Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "No bleaching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

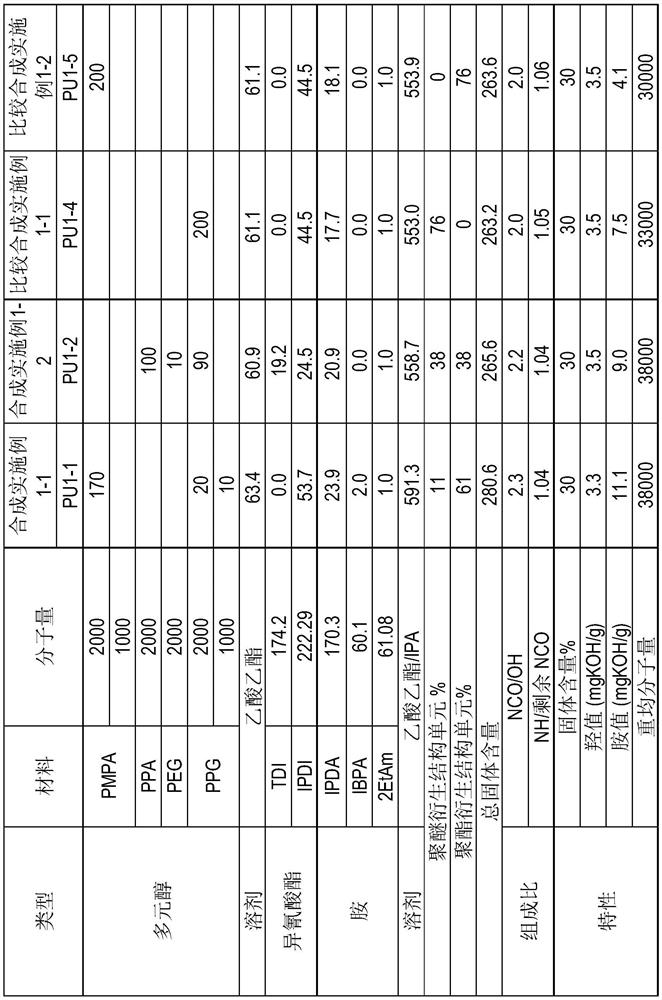

Liquid crystal aligning agent, liquid crystal alignment film and liquid crystal display element

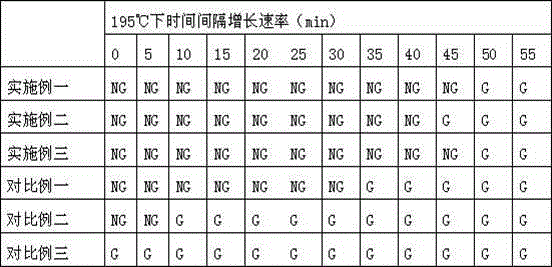

ActiveCN104046369AExcellent afterimage characteristicsGood orientation stabilityLiquid crystal compositionsNon-linear opticsCrystallographyRoom temperature

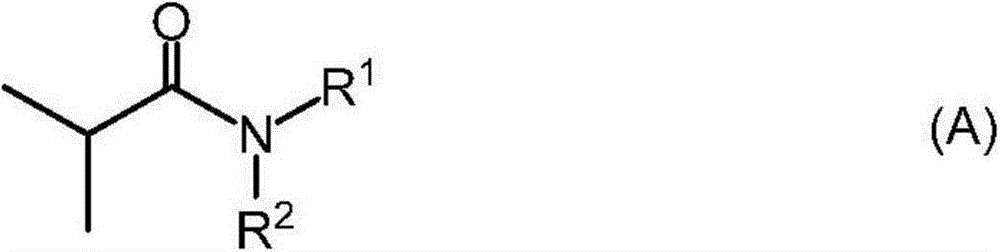

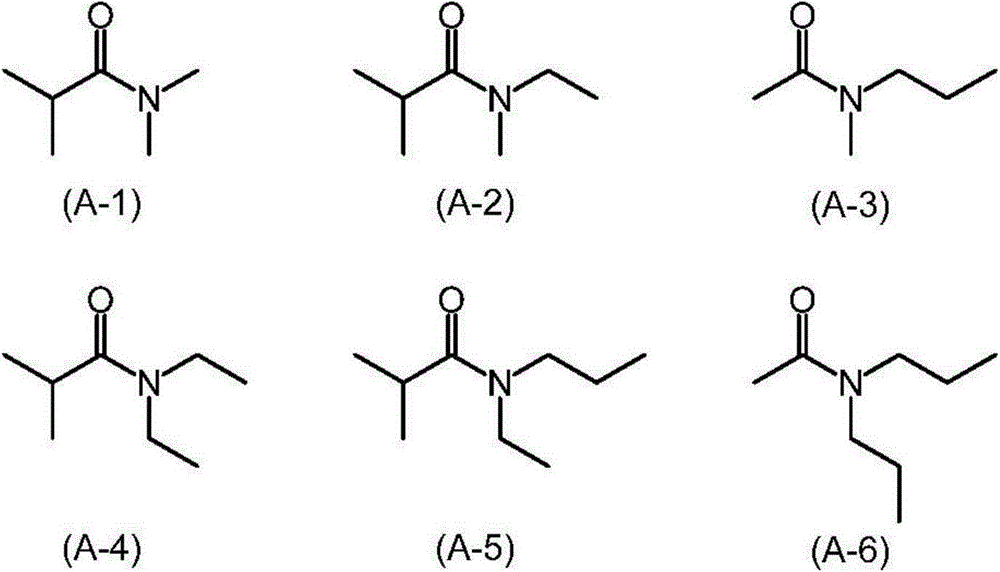

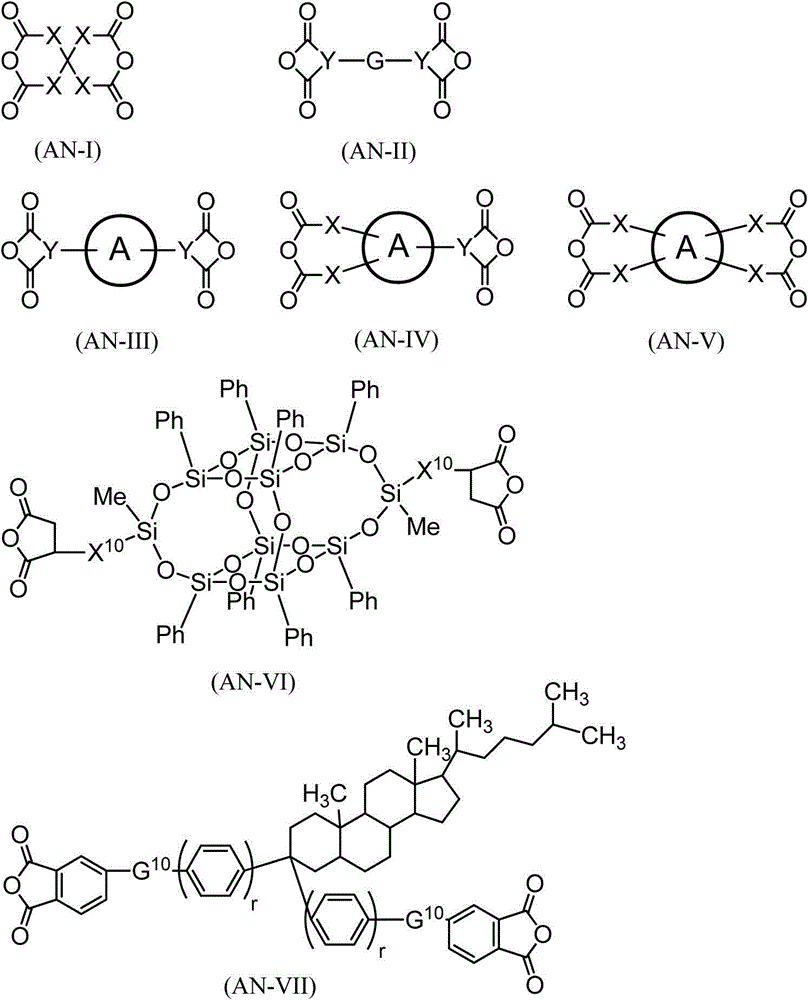

The invention provides a liquid crystal aligning agent, a liquid crystal alignment film and a liquid crystal display element. The liquid crystal aligning agent is a solution containing polyamide acid or derivatives thereof obtained by reacting tetracarboxylic dianhydride with diamine and a solvent, and the solvent contains at least one of compounds represented by the following formula (A). By employing the liquid crystal aligning agent, viscosity chages are not liable to generate at the room temperature, when being coated, the liquid crystal aligning agent is not sunken, when be produced, the liquid crystal aligning agent is not whitened. In addition, the orientation stability of liquid crystal molecules of a liquid crystal alignment film formed by the liquid crystal aligning agent is good. Furthermore, the residual image features of a liquid crystal display element provided with the liquid crystal alignment film are excellent.

Owner:JNC CORP +1

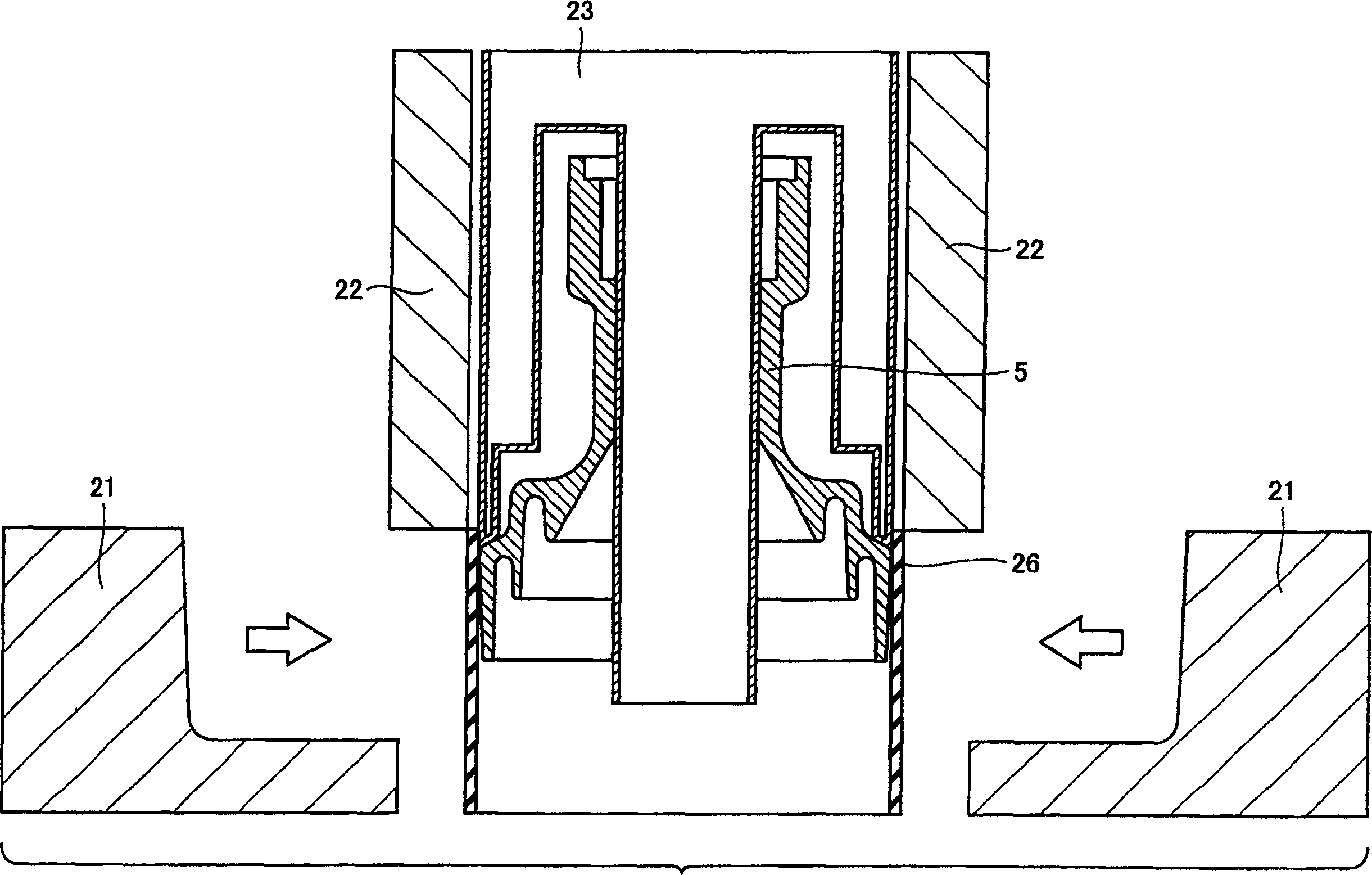

Preservative paper for grape and production method thereof

InactiveCN104621241ANo bleachingMelting fastFruit and vegetables preservationLayered productsWater usePreservative

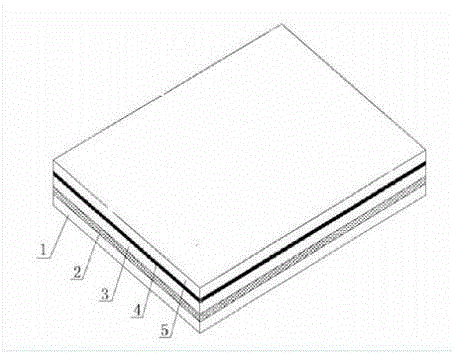

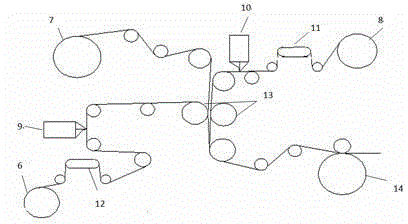

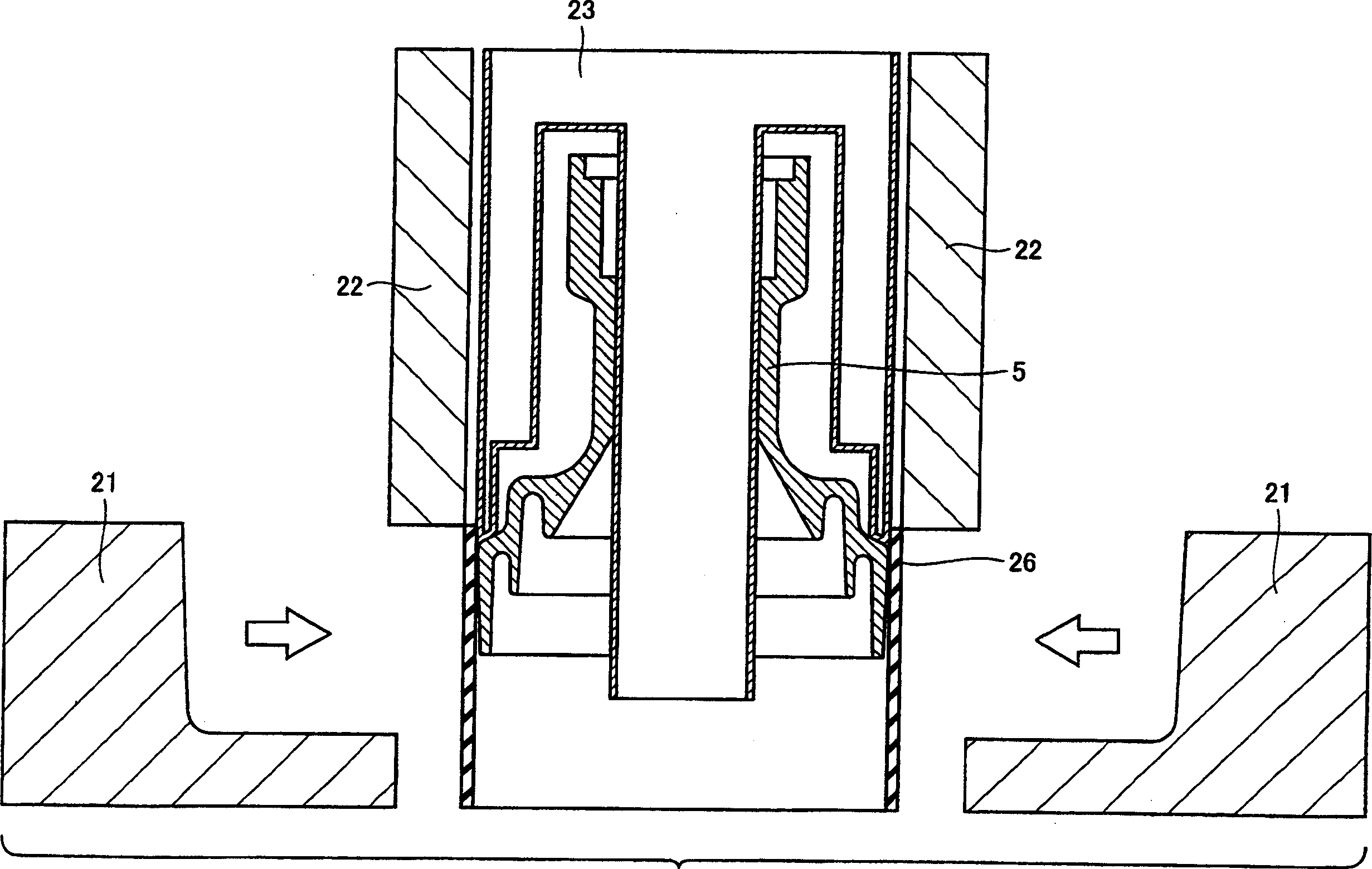

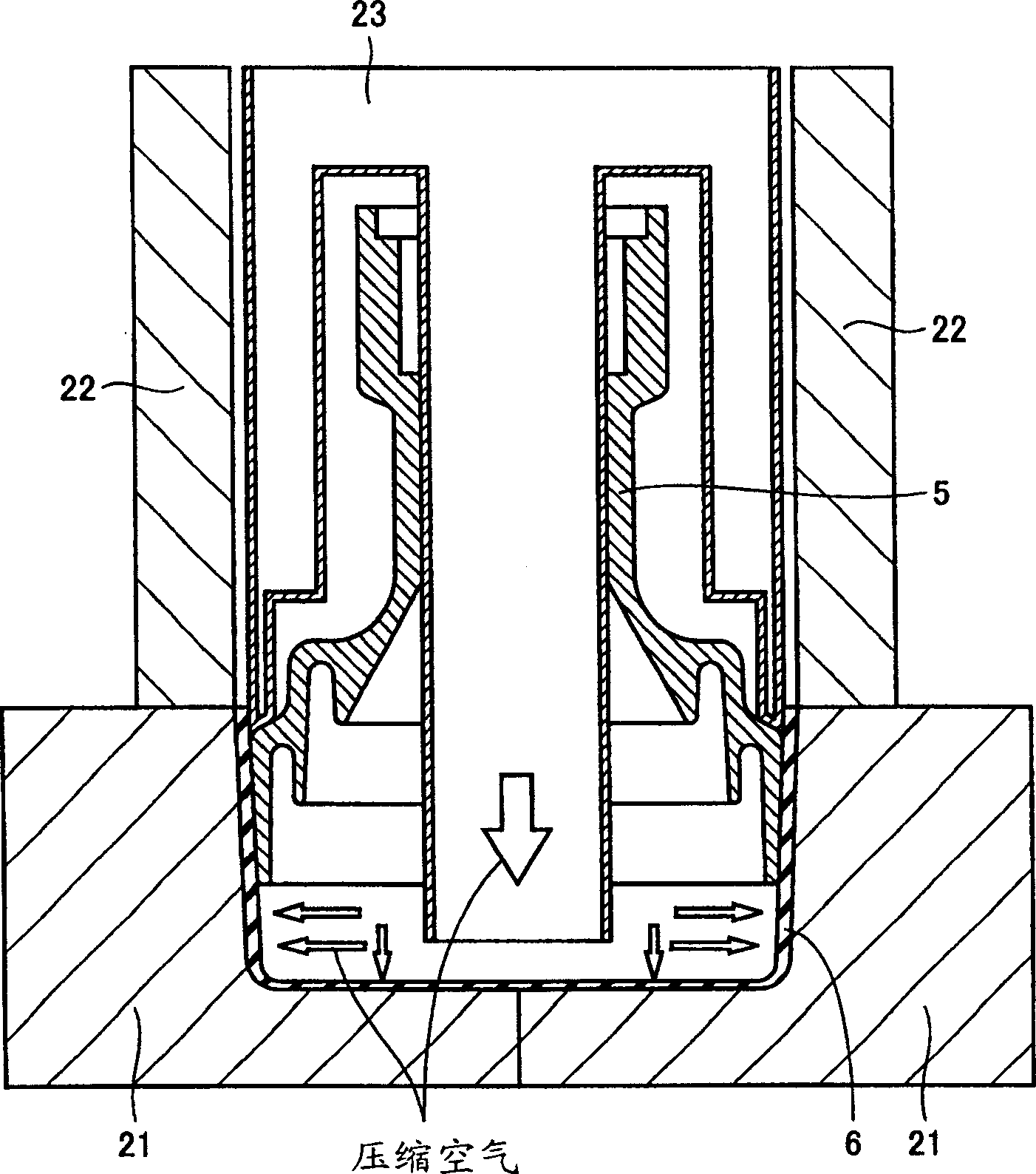

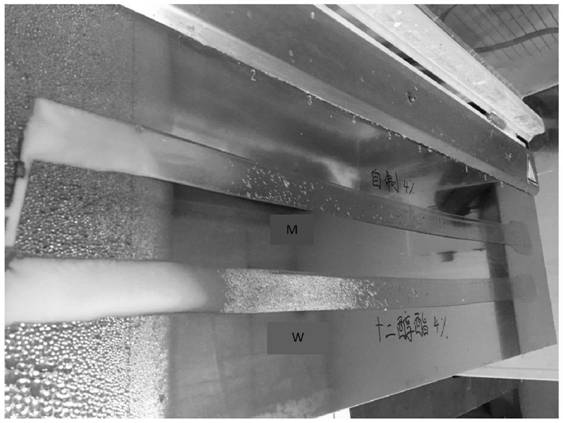

The invention provides preservative paper for grape and a production method thereof. The preservative paper comprises preservative, base materials and an adhesive; the preservative and the base material are adhered through a hot melt adhesive; the preservative paper can be in a form that two agents are clamped among three base materials or one agent is clamped between two base materials. The production method of the preservative paper comprises the following steps: heating to melt the preservative and the hot melt adhesive through a rubber pump; uniformly mixing; conveying to scraper guns (9, 10); uniformly coating the mixture on base materials (1, 5); thermally pressing the medium base materials (3) and (1, 5) through a heat-seal roller (13); coiling through a coiling roller (14) into the preservative paper in the form that two layers of agents are clamped among three layers of base materials. The production method has the characteristics that a thermoplastic hot melt adhesive which is low in softening temperature and fast to solidify is utilized, and the preservative is molten by heating, so that the shortage of decomposing the preservative through water used as a solvent is avoided, and moreover, the production excludes drying, and as a result, the preservative paper is high in quality, and the production efficiency is increased.

Owner:山东营养源食品科技有限公司

Bar code magnetic bead liquid chip detection kit for thalassemia gene

ActiveCN104789672AEasy to operateRapid responseMicrobiological testing/measurementHybridization probeMagnetic bead

The invention provides a bar code magnetic bead liquid chip detection kit for a thalassemia gene. The detection kit comprises a PCR reagent for amplifying the thalassemia gene and a hybridization reagent for detecting the thalassemia gene; the hybridization reagent comprises a liquid chip; the liquid chip comprises a bar code magnetic bead coupled with a specificity hybridization probe, a blank bar code magnetic bead, a dissociative hybridization positive inverted-sequence probe and a hybridization buffer solution. The detection kit is simple to operate, quick in reaction, high in flux, and digitized.

Owner:BIOCHAIN BEIJING SCI & TECH

Hard antibacterial pharmaceutical PVC (polyvinyl chloride) sheet and production method thereof

The invention discloses a hard antibacterial pharmaceutical PVC (polyvinyl chloride) sheet and a production method thereof. The hard antibacterial pharmaceutical PVC sheet comprises, by weight, 800-1200 parts of polyvinyl chloride resin, 20-50 parts of plasticizer, 10-30 parts of stabilizer, 20-40 parts of antibacterial agent, 100-300 parts of glass fibers, 5-15 parts of inorganic nanofiller, 1-5 parts of pigment and 10-20 parts of antibacterial agent stabilizer. The hard antibacterial pharmaceutical PVC sheet and the production method thereof have the advantages that by the aid of the added antibacterial agent, a dustbin can achieve good antibacterial effect to inhibit bacterium growth, so that public health can be protected, and harm of bacteria on the dustbin to human bodies can be reduced; meanwhile, since the antibacterial agent is poor in stability during modification, in a process that the antibacterial agent is added, the antibacterial agent stabilizer also needs to be added to improve stability of the antibacterial agent during modification.

Owner:ZHEJIANG TIANCHENG MEDICAL PACKING

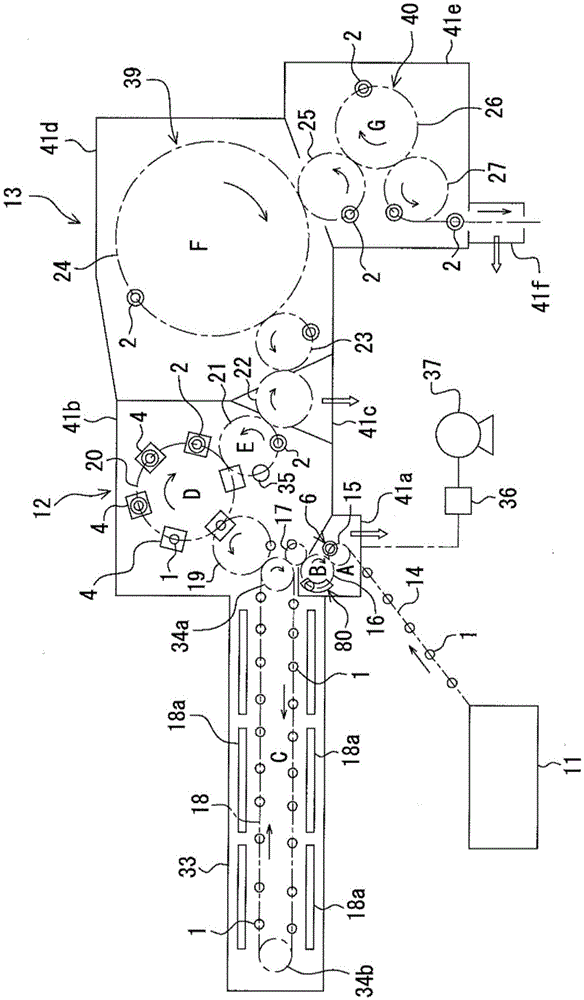

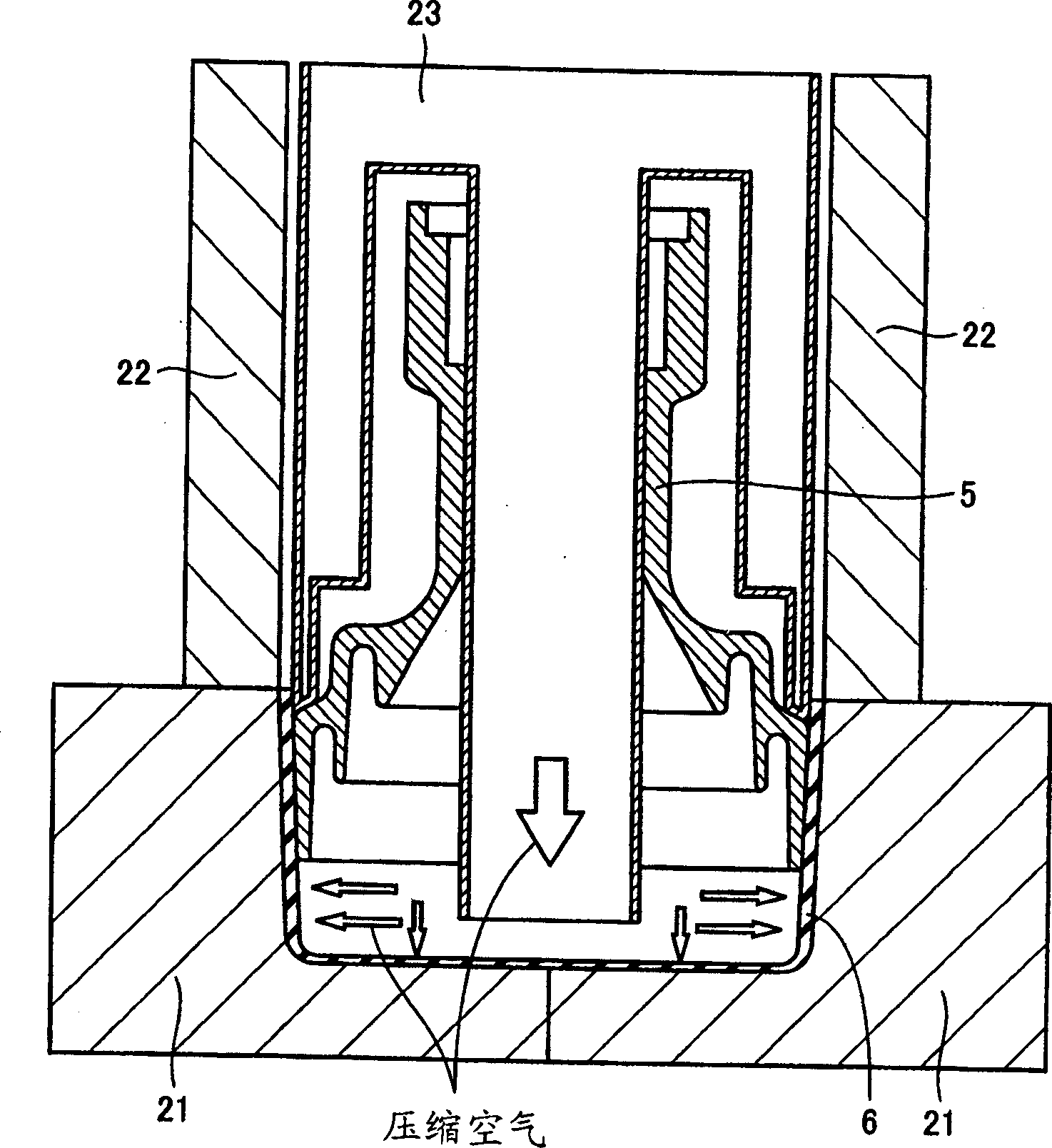

Bottle sterilization method and device

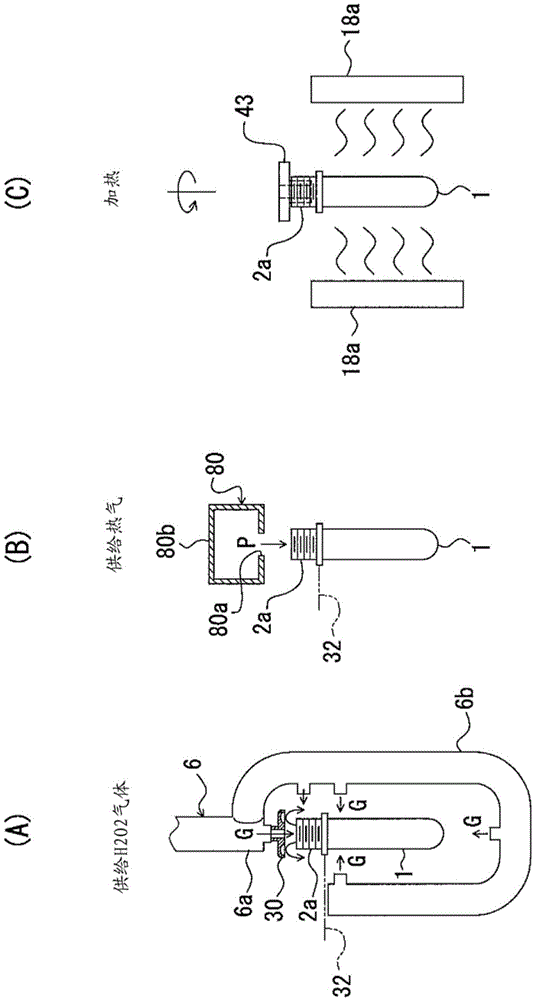

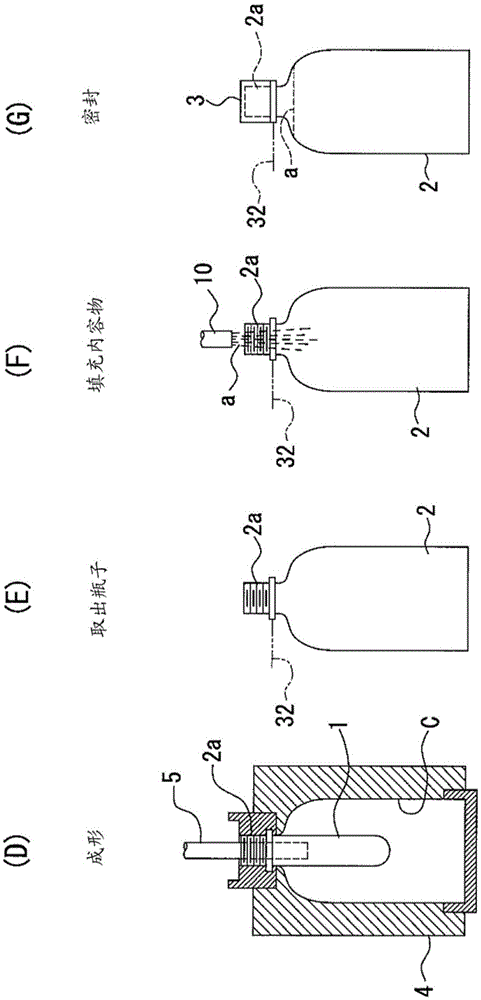

A bottle sterilization method that sequentially performs: a step in which disinfectant is caused to adhere to a resin preform (1) and microbes attached to the preform are sterilized, by gasifying the disinfectant and spraying this gas (G) from a nozzle (6) towards the traveling preform; a step in which hot air (P) is blown on to the preform, the disinfectant adhered to the preform is activated, the microbes attached to the preform are sterilized, and the disinfectant adhered to the preform is removed from the preform; a step in which the preform is heated to a blow molding temperature; and a step in which the preform is blow-molded into a bottle (2) inside a blow molding die. As a result, disinfectant is not brought inside a blow molding machine.

Owner:DAI NIPPON PRINTING CO LTD

Acrylic pressure sensitive adhesive composition

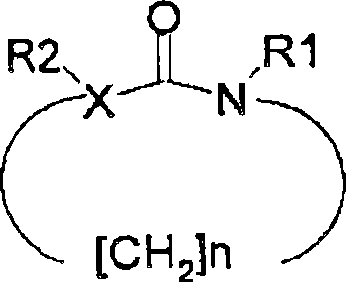

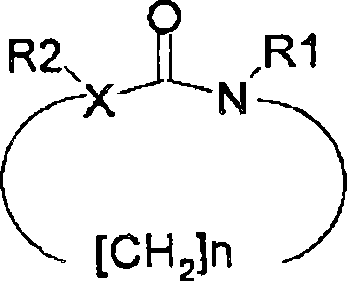

ActiveCN101243154ANo bleachingImprove antistatic performanceAcid polymer adhesivesEster polymer adhesivesRoom temperatureMolten salt

The present invention relates to an acrylic adhesive composition, and more particularly, to an acrylic adhesive composition comprising a room temperature eutectic salt prepared by mixing a metal salt represented by the formula (1), composed of an anion having a perfluoroalkane group, which is a conjugate base of a super acid, and an alkali metal cation with a compound having an amide group represented by the formula (2), which is used to increase the degree of dissociation of the metal salt. The acrylic adhesive composition of the present invention has superior endurance reliability, antistaticity and adhesive force without whitening under high temperature and humidity.

Owner:LG CHEM LTD

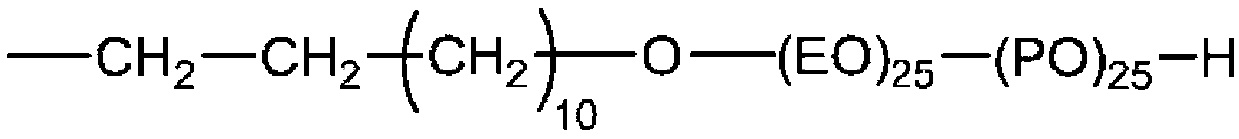

Organopolysiloxane emulsion compositon and resin composition

By incorporating a polyoxyalkylene-modified organo(poly)siloxane compound having a specific structure as an emulsifier or emulsification aid, an organopolysiloxane having a high degree of polymerization can be easily emulsified. The obtained organpolysiloxane emulsion composition has excellent resistance to polar solvents including DMF and is dispersible in water. When incorporated into a resin composition of either the solvent-based type including an organic solvent or the water-based type, the emulsion composition can hence impart slipperiness, wear resistance, and glossiness without causingcissing or blushing.

Owner:SHIN ETSU CHEM CO LTD

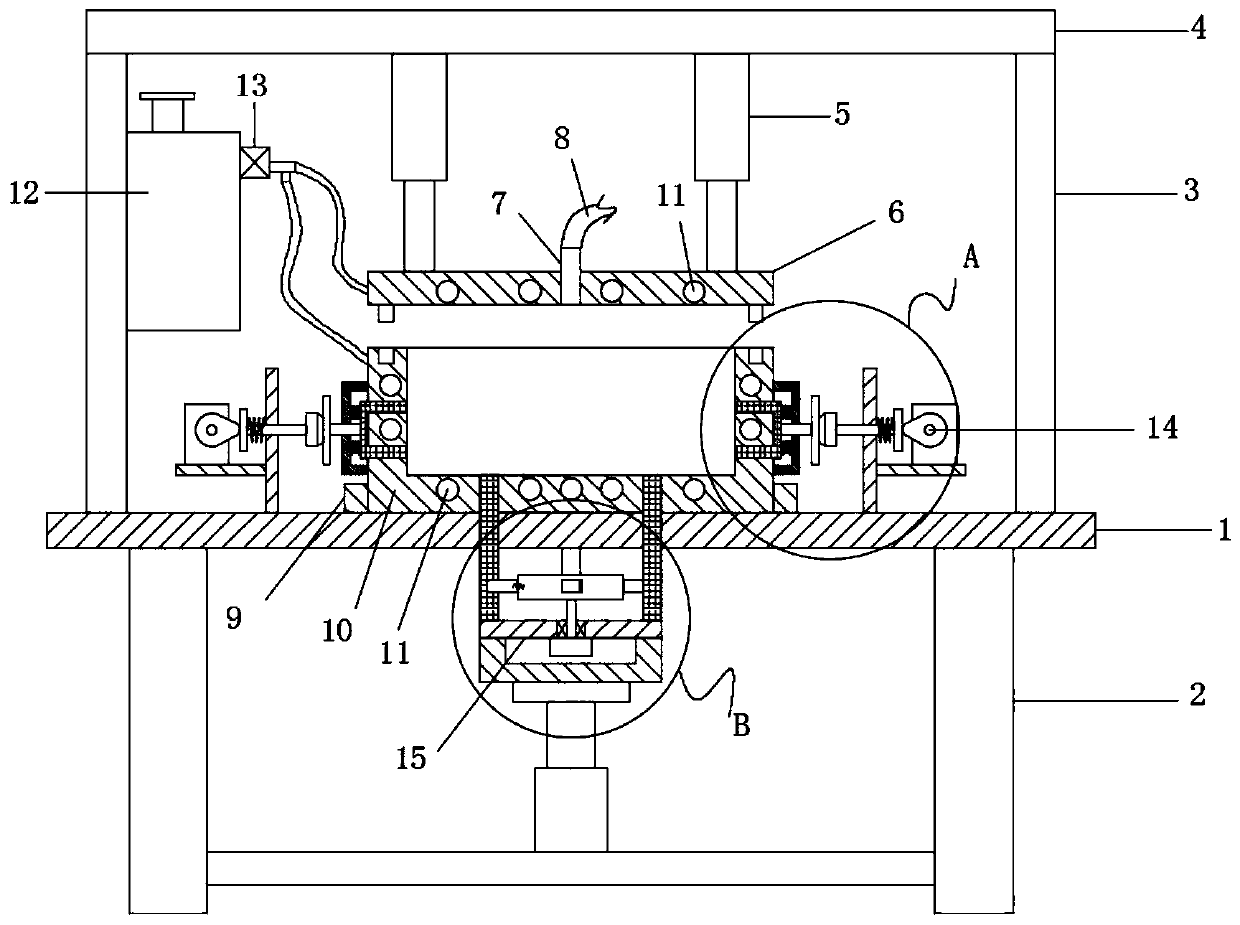

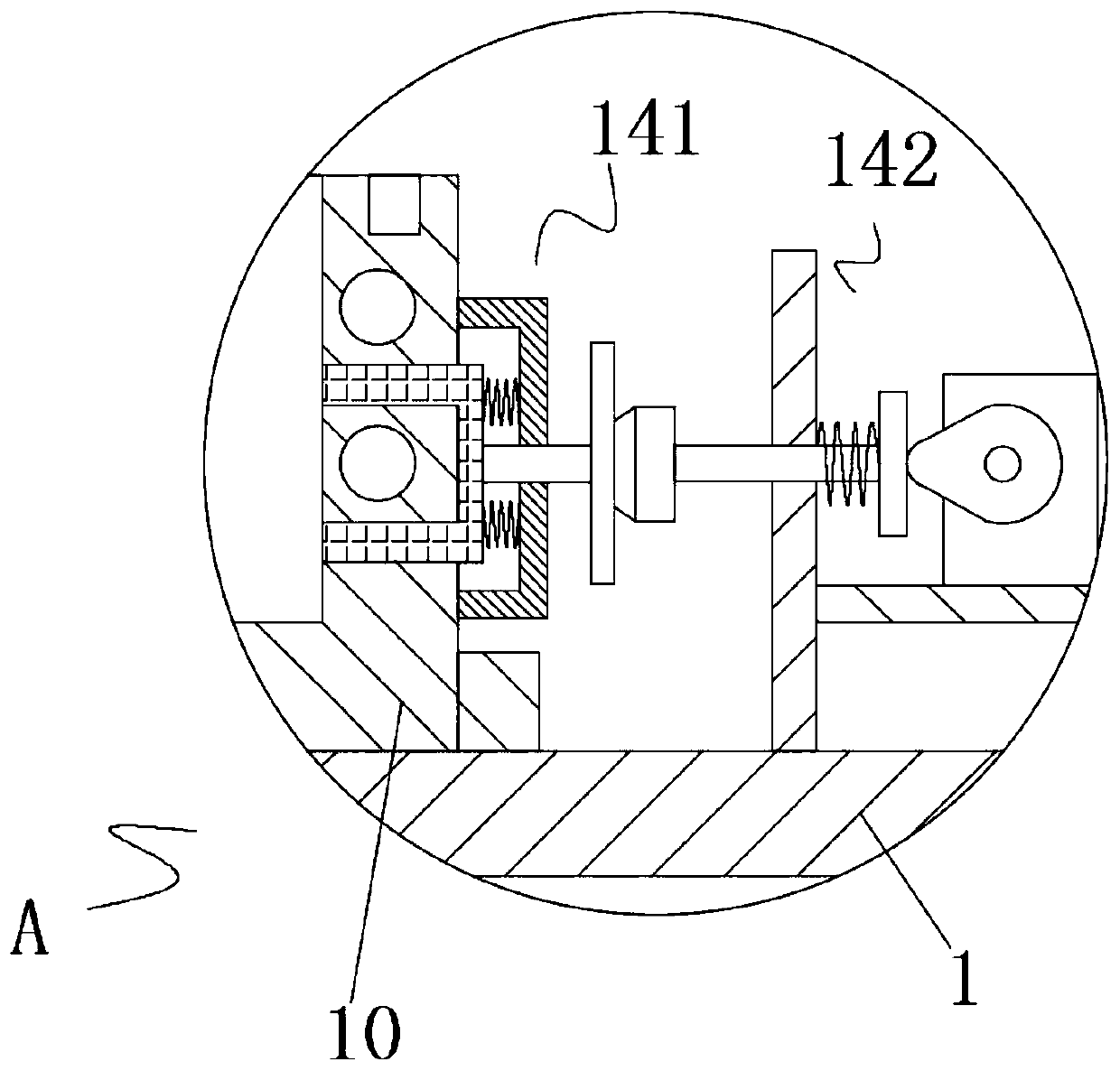

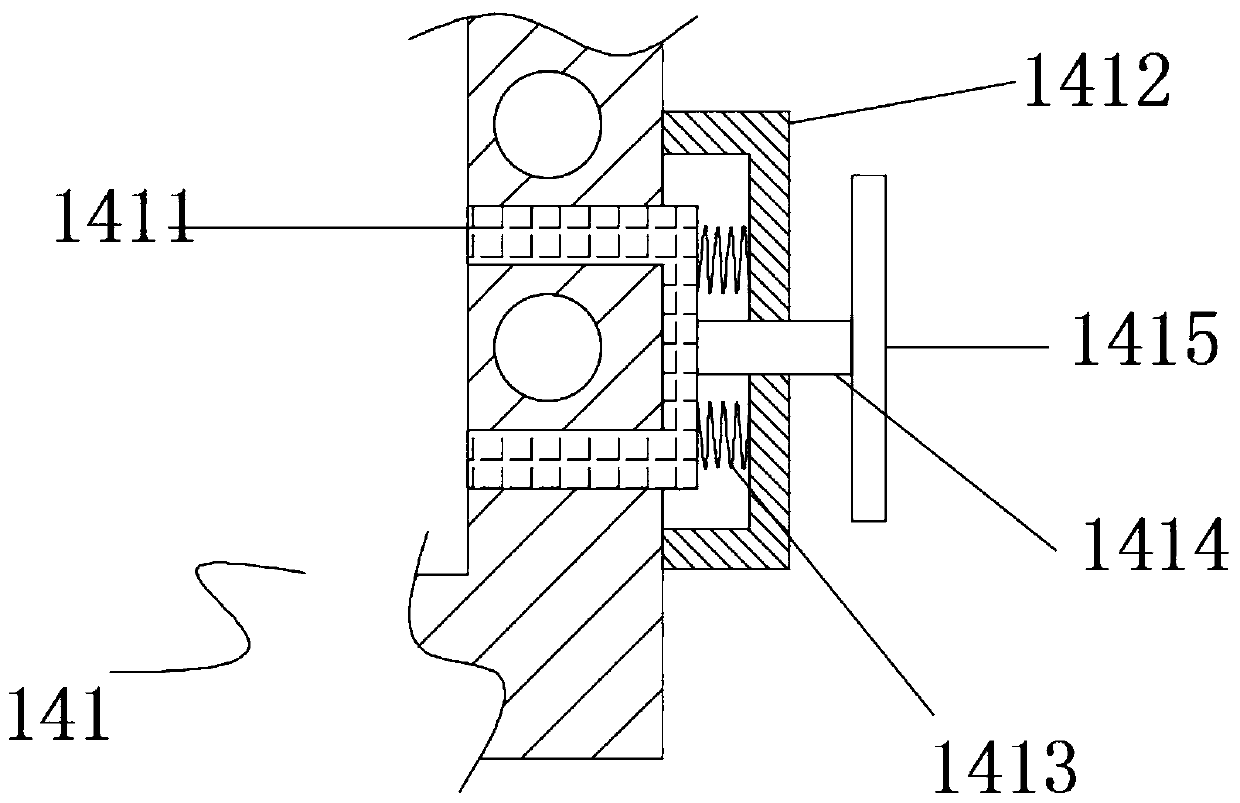

PVC plate die forming equipment

ActiveCN110480969AProtection pass rateConvenient ToppingFlat articlesEngineeringMechanical engineering

The invention discloses PVC plate die forming equipment, and belongs to the technical field of PVC plate production equipment. The PVC plate die forming equipment comprises a workbench. Supports are arranged at the bottom end of the workbench, vertical beams are arranged at the top end of the workbench in a left-and-right symmetry manner, and a cross beam is arranged at the top ends of the vertical beams. During use, an upper die and a lower die are pressed to be sealed through a push rod, molten raw materials are injected into an inner cavity of the upper die and the lower die, the molten rawmaterials in the die cavity are rapidly cool-formed by injecting cooling liquid, after the molten raw materials are formed, vibratory wall separating mechanisms are started, a forming plate is separated from the inner wall of the die cavity, and therefore material ejecting is facilitated; and a vibratory material ejecting mechanism is started, an impacting plate rotary disc impacts on ejector rods, and the top ends of the ejector rods are separated from the bottom wall of the lower die and the forming plate. According to the device, through the arranged vibratory wall separating mechanisms and the arranged vibratory material ejecting mechanism, the problems such as whitening and breaking cannot be caused in the material ejecting process, and the percent of pass of finished products is effectively protected.

Owner:安徽可尔海思新材料科技有限公司

Color cosmetic comprising random terpolymer

Owner:BASF SE

Vinyl chloride-based film for food packaging

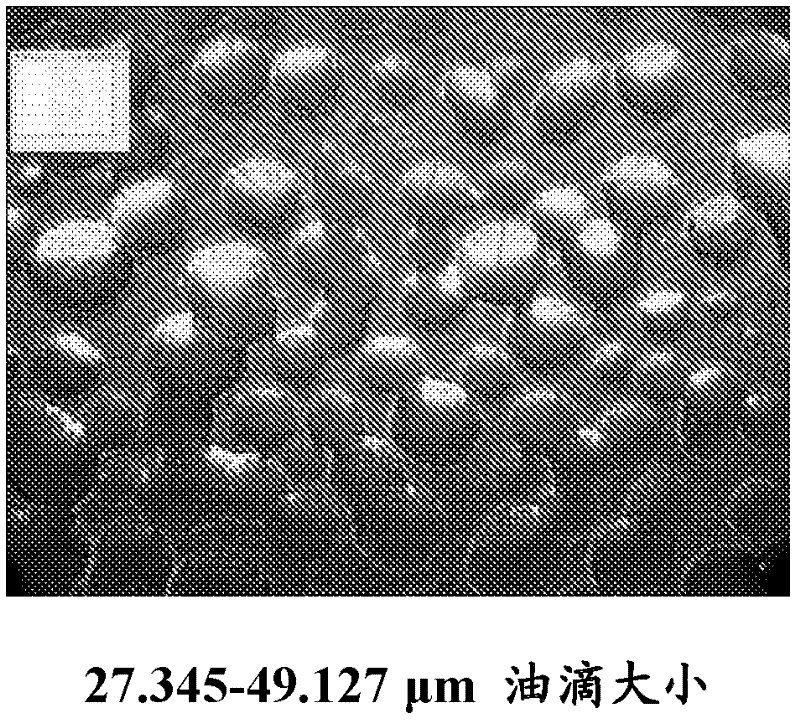

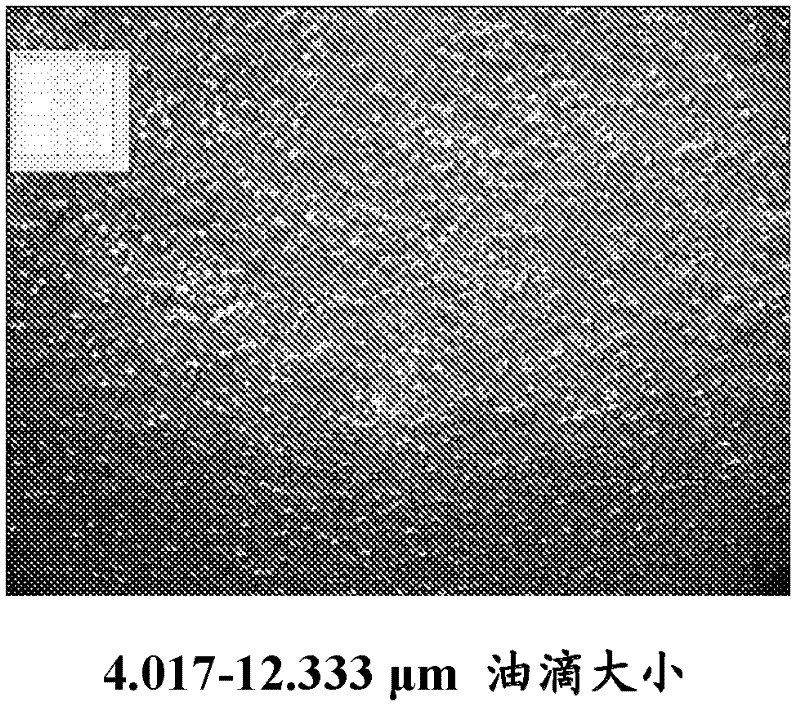

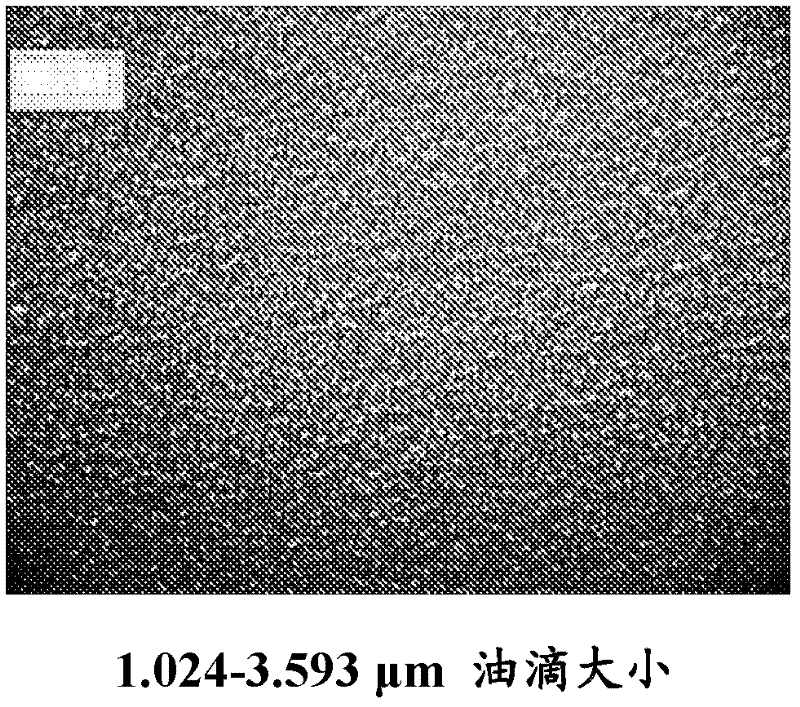

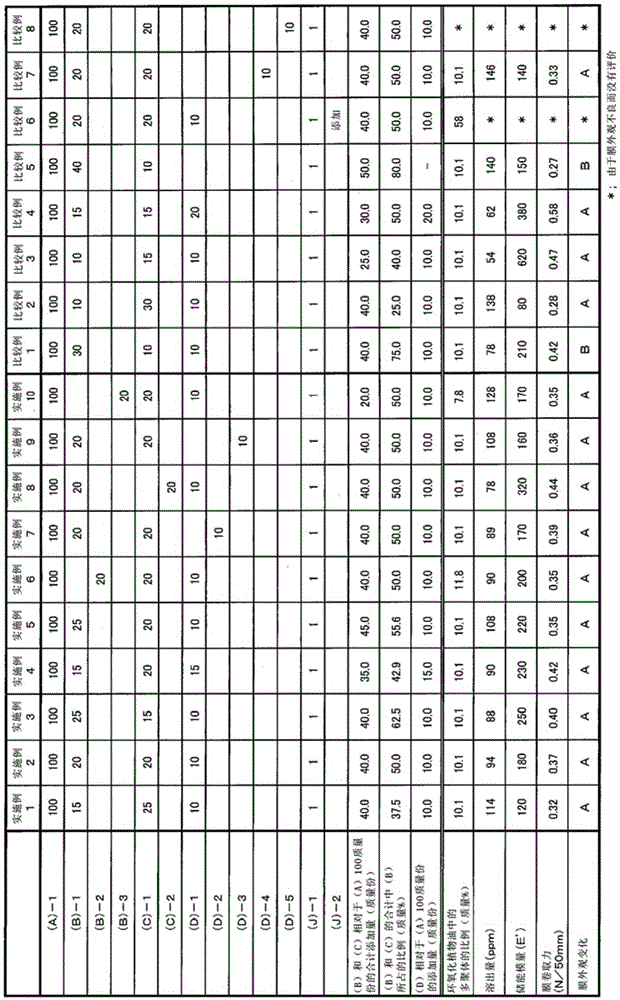

Provided is a vinyl chloride-based film for food packaging, which has good film appearance, packaging adequacy (flexibility) and low dissolvability (safety) at the same time. A film for food packaging, which is obtained by blending (A) a vinyl chloride resin with (B) a modified epoxidized vegetable oil having a multimer content ratio of 5-50% by mass, (C) an aliphatic dibasic acid ester compound with 10 or less carbon atoms, which has a weight average molecular weight of 200-1,000 and (D) a polyester compound having a weight average molecular weight of 3,000-10,000. The blending amount of the mixture of the components (B) and (C) relative to 100 parts by mass of the component (A) is 30-50 parts by mass; the ratio of the component (B) in the mixture of the components (B) and (C) is 30-70% by mass; and the blending amount of the component (D) relative to 100 parts by mass of the component (A) is 5-15 parts by mass.

Owner:MITSUBISHI CHEM CORP

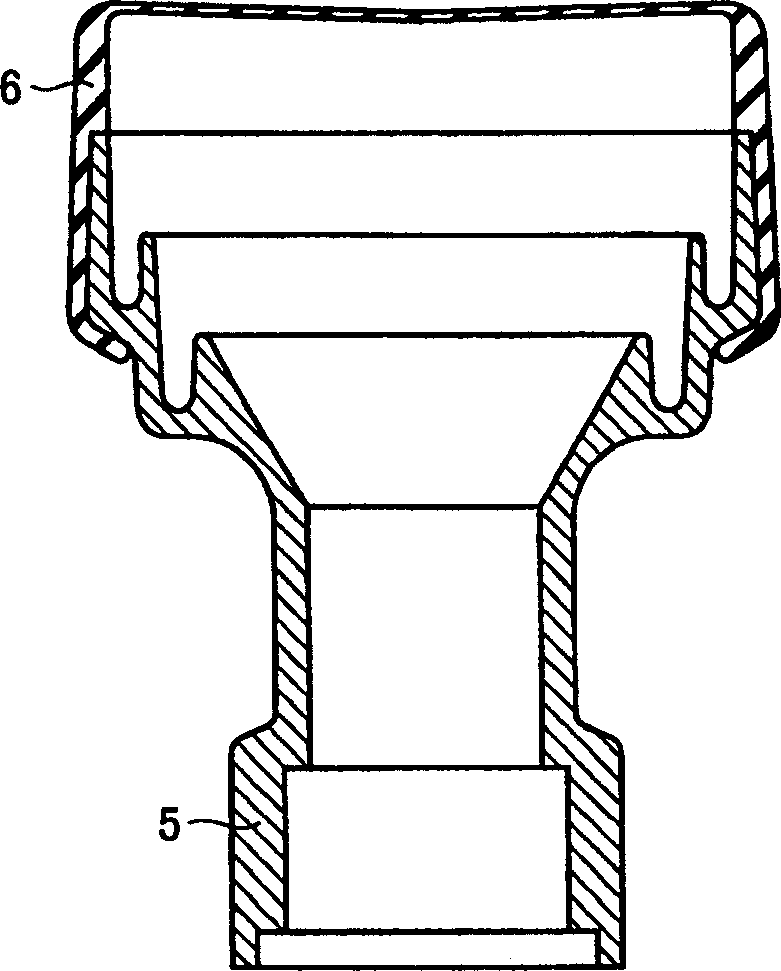

Feed horn structure and its manufacturing method, frequency transformer and satellite communication receiving antenna

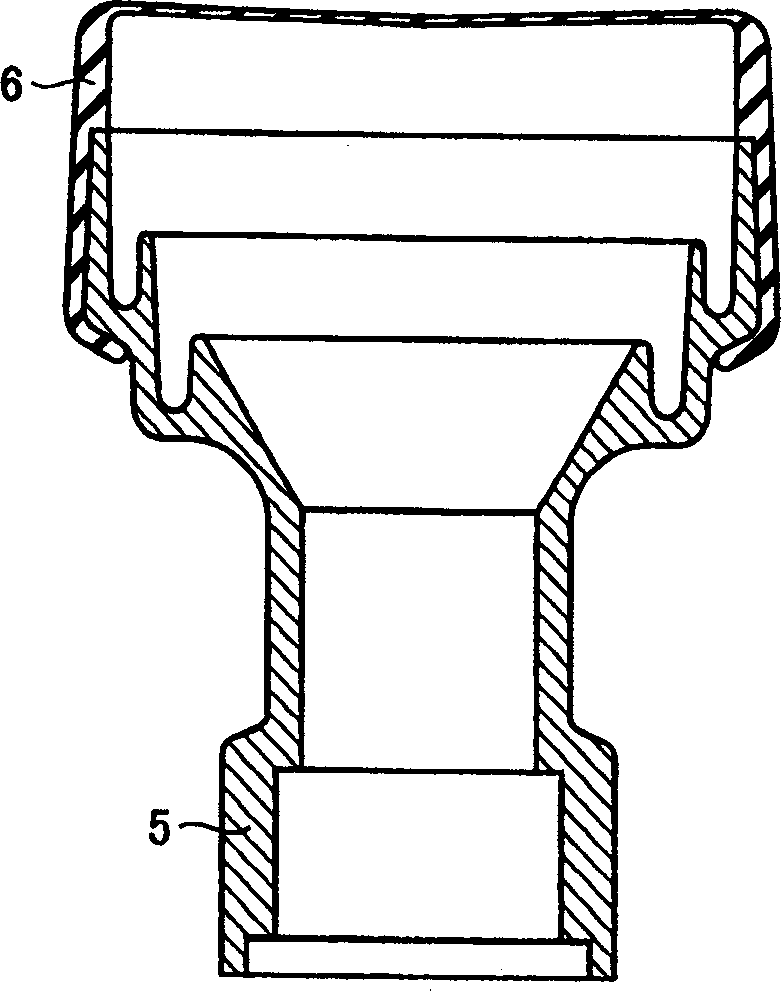

A feed horn structure in which a feed horn and a horn cap can be combined without generating whitening, crack and the like, a manufacturing method thereof, a converter having that feed horn structure, and a satellite communication receiving antenna can be obtained. The feed horn structure of a satellite communication receiving converter includes a cylindrical feed horn (5) receiving a radio wave from an antenna portion and guiding the radio wave, and a horn cap (6) fixed to the feed horn so as to surround one end of the feed horn at antenna side. The feed horn and the horn cap are integrated by integral molding.

Owner:SHARP KK

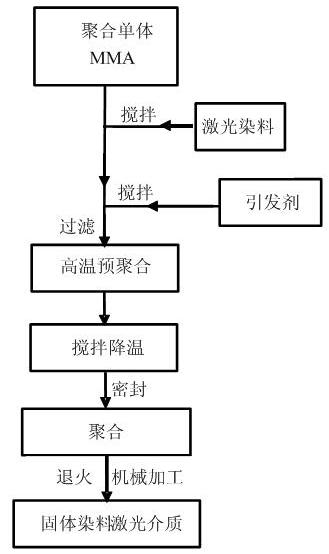

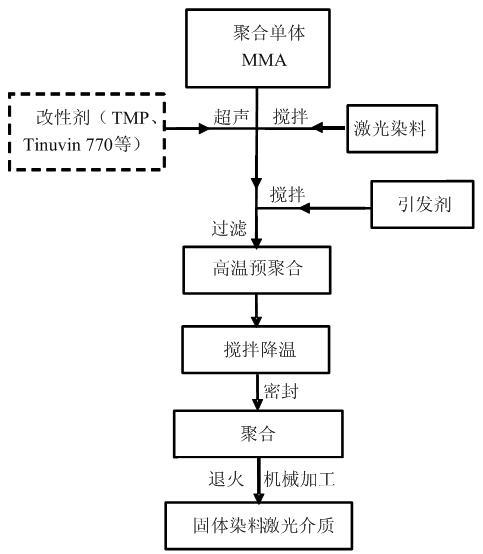

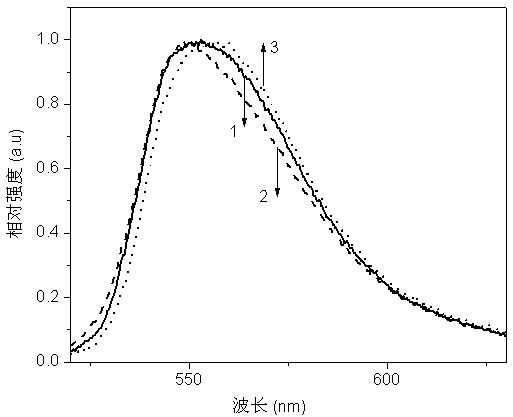

Prepolymerization preparation method of polymer matrix solid dye laser medium

InactiveCN101812247ASmall amount of wavelength shiftImprove Optical UniformityOrganic dyesLaser dyeBulk polymerization

The invention provides a prepolymerization preparation method of a polymer matrix solid dye laser medium, relating to a preparation method of a solid dye laser medium. The preparation method solves the problems of the existing preparation method of the solid dye laser medium that the preparation period is long, the preparation process has the phenomena of layering, whitening or imploding, and the optical property of the obtained solid dye laser medium is bad. The method comprises the following steps of: refining MMA; stirring the MMA and laser dye in a mixing way to obtain laser dye solution; prepolymerizing the laser dye solution in high-temperature water batch; performing body polymerization to the prepolymerized laser dye; and annealing and mechanically machining to obtain the polymer matrix solid dye laser medium. The method firstly prepolymerizes the MMA monomer, thereby shortening induction period of polymerization, reducing volume contraction when polymerizing, shortening preparation period, and avoiding the problems of layering, whitening and imploding during preparing. The laser output slope efficiency of the solid dye medium reaches 48.57%-64.09% and fluorescence band width thereof is 44nm-46nm.

Owner:HARBIN INST OF TECH

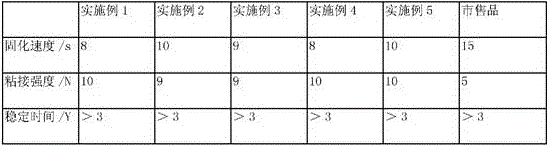

A kind of medical adhesive and preparation method thereof

ActiveCN104368030BLess irritatingEasy to addSurgical adhesivesAbsorbent padsBenzoyl peroxideDIETHYL SEBACATE

The invention provides a medicinal adhesive and a preparation method thereof. The medicinal adhesive comprises polyacrylate, tragacanth, polymethacrylate, squalane, benzoyl peroxide, rosin triglyceride, dimethyl sebacate, p-dihydroxybenzene, p-benzene methane sulfonic acid, dioctyl phthalate, tricalcium phosphate and sodium alginate. The preparation method of the medicinal adhesive comprises the following steps: firstly mixing polyacrylate, tragacanth, polymethacrylate and squalane, then adding benzoyl peroxide and rosin triglyceride, and stirring to obtain a mixture I; then mixing dimethyl sebacate, p-dihydroxybenzene, p-benzene methane sulfonic acid, dioctyl phthalate, tricalcium phosphate and sodium alginate to obtain a mixture II, and then mixing the mixture I and the mixture II, heating, insulating, and cooling to room temperature, so that the medicinal adhesive is obtained. The medicinal adhesive has the advantages of moderate curing speed, long stabilization time and strong bonding strength.

Owner:美迪科(上海)包装材料有限公司

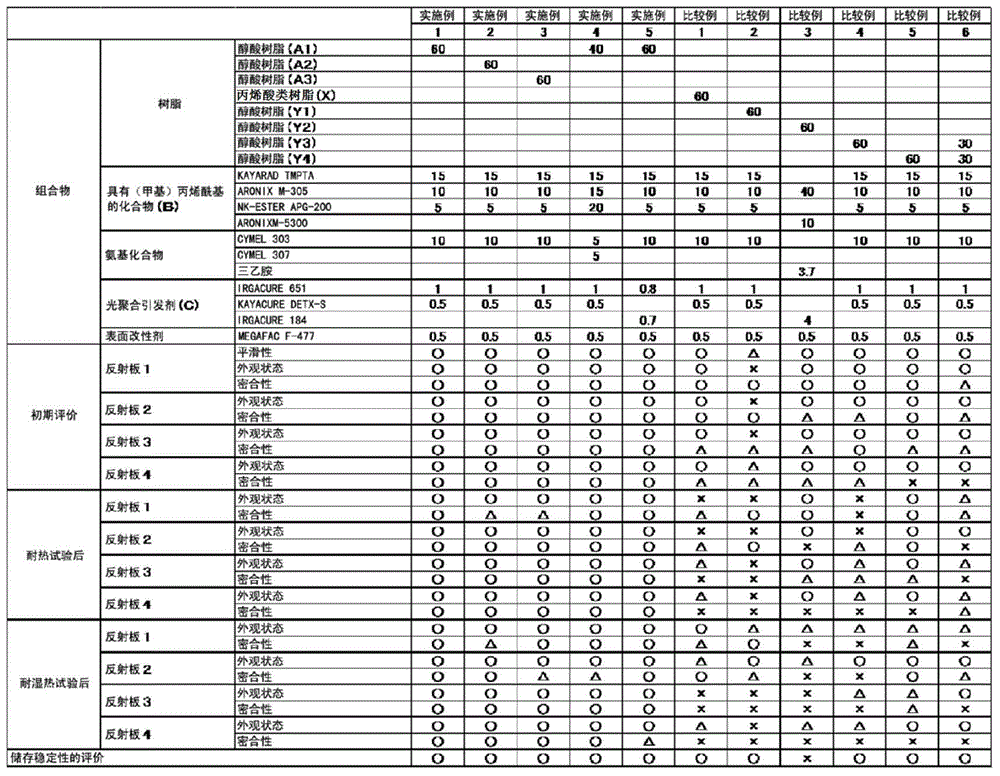

Active energy ray-curable resin composition, undercoating agent containing same, and molded article

ActiveCN105073805AExcellent adhesionGood storage stabilityPolyester coatingsHeat resistancePolymer chemistry

Owner:DIC CORP

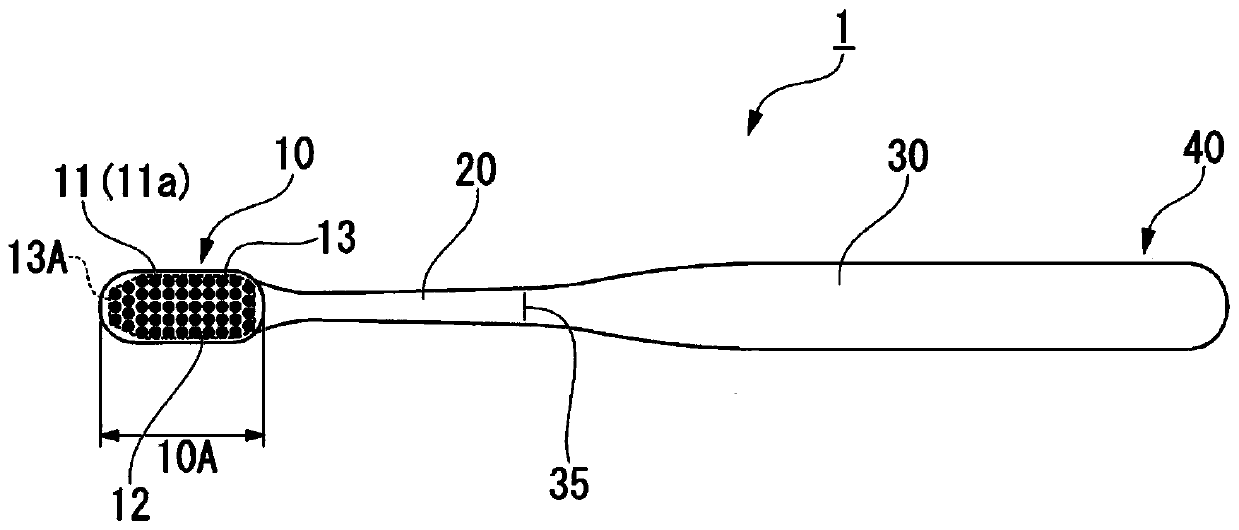

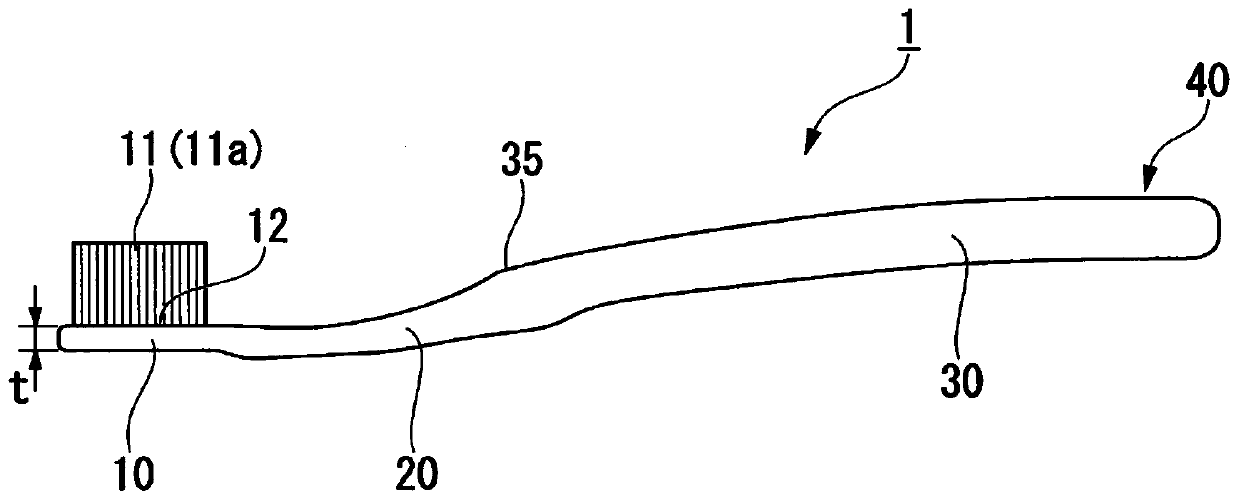

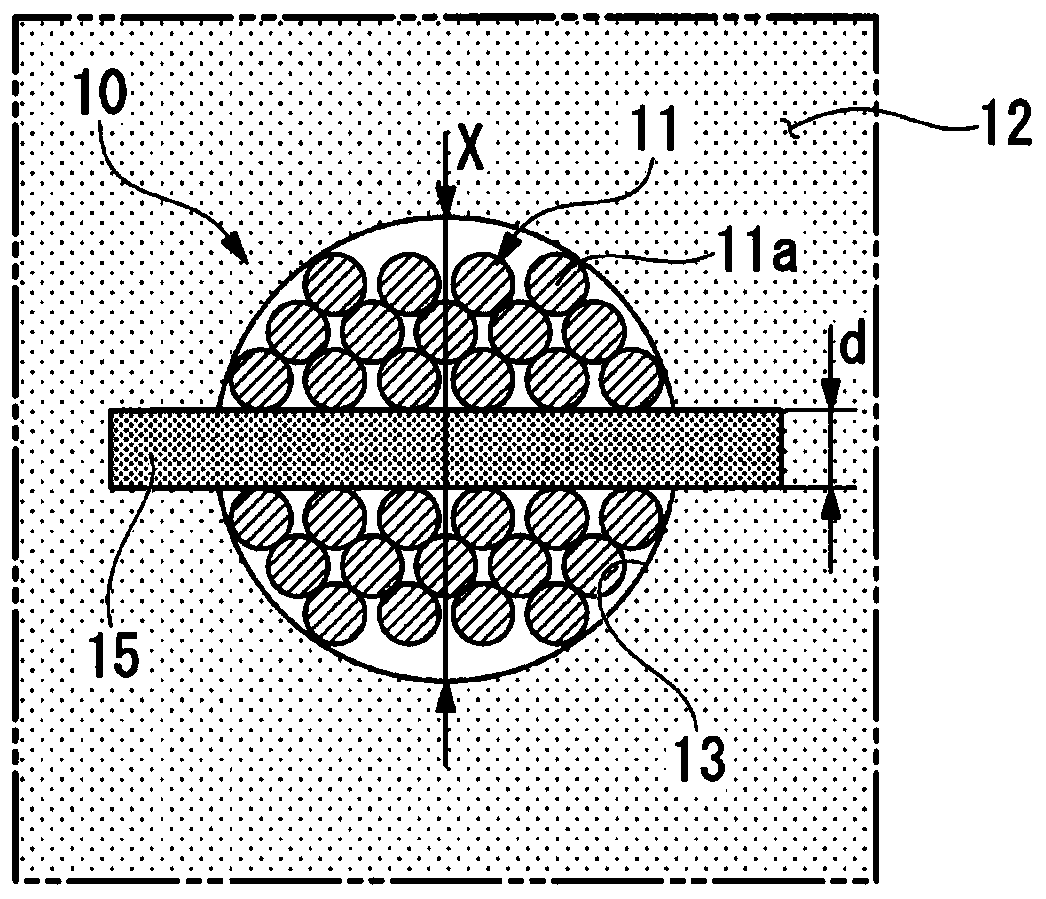

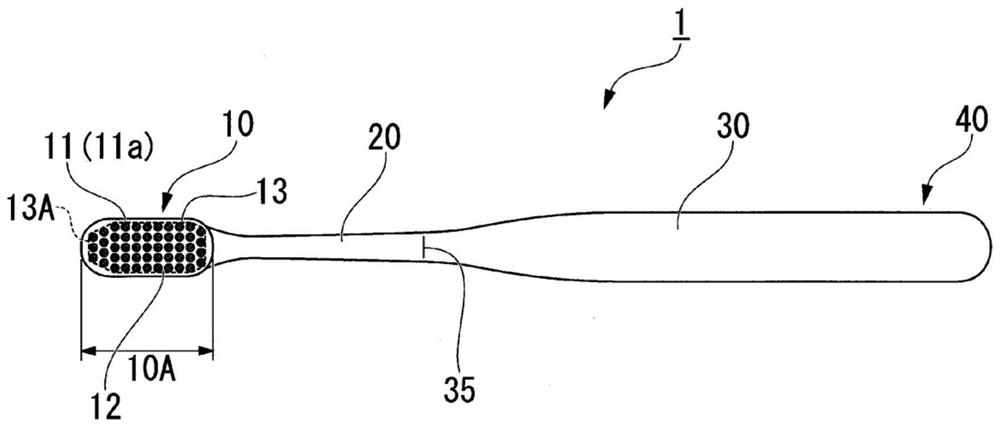

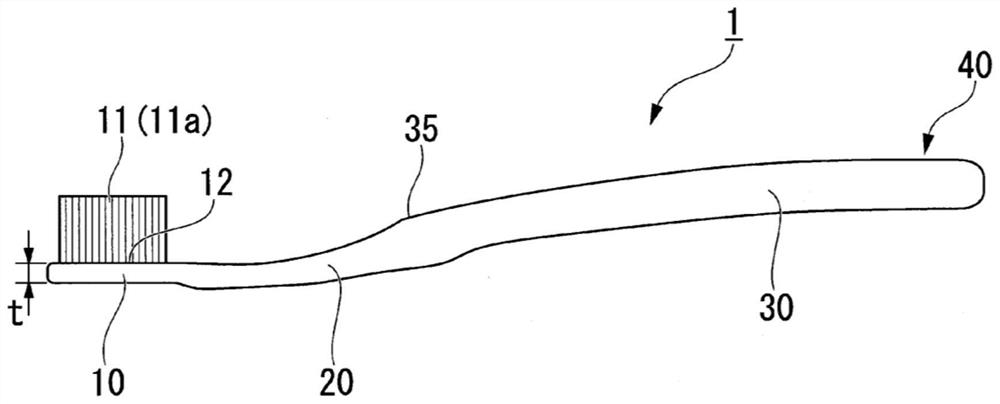

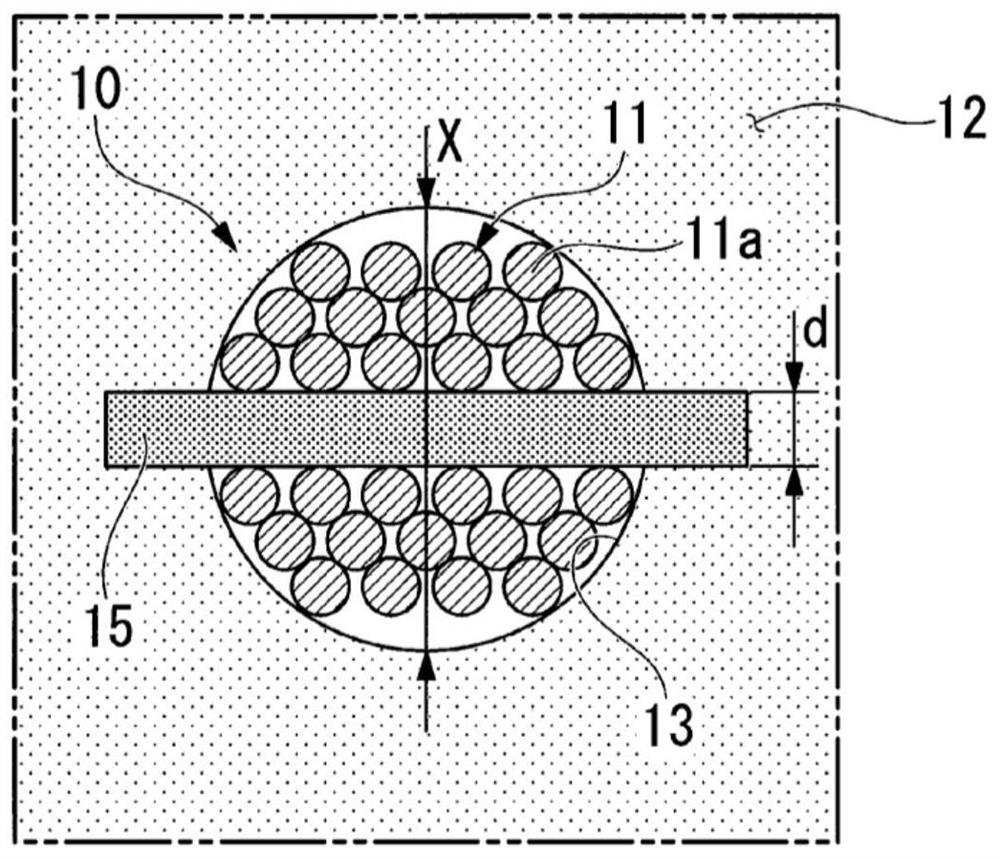

Toothbrush

The present invention provides a toothbrush that has a flat-plate implanted head section in which warpage, resin whitening and cracks are prevented, ensures sufficient implanted bristle strength, andis easy to handle in the mouth. This toothbrush (1) is provided with a head section (10) having a plurality of bristle implanting holes (13) on the bristle implanted surface (12), and bundles of a plurality of bristles are folded into two parts and implanted in the bristle implanting holes (13) using flat plates (15). The thickness of the head section (10) is 2.0-4.0 mm, the bristle implanting hole density of the bristle implanting holes (13) is 25 holes / cm<2> or more, and the toothbrush satisfies the relationship: 0.37 mm <= (X - d) / 2 <= 0.55 mm, wherein X is the inner diameter of the bristleimplanting holes, d is the thickness of the flat plates, and X is 0.9-1.3 mm.

Owner:LION CORP

Feed horn structure and its manufacturing method, frequency transformer and satellite communication receiving antenna

A feed horn structure in which a feed horn and a horn cap can be combined without generating whitening, crack and the like, a manufacturing method thereof, a converter having that feed horn structure, and a satellite communication receiving antenna can be obtained. The feed horn structure of a satellite communication receiving converter includes a cylindrical feed horn (5) receiving a radio wave from an antenna portion and guiding the radio wave, and a horn cap (6) fixed to the feed horn so as to surround one end of the feed horn at antenna side. The feed horn and the horn cap are integrated by integral molding.

Owner:SHARP KK

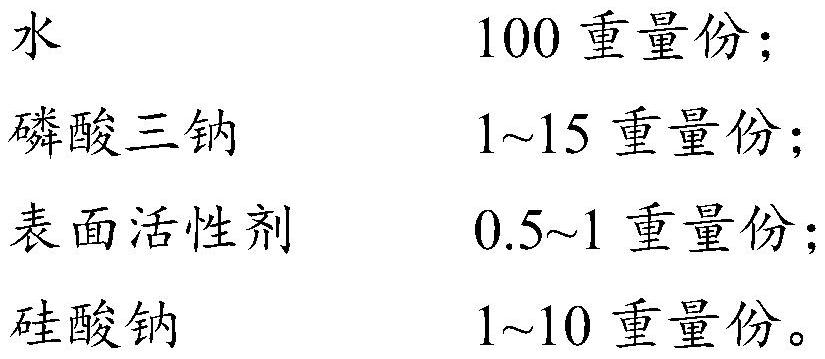

Method for removing laser mark of urea-formaldehyde resin button

ActiveCN112062995ARealize no whiteningMeet the needs of colorless LOGOEdge grinding machinesPolishing machinesPhosphoric acidChemistry

The invention relates to the technical field of garment accessory production, and particularly relates to a method for removing a laser mark of a urea-formaldehyde resin button. The method for removing the laser mark of the urea-formaldehyde resin button comprises the steps of A) polishing the urea-formaldehyde resin button after laser treatment; and B) soaking the urea-formaldehyde resin button obtained in the step A) in post-treatment liquid for a period of time, taking out the urea-formaldehyde resin button, and cleaning the urea-formaldehyde resin button to obtain a laser mark removed urea-formaldehyde resin button, wherein the post-treatment liquid comprises the following components in parts by weight: 100 parts of water; 1-15 parts of trisodium phosphate, 0.5-1 part of a surfactant,and 1-10 parts of sodium silicate. According to the removing method, LOGO on the surface of the button is not whitened, and characters are consistent with the bottom color of the button. Moreover, theurea button with the colorless LOGO can be manufactured without using a LOGO mold, the effect and the performance of the manufactured product meet the colorless requirement of a customer for the LOGO, the production cost is effectively reduced, and the production period is shortened.

Owner:ZHEJIANG WEIXING IND DEV

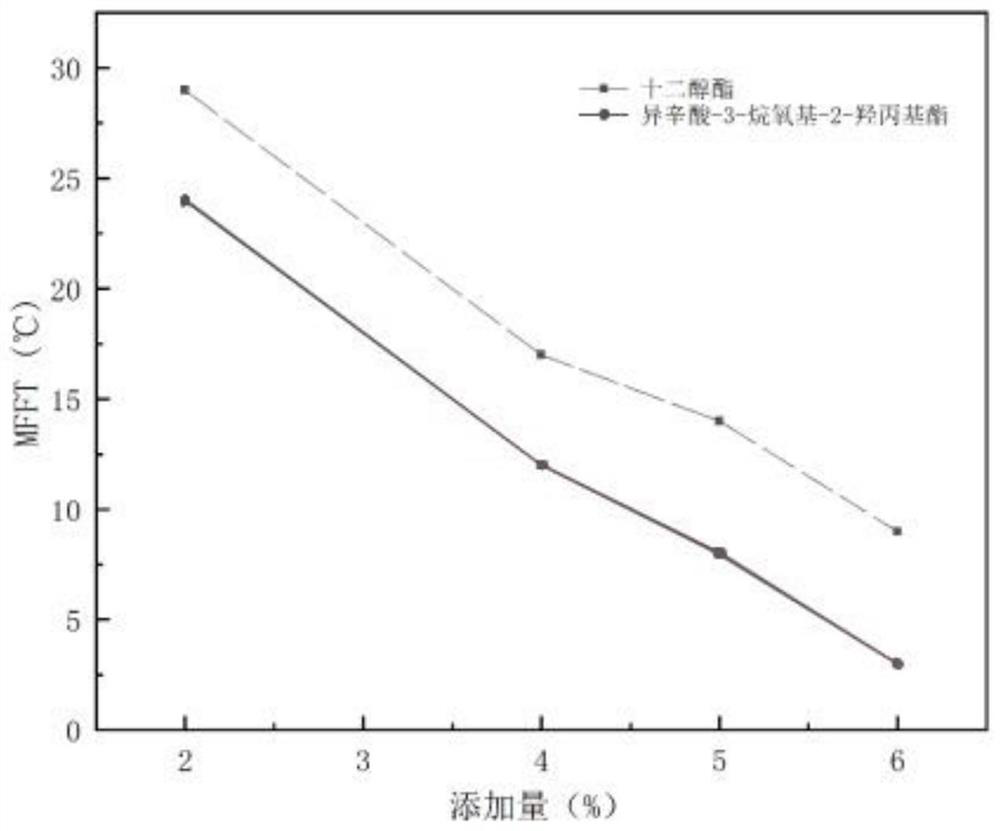

Isocaprylic acid-3-alkoxy-2-hydroxypropyl ester film-forming auxiliary agent and preparation method thereof

PendingCN113387803ANo migration to the surfaceGood film formingOrganic compound preparationCarboxylic acid esters preparationComposite materialEmulsion

The invention relates to an isocaprylic acid-3-alkoxy-2-hydroxypropyl ester film-forming auxiliary agent and a preparation method thereof. The structural expression of thefilm-forming auxiliary agent is shown in the specification, and R1 represents any one of a substituted or unsubstituted C3-C5 alkyl group, a substituted or unsubstituted C3-C5 alkenyl group and a substituted or unsubstituted C3-C5 alkynyl group. When 4 wt% of the prepared film-forming auxiliary agent is added into an emulsion with the glass transition temperature of 46 DEG C, the minimum film-forming temperature is 13-15 DEG C, a continuous and transparent coating film can be formed, excellent film-forming property is shown, and the film-forming auxiliary agent is superior to a traditional film-forming auxiliary agent. The prepared film-forming auxiliary agent has the advantages of being good in compatibility with latex, low in film forming temperature, easy to absorb by latex particles, not prone to volatilization, safe, environmentally friendly and the like, and the market application prospect is wide.

Owner:NANJING FORESTRY UNIV

Amine curing agent and preparation process thereof

The invention discloses an amine curing agent. The amine curing agent is characterized in that the amine curing agent is the condensation of a m-xylylenediamine monomer: a formula shown in the specification. A preparation process of the amine curing agent comprises the following raw materials: m-xylylenediamine and a catalyst with a mass ratio of 100:3, wherein a structural formula of m-xylylenediamine is shown in the specification, the molecular weight of m-xylylenediamine is 136, and an amine value of m-xylylenediamine is 500-600; and the catalyst is an aluminum-nickel alloy. The preparation process comprises the following steps: I, putting m-xylylenediamine and the catalyst into a three-mouth flask, heating by using an infrared lamp to ensure that the temperature is increased to 180+ / -5 DEG C, and preserving heat; II, continuously reacting, and absorbing ammonia gas which is produced in a reaction process by using a sulfuric acid solution; III, picking a sample, measuring the viscosity of the sample, and ending the reaction when the viscosity reaches 600-900CP; and IV, removing the catalyst by virtue of filtration. After being modified, the amine curing agent disclosed by the invention cannot be frozen, cannot have a whitening phenomenon, and is stable in reaction; and the preparation process disclosed by the invention is high in production efficiency, simple in required raw materials and concise in production process.

Owner:苏州市吴中区木渎三兴树脂溶剂厂

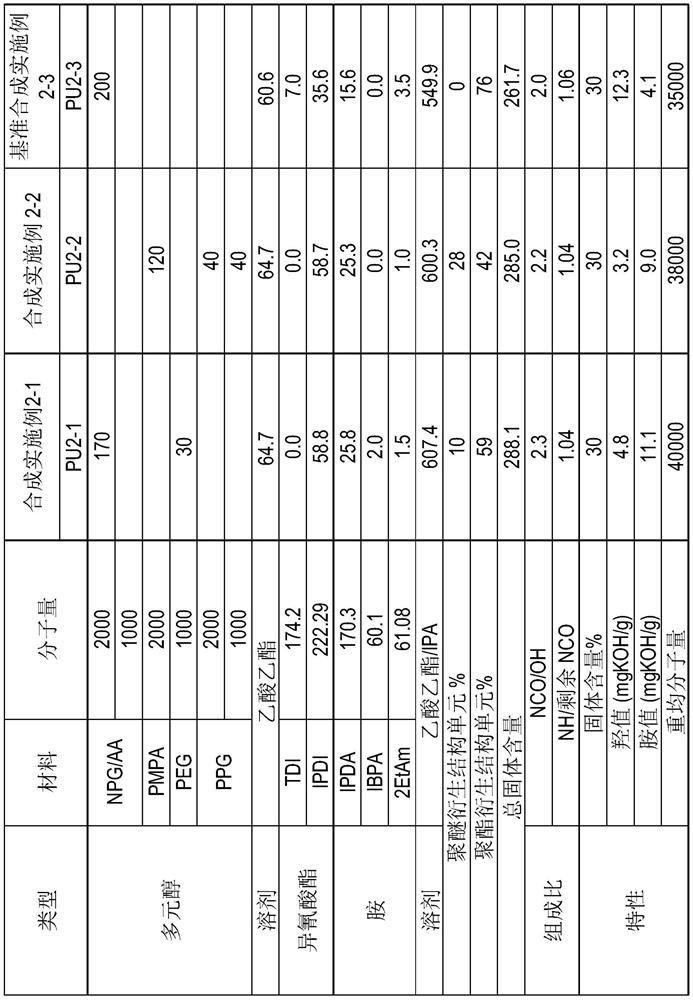

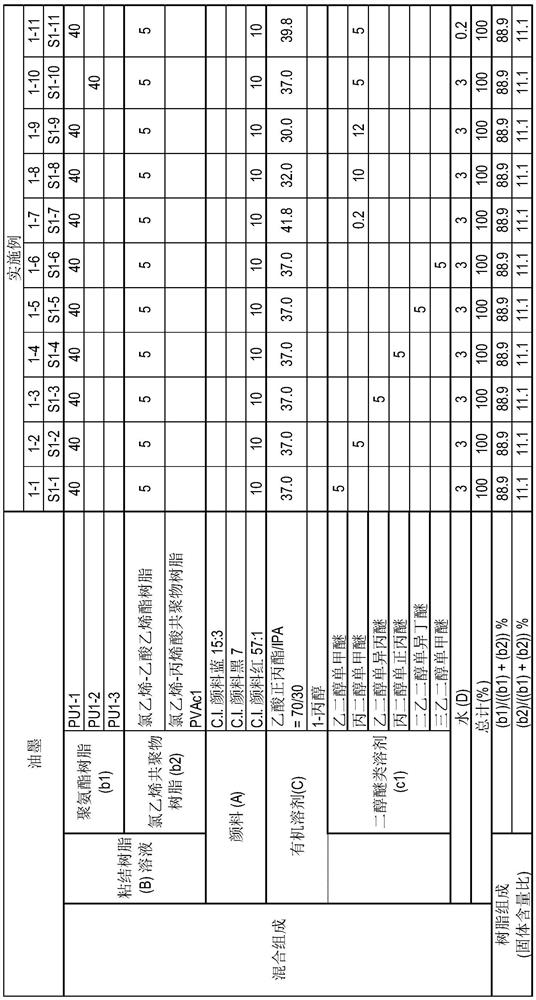

Solvent-based gravure inks, prints and laminated products for laminates

ActiveCN109476941BNo bleachingReduce wear and tearSynthetic resin layered productsCellulosic plastic layered productsPolymer scienceHigh humidity

Owner:TOYO INK SC HOLD CO LTD +1

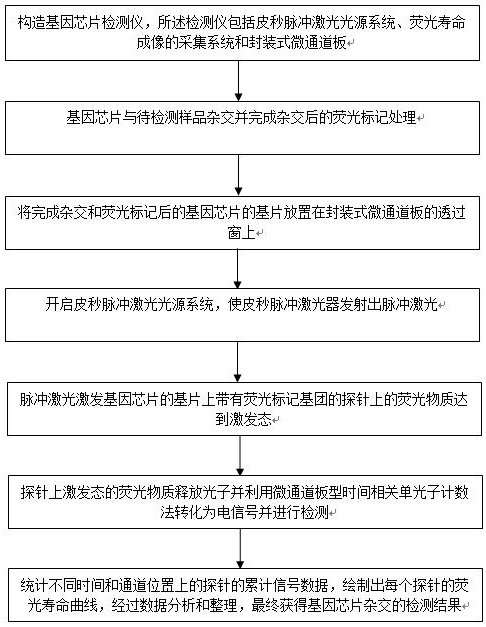

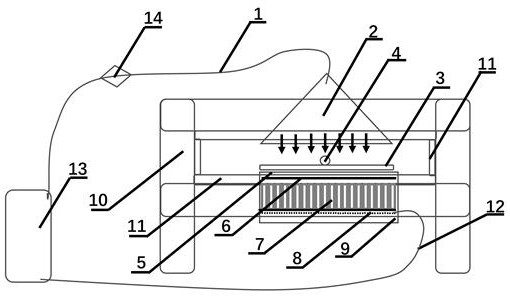

A method for detecting gene chip hybridization result

Owner:BEIJING BIONAXIN BIOTECH CO LTD

Composite nanomaterial and preparation method for early diagnosis and treatment of tumors

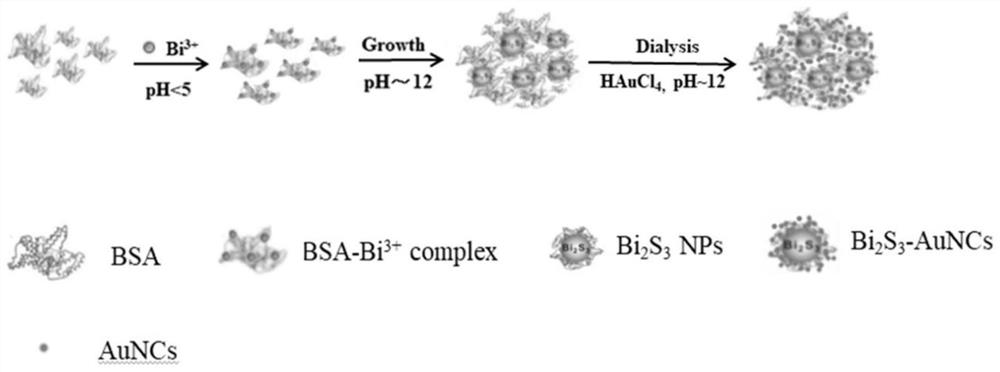

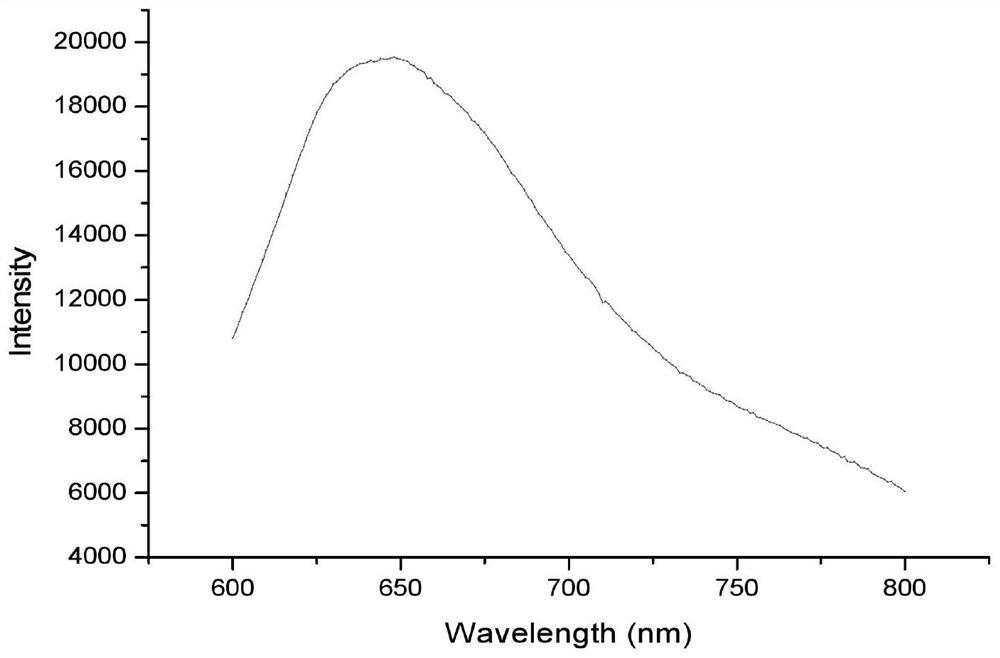

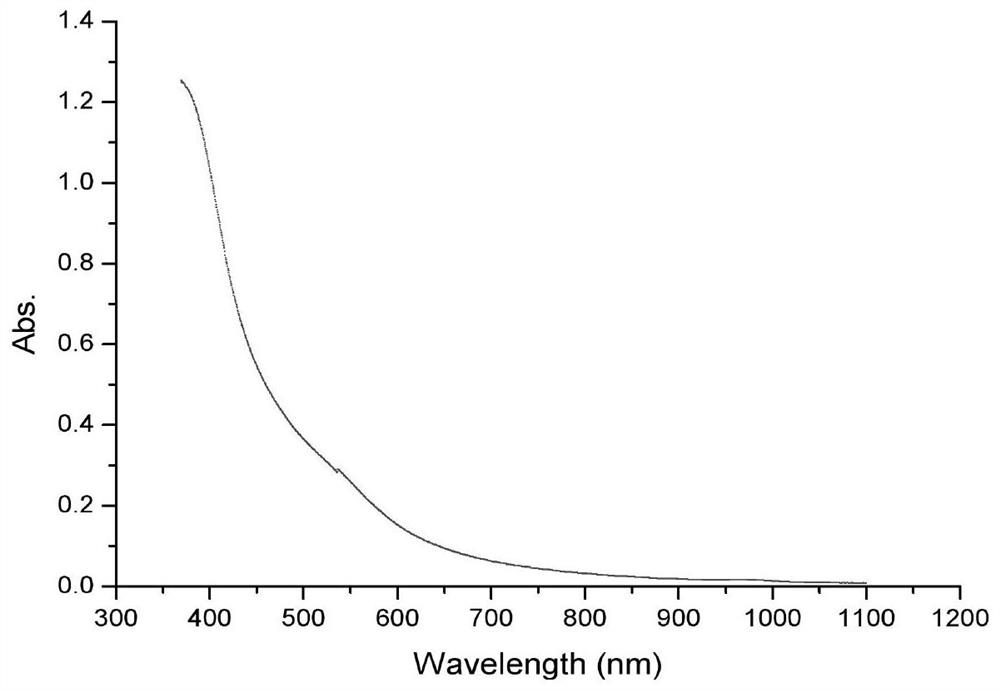

ActiveCN110464843BExcellent light-to-heat conversion performanceCapable of CT imagingEnergy modified materialsX-ray constrast preparationsBismuth sulfideBovine serum albumin

The invention discloses a composite nano material used for early diagnosis and treatment of tumors and a preparation method thereof. The novel nanomaterial is a composite of bismuth sulfide nanoparticles and gold nanoclusters. The preparation method is as follows: first, use bovine serum albumin (BSA) as a stabilizer and reducing agent to prepare bismuth sulfide nanoparticles (Bi 2 S 3 NPs), followed by the addition of chloroauric acid, Au 3+ In situ growth into gold nanoclusters (AuNCs) under alkaline conditions, and then bismuth sulfide-gold nanoclusters (Bi 2 S 3 ‑AuNCs) composites. Thanks Bi 2 S 3 With the functions of photothermal therapy and CT imaging, AuNCs has the ability of fluorescence imaging, AuNCs and Bi 2 S 3 NPs have photothermal therapy synergistic enhancement, and thus the formed complex can achieve better fluorescence imaging and CT imaging-guided photothermal therapy.

Owner:HUBEI UNIV OF TECH

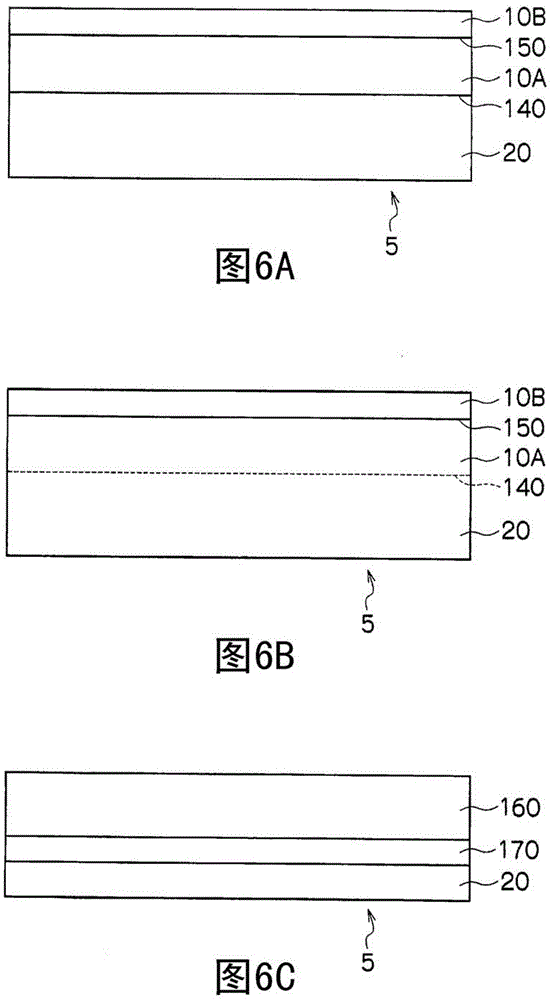

Method for producing coated film

PROBLEM TO BE SOLVED: To prevent the whitening of a coating film even if the coating film is dried after the coating film containing an active ray curable component is irradiated with active rays.SOLUTION: At least one coating solution containing an active ray curable component is prepared to be applied to a support 20 to form at least one coating film 10 and this coating film 10 is irradiated with active rays to be dried. In the irradiation process, the coating film 10 is irradiated with active rays in a wet state to raise the curing ratio of the curable component in the coating film 10 to 10-80% and, in the drying process, until the solid concentration of the coating film 10 reaches 80% of the lapse rate drying start solid concentration from the irradiation completion time of the active rays, the average evaporation speed of the solvent evaporated from the coating film is adjusted to 3.00 g / msecond or below.

Owner:FUJIFILM CORP

Manufacturing method of anti-wearing floor of prefabricated bathroom

InactiveCN107268932ANo loss in color clarityExcellent wear resistance and anti-skidPretreated surfacesCoatingsDisinfectantUltraviolet lights

The invention discloses a manufacturing method of an anti-wearing floor of a prefabricated bathroom. The method includes the steps that the whole bathroom floor is cleaned up and dried in the air, and wax needs to be removed if the floor is waxy; a layer of UV light photocuring shadowless glue is coated on the floor evenly, and the thickness of the glue is 0.03-0.07 mm; a PVC anti-wearing surface film covers the UV light photocuring shadowless glue, extrusion is conducted until bubbles do not exist in the middle of the film so that the surface film is attached flatly; and an ultraviolet light photocuring light is used for illuminating the floor for 10-15 seconds so that the UV light photocuring shadowless glue can be solidified, and a finished product is obtained. All of the materials used in the method are colorless and transparent, and the color clarity does not reduce compared with the impression of an original surface. The anti-wearing property of the floor is tested through a GB / T18102-2007 test method, and completely meets the anti-wearing property of the business level; the floor is soaked for 24 hours in 84 disinfectant liquid, wherein the concentration of the sodium chlorate content is 620 mg / L, and no color fading and whitening phenomena happen on the surface; and by adopting the manufacturing method, the PVC anti-wearing layer can be suitable for different floors, the anti-wearing floor is suitable for industrialized batch production, and easy to be popularized in the market.

Owner:丰县正标卫浴有限公司

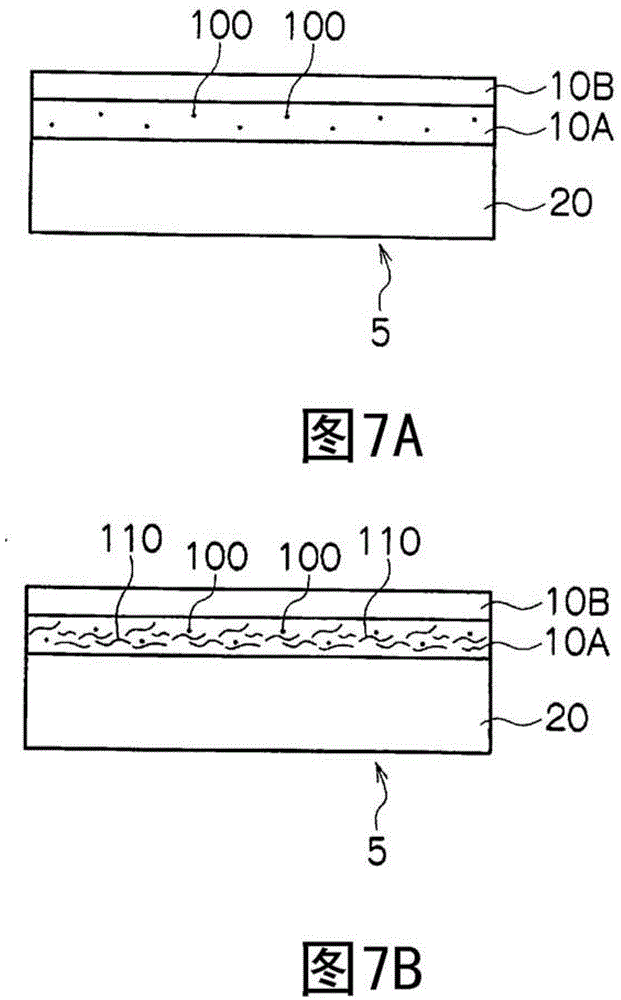

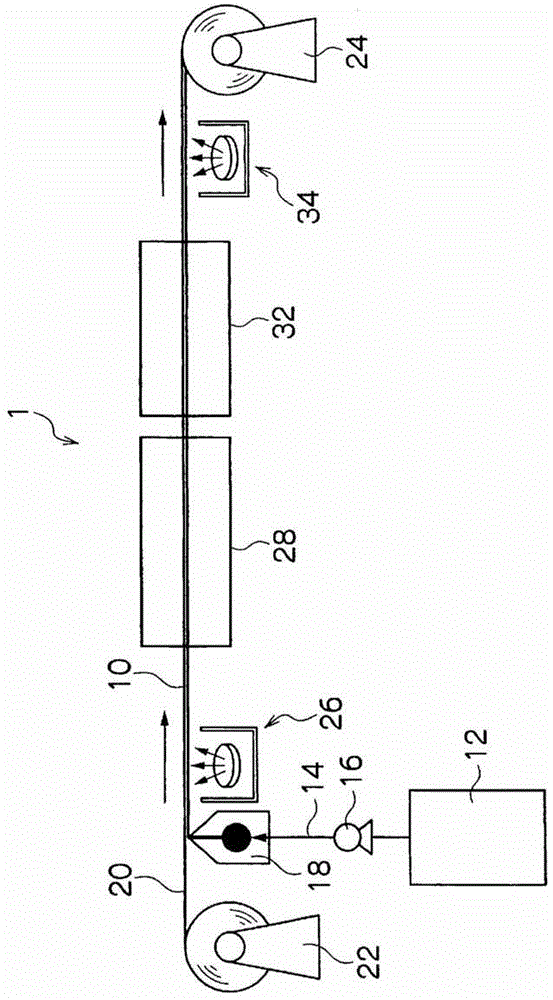

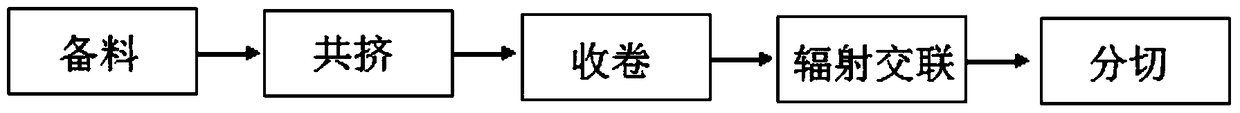

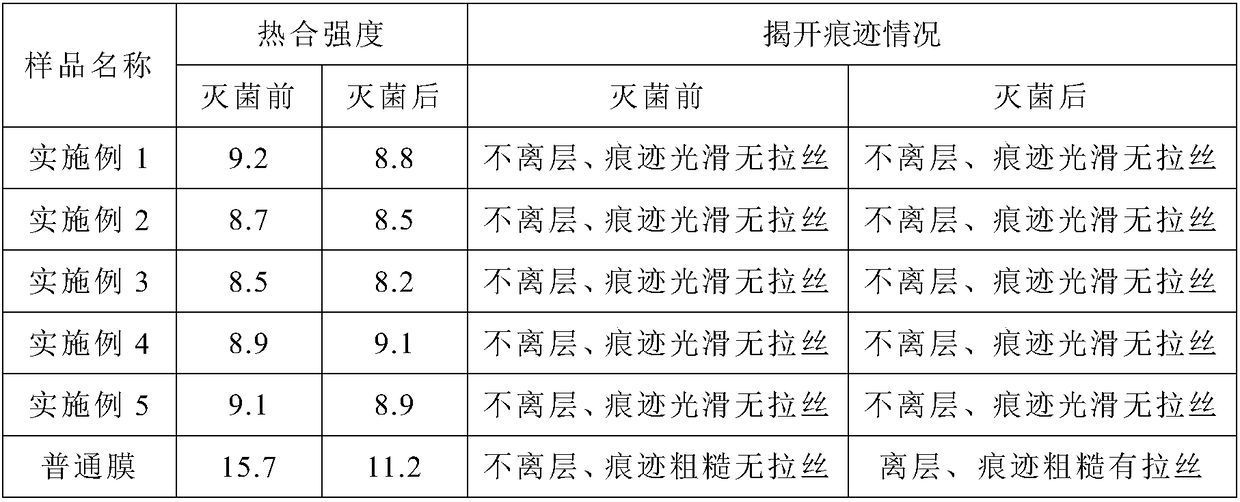

A kind of easy peel film for medical packaging and preparation method thereof

ActiveCN105619981BImprove sterility assurance valueSolve the problem that the sterilization temperature cannot be higher than 110°CSynthetic resin layered productsDomestic containersPolyesterElastomer

The invention discloses a medical packing easy-to-tear-off film and a preparation method thereof. The medical packing easy-to-tear-off film comprises four layers of structures from inside to outside: a thermal bonding layer, a structural layer, an adhesive layer and an outer layer, wherein the thermal bonding layer is prepared from mixed resin consisting of medical-level polyethylene, ethylene-vinyl acetate and ethylene-methyl acrylate; the structural layer is prepared from medical-level polyethylene; the adhesive layer is prepared from maleic anhydride modified ethylene-octene copolymer; the outer layer is prepared from a polyester elastomer. The medical packing easy-to-tear-off film disclosed by the invention can realize sterilization using high-temperature steam at 121 to 135 DEG C or gamma-ray irradiation, and can be stored under the temperature lower than minus 25 DEG C. Furthermore, the film is good in transparency, less in migration separates and good in medicament compatibility, is extremely high in easy-to-tear-off property, and can meet the performance requirement on medical packing, so that the convenience and the safety of medicament taking by a patient are improved.

Owner:湖北恒泰橡塑有限公司

Film-forming aid and preparation method thereof

PendingCN112010739AGood film formingGood compatibilityInksEther preparation from oxiranesOrganic compoundSimple Organic Compounds

The invention belongs to an emulsion film-forming technology, and particularly relates to a film-forming aid and a preparation method thereof. The structural expression formula of the film-forming aidis shown in the specification, and R1 and R2 independently represent any one of a substituted or unsubstituted C1-C20 alkyl group, a substituted or unsubstituted C2-C20 alkenyl group, a substituted or unsubstituted C2-C20 alkynyl group and a substituted and unsubstituted C1-C20 alkoxy group. Excellent film-forming property can be realized only by adding 4wt% of the film-forming aid prepared by the invention into the emulsion, the film-forming temperature is about 14 DEG C, a transparent continuous coating can be formed and the whitening phenomenon is avoided, and the paint has good compatibility, has a boiling point of about 270 DEG C, does not cause migration of organic compounds to the surface, is not easy to volatilize, has low VOC emission, is safe and environment-friendly, and has awide market prospect.

Owner:NANJING FORESTRY UNIV

Medical adhesive made from medical polymer material and preparation method of medical adhesive

The invention provides a medical adhesive made from a medical polymer material and a preparation method of the medical adhesive. The adhesive consists of polyacrylate, tragacanth, polymethacrylate, squalane, benzoyl peroxide, glycerin rosin resin, dimethyl sebacate, hydroquinone, p-benzenemethanesulfonic acid, dioctyl phthalate, tertiary calcium phosphate and sodium alginate. The preparation method comprises the following steps: firstly, mixing the polyacrylate, the tragacanth, the polymethacrylate and the squalane, then adding the benzoyl peroxide and the glycerin rosin resin, and stirring so as to obtain a mixture I; then, mixing the dimethyl sebacate, the hydroquinone, the p-benzenemethanesulfonic acid, the dioctyl phthalate, the tertiary calcium phosphate and the sodium alginate so as to obtain a mixture II; and mixing the mixture I and the mixture II, heating, preserving heat, and cooling to room temperature, so that the medical adhesive is obtained. The medical adhesive disclosed by the invention is moderate in curing speed, long in duration of keeping stable and high in bonding strength.

Owner:WINNER MEDICAL (JIAYU) CO LTD

Preparation method of methyl tin mercaptide

PendingCN114380857AGood heat stabilizerGood compatibilityTin organic compoundsPtru catalystDistillation

The invention belongs to the technical field of preparation of methyl tin mercaptide, and particularly relates to a preparation method of methyl tin mercaptide, which comprises the following steps: S1, planing tin bricks with better quality into tin sheets, and putting the tin sheets into a reactor; s2, metal tin and a first catalyst are put into a reaction kettle, then chloromethane is introduced for halogenation, then a redistribution agent is added for a tinning reaction, distillation is performed, fractions with the gas temperature ranging from 150 DEG C to 230 DEG C are received, and then pure water is used for absorption to obtain a methyl tin chloride aqueous solution; the methyl vinyl chloride comprises dimethyl tin dichloride and methyl tin trichloride; and S3, adding the obtained methyl tin chloride aqueous solution into isooctyl thioglycolate, adding a second catalyst, carrying out a stirring reaction at a temperature of 5-15 DEG C for 0.2-0.4 h, adding an alkali liquor, carrying out a continuous stirring reaction until the pH value of the reaction system reaches 7-9, heating to 60-70 DEG C, carrying out a reaction for 1-1.5 h, standing, cooling, and layering.

Owner:山东大成德广环境科技有限公司

Glue for medical use

The composition of medical adhesive includes (by weight portion) 940-970 portions of butyl cyanoacrylate, 30-60 portions of dimethyl sebacate, 0.1-0.5 portions of p-benzenediol and 0.1-0.8 portion of compound stabilizing agent, in which the described butyl cyanoacrylate is n-butyl alpha-cyanoacrylate, and the described compound stabilizing agent is made from toluene-p-sulfonic acid and dioctyl (0-) phthalate according to 90-100:0-10 weight portion. Its solidifying speed is moderate, adhesive strength is high, it is applicable to various wounds and incision of operation instead of suture needle and silk suture.

Owner:BEIJING COMPONT MEDICAL DEVICES

toothbrush

The present invention provides a toothbrush that does not cause warping, resin whitening, or cracks in the head of the flat wire type hair transplant method, ensures sufficient hair transplant strength, and is excellent in operability in the oral cavity. The toothbrush (1) is provided with a head (10) with a plurality of hair-planting holes (13) on the hair-planting surface (12), and the bundle of hair bundles with a plurality of bristles is folded into two by a flat wire (15) and inserted into the hair-planting holes (13), wherein, the thickness of the head (10) is more than 2.0mm and less than 4.0mm; the hair-planting hole density of the hair-planting hole (13) is 25 holes / cm 2 above; when the inner diameter of the hair-planting hole is X, the thickness of the flat wire is d, and X is more than 0.9mm and less than 1.3mm, the relationship of 0.37mm≤(X-d) / 2≤0.55mm is satisfied.

Owner:LION CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com