Extruded corn sheller

A thresher and extrusion technology, which is applied in the field of corn threshing devices, can solve the problems of broken corn kernels and high corn breakage rate, and achieve the effect of reducing the breakage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

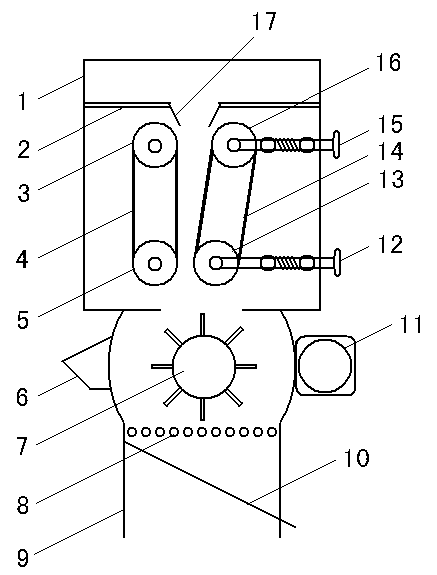

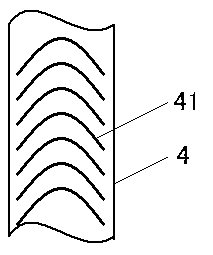

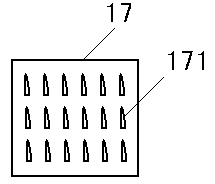

[0023] like figure 1 , figure 2 , image 3 As shown, the box body 1 is fixed on the frame 9, and the upper part of the box body 1 has a shelf plate 2, and the shelf plate 2 is provided with a shelf plate opening. There is a downward iron tooth 171 on the top, and a barb is arranged on the downward iron tooth 171, which limits the ear of corn to the downward direction and is not easy to upward; in order to enhance the downward effect of the ear of corn, a vertical 1- 3 partitions, thereby dividing the shelf opening into 2-4 parts, at least one side of the partition is provided with descending iron teeth 171, and generally both surfaces of the partition are provided with descending iron teeth 171. A fixed upper roll 3 and an adjustable upper roll 16 are arranged side by side at the lower part of the frame plate opening. The fixed upper roll 3 and the adjustable upper roll 16 are arranged in parallel with the frame plate opening and rotate inwardly. Roller 5, fixed upper roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com