Encapsulated refrigeration compressor

A refrigeration compressor and a sealed technology, applied in the field of compressors, can solve problems such as large loss, and achieve the effects of simple structure, easy improvement and convenient assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

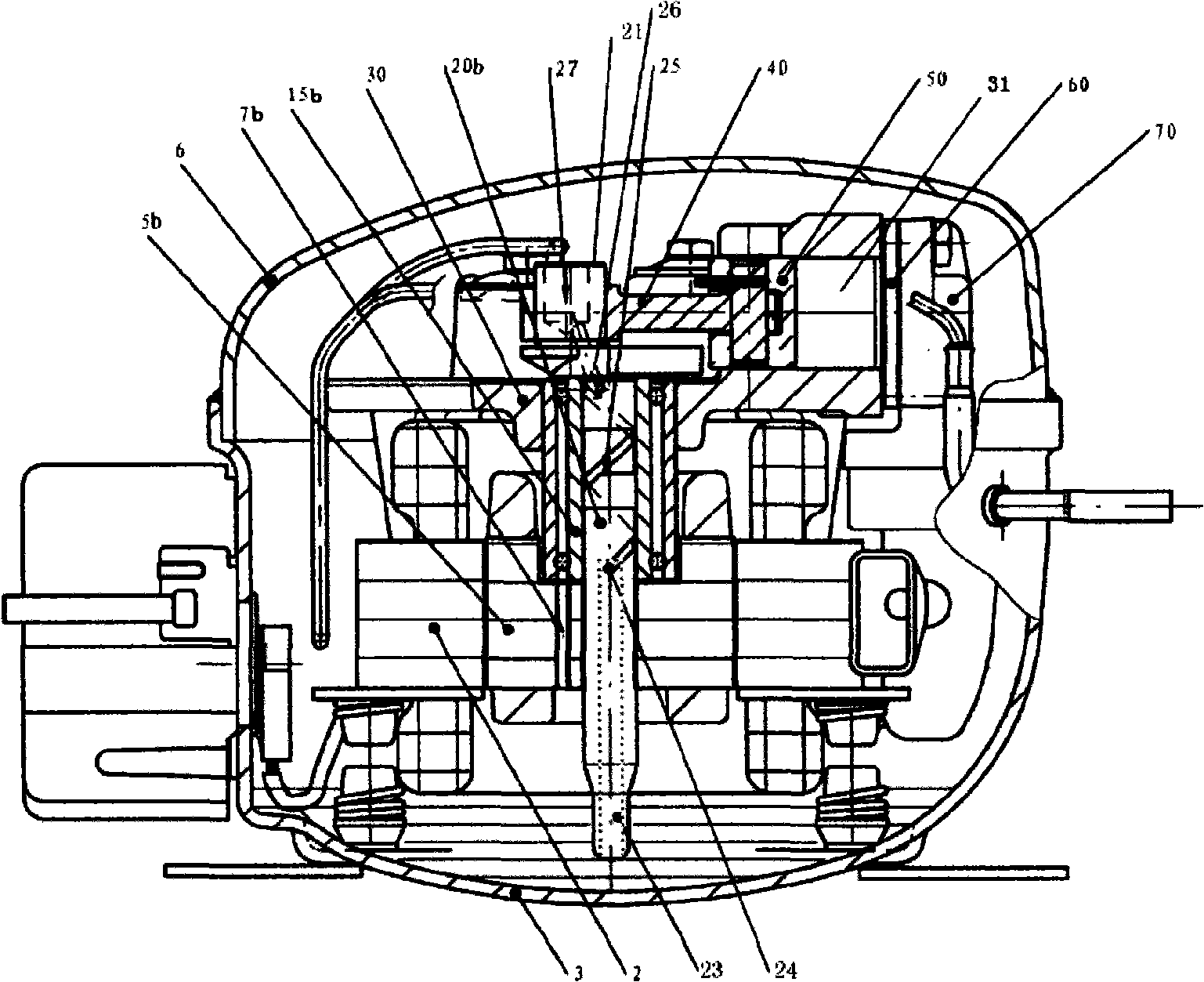

[0034] refer to figure 2 , Fig. 5, Fig. 6 and Fig. 7, a kind of hermetic refrigeration compressor provided by the present invention, it has sealed shell 3 and 6, has the electric motor that is made up of stator 2 and rotor 5b in the sealed shell and is driven by this motor The gas compression device comprises a cylinder block 30, a cylinder 31, a valve group 60, a cylinder head 70, a piston 50, a piston connecting rod 40, and a crankshaft 20b. Mounting hole, the crankshaft 20b passes through the crankshaft mounting hole, one end of the crankshaft 20b has an eccentric shaft 21, the piston connecting rod 40 connects the eccentric shaft 21 with the piston 50 placed in the cylinder 31, and the motor stator 2 is fixedly installed on the cylinder base 30 , the crankshaft 20b has a lubricating oil supply passage: oil suction hole 23 → perforation 24 → spiral oil groove 25 → oblique perforation 26 → eccentric shaft hole 27, it is characterized in that: a double row ball bearing assem...

Embodiment 2

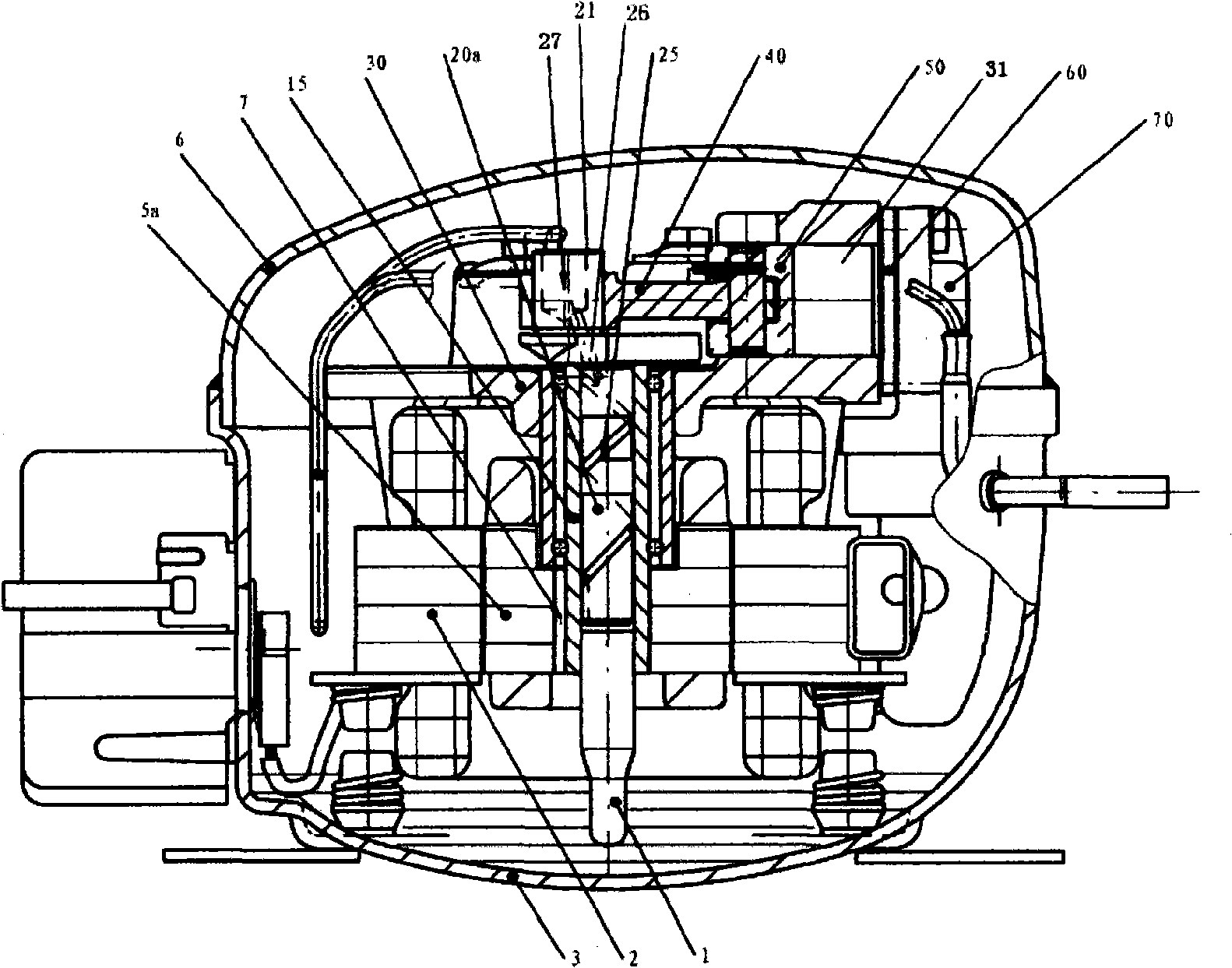

[0039] refer to image 3 , Fig. 8, Fig. 10 and Fig. 11, a kind of hermetic refrigerating compressor, it has sealed casing 3 and 6, has the electric motor that is made up of stator 2 and rotor 5a and the gas compressing device driven by this motor in the sealed casing , the gas compression device comprises a cylinder block 30, a cylinder 31, a valve group 60, a cylinder head 70, a piston 50, a piston connecting rod 40, a short crankshaft 20a and an oil suction pipe 1, the cylinder 31 is connected to the cylinder block 30, and the middle part of the cylinder block 30 is arranged Crankshaft installation hole, the short crankshaft 20a passes through the crankshaft installation hole, one end of the short crankshaft 20a has an eccentric shaft 21, the piston connecting rod 40 connects the eccentric shaft 21 and the piston 50 placed in the cylinder 31, and the motor stator 2 is fixedly installed on the cylinder On the seat 30, the short crankshaft 20a has a lubricating oil supply pass...

Embodiment 3

[0046] refer to Figure 9 , the short crankshaft 20a and the oil suction pipe 1 in the second embodiment are replaced by the crankshaft 20b of the first embodiment, and other structures and working methods are the same as those of the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com