Environment-friendly low-crushing-rate drying and threshing equipment

A broken rate, environmentally friendly technology, applied in threshing equipment, preservation of seeds by drying, agricultural machinery and equipment, etc., can solve the adverse effects of safe storage of corn, affect the use value of corn, and high corn kernel breakage rate. Simple, low cost, low breakage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

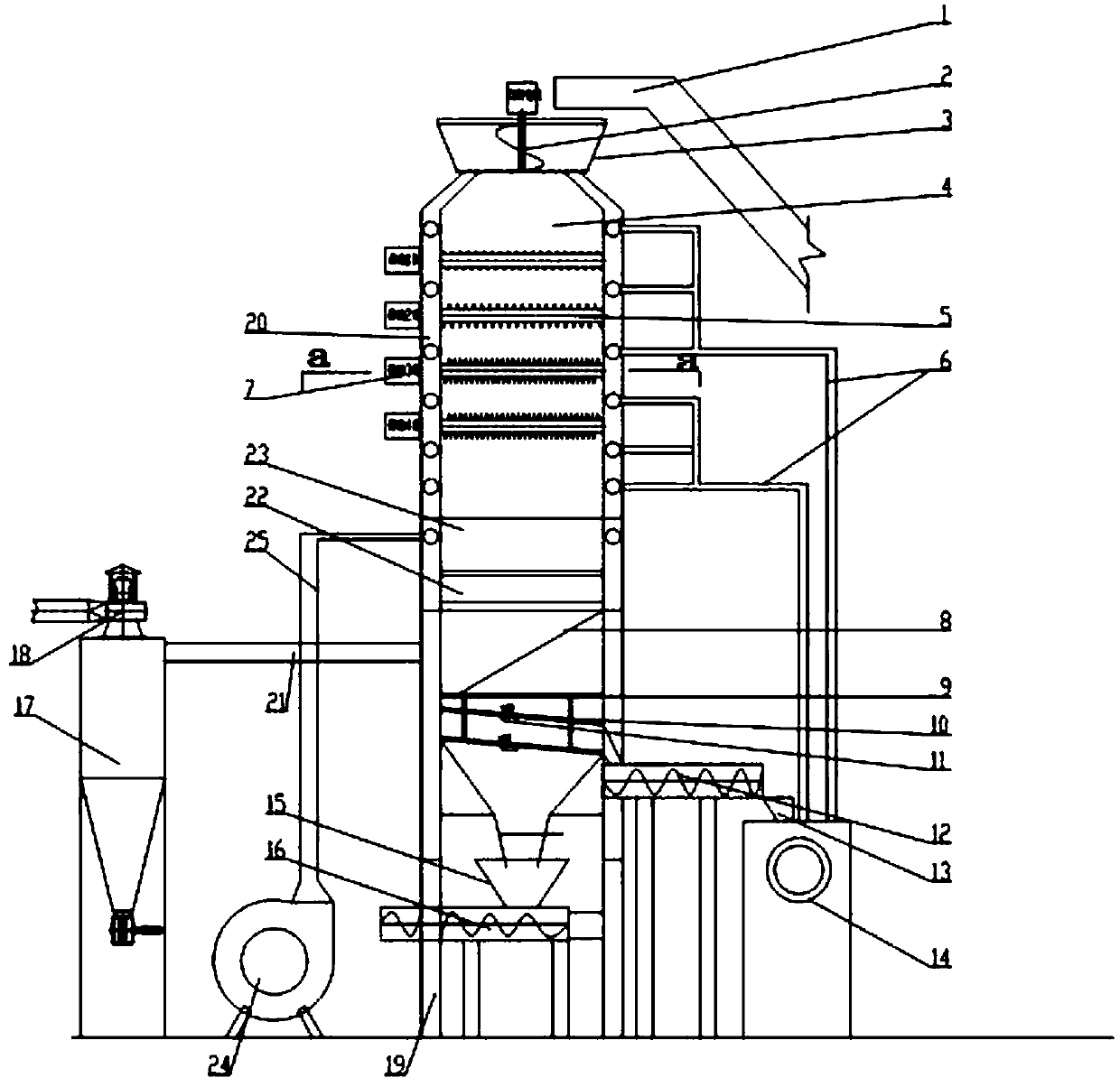

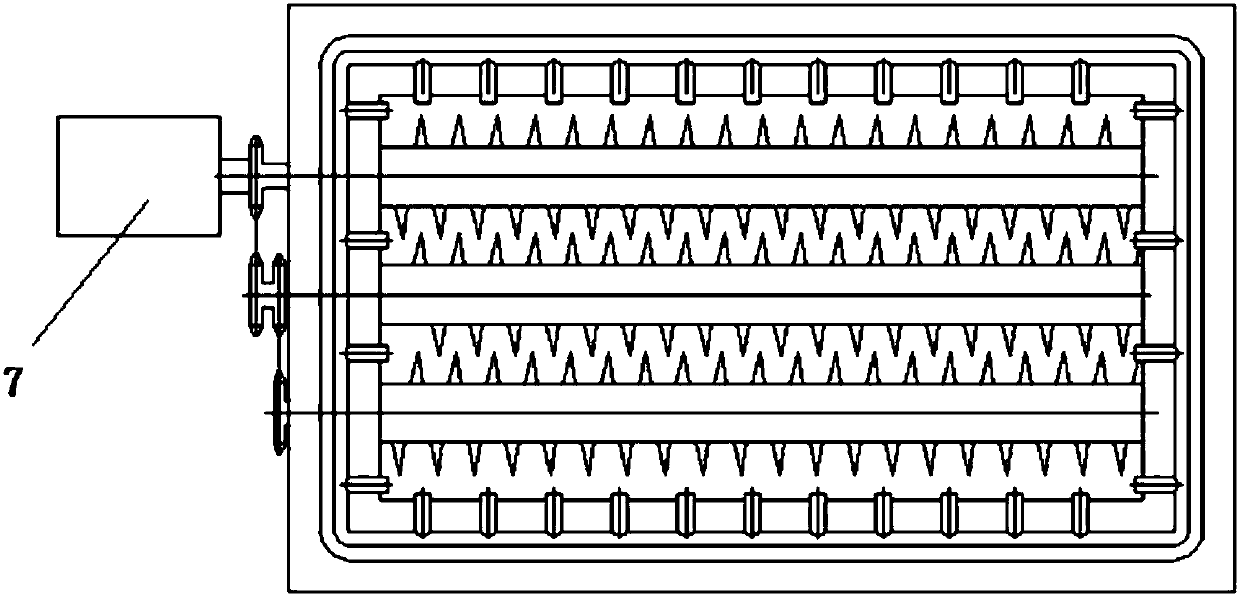

[0022] As shown in the figure: the environment-friendly low breakage rate drying and threshing equipment in this embodiment includes a drying and threshing tower 20 for drying and threshing corn ears, and the drying and threshing tower is sequentially arranged with The feed inlet, the drying and threshing section and the discharge opening form a drying and threshing chamber 4 in the drying and threshing section; the drying and threshing section is provided with a threshing roller 5 for threshing corn kernels, and the threshing roller 5 is provided with The threshing gear, the threshing roller 5 is provided with at least two layers in the up and down direction, which can be as figure 1 The setup shown in is four layers, as in figure 2 As shown, each layer is provided with 3 horizontally staggered threshing rollers, and the 3 threshing rollers on the same layer are driven by the transmission wheel 7. Of course, a driving machine for driving the threshing rollers to rotate on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com