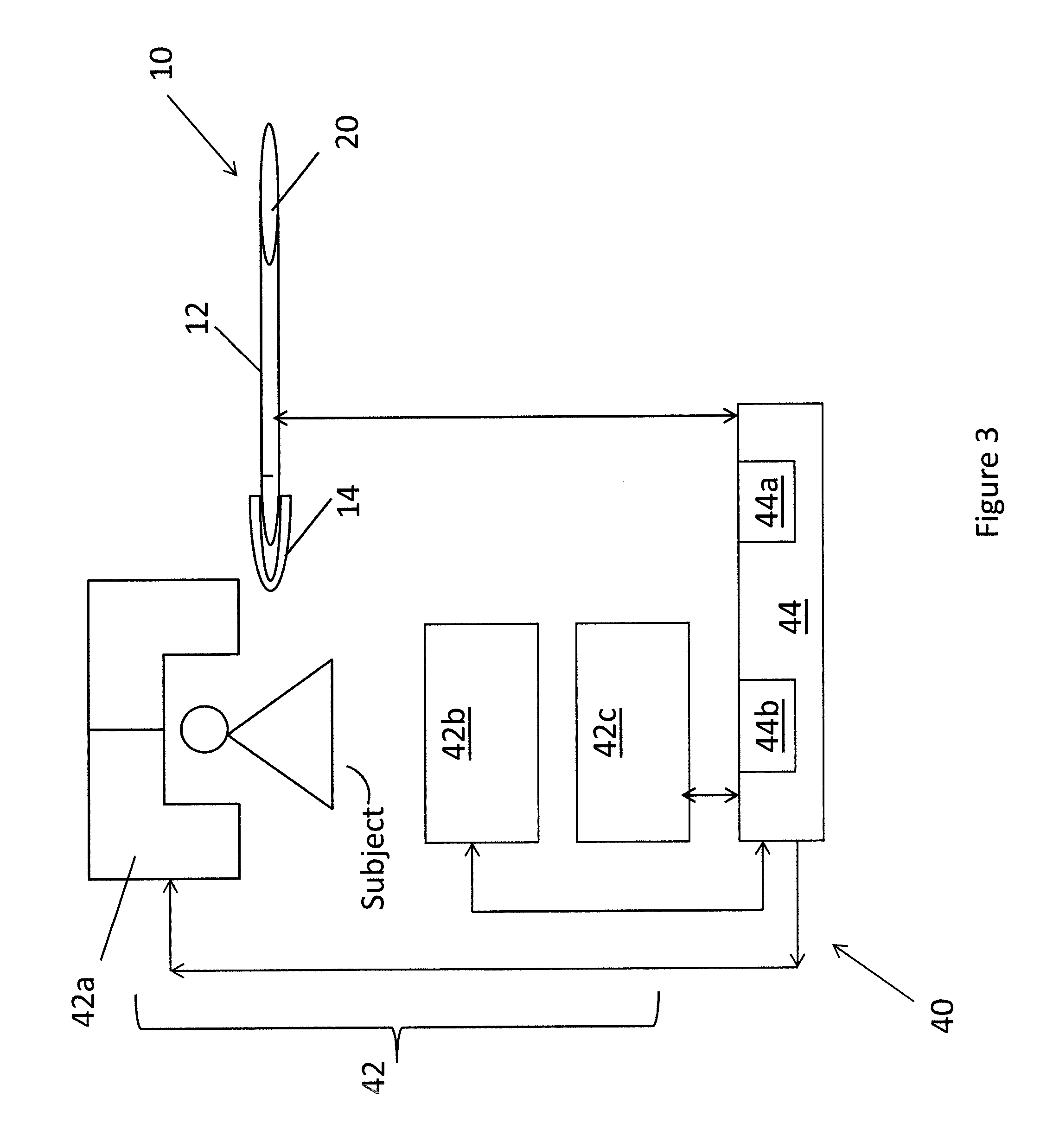

System and method for monitoring mechanical seals

ActiveUS20100106429A1Avoid seal failureAccurate measurementNoise figure or signal-to-noise ratio measurementFrequency analysisMonitoring systemRelative motion

A mechanical seal monitoring system and method that measure the wear of seal faces of a mechanical seal where the mechanical seal seals a rotating machine portion from another portion of the machine. The system preferably uses a wear probe movable relative to a rotating seal component so that the wear probe can contact the rotating component. The wear of the seal is preferably determined by the relative movement that is required for the wear probe to contact the rotating component. Preferably, stress waves induced by the rubbing between the probe and the rotating component are detected by a stress-wave sensor, processed by a signal processor, and either displayed to the user numerically or reported to a monitoring computer. A signal intensity comparison method is preferably used to make the detection process insensitive to background noise generated by sources other than the contact of the wear probe and the rotating component.

Owner:HORAK MICHAEL N

Probe of cantilever probe card

InactiveUS20090212807A1Reduce cleaning frequencyExtended run timeElectrical measurement instrument detailsElectrical testingEpoxyProbe card

A probe of a cantilever probe card (Epoxy probe card) is disclosed. The probe has a tip and a surface region extended from the tip of the probe about 5-10 mil is coated with a nano-film of high electro-conductive nanomaterial. The thickness of the nano-film is about 1-20 nm. Through the coating process, the nano-film coated on the probe of the cantilever probe card can efficiently provide the excellent advantages of no-clean, stable electro-conductivity, minimum overdrive force and longer usage lifetime for the probe of cantilever probe card. Accordingly, the yield of wafer testing can be improved and the frequency of cleaning the probe can be decreased. Furthermore, the total testing cost can be reduced.

Owner:IPWORKS TECH CORP

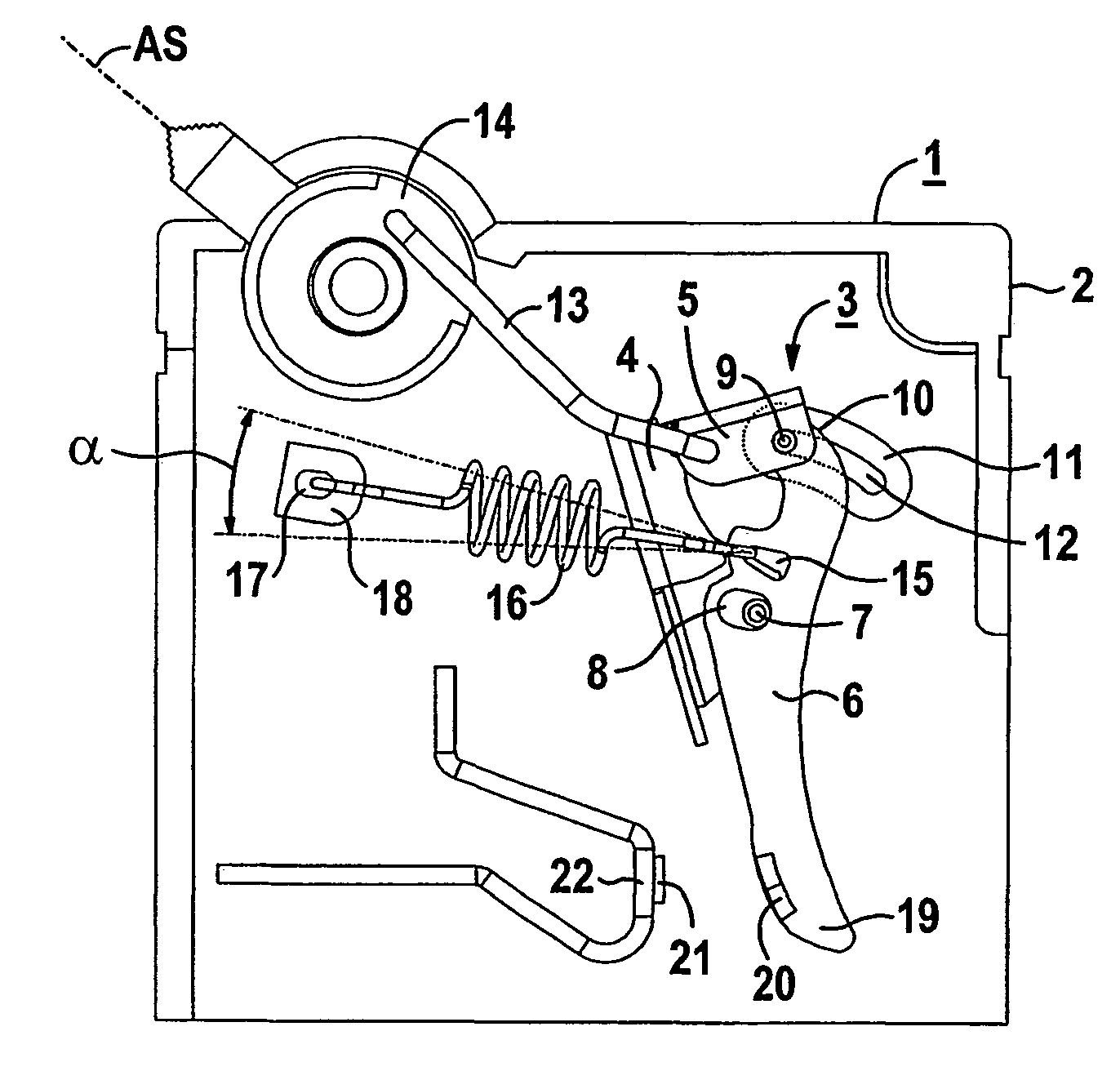

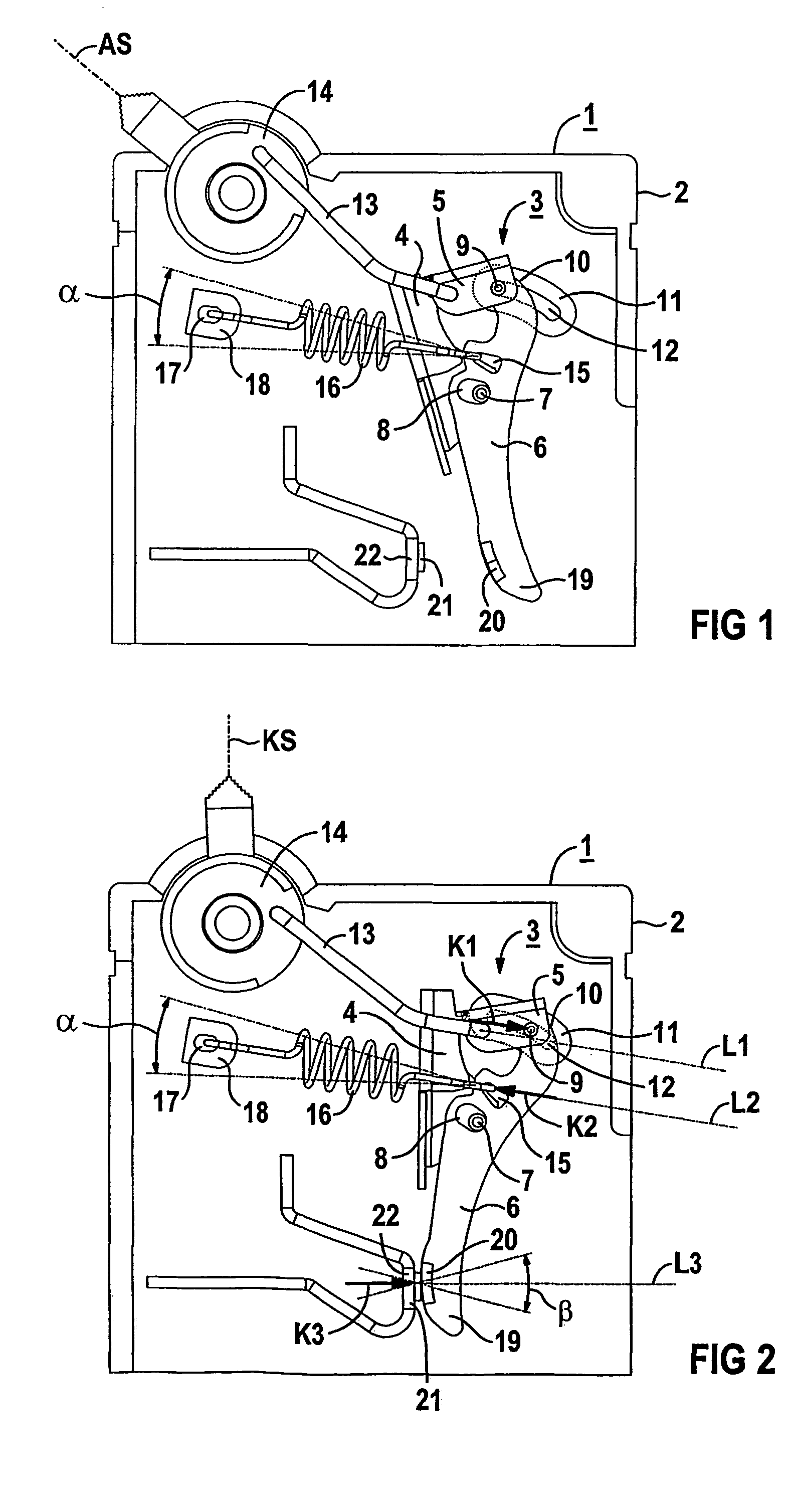

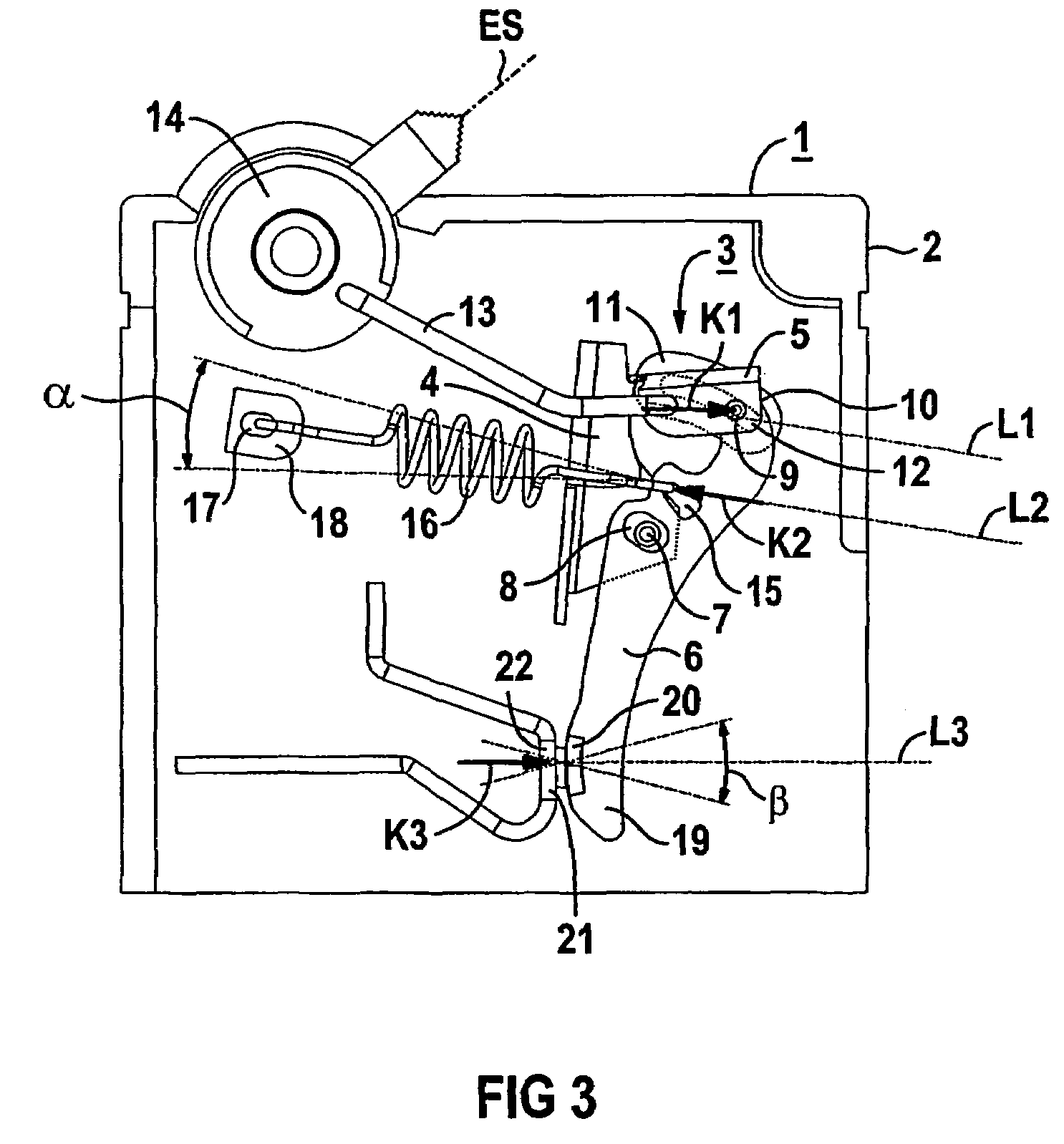

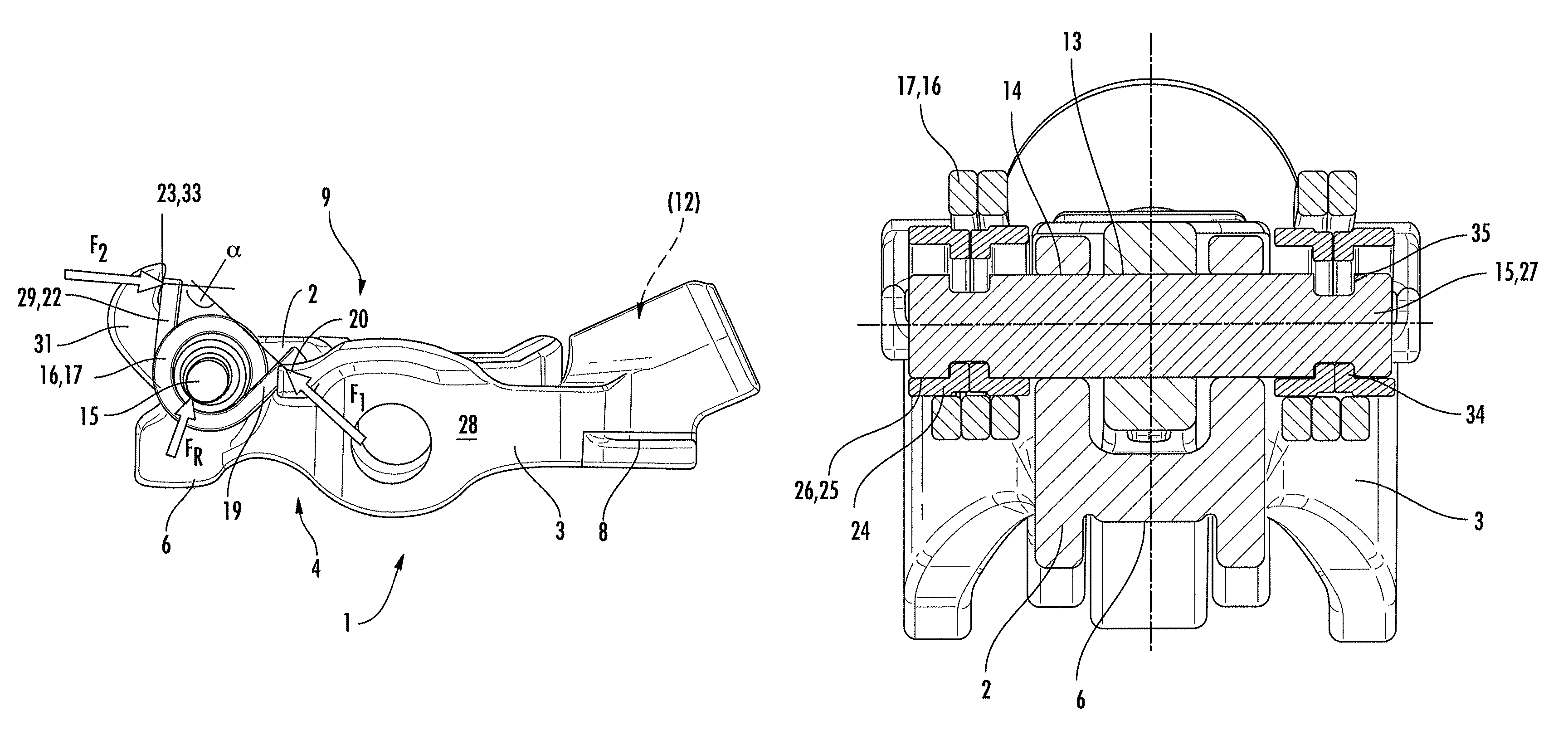

Switching device comprising a breaker mechanism

InactiveUS7009129B2Saving and simplificationHigh guidance stabilityCircuit-breaking switches for excess currentsTumbler/rocker switchesContact forceBolt connection

A switching device including housing and a breaker mechanism, the latter consisting of a trip lever, a catch, a displaceable contact arm and a deflection shaft that is fixed to the housing. The aim is to generate a constant contact force. To achieve this, the end of the catch is coupled to the displaceable contact arm by way of a bolt. The bolt is configured to be displaced in a receiving element that is formed by the housing.

Owner:SIEMENS AG

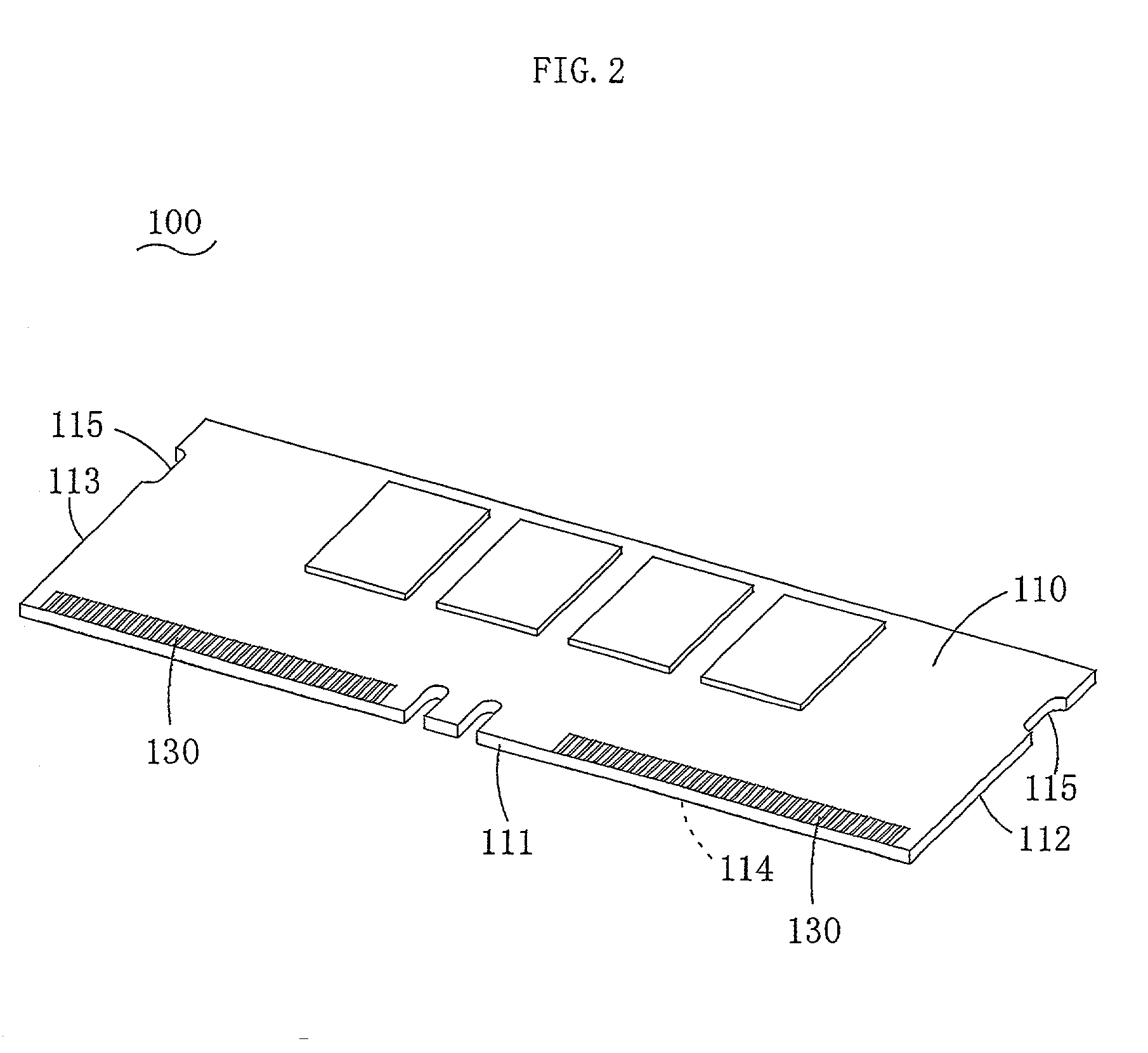

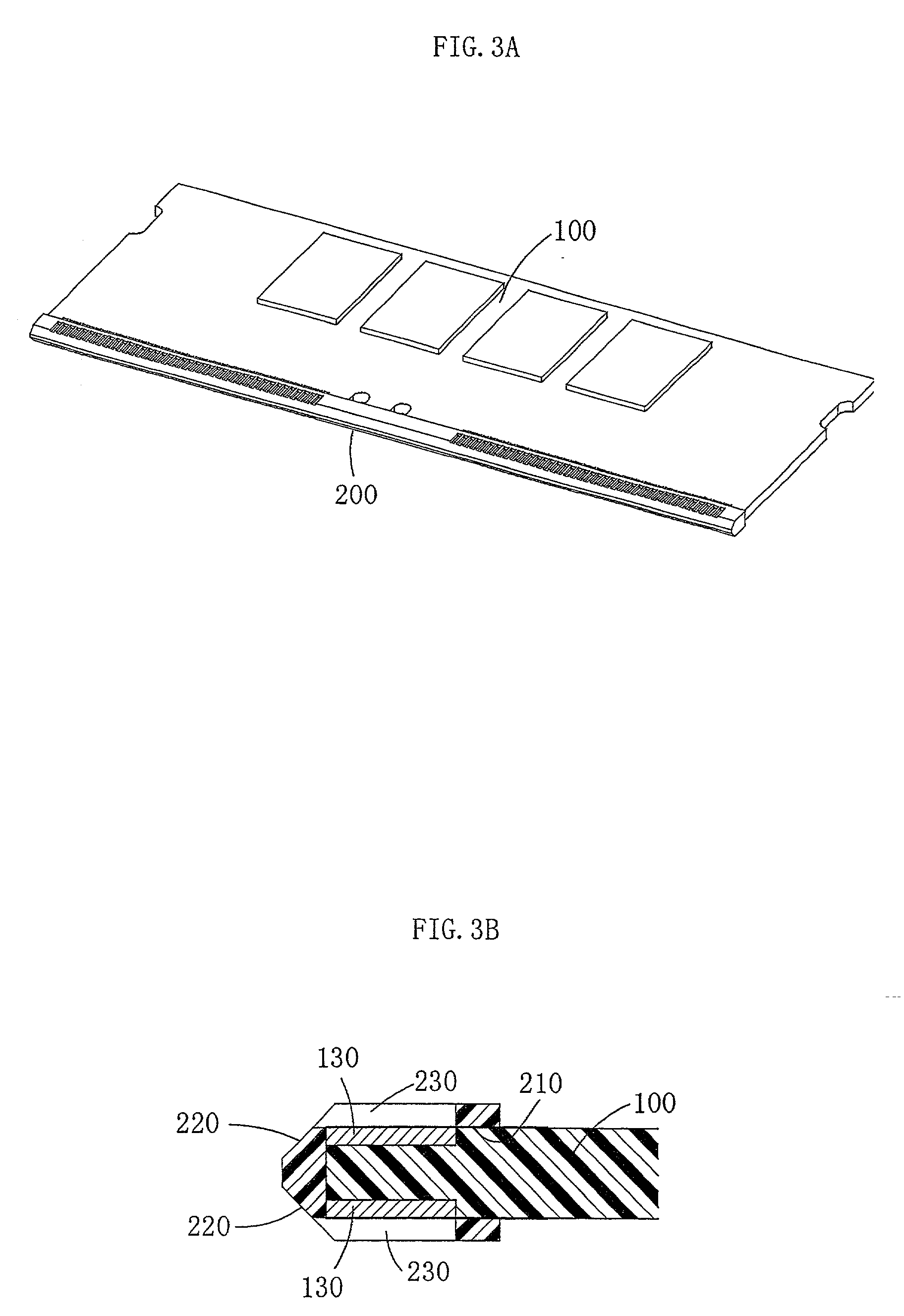

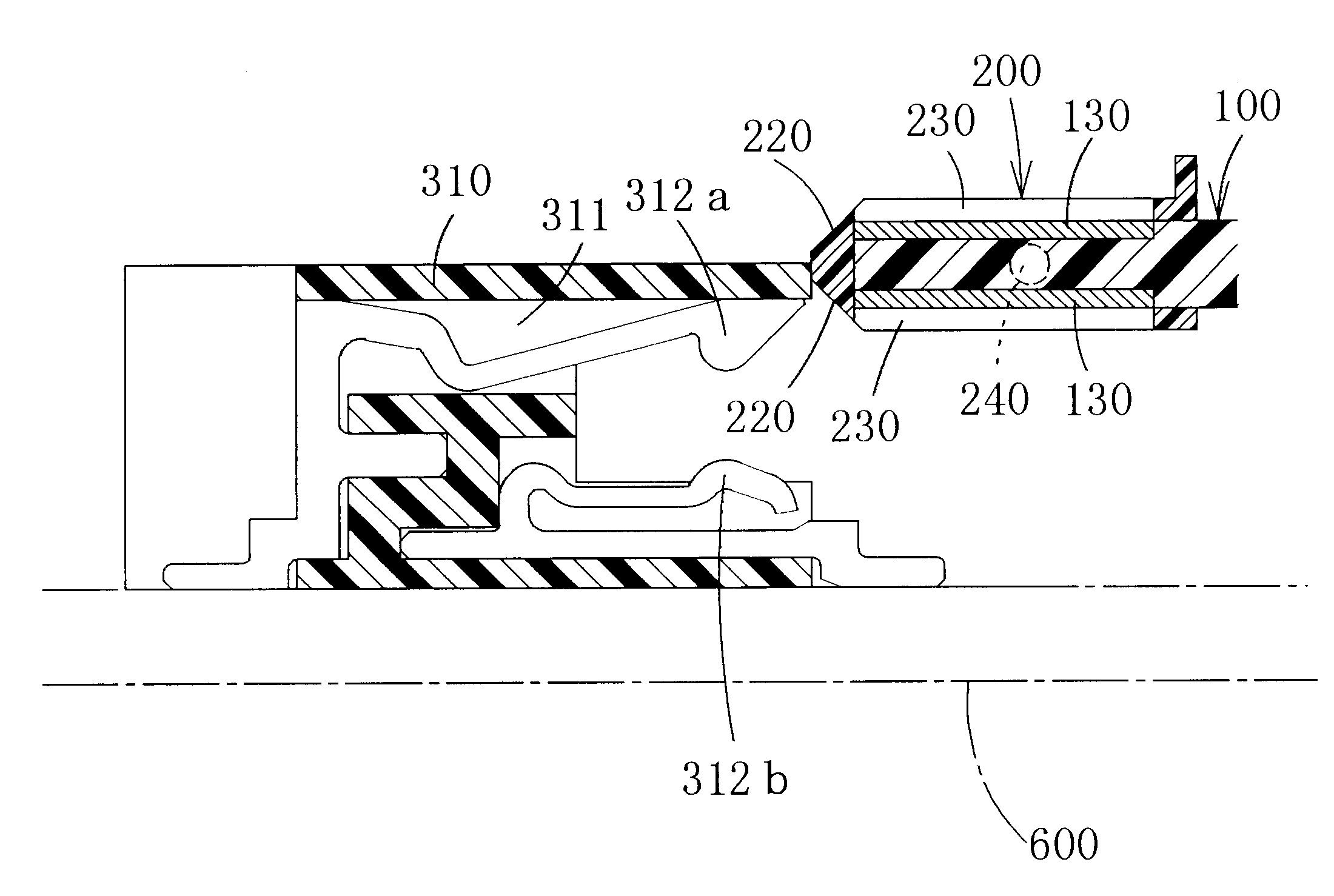

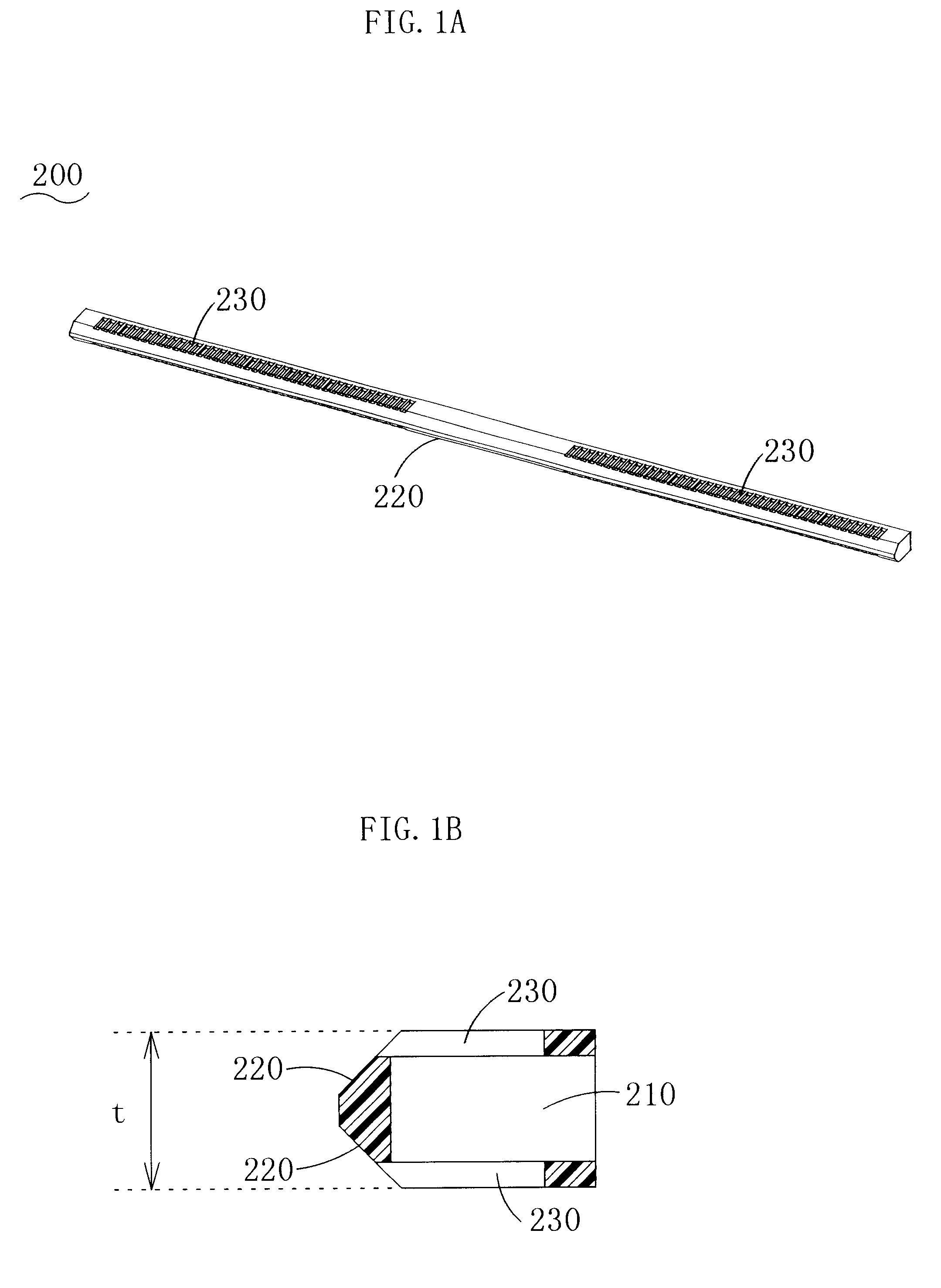

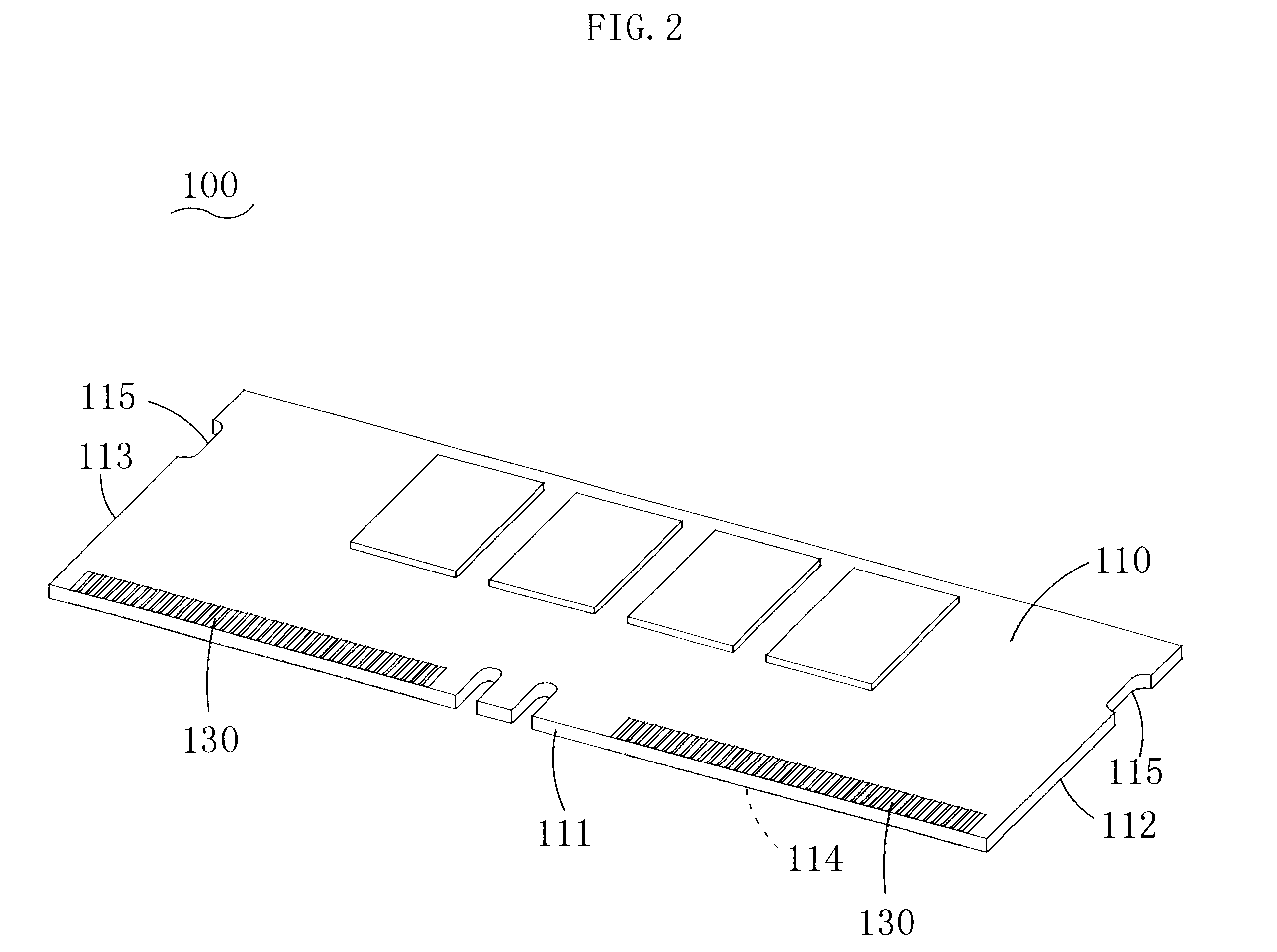

Cap and low insertion force connector for printed circuit board

InactiveUS20010014546A1Insertion forceImprove connection workabilityEngagement/disengagement of coupling partsIncorrect coupling preventionLow insertion forceCountermeasure

A cap that is to be fitted to a printed circuit board, which has a conductive pad on the front side of the rectangular board thereof and which is to be connected to the connector. The cap is formed into a bag and is shaped into a wedge that gets thinner towards the front, and the cap has a window for exposing the conductive pad of the printed circuit board. A low insertion force connector that connects a printed circuit board having conductive pads on the front side of the rectangular board thereof. This low insertion force connector comprises a connector body having at least a pair of contacts that contact the conductive pads and clamp the printed circuit board, a slider that carries the printed circuit board and advances to and retreats from the contact, and a guide that is provided at the front end of the slider and is formed into a wedge-shape, which gets thinner towards the front. The present invention reduces the insertion force of the printed circuit board, enhances the connection workability, and eliminates damages or the like to the contacts and the conductive pad to enhance the reliability. The present invention provides a connector that is also effective in countermeasures against heat and electromagnetic waves.

Owner:JST MFG CO LTD

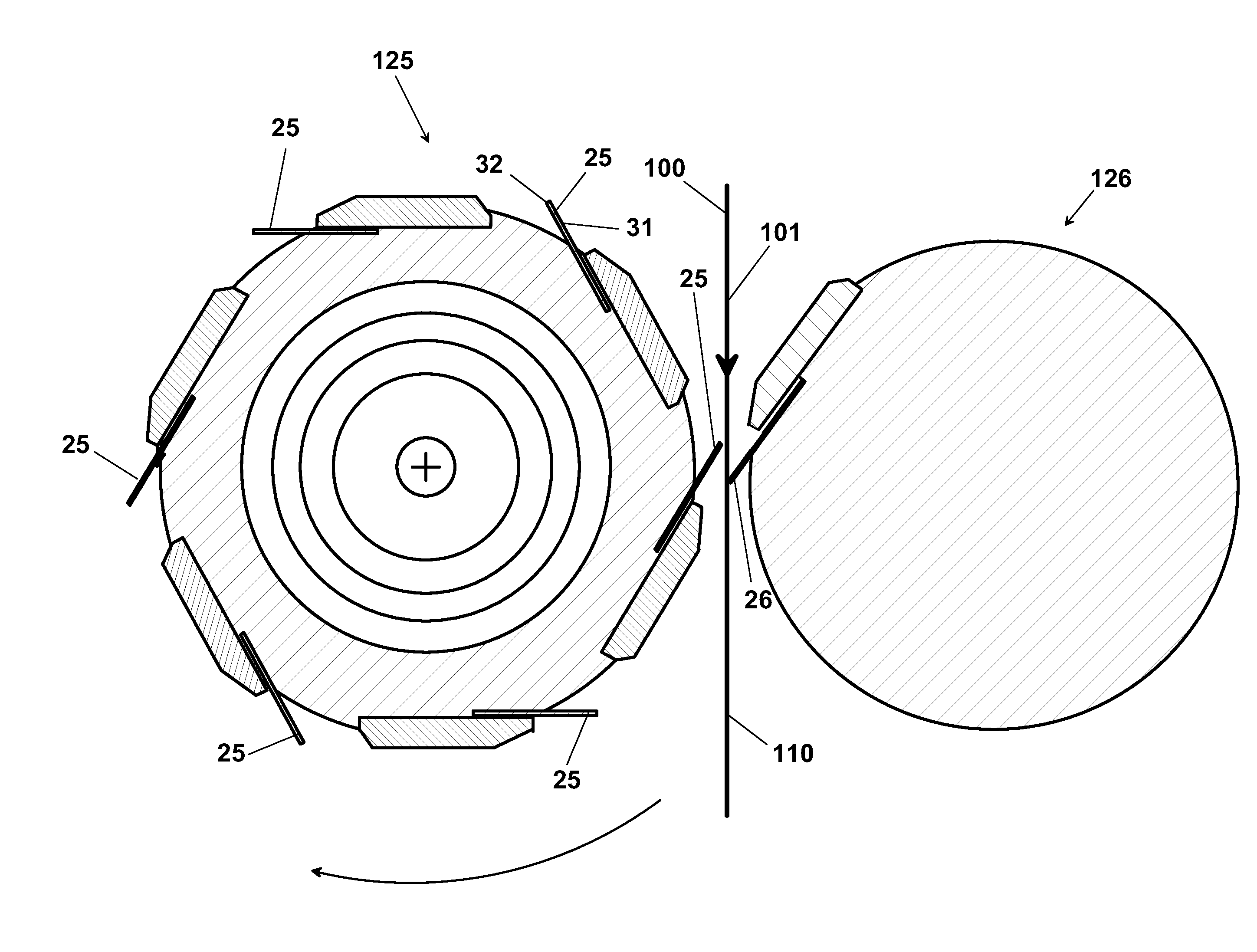

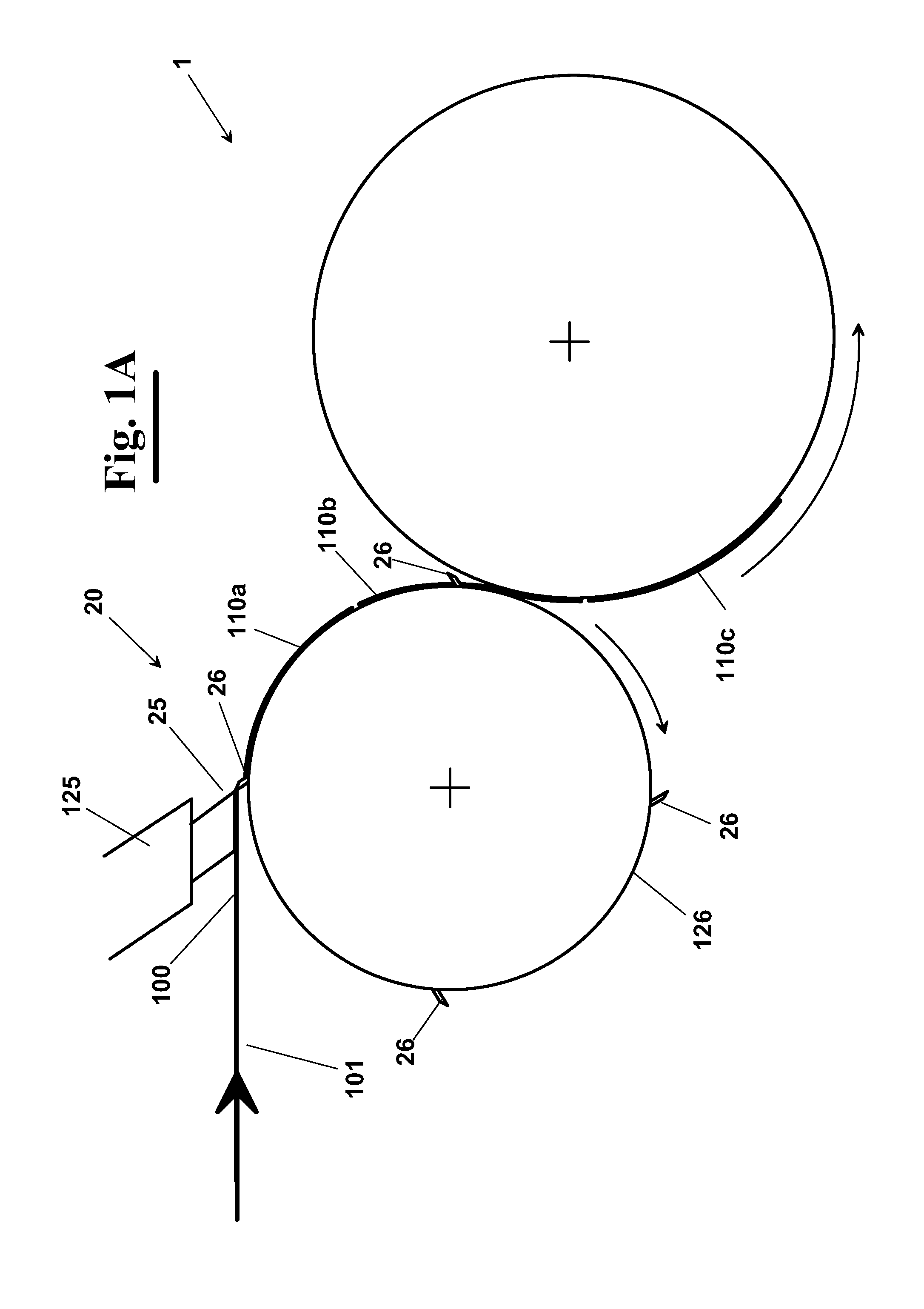

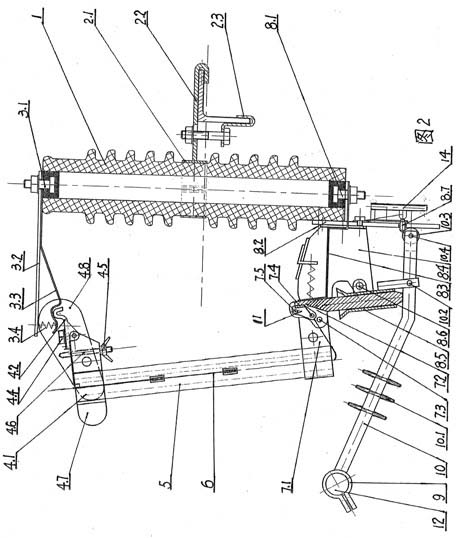

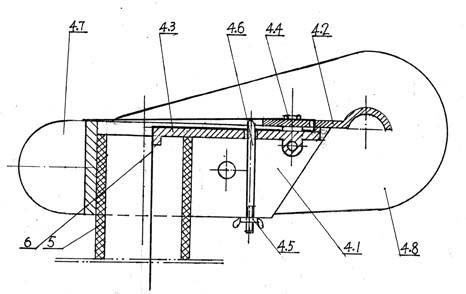

Structure of paper converting machine

InactiveUS20120245011A1Improves cutting phaseQuality improvementMechanical working/deformationStock shearing machinesPaper sheetKnife blades

A paper converting or rewinding machine provides a cutting or perforation section, equipped with at least one blade arranged to work in combination with a stationary knife to provide the division of the web of paper into a plurality of sheets of measured length. The blade can be integral to a fixed support, or alternatively to a cutting roller that rotates about a longitudinal rotation axis. The blade(s) can be a perforation blade, or a cutting blade, with helical shape, and mounted to a perforation roller. The stationary knife can be mounted to a fixed roller. The blade performs a cutting, or perforation, of the web into sheets working in combination with the stationary knife. The blades and the stationary knifes are long substantially as the width of the paper. In particular, the blade has at least one weakened portion of determined size.

Owner:MTC MACCINE TRASFORMAZIONE CARTA SRL

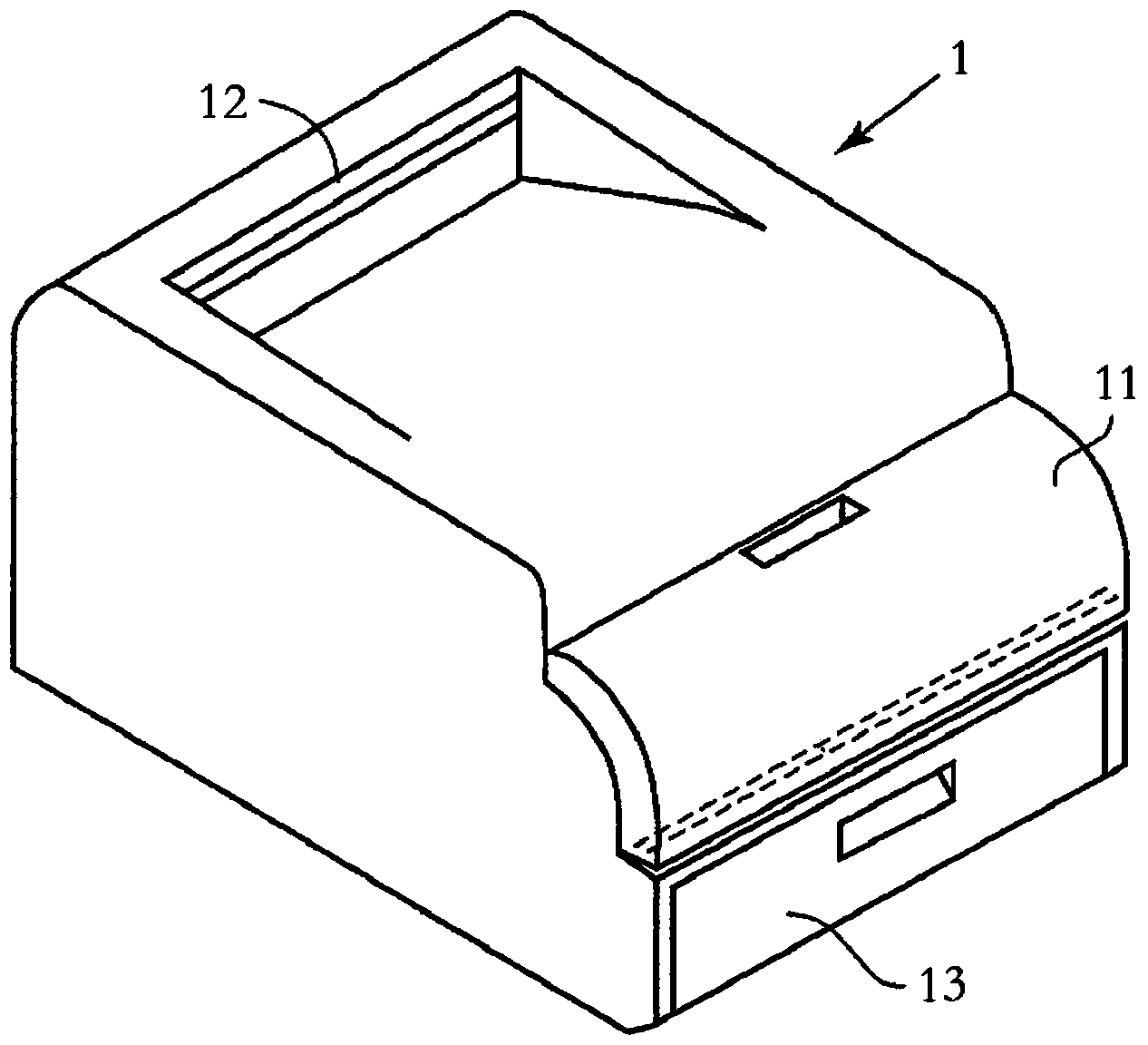

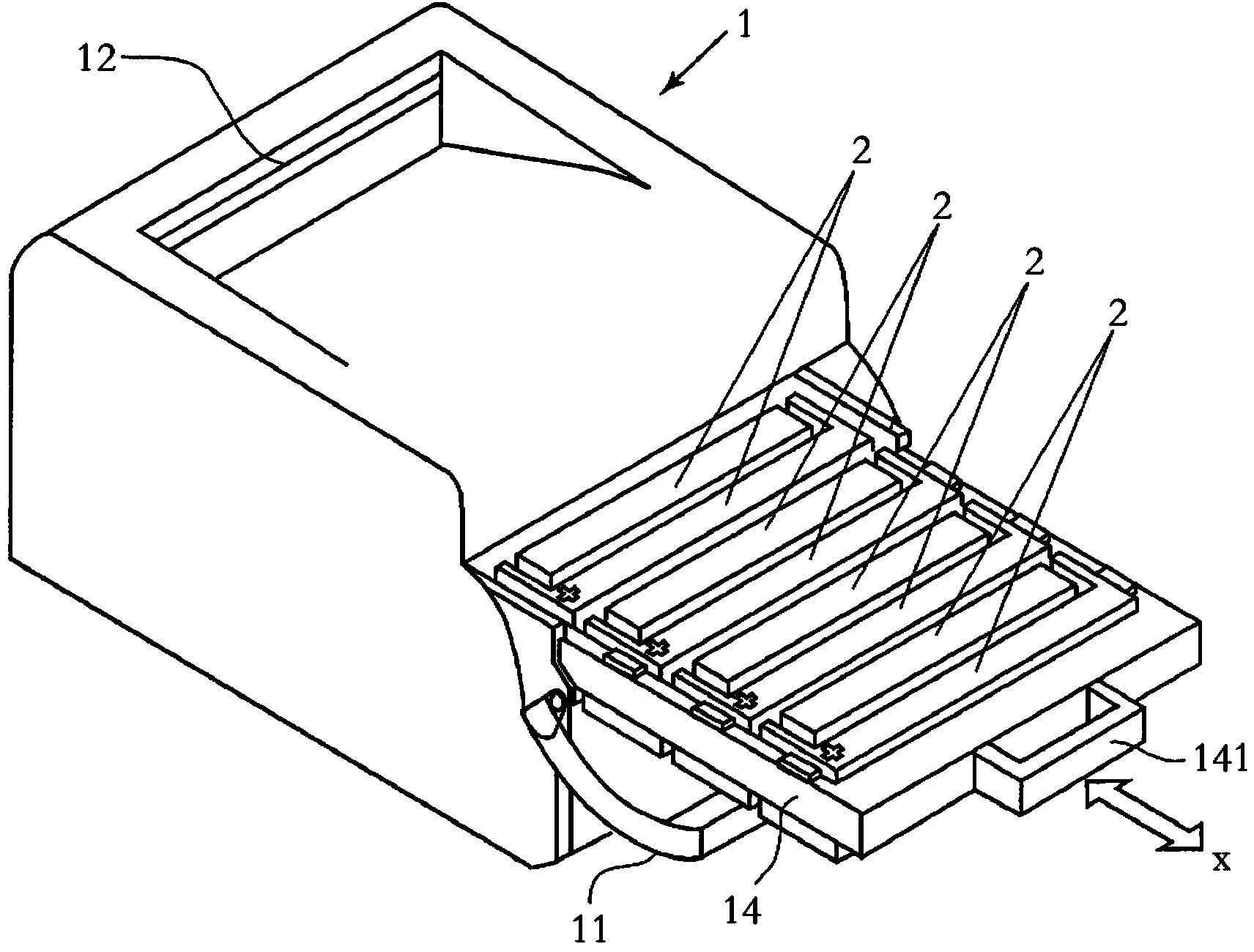

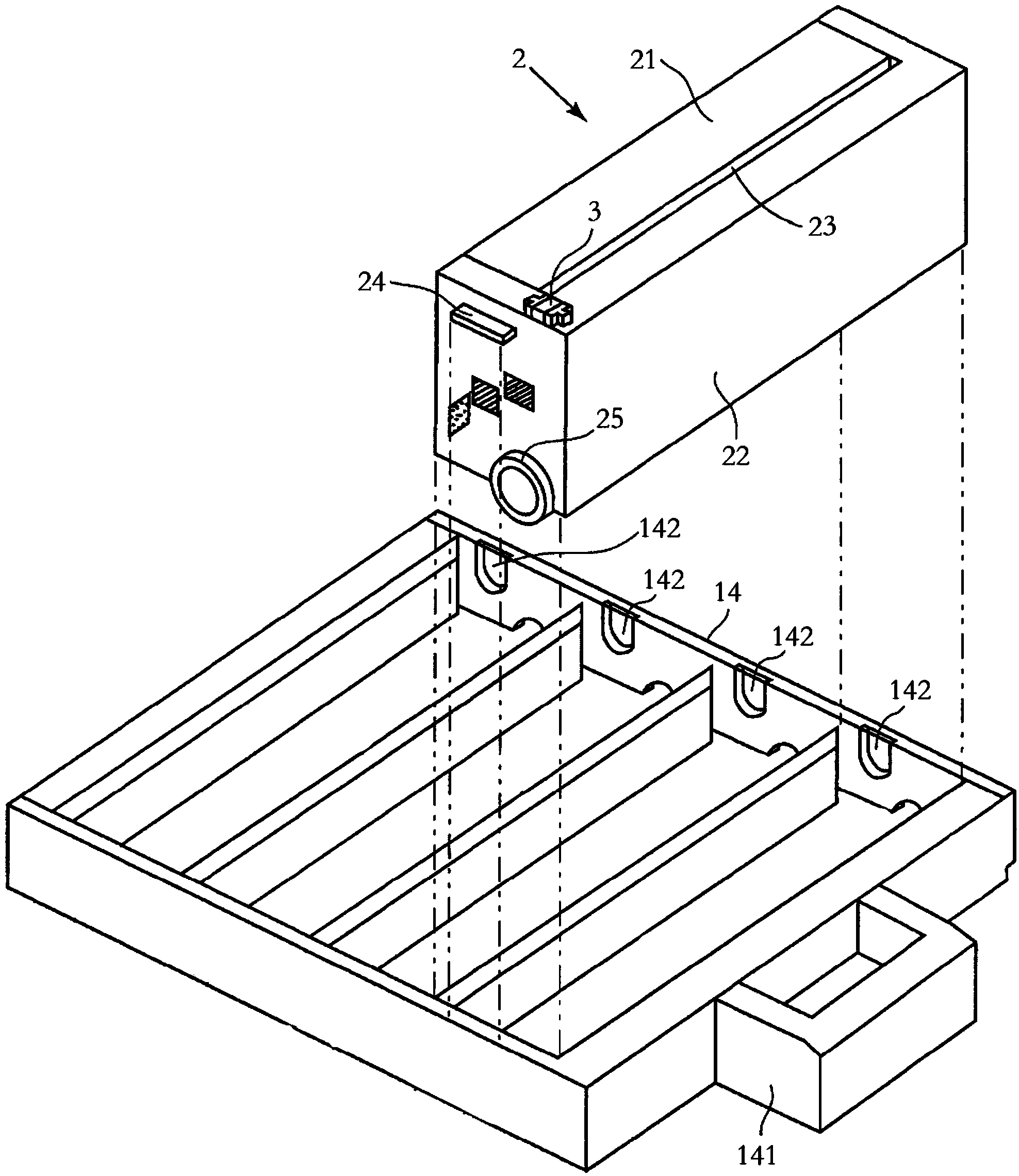

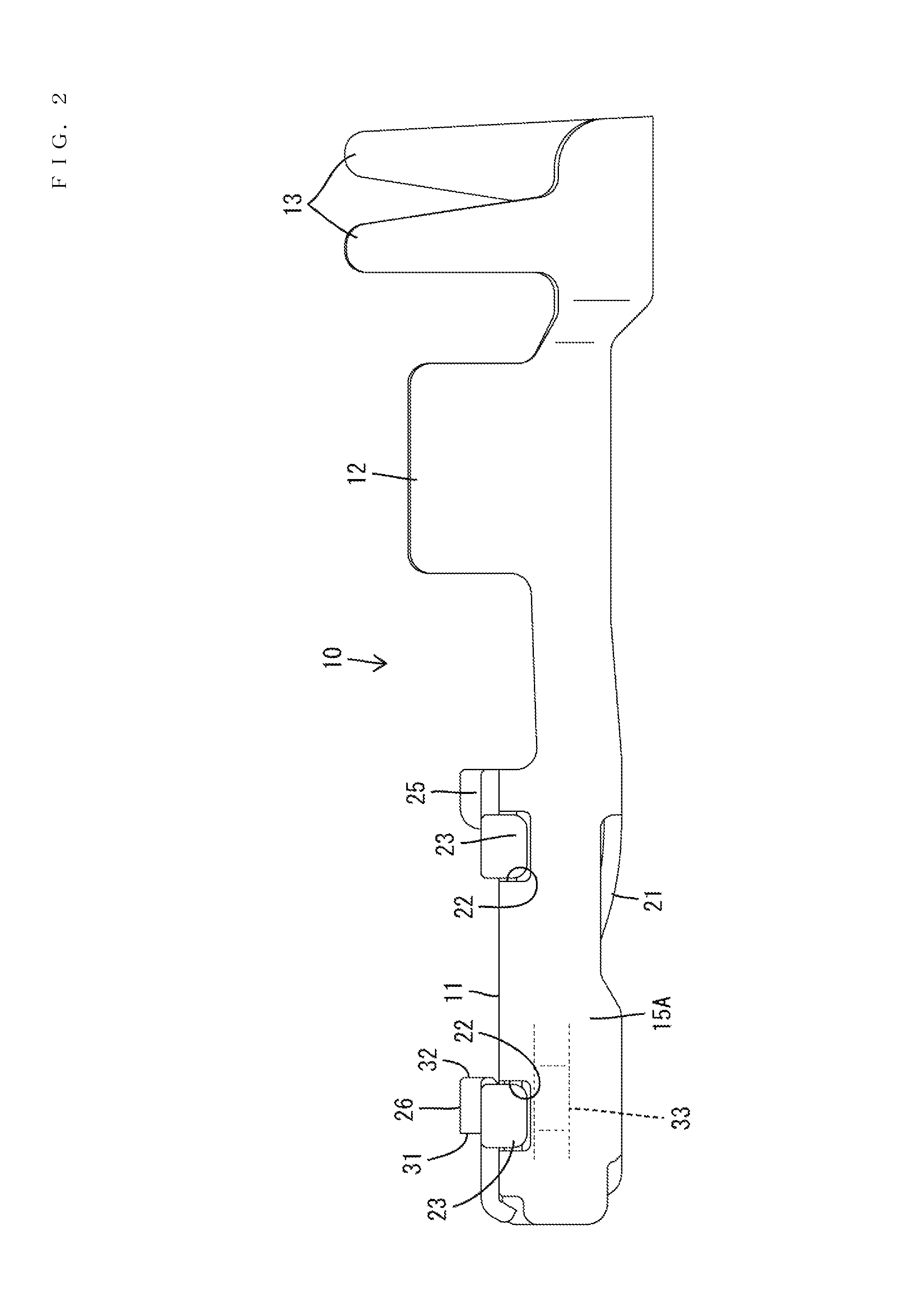

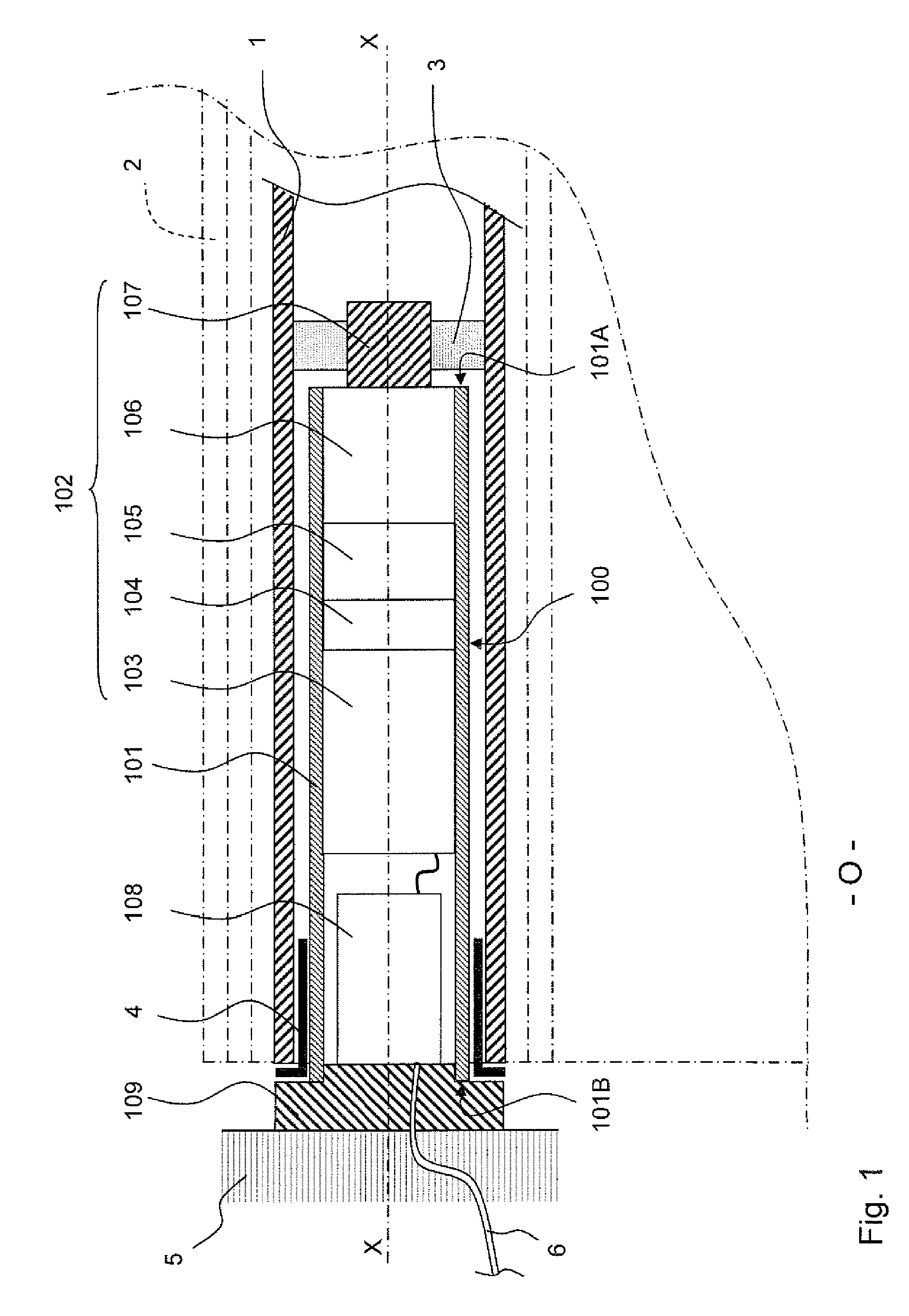

Processing box

InactiveCN103926822AImprove protectionReduce contact forceElectrography/magnetographyFault toleranceBiochemical engineering

The invention provides a processing box. The processing box comprises a developing unit and a drum unit, wherein a shell of the developing unit defines a powder cabin for storing carbon powder, a shell of the drum unit defines form a waste powder cabin for storing the waste powder, a developing roll is installed in an outlet of the powder cabin in a rotating manner, a photosensitive drum is installed in an outlet of the waste powder cabin in the rotating manner, one end of the photosensitive drum or the developing roll is provided with a driving assembly, the driving assembly comprises an installation part, a projection is arranged on the installation part, the driving assembly is installed on the first side wall of the shell in the rotating manner, a consumable chip is installed on the second side wall which is opposite to the first side wall, the consumable chip comprises a substrate, an electronic module which is arranged on the substrate and an electric connection part which is electrically connected with the electronic module, and the electric connection part is obliquely arranged on the substrate in the direction which is opposite to the first side wall. By adopting the processing box, the electric connection stability and the electric connection fault tolerance can be improved, the electric connection structure of the laser printer and the processing box is also effectively protected, and the durability of the laser printer and the processing box can be improved.

Owner:PRINT RITE UNICORN IMAGE PROD CO LTD

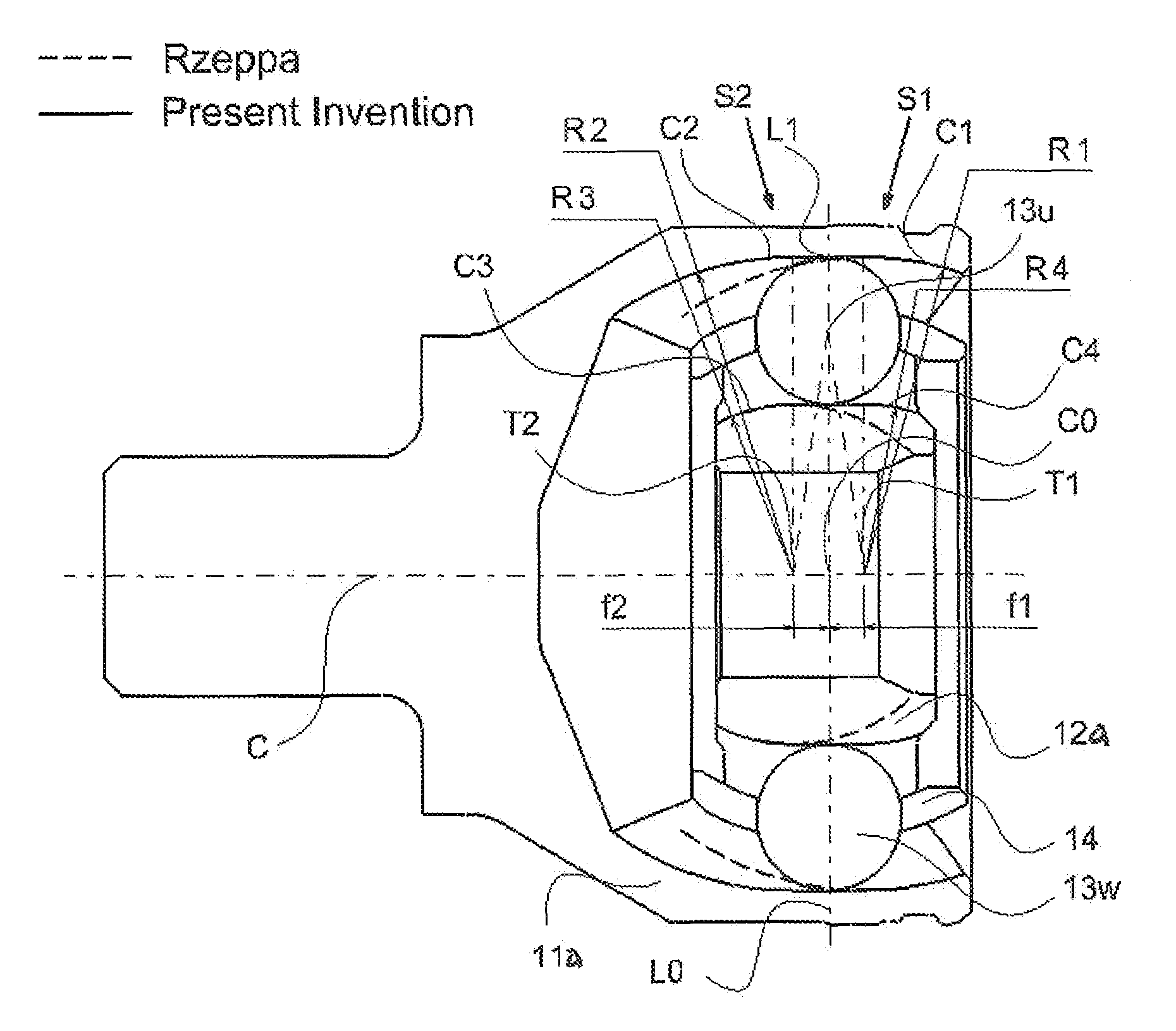

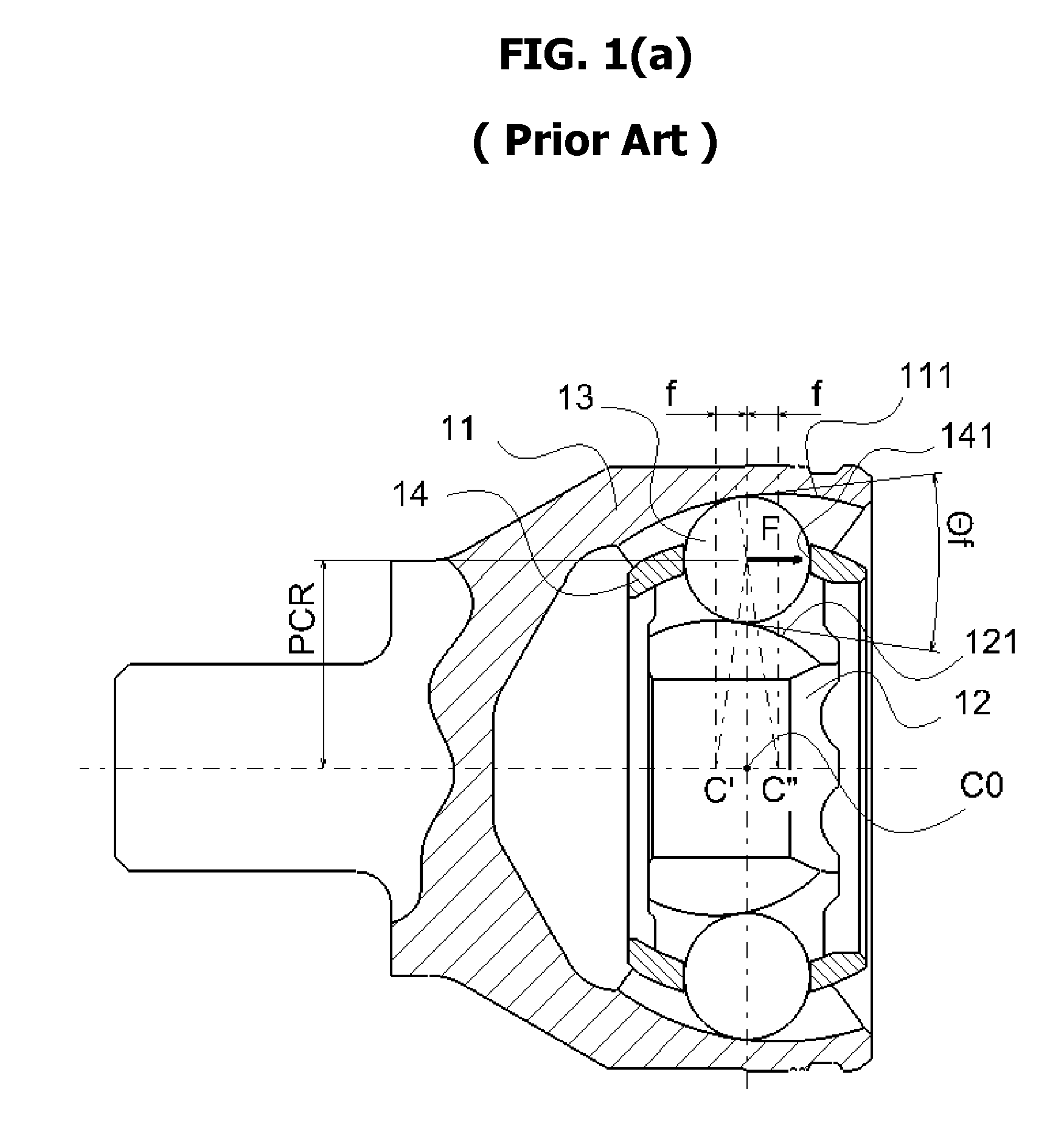

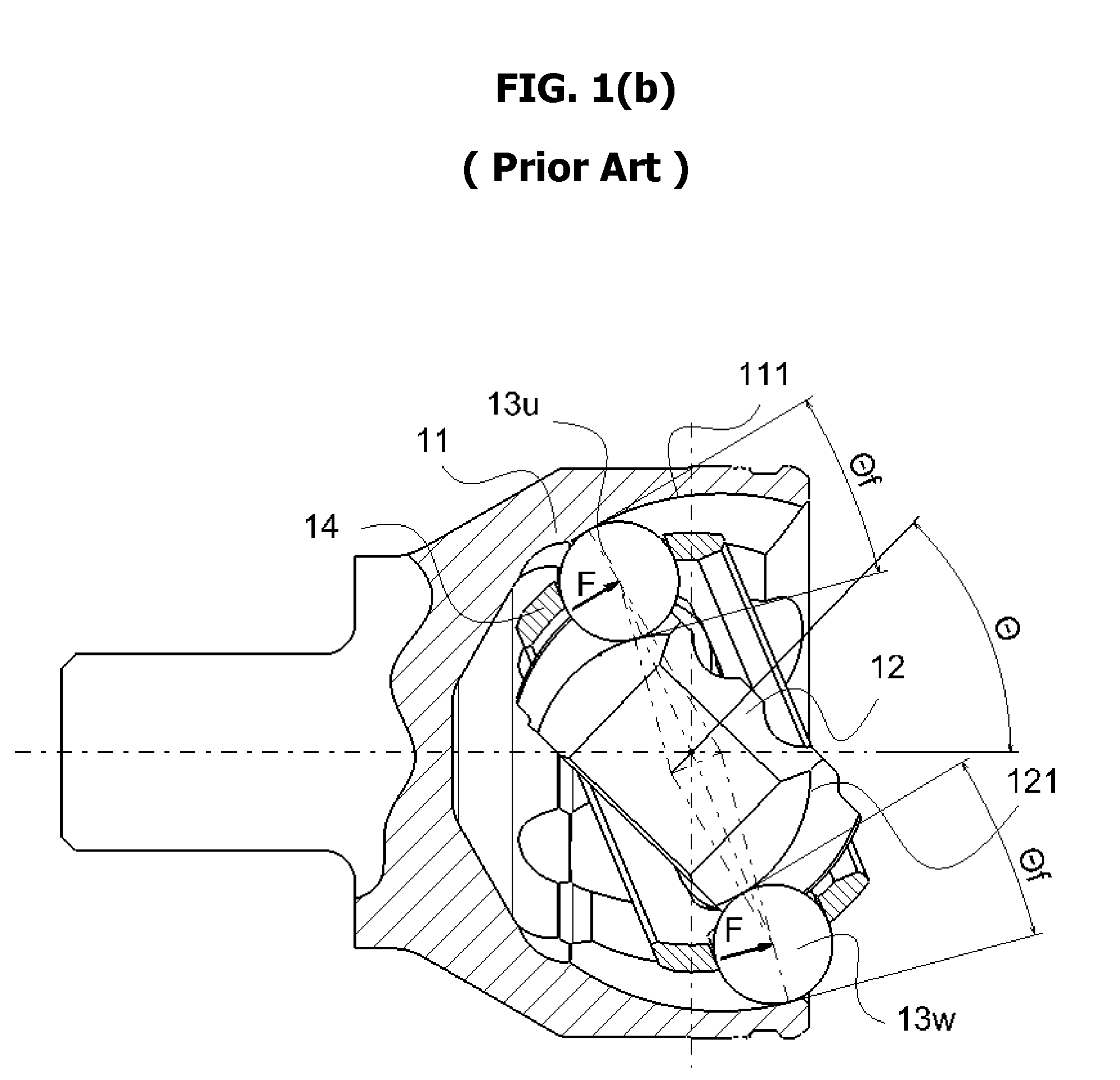

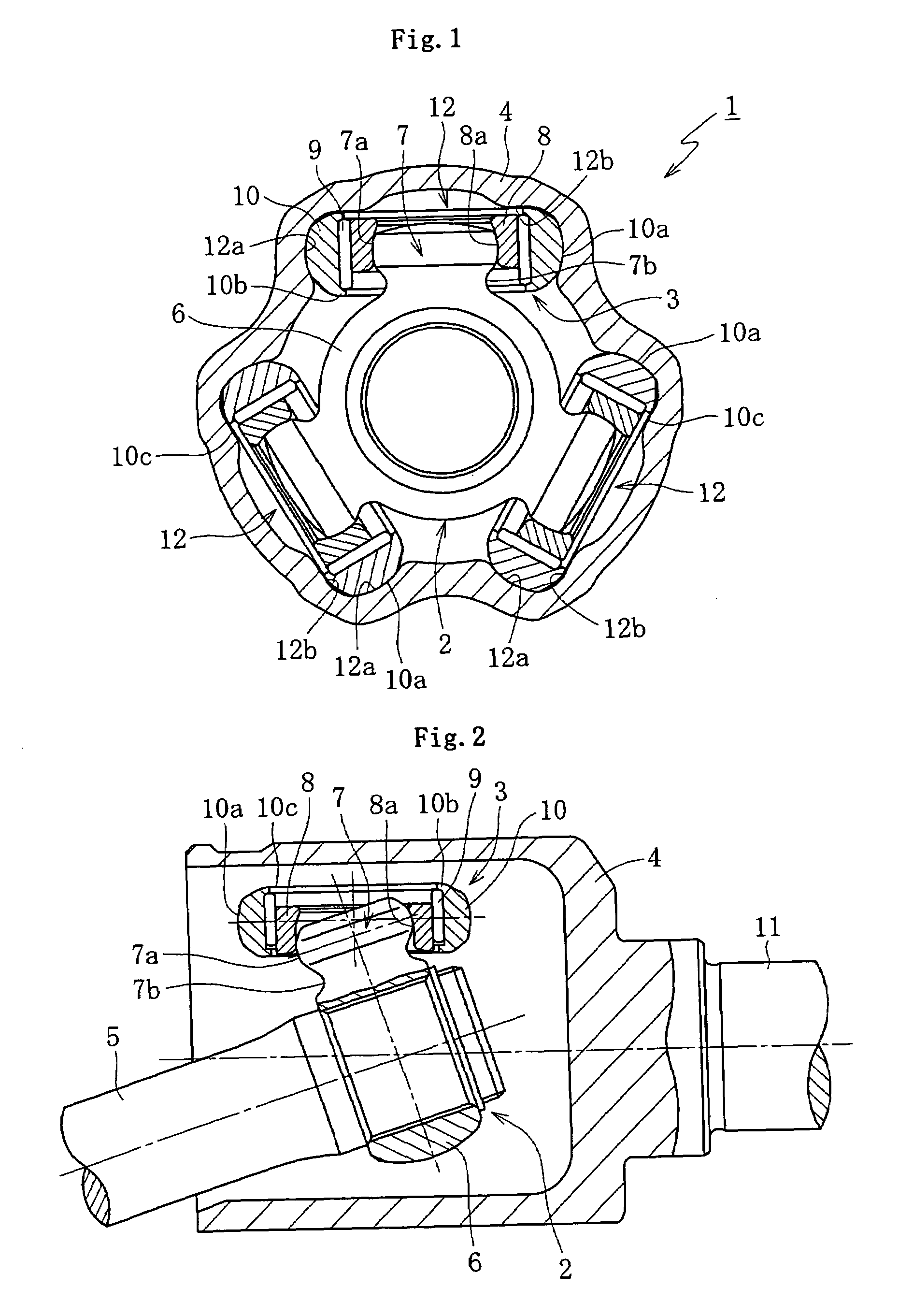

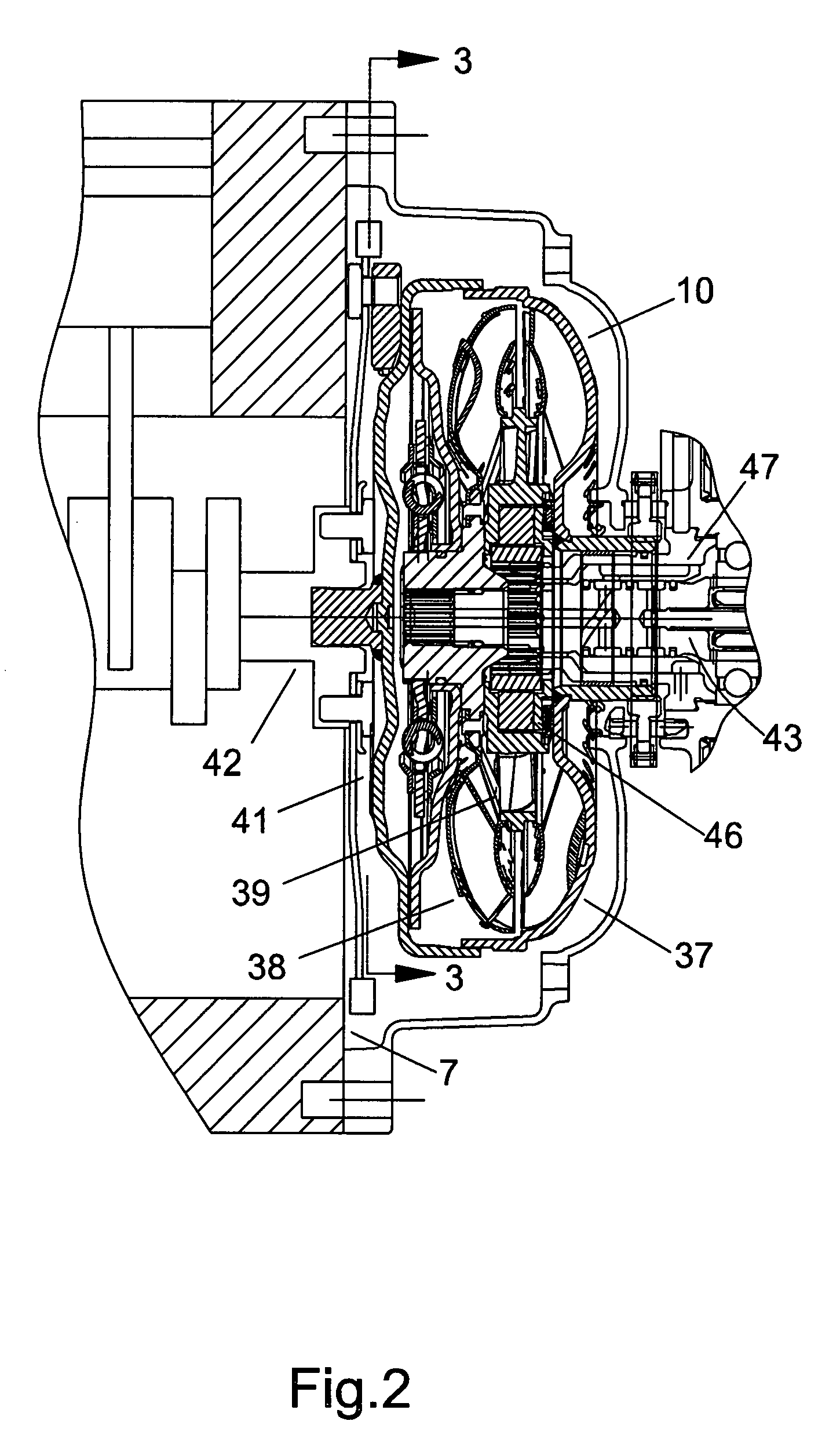

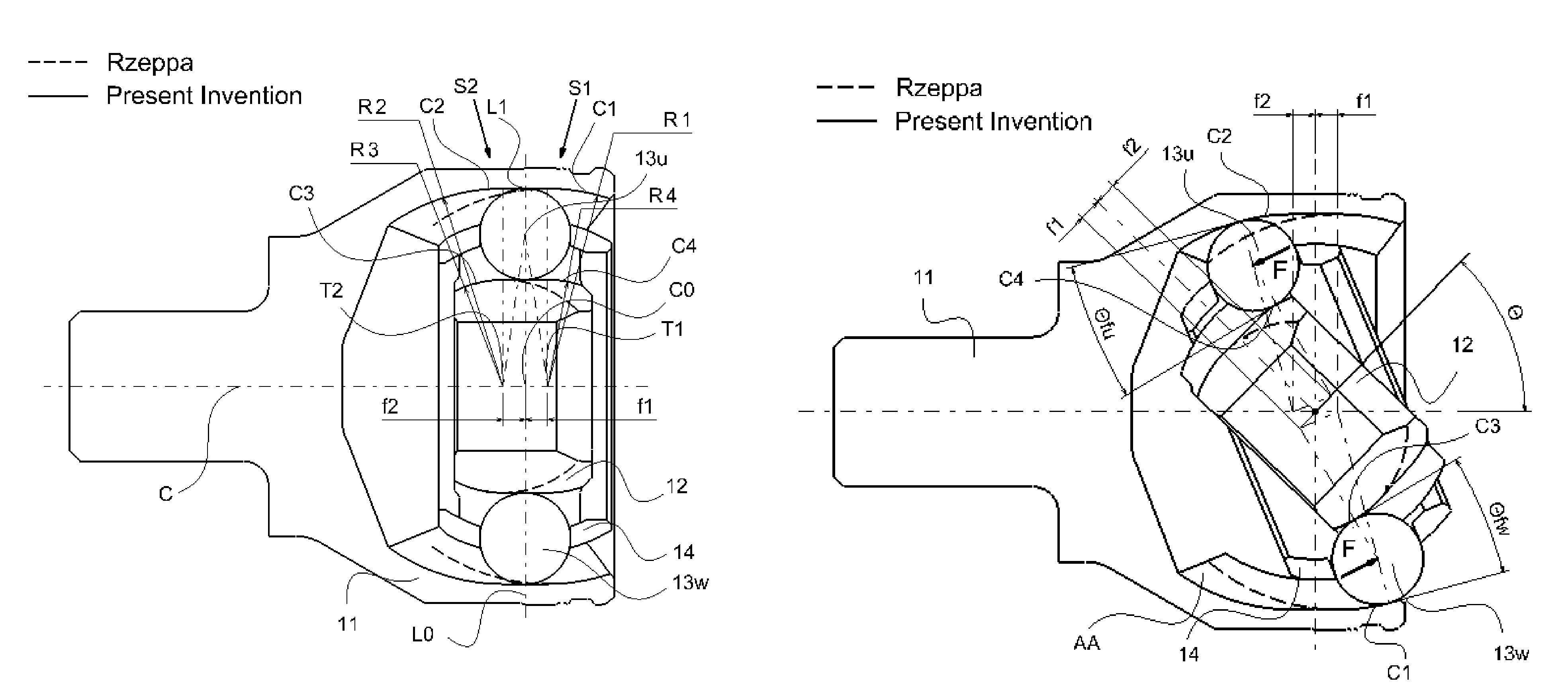

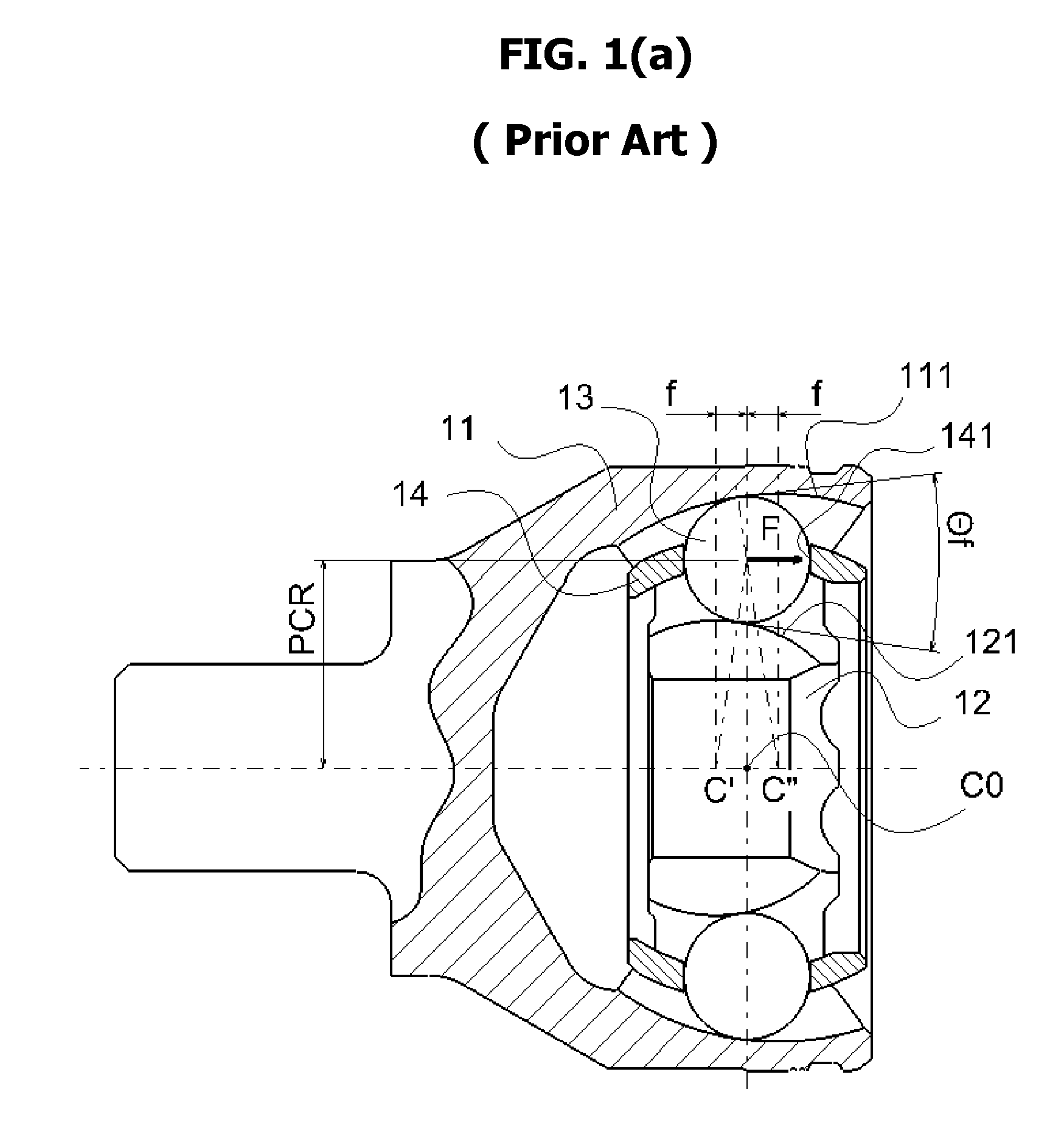

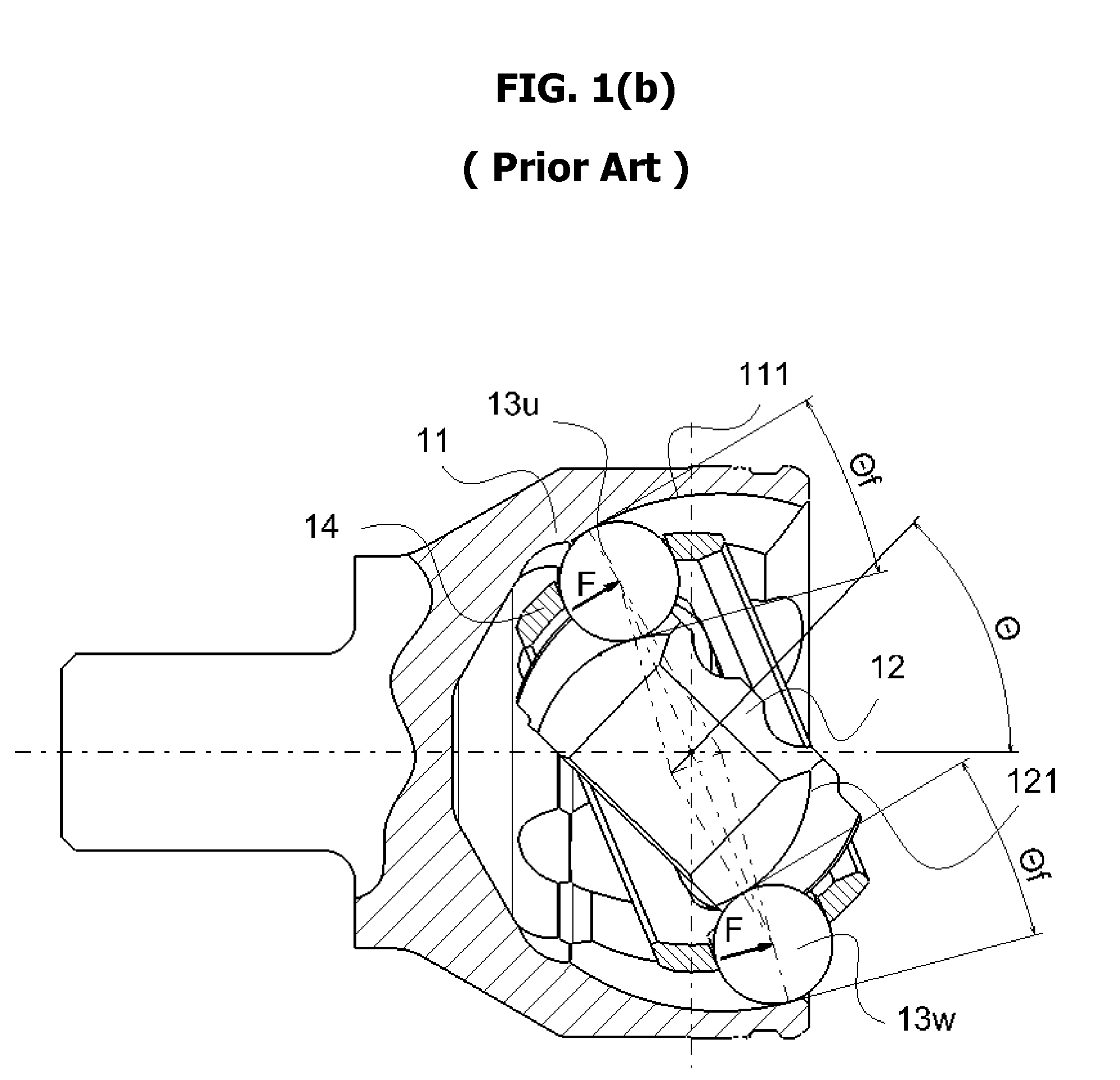

Fixed type constant velocity joint

ActiveUS8096887B2Durable in constructionSuitable strength and durabilityYielding couplingRotary machine partsLinear regionEngineering

A constant velocity joint for a drive system comprises: an outer race having a plurality of guide grooves formed in an axial direction in the inner spherical surface of the outer race; an inner race having a plurality of guide grooves formed in an axial direction in the outer spherical surface of the inner race, said guide grooves of the outer race and the inner race together forming a plurality of ball guide tracks; a plurality of balls disposed in the ball guide tracks; and a cage installed between the inner spherical surface of the outer race and the outer spherical surface of the inner race, said cage having a plurality of windows for retaining the balls therein. Each guide groove of the outer race is shaped to have a longitudinal cross section formed with two circular regions with different centers, a first circular region disposed at a first lateral side of the outer race and a second circular region disposed at a second lateral side of the outer race, and a linear region tangentially extending between these two circular regions, and each guide groove of the inner race is shaped to have a longitudinal cross section formed with two circular regions with different centers, a first circular region disposed at a first lateral side of the inner race and a second circular region disposed at a second lateral side of the inner race, and a linear region tangentially extending between these two circular regions.

Owner:WIA CORP

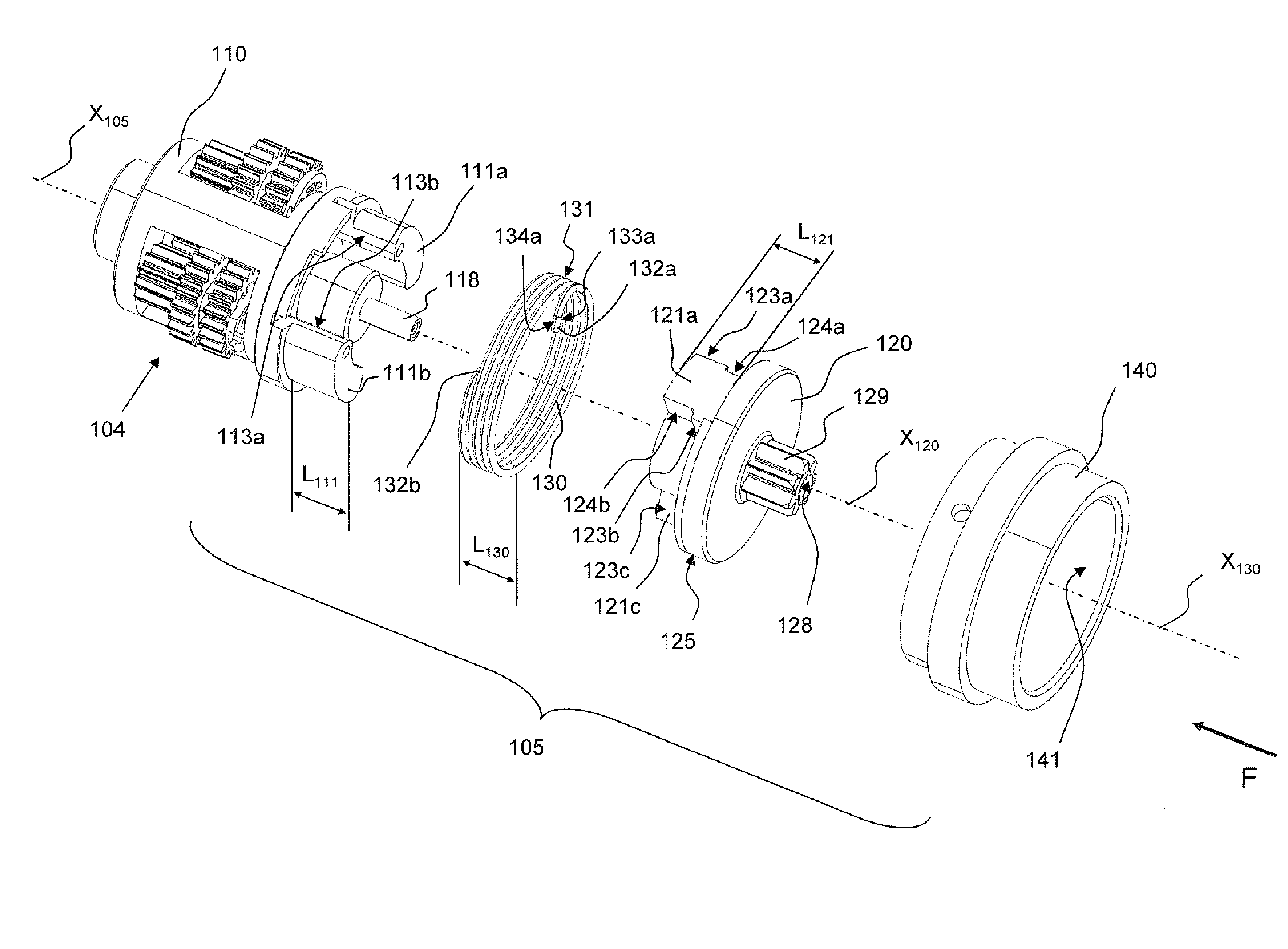

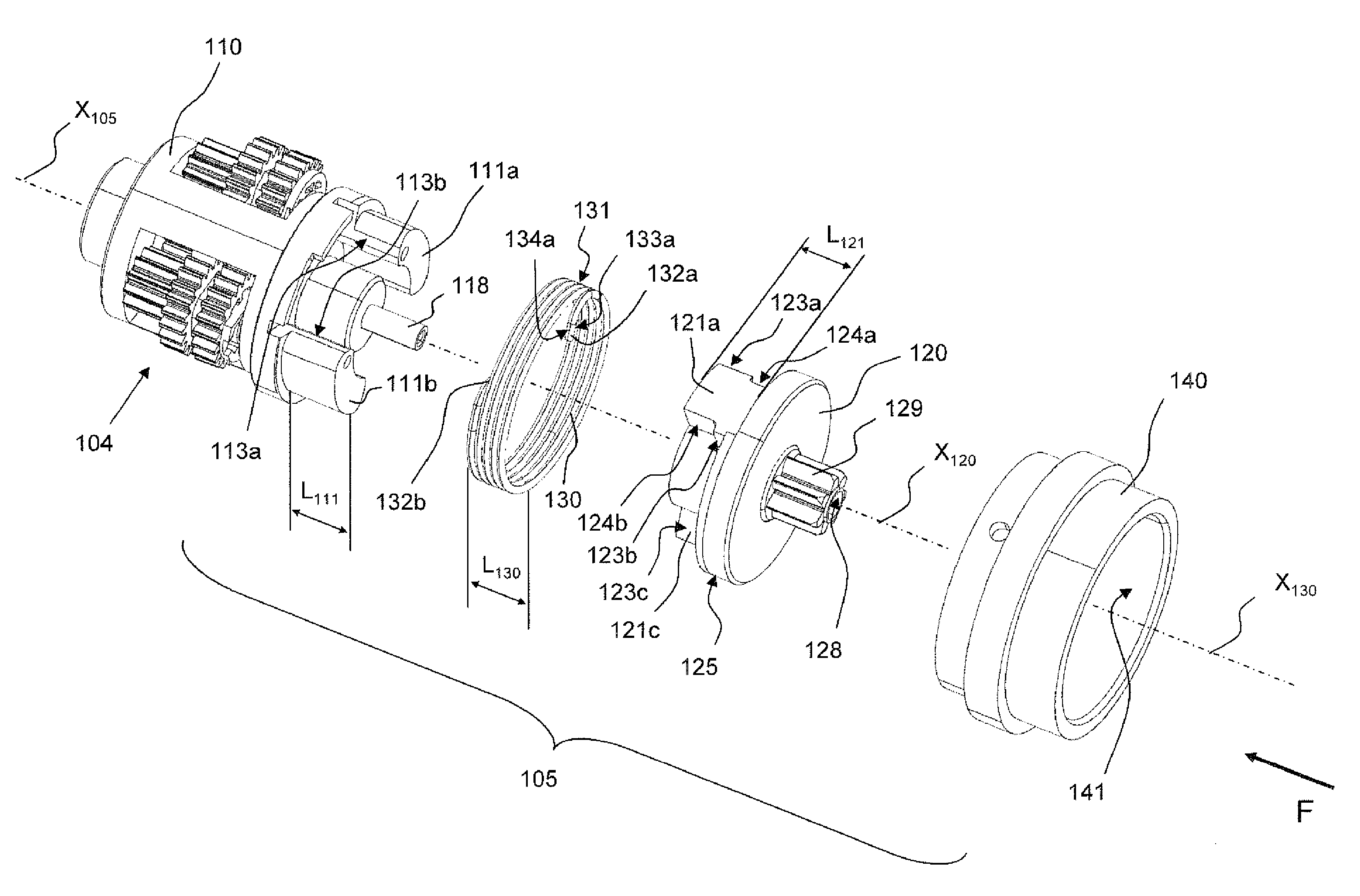

Electric actuator for driving a home-automation screen

ActiveUS20100320855A1Increase contact forceReduce contact forceDoor/window protective devicesMechanical energy handlingContact forceEngineering

Owner:SOMFY ACTIVITES SA

System and method for monitoring mechanical seals

ActiveUS8527214B2Accurate measurementReduce contact forceNoise figure or signal-to-noise ratio measurementFrequency analysisMonitoring systemRelative motion

A mechanical seal monitoring system and method that measure the wear of seal faces of a mechanical seal where the mechanical seal seals a rotating machine portion from another portion of the machine. The system preferably uses a wear probe movable relative to a rotating seal component so that the wear probe can contact the rotating component. The wear of the seal is preferably determined by the relative movement that is required for the wear probe to contact the rotating component. Preferably, stress waves induced by the rubbing between the probe and the rotating component are detected by a stress-wave sensor, processed by a signal processor, and either displayed to the user numerically or reported to a monitoring computer. A signal intensity comparison method is preferably used to make the detection process insensitive to background noise generated by sources other than the contact of the wear probe and the rotating component.

Owner:HORAK MICHAEL N

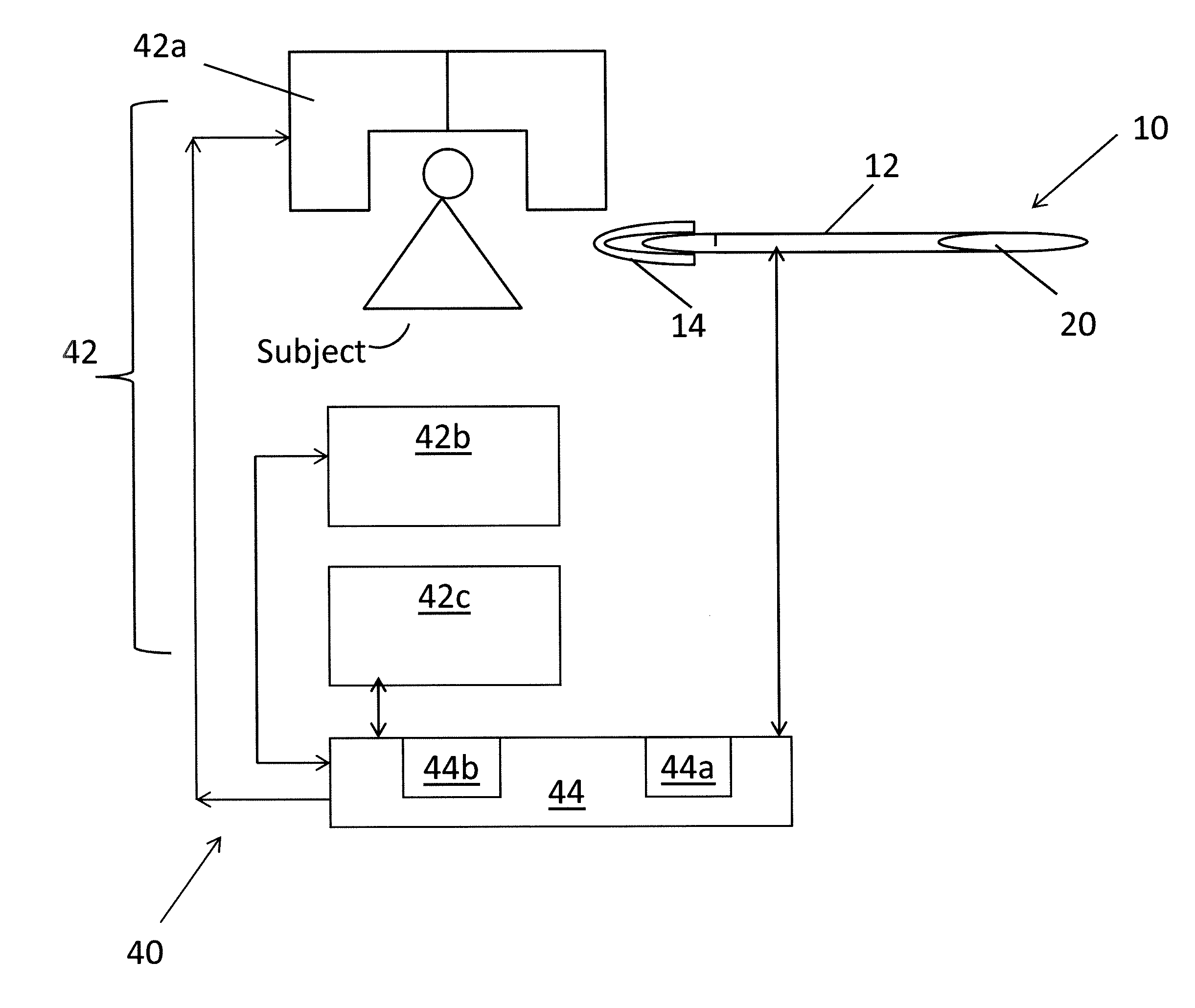

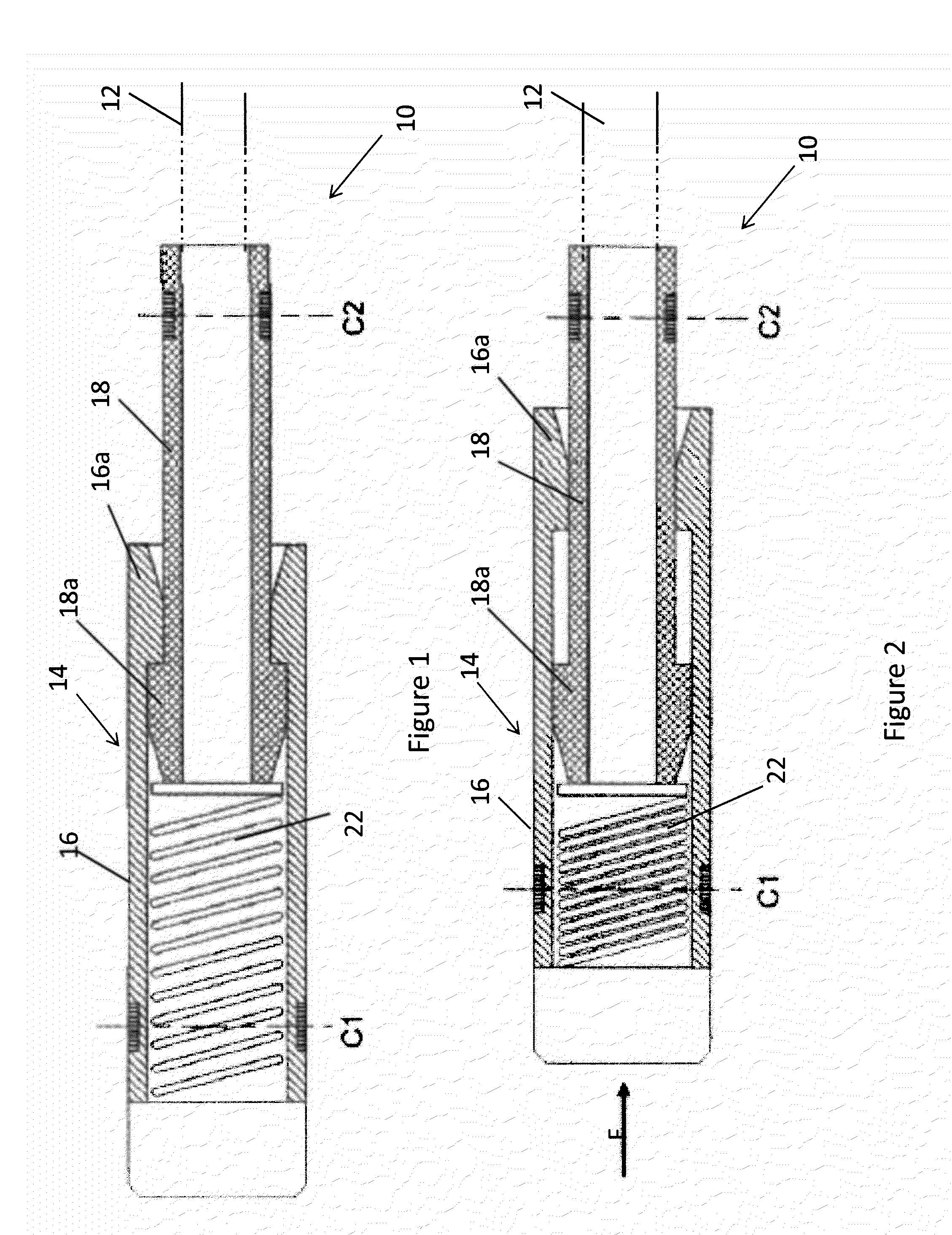

Compressable catheter tip with image-based force sensing

ActiveUS20140018665A1Reduce contact forceHigh riskCatheterSurgical instrument detailsContact forceImaging technique

A catheter (10) comprising a catheter tip (14) that is adapted to have deflection of an associated spring (22) detected by imaging techniques and to have that deflection be translated into an estimation of the tip (14) contact force.

Owner:SIEMENS HEALTHCARE GMBH

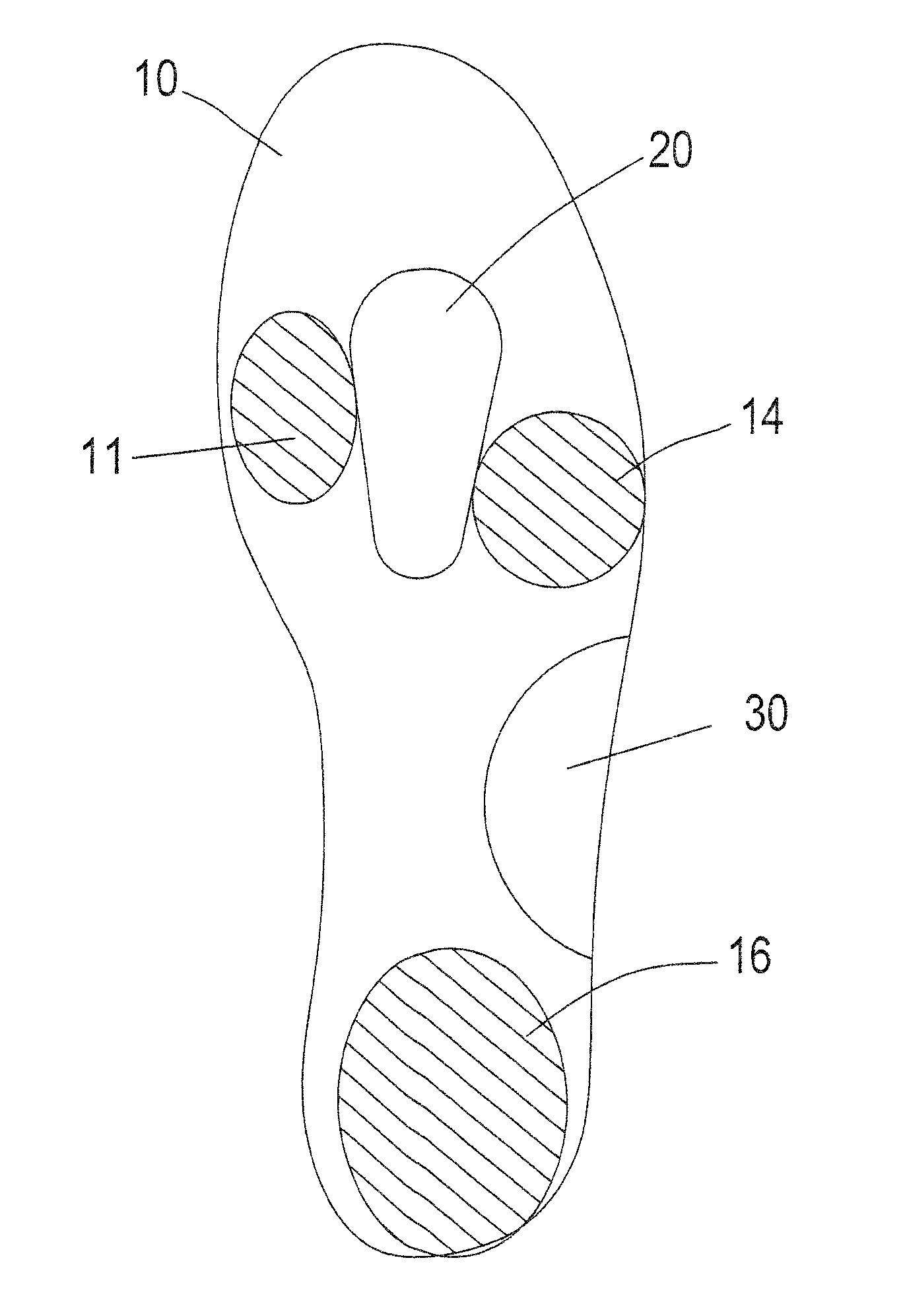

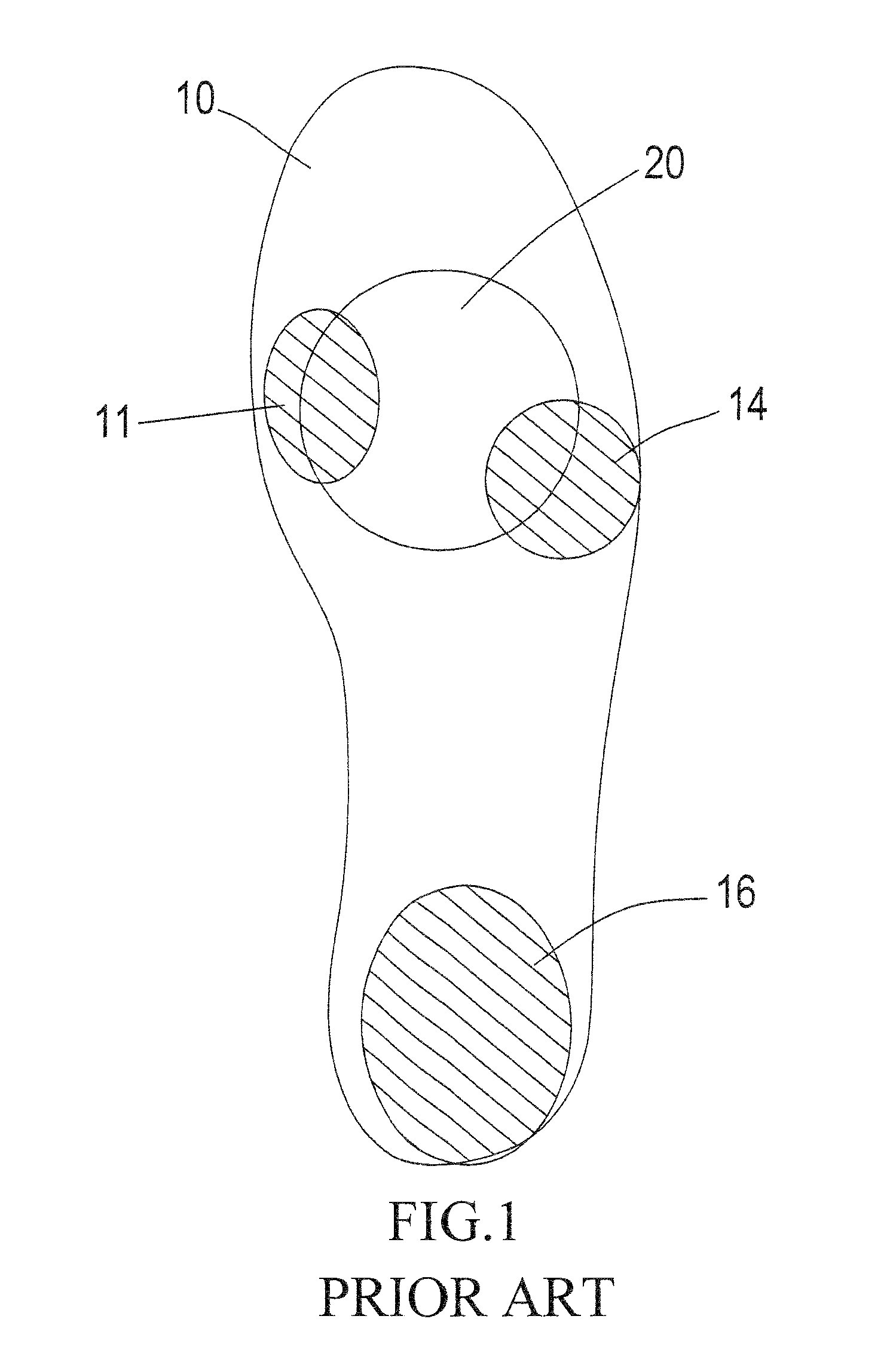

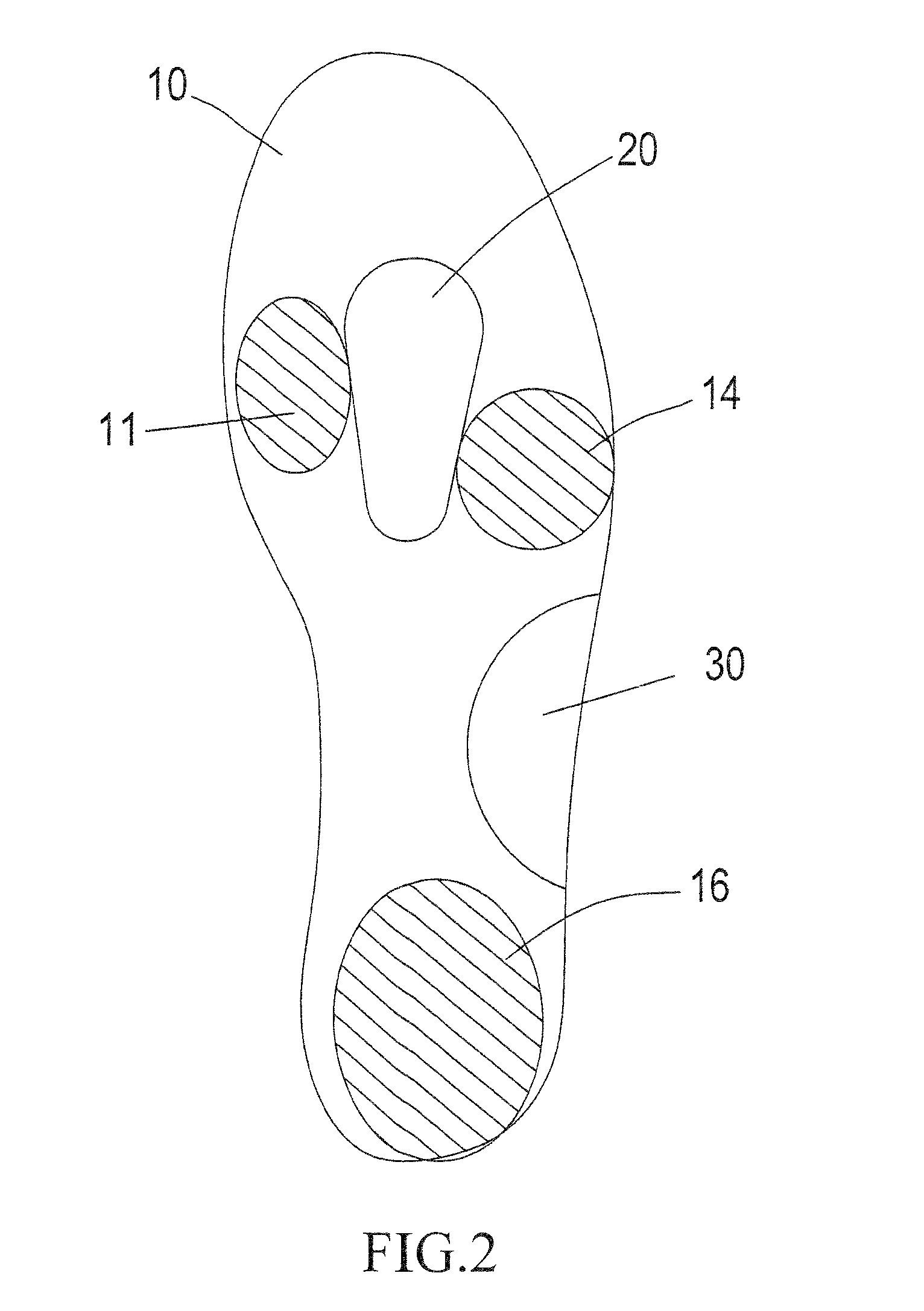

Body balance device

InactiveUS9055781B2Little strengthEasily self-adjust gravity center of bodySolesInsolesCushioningBody balance

The present invention relates to a body balance device, which includes a main body made of a cushioning material. The main body includes a first metatarsal bone section, a fourth metatarsal bone section, and a foot heel section. The main body forms a primary adjustment structure located between the first metatarsal bone section and the fourth metatarsal bone section and a secondary adjustment structure located between the fourth metatarsal bone section and the foot heel section and corresponding to outside of the main body. Both adjustment structures are formed with a structure of through hole or cavity in which a soft material is selectively embedded to allow the human body to reach a balanced condition when standing or walking so as to improve the discomfort of bones and muscles caused by long standing or walking.

Owner:VARITHOTICS

Reversible fulcrum for a strut

InactiveUS6193028B1Eliminate torqueReduce contact forceRail brake actuationEngineeringTension member

A strut having a reversible fulcrum, which can be changed, from a left strut to a right strut, for using in brake beams of the type comprising; a compression member, a "V" shaped tension member having a central apex coupled to the ends of the compression member; a brake shoe linked to the each end of the compression member; and a strut, wherein the strut having a reversible fulcrum comprising: a fulcrum body having a first end and a second end, a central slot passing through a central portion of the fulcrum body at a side portion thereof and an off-center pinhole passing through the fulcrum body at a central portion of a front portion of the fulcrum body; a hollow bell joint, having a dome rotary coupled to a central portion of the tension member and a tubular open end at which the first end of the fulcrum body is coupled; and a crown joint having a first end including an internal annular border, rotary receiving the second end of the fulcrum body, and a second end having two opposite holding skirts to be coupled to the central apex of the tension member.

Owner:STUCKI DE MEXICO S DE R L DE C V

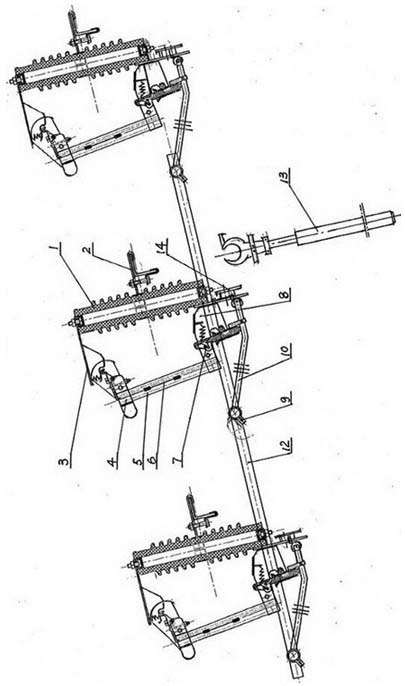

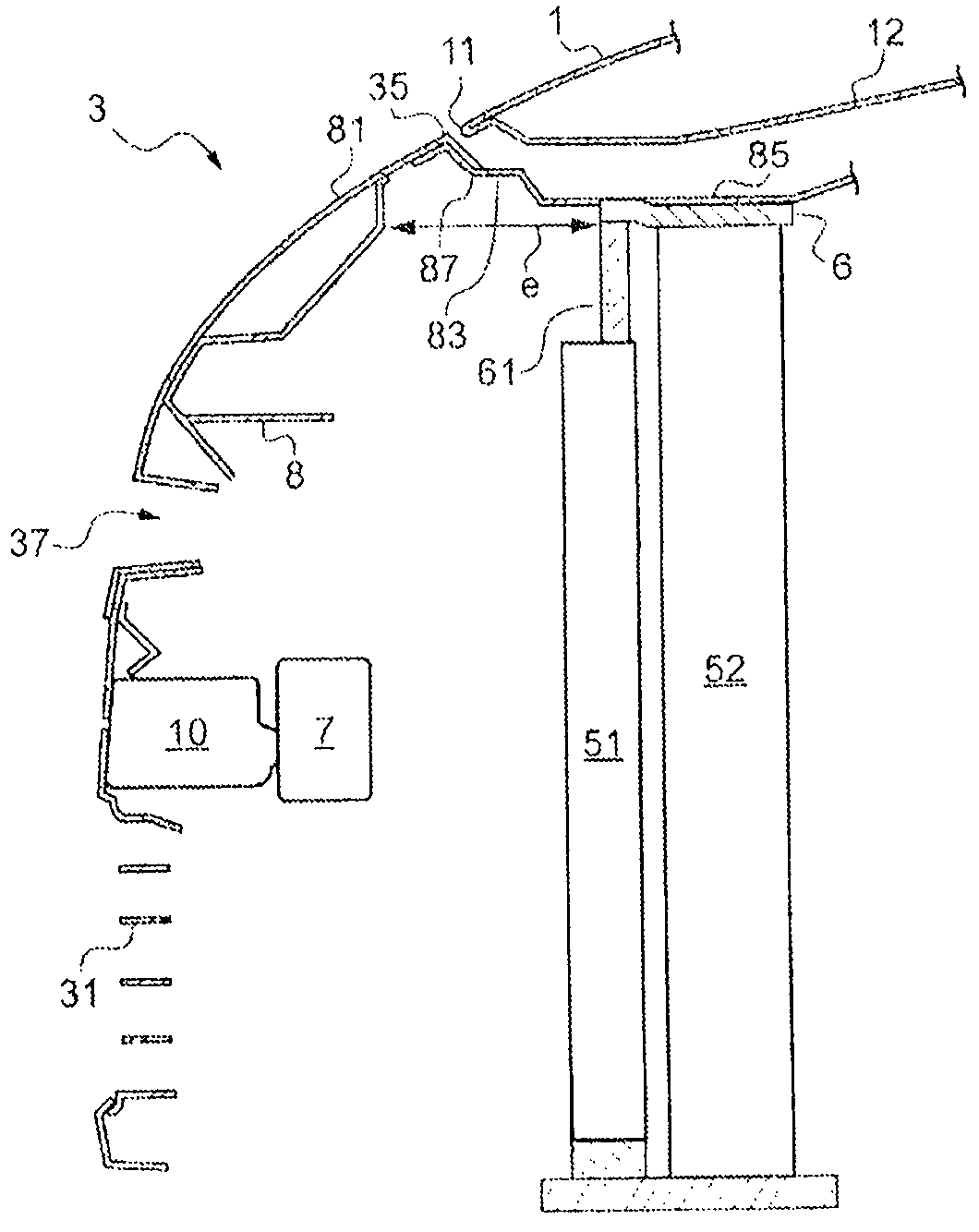

Semi-automatic three-phase synchronous drop-out fuse

InactiveCN102360998AImprove efficiencyReduce labor intensityEmergency protective devicesTransformerSemi automatic

The invention relates to a semi-automatic three-phase synchronous drop-out fuse, and relates to electric power appliances. The fuse comprises three sets of bar-shaped ceramic column insulators 1, an installation plate assembly 2, an upper static contact assembly 3, an upper movable contact assembly 4, an arc extinction pipe 5, a fuse wire 6, a lower movable contact assembly 7, a lower static contact assembly 8, a connecting rod fixed clip 9, a connecting rod push rod 10, a drop-out buckle 11, a connecting rod 12, a link bar 13 with a hand grip and a windproof wind lock 14. In the semi-automatic three-phase synchronous drop-out fuse, structures of an upper movable contact, a lower movable contact, an upper static contact and a lower static contact are improved, and the service life of the fuse wire is prolonged, so that the fuse wire is durable in use; the fuse is provided with a fuse wire box and the windproof wind lock, a push-up three-phase automatic switching-in structure is simpler, more compact, easily and quickly switched in, reasonable in design, easy to manufacture, low in cost and convenient to use, and the aims that three phases drop out synchronously when one phase is fused, and the three phases are switched in synchronously when a switch is pushed up once can be fulfilled; and the semi-automatic three-phase synchronous drop-out fuse can be widely applied to all outdoor transformers.

Owner:余谋幸 +1

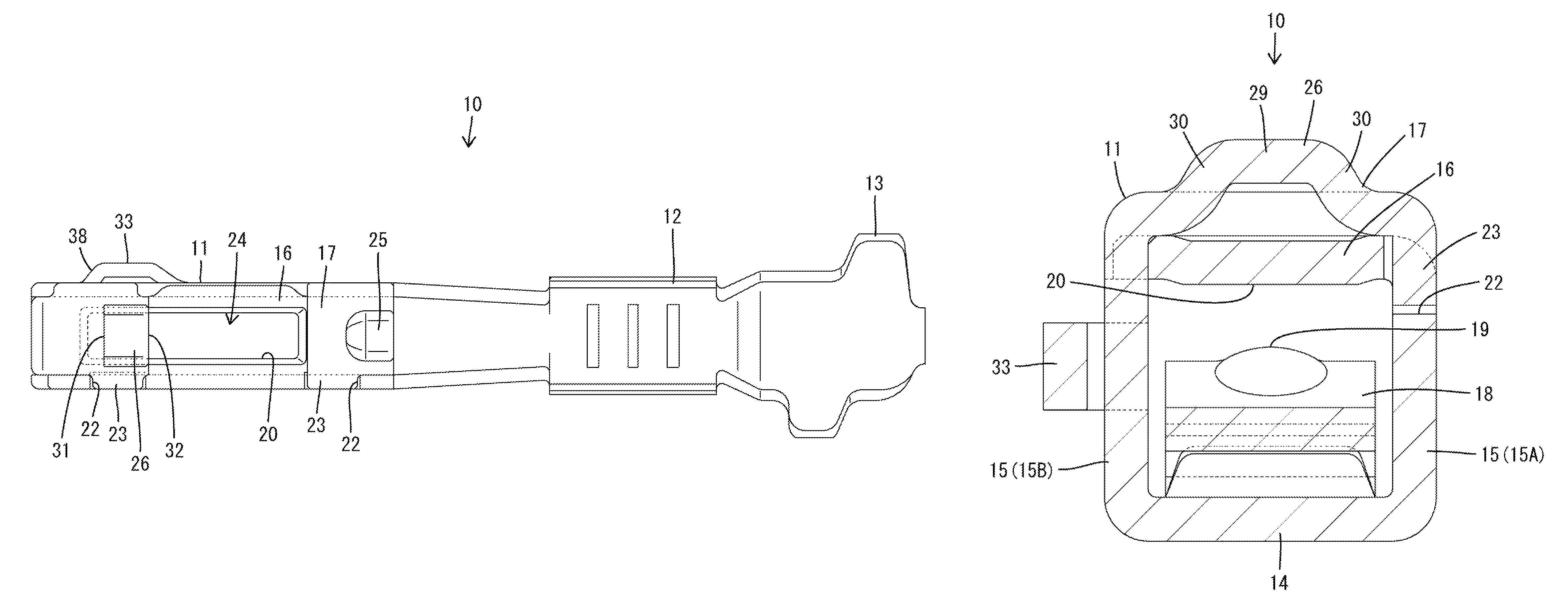

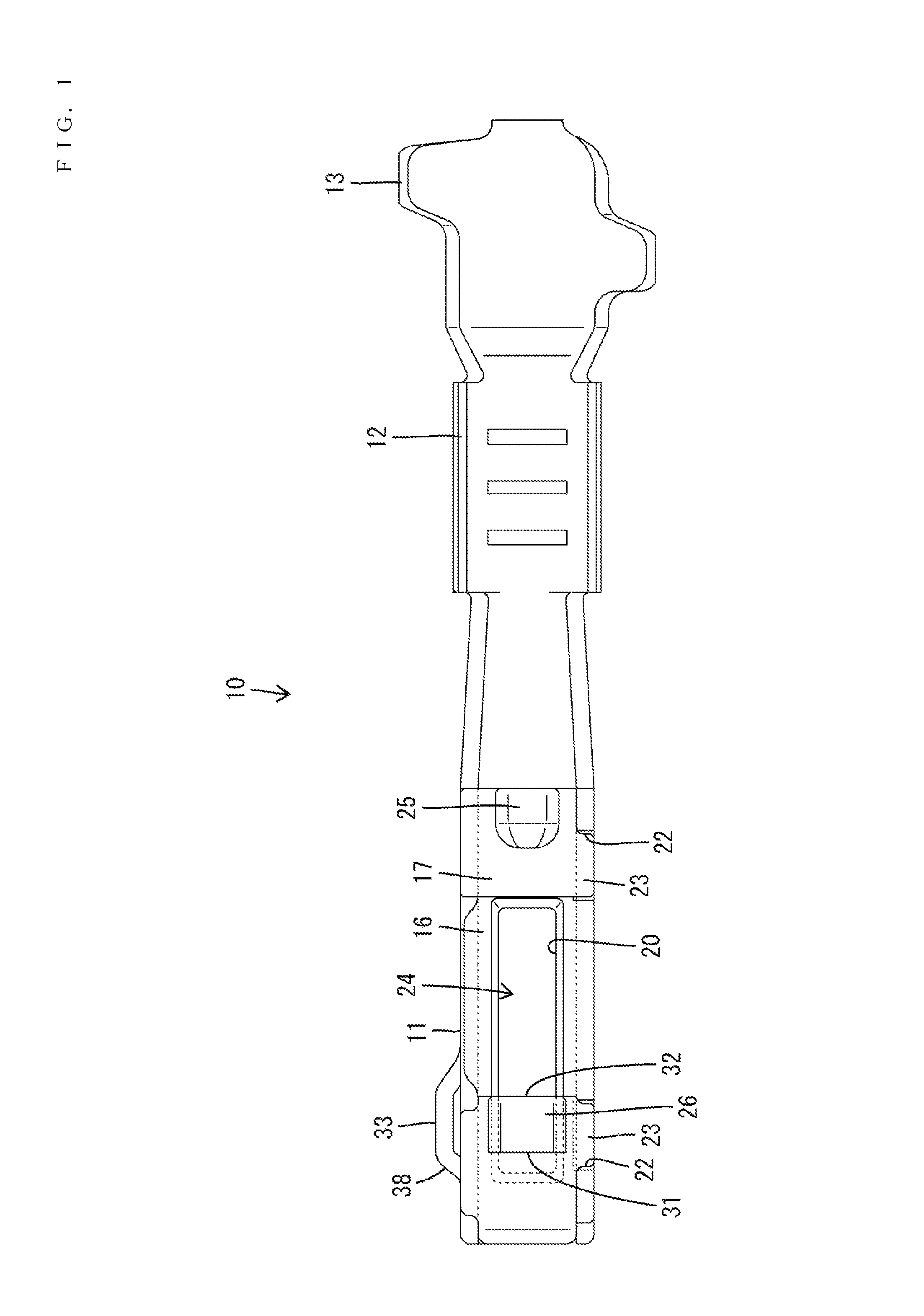

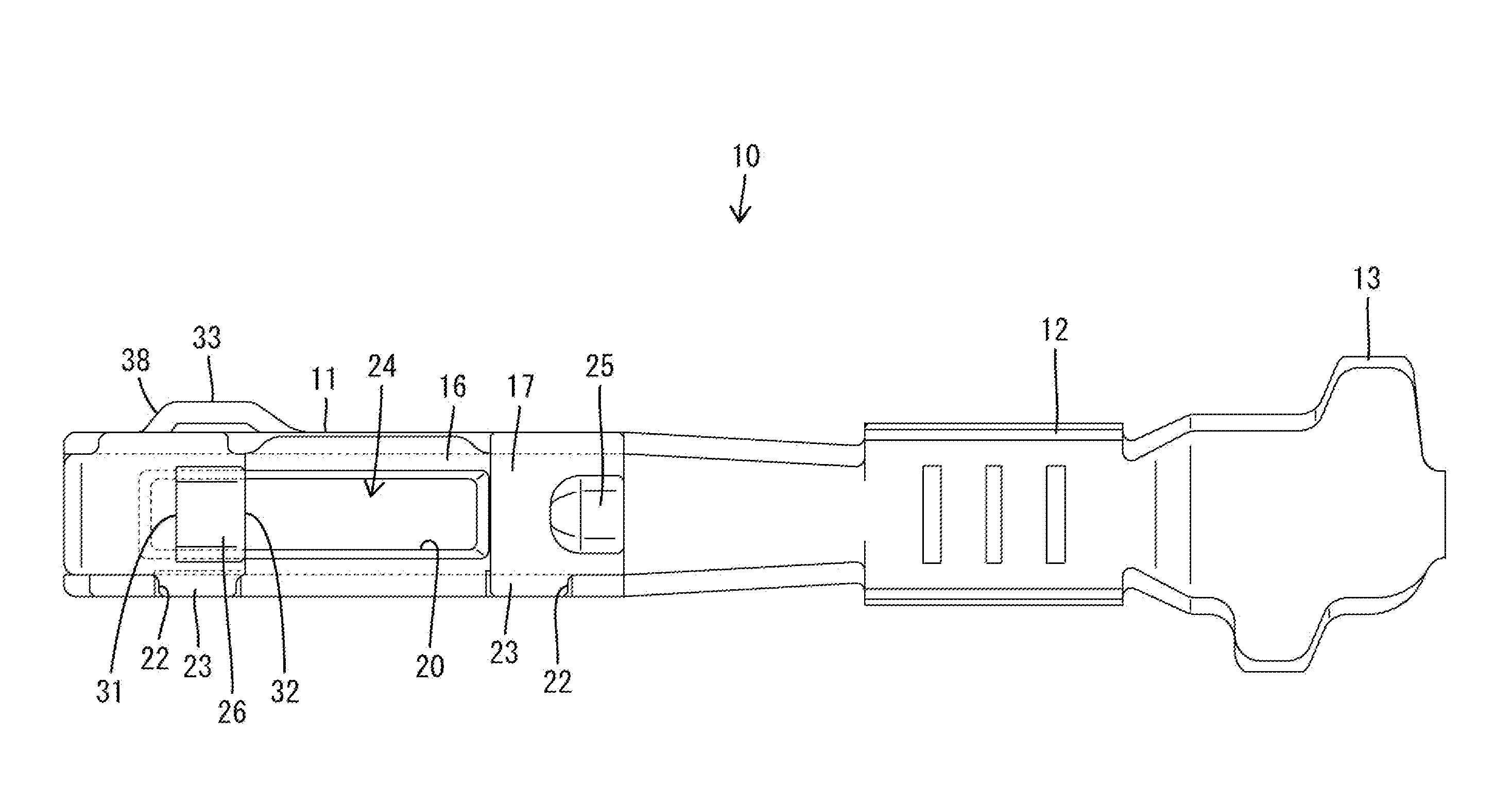

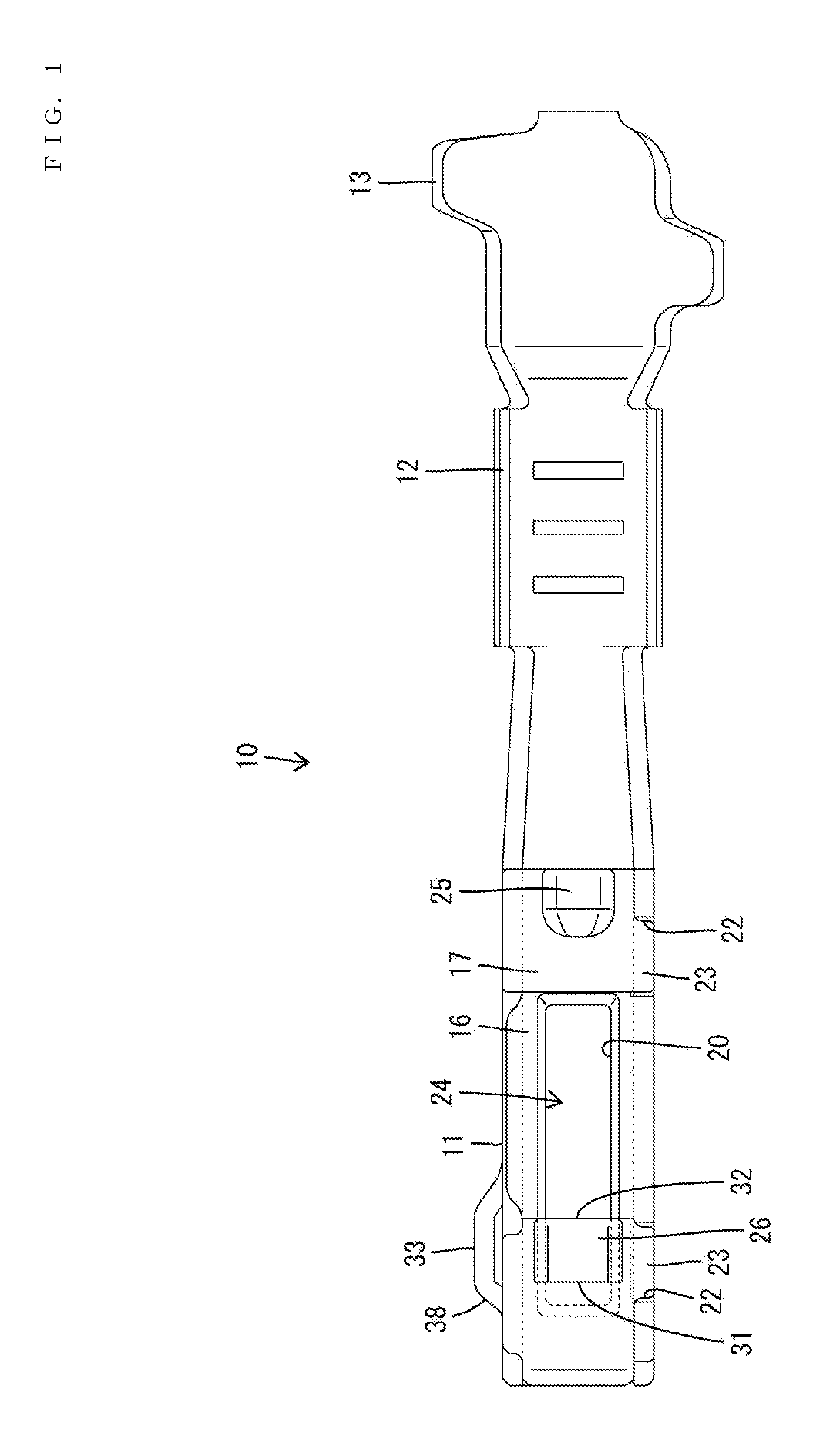

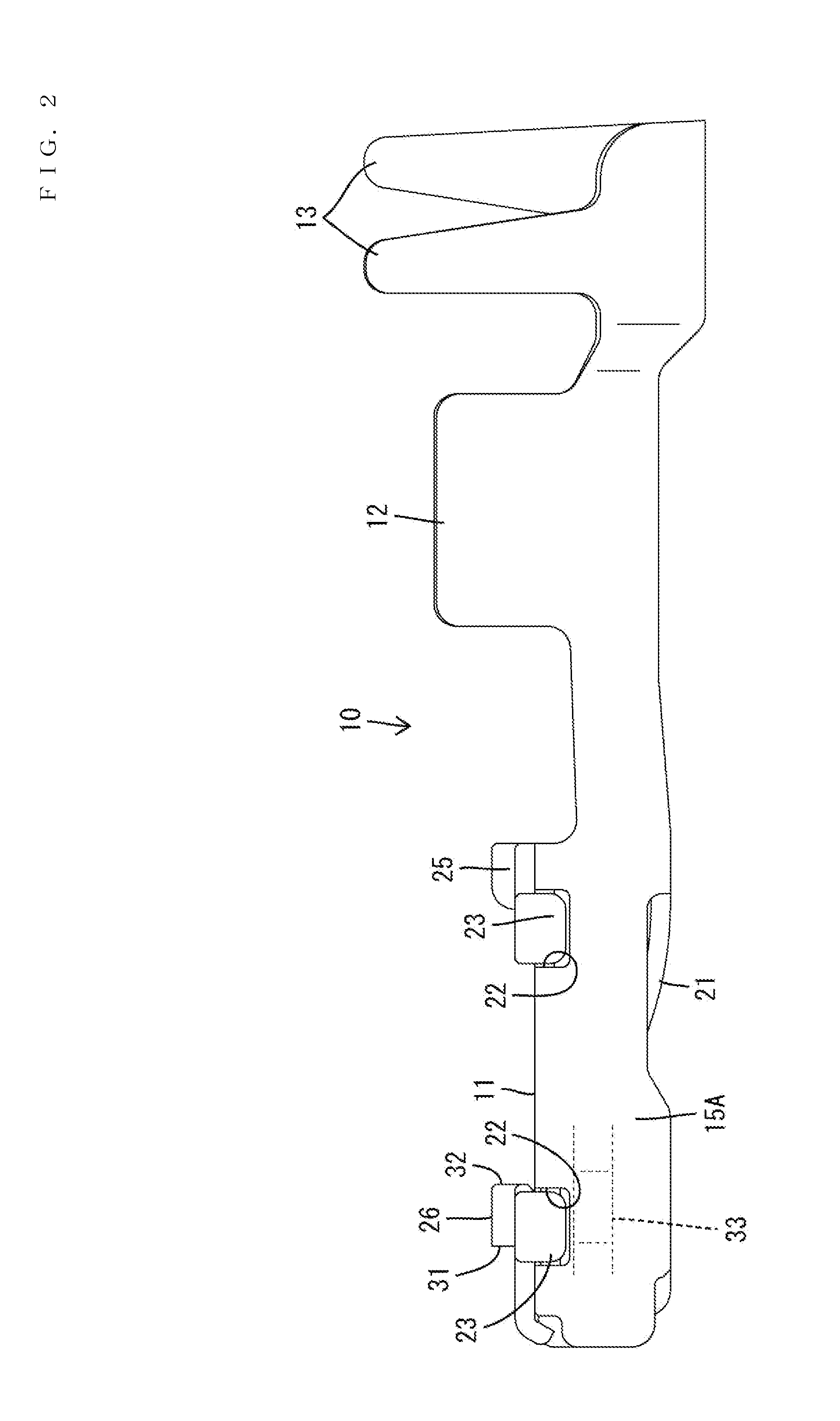

Terminal fitting with stabilizers and connector

ActiveUS9570854B2Reduce contact forceImprove reliabilitySecuring/insulating coupling contact membersCoupling contact membersMechanical engineering

First and second stabilizers (26, 33) project on a main body (11) of a terminal fitting (10) while being spaced apart in a direction intersecting with a front-back direction. The first stabilizer (26) has a front end extending steeply in a direction substantially perpendicular to the front-back direction and the second stabilizer (33) has a front end part (38) inclined to recede. The front end part (38) of the second stabilizer (33) is more forward than the first stabilizer (26) so that the front end of the second stabilizer contacts a facing wall surface of a connector housing (60) before the first stabilizer (26) when an insertion posture is incorrect.

Owner:SUMITOMO WIRING SYST LTD

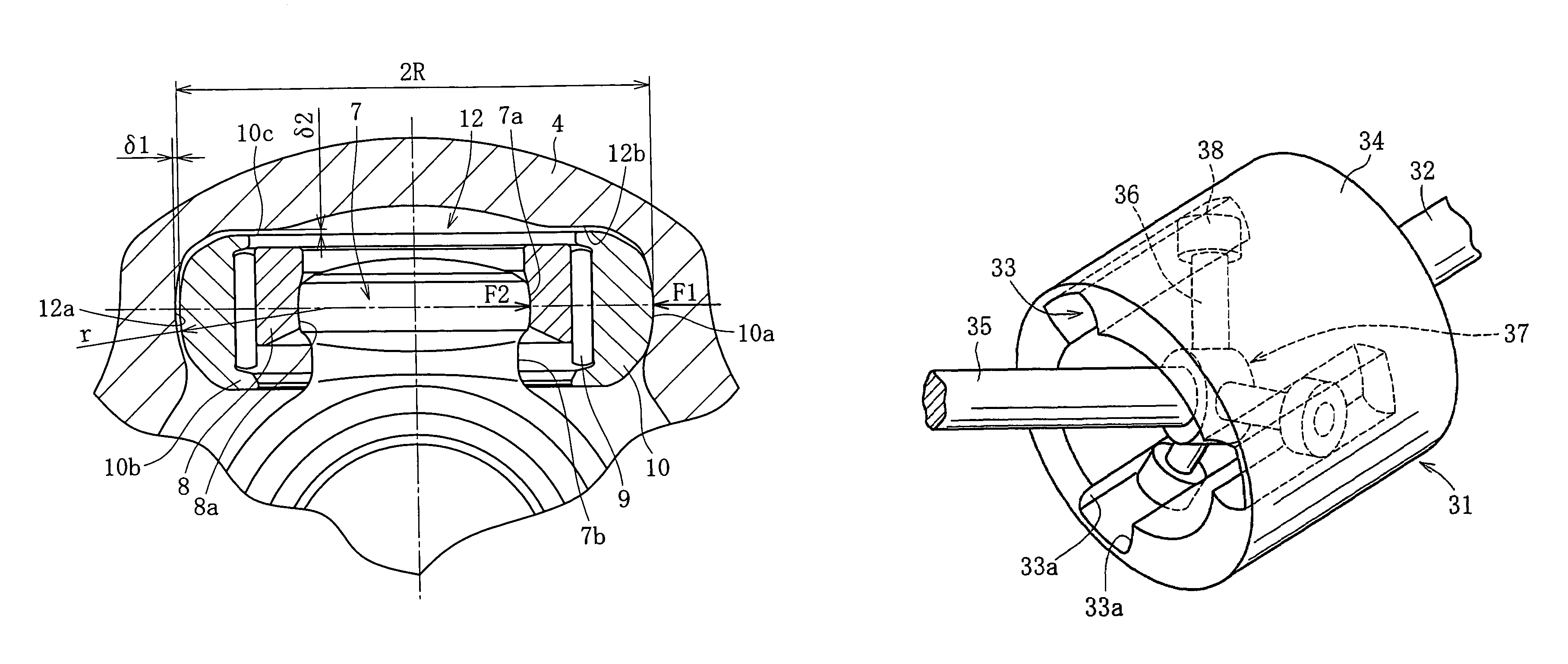

Tripod type constant velocity universal joint

ActiveUS7121950B2Suppress generationIncreased durabilityYielding couplingRotary machine partsUniversal jointEngineering

A tripod type constant velocity universal joint that can suppress generation of shudder by reducing the 3rd order cyclic axial force and has high rotation durability. In a double-roller tripod type constant velocity universal joint, a track gap δ1 between one of the roller guiding surfaces formed on both sides of a track groove, which is on the no-load applied side, and an outer circumferential surface of an outer roller is set to satisfy δ1>0.03 / A. Also, a shoulder gap δ2 between a guide shoulder surface formed at the bottom of the track groove and a side surface of the outer roller is set to satisfy δ2>0.15×A. In both the expressions, a degree of torus A is defined as a ratio of a radius of curvature r of a generatrix of the outer circumferential surface to a radius R of an outer circumference of the outer roller (A=r / R).

Owner:NTN CORP

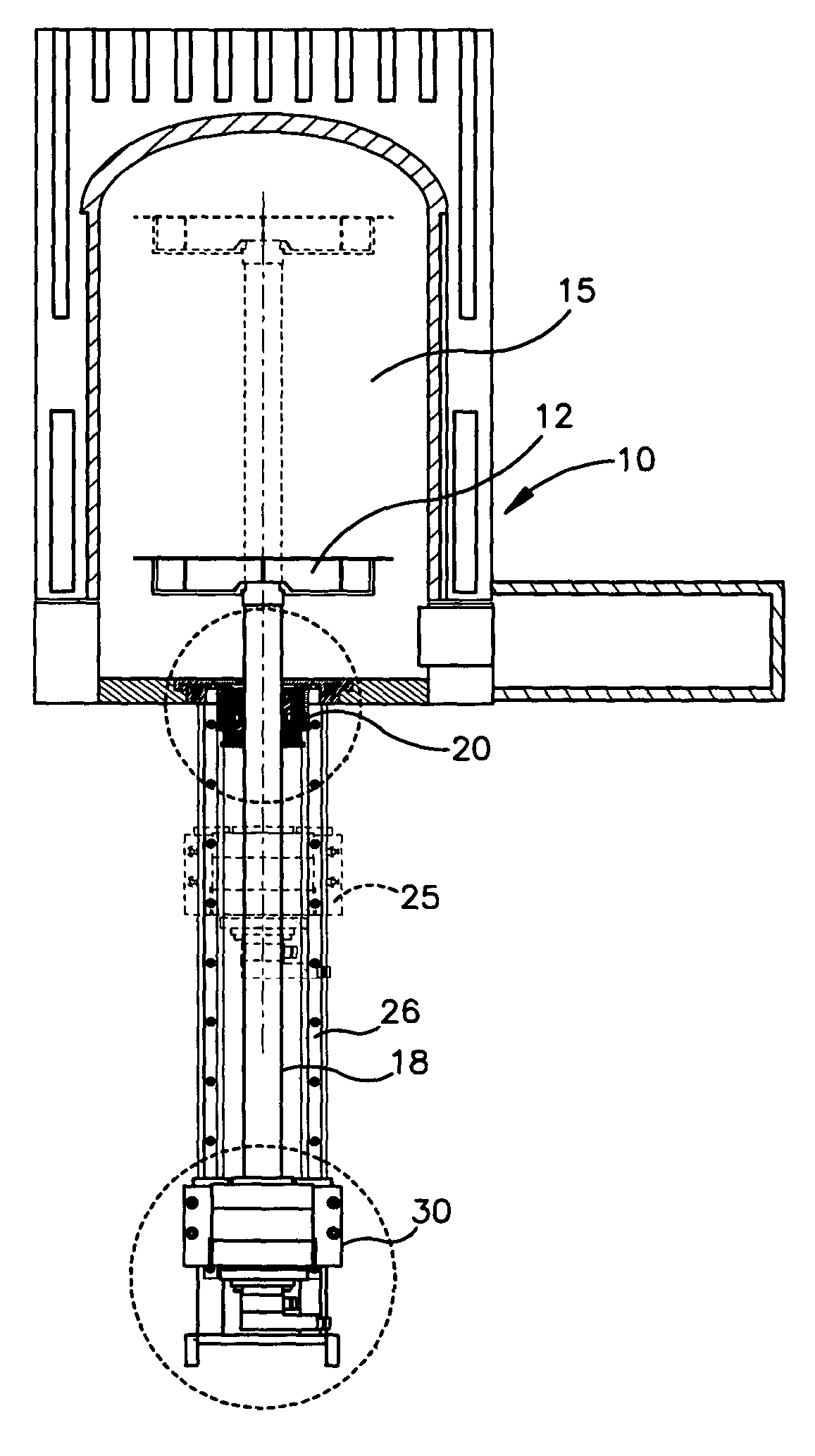

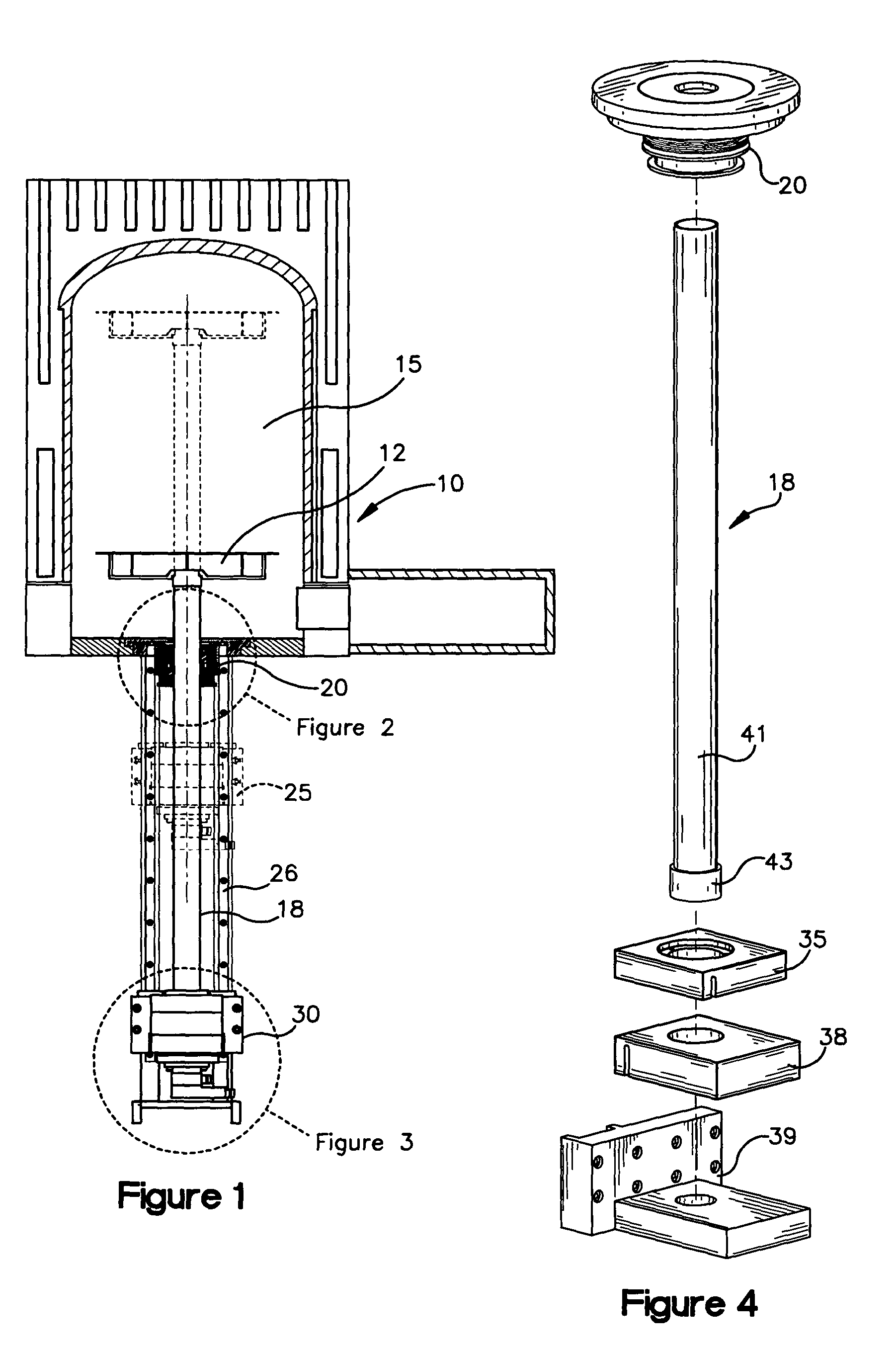

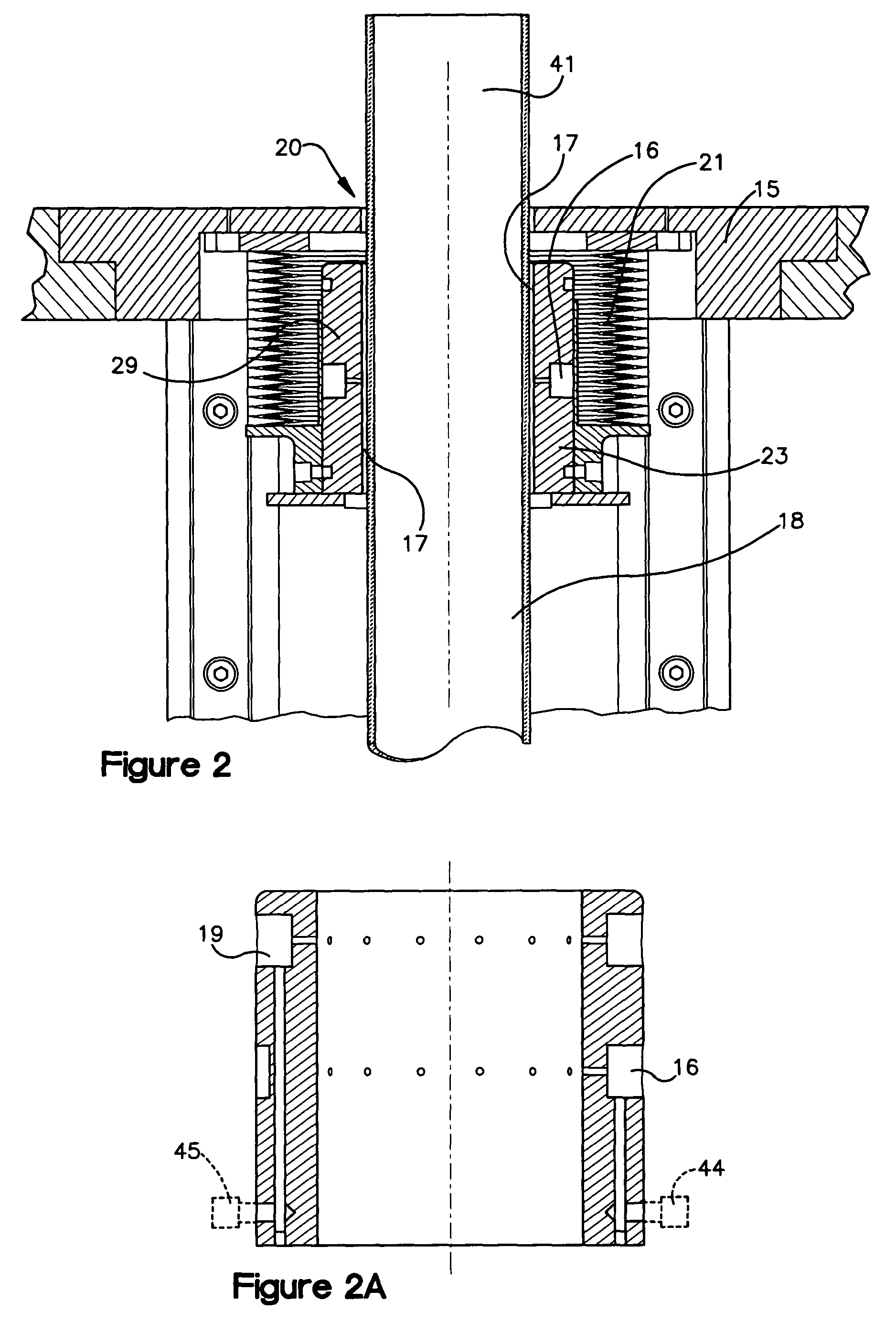

Apparatus for positioning an elevator tube

InactiveUS7026581B2Reduce contact forceAvoid flowDrying solid materials with heatMuffle furnacesEngineeringPosition control

A wafer support position control mechanism selectively positions a semiconductor wafer along an axis of excursion within a process chamber. An elevator tube protrudes through an orifice in the chamber surface and is connected at a first distal end to the wafer support. A compliant, dynamic seal within the orifice engages the elevator tube to form a gas curtain within a gap between the seal and the elevator tube to seal the process chamber. A moveable carriage is connected to the elevator tube at a second distal end for moving the wafer support along the axis of excursion. Rigid mechanical structure couples the second distal end of the elevator tube to the moveable carriage.

Owner:AXCELIS TECHNOLOGIES

Terminal fitting and connector

ActiveUS20150263456A1Large caliberReduce the overall diameterSecuring/insulating coupling contact membersCoupling contact membersEngineeringMechanical engineering

First and second stabilizers (26, 27) project on a main body (11) of a terminal fitting (10) while being spaced apart in a direction intersecting with a front-back direction. The first stabilizer (26) has a front end extending steeply in a direction substantially perpendicular to the front-back direction and the second stabilizer (33) has a front end part inclined to recede. A front end of the second stabilizer (33) is more forward than the first stabilizer (26) so that the front end of the second stabilizer contacts a facing wall surface of a connector housing (60) before the first stabilizer (26) when an insertion posture is incorrect.

Owner:SUMITOMO WIRING SYST LTD

Cap and low insertion force connector for printed circuit board

InactiveUS6439919B1Insertion forceImprove connection workabilityIncorrect coupling preventionPrinted circuit aspectsLow insertion forceCountermeasure

A cap that is to be fitted to a printed circuit board, which has a conductive pad on the front side of the rectangular board thereof and which is to be connected to the connector. The cap is formed into a bag and is shaped into a wedge that gets thinner towards the front, and the cap has a window for exposing the conductive pad of the printed circuit board.A low insertion force connector that connects a printed circuit board having conductive pads on the front side of the rectangular board thereof. This low insertion force connector comprises a connector body having at least a pair of contacts that contact the conductive pads and clamp the printed circuit board, a slider that carries the printed circuit board and advances to and retreats from the contact, and a guide that is provided at the front end of the slider and is formed into a wedge-shape, which gets thinner towards the front.The present invention reduces the insertion force of the printed circuit board, enhances the connection workability, and eliminates damages or the like to the contacts and the conductive pad to enhance the reliability. The present invention provides a connector that is also effective in countermeasures against heat and electromagnetic waves.

Owner:JST MFG CO LTD

Passive valve with stop pad

ActiveUS20090126359A1Reduce turbulenceFlow noise is generatedExhaust apparatusSilencing apparatusExhaust gasEngineering

A passive valve assembly for an exhaust component includes a vane that is positioned within an exhaust gas flow path. The vane is pivoted from a closed position to an open position in response to exhaust gas flow overcoming a biasing force. A stop is positioned within the exhaust component and cooperates with the vane to define a closed position for the vane.

Owner:FAURECIA EMISSIONS CONTROL TECH GERMANY

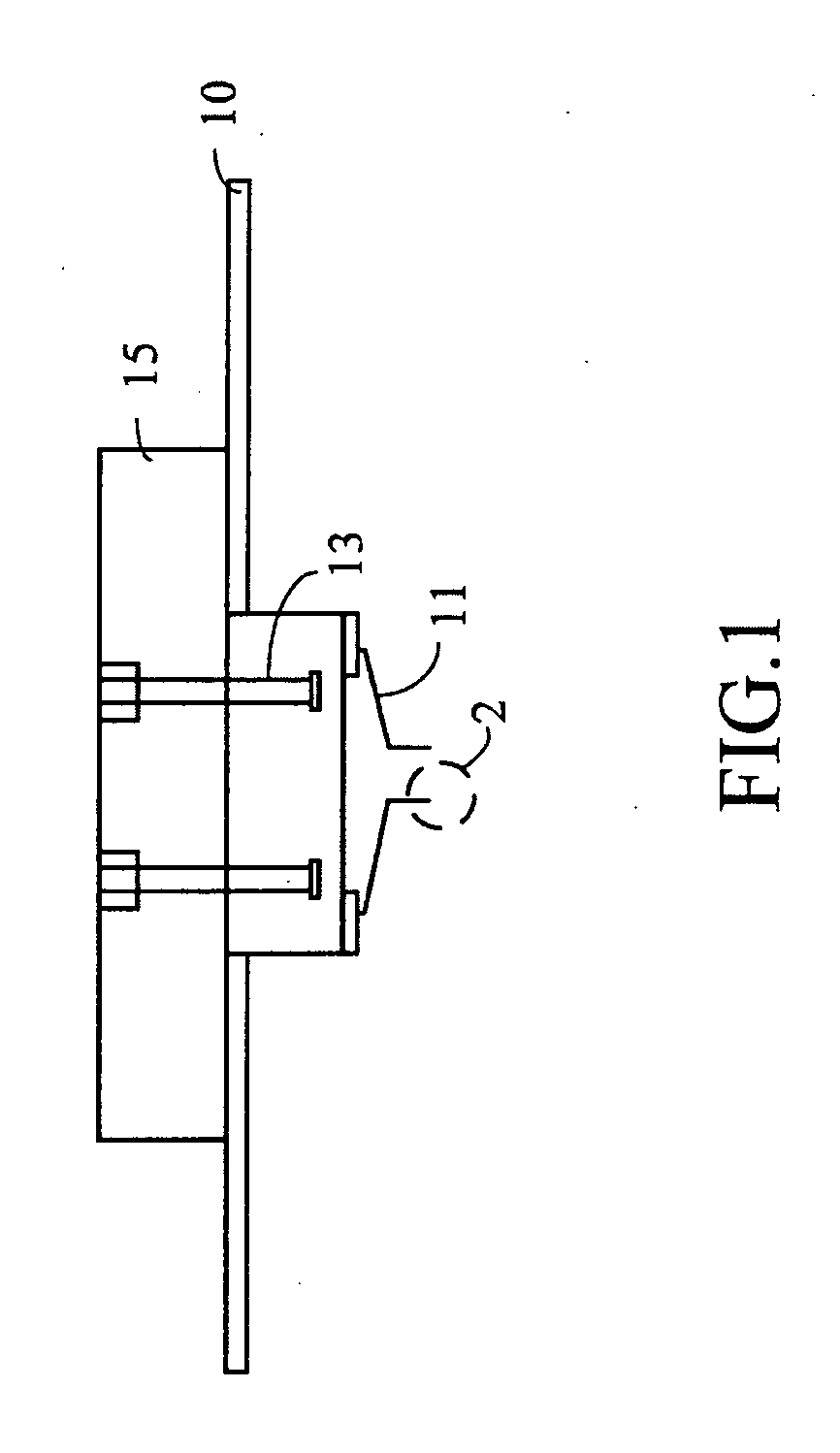

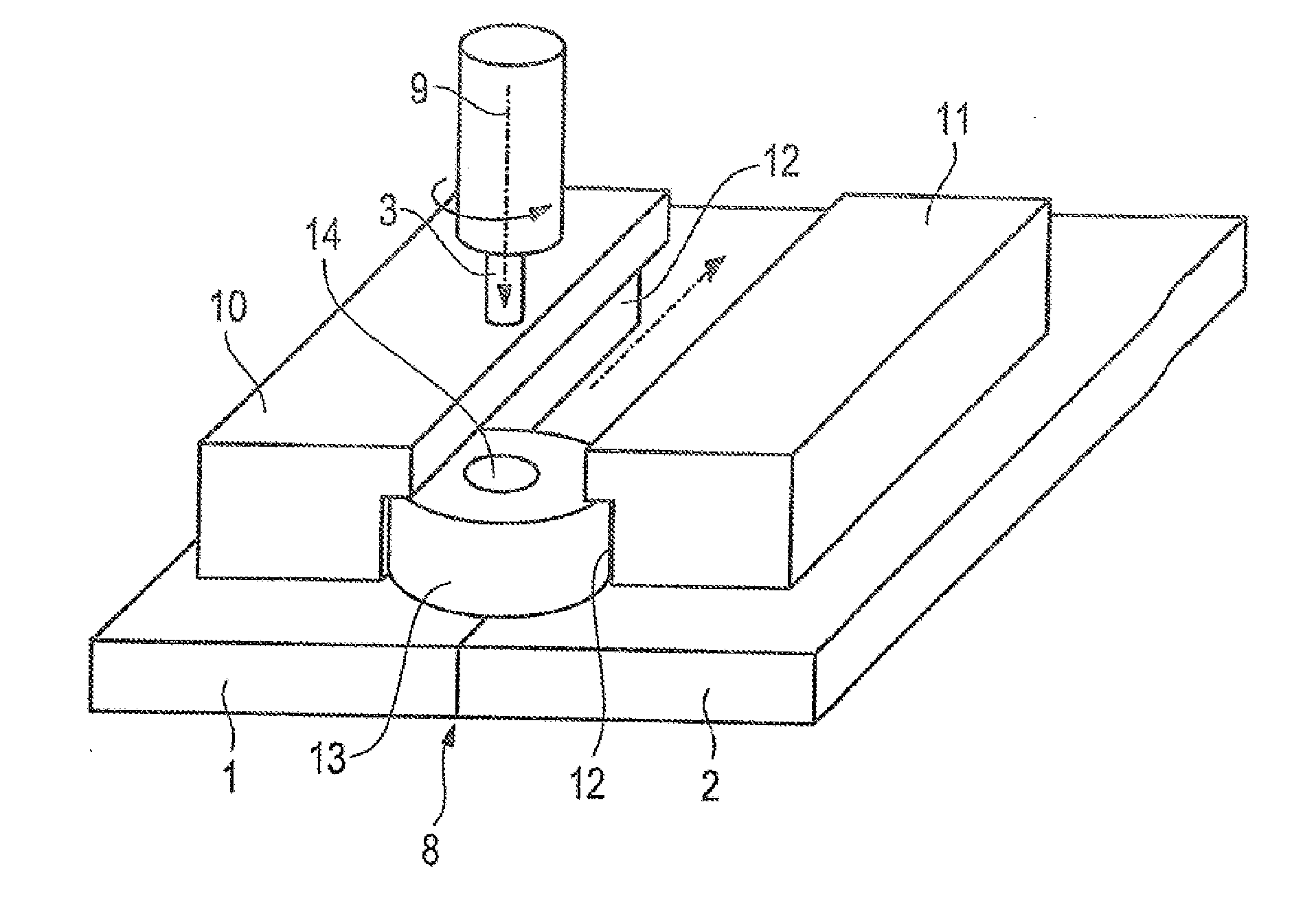

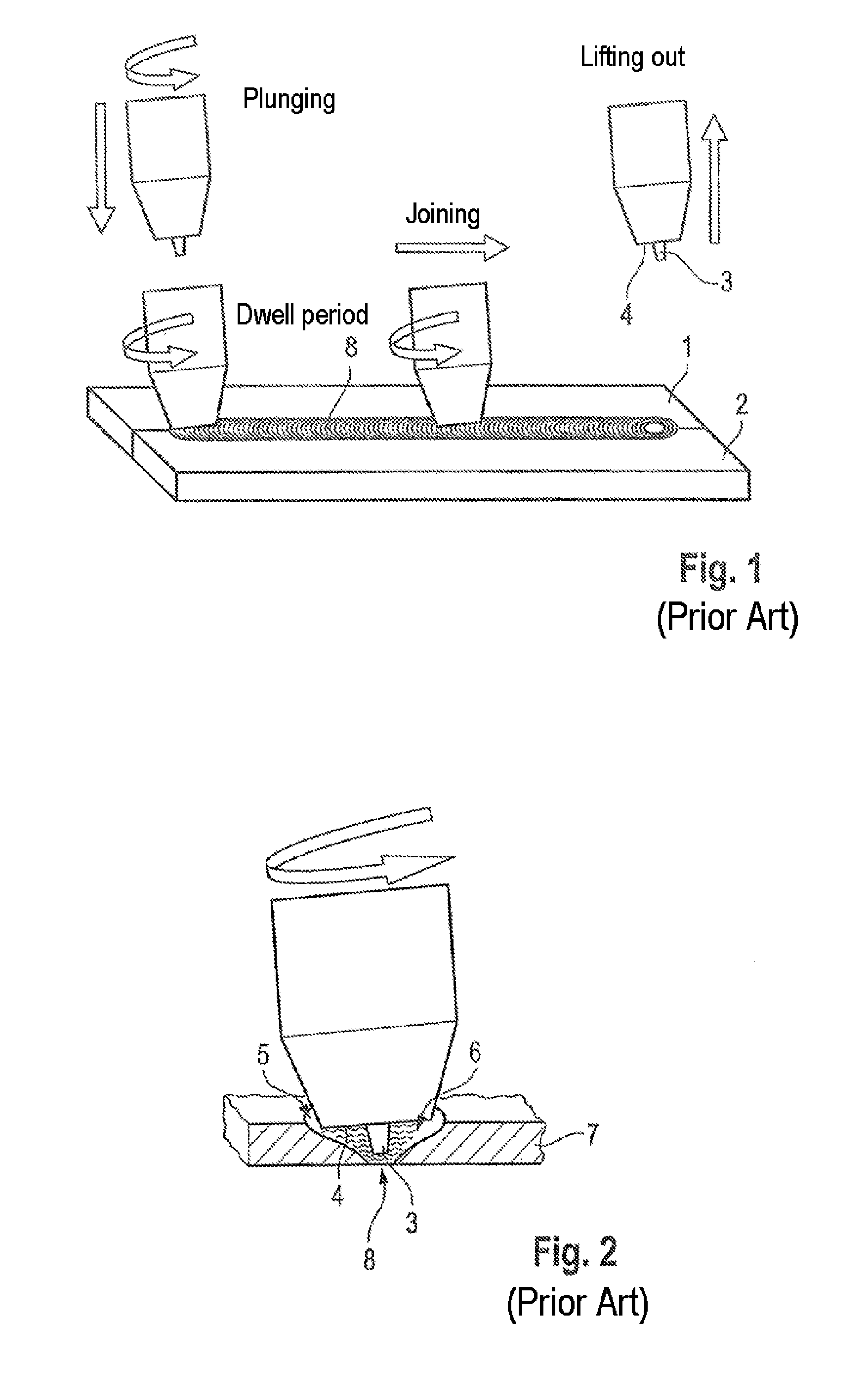

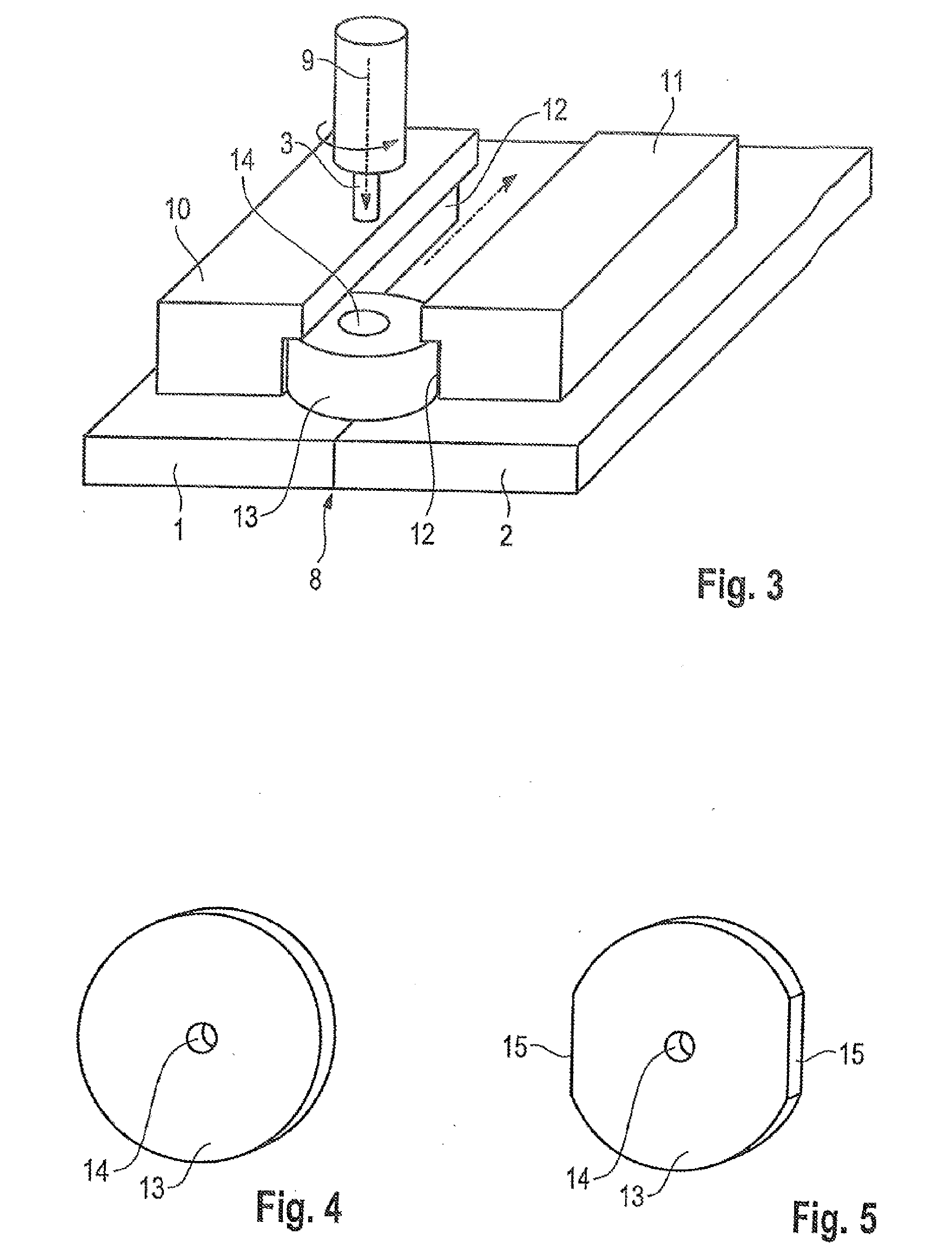

Friction stir welding apparatus and method for joining workpieces by means of a friction stir welding process

InactiveUS20150069114A1Reduction in force flowReduction in contact forceWelding/cutting auxillary devicesAuxillary welding devicesFriction stir weldingWelding process

The invention relates to a friction stir welding apparatus for joining workpieces 1, 2, having a welding pin 3, which is rotatable about its center axis 9 by means of a drive, and having at least one clamping apparatus for clamping the workpieces 1, 2 to be joined, characterized in that the clamping apparatus comprises at least two clamping elements 10, 11, which respectively have an undercut guideway 12, the guideways 12 being arranged parallel to one another and parallel to a joining region 8, in that between the clamping elements 10, 11 is arranged a sliding element 13, which is secured by the guideways 12 against the workpieces 1, 2 and is translatorily displaceable along the guideways 12, and in that the sliding element 12 is provided with an opening 14 for the lead-through of the welding pin 3, and further relates to a method for friction stir welding, using the above-stated apparatus.

Owner:TECH UNIV MUNCHEN

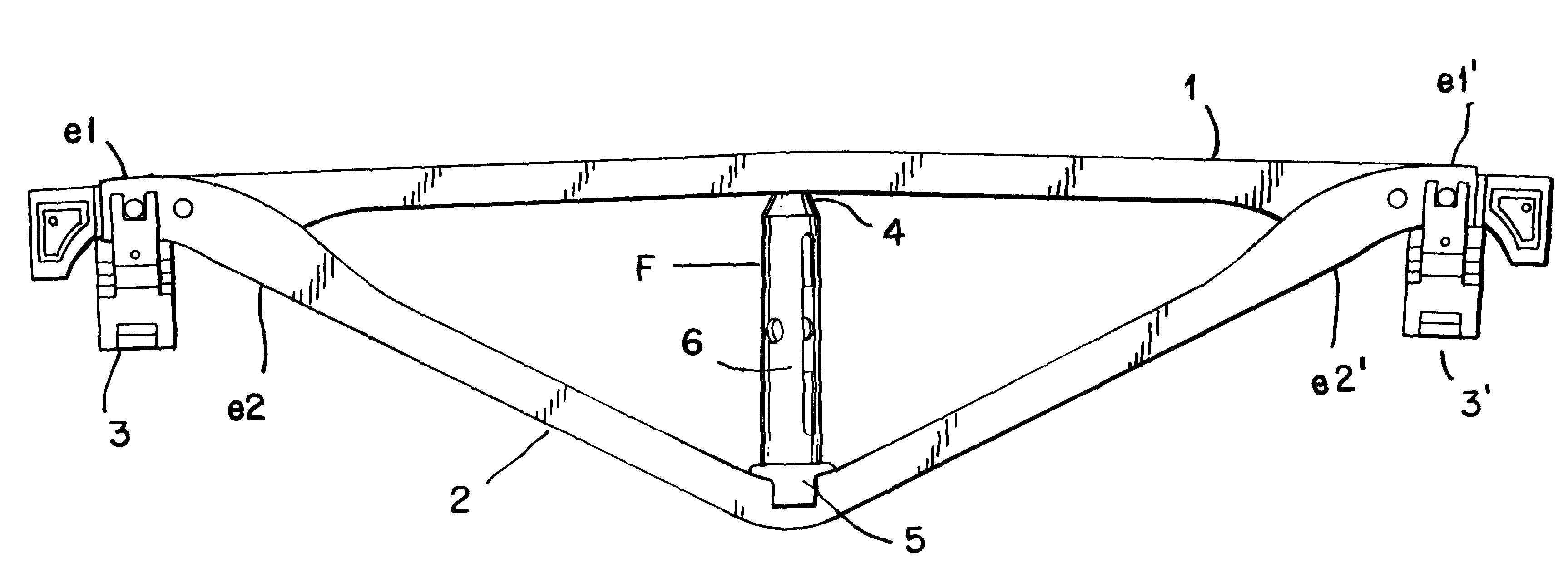

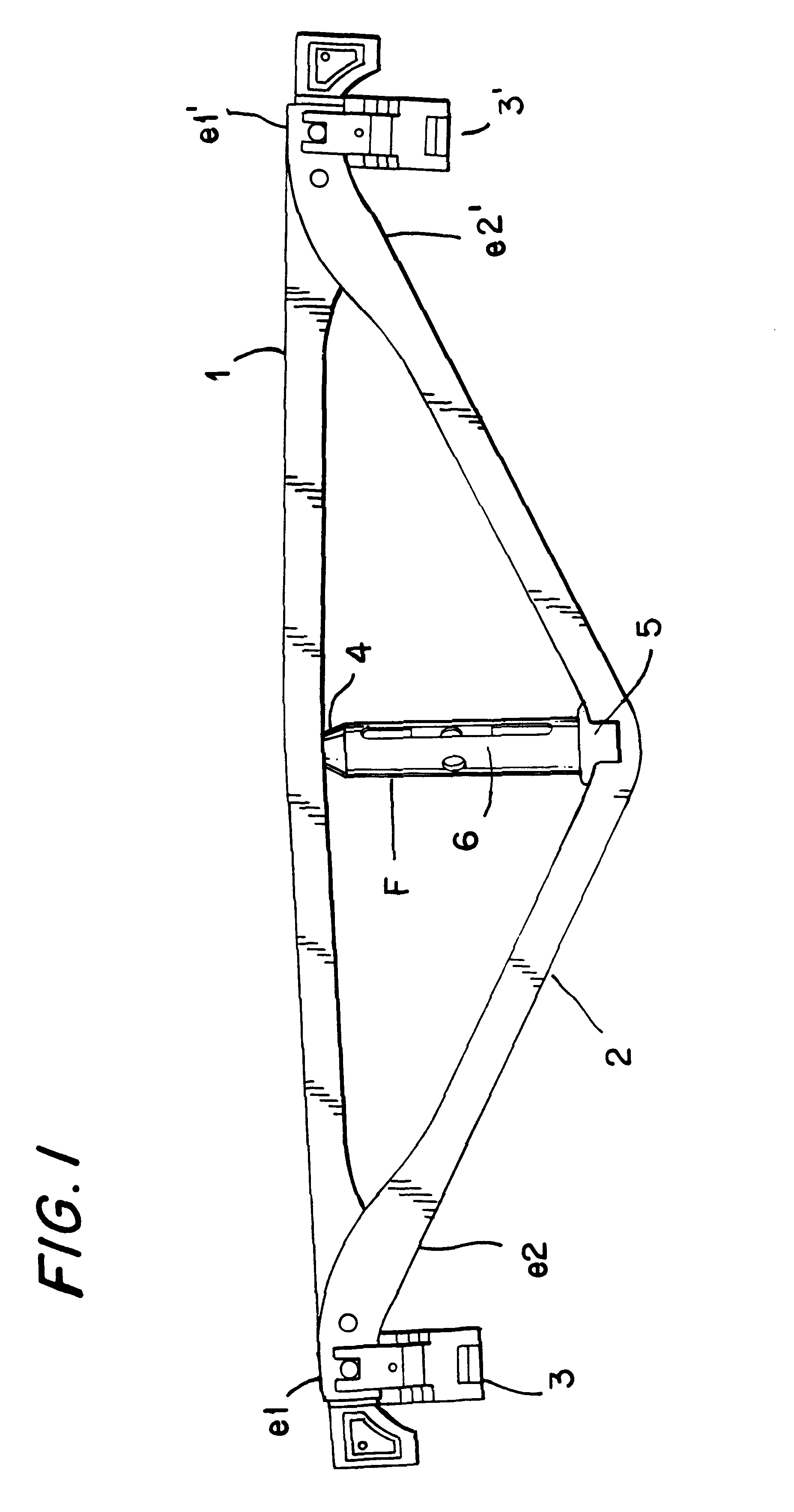

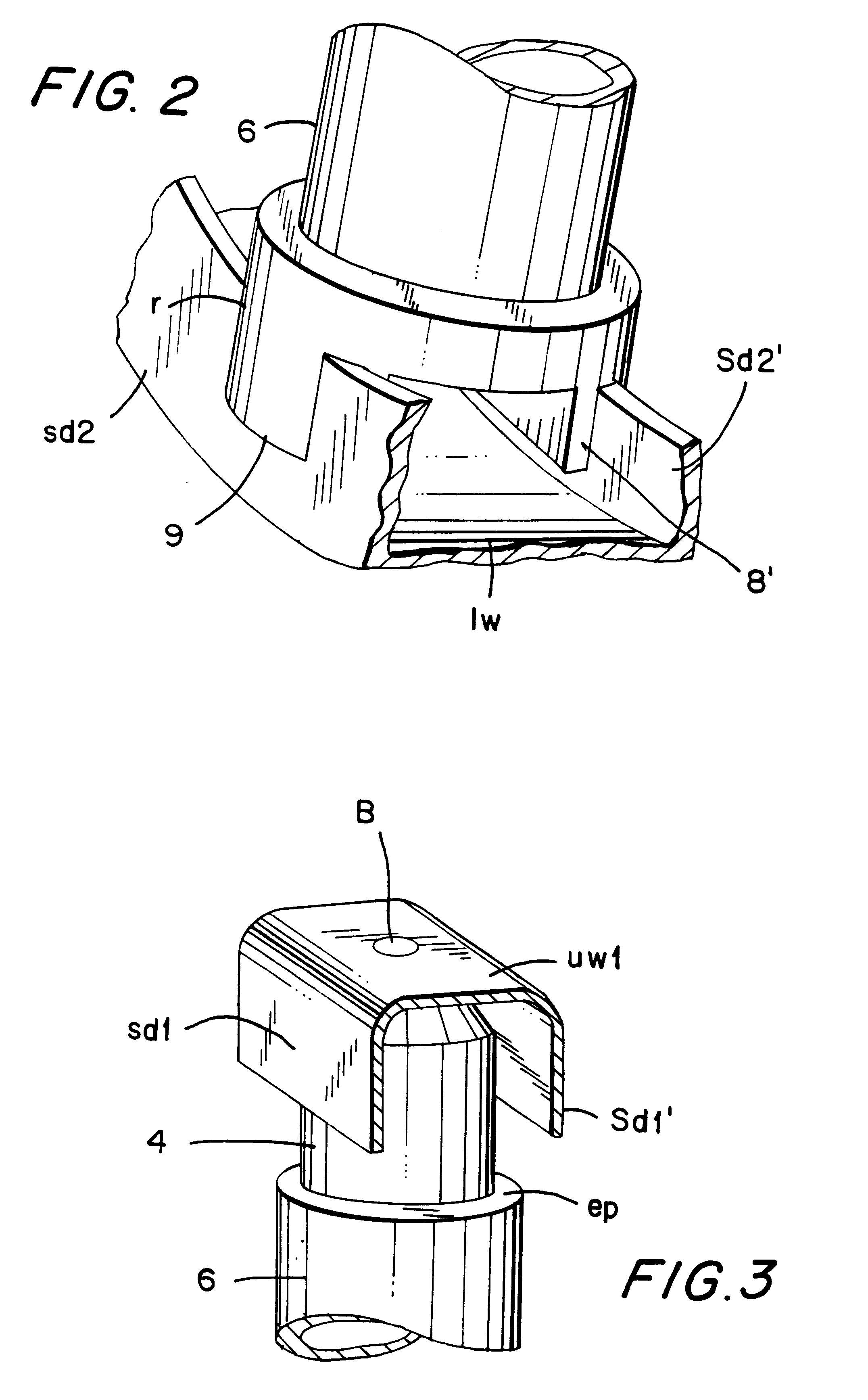

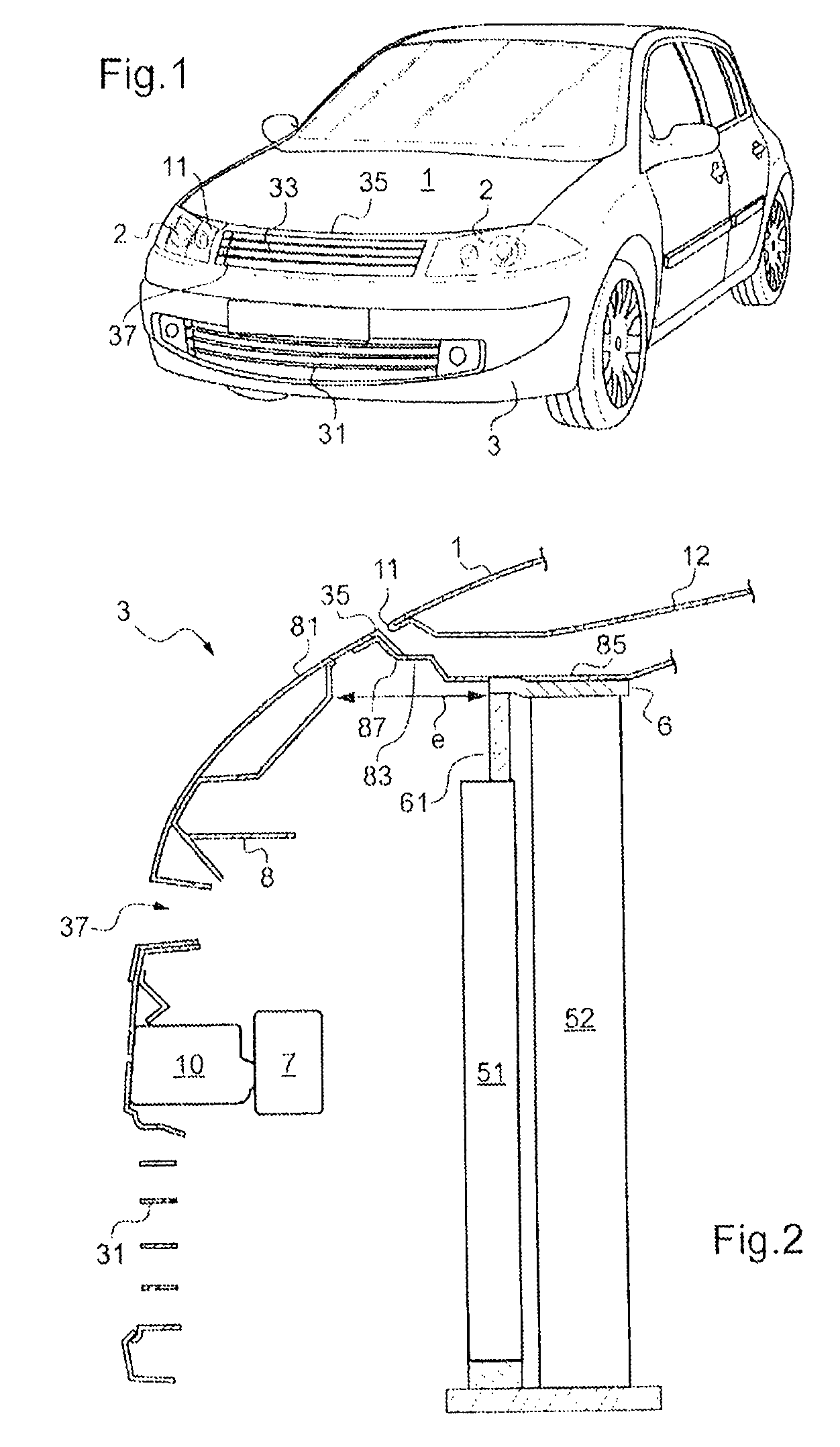

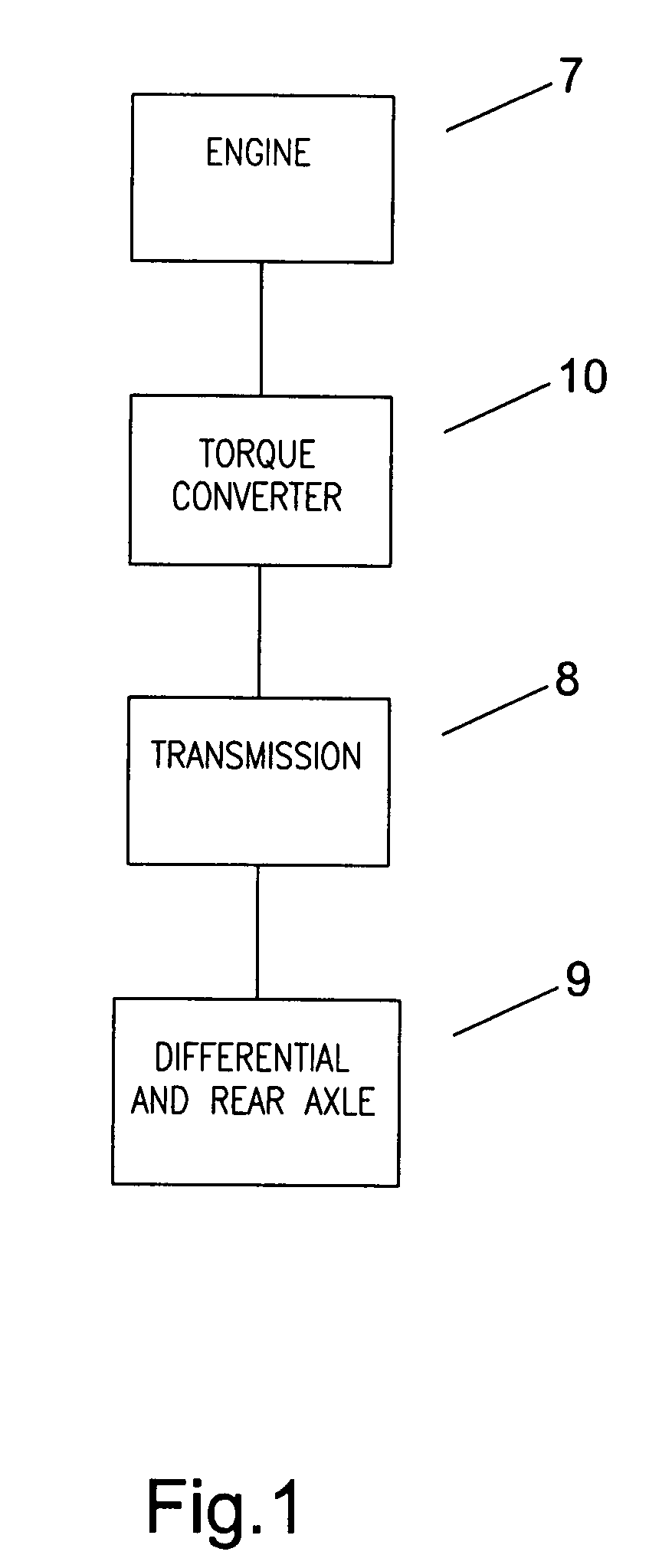

Automobile comprising a front bumper with a central portion extending as far as the bonnet of said vehicle

ActiveUS8491038B2Good deformationReduce riskVehicle seatsPedestrian/occupant safety arrangementEngineeringMechanical engineering

An automobile including a front cross-member, an attachment element arranged at the rear of the cross-member, a bonnet that closes off an engine compartment and including one free edge, and a front bumper mounted in front of the front cross-member and including a central portion that extends as far as the bonnet and includes a tab for attaching to the attachment element. The attachment tab includes a frangible area, located to the front of the attachment area and capable of breaking, and the frangible area is arranged next to an empty space formed in the compartment, with a view to having the central portion of the bumper bend into the empty space when the frangible area breaks.

Owner:CHALLAL HICHAM +1

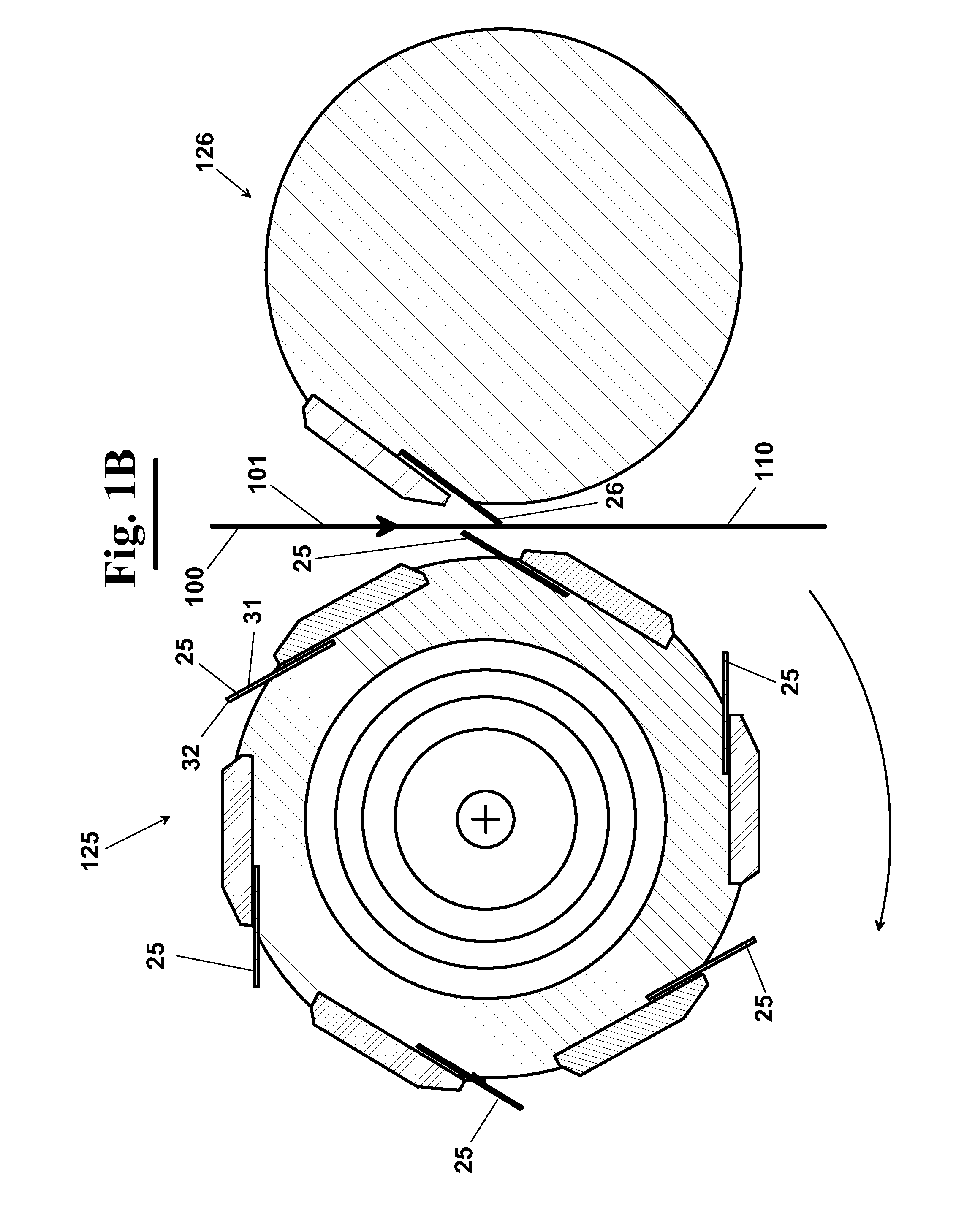

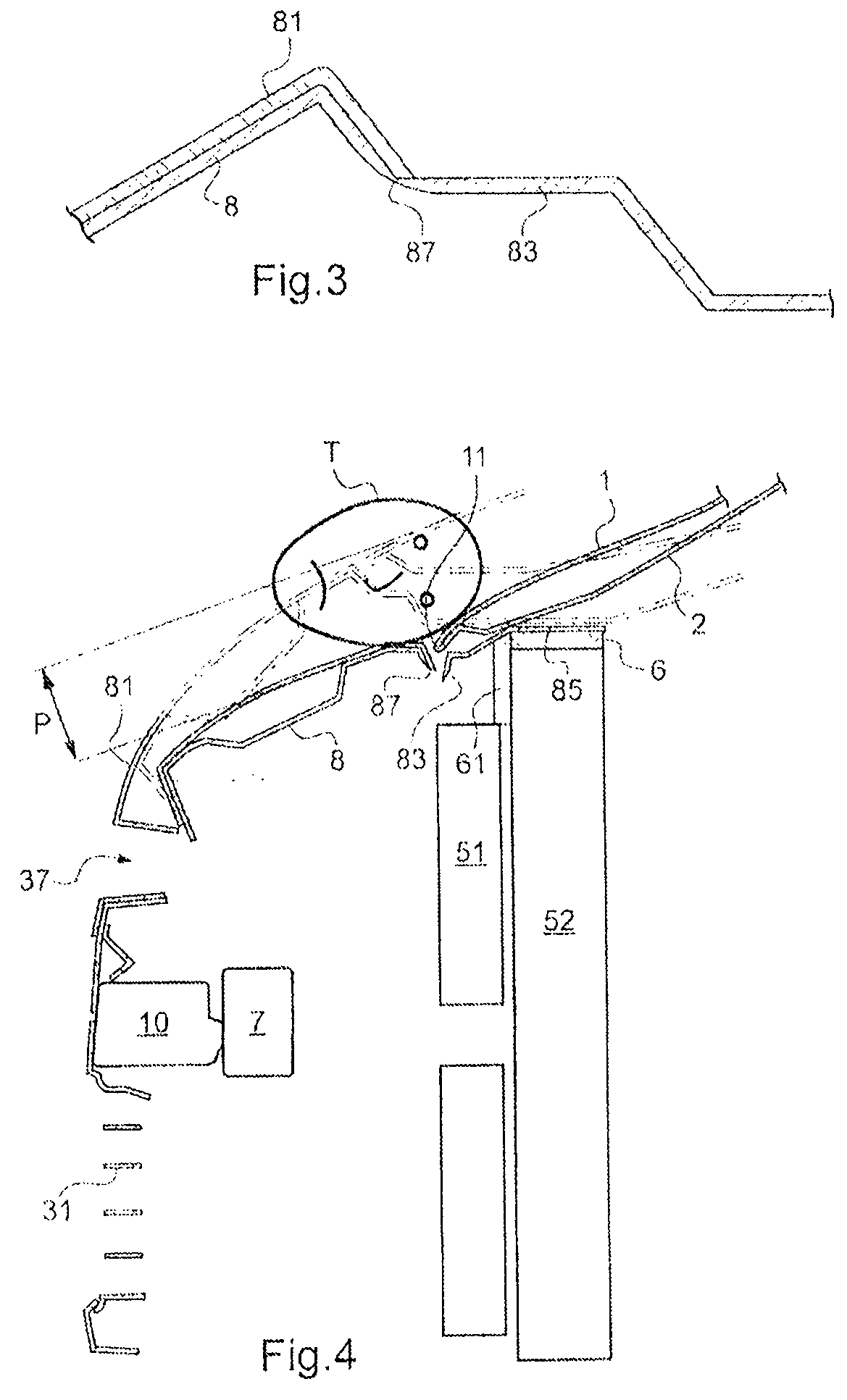

Wedge one-way clutch

InactiveUS8020681B2Reduce contact forceShorten the axial widthFriction clutchesInterengaging clutchesEngineeringClutch

Owner:SCHAEFFLER TECH AG & CO KG

Fixed type constant velocity joint

ActiveUS20100190558A1Reliable constructionSuitable strengthYielding couplingRotary machine partsLinear regionEngineering

A constant velocity joint for a drive system comprises: an outer race having an inner spherical surface, and a plurality of guide grooves formed in an axial direction in the inner spherical surface of the outer race; an inner race having an outer spherical surface, and a plurality of guide grooves formed in an axial direction in the outer spherical surface of the inner race, said guide grooves of the outer race and said guide grooves of the inner race together forming a plurality of ball guide tracks; a plurality of balls disposed in the ball guide tracks; and a cage installed between the inner spherical surface of the outer race and the outer spherical surface of the inner race, said cage having a plurality of windows for retaining the balls therein; wherein each of the guide grooves of the outer race is shaped to have a longitudinal cross section formed with two circular regions with different centers, a first circular region disposed at a first lateral side of the outer race and a second circular region disposed at a second lateral side of the outer race, and a linear region tangentially extending between these two circular regions; and wherein each of the guide grooves of the inner race is shaped to have a longitudinal cross section formed with two circular regions with different centers, a first circular region disposed at a first lateral side of the inner race and a second circular region disposed at a second lateral side of the inner race, and a linear region tangentially extending between these two circular regions.

Owner:WIA CORP

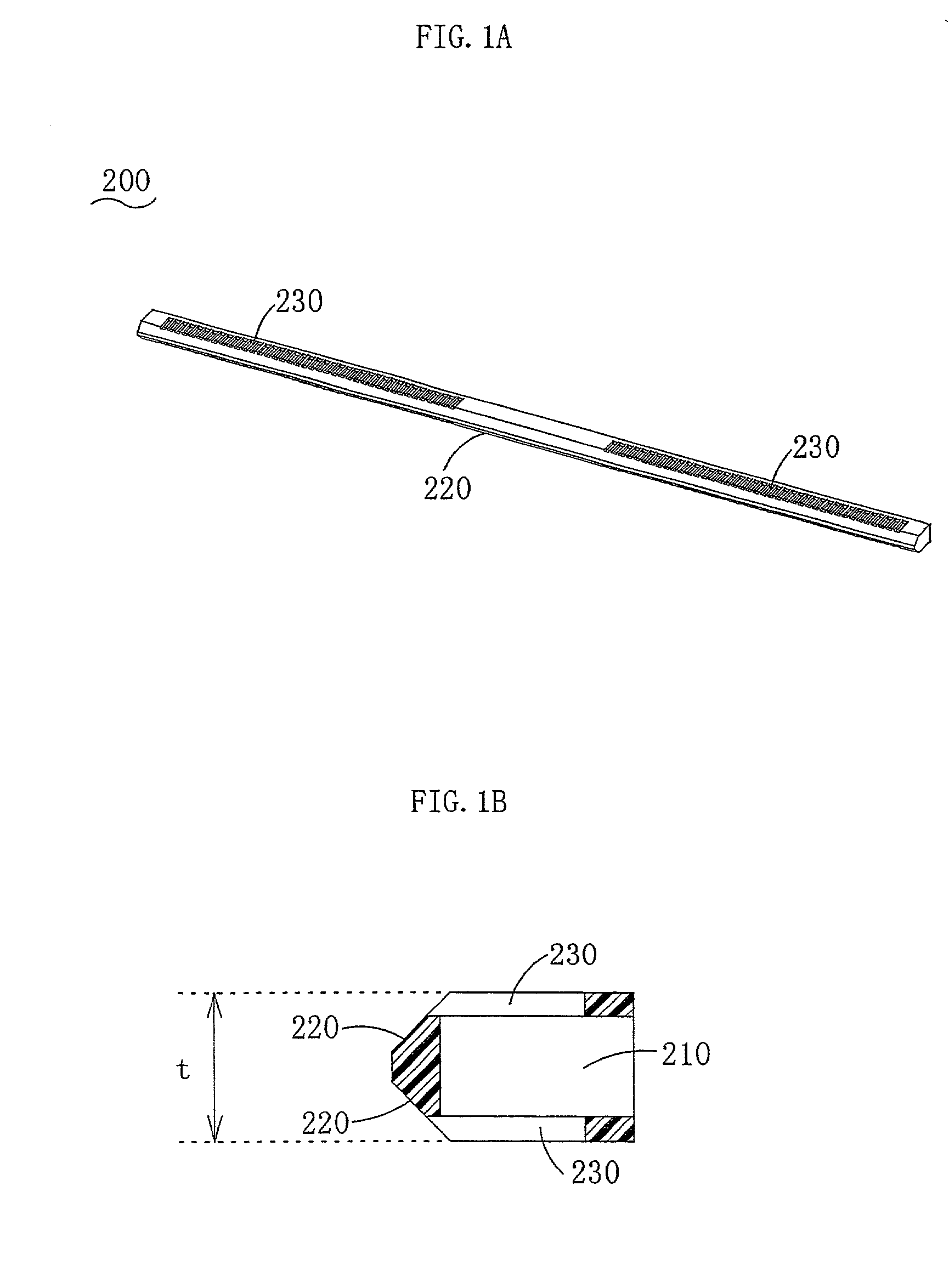

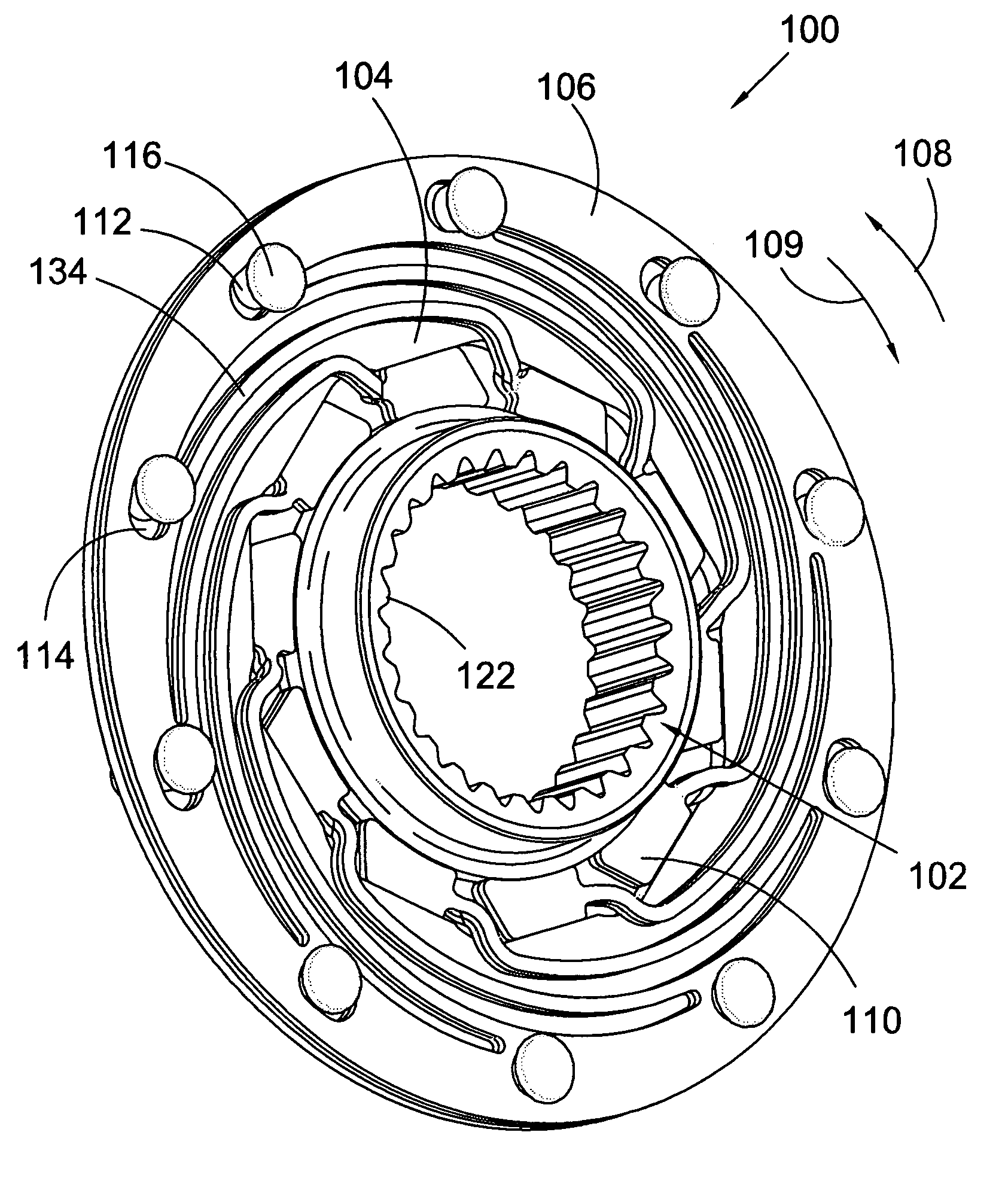

Electric actuator for driving a home-automation screen

ActiveUS8253288B2Reduce contact forceReduce vibrationDoor/window protective devicesMechanical energy handlingContact forceEngineering

This electric actuator for driving a home-automation screen is provided with a spring brake (105) comprising a helical spring (130), a friction part (140) having a friction surface (141) against which the helical spring (130) bears radially. Said brake further comprises an inlet part (110) suitable for driving the spring in rotation in a direction reducing the contact force between the spring (130) and the friction part (140), and an outlet part (120) connected to the screen.While the screen is being lowered, the inlet part (110; 210) drives the spring (130; 230) in rotation with the contact force being decreased to the extent that the outlet part (120; 220) is released in rotation, without direct contact between the inlet part and the outlet part. The inlet part (110; 210) has at least two contact surfaces (113a, 113d; 213b, 217c) suitable for transmitting drive torque (CM) for raising the screen (2), by direct contact, to at least two corresponding contact surfaces (123a, 123d; 223b, 227a) of the outlet part (120; 220).

Owner:SOMFY ACTIVITES SA

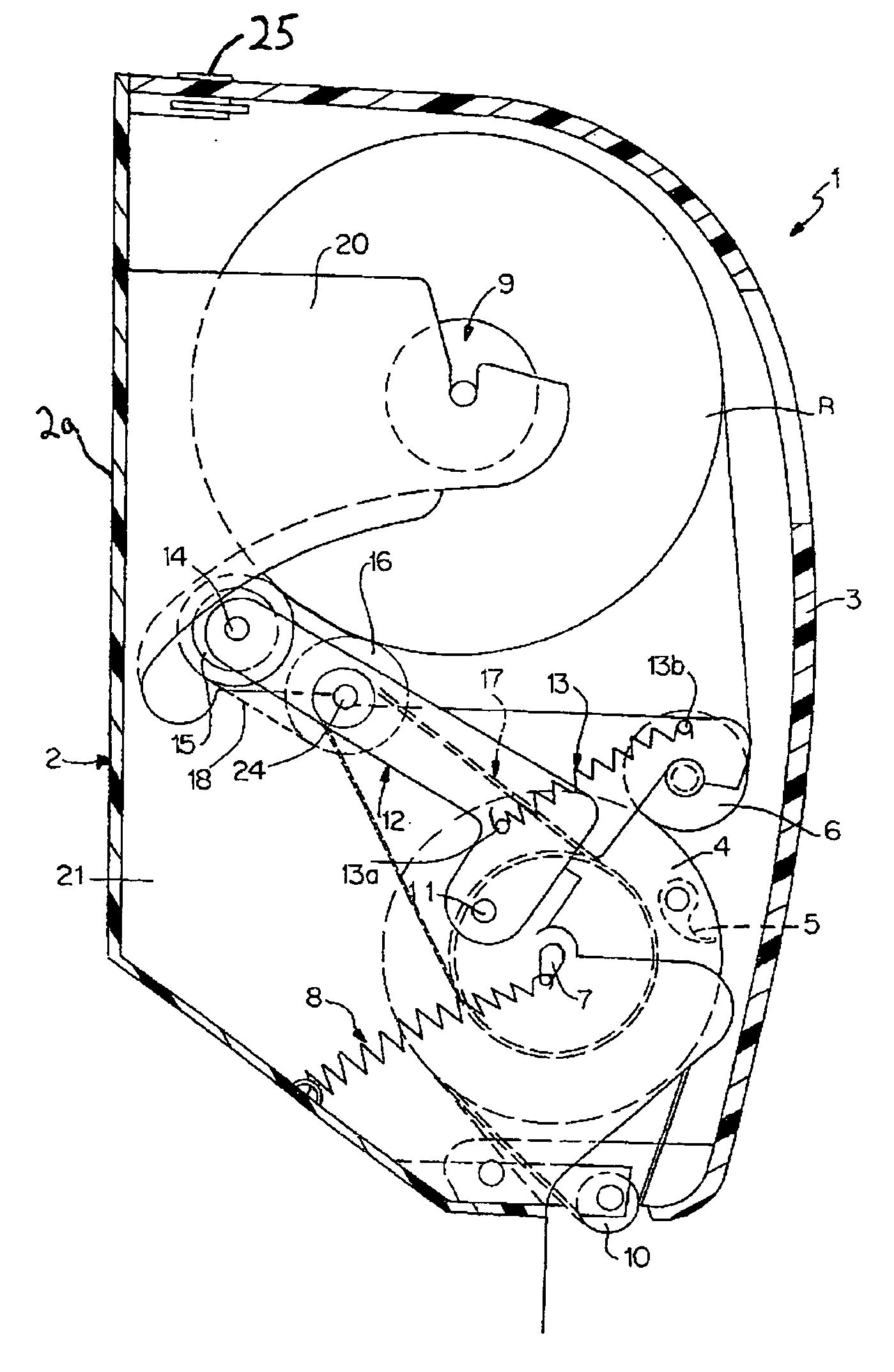

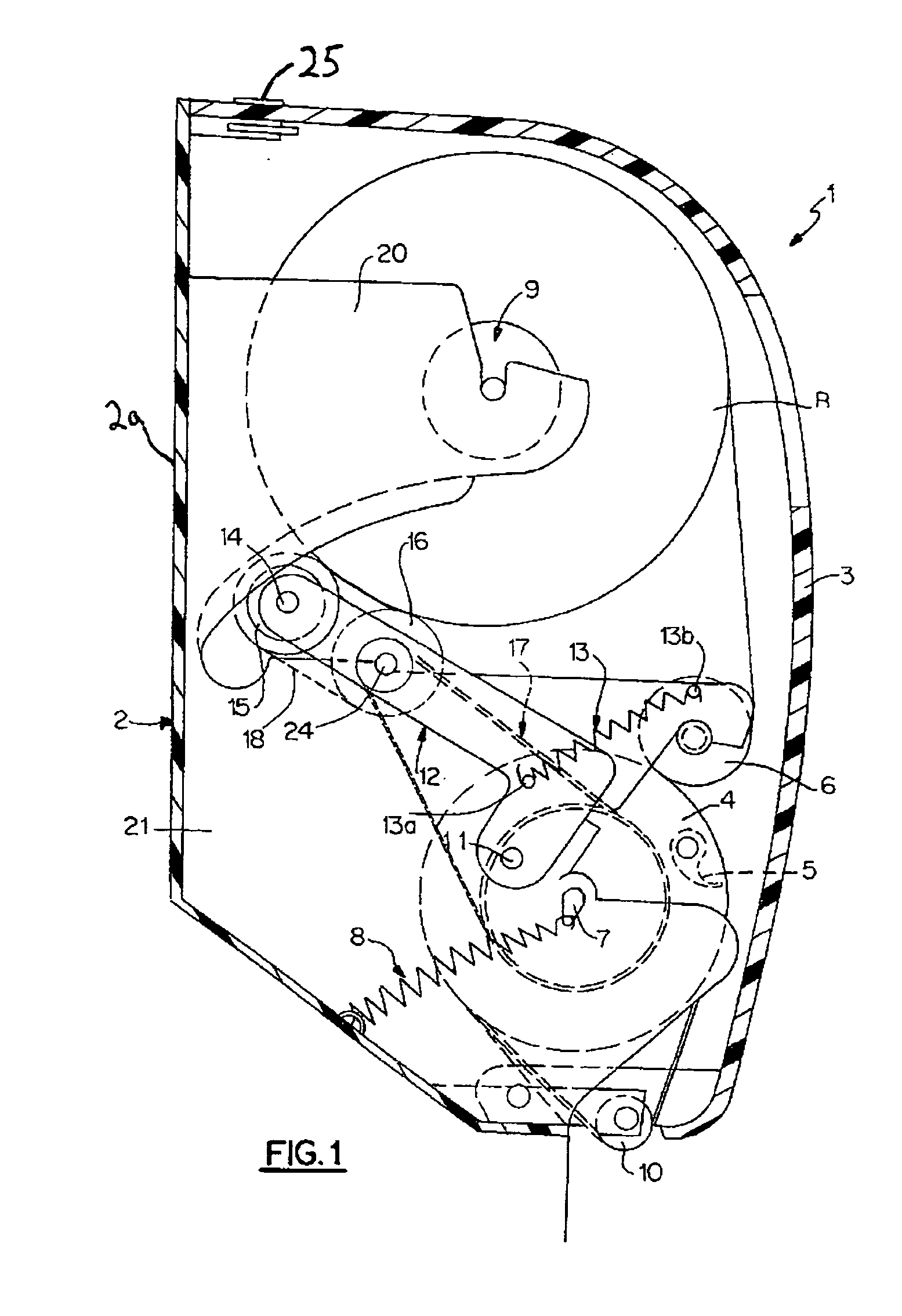

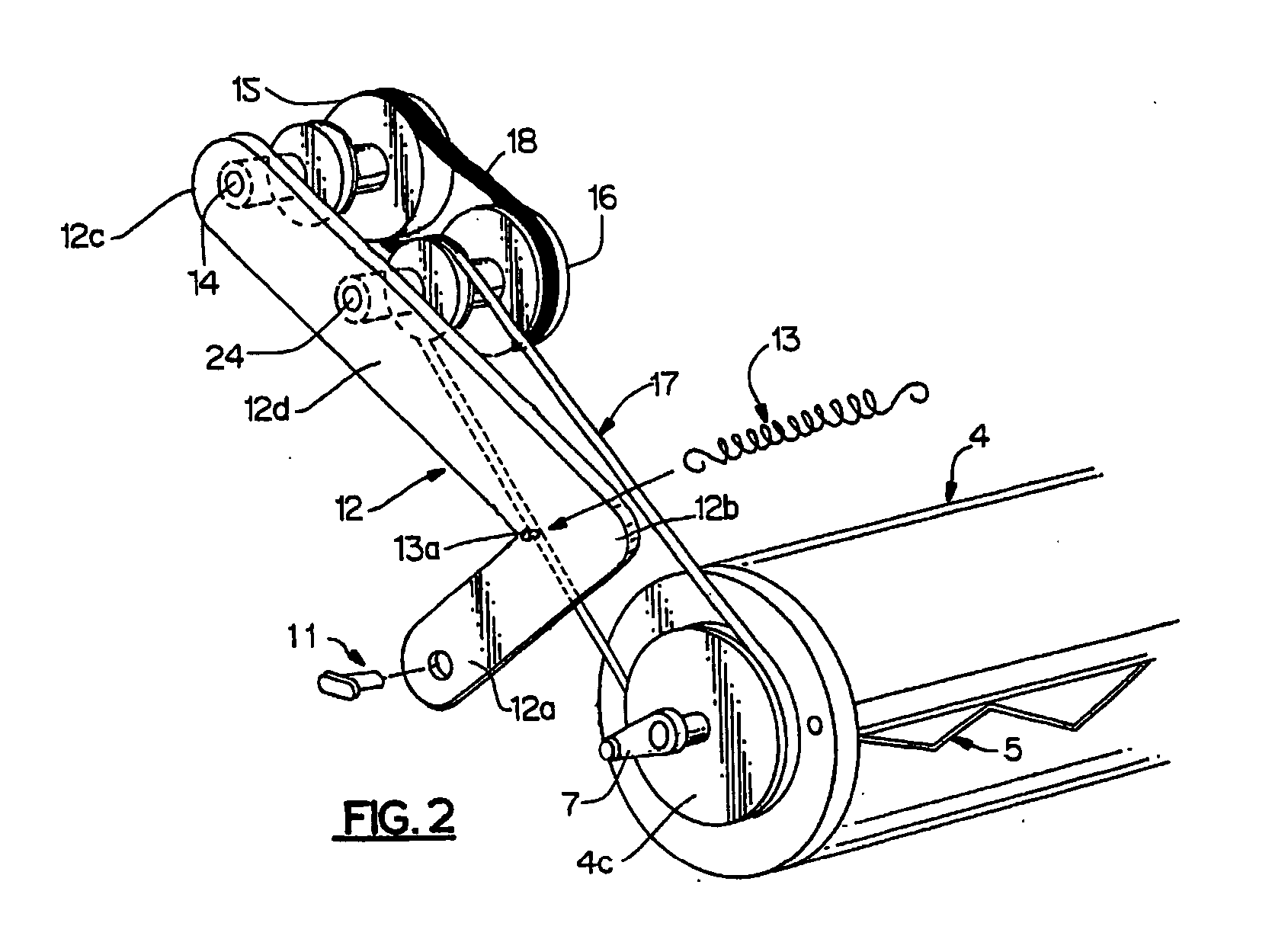

Supply roll surface drive for a dispensing apparatus

InactiveUS20070145062A1Good compensationReduce contact forceCoin-freed apparatus detailsApparatus for dispensing discrete articlesPaper towelEngineering

An apparatus that dispenses a sheet of absorbent material from a roll of absorbent material includes a housing and a drum in the housing. A cutting device is incorporated in the drum. A one-way bearing on a shaft of the drum enables the drum to rotate only in one direction upon activation of the drum. A tensioning device provides tension to a strip of paper material passing between the tensioning device and the drum. The apparatus also includes a supply roll surface drive that controls rotation of the roll of absorbent material. The supply roll surface drive includes two independently rotatable pulleys and a belt wrapped around the pulleys. The belt contacts the roll of paper towels along a plurality of contact points to control rotation of the roll of absorbent material.

Owner:TISSUE NORTH AMERICA

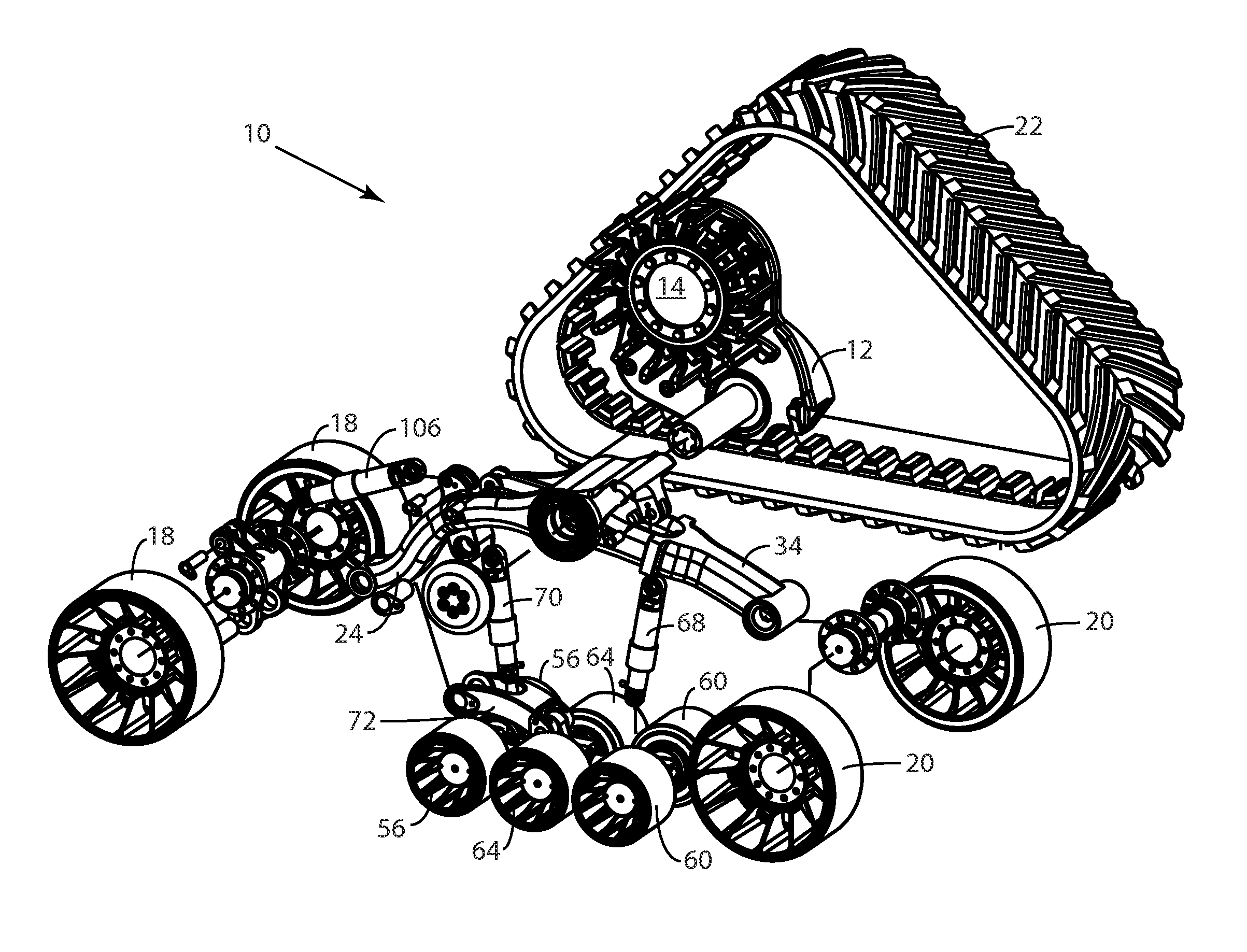

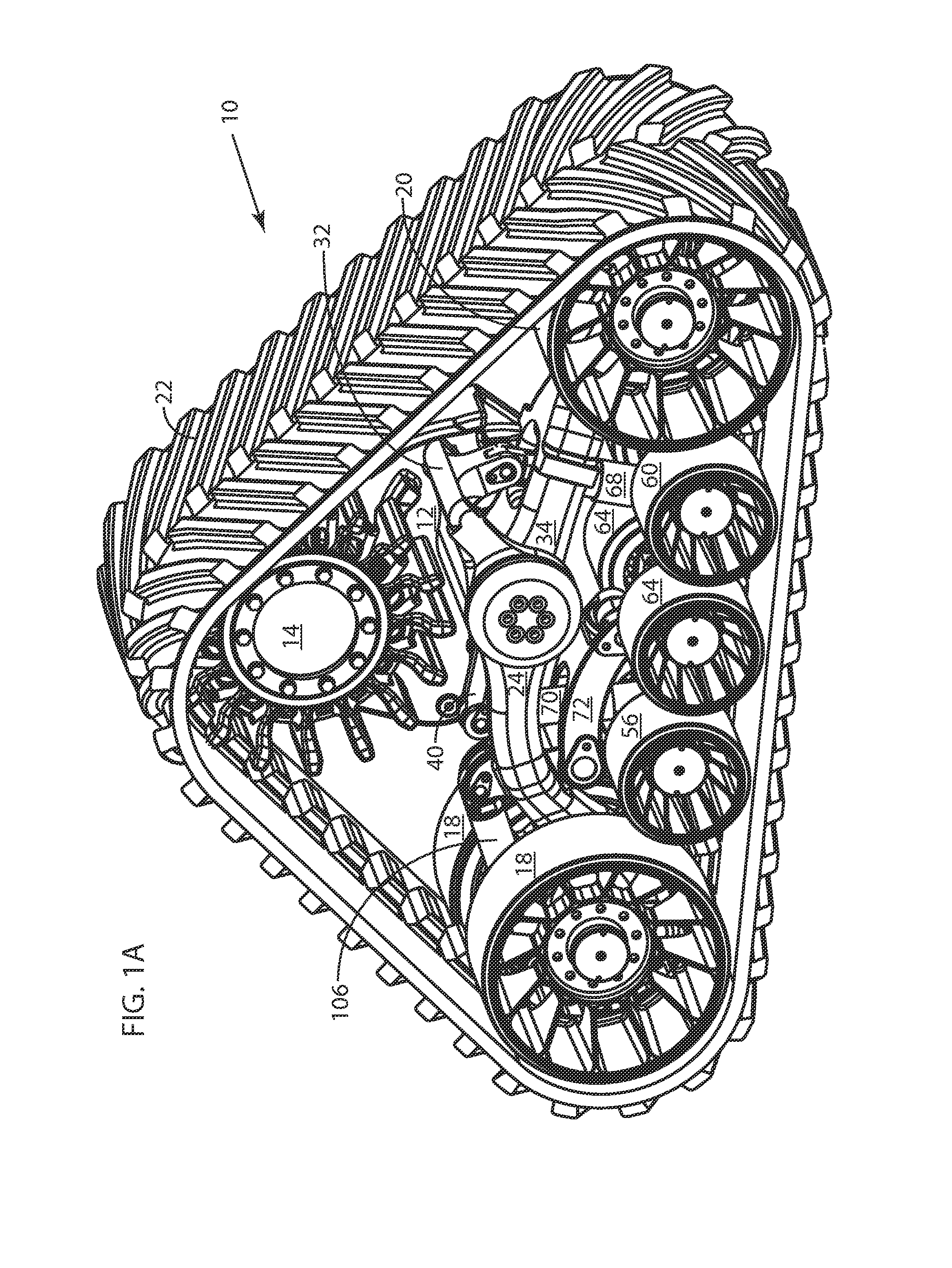

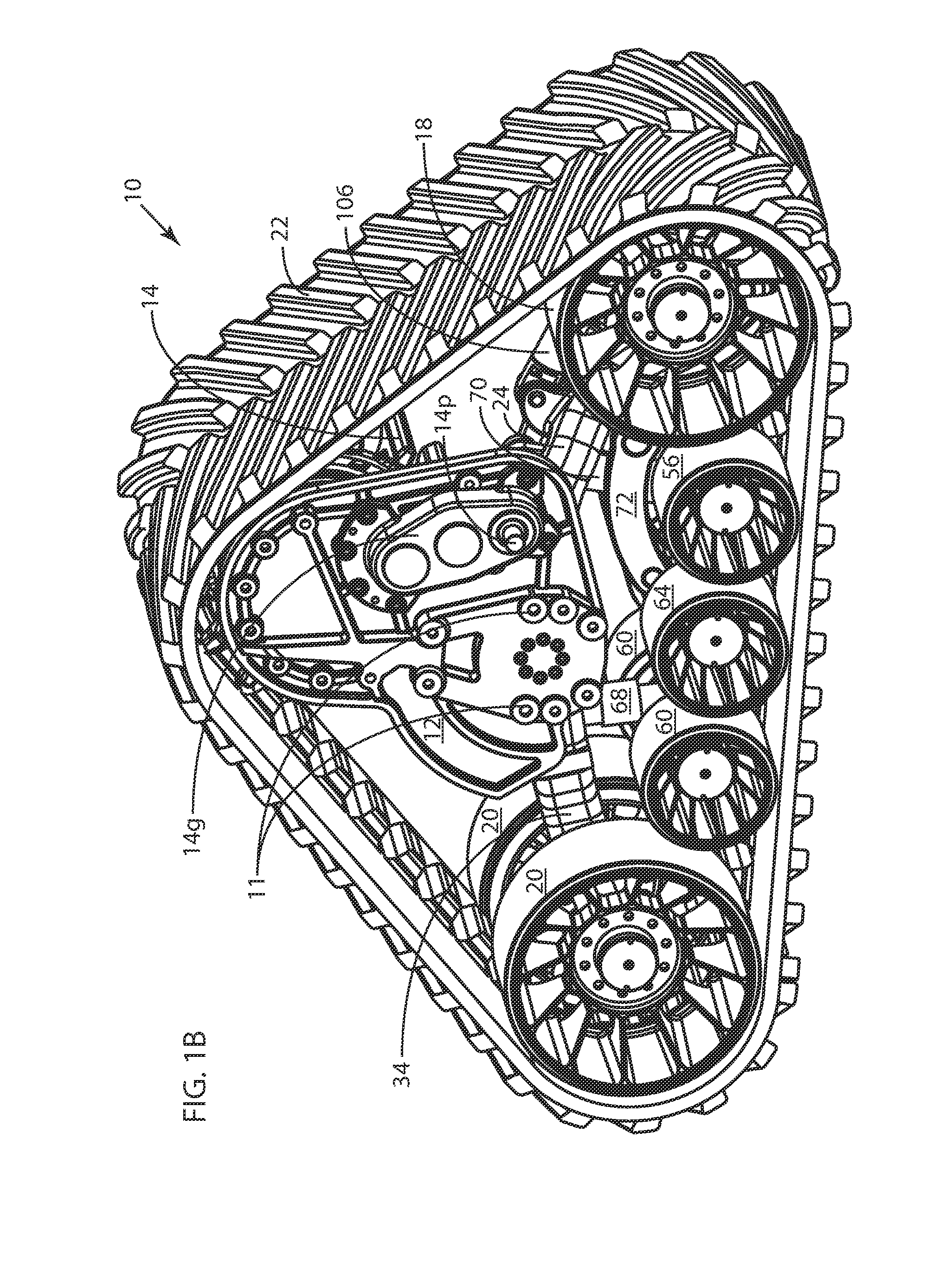

Track-module bogie-suspension system

ActiveUS20160236733A1Improve carrying capacityReduce contact forceResilient suspensionsEndless track vehiclesBogieDrive wheel

Track-module bogie-suspension apparatus for attachment to a track module having a frame, a drive wheel and an endless track. The bogie-suspension apparatus comprises (a) a bogie assembly having a bogie mount, at least one rotatable ground-engaging bogie wheel thereon, and forward and rearward bogie-mount connections; (b) first and second load- and ground-responsive suspension joints spaced from one another in a forward / rearward direction; and (c) leading and trailing suspension elements each having an upper end and a lower end, the upper ends of the leading and trailing suspension elements rotatably attached to the first and second suspension joints, respectively, and the lower ends thereof rotatably attached to the rearward and forward bogie-mount connections, respectively.

Owner:ATI TECH INC

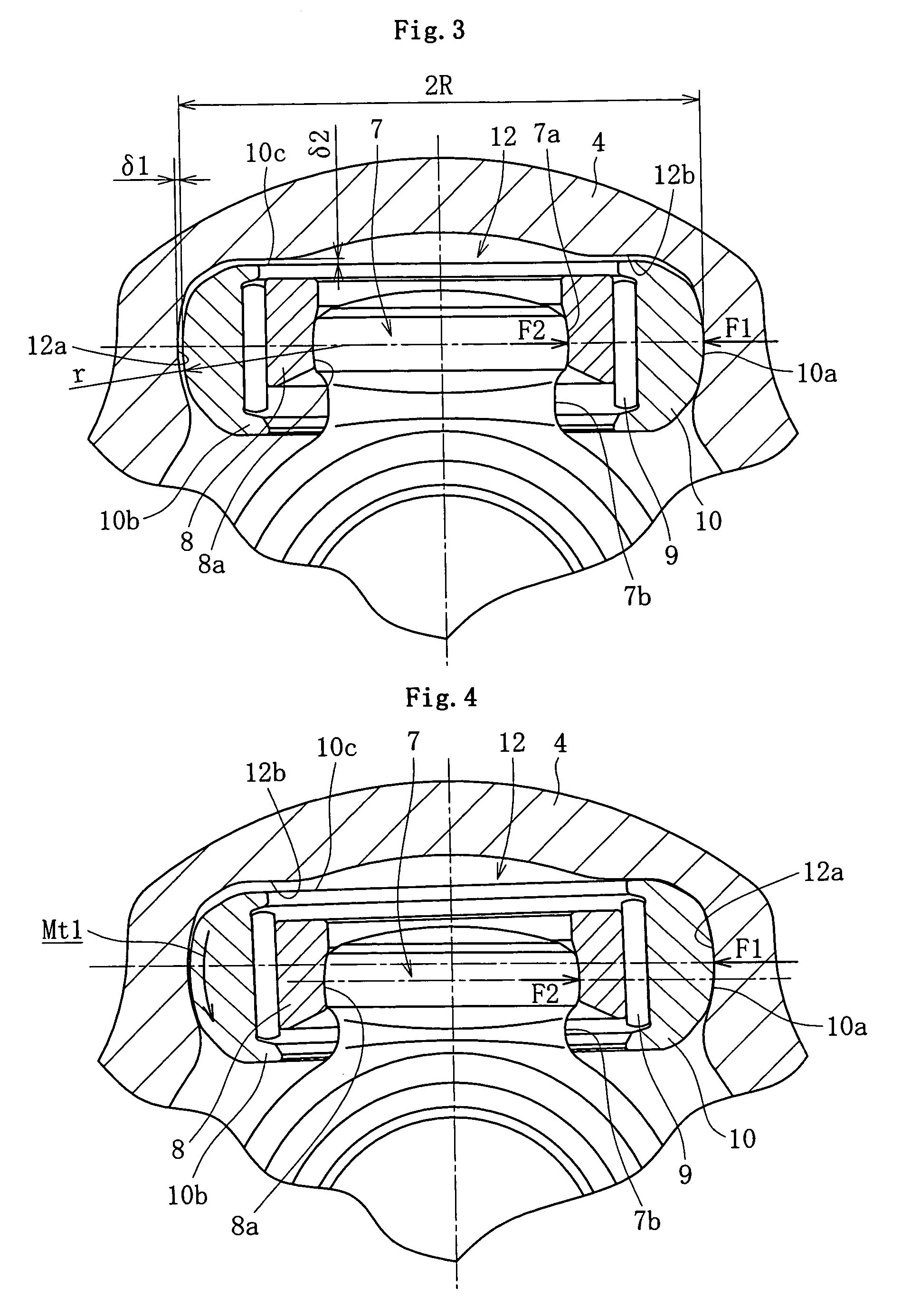

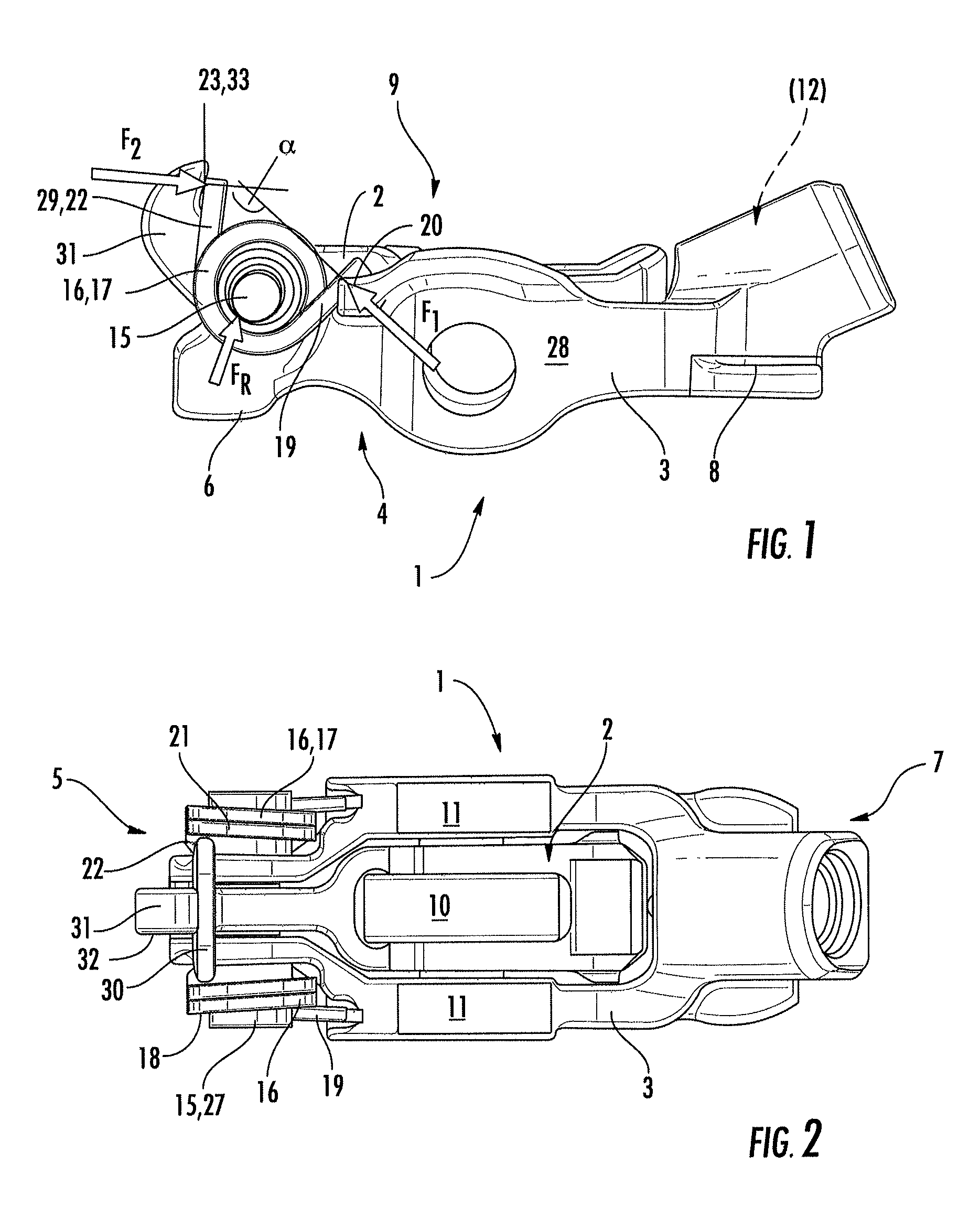

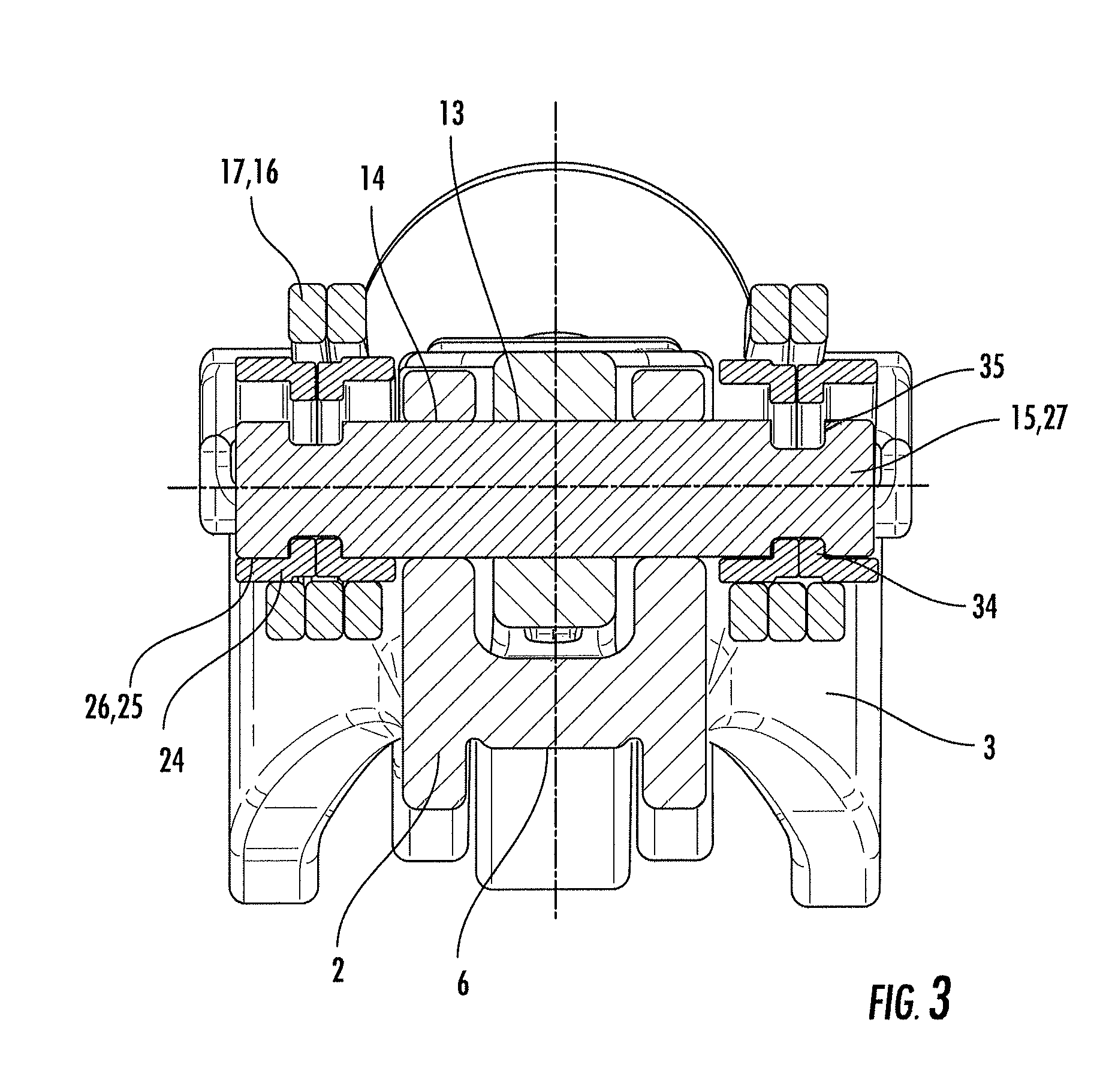

Switchable cam follower

ActiveUS8783219B2Reduce wearHigh righting momentControlling membersValve arrangementsCouplingEngineering

A switchable cam follower (1) of a valve train of an internal combustion engine is proposed, having an inner lever and an outer lever (2, 3), wherein the levers (2, 3) can be connected to one another via coupling means (12) and run on a common pin (15) such that they can be moved pivotably relative to one another, which pin (15) is projected around by at least one group of turns (16) of a swivel pin spring (17) as cam restoring spring, wherein a first limb (19) which protrudes from an end side (18) of the group of turns (16) acts on a first clamping point (20) of the outer lever (3) and a second limb (22) which protrudes from another end side (21) of the group of turns (16) acts on a second clamping point (23) of the inner lever (2), in the rotational direction in such a way that the levers (2, 3) are present such that they are stressed towards one another, wherein the pin (15) runs in a “floating” manner with respect to the holes (13, 14), wherein the group of turns (16) comprises a bush (24) with play, wherein axial fixing of the pin (15) is produced via the offset contact of the group of turns (16) on the bush (24), which offset contact is brought about by the system stressing, and therefore the offset contact of said bush (24) on the pin (13), and wherein, in order to reduce a resulting contact force (FR) in the region of the contact of the group of turns (16) on the bush (24), the clamping points (20, 23) of the two limbs (19, 22) of the group of turns (16) are positioned in such a way that an angle (α) which is enclosed by intersecting force vectors at the clamping points (20, 23) [direction of action of the two contact forces (F1, F2)] lies in the range (90°<α<180°).

Owner:SCHAEFFLER TECH AG & CO KG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com