Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Reduce broken rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

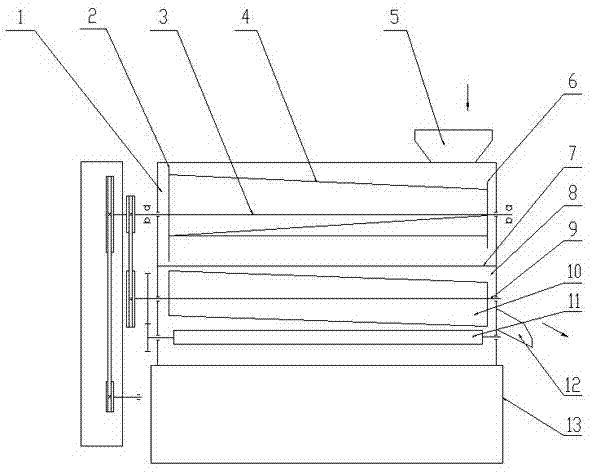

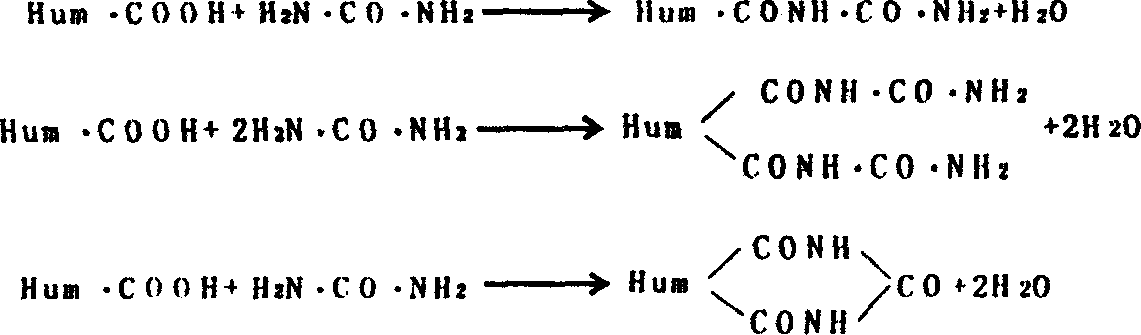

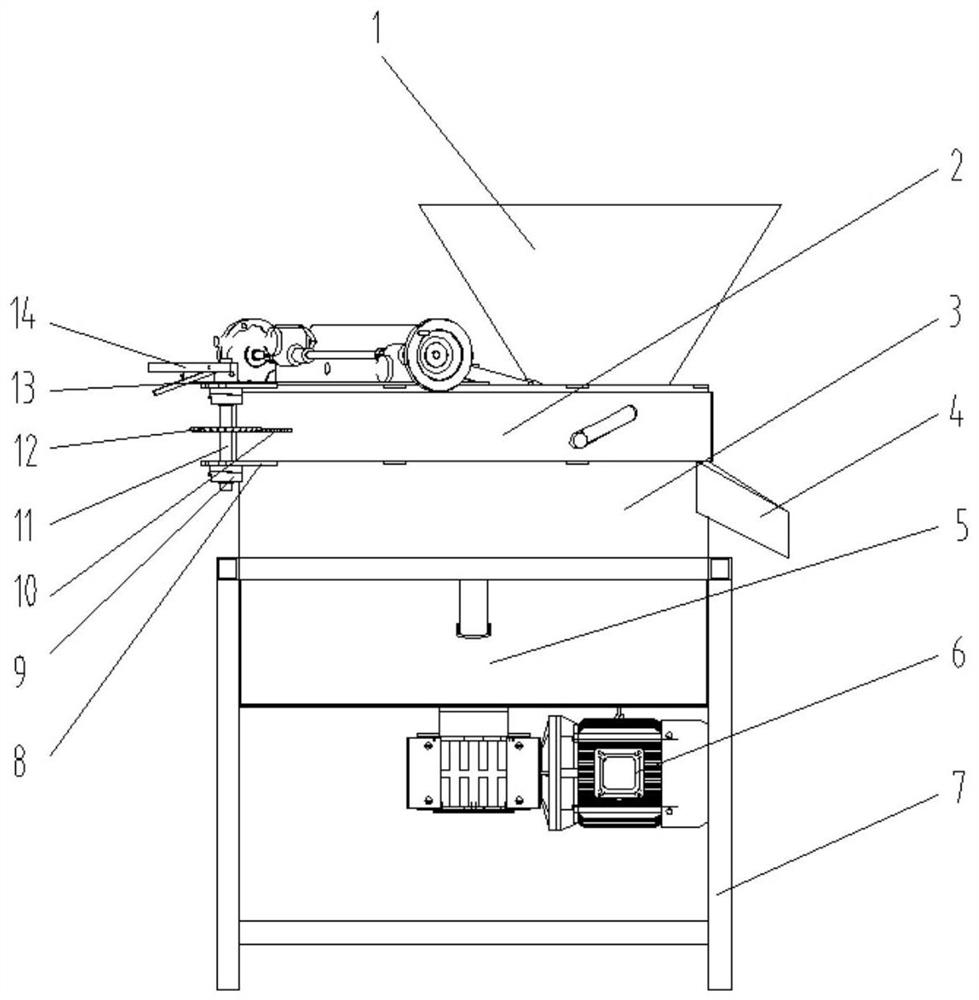

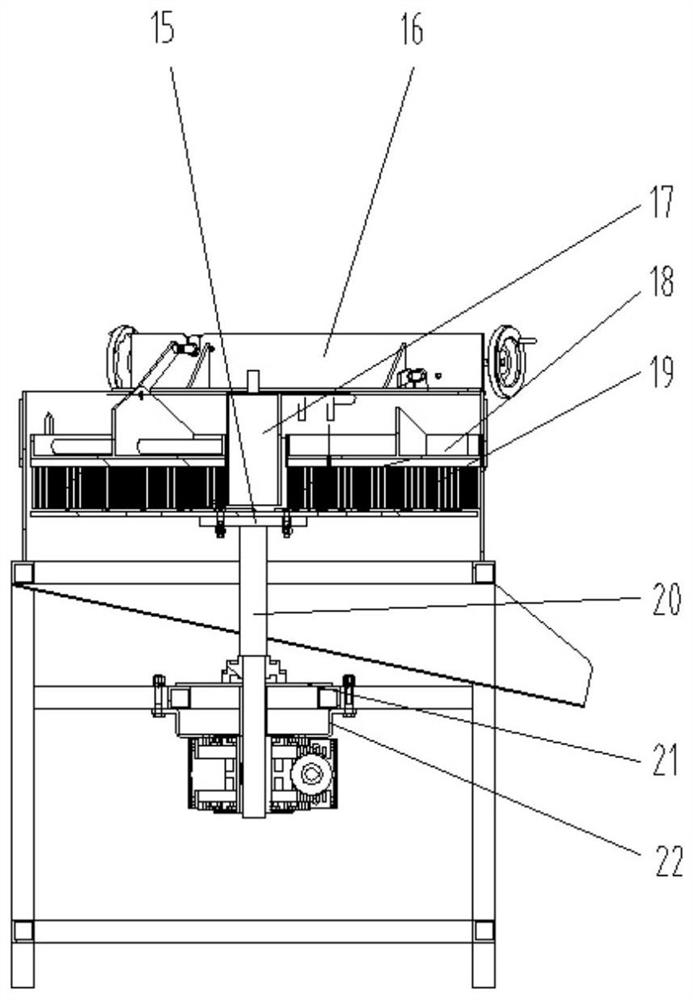

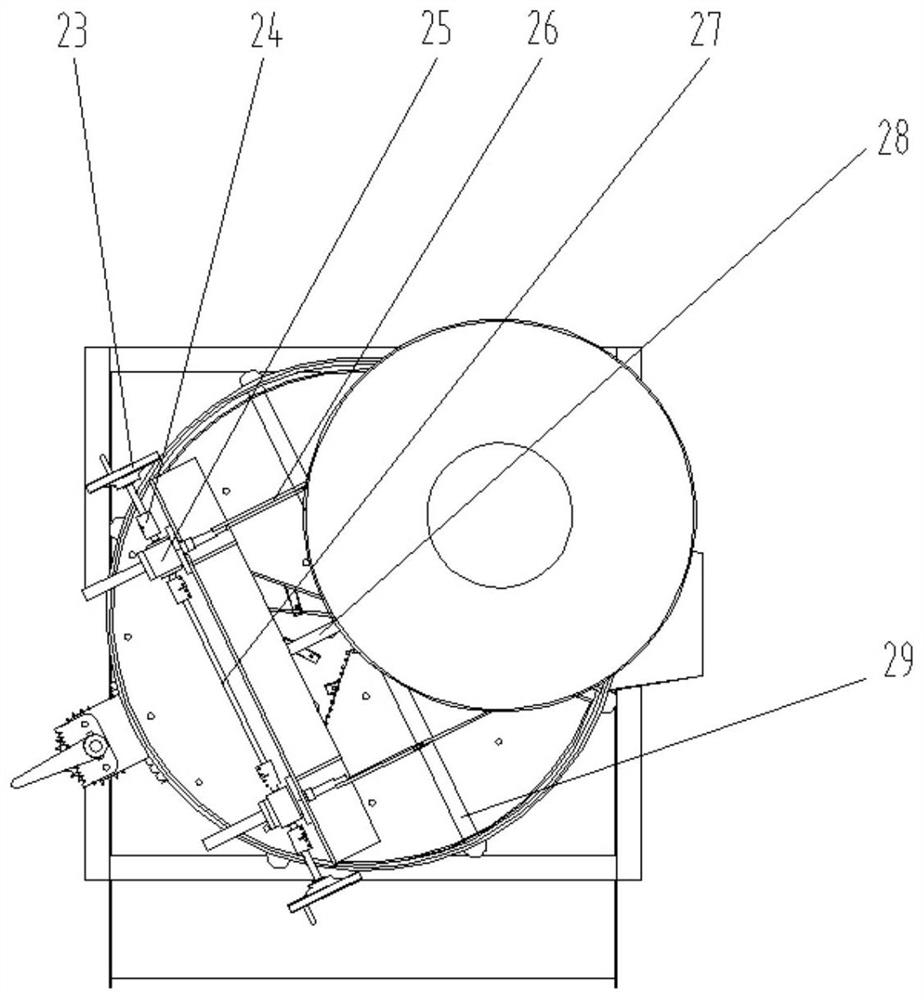

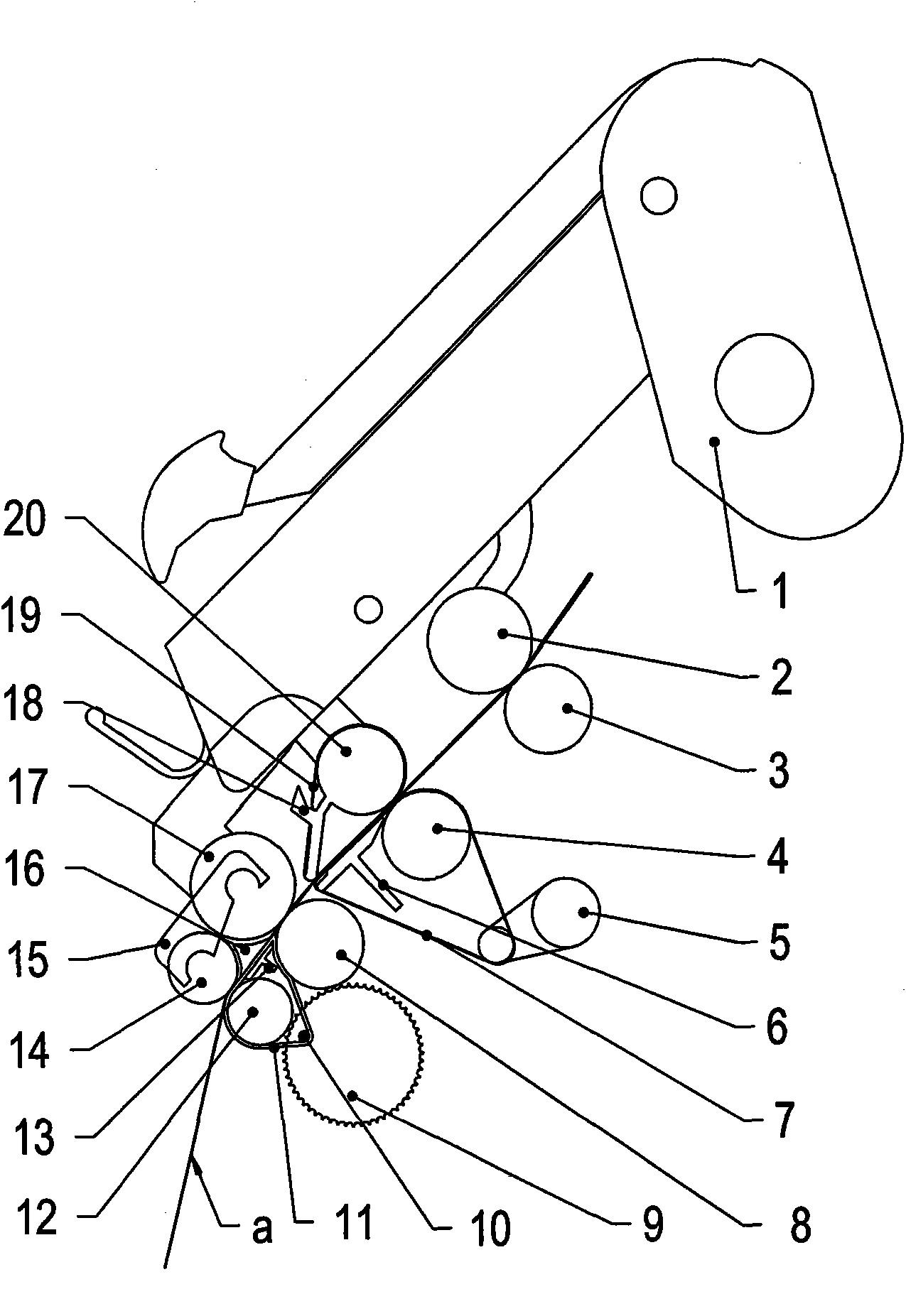

Oil tea fruit unshelling separator

InactiveCN102948912AReduce broken rateGood liquidityFatty-oils/fats productionHuskingMechanical engineeringCamellia oleifera

An oil tea fruit unshelling separator relates to an oil tea fruit unshelling and shell and tea seed seperation combination device. The oil tea fruit unshelling separator comprises a feed hopper, a unshelling rotary drum part, a shell and tea seed separating part, a power transmission part and a machine frame and is characterized in that the unshelling rotary drum part is positioned above the shell and tea seed separating part, the unshelling rotary drum part and the shell and tea seed separating part are arranged on the machine frame, the feed hopper is arranged above the unshelling rotary drum part, and the power transmission part is sequentially connected with the unshelling rotary drum part and the shell and tea seed separating part through a belt. The oil tea fruit unshelling separator has the beneficial effects of being capable of unshelling oil tea fruit, simultaneously also being capable of separating shells and tee seeds and unshelling fresh-picked wet tea fruits, retting piled micro-cracked fruit and cracked dried tea fruit and the characteristics of high unshelling efficiency, high seperation efficiency, little tee seed loss, low power dissipation, light and ingenious structure, is convenient to use and maintain and the like.

Owner:JIANGXI AGRI MACHINERY RES INST

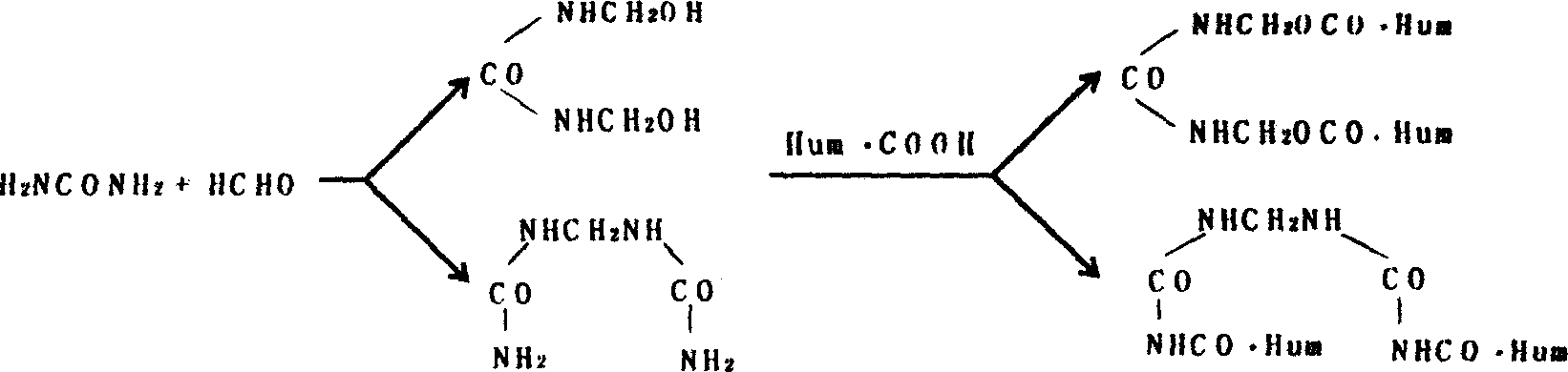

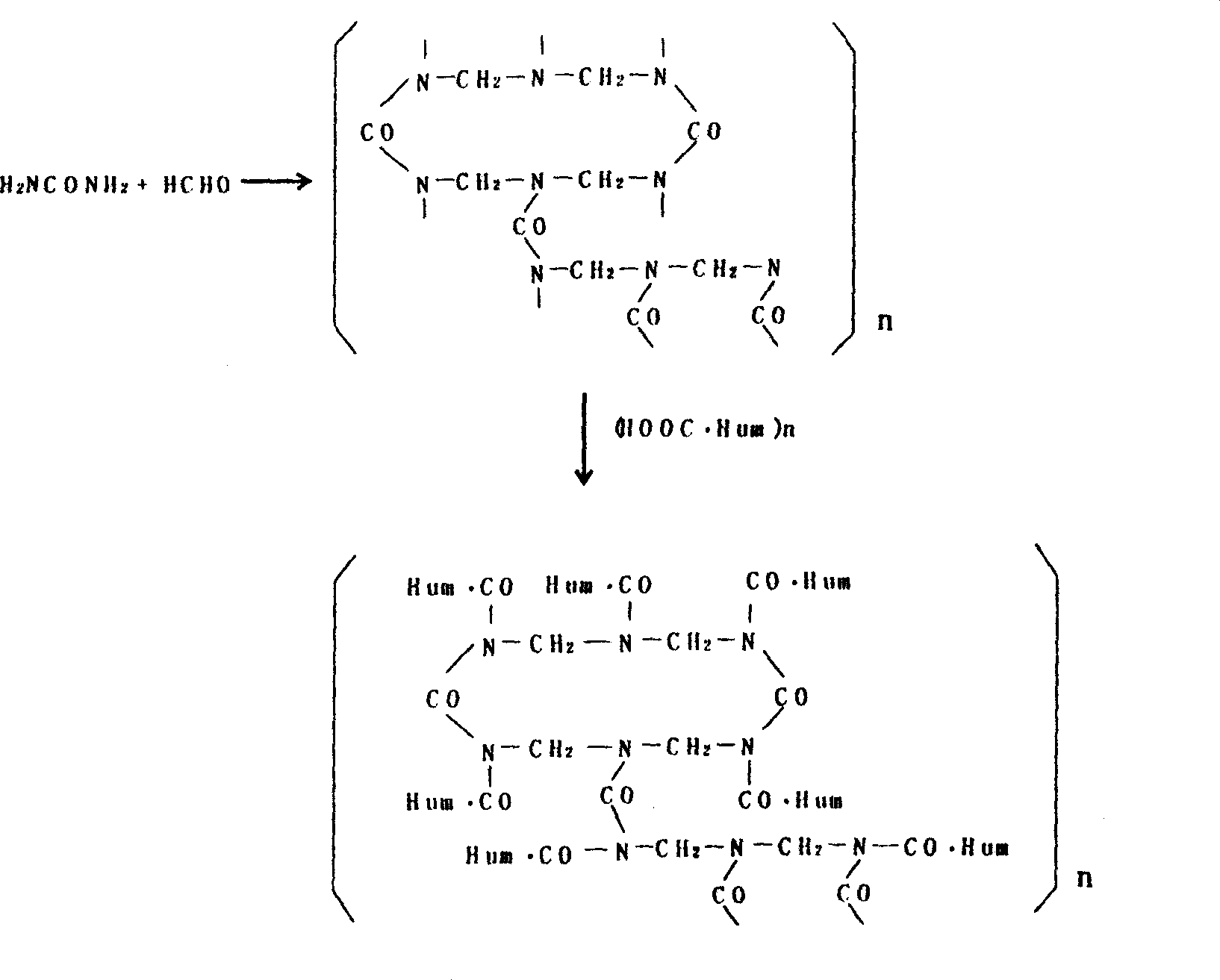

Humic acid long-acting compound fertilizer and its preparing method

InactiveCN1491924AHigh strengthReduce broken rateFertiliser formsOrganic fertilisersLong actingChemistry

The present invention relates to long-acting compound fertilizer, and is especially a kind of long-acting compound humic acid fertilizer. The long-acting compound humic acid fertilizer consists of composite of humic acid, urea and formaldehyde in 25-40 wt% and soluble nitrogen fertilizer, phosphate fertilizer and potash fertilizer 60-75 wt%. The composite of composite of humic acid, urea and formaldehyde consists of turf, urea, ammonium and formaldehyde solution; and the soluble nitrogen fertilizer, phosphate fertilizer and potash fertilizer are in the weight ratio of 12-25 to 30-40 to 10-20. The product is suitable for various soil, especially for growing green vegetable, flower and fruit tree.

Owner:SHENYANG INST OF APPLIED ECOLOGY - CHINESE ACAD OF SCI

Method for preparing agilawood-sheet health care cut tobacco

InactiveCN103222678AReduce manufacturing costReduce broken rateTobacco treatmentAdhesiveBiological agent

The invention belongs to the technical field of cigarette manufacturing, in particular to a method for preparing agilawood-sheet health care cut tobacco. The method comprises the following steps: crushing dregs or fragments generated in agilawood silk produced by agilawood leaves into 30-100 meshes of grain size of powder, and adding a special adhesive for tobacco sheets and an alcoholized biological agent for strengthening the cut tobacco, wherein the adhesive is 1.5-8 percent of the weight of agilawood leaf powder, and the alcoholized biological agent is 3-4 percent of the weight of agilawood leaf powder; mixing and stirring with water into thick liquid, and preparing the thick liquid into agilawood sheets with a squeeze method or a thick liquid method; cutting the agilawood sheets into sheet silk flocks with the size same with the tobacco; and uniformly mixing with the cut tobacco according to 0.5-15 percent of the weight of the cut tobacco. The health care cut tobacco prepared by the method plays a certain health care role for heart and cerebral vessels of involuntary smoker, meanwhile the cost can be greatly reduced, the paper-fishy smell in smoking is eliminated, and the aroma of the cigarette is mellower.

Owner:李贵生

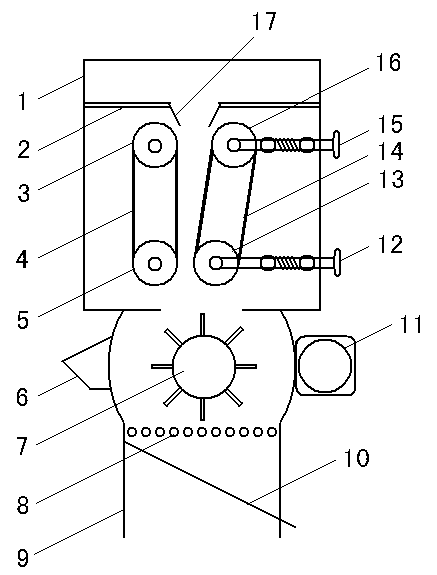

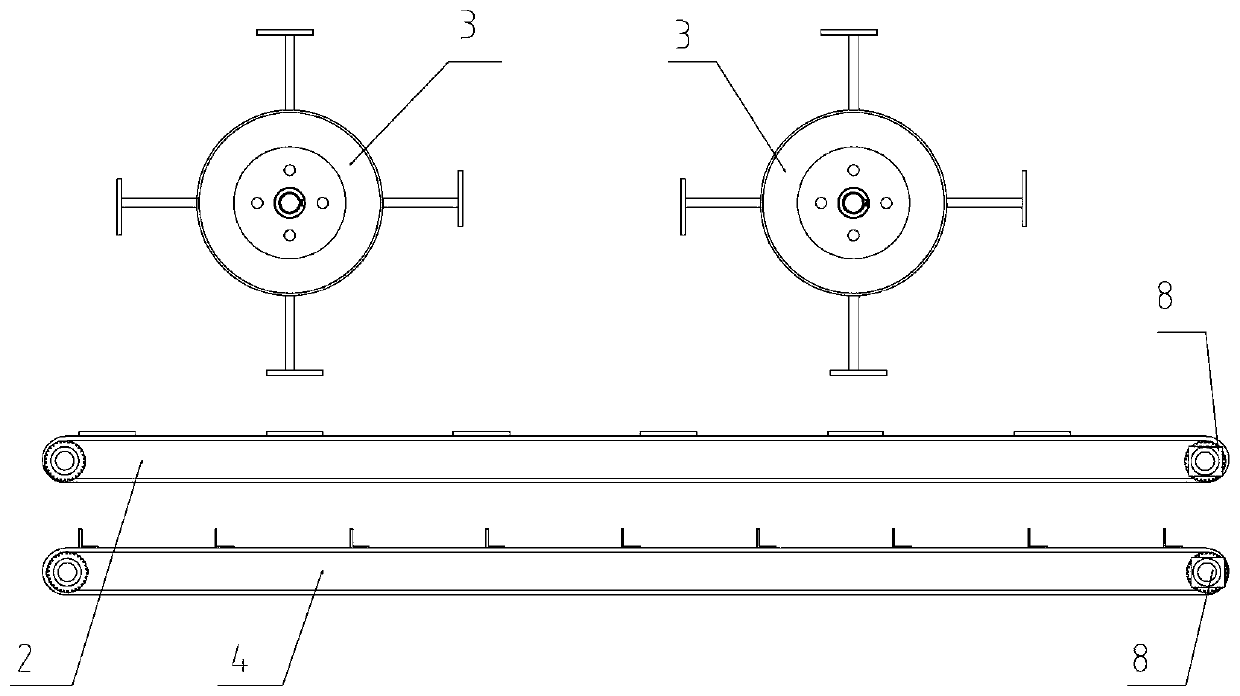

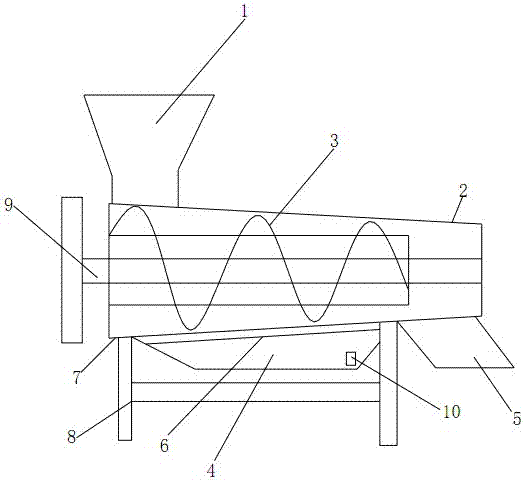

Extruded corn sheller

InactiveCN103190252AReduce broken rateReduce breakage rateThreshersEngineeringMechanical engineering

The invention discloses an extruded corn sheller, and relates to a corn threshing device. The extruded corn sheller comprises a frame and threshing equipment, wherein a corncob extruding device is arranged at the upper part or front side part of the threshing equipment; furthermore, the structure of the corncob extruding device is characterized in that a plurality of pairs of rollers are sequentially arranged; each pair of rollers include two opposite rollers; a gap is reserved between each pair of rollers; and at least one roller shaft in each pair of rollers can be movably fixed, so as to ensure an adjustable distance between two rollers. The structure of the corncob extruding device is characterized in that a plurality of rollers arranged sequentially form one group; the group of rollers are connected through belts and opposite to another group of rollers which are connected through the belts; a V-shaped structure is formed between the belts; and one pair of roller shafts can be movably fixed, so as to ensure the adjustable distance between two opposite rollers. The extruded corn sheller has the beneficial effects that the corn is shelled by a method of first extruding and then shelling; and niblet is not easily damaged. Therefore, the crushing rate of the corn is greatly reduced.

Owner:李振勇

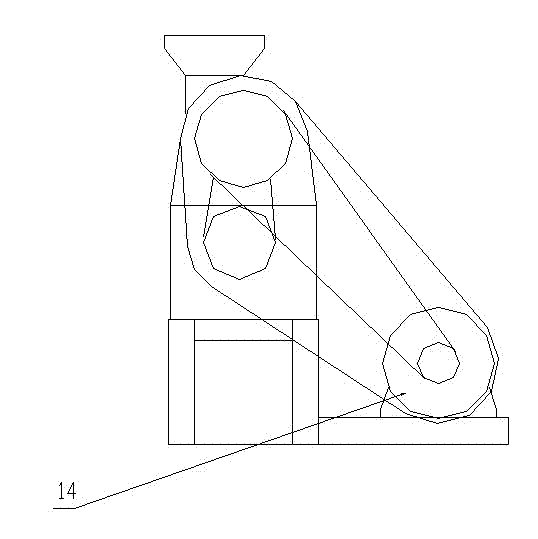

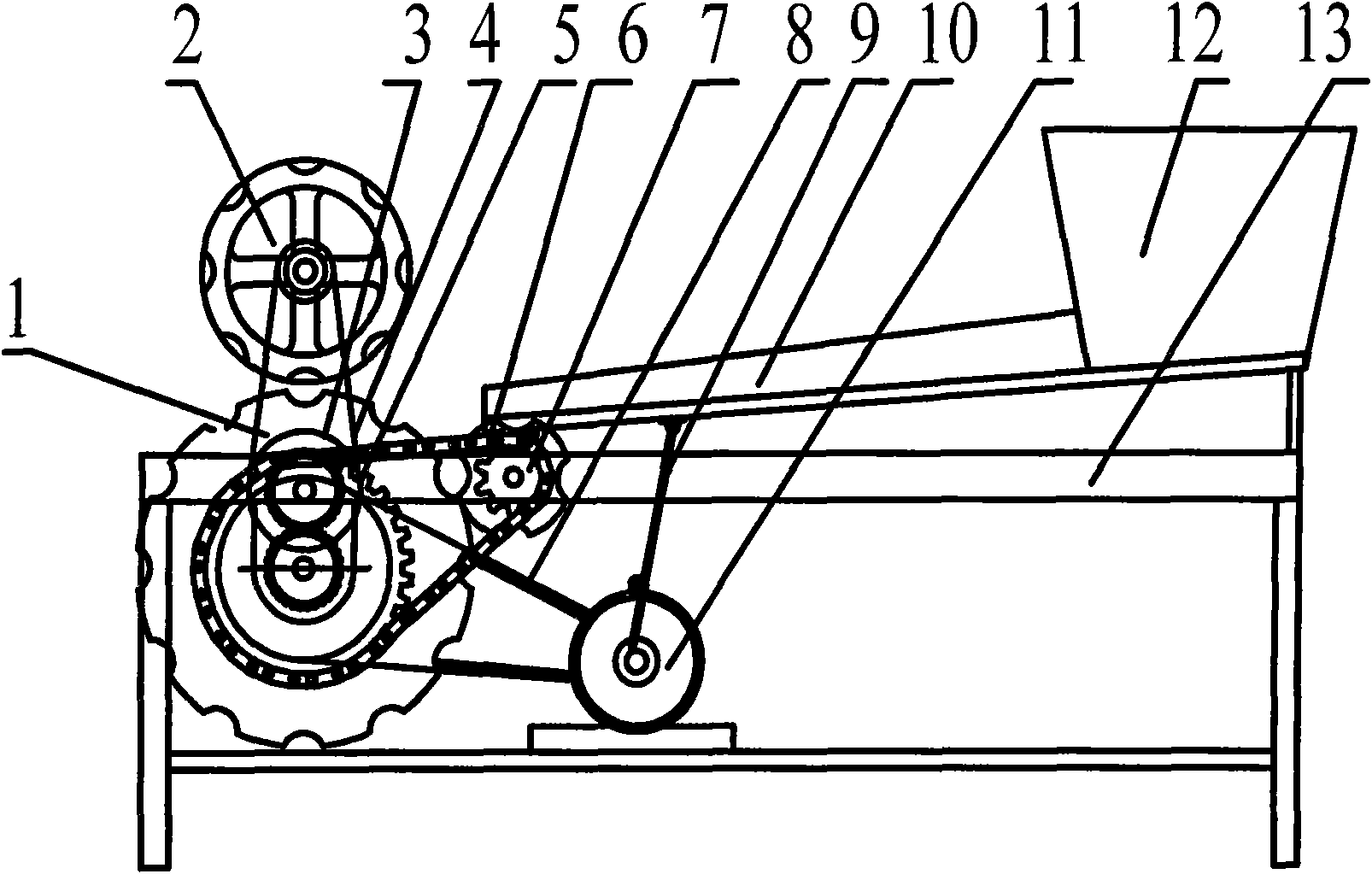

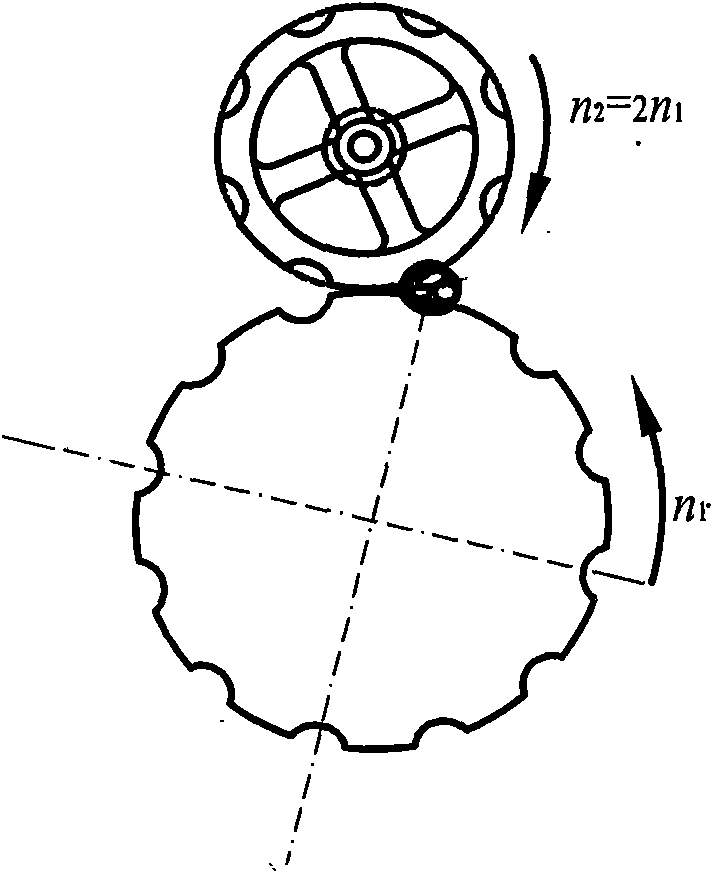

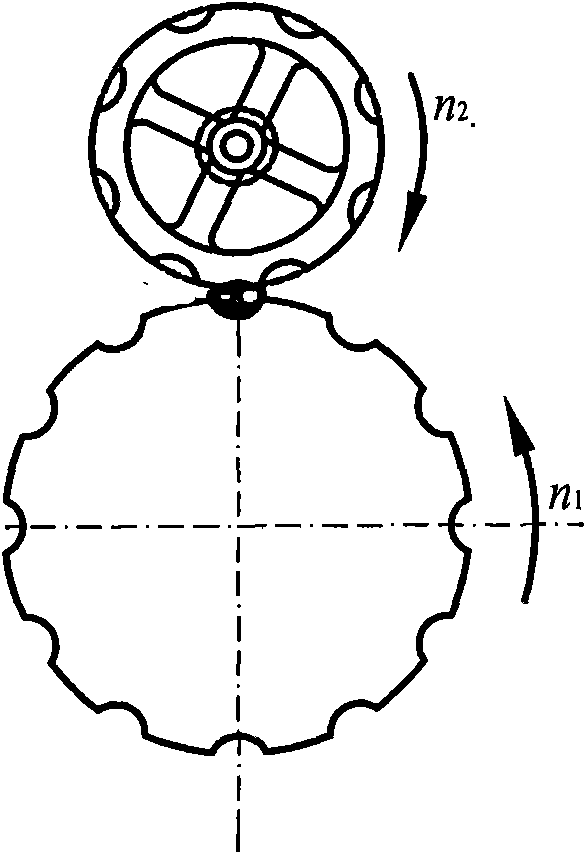

Extrusion-type walnut crusher

InactiveCN101564196AReduce broken rateImprove integrityHuskingHullingProduct processingAgricultural engineering

The invention relates to an agricultural and sideline product processing apparatus, in particular to an extrusion-type walnut crusher, which is mainly used in mechanical equipment processed in rural workshops and agricultural and sideline product markets. The extrusion-type walnut crusher comprises a stand, wherein a feed opening is fixed on the stand and connected with a conveying sloping plate; and the front of the stand is provided with a double-speed extrusion-type crusher consisting of an extrusion wheel main running wheel, an extrusion wheel high-speed wheel and a reverse power driving wheel. The extrusion-type walnut crusher adopts an extrusion mode to crush walnut shells, rotates at a certain angle under the action of a double-speed extrusion roller after primary crushing, completes secondary extrusion and the crushing of the walnut shells, and obtains complete walnut kernels after manual peeling. In general, the volume of walnuts is approximately consistent, and uncrushed walnuts with special small dimension after manual cleaning and peeling are sent into the walnut crusher again for secondary processing.

Owner:徐州徐工特种汽车有限公司

Low-density high-strength ceramsite proppant prepared from flint clay as raw material and preparation method thereof

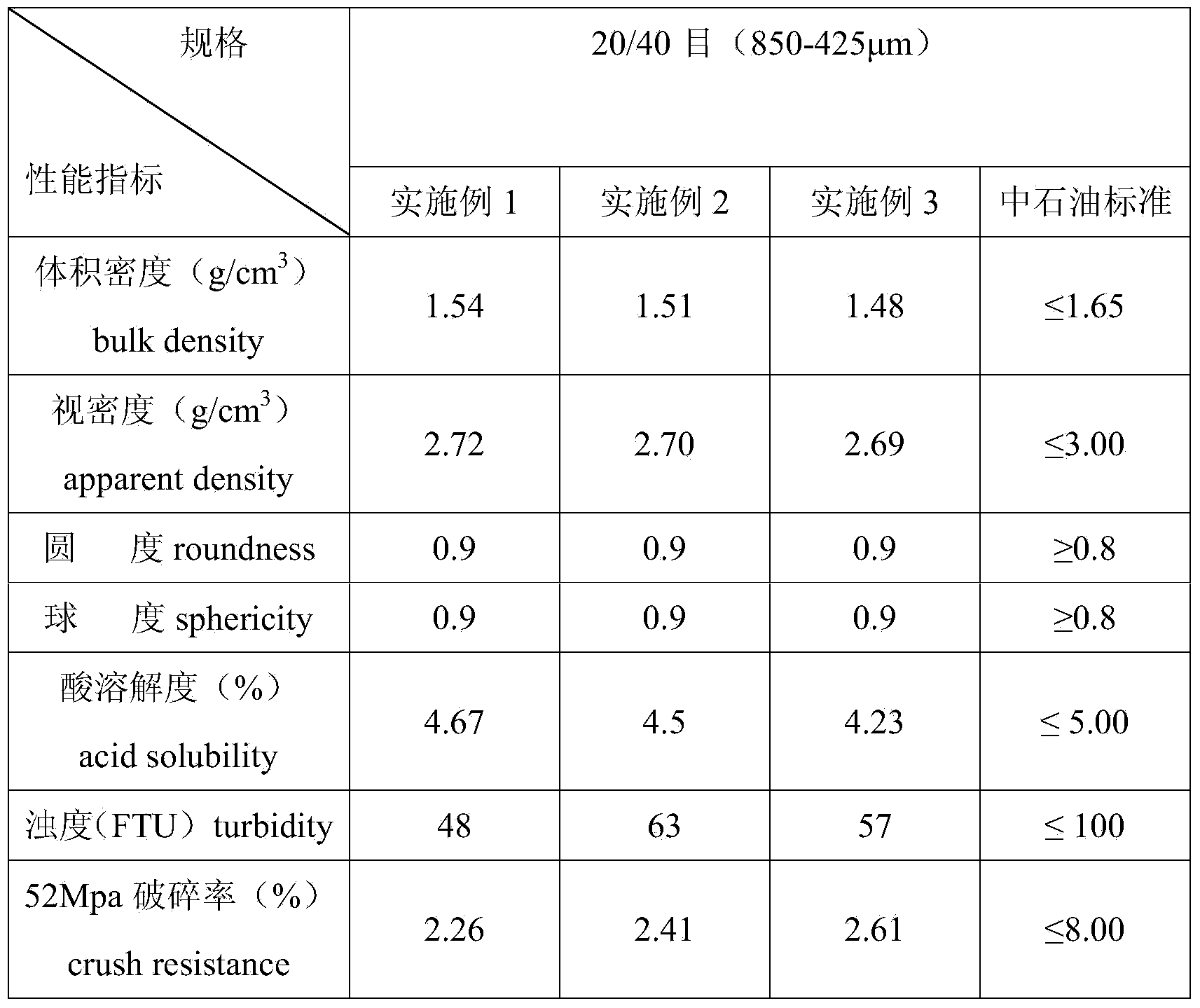

InactiveCN103468239ASmall bulk densityReduce broken rateFluid removalClaywaresVolumetric densityApparent density

The invention relates to a low-density high-strength ceramsite proppant prepared from flint clay as a raw material. In percentage by weight, a composition contains raw materials in content after the raw materials are mixed: 40-50% of Al2O3, 45-55% of SiO2, 0.5-3% of Fe2O3, 0.5-3% of TiO2, 0.1-2% of CaO+MgO, 0.1-1% of K2O+Na2O and the balance of ignition loss. According to the low-density high-strength ceramsite proppant prepared from flint clay as a raw material and the preparation method thereof, low-density high-strength ceramsites are prepared from the flint clay, so that the contradiction between the density and strength of the ceramsite proppant is solved, and the strength is relatively high while the density is low; the low-density high-strength ceramsite proppant has the advantages of low apparent density and bulk density, low broken rate, stable quality, high normal-temperature strength and low production energy consumption; the preparation method is simple, the material proportioning is simple, and the operation is convenient.

Owner:ZIBO JIAFENG MINING

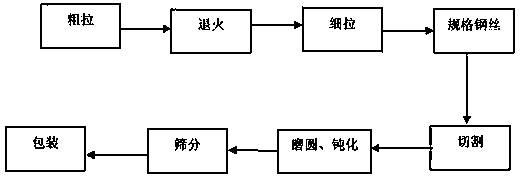

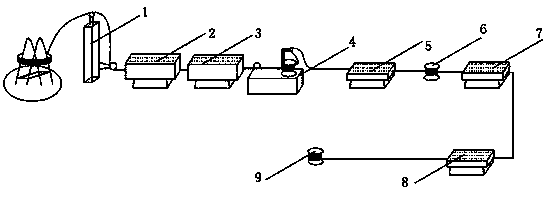

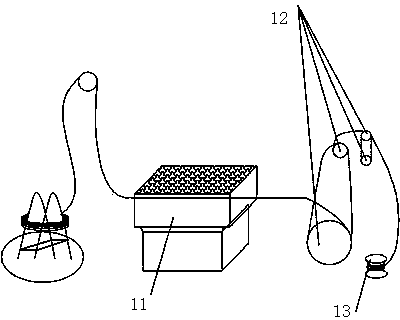

High-hardness and long-service-life steel wire cut shot producing method and production line

Provided is a high-hardness and long-service-life steel wire cut shot producing method and production line. The high-hardness and long-service-life steel wire cut shot producing method is characterized by comprising the following steps of coarsely drawing and annealing steel wires, finely draying the steel wires and cutting, rounding, passivating and sieving the steel wires. The steel wire cut shots produced in the method are high in hardness, the hardness of the steel wire cut shots can reach 58-60 HRC, the steel wire cut shots are low in broken rate and long in durability, and the durability is more than 4000 times. The producing method is high in processing speed and can meet the requirements of domestic shot blasting industries.

Owner:山东开泰工业科技有限公司

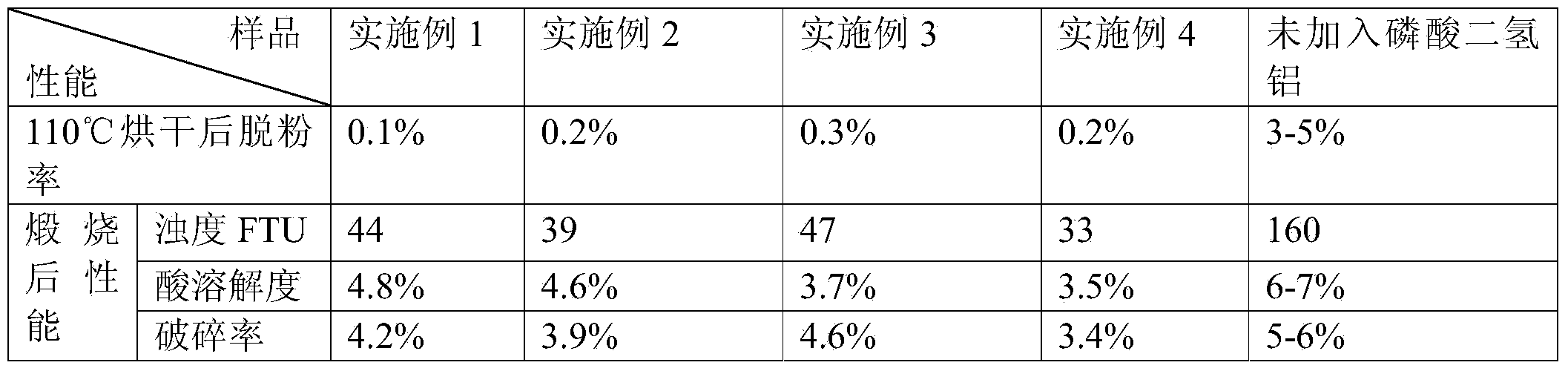

Ceramic proppant added with aluminium dihydrogen phosphate and preparation method of ceramic proppant

InactiveCN103509547AHigh strengthReduce broken rateFluid removalDrilling compositionPelletizingSolubility

The invention relates to a ceramic proppant added with aluminium dihydrogen phosphate and a preparation method of the ceramic proppant. The ceramic proppant is prepared by adding aluminium dihydrogen phosphate into granulation powder. The preparation method comprises the following steps: firstly, adding part of granulation powder into a granulator, then adding aluminium dihydrogen phosphate and finally adding the rest of granulation powder one or more times to prepare ceramsite blank balls; finally, calcining the ceramsite blank balls to obtain the ceramic proppant. The ceramic proppant has lower turbidity, acid solubility and breakage rate; the intensity of the blank balls in the preparation process is improved; the breakage rate of the finished product is reduced by 1 to 2 percent; powder fall-off and cracks are reduced; product quality is improved. Moreover, the preparation method is simple and is easy to operate.

Owner:ZIBO JIAFENG MINING

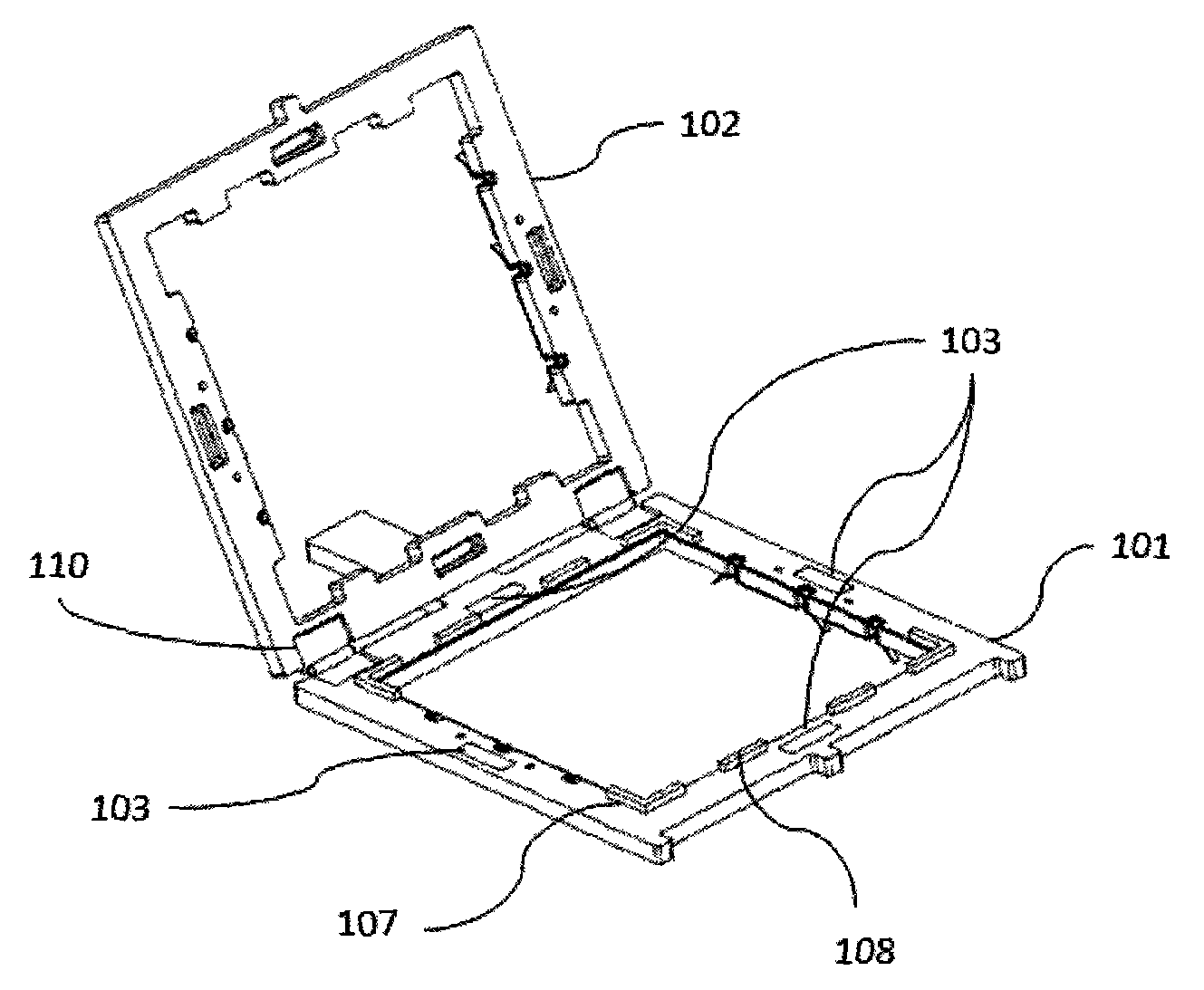

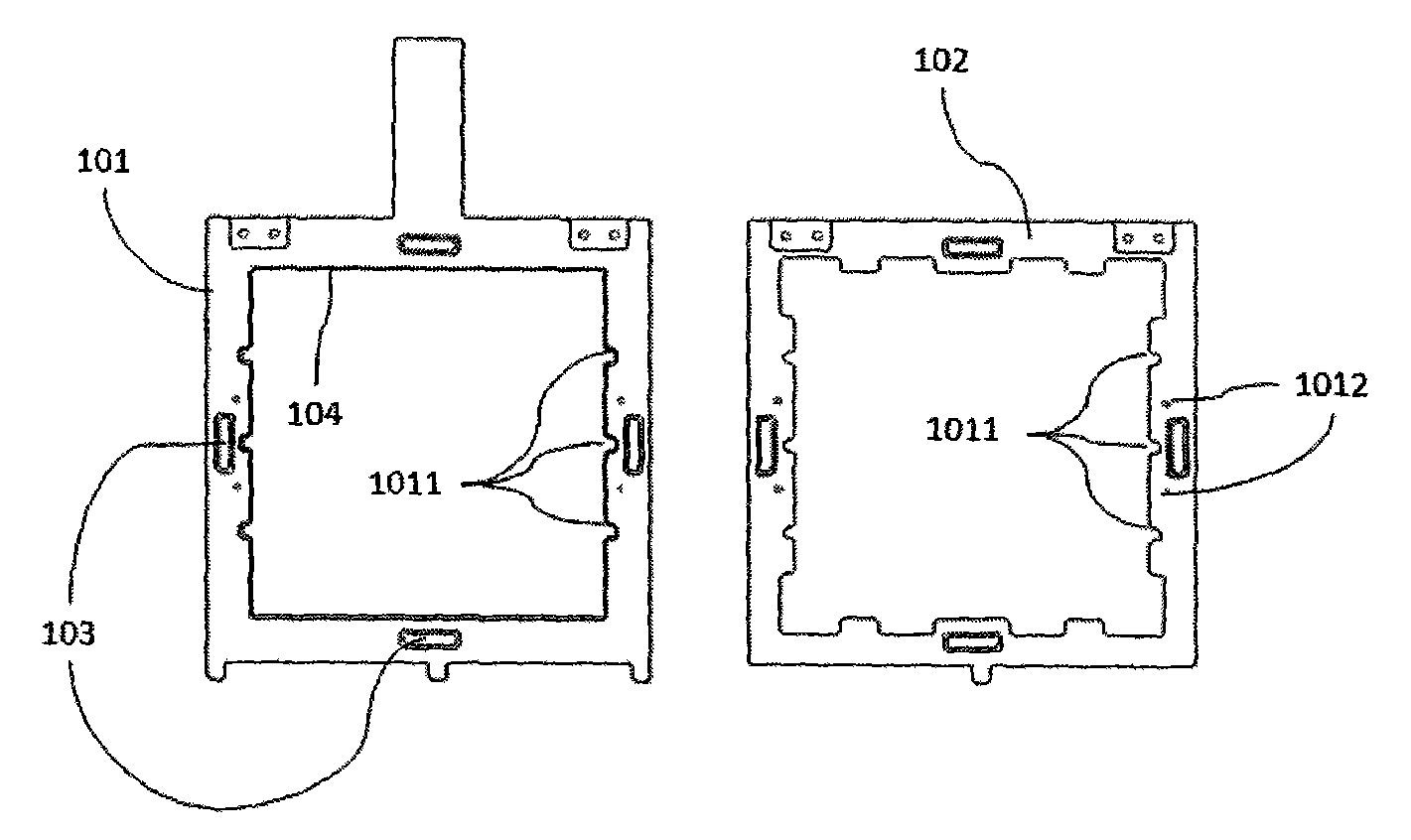

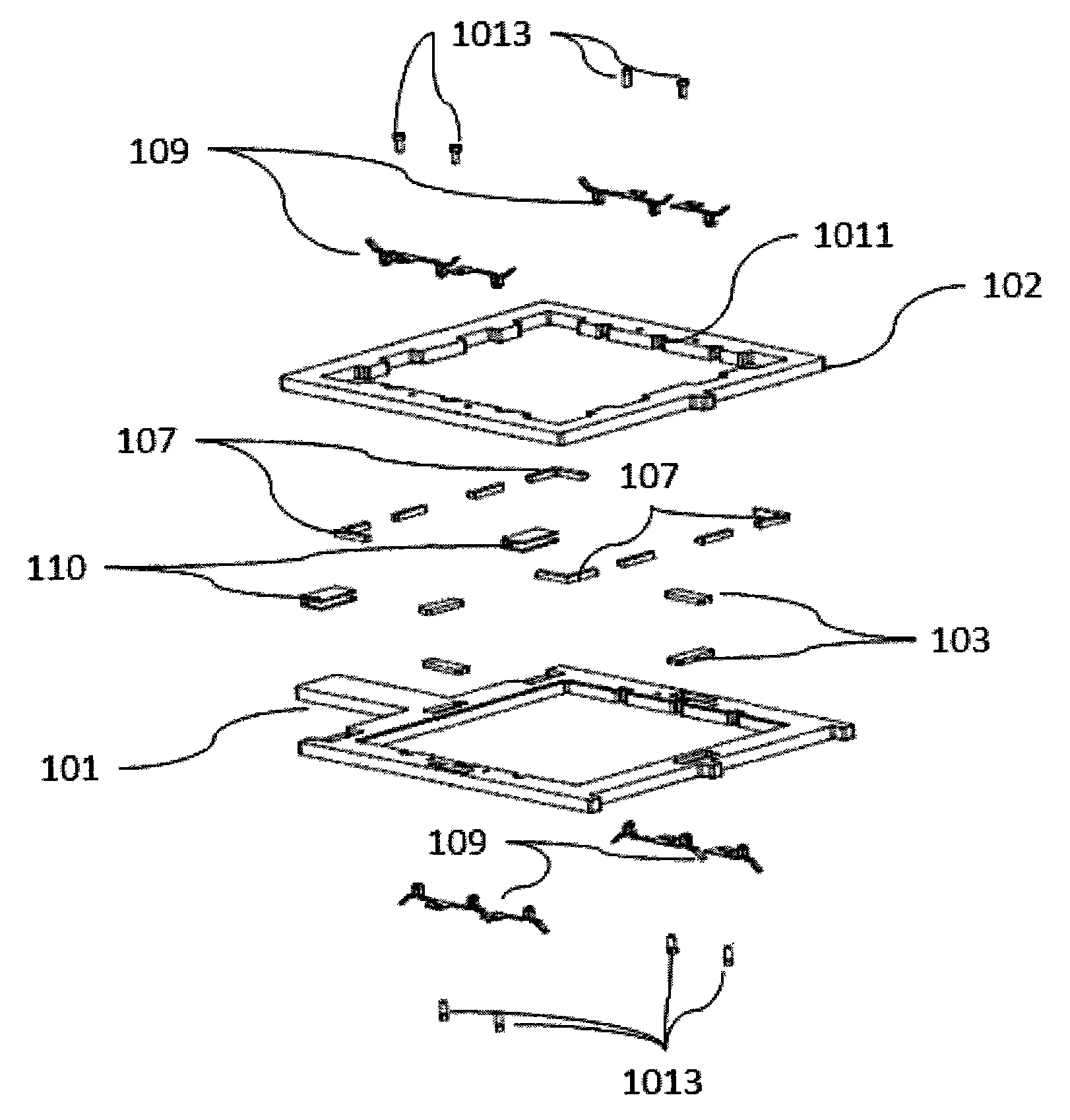

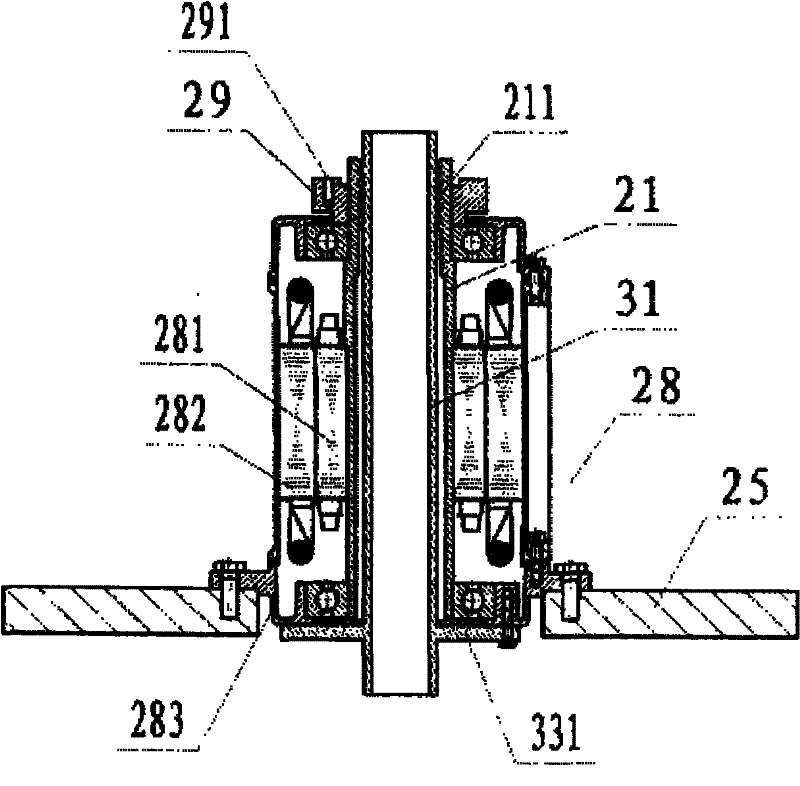

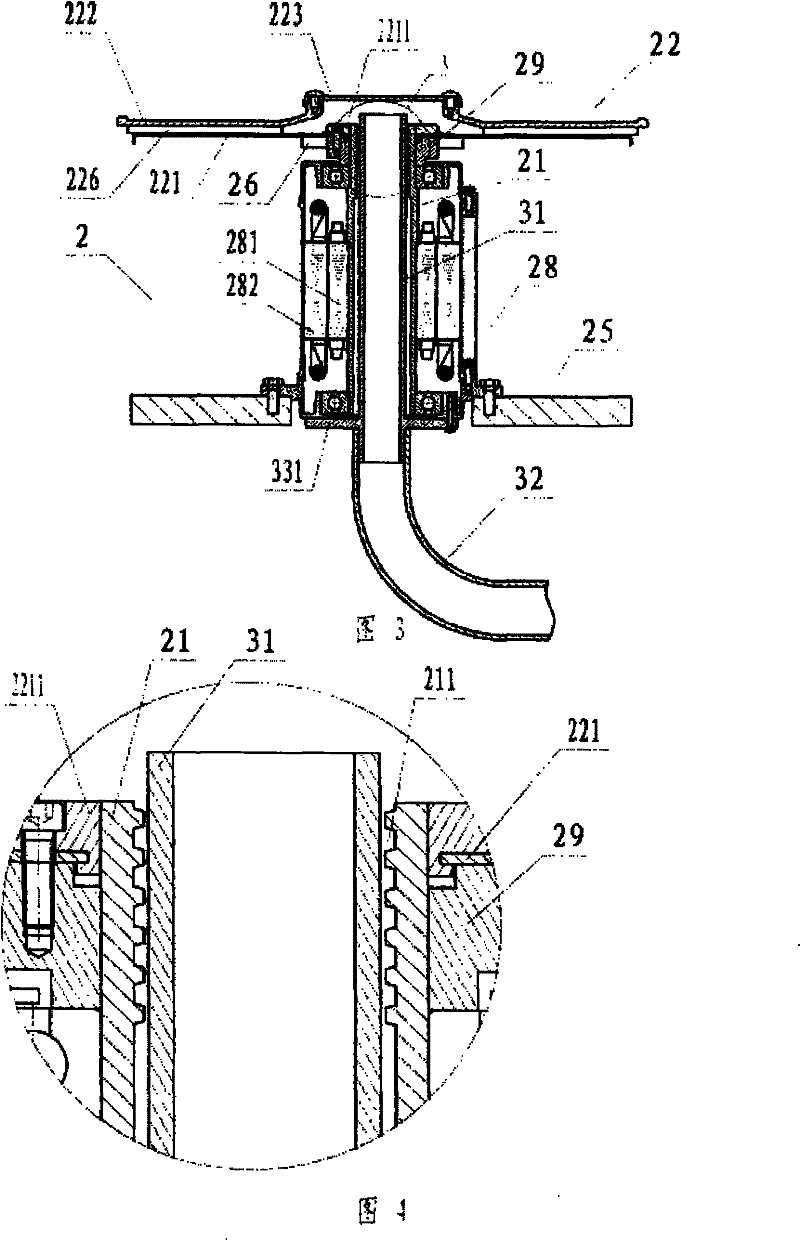

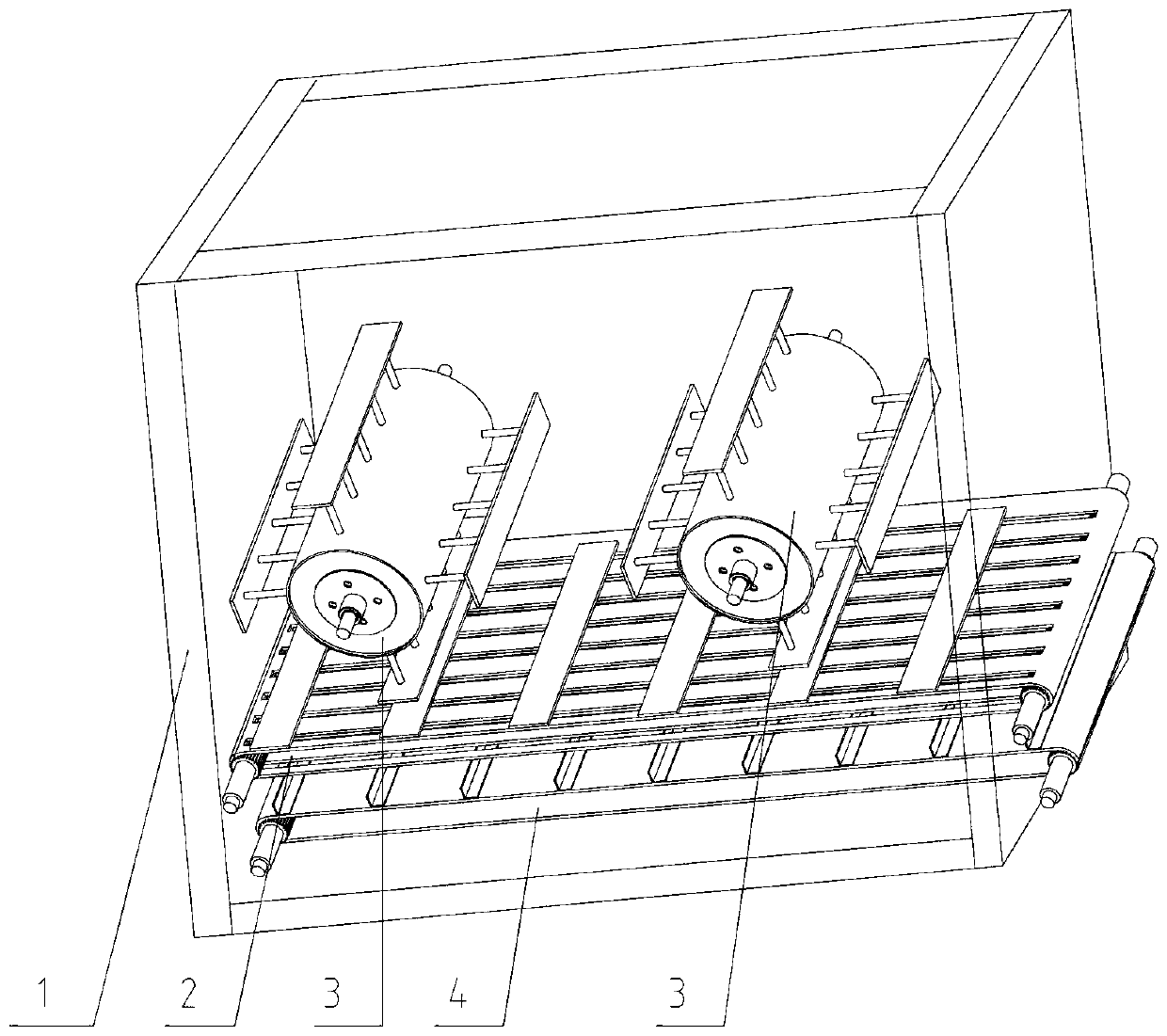

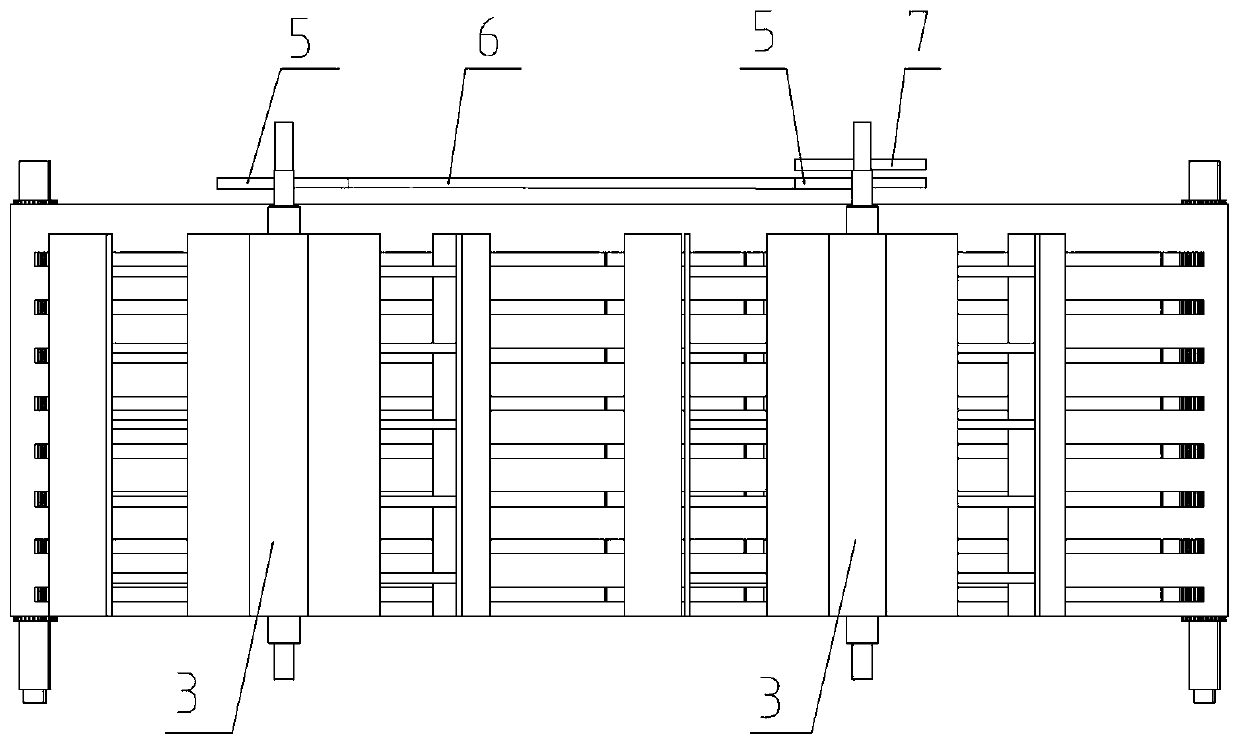

Electroplating clamp of solar cell

ActiveCN104032360AFast positioning and assemblyReduce broken rateElectrolysis componentsSemiconductor devicesMagnetEngineering

The invention provides an electroplating clamp of a solar cell. The electroplating clamp of the solar cell, provided by the invention, comprises a first frame, a second frame and a plurality of magnets, wherein the first frame and the second frame are of a hollow shape, edge parts of the first frame and the second frame are in contact and clamp the cell; and the plurality of magnets are respectively symmetrically fixed on the first frame or second frame, and the first frame and the second frame are jointed by using a magnetic force. The electroplating clamp of the solar cell, provided by the invention, is capable of rapidly locating the cell, quick in assembly, and continuous in production, ensures that the cell is uniformly conducted, and is capable of reducing the breakage rate of the cell.

Owner:平邑经济开发区投资发展有限公司

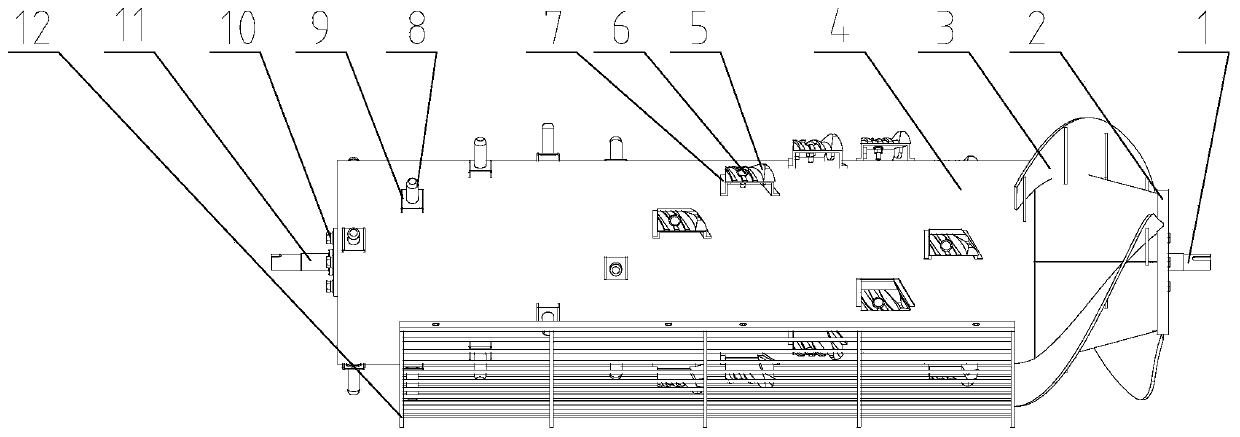

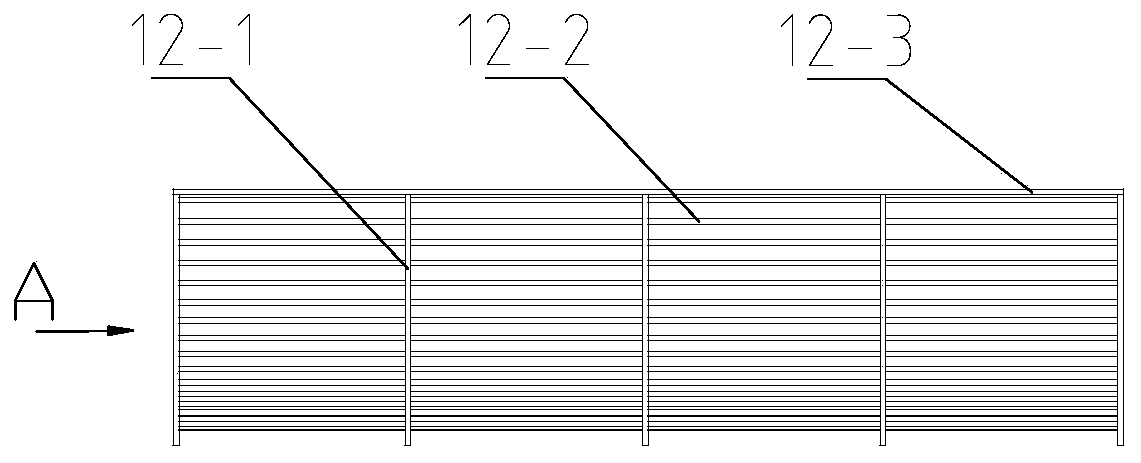

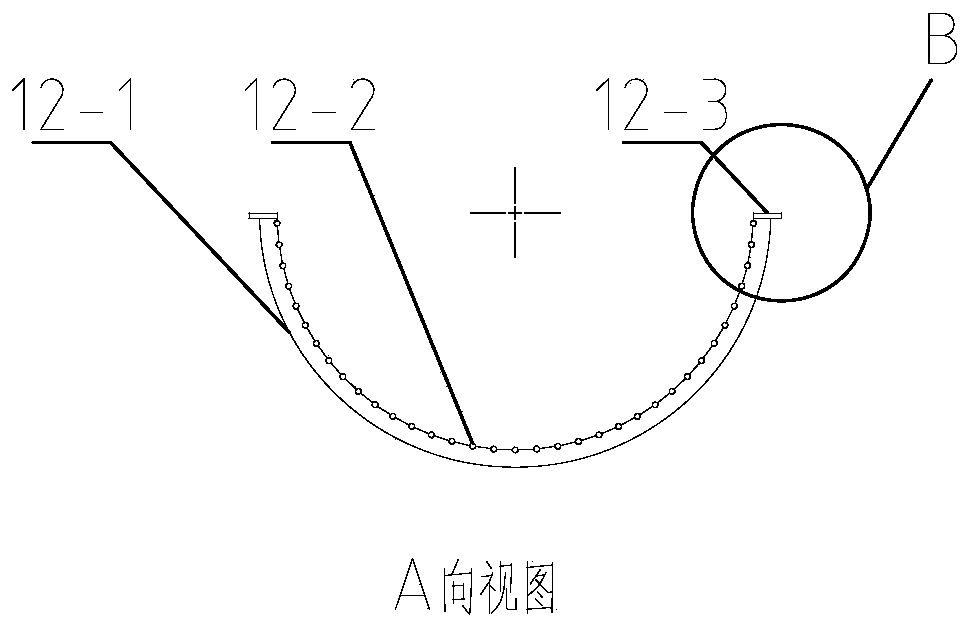

Combined longitudinal axial flow threshing and separating device and method and corn kernel harvester

PendingCN110741814AReduce broken rateImprove cleaning rateThreshersAgricultural engineeringStructural engineering

The invention discloses a combined longitudinal axial flow threshing and separating device and method and a corn kernel harvester. The combined longitudinal axial flow threshing and separating devicesolves the problems of insufficient threshing and difficult control of kernel breakage rate in the prior art, and has low kernel loss rate, long threshing time for ears, full threshing and low kernelbreakage rate. The technical scheme includes that the device comprises a rotary drum body, wherein a plurality of grain rod blocks and threshing nail teeth are uniformly distributed on the surface ofthe rotary drum body along a spiral line, the grain rod blocks are fixed to the front half section of the rotary drum body, and the threshing nail teeth are fixed to the rear half section of the rotary drum body; and a threshing concave plate is mounted below the rotary drum body, fruit clusters can be threshed under the combined action of the grain rod blocks and the threshing concave plate, andthe mixture formed after threshing can complete grain separation under the disturbance of the threshing nail teeth.

Owner:SHANDONG ACADEMY OF AGRI MACHINERY SCI

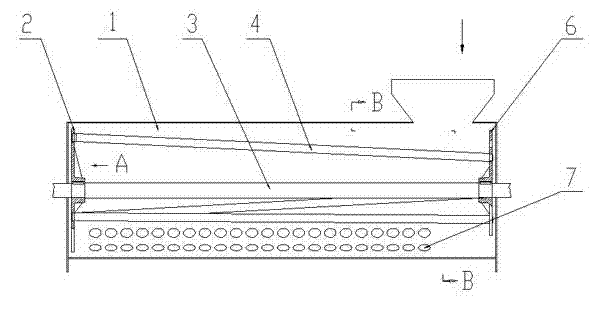

Tea leaf high-voltage electrostatic field dryer

InactiveCN103859069AProtective ingredientsReduce broken ratePre-extraction tea treatmentAgricultural engineeringTea leaf

The invention relates to tea leaf dryers, and specifically relates to a tea leaf high-voltage electrostatic field dryer. Drying technology brings direct influence for output and quality of tea leaf, present drying technology usually employs flat type, tunnel type or hot-air circulating type dryers for drying, and the flat type, tunnel type or hot-air circulating type dryers respectively have problems of influencing quality, appearance and output of tea leaf. The high-voltage electrostatic field dryer comprise a baking oven, an evaporating chamber, an air inlet, an air outlet, an air exhaust device and a high-voltage electrostatic field generating assembly; and the high-voltage electrostatic field generating assembly mainly consists of a power supply, a pressure regulating rectifier, an upper pole plate, a lower pole plate and a controller. The tea leaf drying process is performed at a normal temperature when the high-voltage electrostatic field dryer is employed, so that the compositions of tea leaf are effectively protected, and dried tea leaf is small in color and shape variation; the broken rate of tea leaf is low, the quality and the beauty of tea leaf are effectively guaranteed, the output is improved, and especially quality guarantee is provided for production of high-grade tea leaf.

Owner:高松

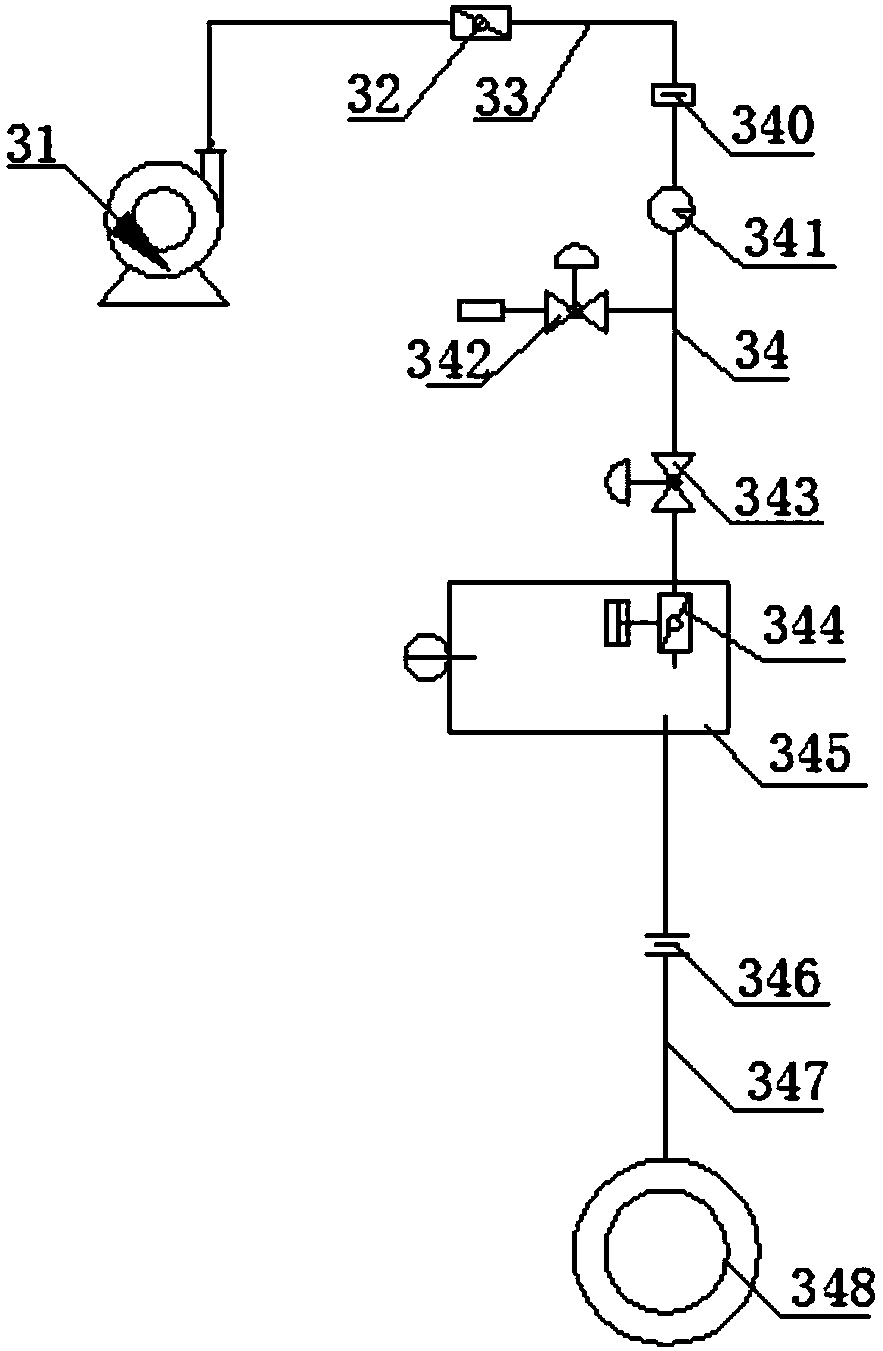

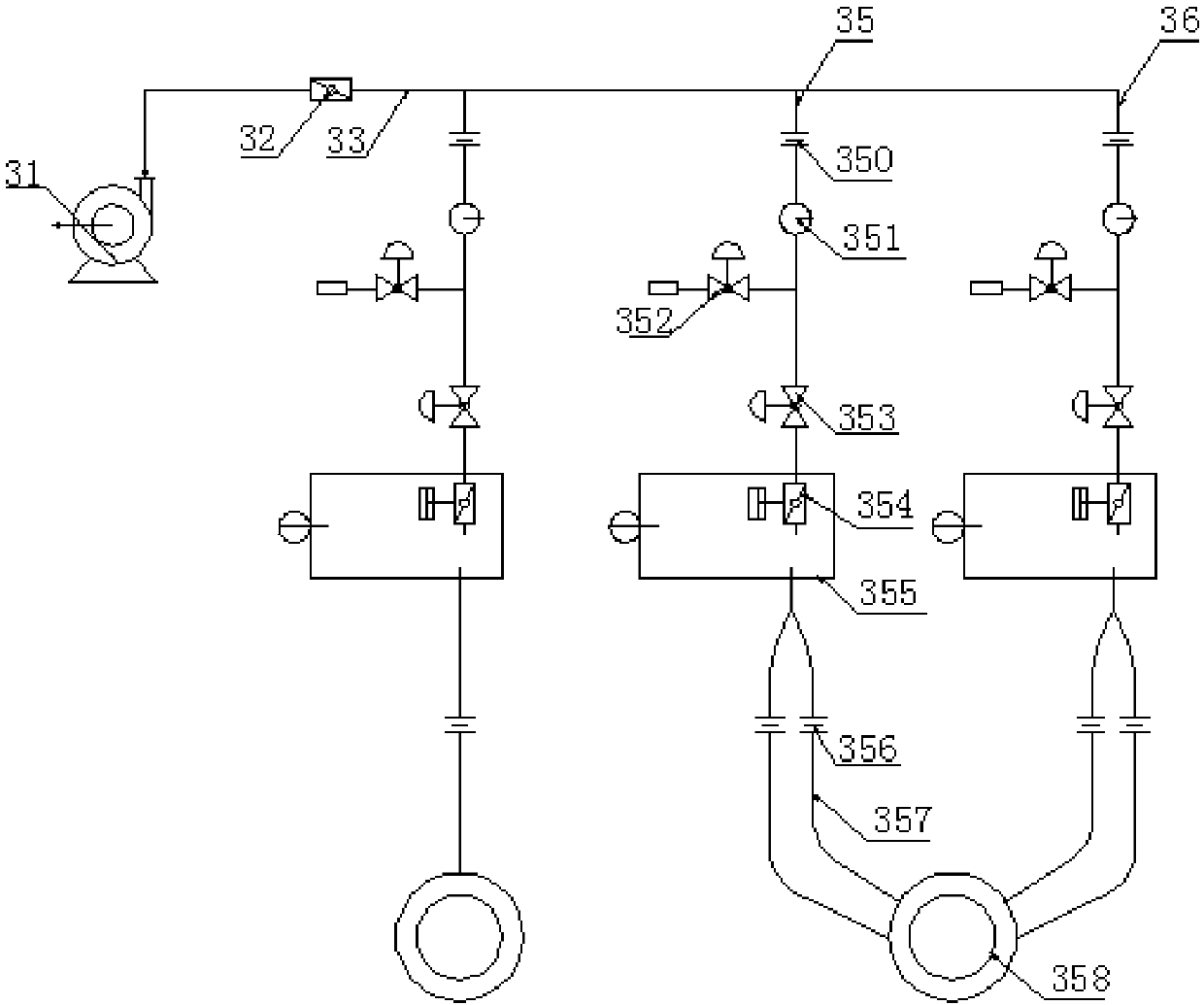

Self-adaptive control system for performing air conveying on fragile materials

PendingCN108338404AReduce broken rateReduce short ratioCigarette manufactureTraffic volumeSelf adaptive

The invention discloses a self-adaptive control system for performing air conveying on fragile materials. The system comprises a PLC intelligent controller, an intelligent power saver and a conveyingdevice which are connected electrically and mutually; the conveying device comprises a centrifugal fan electrically connected with the intelligent power saver; the output end of the centrifugal ventilator is connected with a first roll-packing machine through a conveying pipeline; the conveying pipeline comprises a total pipeline connected with the centrifugal ventilator as well as a first branched pipeline connected with the first roll-packing machine; the total pipeline is communicated with the first branched pipeline; a first pneumatic regulating butterfly valve, a first pneumatic regulating valve, a pressure transmitter and a first flowmeter are arranged sequentially from one end, near the first roll-packing machine, of the first branched pipeline to one end, near the total pipeline ofthe first branched pipeline; a butterfly valve is arranged on the total pipeline; the butterfly valve is positioned between the centrifugal ventilator and the first branched pipeline; the first branched pipe and the first roll-packing machine are connected through a first pneumatic shut-off valve; the first roll-packing machine is connected with a wire feeding machine through a wire feeding pipeline; and a second flowmeter is arranged on the first wire feeding pipeline.

Owner:SHANXI LEPU ENERGY SAVING TECH CO LTD

Rolled high-wearable steel ball and production method thereof

InactiveCN106435363AReduce broken rateHigh volume hardnessFurnace typesHeat treatment furnacesMetallurgyMaterials science

The invention relates to a rolled high-wearable steel ball. A steel ingot of the rolled high-wearable steel ball comprises, by weight, 0.80%-0.90% of C, 0.2%-0.4% of Si, 0.80%-1.0% of Mn, not larger than 0.25% of Ni, not larger than 0.035% of P, not larger than 0.035% of S, 0.70%-0.90% of Cr, not larger than 0.015% of Mo, not larger than 0.25% of Cu and the balance Fe and inevitable impurities. The rolled high-wearable steel ball is low in damage percentage (the damage percentage is 0.5% or zero), high in size hardness (HRC is larger than or equal to 58) and long in service life.

Owner:邯郸市伟业地热开发有限公司

Vertical green walnut peeling machine

PendingCN111869894AImprove cleaning rateReduce broken rateHuskingHullingElectric machineryScrub brushes

The invention relates to a vertical green walnut peeling machine. The vertical green walnut peeling machine consists of a machine frame body device, a knife rest device, a gap adjusting device and a scrubbing brush and balance adjusting device, wherein the knife rest device comprises a blade mounting disc, a U-shaped blade is fixed on the blade mounting disc, and the blade mounting disc is drivenby a motor speed reducer; a cylindrical machine body is located on the blade mounting disc and connected to a rack, a feeding hopper is arranged at the upper part of the machine body, an opening is formed in the side wall of the lower part of the machine body and connected with a discharging opening, and a material guide plate is arranged on one side close to the discharging opening, in the machine body; the scrubbing brush and balance adjusting device is connected to the upper part of the machine body, green walnuts entering the position between the blade mounting disc and a scrubbing brush are cut and extruded through relative movement formed by rotation of the blade mounting disc below the machine body and the scrubbing brush, and therefore the task of removing green walnut peels is completed. According to the vertical green walnut peeling machine, the green walnut peels are removed in a green walnut peeling manner combining the U-shaped blade and the scrubbing brush, the green walnut peeling rate is high, and the walnut breaking rate is low.

Owner:INST OF AGRI MECHANIZATION XINJIANG AGRI INST

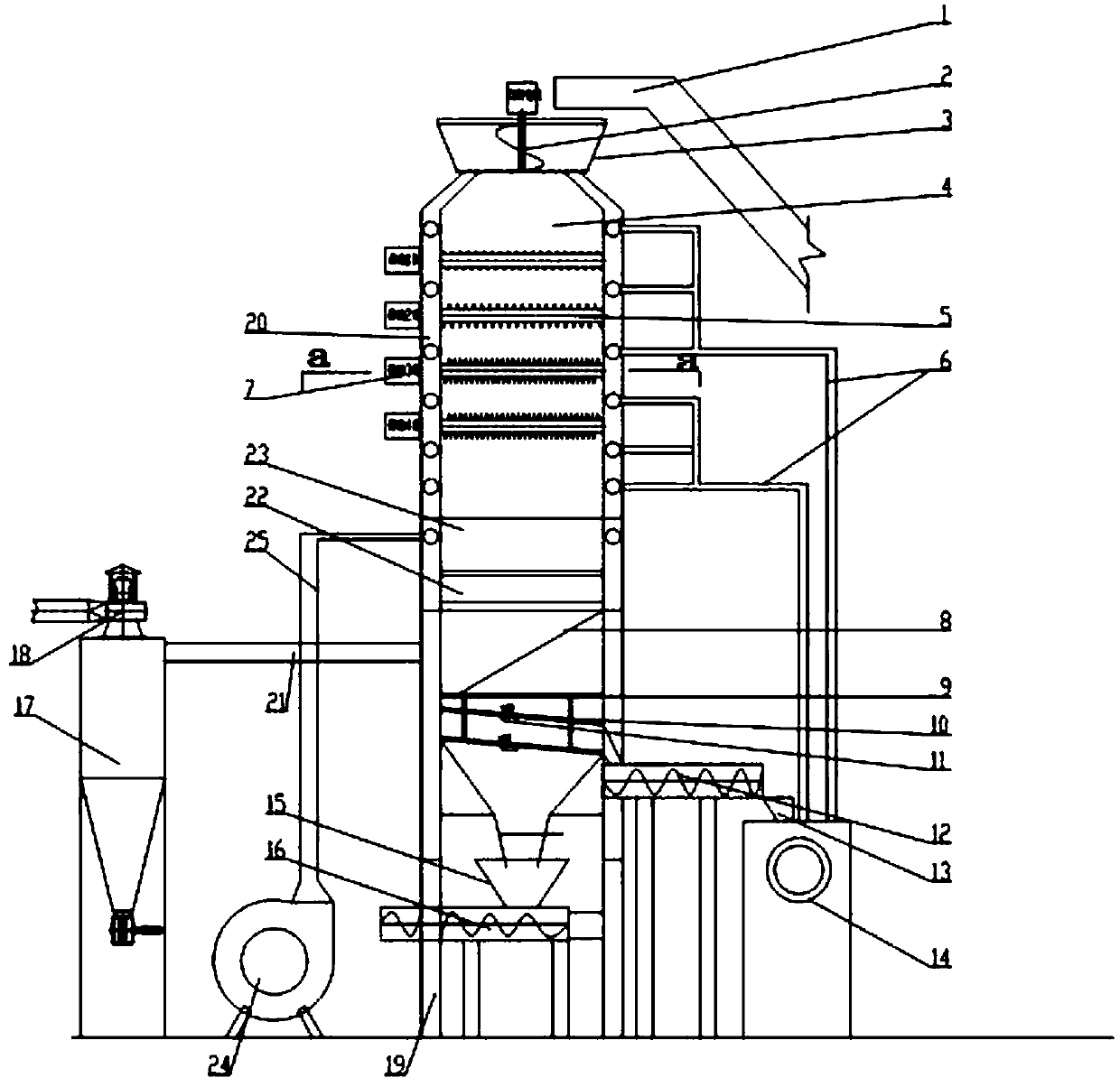

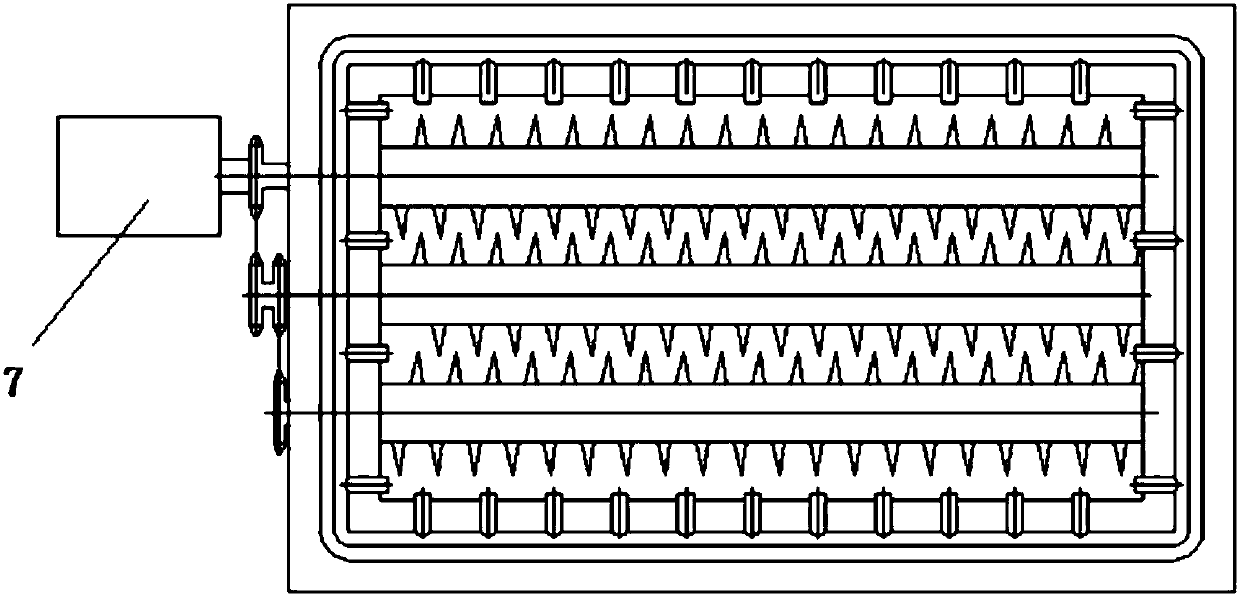

Environment-friendly low-crushing-rate drying and threshing equipment

PendingCN107593121AImprove drying efficiencyReduce broken rateSeed preservation by dryingThreshersEngineeringThreshing

The invention discloses environment-friendly low-crushing-rate drying and threshing equipment. The environment-friendly low-crushing-rate drying and threshing equipment comprises a drying and threshing tower used for drying and threshing corncobs, and the drying and threshing tower is provided with a feed inlet, a drying and threshing section and a feed outlet; the drying and threshing section isprovided with a threshing roller used for threshing the corncobs, the threshing roller is provided with threshing teeth and is arranged to be at least two layers in the longitudinal direction, the densities of the threshing teeth on the threshing roller are gradually increased from the top layer to the bottom layer, and the lengths of the threshing teeth on the threshing roller are gradually increased from the top layer to the bottom layer; a hot air pipe used for drying the corncobs is arranged at the portion, located between the two adjacent layers of the threshing roller, on the tower wallof the drying and threshing tower. The corncobs are gradually dried from top to bottom, gradual fine threshing is conducted, the drying efficiency is improved, and the niblets are also low in crushing rate; the structure is simple and compact, the cost is low, and application and popularization are facilitated.

Owner:ZHENGZHOU WANGU MACHINERY

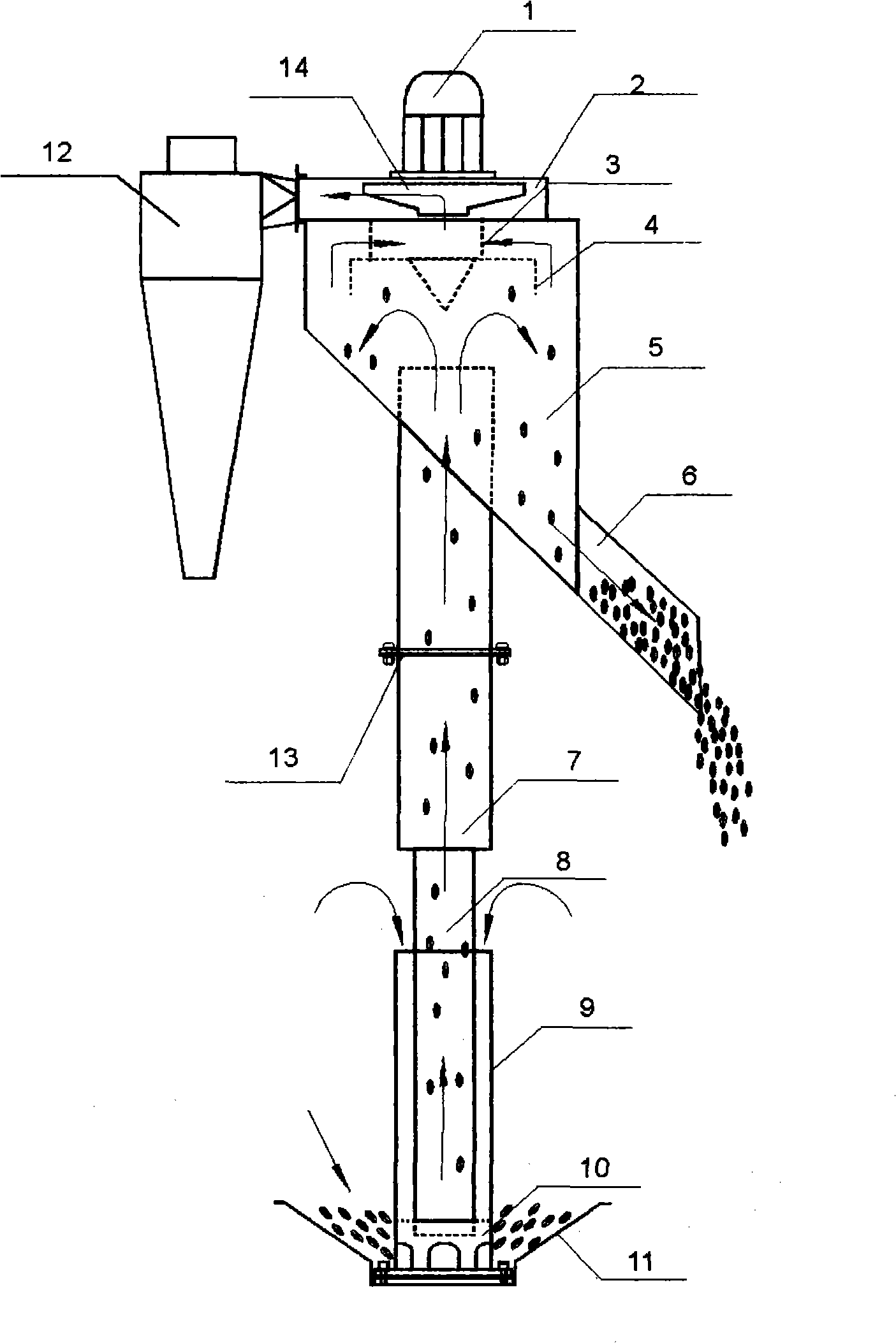

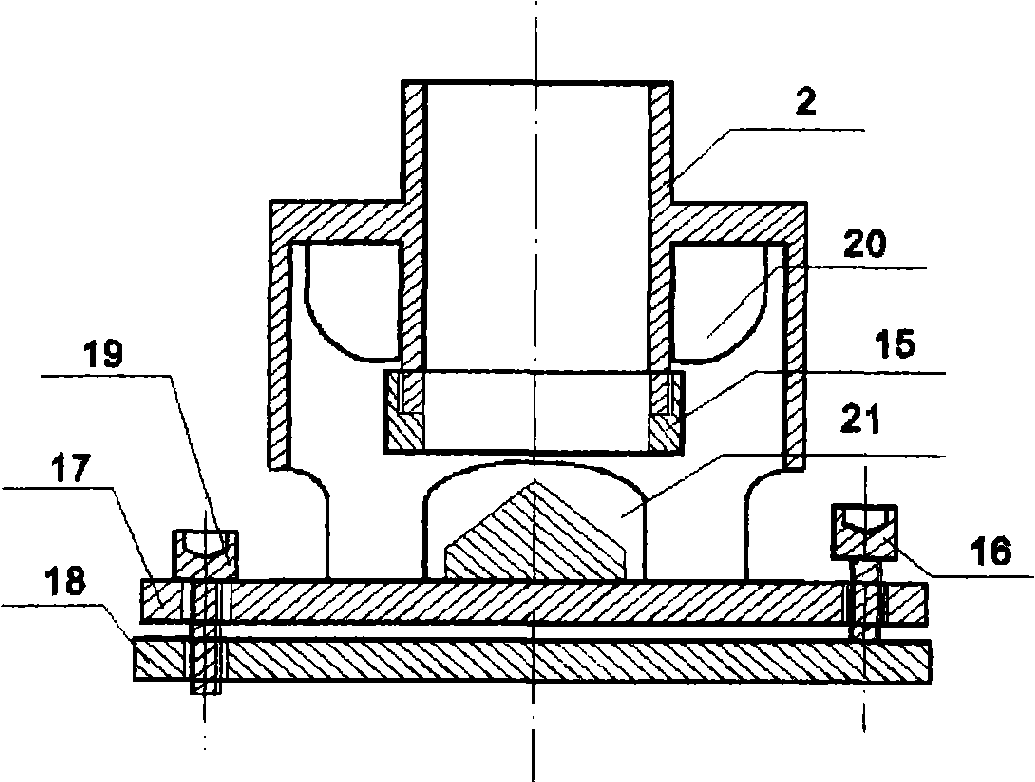

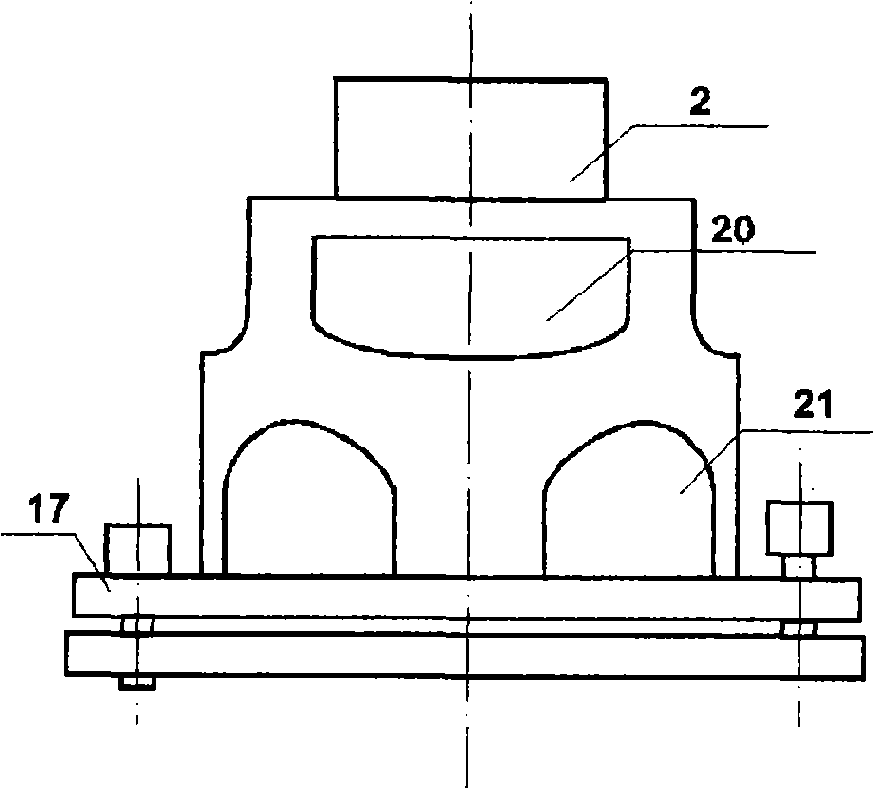

Buffering type air hoister

InactiveCN101274708AReduce broken rateReduce wind resistanceBulk conveyorsGastric tube feedingFeeding tube

The invention relates to a buffer-typed pneumatic lifter. The buffer-typed pneumatic lifter essentially consists of a motor 1, an air blower 2, a discharger 5, a dust collector 12, a pressure discharging tube 6 and a material acceptor and is characterized in that the air blower 2 which is connected with the motor 1 is directly installed at the center of the top part of the discharger 5; a feeding tube consists of a buffer tube 7 of an upper section and an accelerating tube 8 of a lower section, a feeding base 10 is arranged under the accelerating tube 8 and is provided with a plurality of air inlets 20 and a plurality of feeding ports 21; an adjusting disc 17 of the end port of the feeding base 10 is fixed on a ground fixed disc 18 inside a material accepting disc 11, and the lower end of an outer sleeve 9 is also provided with feeding ports 22 which are matched with the feeding ports 21 mutually. The buffer-typed pneumatic lifter has the advantages that (1) the pressure of the materials can be quickly reduced after being buffered by the buffer tube 7 after the accelerating lift of the accelerating tube 8, therefore, the impact between the materials and the top part of the discharger is reduced and the crushing rate of the material is effectively reduced; (2) wind speed is lowered after the material is buffered by the buffer tube 7, the resistance of wind pressure is decreased and wind resistance loss is reduced; (3) since the weight of the whole machine is fixed on the ground fixed disc, the gravity center of the whole machine is stable, the lifter is not needed to be hung on the beam of a house by an iron wire, and the usage is safe and reliable.

Owner:黄华静

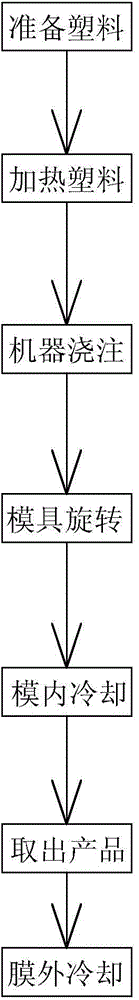

Production method of simulated charcoal

The invention discloses a production method of simulated charcoal. The production method comprises the following steps of a, preparing plastics, and heating the plastics to be fluidic; and b, pouring the fluidic plastics into a simulated charcoal mould through a machine, rotating the mould without centering to uniformly paste the fluidic plastics on the wall of an inner cavity of the mould, taking out a product when the fluidic plastics are cooled to be solid and have certain elasticity, and completely cooling outside the mould. By using the method in which the plastics are used as raw materials and the molding quality is controlled through machine pouring, the production efficiency of the simulated charcoal can be greatly increased, meanwhile, the breakage rate of finished products in demolding can be reduced, and the finished products are uniform in thickness and attractive in appearance.

Owner:中山市商贤电器科技有限公司

Shrimp pond bait feeding method, control module and device

PendingCN113261523ASimple structureReduce broken rateClimate change adaptationPisciculture and aquariaMechanical engineeringShrimp culture

The invention belongs to the field of shrimp culture, and discloses a shrimp pond bait feeding method. The feeding method can realize uniform and accurate bait feeding in a shrimp pond, monitors whether the real-time discharging and feeding speed on a feeding path is equal to the expected discharging and feeding speed or not, and adjusts the real-time discharging and feeding speed to the preset discharging and feeding speed if the real-time discharging and feeding speed is not equal to the expected discharging and feeding speed. The invention further discloses a shrimp pond bait feeding control module and device, in particular to a shrimp pond bait feeding device. The shrimp pond bait feeding method can be well and automatically implemented, the structure is simple, use is convenient, the shrimp pond bait feeding device is arranged on a catamaran and comprises a connecting assembly, a bait feeding unit and a bait feeding control module, the bait feeding unit comprises a bait box, an electric push rod and an opening plate, the bottom of the bait box is of a bucket-shaped structure, a bait feeding opening is formed in the bottommost part of the bait box, the electric push rod is arranged on the outer surface of the bottom of the bait box, and when the electric push rod acts, the opening plate closes or opens the bait feeding opening.

Owner:SHANGHAI OCEAN UNIV

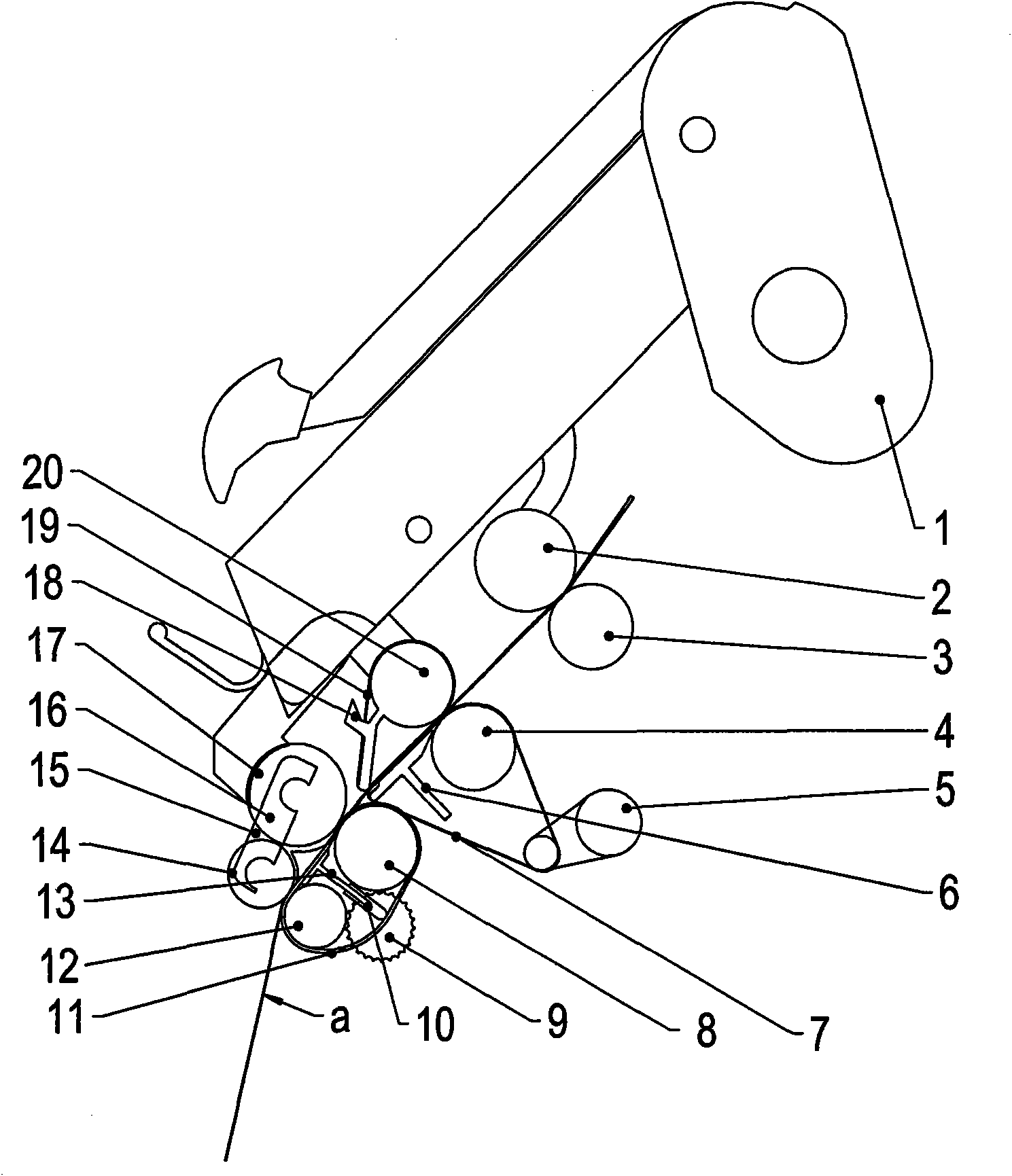

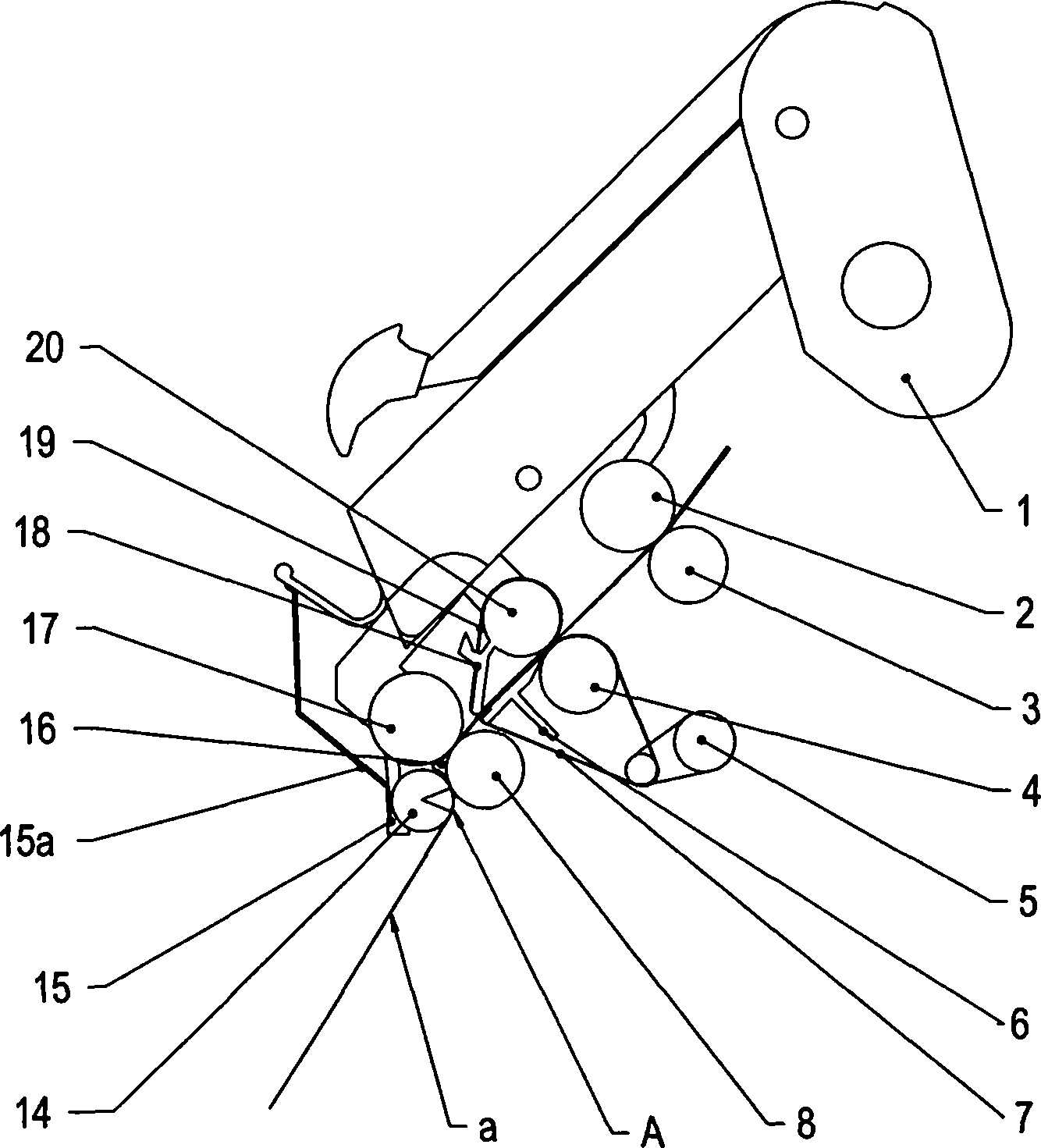

Mechanical compact spinning fiber bundling device

InactiveCN102465365ANo need to increase energy consumptionCompact spinningDrafting machinesYarnFiber bundle

The invention relates to a mechanical compact spinning fiber bundling device, which belongs to fiber bundling devices which realize compact spinning according to a mechanical principle. The device comprises a yarn guiding leather roller 14 which is arranged in front of a front leather roller 17 and a front roller 8, and a bundling device 16. A permanent magnet is embedded in the bundling device, and funnel-shaped fiber channels which are reduced gradually are formed on the bundling device along a fiber moving direction. A yarn guiding roller 12 is arranged in front of the front roller, a leather collar 11 is sleeved on the yarn guiding roller, and a bracket 13 is arranged inside the leather collar. The leather collar wraps the yarn guiding roller and the bracket, or the leather collar wraps the yarn guiding roller, the bracket and the front roller. A gear 9 is arranged between the front roller and the yarn guiding roller and matched with gears at the corresponding positions of the front roller and the yarn guiding roller. The compact spinning can be realized under the condition that energy consumption is not increased, and a counter-wrapping arc can be effectively eliminated, so that spinning evenness, snicks, nubs and neps are not worsened.

Owner:RIZHAO YUXIN MOTIVE POWER

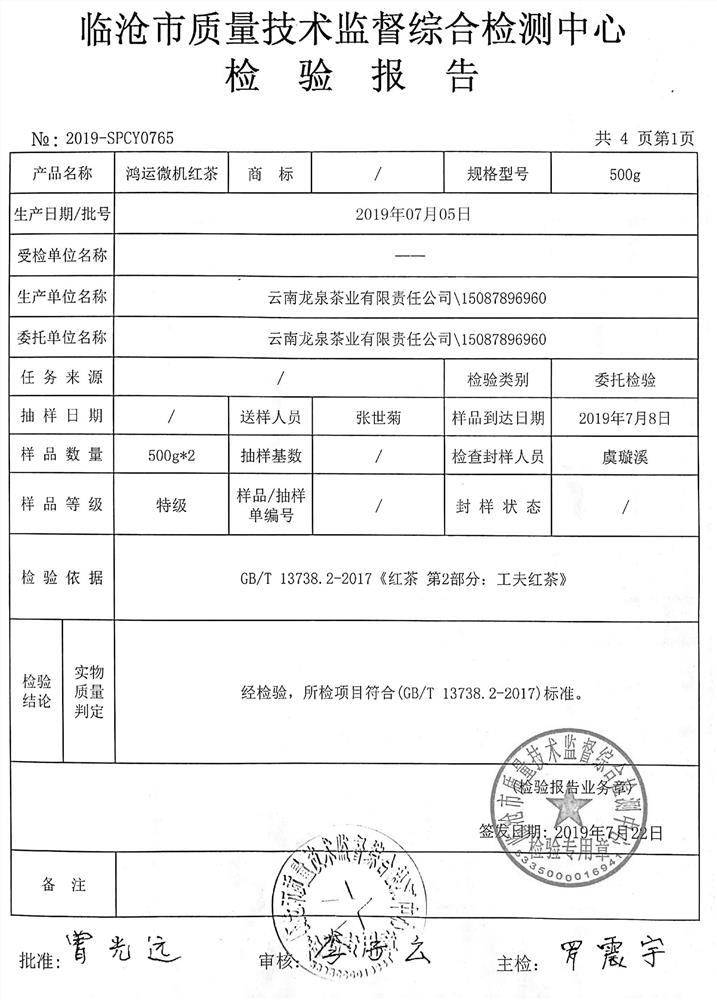

Novel processing technology of Yunnan big-leaf Yunnan black tea

PendingCN112106851AReduce broken rateImproving the traditional fermentation process modePre-extraction tea treatmentMouthfeelEngineering

The invention relates to a novel processing technology of Yunnan big-leaf Yunnan black tea. The novel processing technology comprises the following steps: 1) tea picking; 2) withering; 3) standing; 4)rolling; 5) deblocking; 6) fermenting; 7) mechanical carding; 8) drying for three times; 9) stalk picking; and 10) drying again. Independent scattered fermentation (namely, an independent wooden frame is adopted) is created, a fermentation frame made of Yunnan special green wood is used for fermentation, a specially-made withering tank special for big-leaf tea is used for withering, and meanwhilea traditional fermentation process mode and a key control process for withering and fermentation are improved; the alpine big-leaf tea can bring rich taste and feel a breath from a wide mountain, thetea soup is high in fineness and mellowness and smooth in permeability, and the alpine big-leaf tea is extremely small in bitterness and sweetness accordingly; and the taste is mellow, the sweetnessof the bitter taste enables the oral cavity to promote the secretion of saliva or body fluid, and the sweet aroma is remained in the oral cavity and the throat for a long time, and the strong aroma isa generous gift.

Owner:云南龙泉茶业有限责任公司

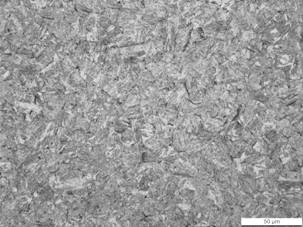

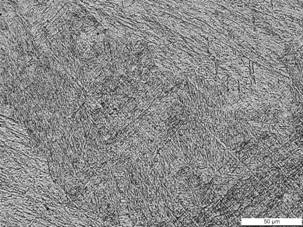

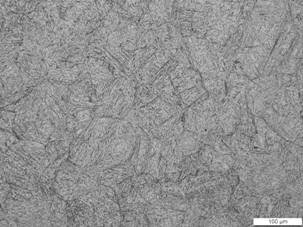

Cast steel shot with low-carbon martensite structure and preparation process for cast steel shot

ActiveCN113789477AImprove plasticity and toughnessReduce broken rateFurnace typesHeat treatment furnacesAlloy elementQuenching

The invention discloses a cast steel shot with a low-carbon martensite structure and a preparation process for the cast steel shot. The cast steel shot comprises the following chemical elements in percentage by mass: 0.25-0.75% of C, greater than 1.2% and less than or equal to 2.10% of Mn, 0.25-0.50% of Si, greater than 0.05% and less than or equal to 0.10% of P, less than 0.05% of S and the balance Fe, inevitable impurities and alloy elements brought in by raw materials during smelting. In the preparation process, a high-temperature or ultra-high-temperature quenching heating temperature higher than a conventional quenching heating temperature is adopted, and a quenched metallographic structure is the low-carbon martensite structure containing austenite films among laths. The cast steel shot has the advantages of being higher in obdurability, better in use performance, simple in preparation process, high in yield, good in quality and price advantages, environmentally-friendly and wide in application.

Owner:DALIAN JIAOTONG UNIVERSITY +1

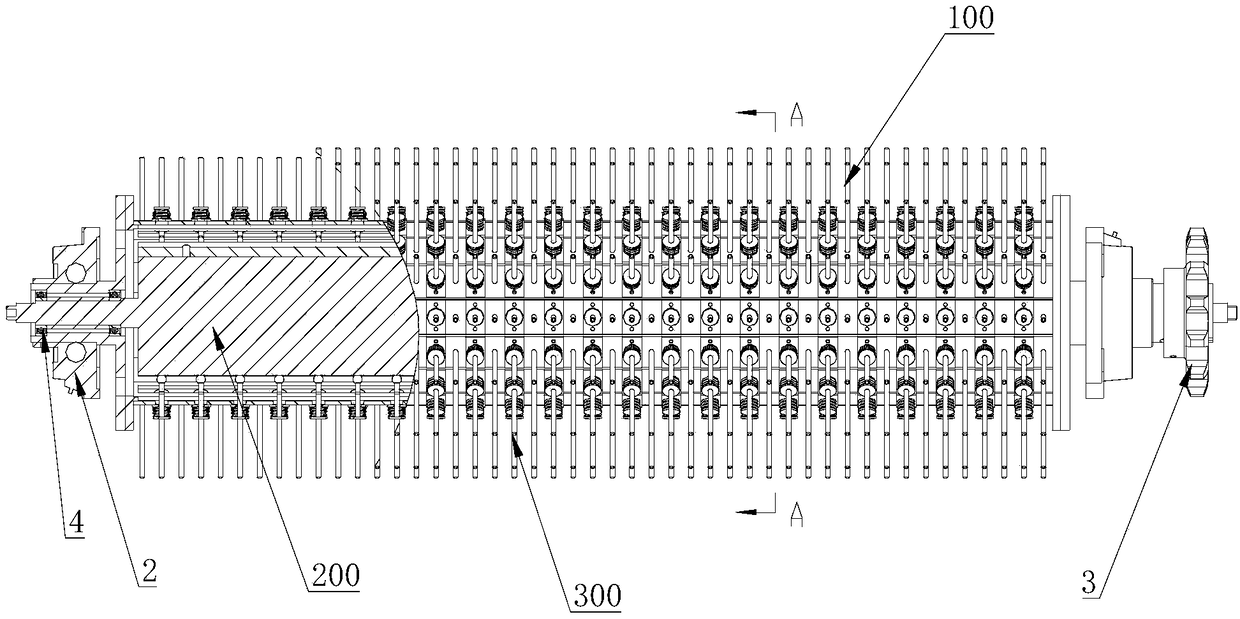

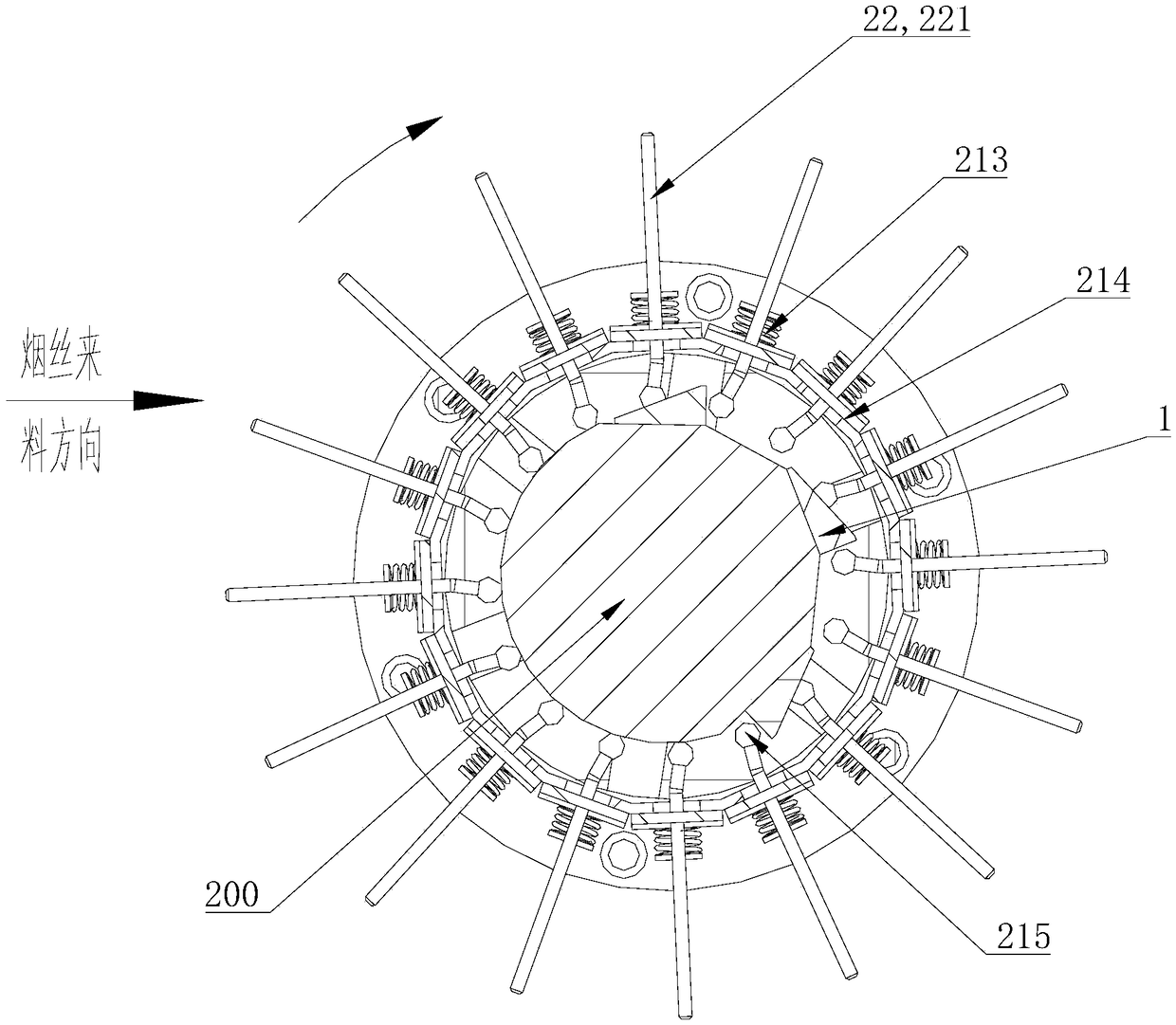

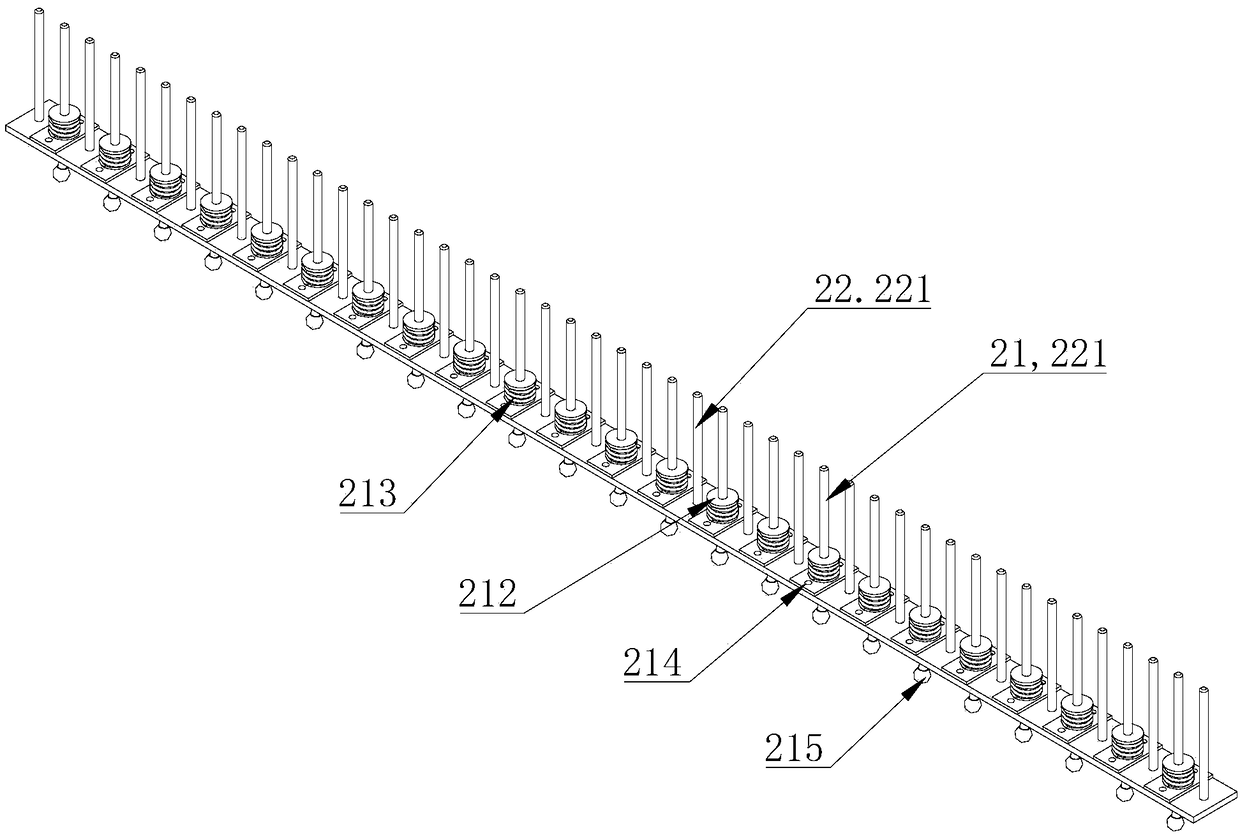

Novel cut tobacco loosing and fluffing roller device

PendingCN109315821AReduce processing intensityReduce broken rateTobacco preparationEngineeringMechanical engineering

The invention discloses a novel cut tobacco loosing and fluffing roller device. The device comprises a fixed mandrel, material stirring roller assemblies and elastic material stirring nail assemblies;the material stirring roller assemblies rotate around the axis of the fixed mandrel; the elastic material stirring nail assemblies rotate around the axis of the fixed mandrel along with the materialstirring roller assemblies and interact with the fixed mandrel in the rotation process of the material stirring roller assemblies to reciprocatingly swing and move relatively, and therefore cut tobacco is loosened and fluffed. The elastic material stirring nail assemblies can interact with the fixed mandrel in the rotation process of the material stirring roller assemblies so that the elastic material stirring nail assemblies can reciprocatingly swing and move relatively, caked cut tobacco winding among the elastic material stirring nail assemblies is fluffed and loosened, and therefore a condition is created for effective separation of stems, stem blocks and other impurities in the cut tobacco.

Owner:QINHUANGDAO TOBACCO MACHINERY

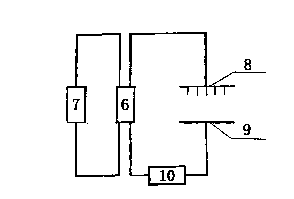

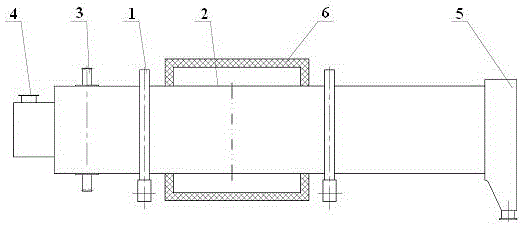

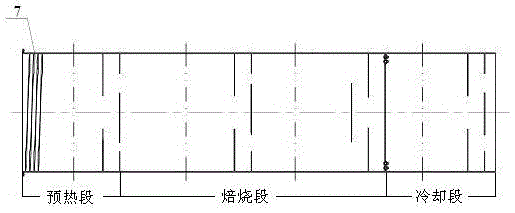

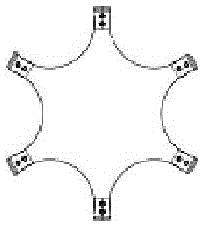

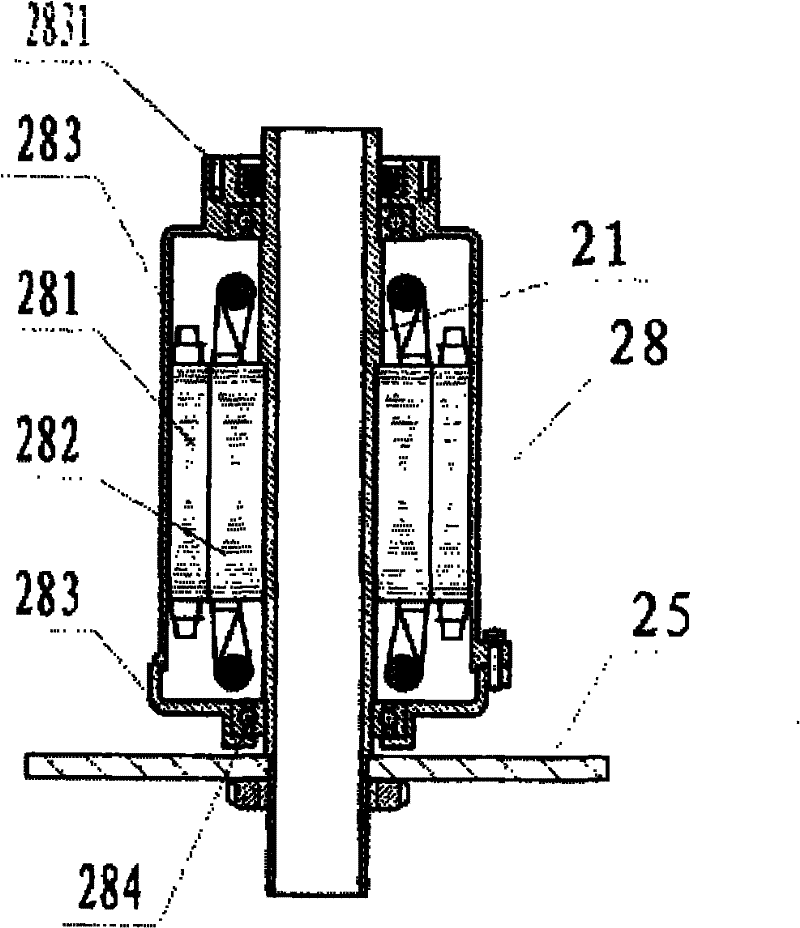

High temperature roasting furnace of hydrogenation catalyst

InactiveCN106698358AReduce wearReduce broken rateOxide/hydroxide preparationHeating systemTransmission system

The invention relates to a high temperature roasting furnace of a hydrogenation catalyst. The roasting furnace comprises a barrel body and a transmission system connected with the barrel body, wherein the barrel body is supported by a supporting system, and the interior of the barrel body is divided into a preheating section, a roasting section and a cooling section; one end of the barrel body is connected with a material feeding system, and the other end of the barrel body is connected with a material discharging system; a heating system is arranged outside the preheating section; a finned shoveling plate, a sectioned material baffle and a helical material baffle located at the material feeding system end are arranged in the barrel body; an anti-radiation plate is arranged between the roasting section and the cooling section. The high temperature roasting furnace has the advantages of guaranteeing uniform heating of a material, reducing the energy consumption and the like.

Owner:TIANHUA INST OF CHEM MACHINERY & AUTOMATION

Electric motor with hollow ventilating main shaft and feeder with the same

ActiveCN102263455AReduce broken rateLarge coverage areaClimate change adaptationPisciculture and aquariaStatorEngineering

The invention belongs to the technical field of aquaculture machineries, and in particular relates to a motor with a hollow ventilating main shaft and a feeding machine with the same. The motor is characterized in that the main shaft is of a hollow structure, the lower end of a shell is connected with a flange, a bearing is arranged between the shell and the main shaft, a stator is fixed on the shell, the shell is connected with a base by virtue of the flange, a rotor is fixed on the main shaft, thereby forming an inner rotor motor; or the stator is fixed on the main shaft, the rotor is fixed on the shell, the main shaft is fixed on the base, thereby forming an outer rotor motor. The feeding machine with the motor is characterized in that a feed delivery pipe is arranged between a feeding mechanism and a throwing mechanism; the upper part of a 360-degree throwing tray is closed, the lower part of the throwing tray is provided with a feed port, and the throwing tray is arranged on the main shaft; the inner hole of the main shaft is dead against the feed port, a hollow shaft enters into the feed port at the lower part of the throwing tray; and the throwing mechanism is installed in fish ponds, the feeding mechanism is installed on the shore, and the negative pressure generated by rotating the throwing tray absorbs the feed to the throwing tray from the feeding mechanism so as to throw out the feed.

Owner:吴海钧

Bridge-crossing conveying vibrating-pressing threshing device of combine harvester

PendingCN110278765AReduce broken rateImprove cleaning rateMowersThreshersEngineeringCombine harvester

The invention relates to a bridge-crossing conveying vibrating-pressing threshing device of a combine harvester, and belongs to the technical field of agricultural machinery. A conveying mechanism of the device is composed of an upper plant conveying vibrating-pressing belt and a lower grain conveying belt. The conveying mechanism is provided with at least one vibrating-pressing threshing cylinder; the plant conveying vibrating-pressing belt is composed of a vibrating-pressing belt which surrounds driving roller shafts at the two ends, and the vibrating-pressing belt is composed of a hollow-out adhesive tape which is provided with leakage holes and flexible vibrating-pressing plates which are uniformly distributed in the length direction of the adhesive tape at intervals. The grain conveying belt is composed of a rubber belt surrounding driving rollers at two ends and L-shaped baffles distributed in the length direction of the rubber belt at intervals; the vibrating-pressing threshing cylinder comprises a rotating roller, and connecting tooth rows extending in the radial direction are uniformly distributed on the outer circumference of the rotating roller; the outer ends of the connecting tooth rows are fixedly connected with tangential threshing plates; threshing intervals are formed between the threshing plates and the vibrating-pressing plates adjacent to the threshing plates. According to the device, the problem that an existing combine harvester cannot achieve non-destructive and efficient complete threshing of grains different in maturity degree is well solved.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI +2

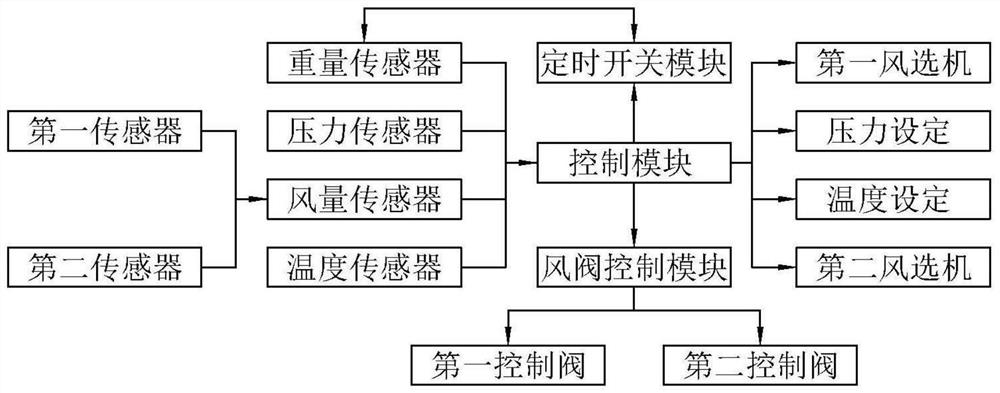

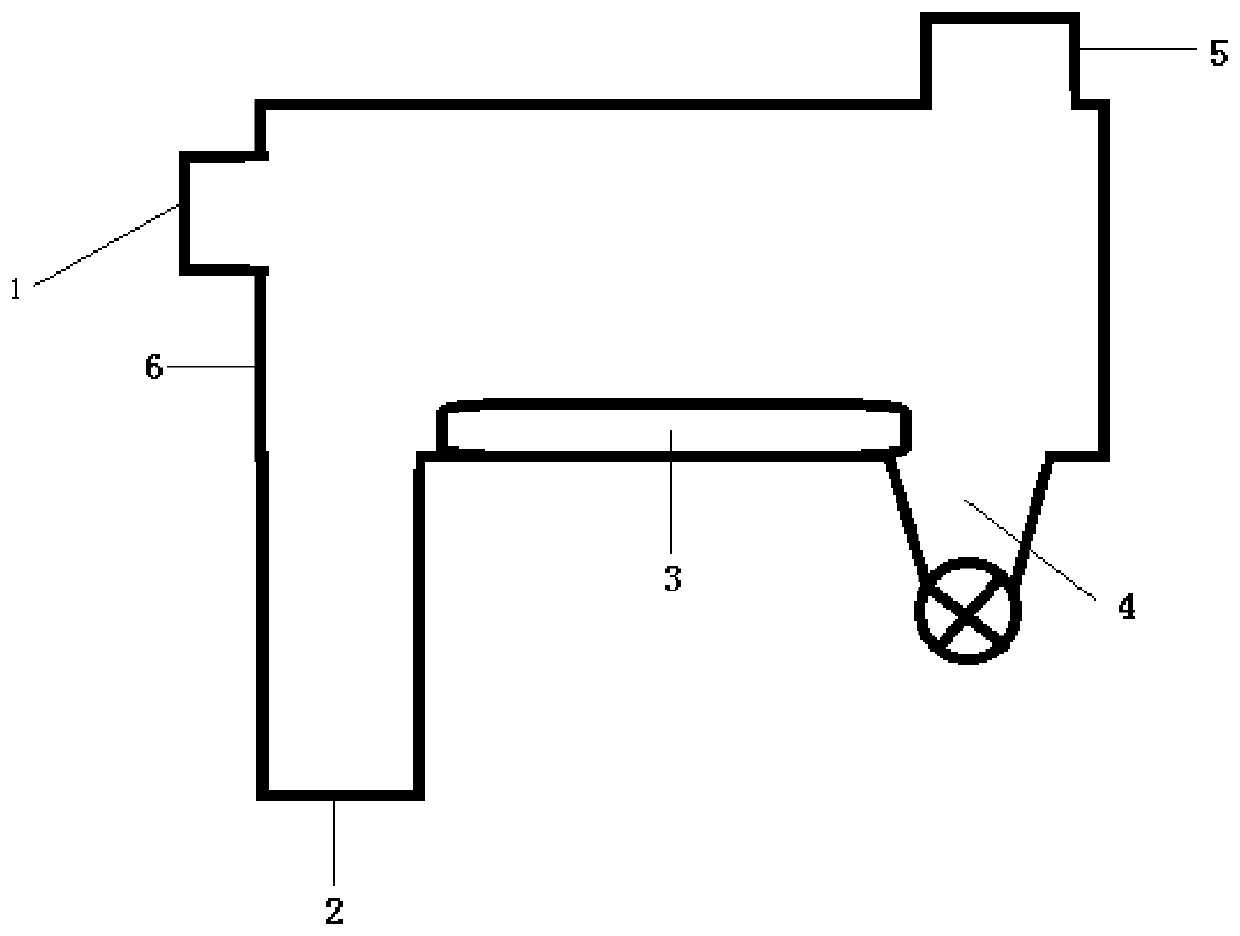

Air volume control device, system and method of cut tobacco winnowing machine

PendingCN114632701AReduce broken rateReduce power consumptionGas current separationProcess engineeringAir volume

The invention discloses an air volume control device, system and method of a tobacco winnowing machine. The device comprises a winnowing box body, a first winnowing machine and a second winnowing machine. A feeding port is formed in the top of the winnowing box body, the first winnowing machine is arranged on one side of the winnowing box body, a discharging port opposite to the first winnowing machine is formed in the other side of the winnowing box body, and the second winnowing machine is arranged at the bottom of the winnowing box body; the first winnowing machine conveys air in the horizontal direction towards the discharging port, the second winnowing machine conveys air in the vertical direction towards the feeding port, and therefore floating separation and flotation are conducted on cut tobacco through vertical and horizontal two-way air inlet. According to the tobacco shred winnowing device, the tobacco shred is subjected to floating separation and flotation through vertical and horizontal two-way air inlet of the box body, objects with large density such as wet masses and slivers fall down through the winnowing box body, objects with low density such as normal tobacco shred are sent out of the box body through the discharging pipe, and therefore the flexible processing purpose of tobacco shred winnowing is achieved.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

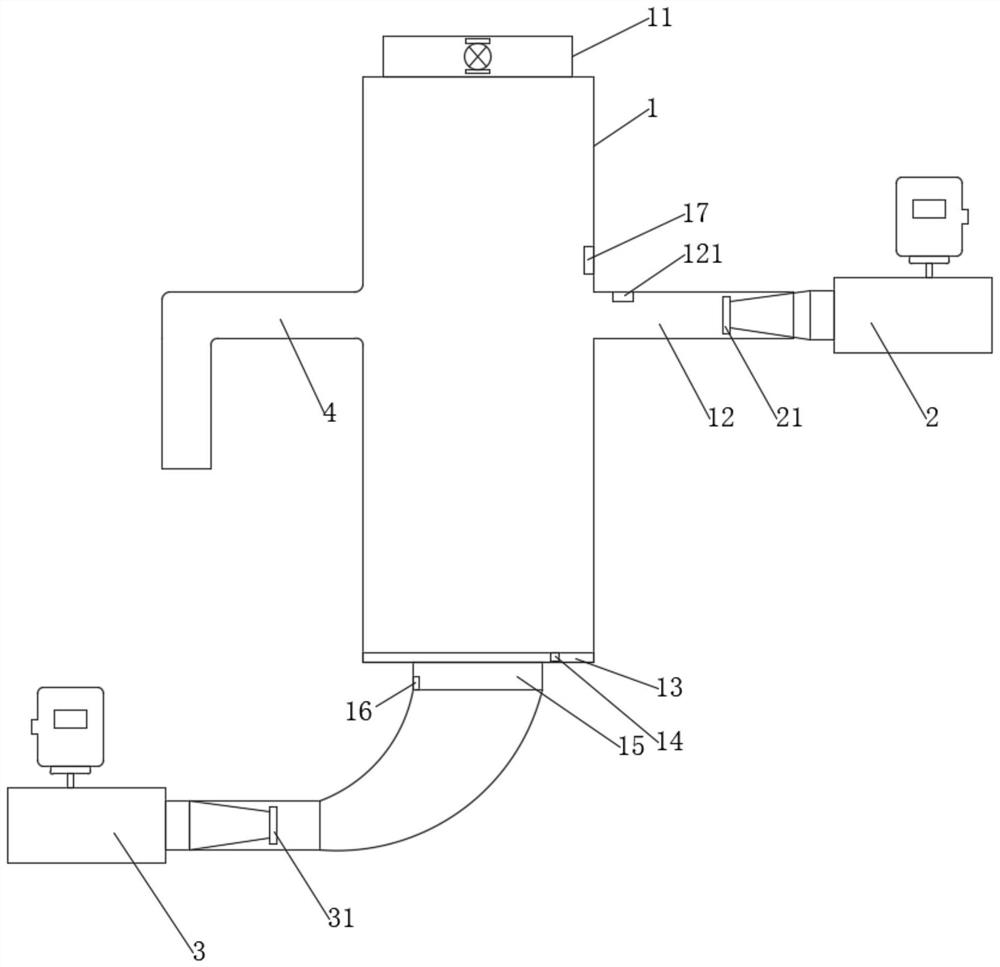

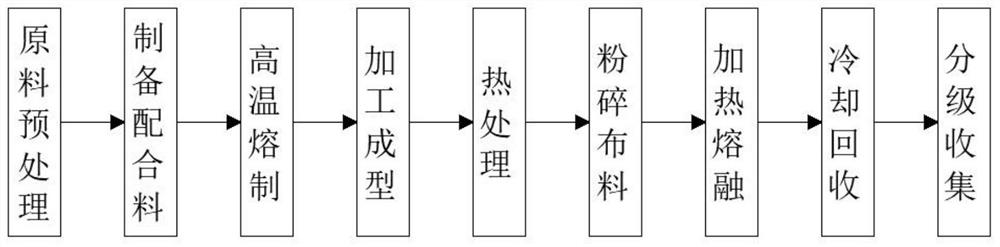

Production principle and process of special fracturing propping agent with strong anti-pressure ability

PendingCN112479696AStrong ability to withstand pressureReduce broken rateFluid removalDrilling compositionChemistrySodium silicate

The invention discloses a production principle and process of a special fracturing propping agent with strong anti-pressure ability. The production principle of the fracturing propping agent is as follows: calcium silicate and sodium silicate are prepared through high-temperature composite reaction of silicon dioxide, sodium carbonate and calcium carbonate, and the chemical reaction is carried outin a high-temperature environment; the production process of the fracturing propping agent comprises the following steps of 1, pre-processing raw materials, 2, preparing a batch, 3, melting at high temperature, 4, processing and forming, 5, heat treatment, 6, crushing and distributing, 7, heating and melting, 8, cooling and recycling, and 9, graded collection. According to the production principle and process of the special fracturing propping agent with strong anti-pressure ability, a novel propping agent material can be prepared, the pressure resistance is high, the breakage rate is low, and the fracturing propping agent has the characteristics of good spheronization, good fluidity, electrical insulation, stable chemical properties, high heat resistance, high mechanical strength and thelike.

Owner:SICHUAN HAYWARD PETROLEUM ENG TECH

Corn threshing machine

The invention discloses a corn threshing machine. The corn threshing machine comprises a feeding inlet, a tapered shell, a helical plate tooth drum, a corn kernel collection hopper, a cob discharginghopper, a sieve plate, a concave grille plate, a rack, a rotary shaft and a fan, wherein the rack is provided with the tapered shell, the helical plate tooth drum is arranged in the tapered shell, therotary shaft penetrates through the helical plate tooth drum, the feeding inlet is connected with the upper portion on the left side of the tapered shell, and the concave grille plate is arranged onthe bottom of the tapered shell; the lower portion of the concave grille plate is provided with the corn kernel collection hopper through the sieve plate, the fan is arranged on one side of the corn kernel collection hopper, and the cob discharging hopper is arranged on the lower portion at the right end of the tapered shell. The corn threshing machine has the advantages of high threshing rate, low breakage rate and low power consumption, and is convenient and reliable to use and high in practicability.

Owner:赵大娥

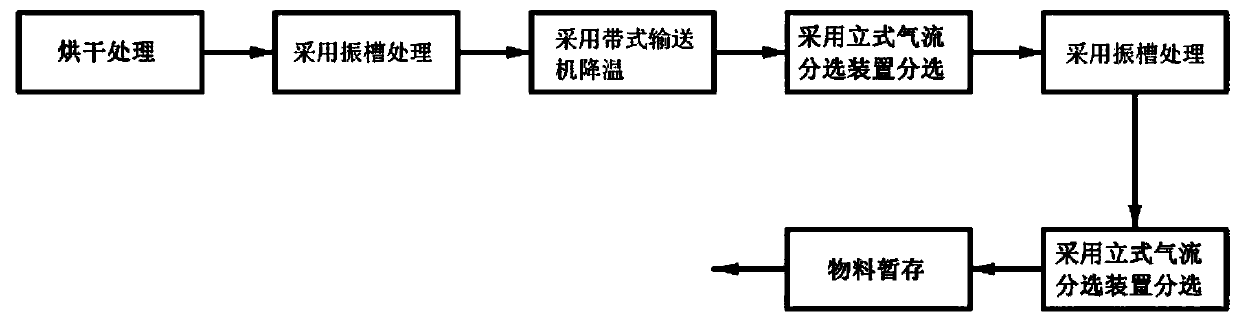

Method for drying tobacco shreds, tobacco shreds, tobacco products and application

ActiveCN111528510AReduce broken rateIncrease fill valueTobacco preparationTobacco productEngineering

The invention belongs to the field of tobacco products, and relates to a method for drying tobacco shreds, which comprises the following steps: (1) drying the tobacco shreds to obtain a 50-80 DEG C dried material; (2) treating the dried materials through a vibration tank, wherein the conveying speed ranges from 0.26 m / s to 0.35 m / s, the time ranges from 35 s to 50 s, the vibration frequency rangesfrom 4.10 Hz to 4.70 Hz, the amplitude ranges from 23 mm to 30 mm, and first materials are obtained; (3) conveying the first material by using a belt conveyor at a conveying speed of 0.6-0.7 m / s for8-40 seconds, and performingcooling to obtain a second material; (4) carrying out airflow separation on the second material at the airflow velocity of 4.3-6.8 m / s and the temperature not higher than that of the second material to obtain a material; (5) treating the material obtained in the step (4) in a vibration tank to obtain a third material; and (6) performing third material airflow separation. The invention relates to tobacco shreds, tobacco products and application. According to the method, the tobacco shred breakage rate is reduced, the filling value is increased, the ratio of macular cigarettes to mildewed cigarettes is reduced, and the sensory quality of cigarettes is improved.

Owner:XIAMEN TOBACCO IND

Crystal pulling method for crystal bar

InactiveCN104818523AIngot quality is goodReduce broken ratePolycrystalline material growthBy pulling from meltElectric fieldSemiconductor

The invention relates to the technical field of refrigerating piece production, in particular to a crystal pulling method for a crystal bar. The crystal bar is subjected to crystal pulling in a crystal pulling furnace. The crystal pulling method includes the steps of a, heating the crystal bar to 280-320 DEG C within 30-40 minutes, and keeping the temperature for 10-15 minutes; b, cooling the crystal bar to 50-60 DEG C within 7-9 minutes; preferably, in the step a, the crystal bar is heated in a 10-12V / cm electric field one-millimeter in amplitude and 40-60 hertz in frequency. The crystal pulling method for the crystal bar has the advantages of better produced crystal bar quality, low breakage rate during crystal bar cutting and easiness in implementation.

Owner:HENAN HONGCHANG ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com