Novel cut tobacco loosing and fluffing roller device

A spinning roller and loosening technology, which is applied in tobacco, tobacco preparation, application, etc., can solve the problems of poor adaptability of material layer thickness, easy scaling, high shredded tobacco rate, etc., to ensure loosening and complete blanking, prevent Fouling and carry-back, reducing the effect of processing intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

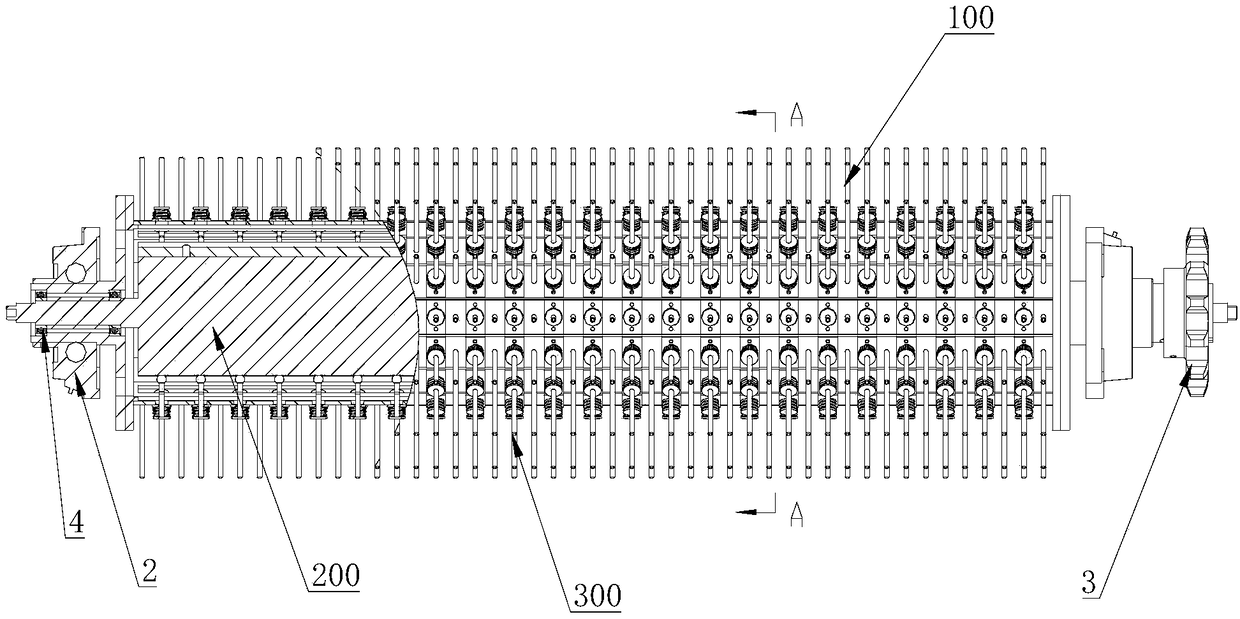

[0039] like Figure 1 to Figure 4 As shown, a novel shredded tobacco loosening roller device 100 is introduced in this embodiment, which includes a fixed mandrel 200; a material pulling roller assembly 300 that rotates around the axis of the fixed mandrel 200; With the push roller assembly 300 jointly rotating around the axis of the fixed mandrel 200, the elastic push nail assembly 21 interacts with the fixed mandrel 200 during the rotation of the push roller assembly 300, so that the elastic push nail assembly 21 generates Reciprocating swing and relative displacement loosen and flick the shredded tobacco. By being arranged in the rotation process of the material-setting roller assembly, the elastic material-setting nail assembly can interact with the fixed mandrel, so that the elastic material-setting nail assembly can produce reciprocating swinging motion and relative displacement. The springiness and looseness of inter-clumped shredded tobacco create conditions for the ef...

Embodiment 2

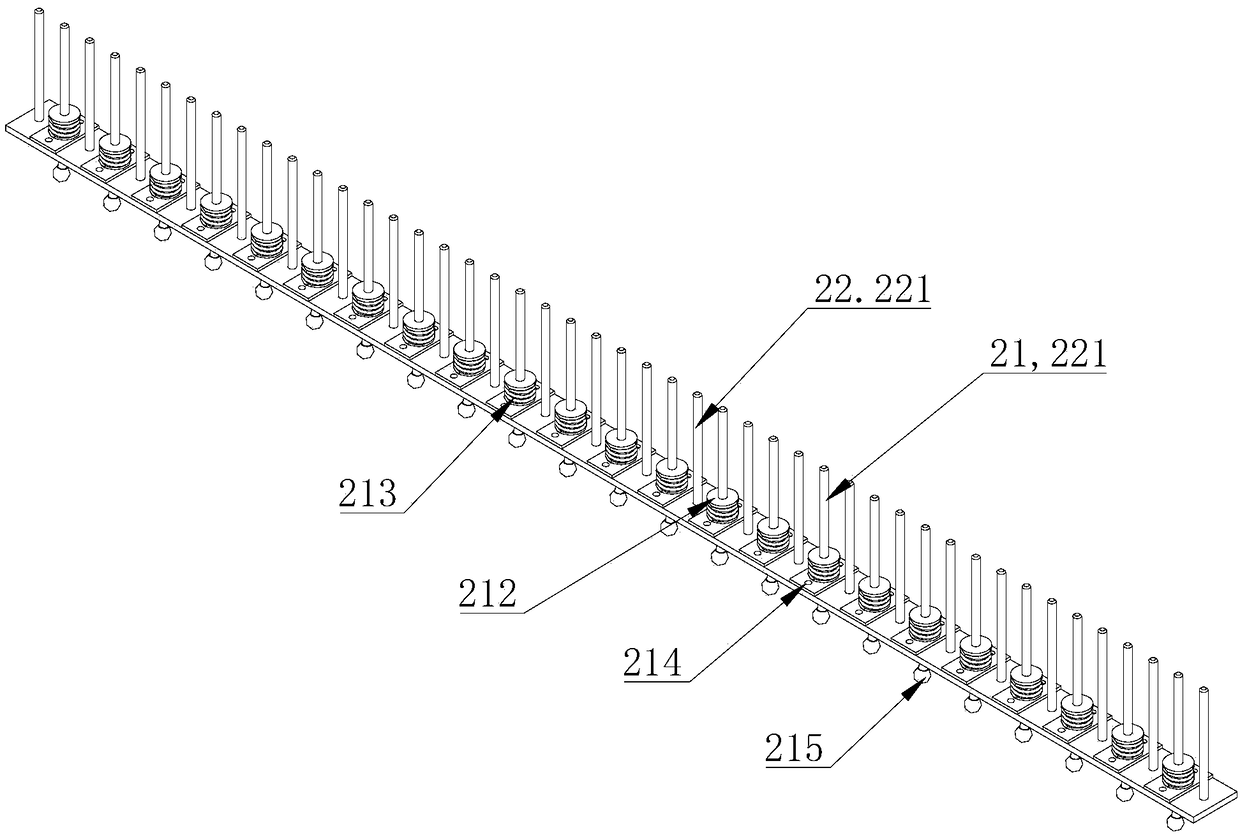

[0050] like Figure 3 to Figure 4 As shown, in this embodiment, each elastic push nail assembly 21 also includes an upper connecting plate 212 and a lower connecting plate 214 arranged perpendicularly to the elastic pushing nail 211, and the upper connecting plate 212 and the lower connecting plate 214 are all sleeved on the On the elastic screw 211, the spring 213 is located between the upper connecting plate 212 and the lower connecting plate 214. The elastic screw 212, the upper connecting plate 212, the spring 213 and the lower connecting plate 214 are all rigidly connected to each other. The elastic screw 212 One end passes through the lower connecting plate 214 and is connected with the collision ball 215 .

[0051] In this embodiment, both the upper connecting plate 212 and the lower connecting plate 214 are flat plates for fixing the spring 213 and the elastic screw 211. The upper connecting plate 212 is located at the end of the elastic screw 211 away from the collisi...

Embodiment 3

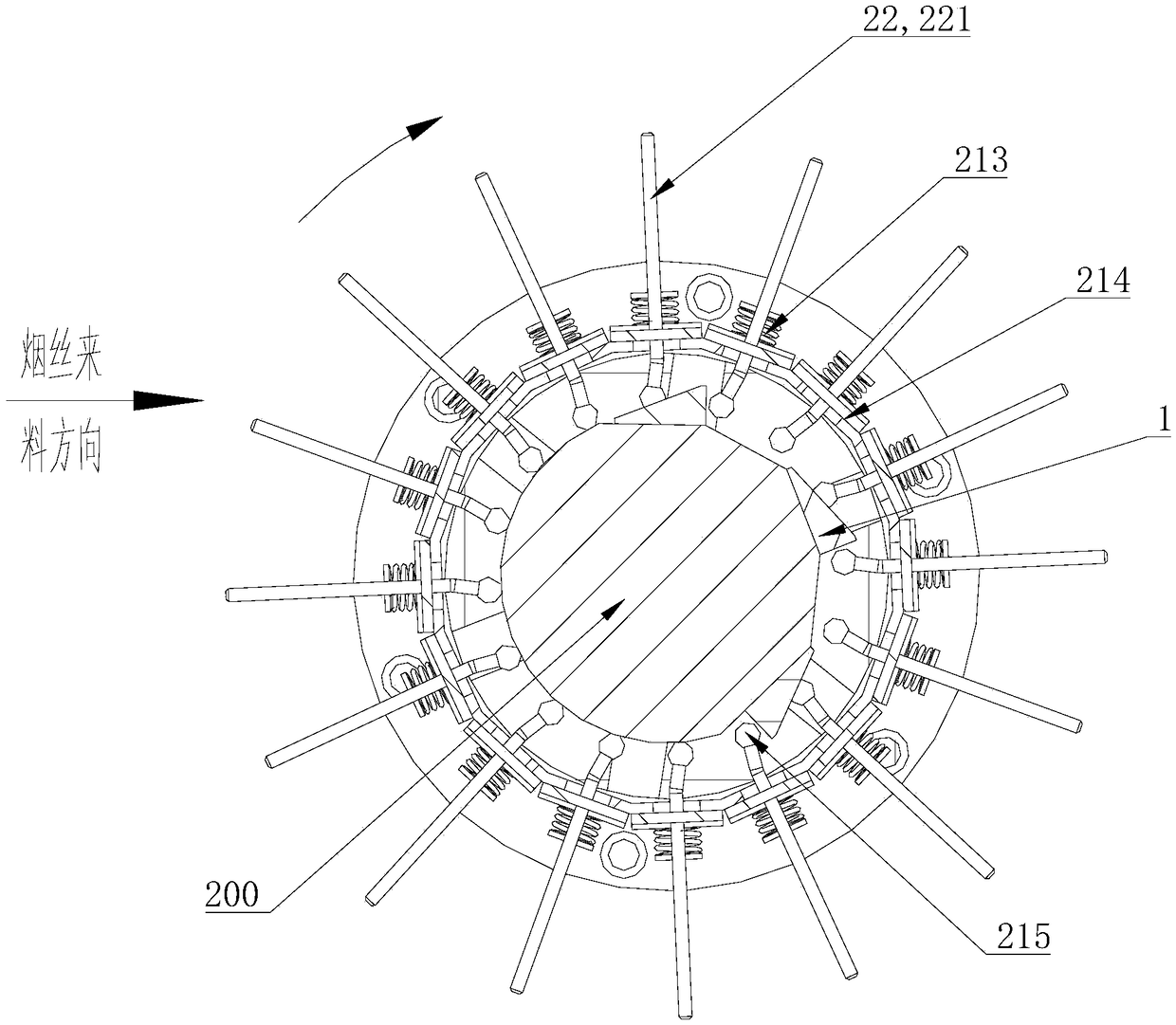

[0057] like Figure 1 to Figure 4 As shown, in the present embodiment, shredded tobacco is fed to the filament-elastic roller device 100 in a horizontal direction perpendicular to the axial surface of the filament-elastic roller device 100, and the drive sprocket 3 drives the material-pushing roller assembly 300 to rotate, and the material-picking roller assembly 300 The direction of rotation is clockwise from the feed side, the feed direction and rotation direction are as follows figure 2 shown.

[0058] In the present embodiment, each rigid screw assembly 22 and the elastic screw assembly 21 rotate together, and the collision ball 215 of the elastic screw assembly 21 moves along the outer periphery of the fixed mandrel 200. When the elastic screw assembly 21 When moving to the position of the protrusion 1 of the fixed mandrel 200, the elastic pushing nail assembly 21 includes a collision ball 215 and continues to move along the outer surface of the protrusion 1. Since the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com