Production method of simulated charcoal

A technology for simulating charcoal and a production method, applied in the field of simulating charcoal production, can solve problems such as low work efficiency, uneven thickness of finished products, broken products, etc., and achieve the effects of improving production efficiency, uniform thickness of finished products, and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

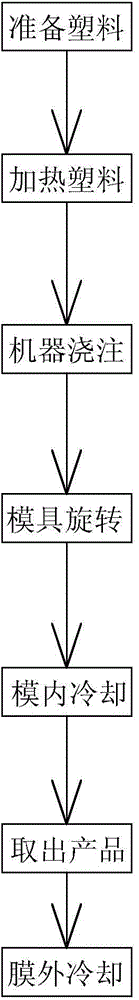

[0011] refer to figure 1 , the present invention is a kind of imitation charcoal production method, comprises the following steps: a, prepares plastics, and plastics is heated into fluid state; The non-centered rotation makes the fluid plastic evenly adhere to the cavity wall of the mold. When the fluid plastic cools to a solid state and becomes elastic, the product is taken out and completely cooled outside the mold. The invention adopts plastics as raw materials and controls the molding quality by machine pouring, which can greatly improve the production efficiency of simulated charcoal, and at the same time reduce the breakage rate of the finished product when it is released from the mold, and the finished product has uniform thickness and beautiful appearance.

[0012] As shown in the figure, the plastic material can be set as PVC material or PT material during specific implementation, but it is not limited thereto.

[0013] The above-mentioned embodiments are only prefer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com