Buffering type air hoister

A hoist and pneumatic technology, applied in the field of buffer type pneumatic hoist, can solve the problems of wear, damage and severe impact of the feeding pipe, and achieve the effects of reducing wind resistance loss, prolonging service life and reducing wind pressure resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

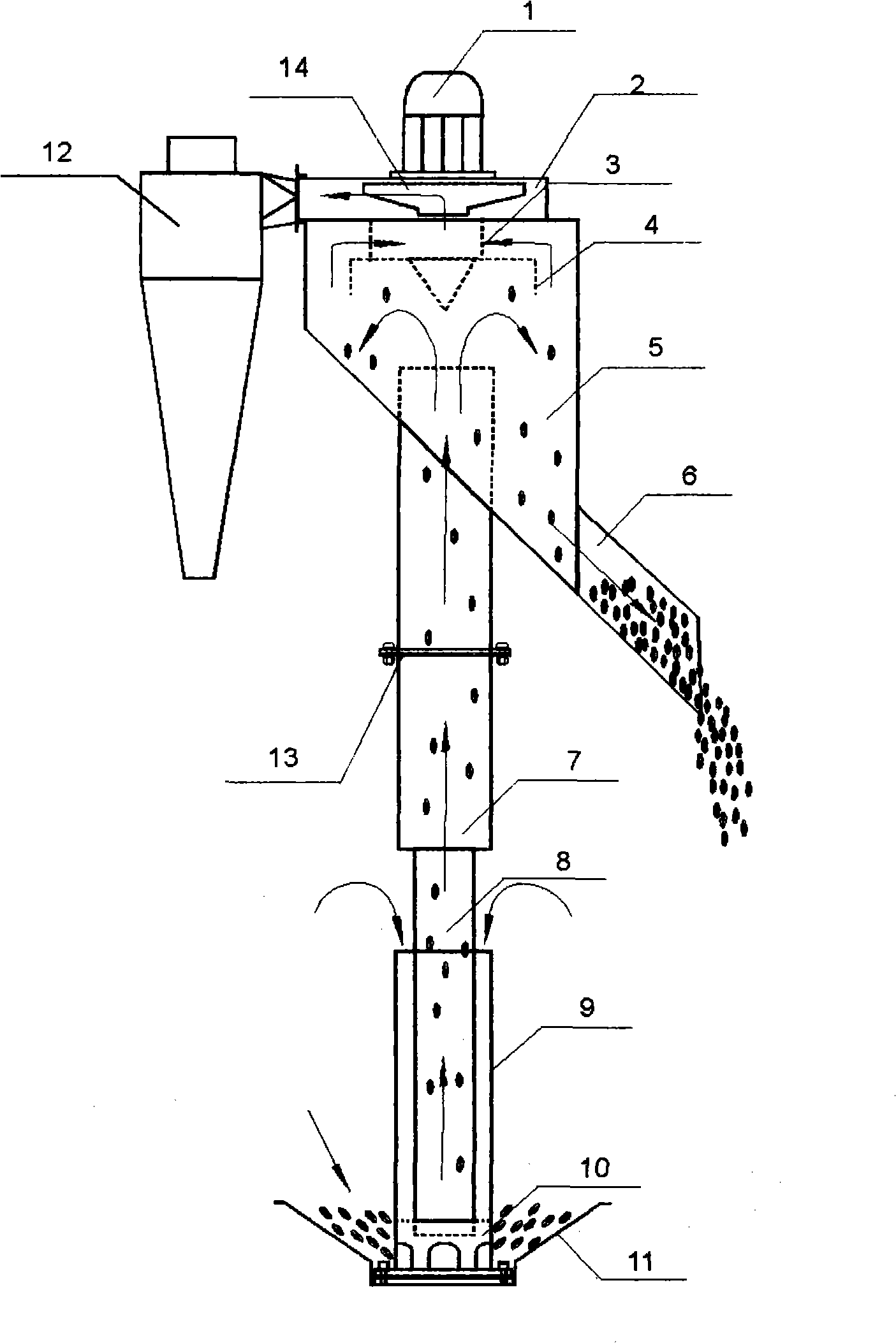

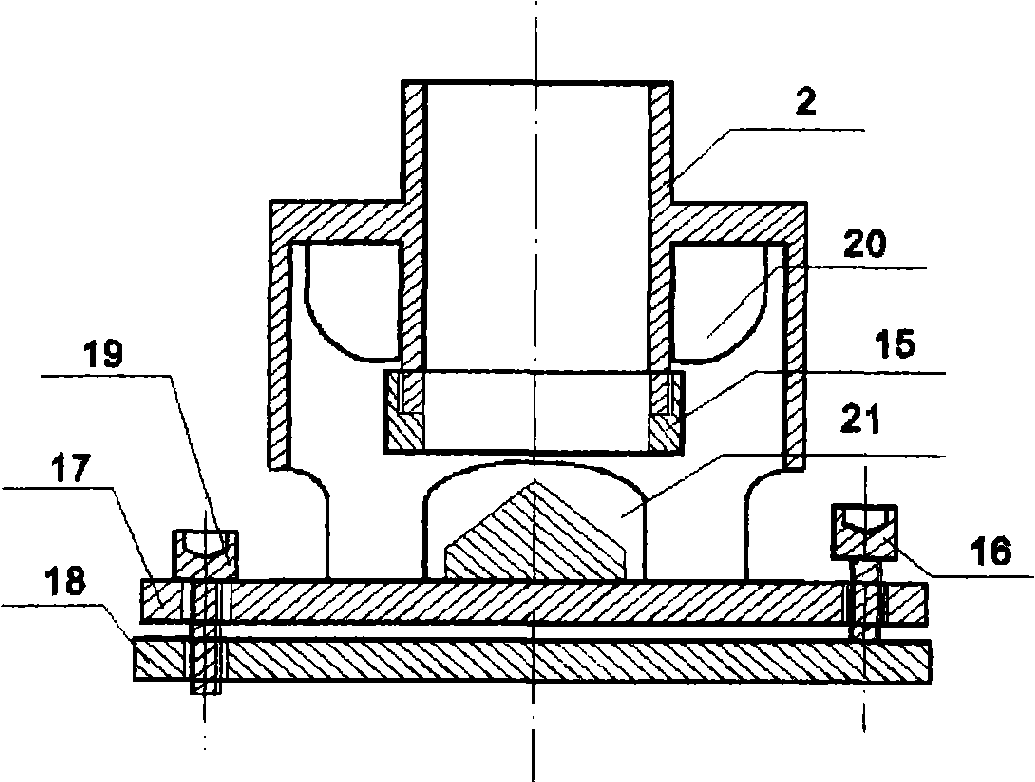

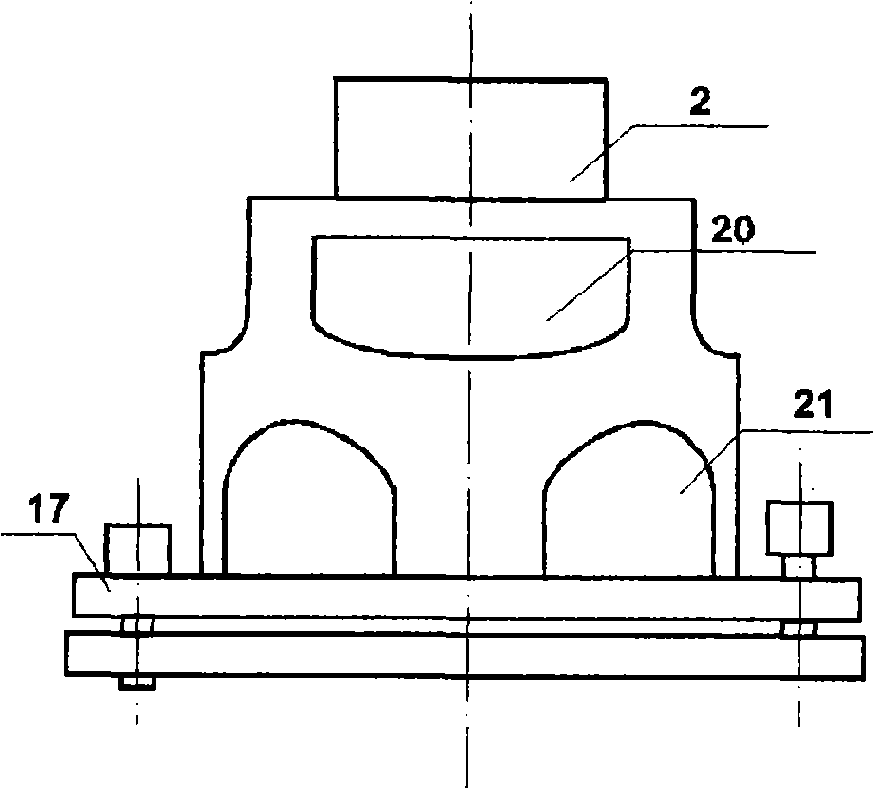

[0014] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 Shown: a kind of cushioning type pneumatic hoist of the present invention, mainly by motor 1, blower fan 2, unloader 5, dust collector 12 on one side of unloader 5, pressure discharge pipe 6 and by feeder The material receiving device composed of pipe and outer casing is characterized in that: the fan 2 connected with the motor 1 is directly installed on the top of the unloader 5, and the working surface of the fan impeller 14 communicates with the working chamber of the unloader; The pipe 6 is connected to the bottom of the unloader 5 and also communicates with the working chamber of the unloader 5; the feed pipe is composed of the buffer pipe 7 of the upper section and the acceleration pipe 8 of the lower section, and the upper end of the buffer pipe 7 is connected with the unloading pipe of the elevator. The device 5 is connected, and the accelerator tube 8 is provided with a feeding s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com