Motor test system and method

A technology for motor testing and motor stators, which is used in motor generator testing, measuring electricity, measuring devices, etc., can solve problems such as low stability and consistency, improve stability and consistency, avoid direct contact, and reduce mechanical The effect of friction loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following embodiments of the present invention are only for the convenience of describing the structure, and do not limit the structure to be protected by the present invention.

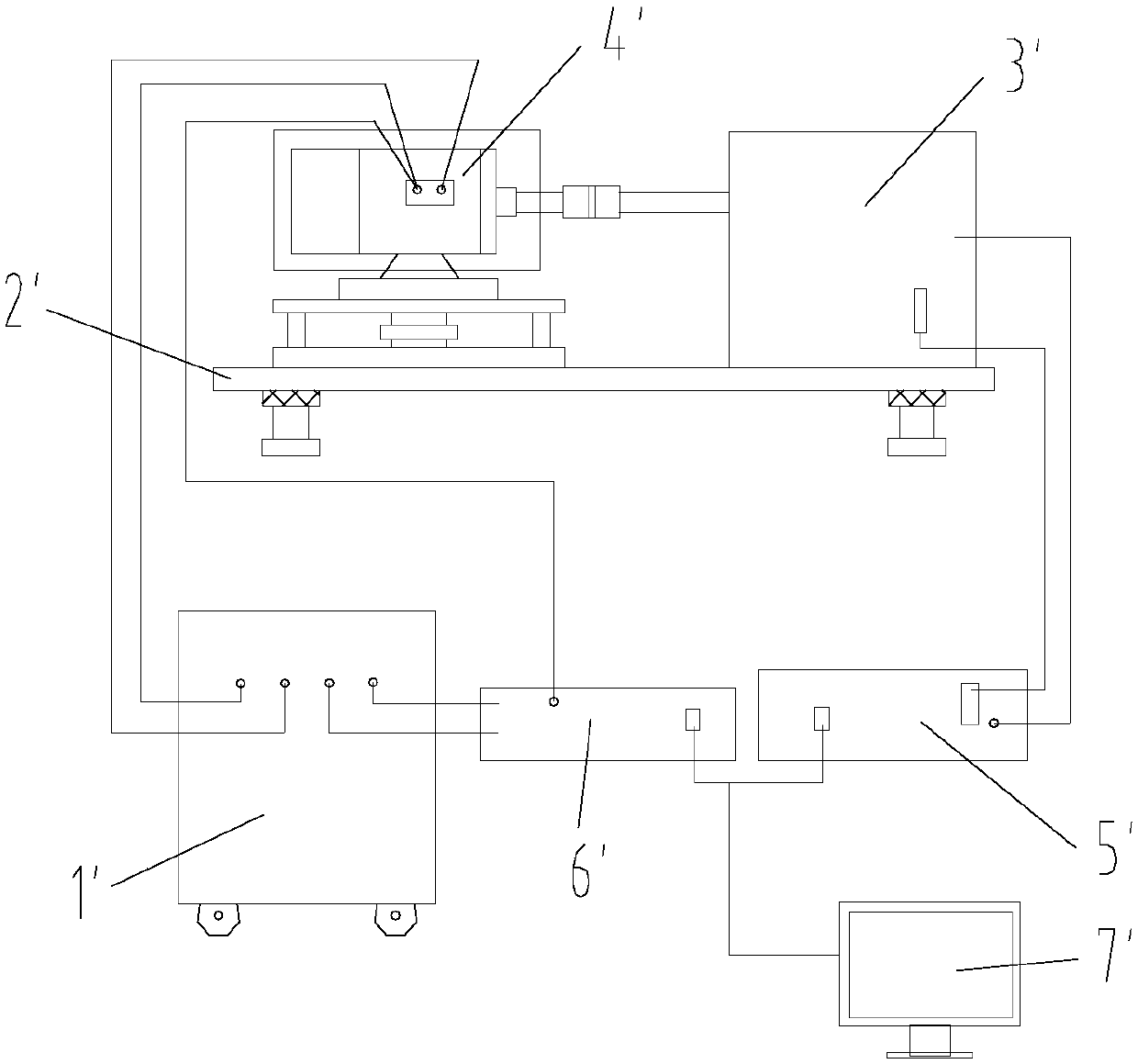

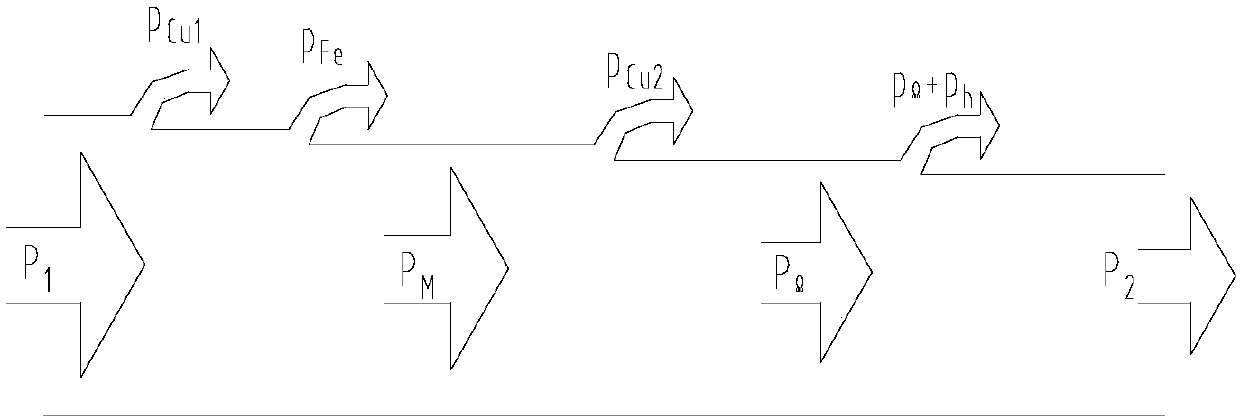

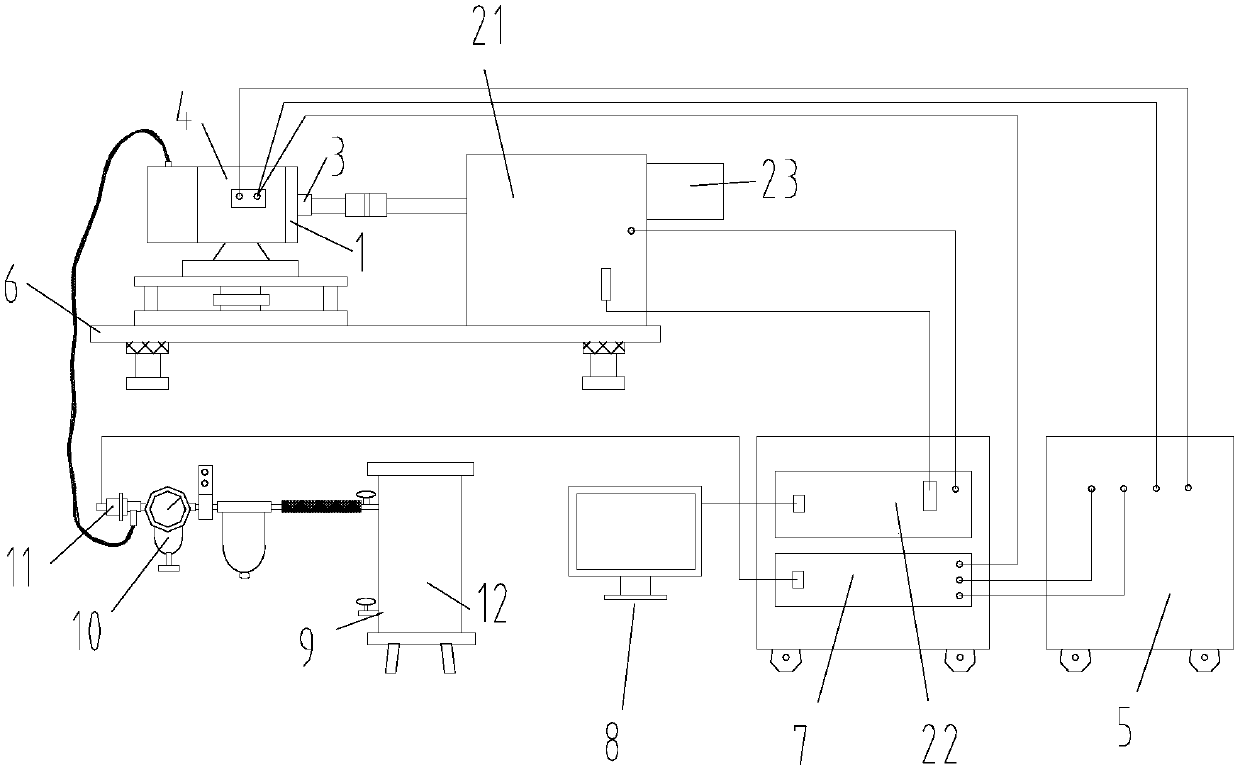

[0035] see in conjunction Figure 3 to Figure 5 As shown, according to an embodiment of the present invention, the present invention provides a motor testing system, including a fixture 1 for clamping the stator of the motor to be tested, a dynamometer for testing the power of the motor to be tested, and the dynamometer The connecting shaft 3 and the bearing 4 connected by the extending shaft of the machine, the bearing 4 includes a main shaft 41 connected to the connecting shaft 3 and a shaft sleeve 42 sleeved outside the main shaft 41; wherein, the shaft sleeve 42 is fixedly arranged with the fixture 1, and the main shaft 41 is suspended in the axle sleeve 42. The present invention suspends the main shaft 41 connected with the rotor of the motor to be tested in the shaft sleeve 42, avoi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com