Super highly effective hollow direct drive generating plant possessing anti-gravity magnetic suspension bearing

A technology for magnetic suspension bearings and power generation equipment, applied in the field of electrical appliances, can solve problems such as inability to effectively utilize low-grade energy, and achieve the effects of high mechanical energy conversion efficiency, improved utilization, and extended reliability and working life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

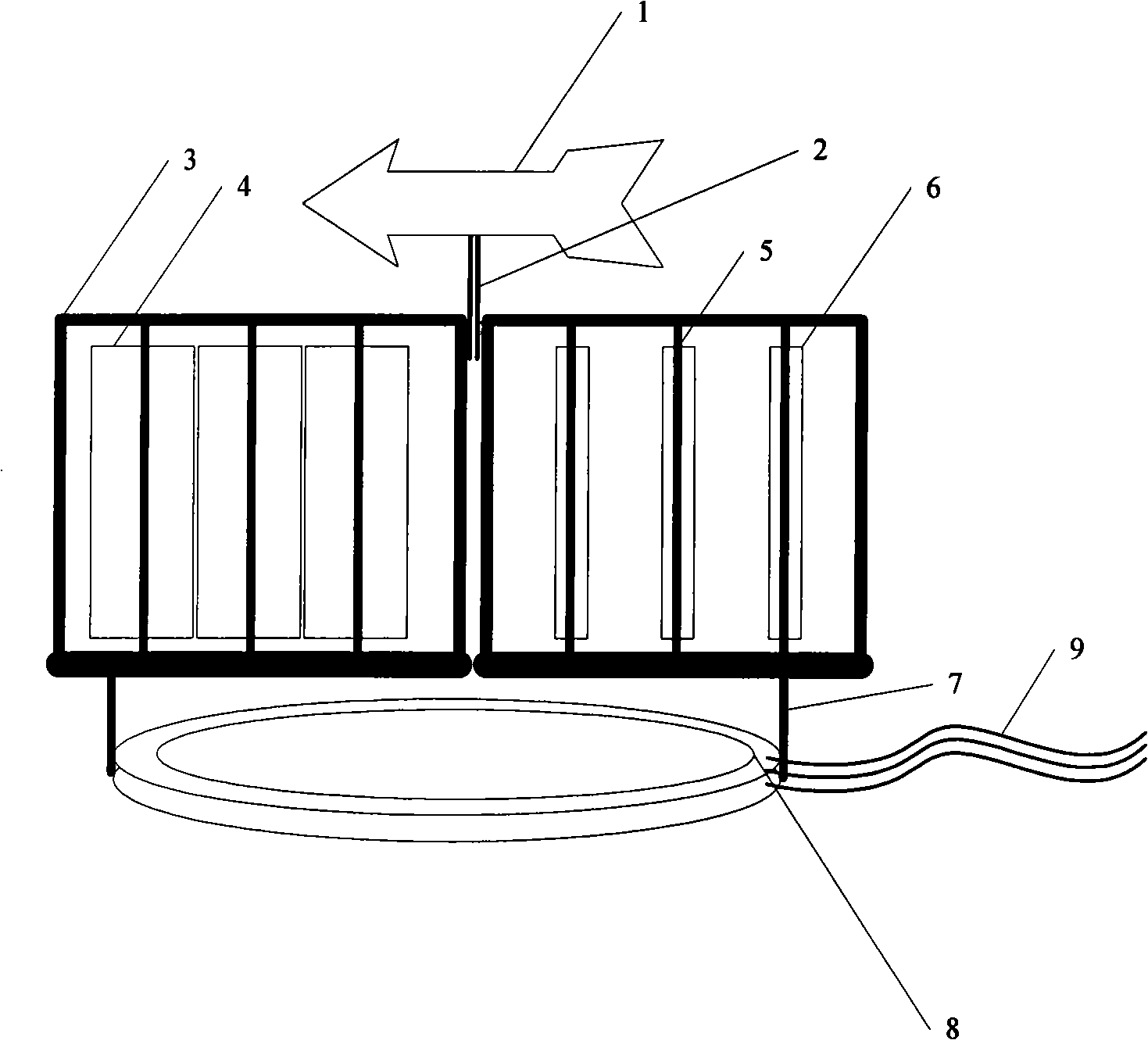

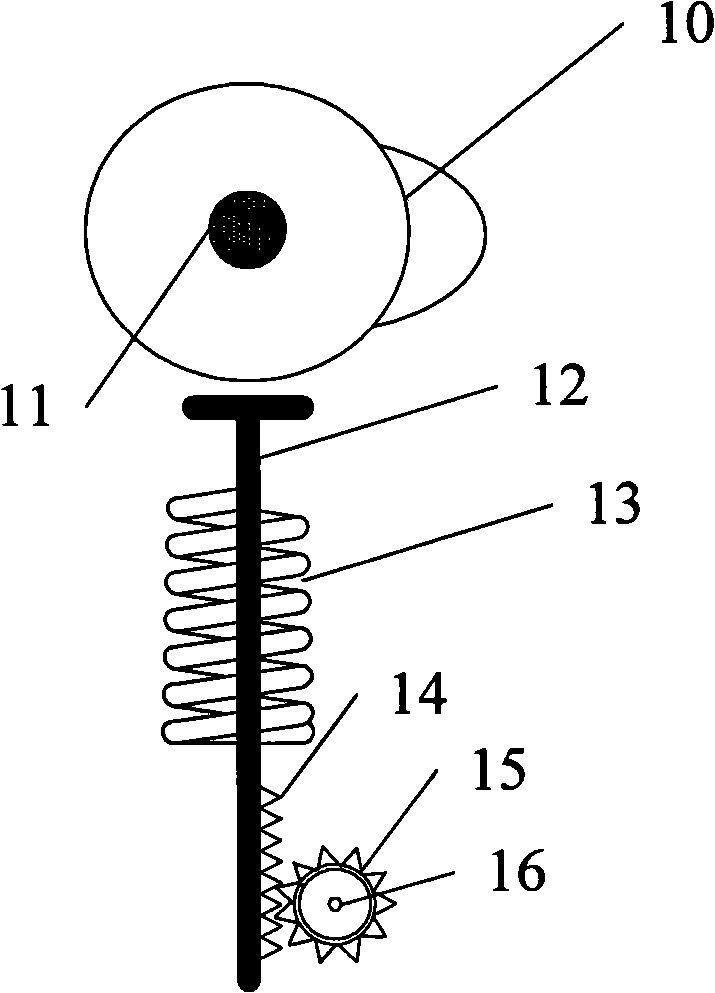

[0024] Depend on Figure 1-Figure 7 Given, the present invention converts wind energy into mechanical energy with a wind wheel structure without reverse resistance, and then uses an air-core direct-drive generator to convert the mechanical energy into electrical energy, and then the conversion controller converts and stores the electrical energy from the generator for load Application, the upper part of the wind rotor matrix with linearly superimposed power is equipped with a wind rudder, and a conversion controller is installed between the air-core direct-drive generator and the power grid to realize the air-core direct-drive generator and counter-generator connected to the shaft of the wind rotor matrix. The electric energy sent out is controlled for conversion and storage, and the wind vane 1 passes through the cam transmissi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com