A Porous Metal Matrix Composite Bearing Based on Elastohydrodynamic Lubrication

A composite material and porous metal technology, applied in the field of bearings, can solve the problems of lack of elastohydrodynamic lubrication and limit the bearing capacity of ball bearings, and achieve the effects of improving thermal conductivity, increasing bearing capacity, and reducing mechanical friction loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

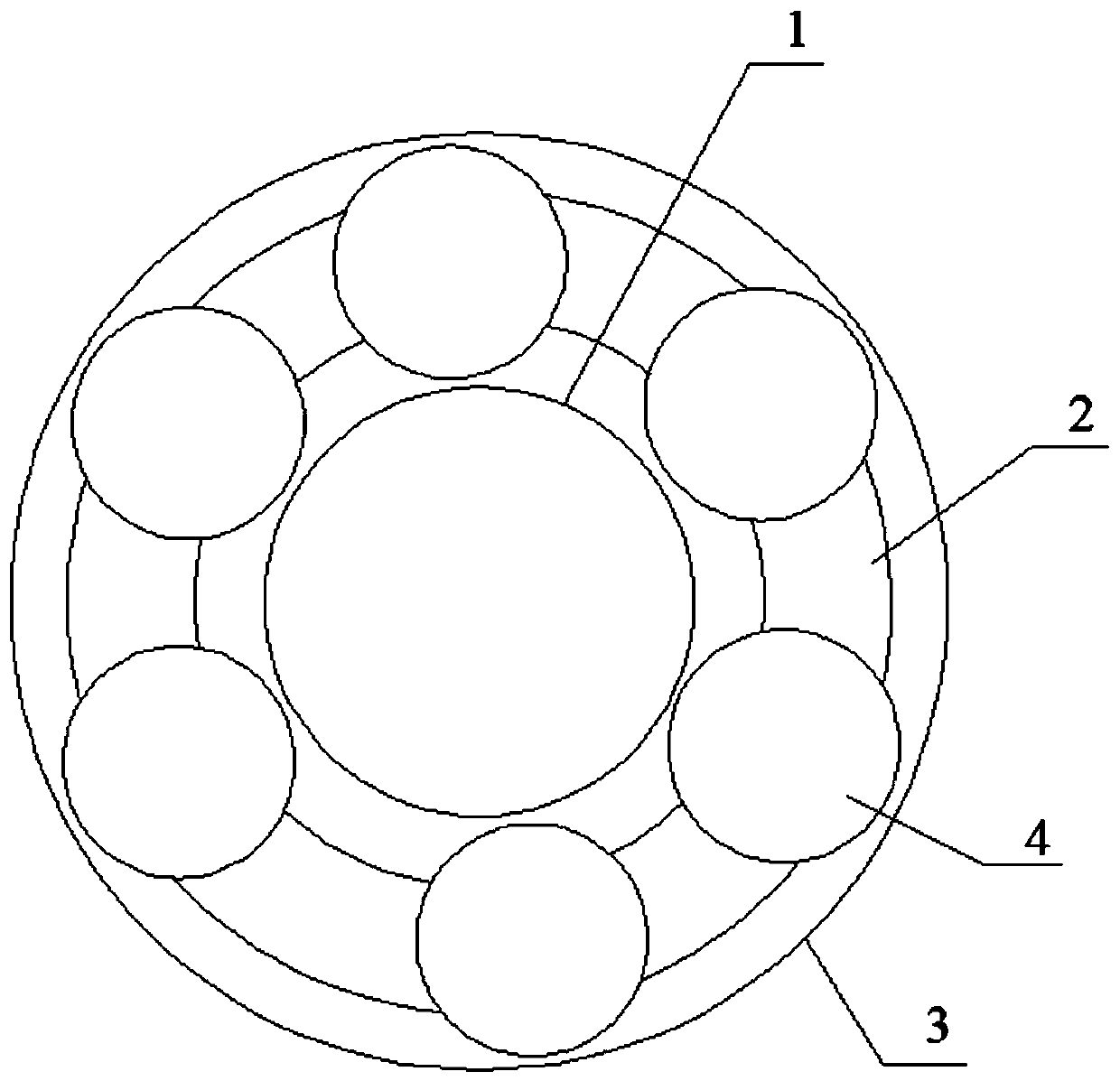

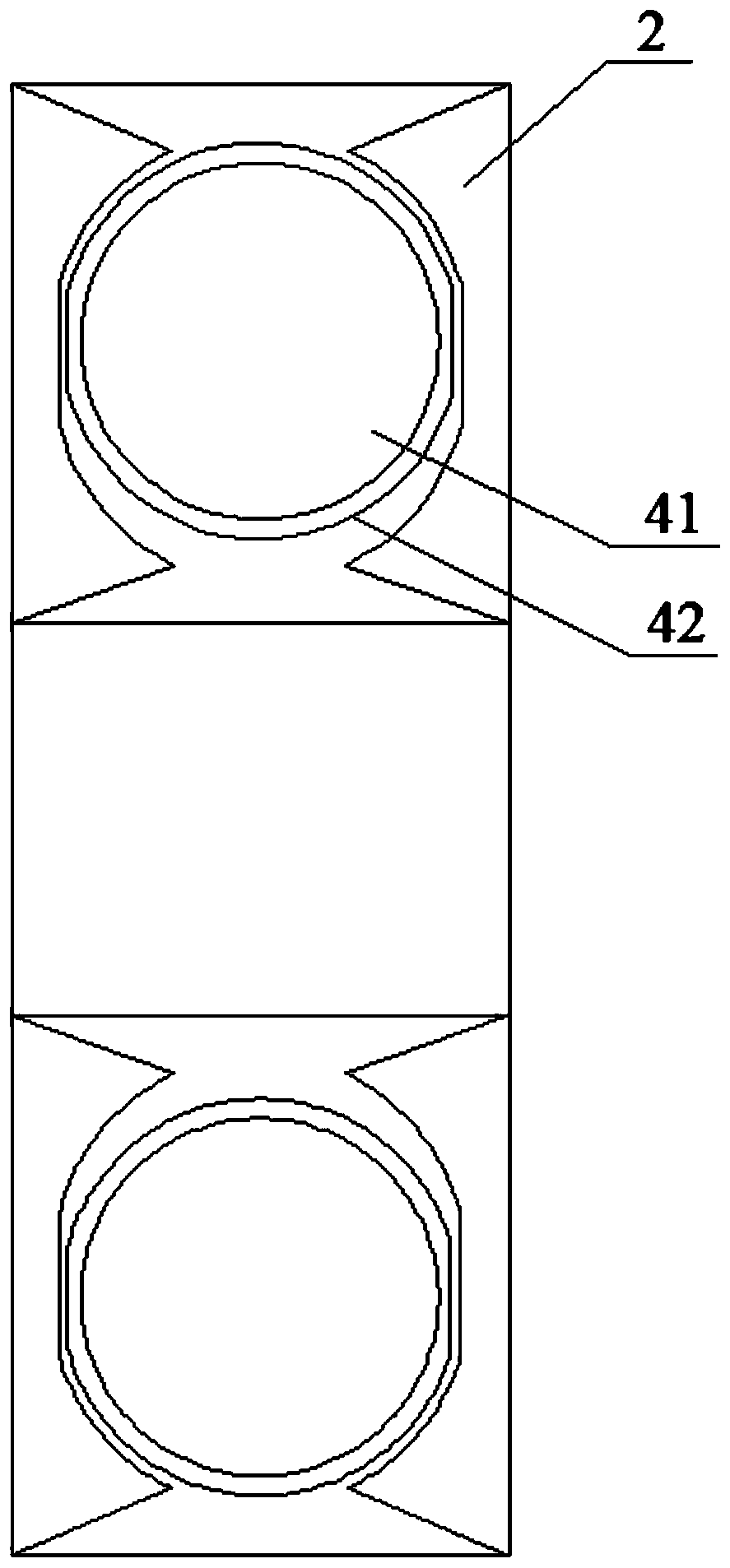

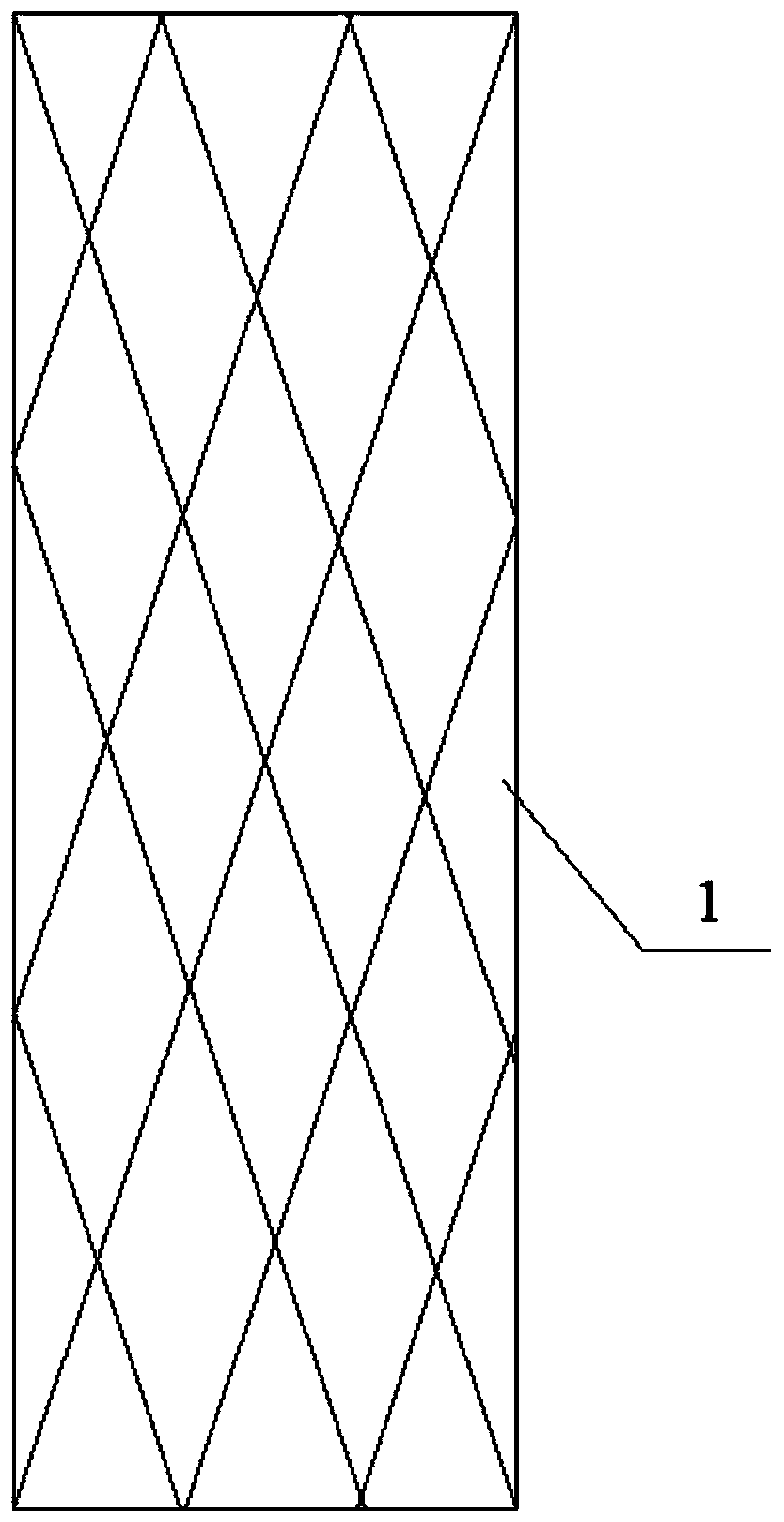

[0028] A porous metal matrix composite bearing based on elastohydrodynamic lubrication, specifically as Figure 1~3 As shown, it includes a bearing inner ring 1, a rolling ball cage 2 and a bearing outer ring 3 arranged in sequence from inside to outside, and a number of rolling balls evenly distributed around the bearing inner ring 1 are installed in the rolling ball cage 2 4, and the rolling ball 4 includes a spherical matrix 41 with a porous surface, and the outer surface of the spherical matrix 41 is wrapped with an elastic reinforcement layer 42 . The bearing inner ring 1, rolling ball cage 2, bearing outer ring 3 and rolling balls 4 are assembled according to the deep groove ball bearing structure in the prior art or other bearing components with balls.

[0029] The spherical base 41 is a metal ball or an alloy ball, such as a copper ball, a shot ball, a stainless steel ball, or a titanium alloy ball. The elastic reinforcement layer 42 is made of rubber, ceramic or resi...

Embodiment 2

[0040] A preparation method of the spherical base 41 is specifically implemented according to the following steps:

[0041] Step 1: Soak the spherical matrix 41 in alkali solution, then ultrasonically treat at 60°C, wash, and dry at 100°C to obtain the pretreated spherical matrix A;

[0042] Wherein, the lye is a sodium hydroxide solution with a mass concentration of 10%;

[0043] Step 2, place the pretreated spherical matrix A in step 1 in a hydrogen furnace, and keep it warm at 300°C for 10 hours, and obtain the pretreated spherical matrix B after the heat preservation is completed;

[0044] Step 3, compound a layer of elastic reinforcement material (ceramic) on the outer surface of the pretreatment ball base B in step 2 to form an elastic reinforcement layer 42 to obtain a spherical base 41, as follows: the pretreatment ball base B is packed into a centrifuge In the casting machine, the molten elastic reinforcement material (ceramic) is used for centrifugal casting, and afte...

Embodiment 3

[0046] A preparation method of the spherical base 41 is specifically implemented according to the following steps:

[0047] Step 1: Soak the spherical matrix 41 in alkali solution, then ultrasonically treat it at 35°C, wash it, and dry it at 60°C to obtain the pretreated spherical matrix A;

[0048] Wherein, the lye is a 10% sodium hydroxide solution with a mass concentration of thiourea dioxide added, and the mass fraction of thiourea dioxide in the sodium hydroxide solution is 0.05%;

[0049] Step 2, put the pretreated spherical matrix A in step 1 in a hydrogen furnace, and keep it warm at 400°C for 6 hours, and obtain the pretreated spherical matrix B after the heat preservation is completed;

[0050] Step 3, compound a layer of elastic reinforcement material (resin) on the outer surface of the pretreatment spherical matrix B in step 2 to form an elastic reinforcement layer 42 to obtain a spherical matrix 41, specifically as follows: put the pretreatment spherical matrix B ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com