hermetic compressor

A closed compressor, compression chamber technology, applied in liquid variable capacity machinery, rotary piston machinery, mechanical equipment, etc., can solve problems such as compression loss and excessive compression, reduce mechanical friction loss, improve compressor Efficiency, effect of preventing refrigerant leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Hereinafter, a vane rotary compressor according to the present invention will be described in detail based on embodiments shown in the drawings.

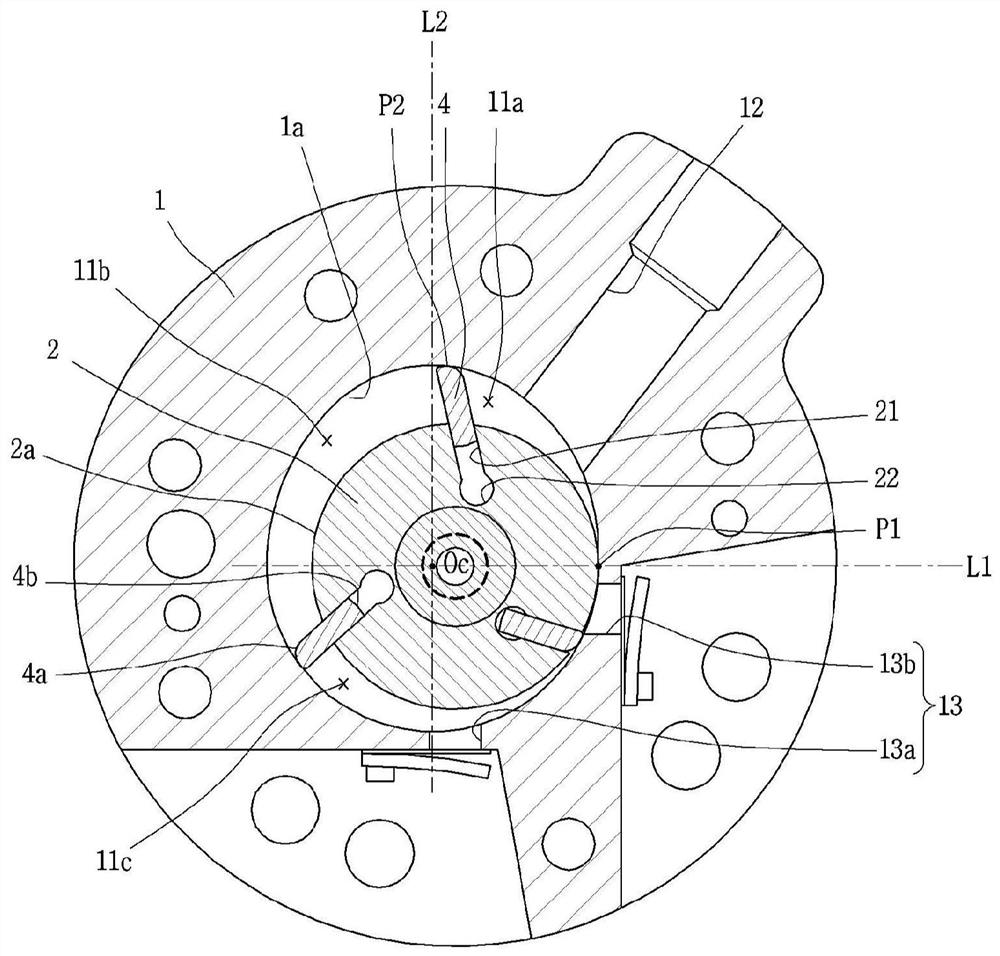

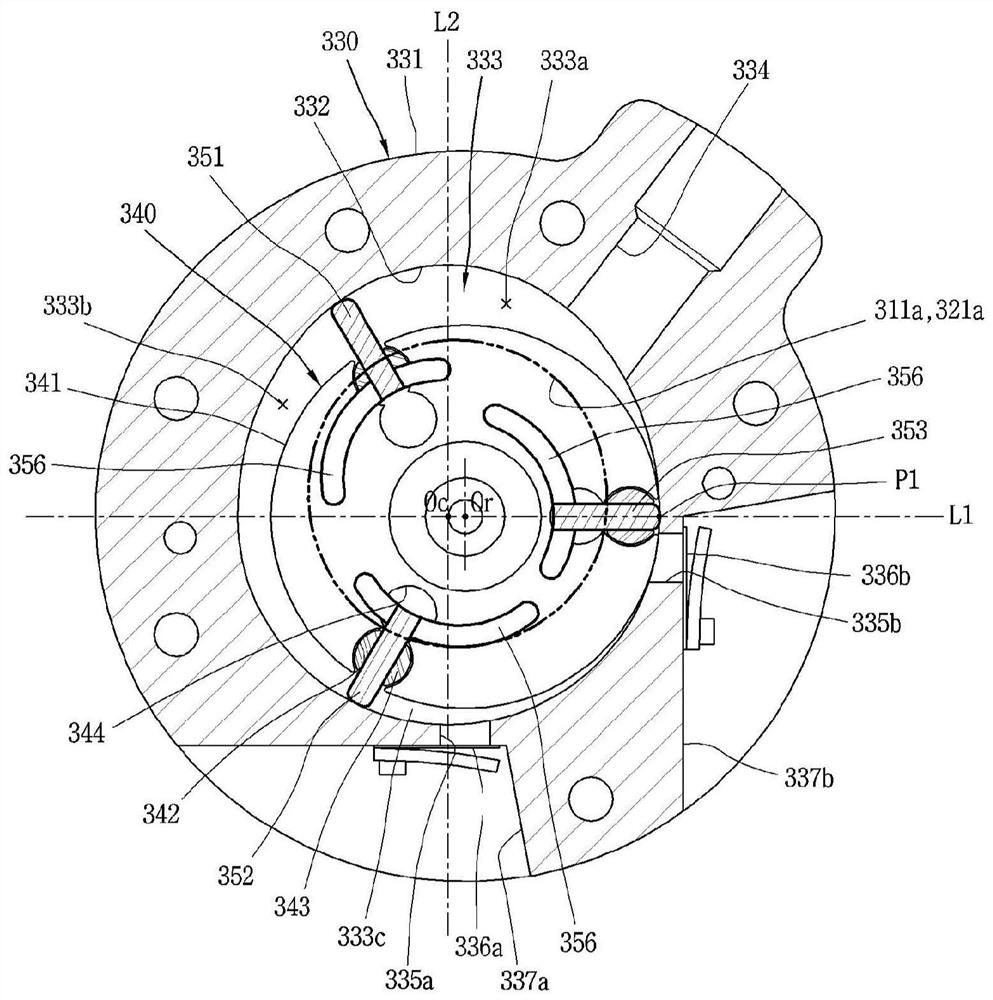

[0055] figure 2 is a longitudinal sectional view of a vane rotary compressor according to the present invention, image 3 is along figure 2 Cross-sectional view of the "V-V" section of the compression section in a rotary vane compressor of .

[0056] like figure 2 As shown, in the vane rotary compressor according to the present invention, the motor section 200 is installed inside the casing 100 , and the compression section 300 mechanically connected through the rotation shaft 250 is installed on one side of the motor section 200 . Depending on how the compressor is installed, the casing 100 may be divided in a vertical or lateral direction, or vertically or laterally. When the housing 100 is divided vertically, the motor section and the compression section are arranged on the upper side and the lower side, respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com