Low-density high-strength ceramsite proppant prepared from flint clay as raw material and preparation method thereof

A technology of high-strength ceramsite and proppant, which is applied to clay products, earth square drilling, and other household appliances. It can solve the problems of low plasticity and difficulty in dispersing, and achieve low breakage rate, low production energy consumption, and simple preparation method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

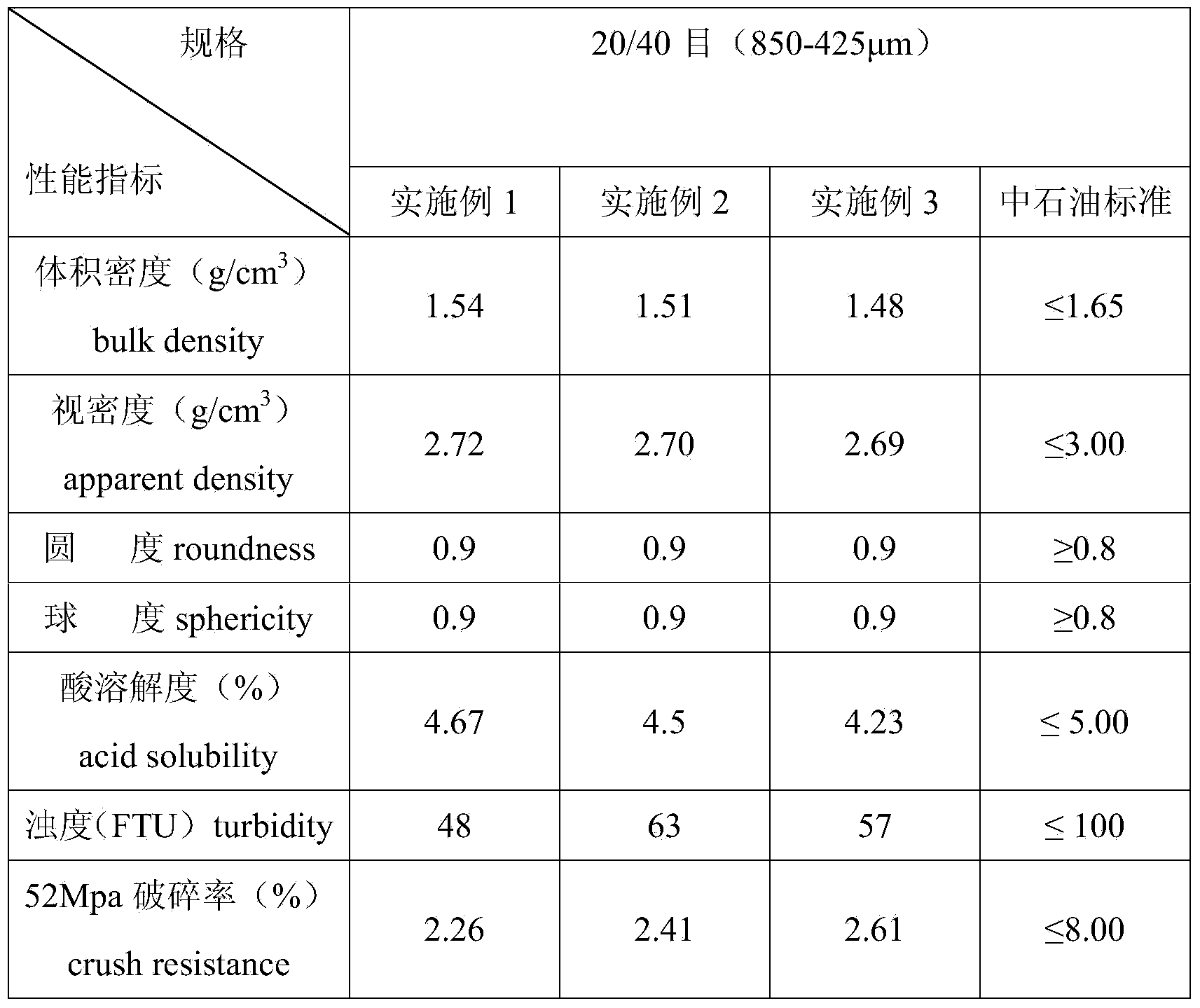

Examples

Embodiment 1

[0039] The chemical composition and mass percentage of burnt gemstones are as follows:

[0040] Al 2 o 3 : 46%, SiO 2 : 51%, Fe 2 o 3 : 1%, TiO 2 : 1%, CaO: 0.4%, MgO: 0.4%, K 2 O: 0.1%, Na 2 O: 0.1% and loss on ignition.

[0041] The preparation method of the low-density high-strength ceramsite proppant using burnt gem as raw material is as follows:

[0042] (1) Carry out calcination treatment of the raw coke gem raw ore, the calcination temperature is 1000°C, and calcination is performed for 2.5 hours;

[0043] (2) Crushing and grinding the calcined raw materials to 120 mesh;

[0044] (3) Add water to the raw material after grinding, stir and wet grind it into a slurry, so that the solid content of the slurry is 70%, and take samples every 10 minutes to detect the particle size with a laser particle size analyzer, and the particle size reaches 800 mesh;

[0045] (4) Spray-dry the mud that has reached the particle size with a spray drying tower to a moisture content...

Embodiment 2

[0050] The chemical composition and mass percentage of burnt gemstones are as follows:

[0051] Al 2 o 3 : 43%, SiO 2 : 52%, Fe 2 o 3 : 1.5%, TiO 2 : 2.5%, CaO: 0.2%, MgO: 0.5%, K 2 O: 0.2%, Na 2 O: 0.1% and loss on ignition.

[0052] The preparation method of the low-density high-strength ceramsite proppant using burnt gem as raw material is as follows:

[0053] (1) Carry out calcination treatment of the raw coke gem raw ore, the calcination temperature is 1200°C, and calcination is performed for 3 hours;

[0054] (2) Crushing and grinding the calcined raw materials to 300 mesh;

[0055] (3) Add water to the ground raw material and wet grind it into slurry with stirring and wet grinding. The solid content of the slurry is 68%. Sampling is carried out every 10 minutes with a laser particle size analyzer to detect the particle size, and the particle size reaches 500 mesh;

[0056] (4) Spray-dry the mud that has reached the particle size with a spray drying tower to a ...

Embodiment 3

[0061] The chemical composition and mass percentage of burnt gemstones are as follows:

[0062] Al 2 o 3 : 41%, SiO 2 : 54%, Fe 2 o 3 : 2.5%, TiO 2 : 1.5%, CaO: 0.2%, MgO: 0.3%, K 2 O: 0.3%, Na 2 O: 0.2% and loss on ignition.

[0063] The preparation method of the low-density high-strength ceramsite proppant using burnt gem as raw material is as follows:

[0064] (1) Carry out calcination treatment of raw coke gem raw ore, calcination temperature is 800°C, calcination for 4 hours;

[0065] (2) Crushing and grinding the calcined raw materials to 200 mesh;

[0066] (3) Add water to the raw material after grinding according to the solid content of 69% and use a stirring mill to wet grind it into a slurry, take samples every 10 minutes and use a laser particle size analyzer to detect the particle size, and the particle size reaches 1500 mesh;

[0067] (4) Spray-dry the mud that has reached the particle size with a spray drying tower to a moisture content of less than 6%;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com