High-hardness and long-service-life steel wire cut shot producing method and production line

A technology for cutting steel wire shot and production method, which is applied in the field of cutting steel wire shot with high hardness and long life, and achieves the effects of low crushing rate, high hardness and long Owen life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

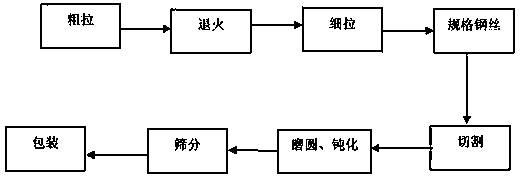

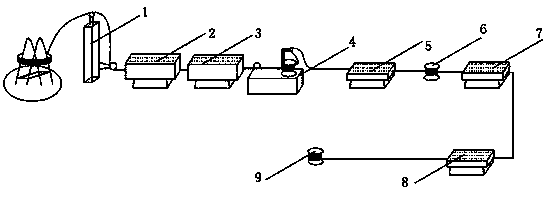

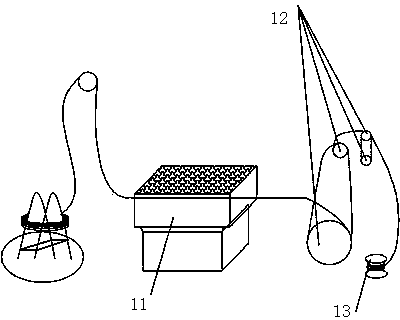

[0024] Such as Figure 1 to Figure 5 as shown,

[0025] The principle is: use selected raw material scrap steel, add rare metals and alloys with the best ratio, smelt in an electric furnace, and transform it into steel wire through modern equipment production, and undergo multiple electric heat treatments, drawing, cutting shots, rounding passivation, automatic Screening, during the process of forming steel particles from liquid metal, its chemical composition and particle size are strictly controlled to ensure that its mechanical properties are suitable for various purposes. There is the most stringent quality management in each production link. The steel shot produced has a tight internal structure, is not easy to break, has a uniform particle size distribution, has appropriate hardness, strong impact resistance and long service life.

[0026] It is described in detail in conjunction with the technological process below:

[0027] A production method and production line of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com