Electric pump

a technology of electric pumps and impellers, applied in the direction of pump components, piston pumps, non-positive displacement fluid engines, etc., can solve the problems of impeller wear and fluctuation of fluid pressure, and achieve the effect of controlling the occurrence of unpleasant noise and reducing the vibration of the impeller

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

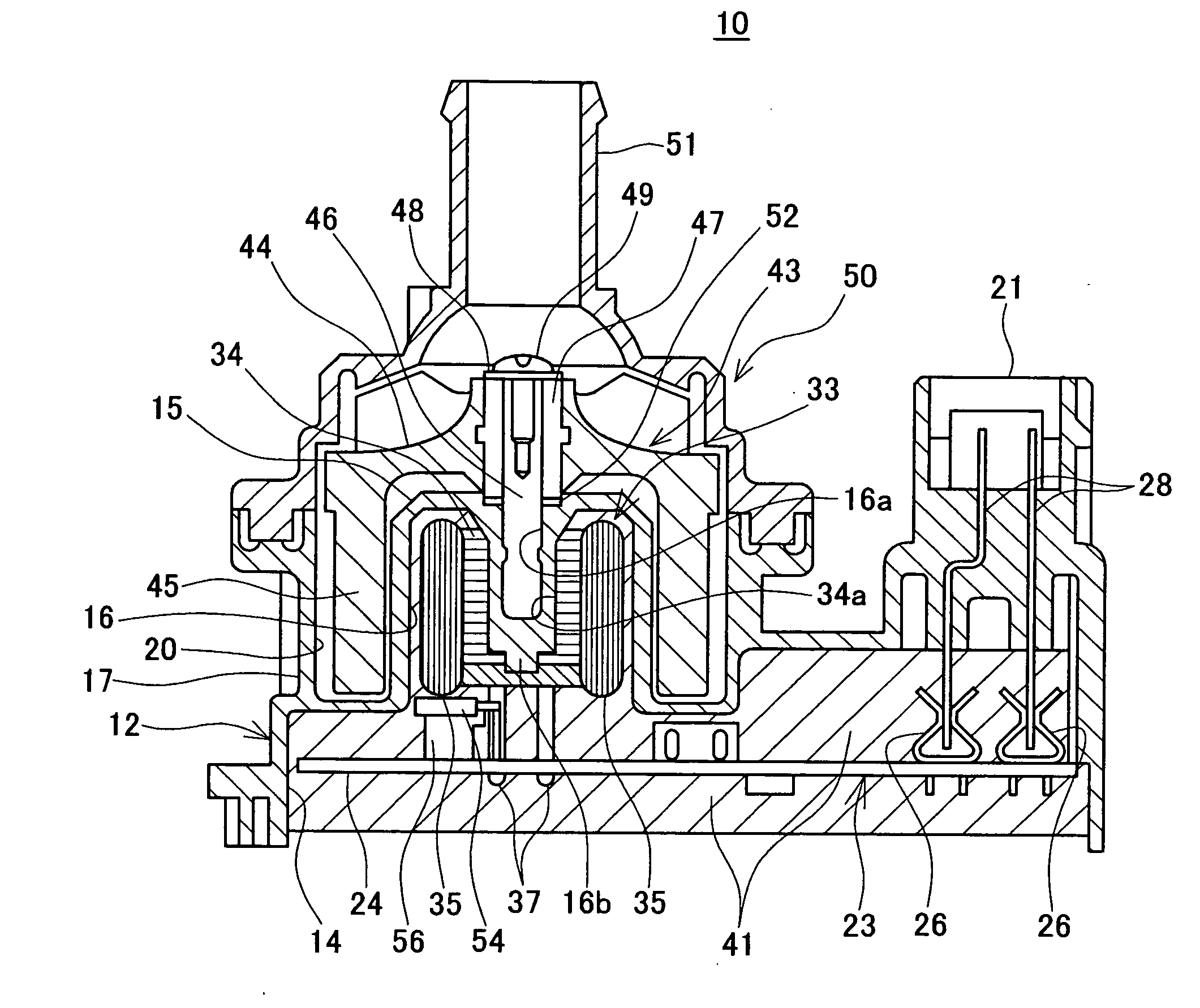

[0020]An electric pump 10 according to the first representative embodiment will be explained with reference to the drawings. The electric pump 10 may be used to circulate cooling water to cool the engine of an automobile, and be installed in the engine room of the automobile.

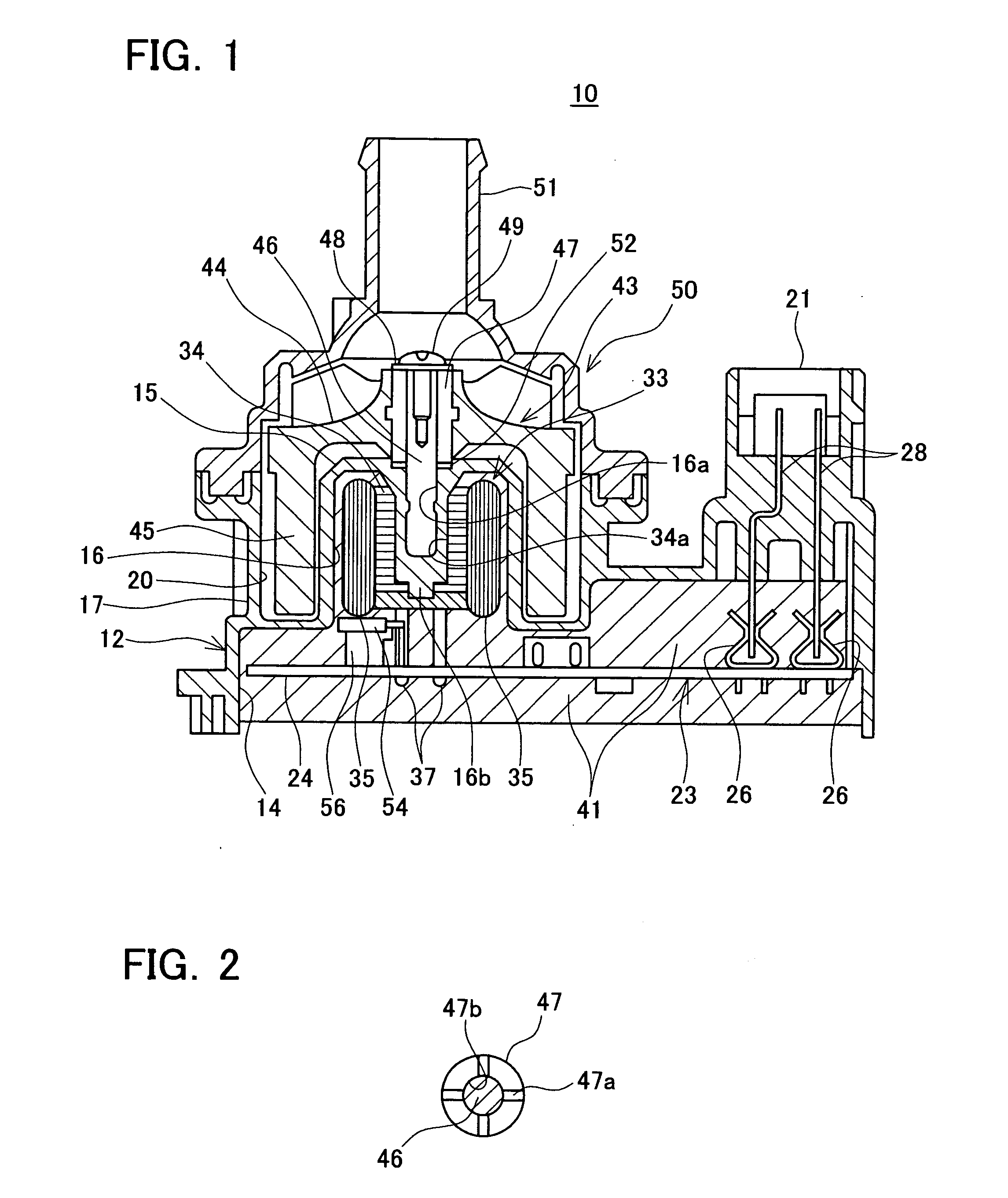

[0021]As shown in FIG. 1, the electric pump 10 includes a lower body 12 and an upper body 50 fixed to the lower body 12. Each of the lower body 12 and the upper body 50 may be formed integrally from a material such as resin. A cylindrical shaped protrusion 15 is formed in the top of the lower body 12 (on the left side in the figure). A shaft installation hole 16a is provided in the center of the protrusion 15. The lower end of a shaft 46 is fixed in the shaft installation hole 16a. The top end of the shaft 46 projects higher than the top surface of the protrusion 15. An impeller 43 is rotatably attached to the top end of the shaft 46.

[0022]An external wall 17 is formed in a cylindrical shape around the protrusio...

second embodiment

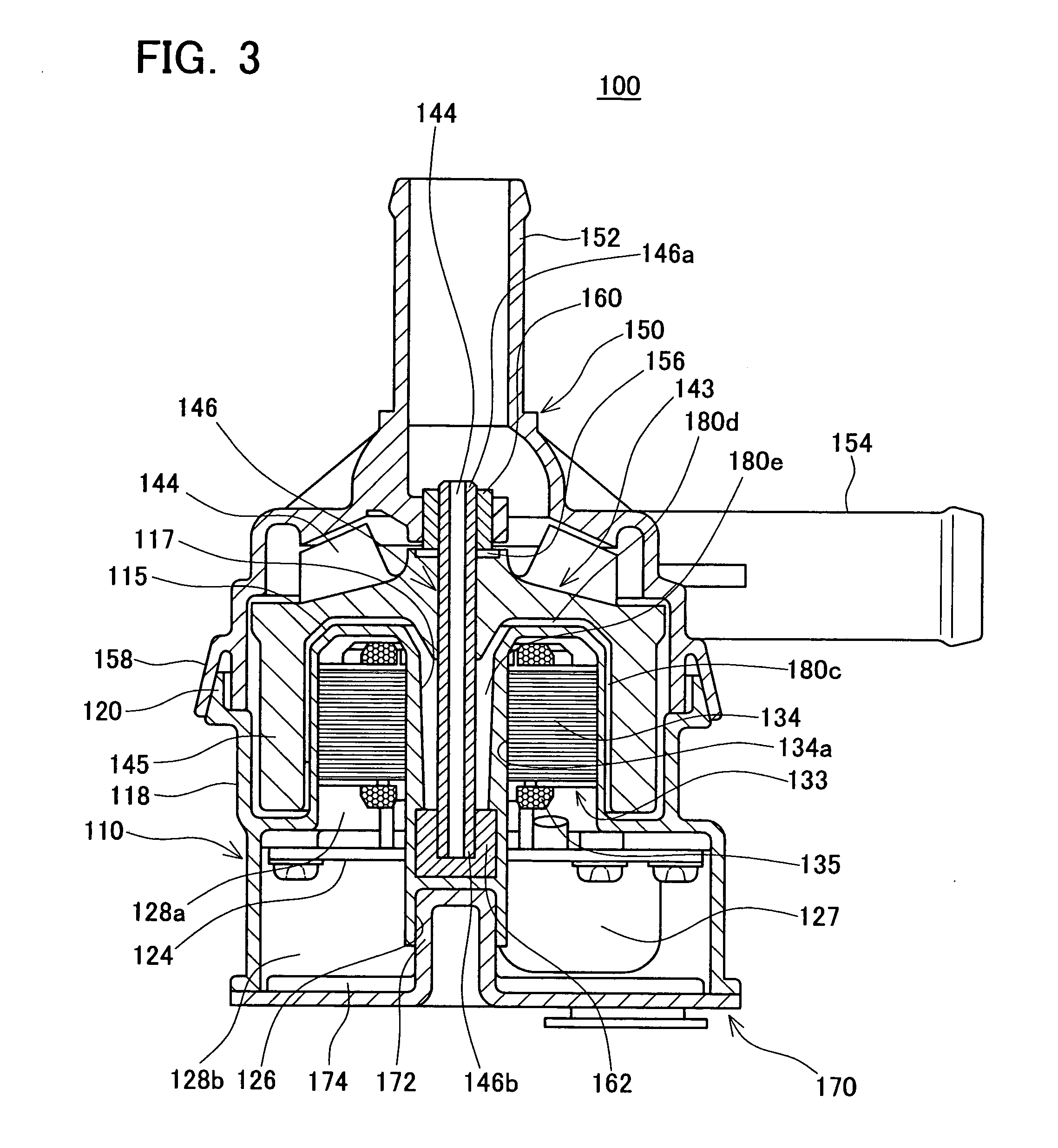

[0040]Next, the electric pump 100 according to a second representative embodiment is explained. The electric pump 100 may also be used to circulate cooling water to cool the engine of an automobile.

[0041]As shown in FIG. 3, the electric pump 100 includes a lower body 110, an upper body 150 fixed to the top end of the lower body 110, and a lid 170 fixed to the bottom end of the lower body 110. A cylindrical shaped protrusion 115 is formed in the top of the lower body 110. An external wall 118 is formed in a cylindrical shape around the protrusion 115. The protrusion 115 and the external wall 118 are disposed concentrically. A cylindrical portion 145 of an impeller 143 is housed between the protrusion 115 and the external wall 118.

[0042]A bearing installation hole 117 is provided in the center of the protrusion 115, and a bearing 162 is installed in the bottom of the bearing installation hole 117. A bottom end 146b of a hollow shaft 146 is inserted into the bearing 162. The bearing 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com