Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

72results about How to "Low outgassing rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-temperature thermal insulation paper, preparation method and application thereof

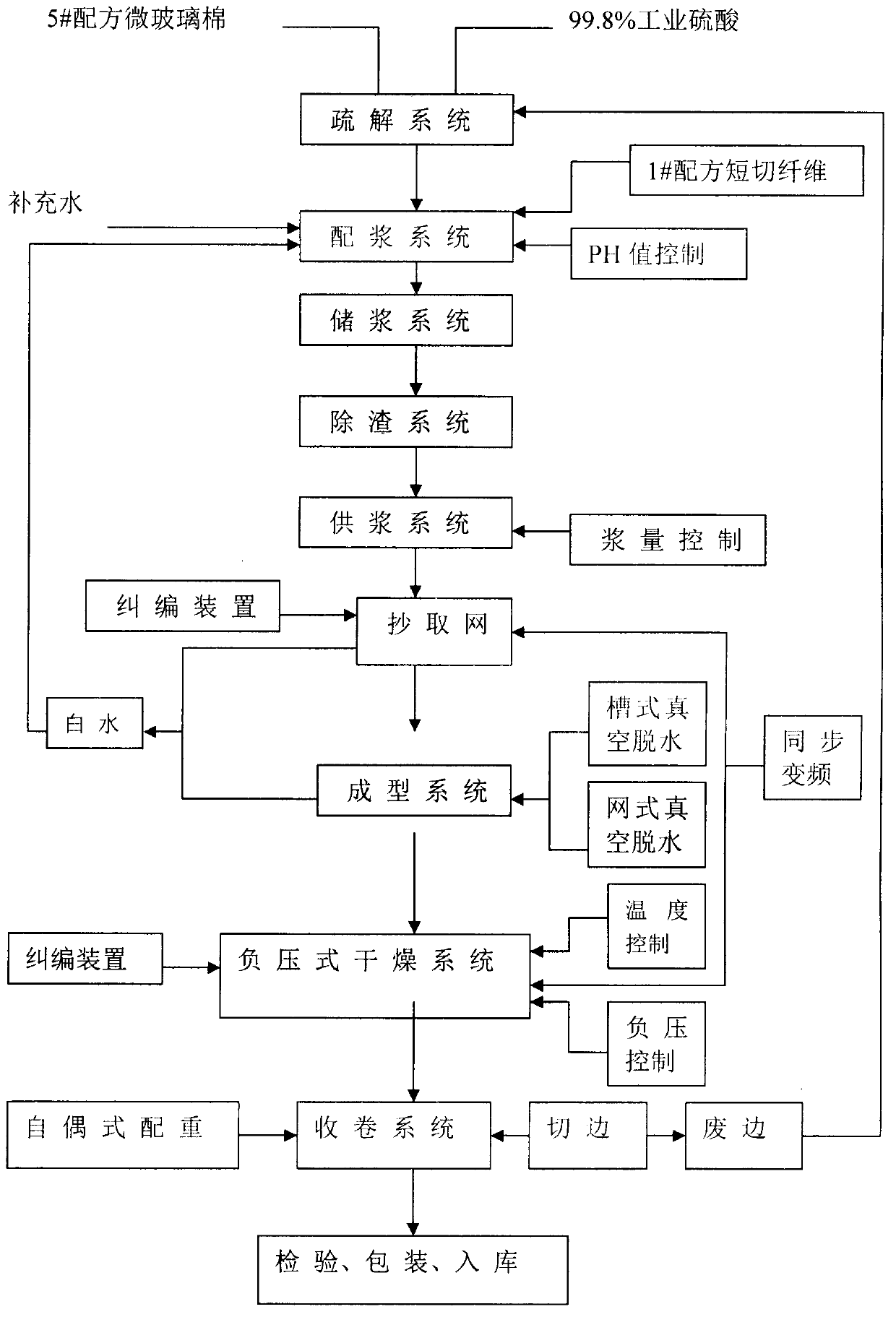

ActiveCN101058961AGood insulation performanceImprove flame retardant performanceSynthetic cellulose/non-cellulose material pulp/paperChemical/chemomechanical pulpFiberGlass fiber

The present invention involves a low-temperature insulating paper, and relates to a preparation method of said low-temperature insulating paper and its applications. The invention prepares the low-temperature insulating paper with superfine alkali-free glass fiber and wet paper preparation process; the definite quantity of said low-temperature insulating paper is 10-20 g / m2 and the thickness is 0. 06 - 0. 09 g / m2. The preparation method of said low-temperature insulating paper includes: beating, stirring and scattering the superfine alkali-free glass fiber, and drying after stripping in paper machine, last coiling and preparing the products. The low-temperature insulating paper in the invention can be used for vacuum multi-layer insulation structure of copious cooling liquid accumulating container and complement pipes. The low-temperature insulating paper in the invention has good adiabaticity, the degassing ratio is small in vacuum, the profiling performance is good, and it has long life and wide uses.

Owner:HANGZHOU FUSHIDA SPECIAL MATERIAL

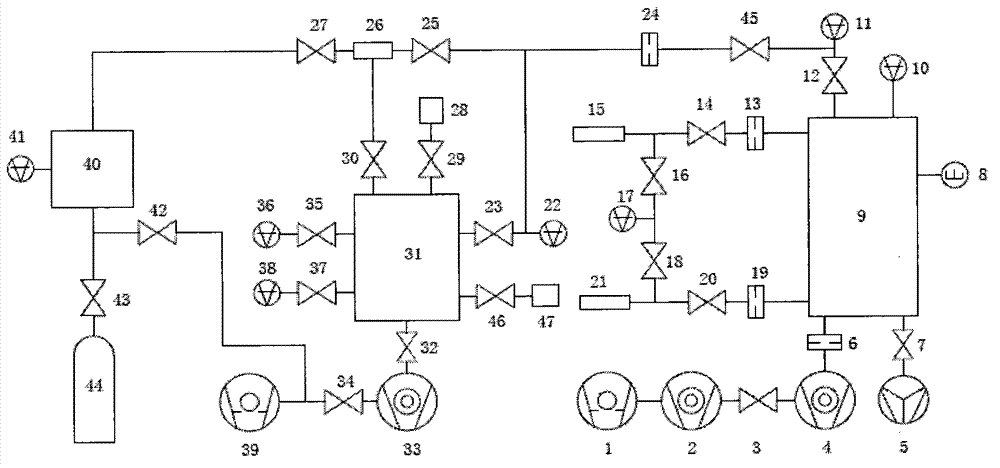

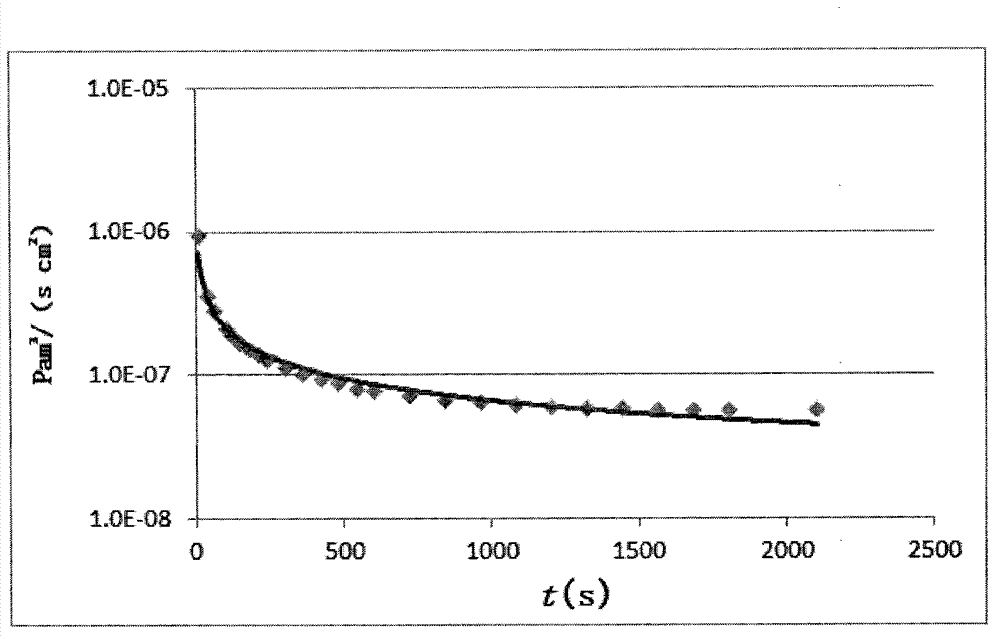

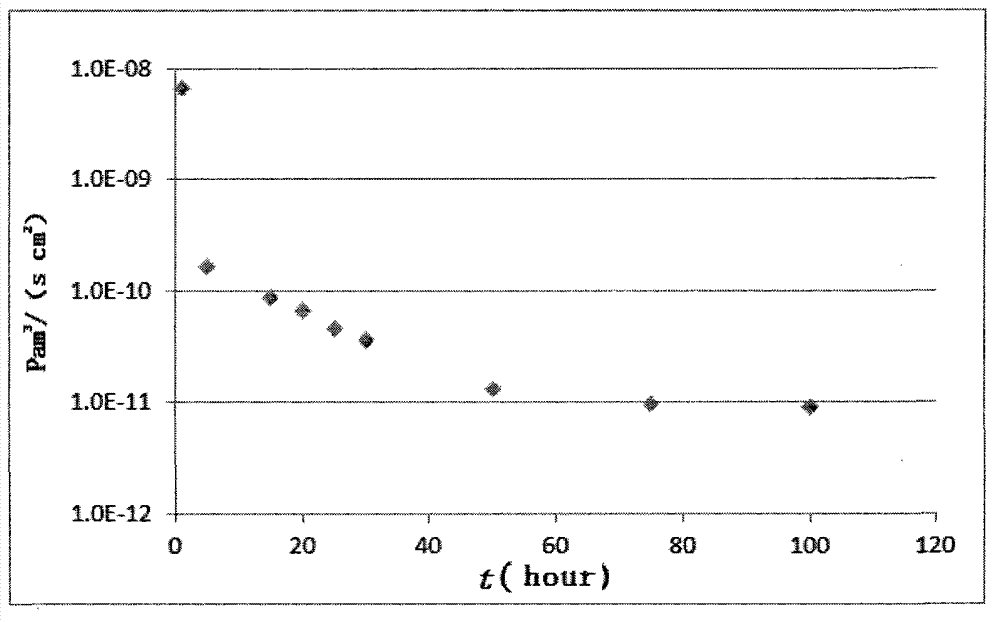

Composite material deflating rate test system with self calibration function and method

InactiveCN102967527AWith self-calibration functionHigh measurement accuracyMaterial analysisCapacitanceData reliability

The invention belongs to the technical field of measurement, and in particular relates to a composite material deflating rate test system with self calibration function and a method. The system comprises a dry pump, a molecular pump, an ultra high vacuum metal angle valve, a getter pump, small pores, a quadrupole mass spectrometer, a vacuum chamber, an extractor gauge, a composite vacuum gauge, a sample room and a capacitance diaphragm gauge. The system combines three material deflating rate test methods, an accumulation method, a dynamic flow method and a double path method, and can test gas flow within the range of 1Pam<3> / s-6* 10<-12>Pam<3> / S ( if the surface area A equals to 6000 cm<2>, deflating rate measurement limit reaches 1*10<-15>Pam<3> / (s cm<2>)). The system covers material deflating rate test range 13 orders of magnitude, adopts a symmetric structure in design, and improves test efficiency and data reliability; besides, the system has function of automatic calibration on the ultra high vacuum gauge, the mass spectrometer and gas micrometeor, and has characteristics of multiple functions and high degree of integration.

Owner:北京宏宇永达科技发展有限公司

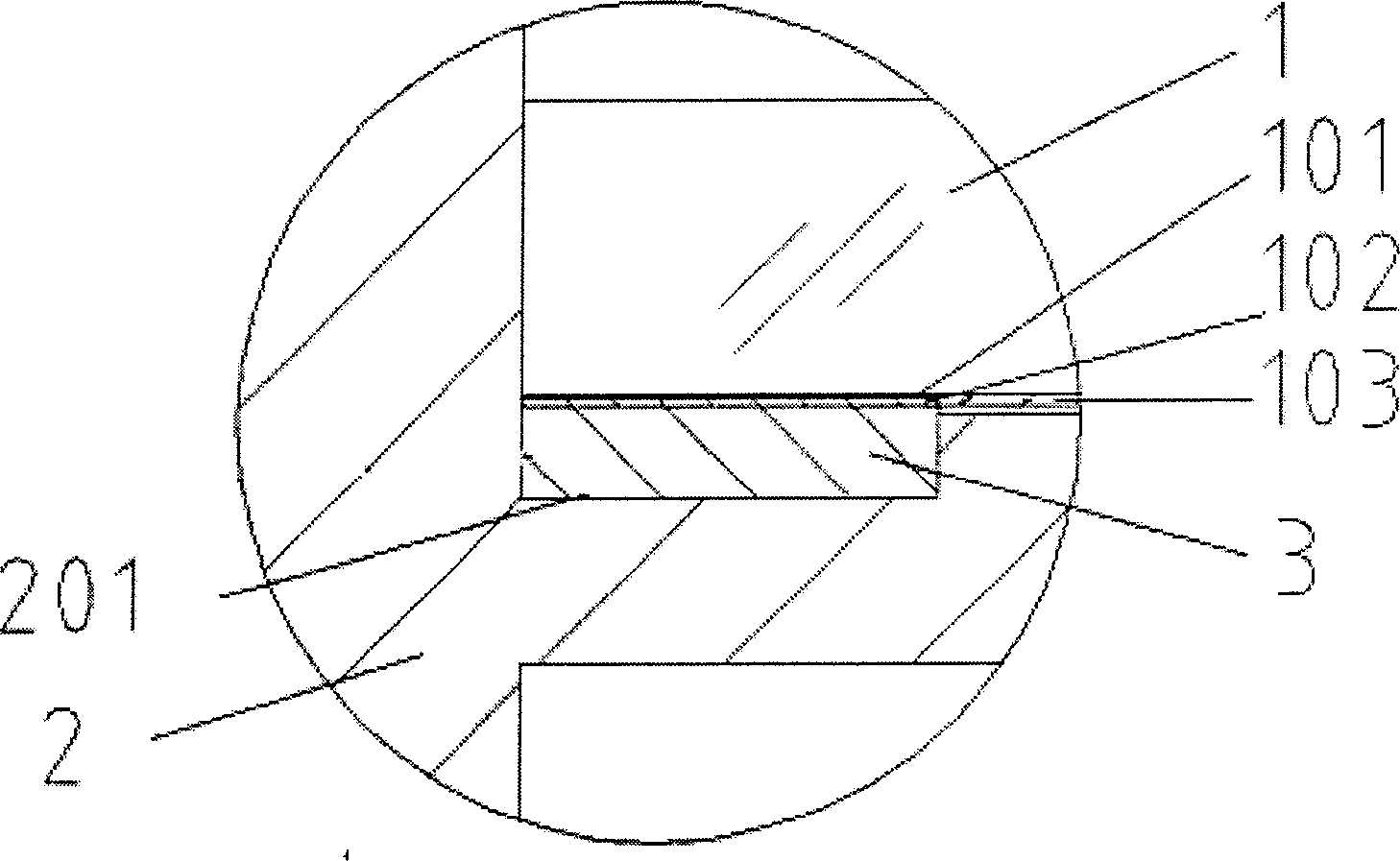

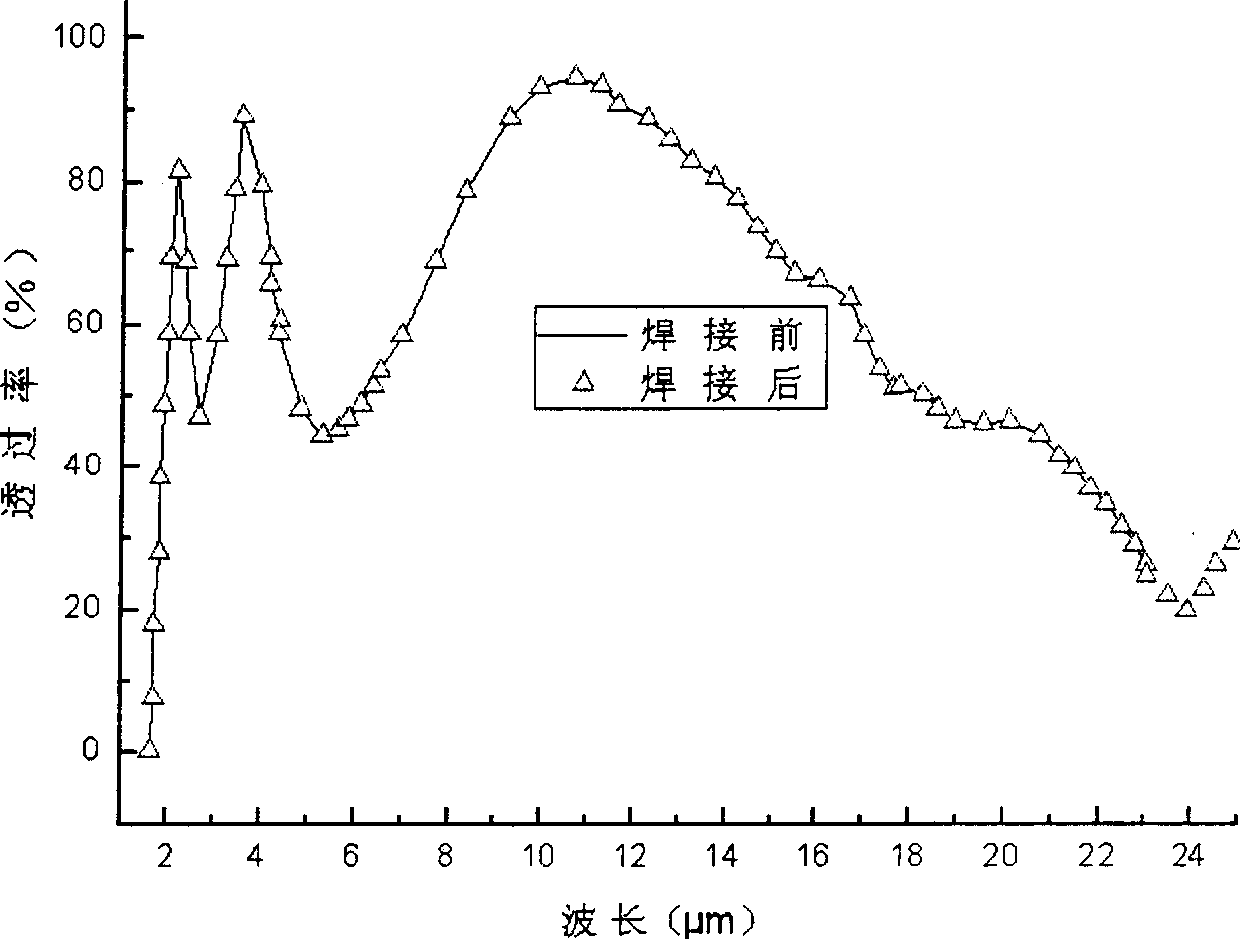

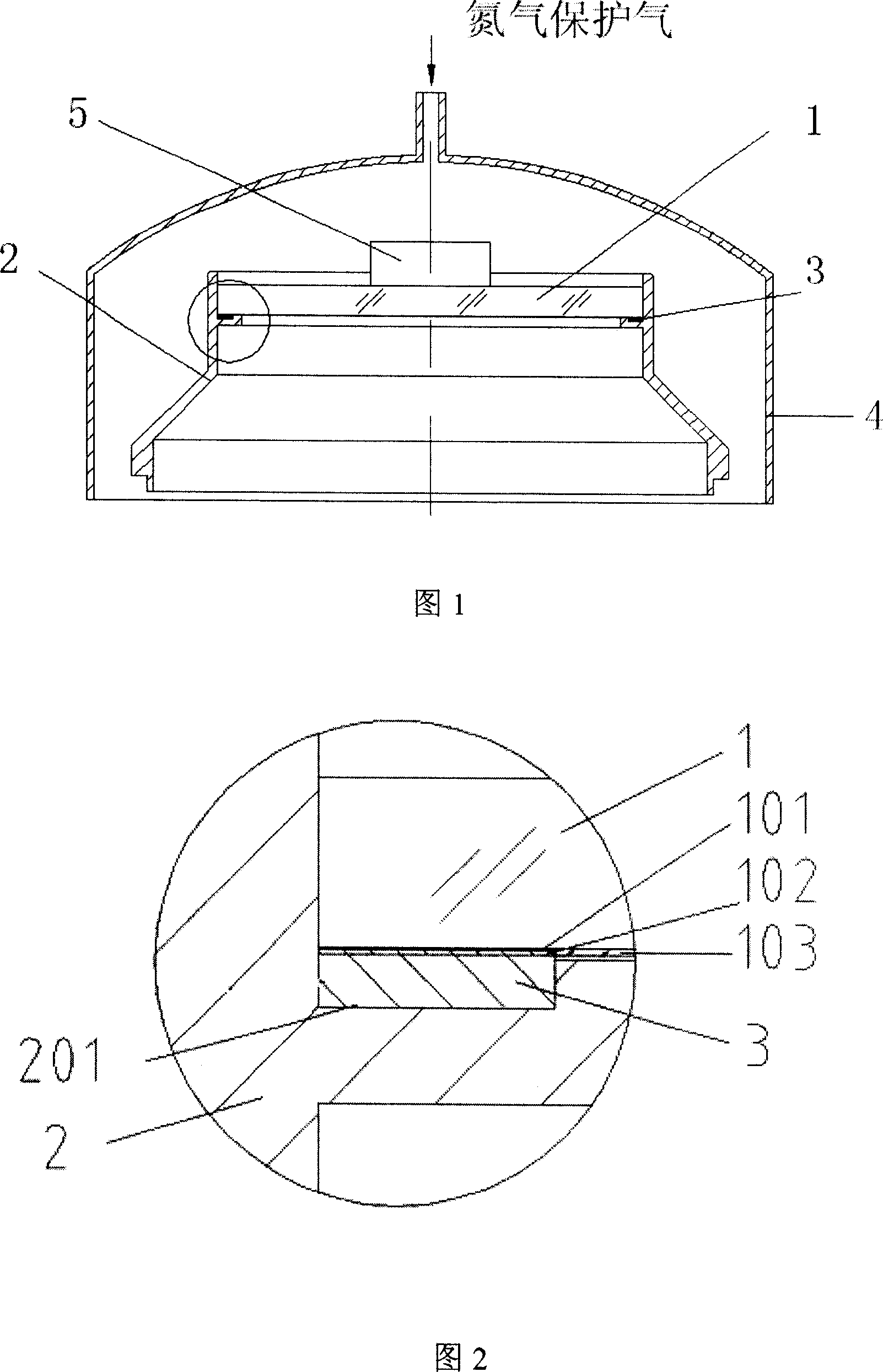

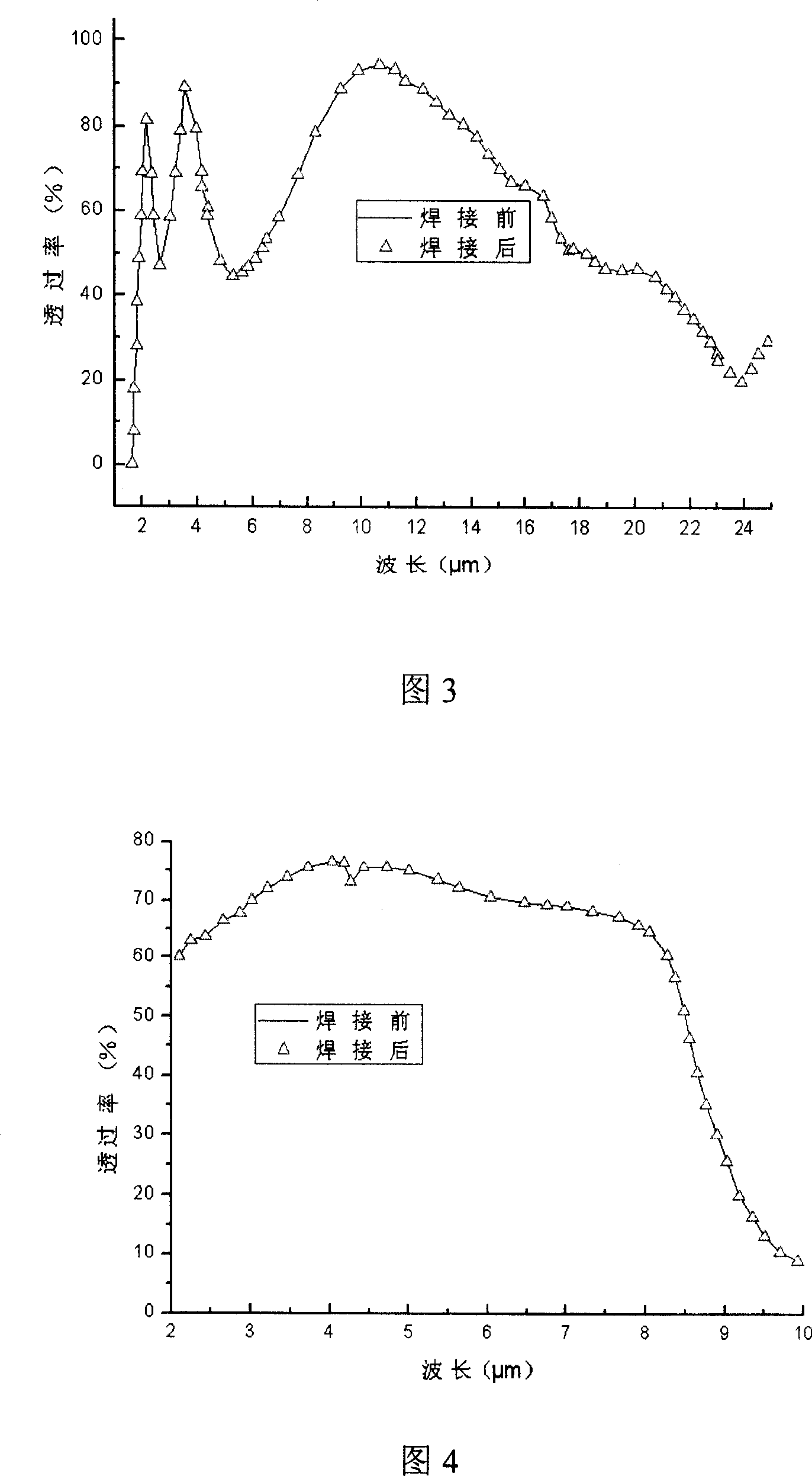

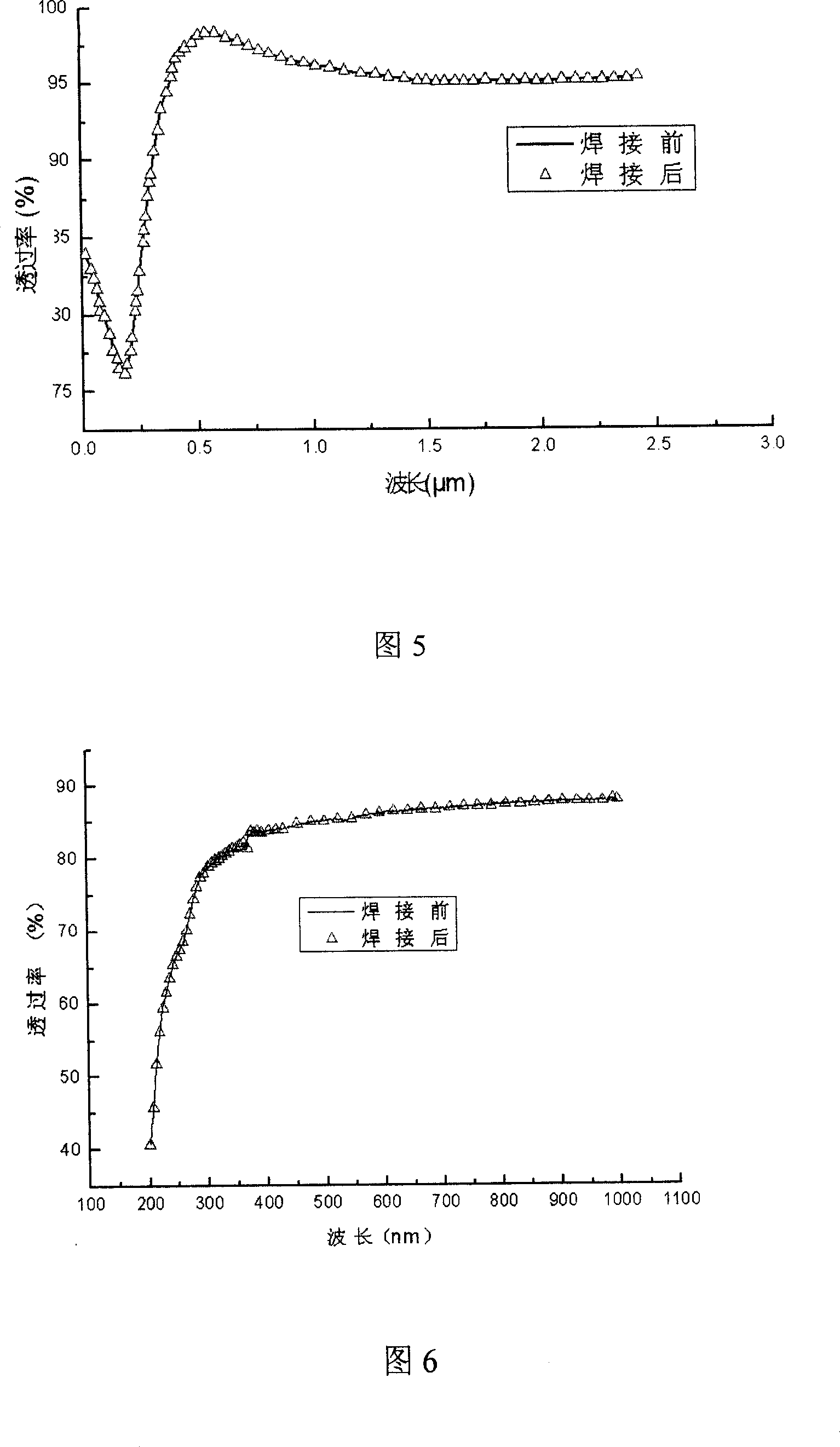

Vacuum seal welding method for window and optic window of low temperature metal Dewar

InactiveCN1820885AExcellent air leakage rateLow outgassing rateVacuum evaporation coatingSoldering apparatusIndiumInfrared window

The present invention discloses the method of low temperature vacuum sealing and welding between the window frame and the optical window of metal Dewar. In the welding between the window frame of kovar alloy material and the optical window of infrared transmitting material, the optical window is first vacuum plated to form Cr / Au coating as the transition layer in the parts to be welded, and the welding in performed with In as welding material at low temperature. The present invention has the outstanding advantage of low temperature welding producing no negative effect on the antireflective coating in the infrared window. Using soft In as the welding material can buffer the difference between the optical window material and the kovar alloy material in expansion coefficient. The metal Dewar has gas leakage rate superior to 3E(-12) torr.liter / sec and gas releasing rate far lower than that of traditional technological process.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

Luminescent film and its preparation method and use

InactiveCN1632052AUniform surfaceControl thicknessImage/pattern display tubesLuminescent compositionsPolymer scienceEvaporation

The invention include a lightening film and its preparing method and application. The chemical formula of lightening film: Y3(1-x-y)(AlzGa(1-z))5O12:Tb3x, A3y, 0.0001<x íœ0.3; 0.0001<yíœ0.3; 0íœzíœ1; A=Ce, Nd, Tm, Pr or mix of the two elements. Its preparing method is: burn the material for making target according to need, use electron beam evaporation coating to grow lightening film on the washed substrate and the time for growth id decided by speed and width of growth, finally place the film into program furnace to be heated to reach 500-700deg.C by the speed of 100deg.C / h, and kept for 2-3h. The lightening film prepared by the invention has average and compact surface without crack, average size of particle, and its width can be controlled, with outstanding lightening performance.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

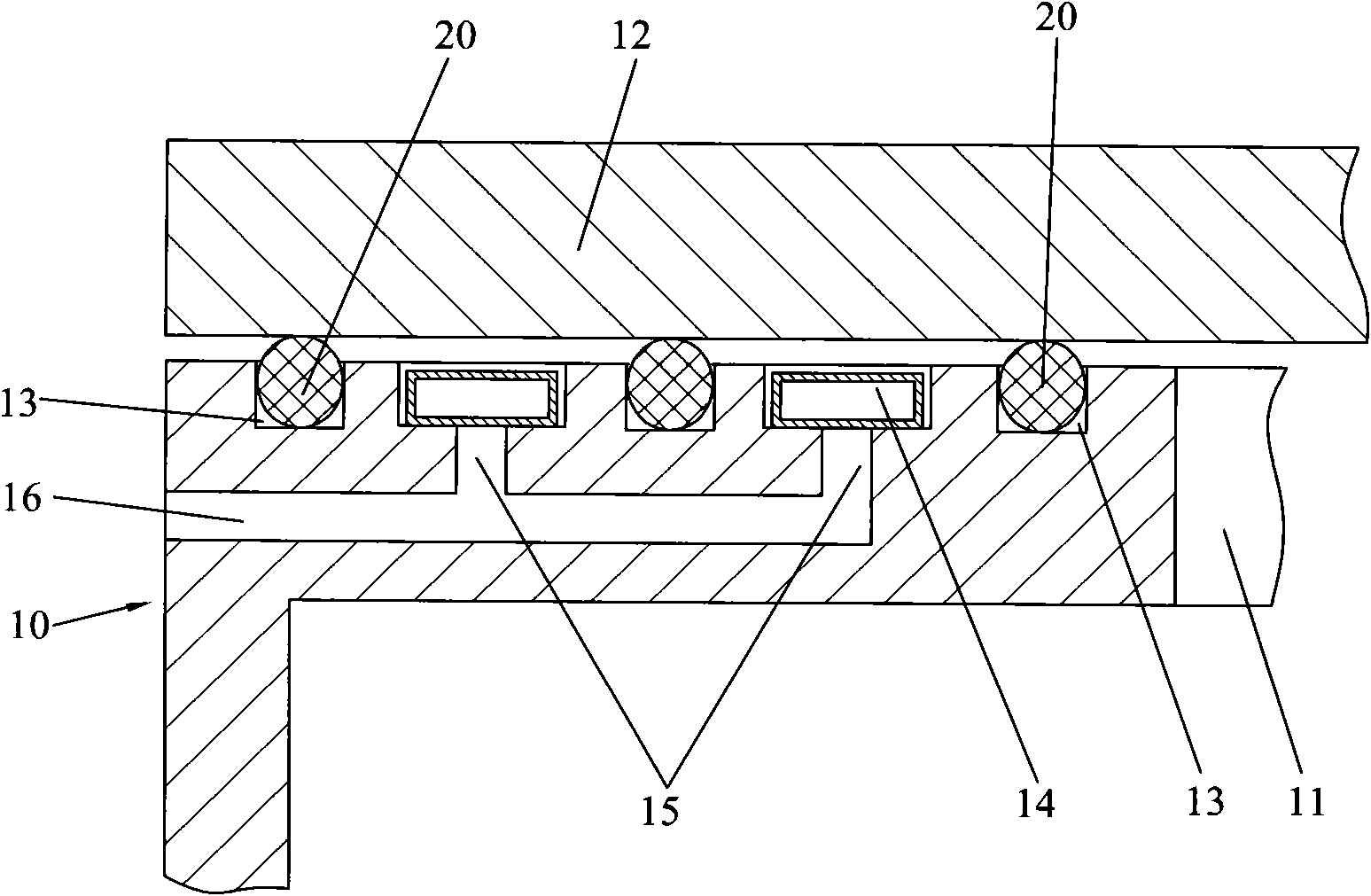

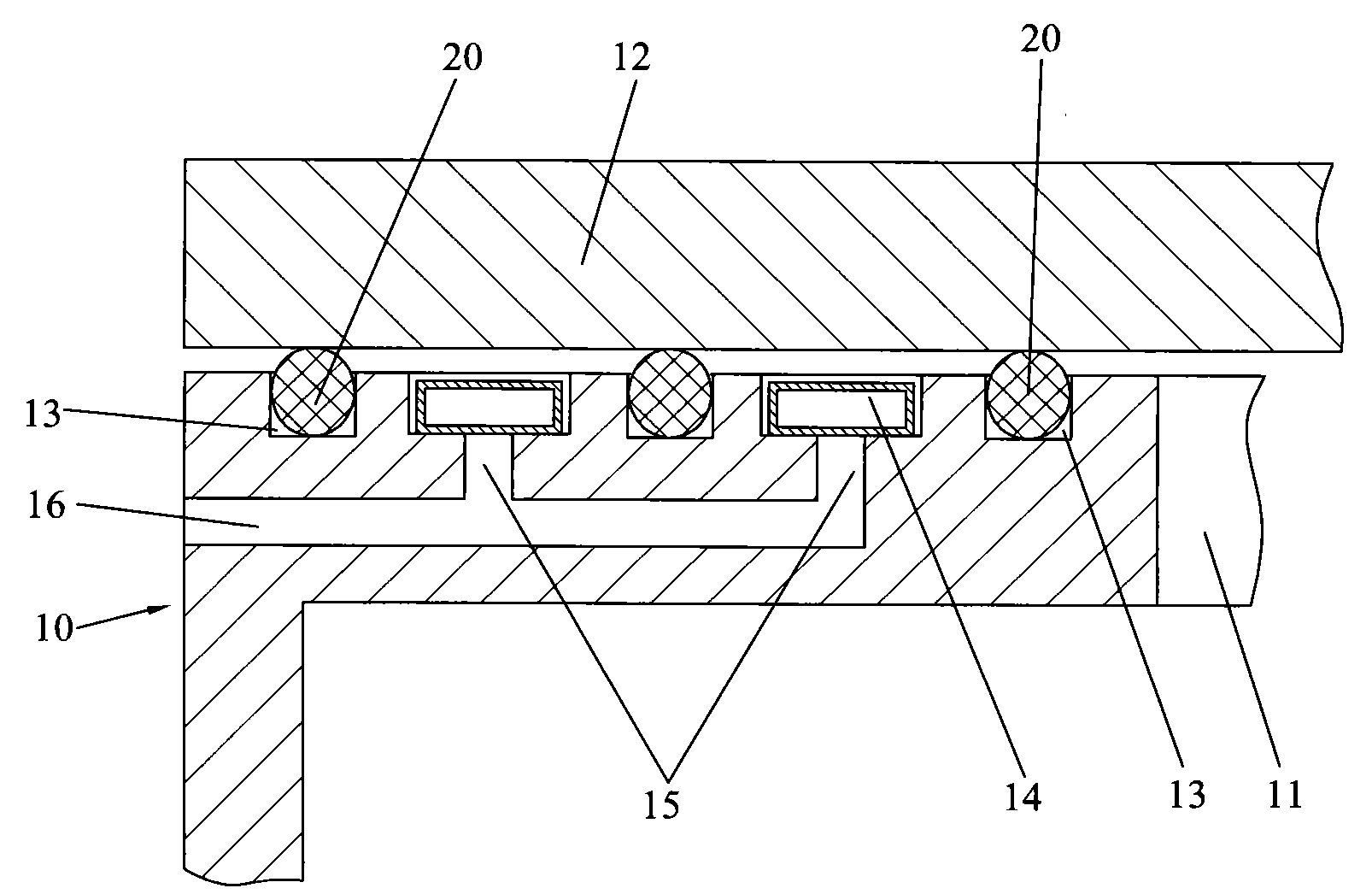

Multilayer rubber sealing ring sealing device

InactiveCN101881335AControl deformationCompact structureEngine sealsPressure/vacuum vesselsEngineeringVacuum chamber

Owner:DONGGUAN ANWELL DIGITAL MASCH CO LTD

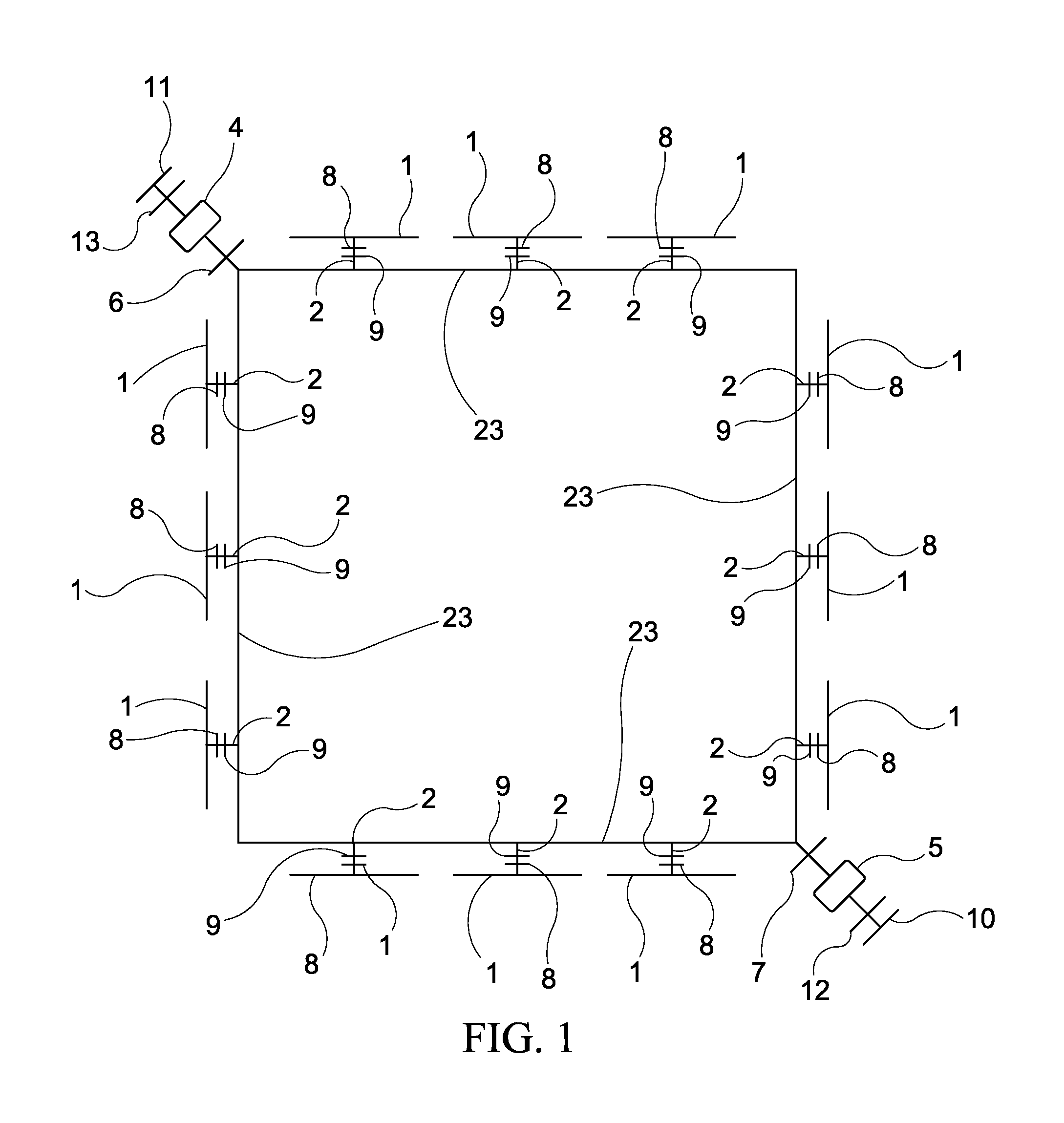

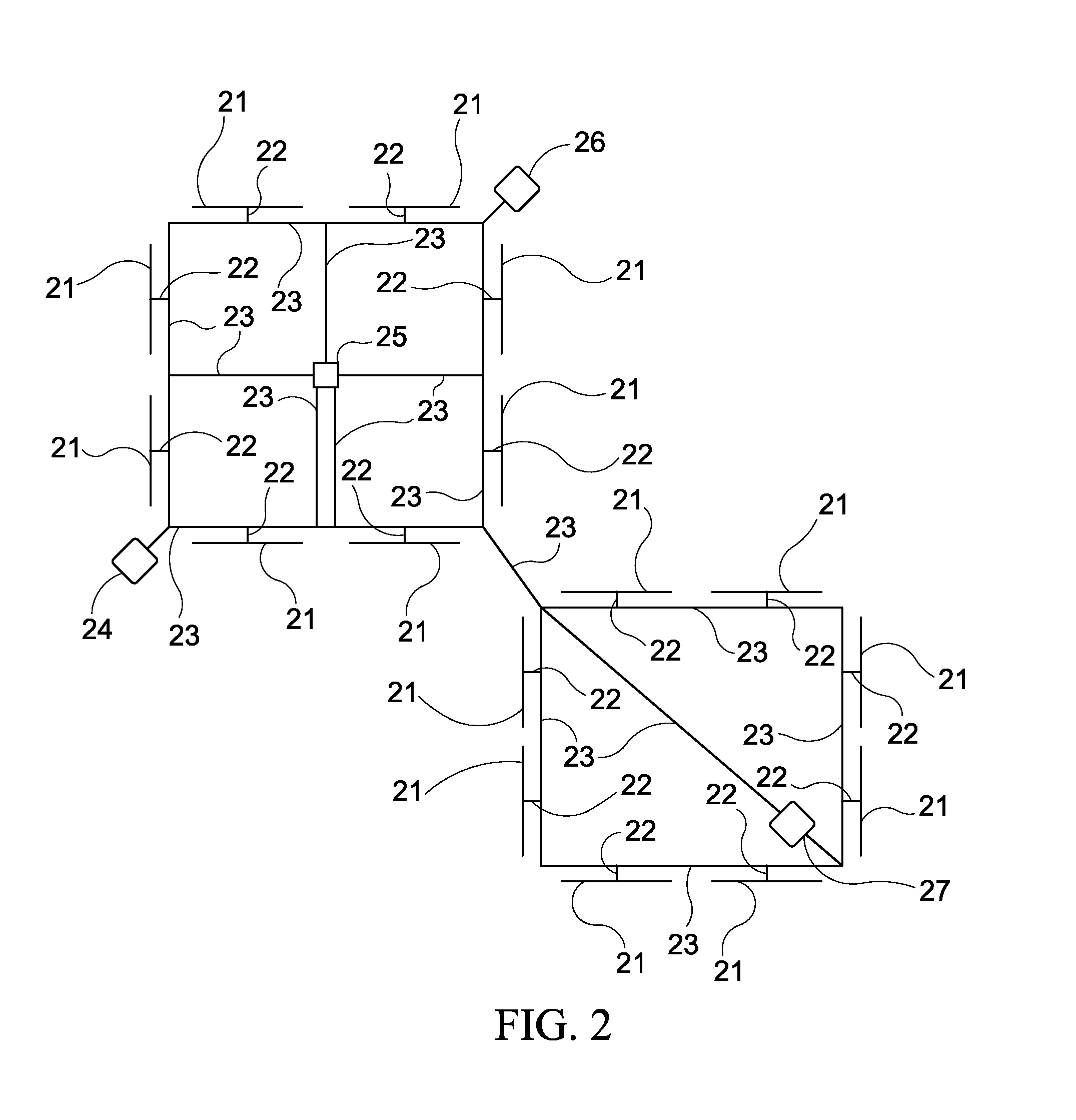

Vacuum system comprising vacuum insulated glass units

InactiveUS20140116516A1Process can be speededReduce stressDoors/windowsPressure pumpsVacuum pumpElectrical and Electronics engineering

Owner:JONES ROBERT S

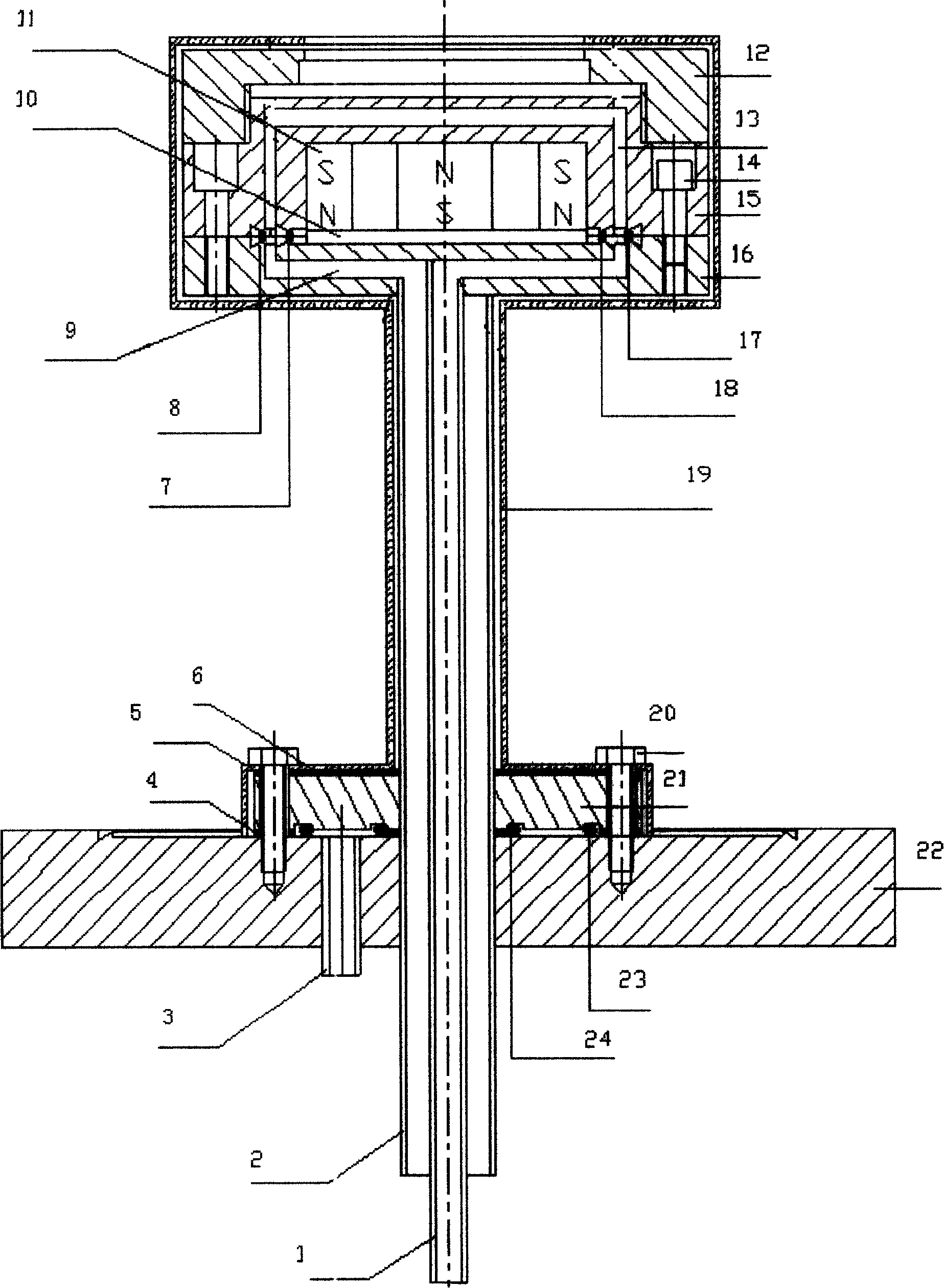

Magnetron sputtering cathode target for ultrahigh vacuum system

InactiveCN101161855AStable deliveryGuarantee normal performanceVacuum evaporation coatingSputtering coatingUltra-high vacuumEngineering

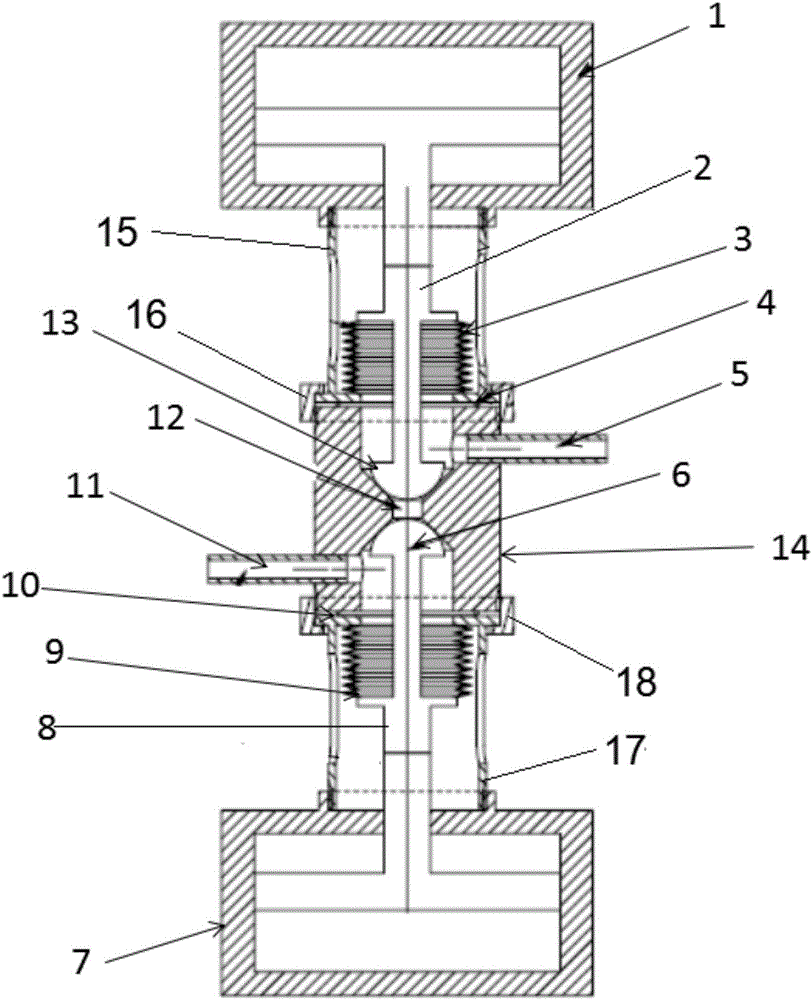

The invention discloses a magnetic control sputtering cathode target for an ultrahigh vacuum system. An upper flange and a lower flange (15 and 16) are inside provided with cooling troughs (13 and 9) which are communicated with each other, a water inlet pipe and a water outlet pipe (1 and 2) which separate from the cooling trough (9) are welded with the cooling trough (9), the upper end part of the upper flange (15) is in screw joint with a target material mounting frame (12), the chamber of the upper flange is inside provided with a magnet holder (10) and a magnet (11), metal obturating rings (17 and 18) which are positioned at an inner layer and an outer layer edges (7 and 8) are arranged between the lower end surface of the upper flange and the lower flange (16) and are fixed by a bolt (14), a small flange (21) is welded outside the water outlet pipe (2); insulation sheets (4 and 6) are arranged between the small flange (21) and a shield enclosure (19) and a base flange (22), two O-shaped cushion rubbers are arranged between the small flange and the base flange (22) which is communicated with an exhaust tube (3), the two cushion rubbers are fixed by a bolt (20) sleeved by an insulating sleeve (5). The invention has a vacuum degree up to 6x10<-8>Pa, which can realize the preparation of metal or nonmetal film with high quality and purity.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

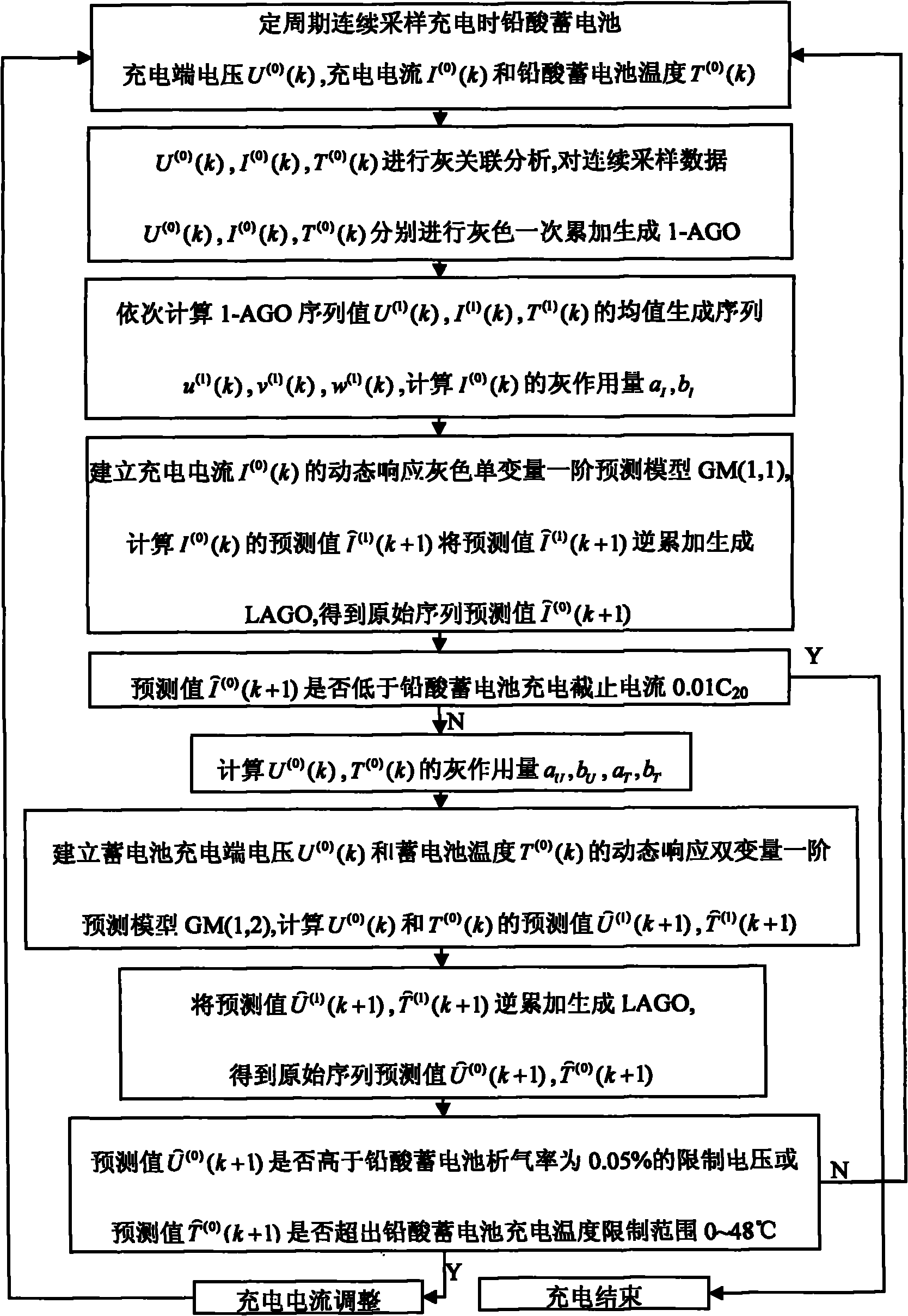

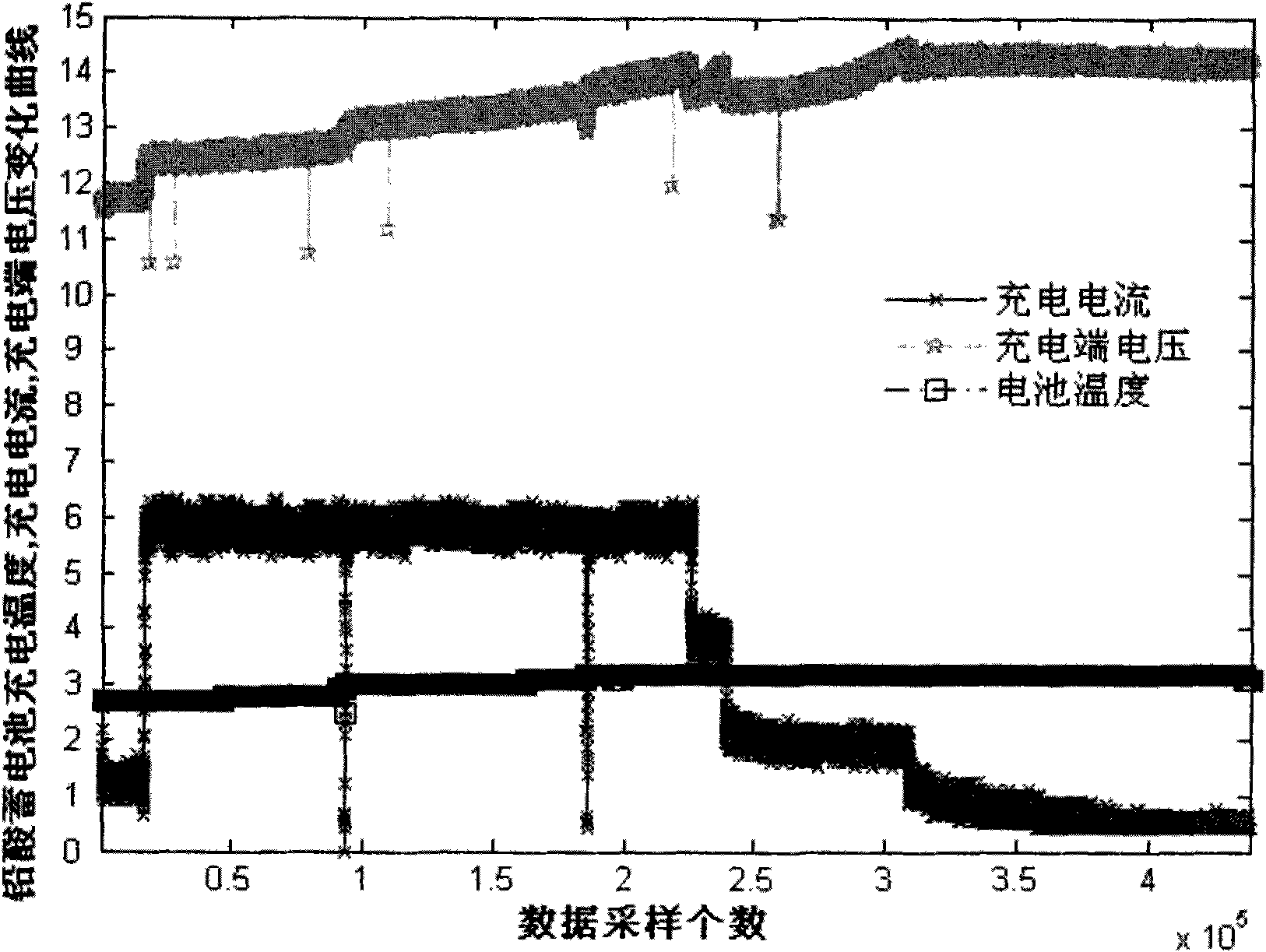

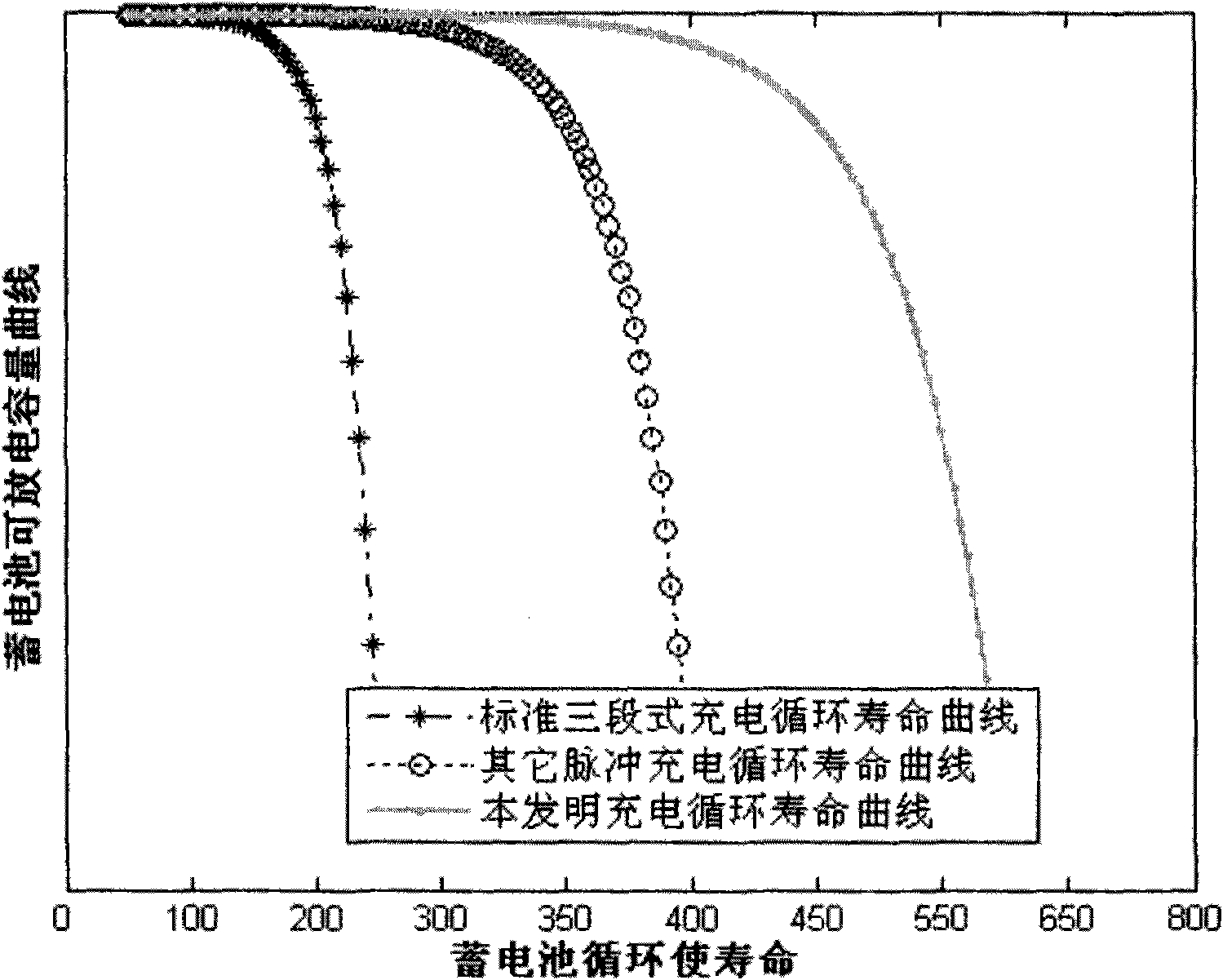

Grey system prediction theory-based nondestructive fast charging method for lead-acid battery

InactiveCN102097665ALow outgassing rateInhibition of thermal runawaySecondary cells charging/dischargingCharge currentBattery charge

A grey system prediction theory-based nondestructive fast charging method for lead-acid battery belongs to the technical field of lead-acid battery charging. The method comprises the following steps of: sampling a lead-acid battery charging terminal voltage U(O) (K), a lead-acid battery charging current I (O) (K), and a lead-acid battery charging temperature T (O) (K) continuously and periodically during charge of the lead-acid battery; performing grey association analysis on the continuously sampled data of the lead-acid battery charging terminal voltage U(O) (K), the lead-acid battery charging current I (O) (K), and the lead-acid battery charging temperature T (O) (K) by taking the charging current I (O) (K) as a reference sequence of grey association analysis, and ensuring that the association degree of the lead-acid battery charging terminal voltage U(O) (K), the lead-acid battery charging temperature T (O) (K), and the lead-acid battery charging current I (O) (K) meets modeling requirements. The data output by a sensor is used for periodical and continuous sampling, a grey dynamic prediction model is established according to a continuously sampled value, and pre-correction for each charging parameter is performed by the model prediction value, so dynamic real-time performance, safety and reliability of the battery charge are guaranteed, a charging speed is improved, and the thermal runaway and the undercharge are prevented simultaneously.

Owner:安徽翰邦科技咨询有限公司

Liquid helium heat sink support structure for reducing experimental cost

InactiveCN101592554ALow outgassing rateIncrease the effective test spaceEngine testingEngineeringHeat sink

The invention relates to a liquid helium heat sink support structure used for spatial environment simulation equipment, which consists of a liquid nitrogen heat sink and a framework thereof, a liquid helium heat sink, and a polyfluortetraethylene pad, wherein the liquid helium heat sink is directly arranged on the liquid nitrogen heat sink through the polyfluortetraethylene pad. The structure can make the heat sink reduce a set of framework so as to increase the effective experimental space in a vacuum container, reduce the outgassing rate of a material in the vacuum container, and improve the static vacuum degree in the vacuum container; and the required material is reduced, and the liquid helium required to be consumed for precooling the liquid helium heat sink is also reduced, so that the experimental cost is reduced.

Owner:BEIHANG UNIV

Method for preparing fluorophlogopite compound titanium dioxide

ActiveCN102093759AImprove product qualityHigh whitenessInorganic pigment treatmentTitanium dioxideFiltrationTitanium metal

The invention discloses a method for preparing fluorophlogopite compound titanium dioxide. The method comprises the steps of: soaking fluorophlogopite powder in water to obtain mixed solution, adding oxalic acid to adjust the pH value to be between 2 and 3, and then adding a nonionic surfactant; then adding titanium tetrachloride and stirring, and stopping adding and preserving heat for a period of time when the hue of the mixed solution turns blue, wherein titanium metal can be cladded on the surface of fluorophlogopite through the process; and then performing filtration treatment to obtain primary raw materials of the fluorophlogopite compound titanium dioxide, and then performing drying and calcination treatment to finally obtain a finished product of the fluorophlogopite compound titanium dioxide. The fluorophlogopite compound titanium dioxide prepared by the method can be used for coatings, and the coatings have high whiteness (can reach over 99.8), bright and clean surfaces as well as good high temperature resistance and weather resistance, and can never change color and fade. The fluorophlogopite compound titanium dioxide also has the characteristics of good electrical insulating property, antistatic performance, acid and alkali corrosion resistance, strong coloring power and the like, and is simple in processing technology and low in cost.

Owner:JIANGYIN YOUJIA PEARLESCENT MICA

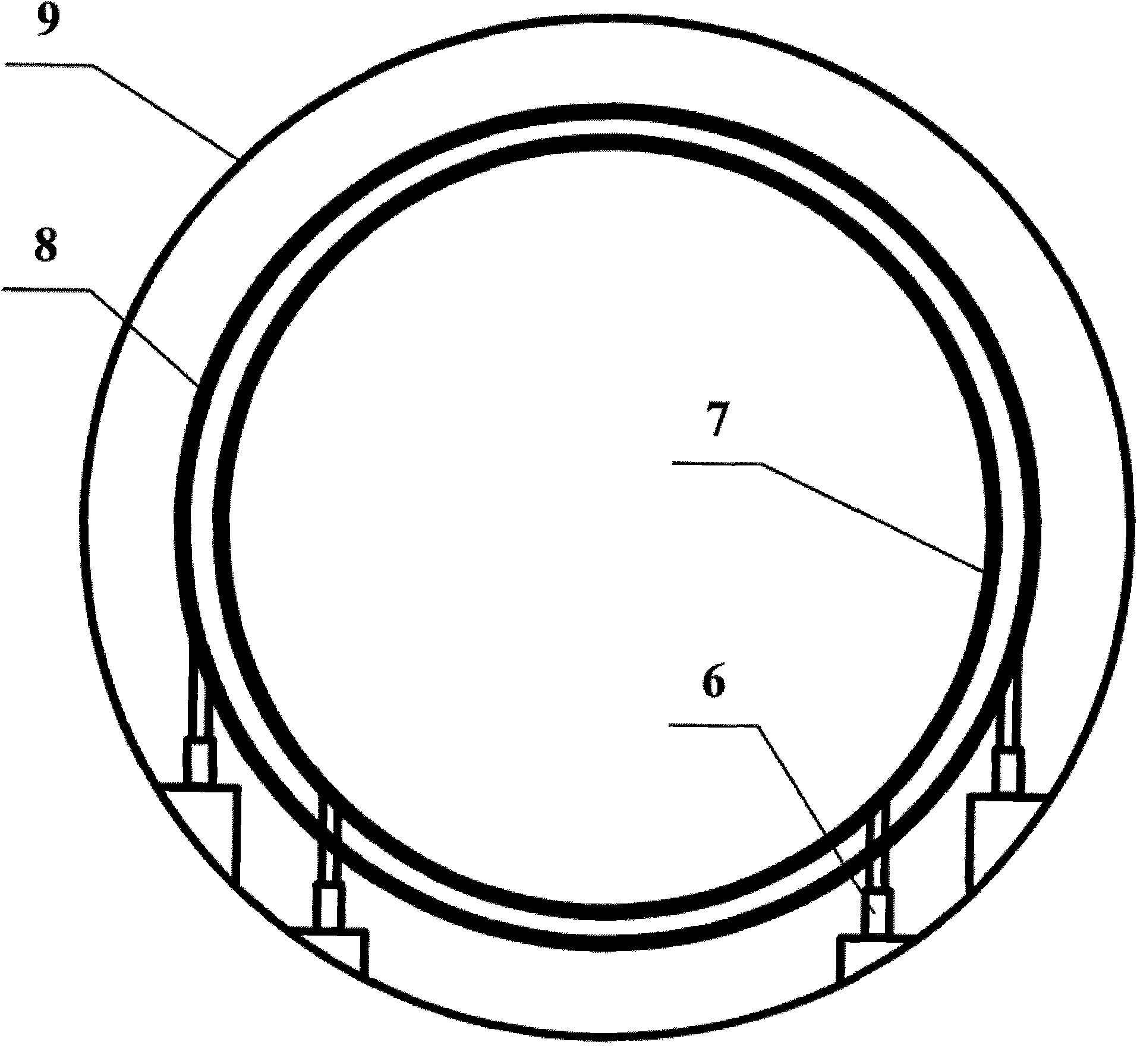

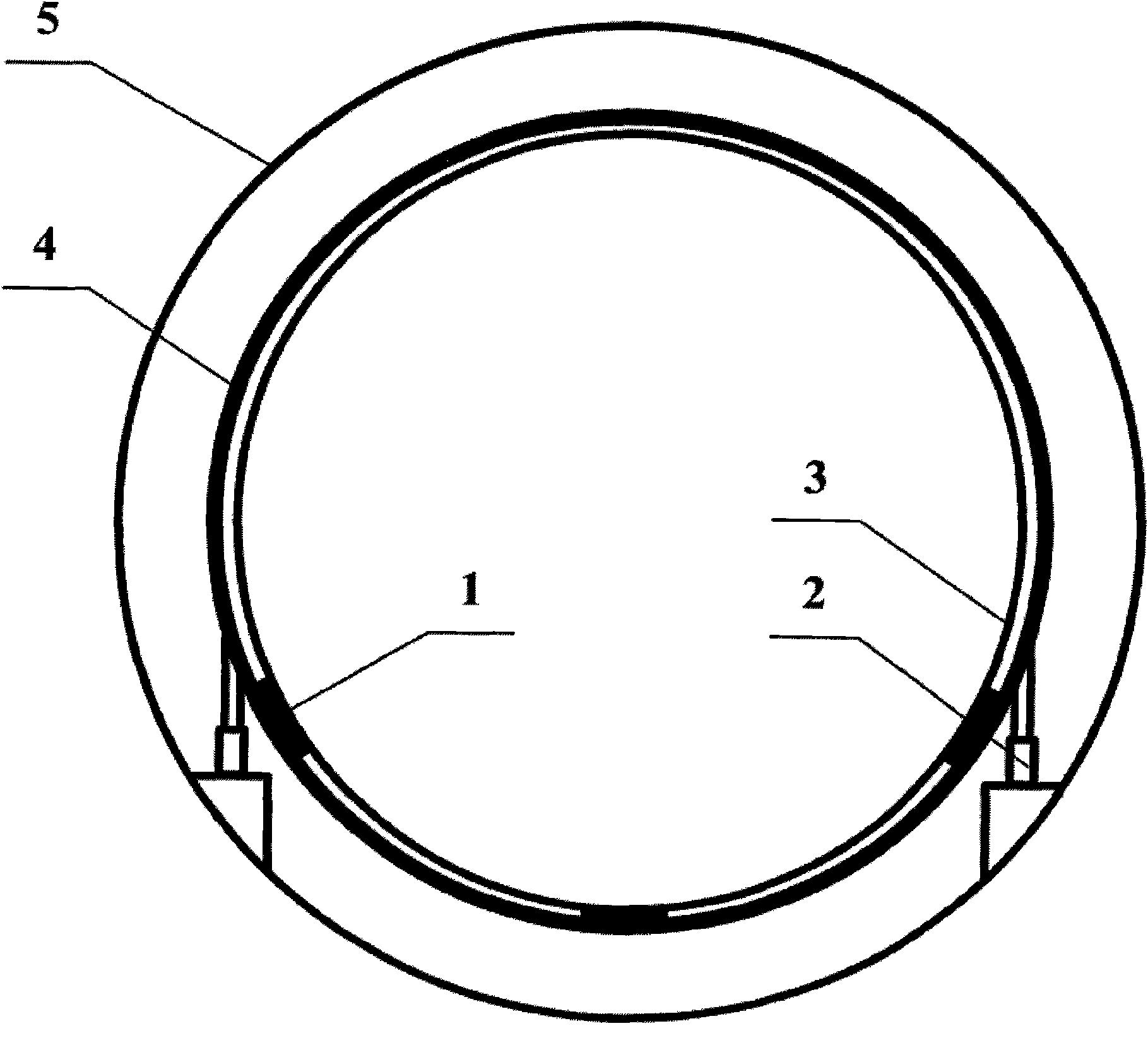

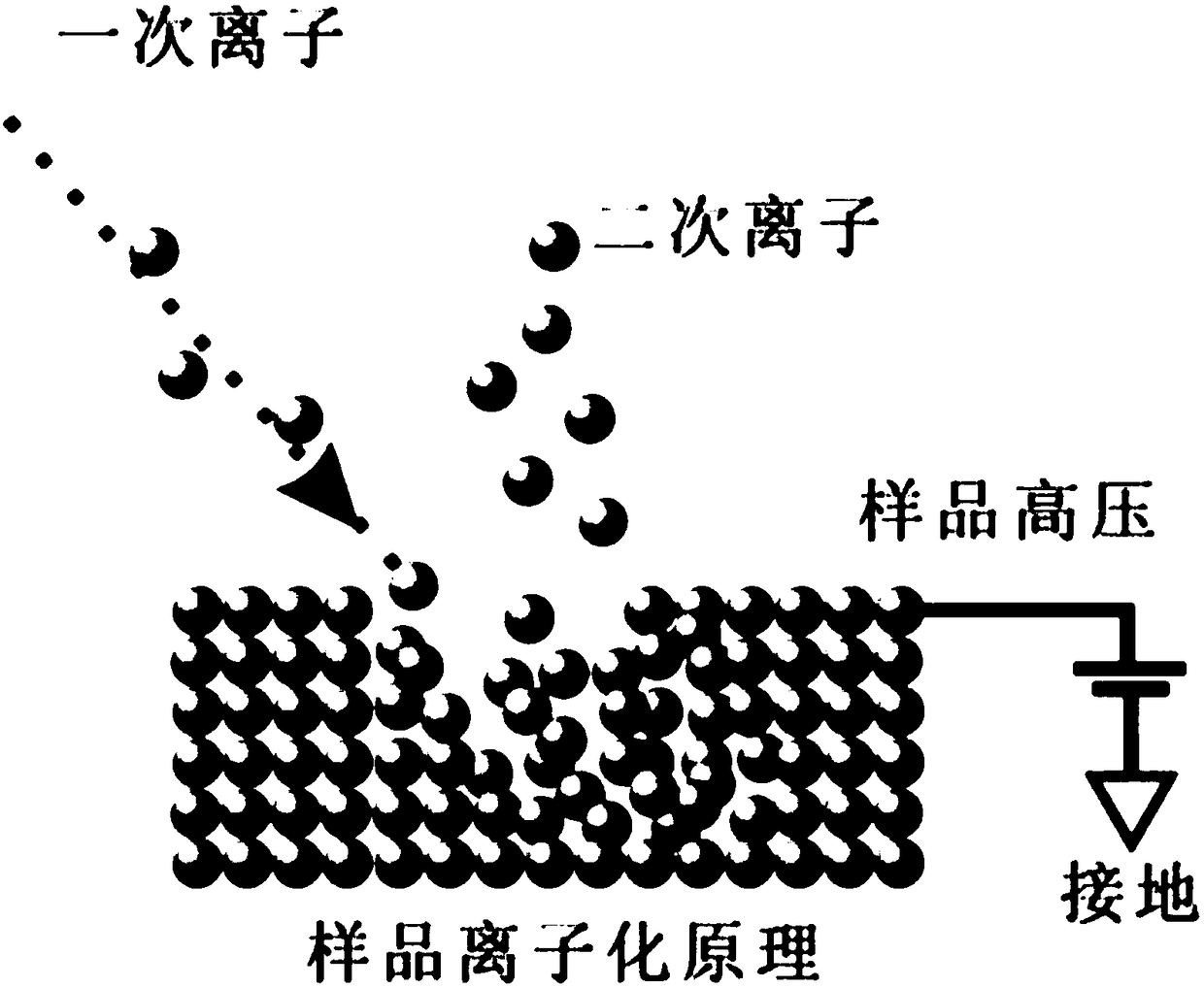

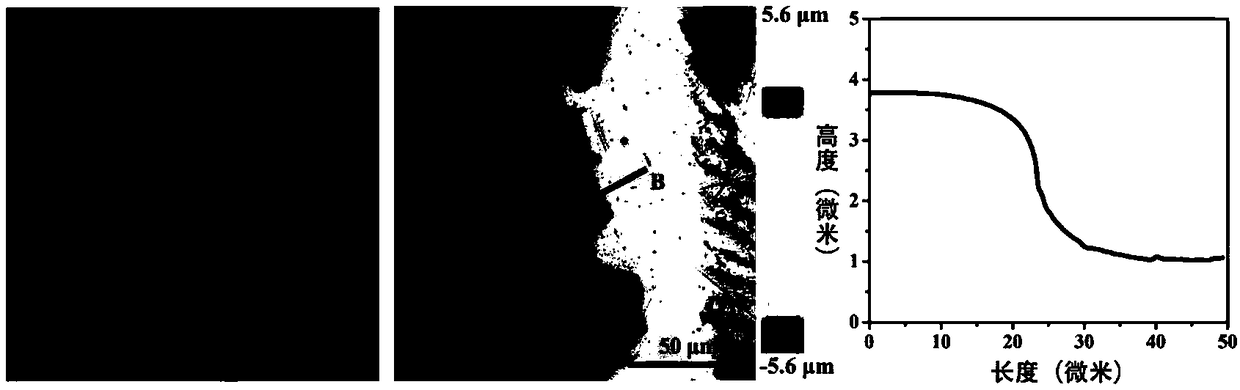

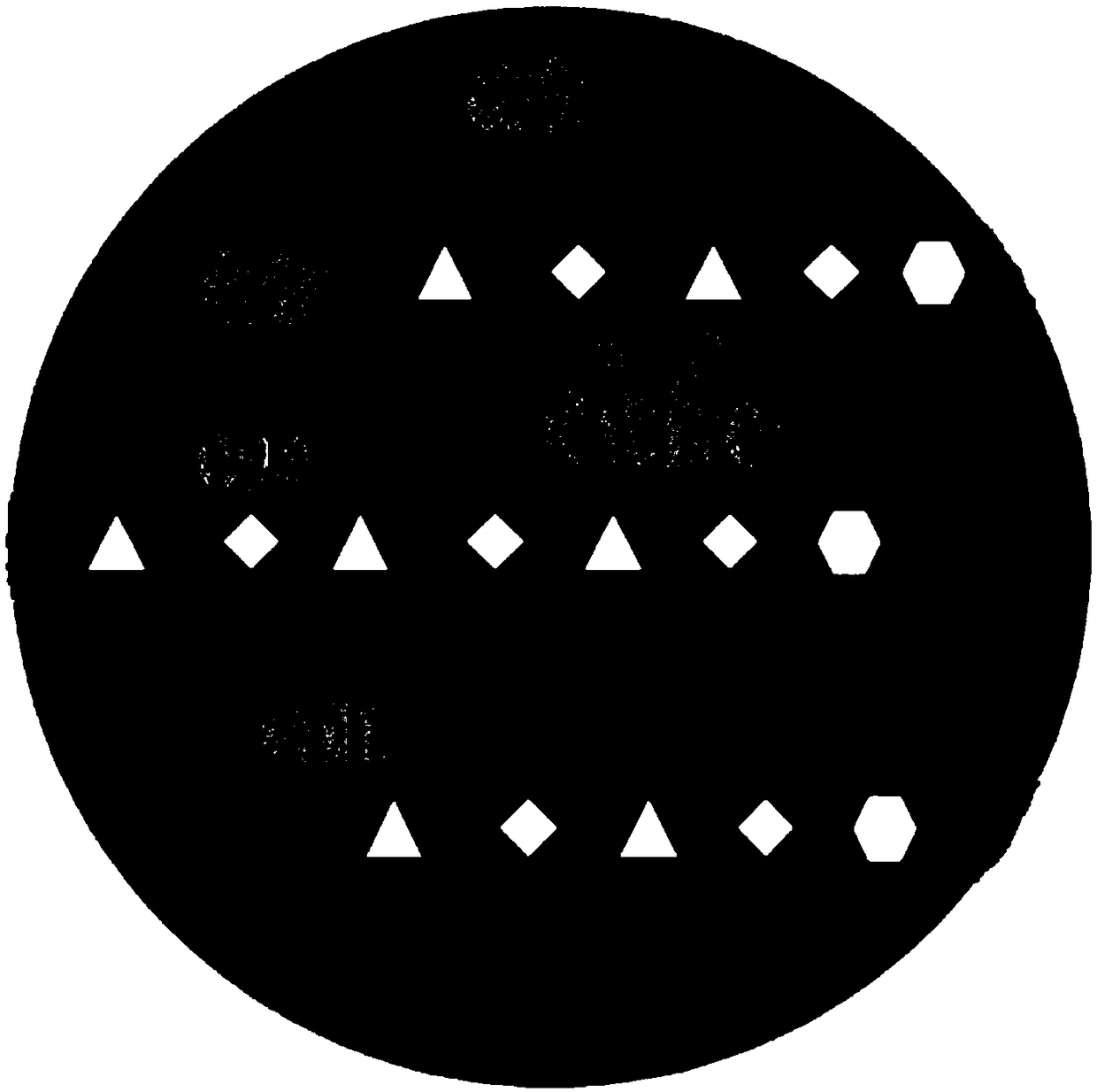

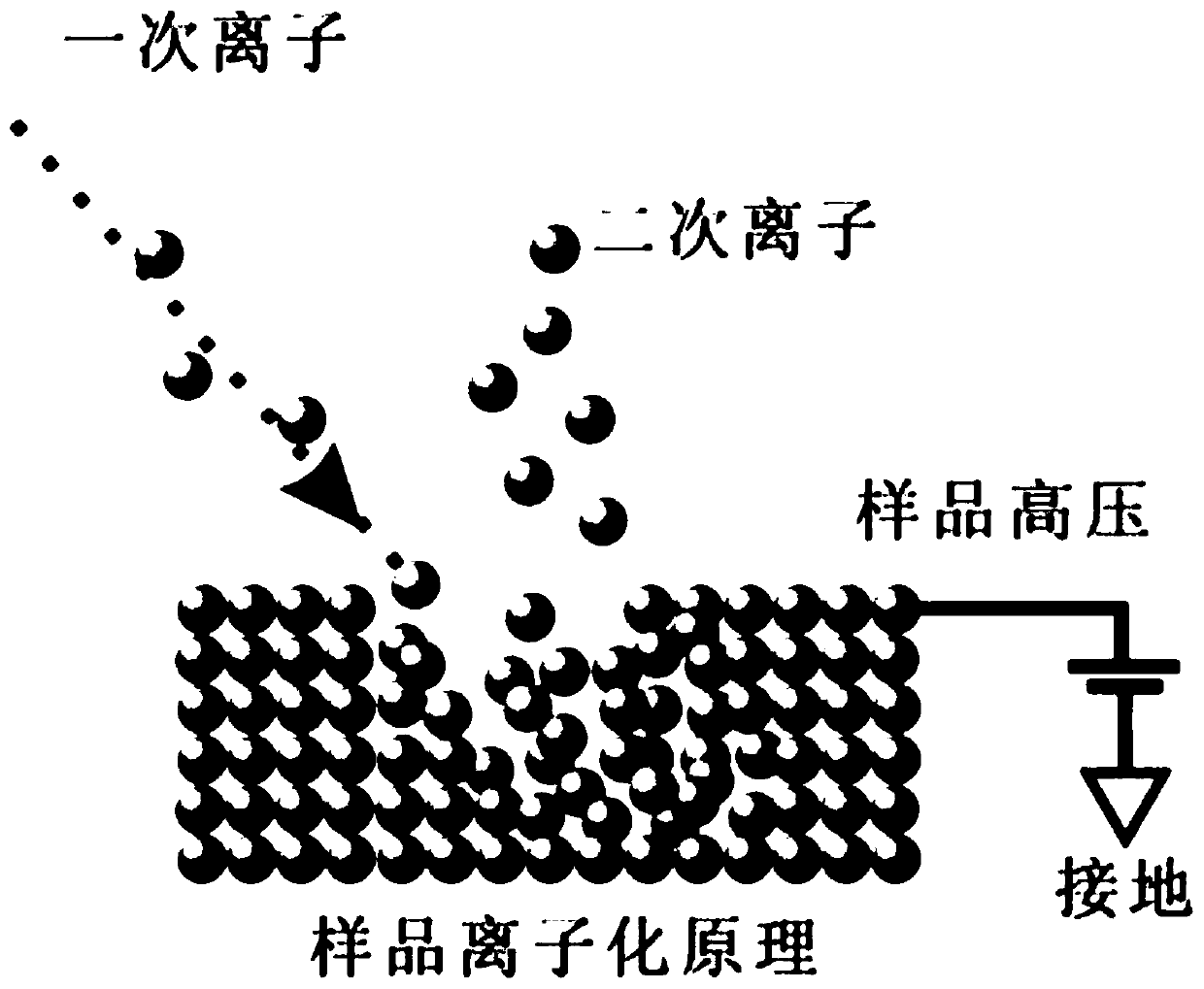

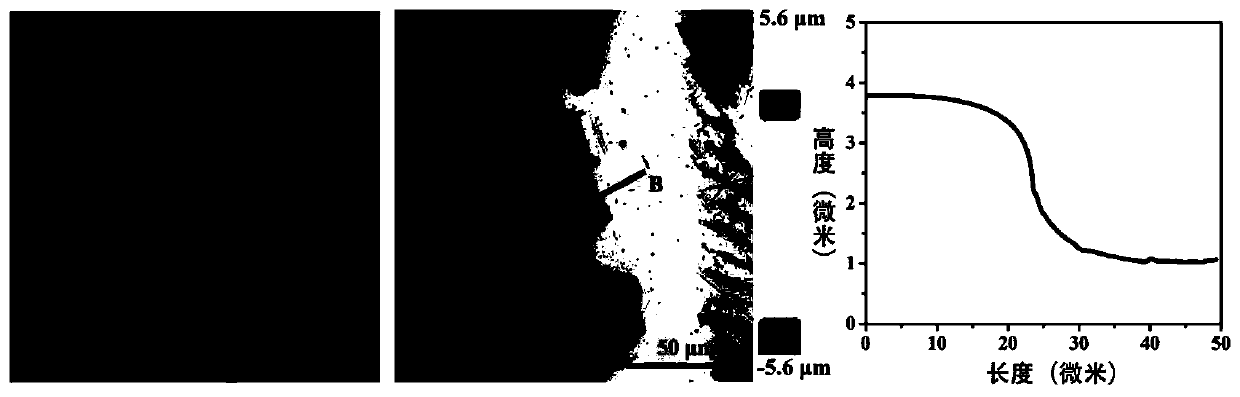

Preparation method of secondary ion probe sample target

InactiveCN108375497ALow outgassing rateIncrease vacuumPreparing sample for investigationMaterial analysis by electric/magnetic meansEpoxyGlass chip

The invention belongs to the field of analysis and test of secondary ion probes, and particularly relates to a preparation method of a secondary ion probe sample target, for improving flatness of sample grains and reducing outgassing rate of the sample target. The sample target mainly comprises a glass sheet, epoxy resin and sample grains. The preparation method, based on a main body, namely a circular glass sheet, includes the steps of firstly, cutting to form a plurality of grooves on the glass sheet, placing the sample grains in the grooves, injecting the epoxy resin into the grooves to cure, and carrying out fine grinding and polishing on the sample target after finishing curing. The preparation method has the advantages that the outgassing rate of the sample target is low due to the fact that the epoxy resin is placed in the grooves of the glass sheet only, and accordingly vacuum keeping of a sample chamber is facilitated; since glass and mineral grains(such as zircon and apatite)have the similar hardness, the mineral grains, the epoxy resin and the glass sheet are kept at the same plane effectively during the polishing, and further flatness of edges of the mineral grains areimproved.

Owner:INST OF GEOLOGY & GEOPHYSICS CHINESE ACAD OF SCI

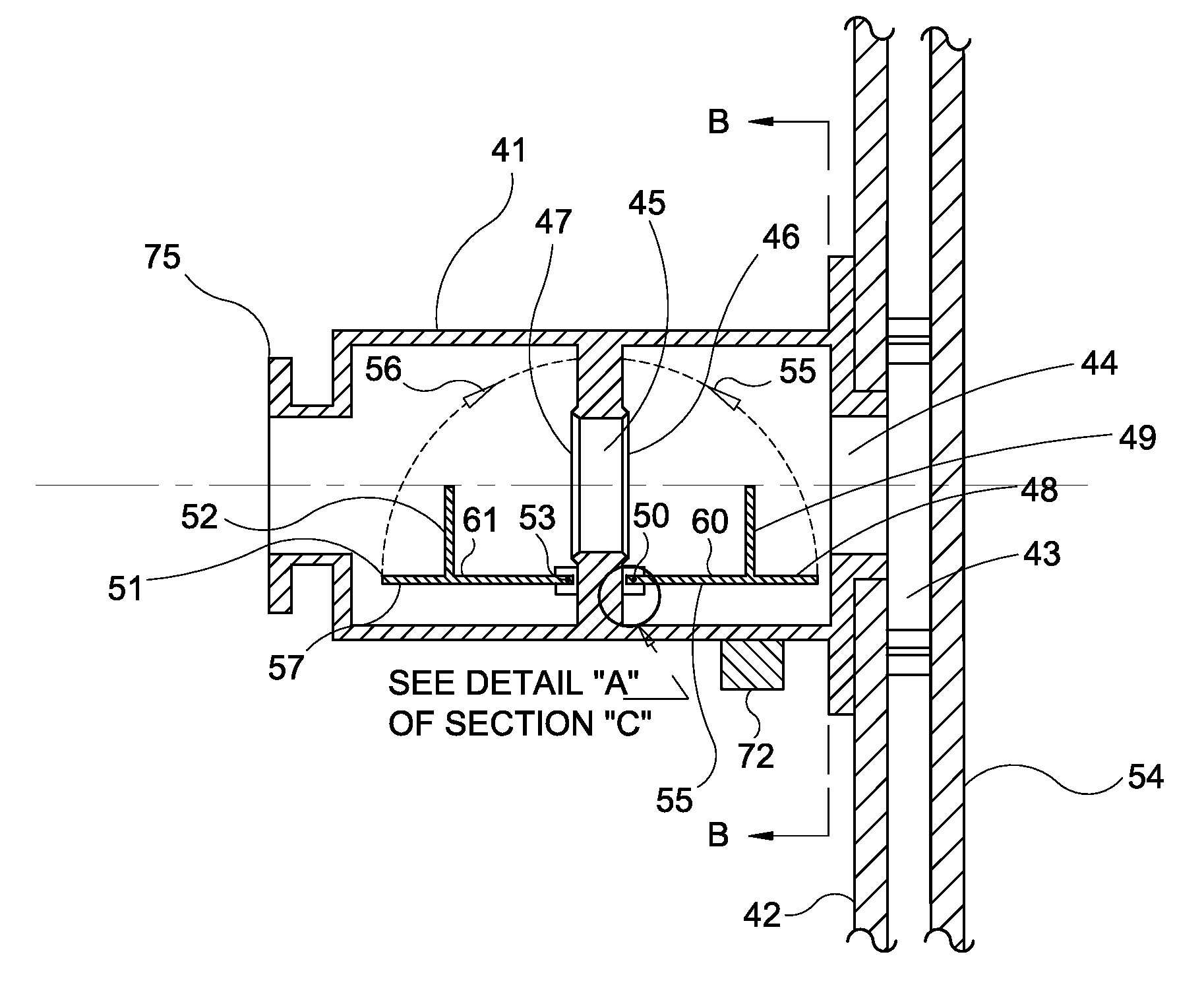

Accelerated outgassing via vacuum/heat process

InactiveUS8268241B1Low outgassing rateReduce eliminateBiocideDrying solid materials without heatProcess engineeringAtmospheric pressure

A process wherein outgassing rates of volatile organic compounds (VOCs) in an object, particularly habitable vehicles, are accelerated by placing the subject object in a vacuum chamber and placing heat sources either inside the object being treated, outside the object, or both. The process includes measuring and monitoring the temperature of selected surfaces inside the object being treated. The heat sources are adjusted to maintain a temperature which is safe for the materials and which will promote maximum outgassing rates. During the treatment process, while a vacuum and heat are being applied to the subject object, the gasses in the chamber are monitored for both their composition and quantity. When the outgassing rates of the VOCs reach acceptable levels, the process cycle is terminated. The vacuum in the chamber is broken to restore atmospheric pressure, and the object being treated is removed from the chamber.

Owner:COOPER HENRY W

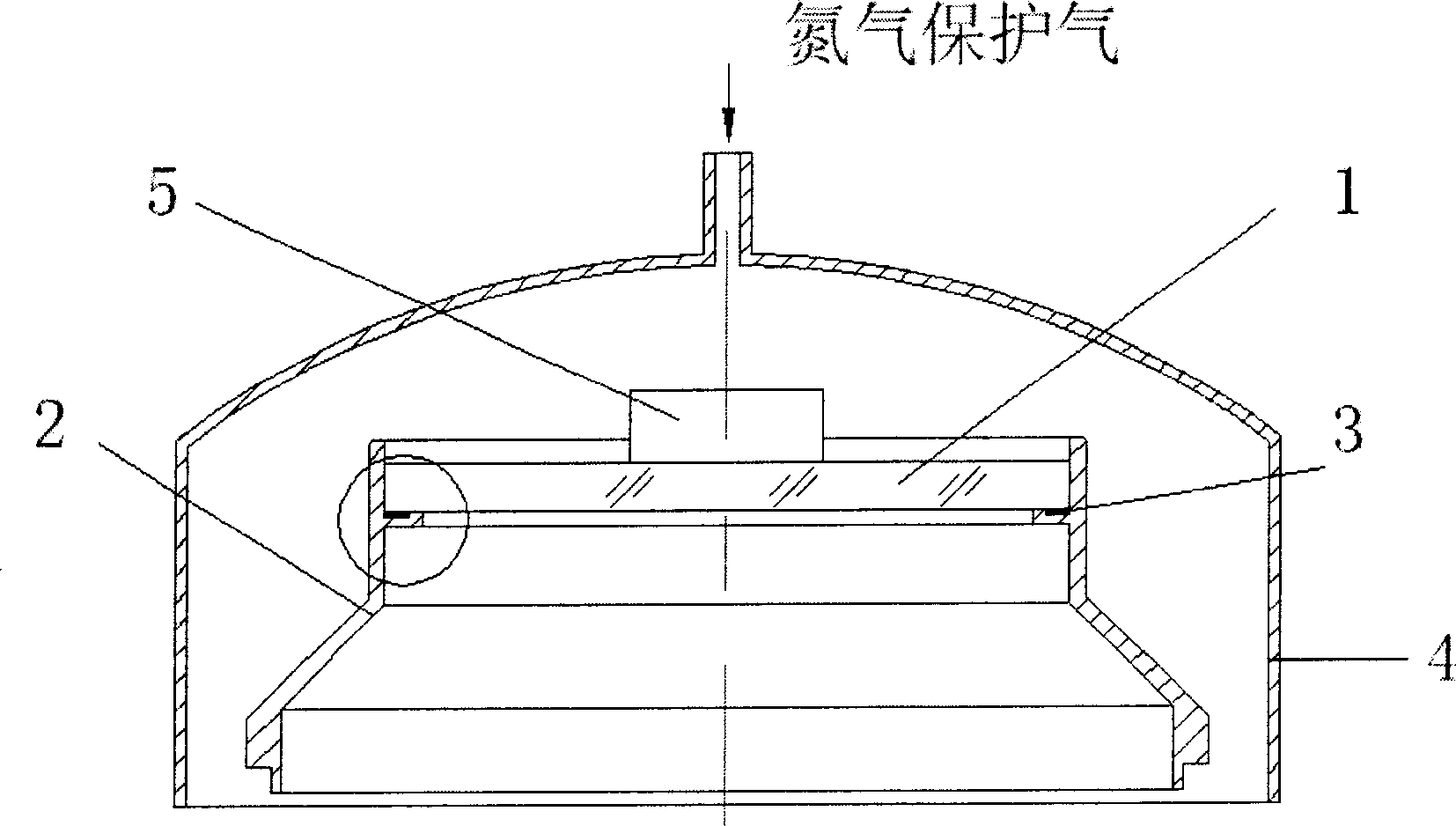

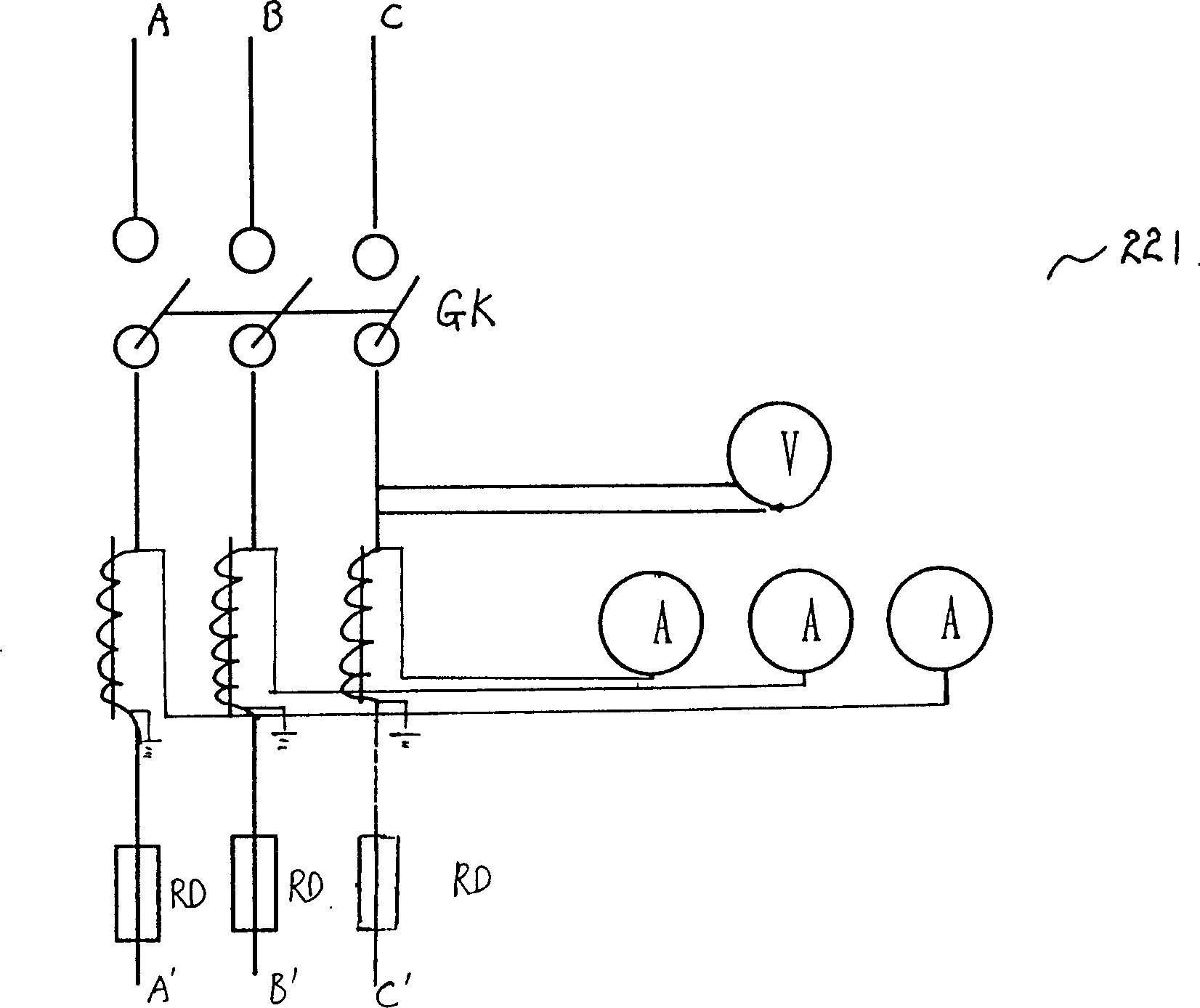

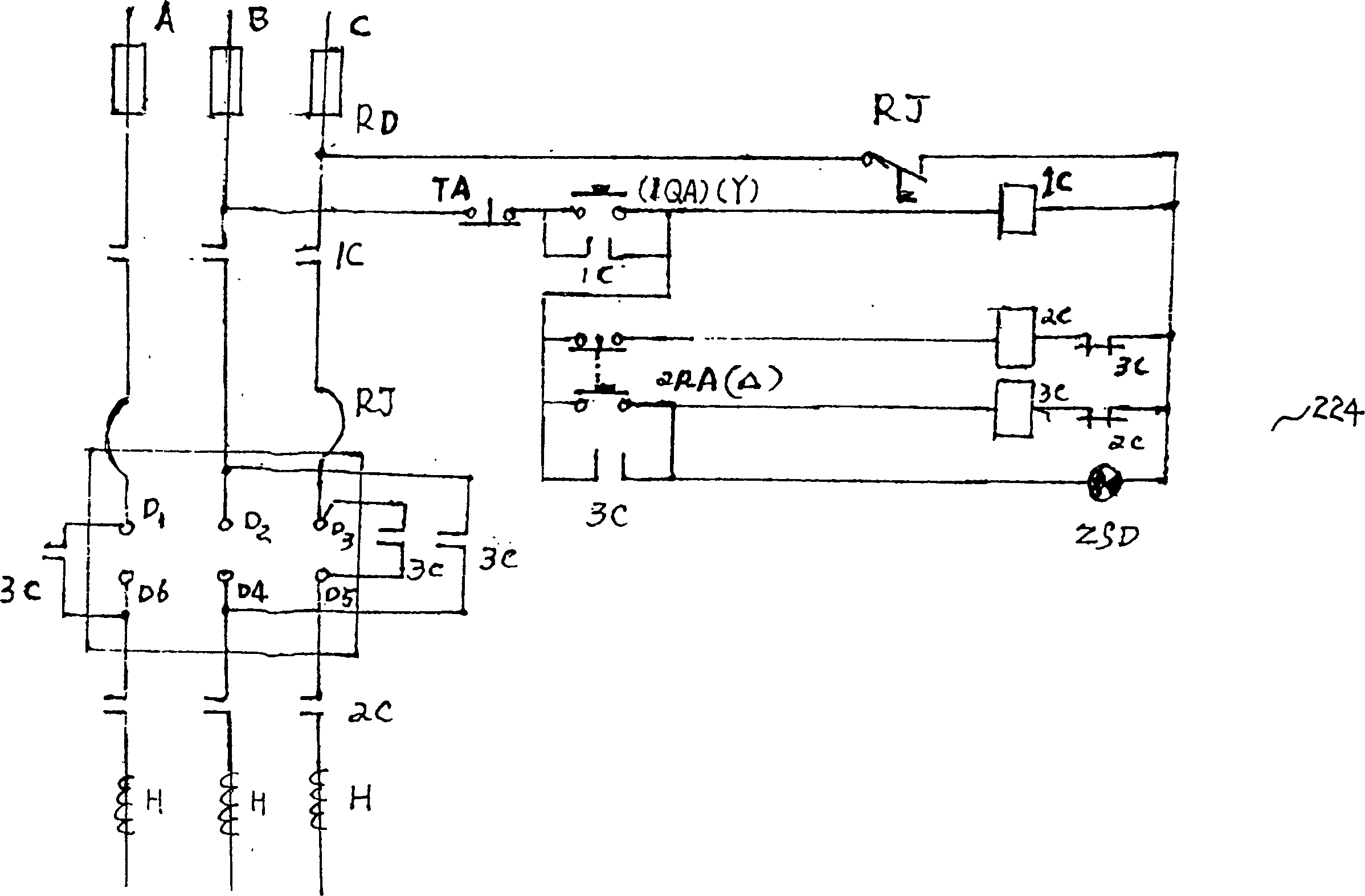

Preparing method and apparatus of artificial crystal synthetic mica

InactiveCN1253372CStrong light transmissionEasy to peelElectric discharge heatingAluminium silicatesEngineeringImpurity

The invention discloses a preparation method and device for artificial crystal synthetic mica. The method and device provided by the invention provide reliable guarantee for obtaining high-quality synthetic mica. In addition to being used as synthetic mica, each component in the raw material for preparing synthetic mica provided by the invention also has the function of removing impurities in the raw material, which lays a good foundation for forming synthetic mica and obtains high-quality synthetic mica.

Owner:辽宁中科晶体产业有限公司

High-strength ultrathin heat-insulation paper, preparation method and application thereof

InactiveCN103866602AReduce thicknessIncreasing the thicknessSynthetic cellulose/non-cellulose material pulp/paperRaw material divisionGlass fiberFiber

The invention discloses high-strength ultrathin heat-insulation paper, a preparation method and application thereof. The low-temperature heat-insulation paper is prepared by mixing micro glass wool and alkali-free short cut fiber according to a ratio of 100:2-3. The preparation method of the high-strength ultrathin heat-insulation paper comprises: mixing micro glass wool and alkali-free short cut fiber according to a ratio of 100:2-3, and then performing defibering, pulp preparing, pulp storage, slag removing, pulp supply, beater-addition, dewatering, negative-pressure drying and rolling. The finished product has the thickness of 0.04-0.06 mm and the gram weight of 9-10 m<2>, and is relatively high in tensile strength. Also the finished product is good in heat insulation performance, small in outgassing rate in vacuum, relatively reliable in performances and relatively environment-friendly, is applicable to deep-cold liquid storage and transportation containers, low-temperature pressure containers, and vacuum multi-layer heat-insulation structures of matched pipelines, and is relatively wide in application.

Owner:CHANGZHOU JUNENG COMPOUND NEW MATERIAL

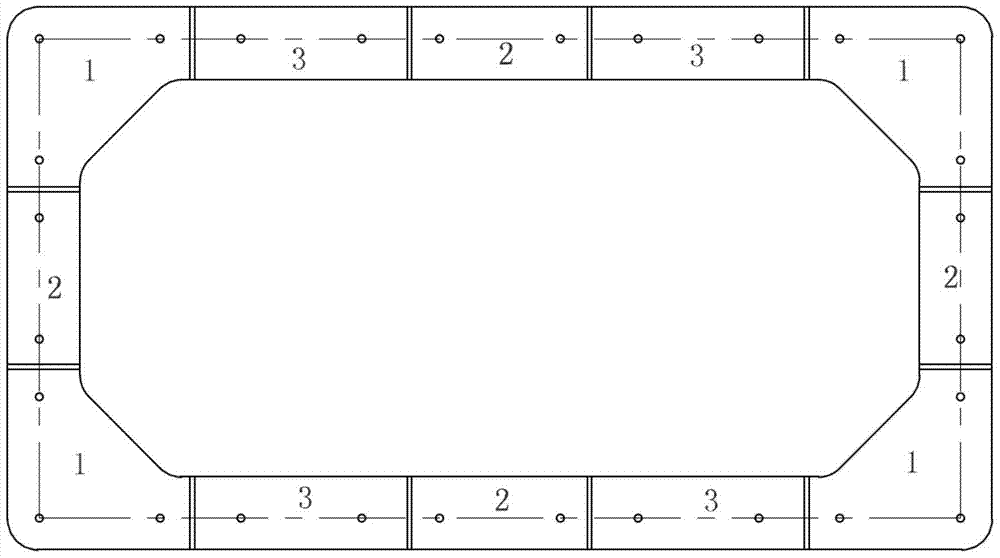

Ceramic shielding structure between ion source discharge chamber and accelerator

ActiveCN106935471ARealize insulation shieldingLow outgassing rateShielding materialsElectric discharge tubesMaterials scienceIon source

The invention belongs to the technical field of insulation and shielding between a high-power long-pulse ion source discharge chamber and an accelerator, and particularly relates to a ceramic shielding structure between an ion source discharge chamber and an accelerator. The ceramic shielding structure is applied between the high-power long-pulse ion source discharge chamber and the accelerator in a Tokamak device. the ceramic shielding structure is designed in the following aspects: according to space geometric sizes of the neutral beam ion source discharge chamber and the accelerator, a distribution area with the ceramic insulation and shielding structure arranged is determined; multiple ceramic sheets are adopted for crimping, a ceramic screw and a ceramic nut are used for fixing each ceramic sheet on the discharge chamber, and a ceramic shielding structure is formed; the complete ceramic shielding structure altogether comprises ceramic sheets with three sizes, and the number of ceramic sheets with each size is four; and the thickness of each ceramic sheet is 3 mm. By adopting the above scheme of the invention, while insulation and shielding between the ion source discharge chamber and the accelerator can be realized, the processing difficulty is reduced, and the processing cost is reduced.

Owner:SOUTHWESTERN INST OF PHYSICS

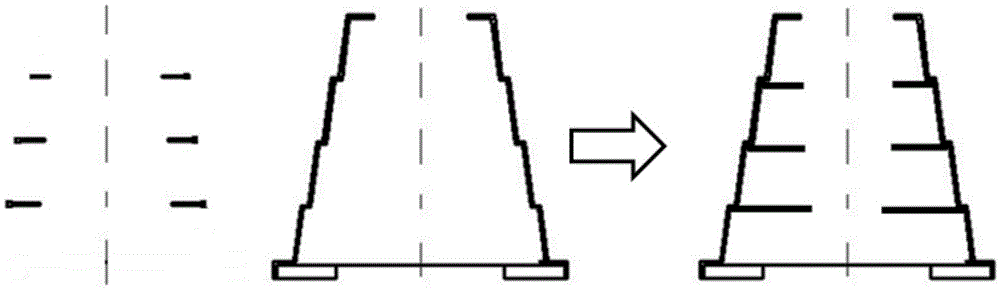

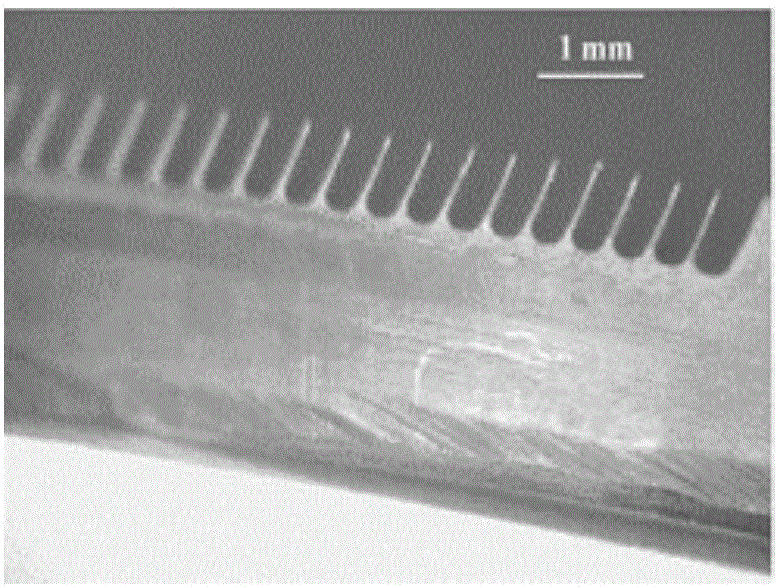

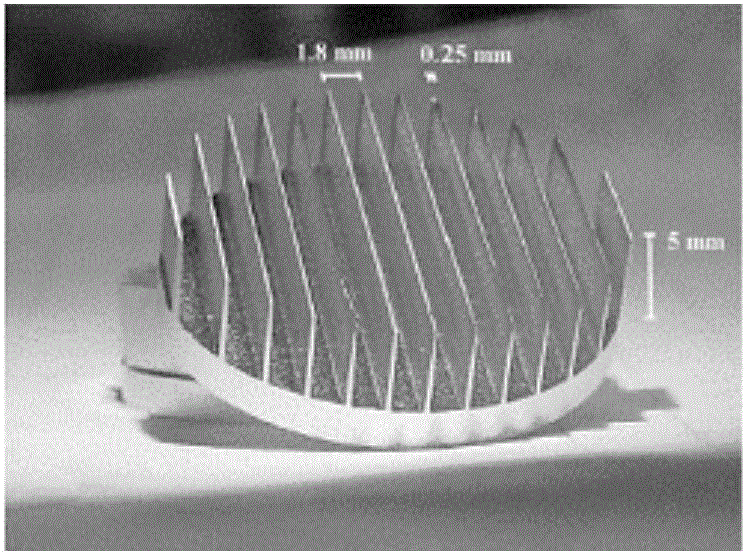

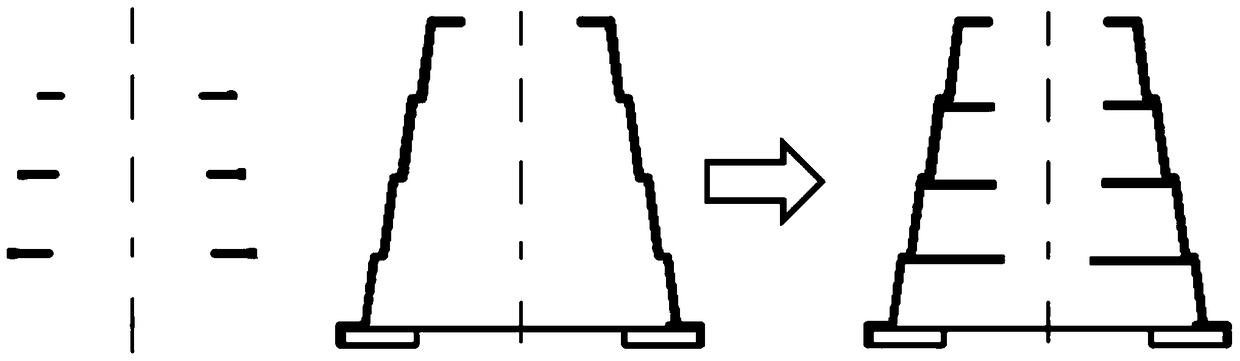

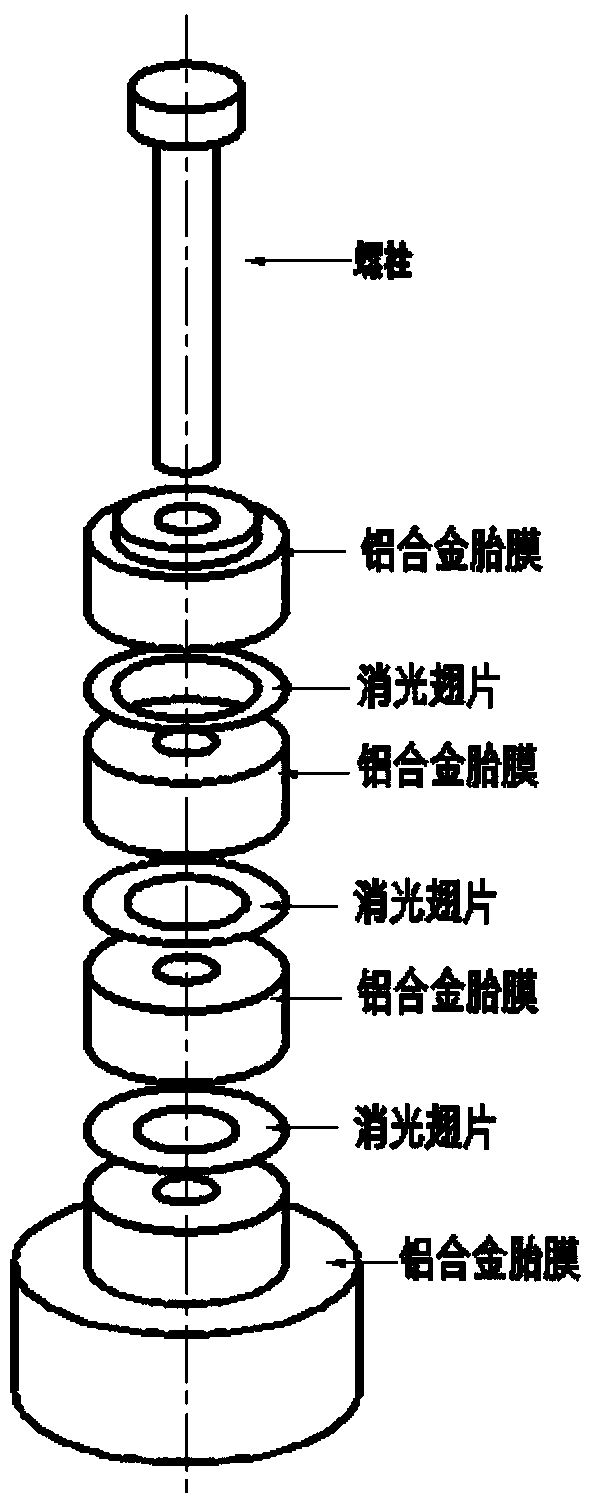

Molding method of integrated cold shield for infrared detector

ActiveCN105486411AMaintain vacuum for long lifeGood for maintaining vacuum and long lifeRadiation pyrometryCold shieldSecondary bonding

The invention discloses a molding method of an integrated cold shield for an infrared detector. Extinction fins of the cold shield are directly electro-casted with a cold shield body, secondary bonding is avoided, glue for packaging is effectively controlled, the vacuum service life of the detector can be maintained for long time; and design of the cold shield body is simplified, bonded fitting and positioning surfaces are not embodied in the cold shield body, the total weight of the cold shield is decreased, power requirement for a refrigerator is lowered, and work of the cold shield is higher.

Owner:11TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

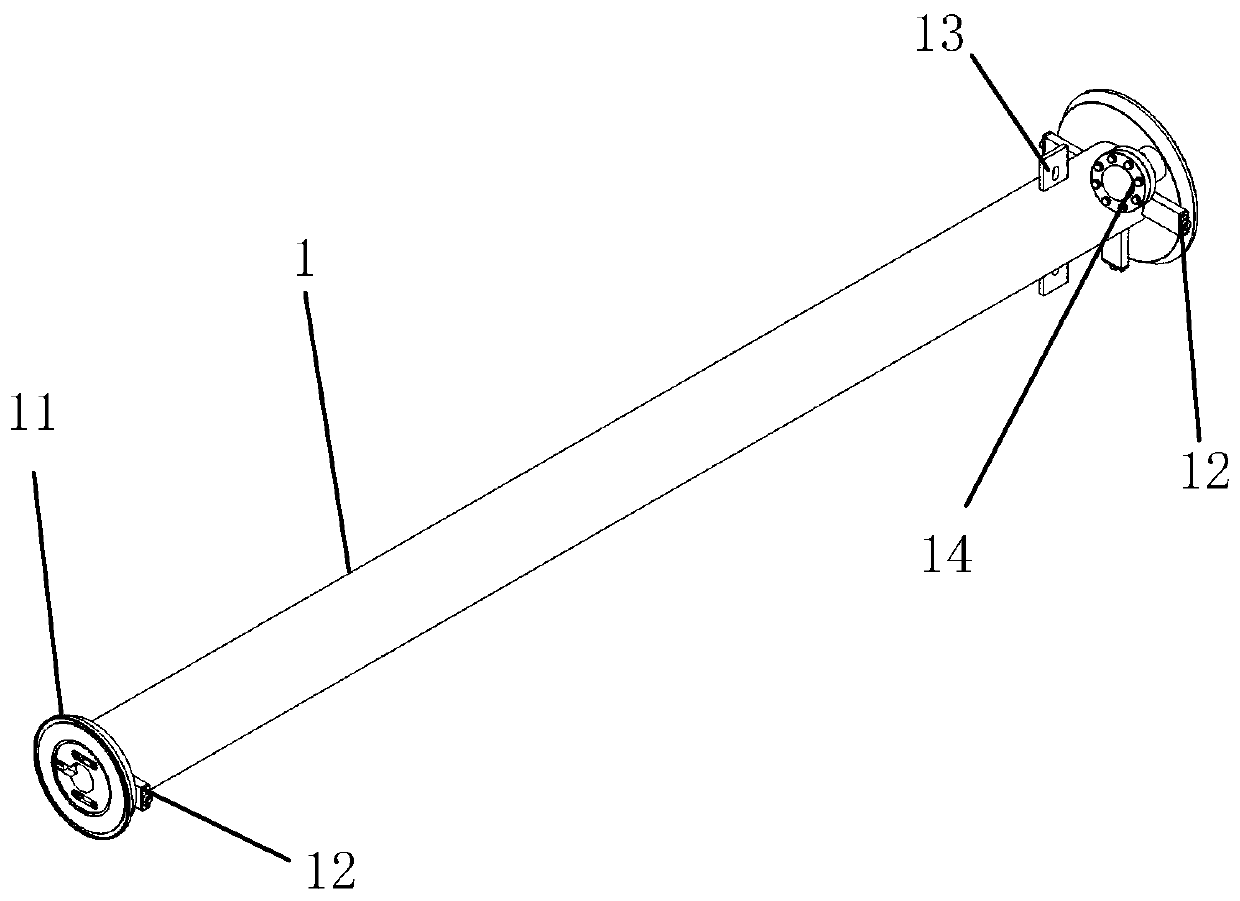

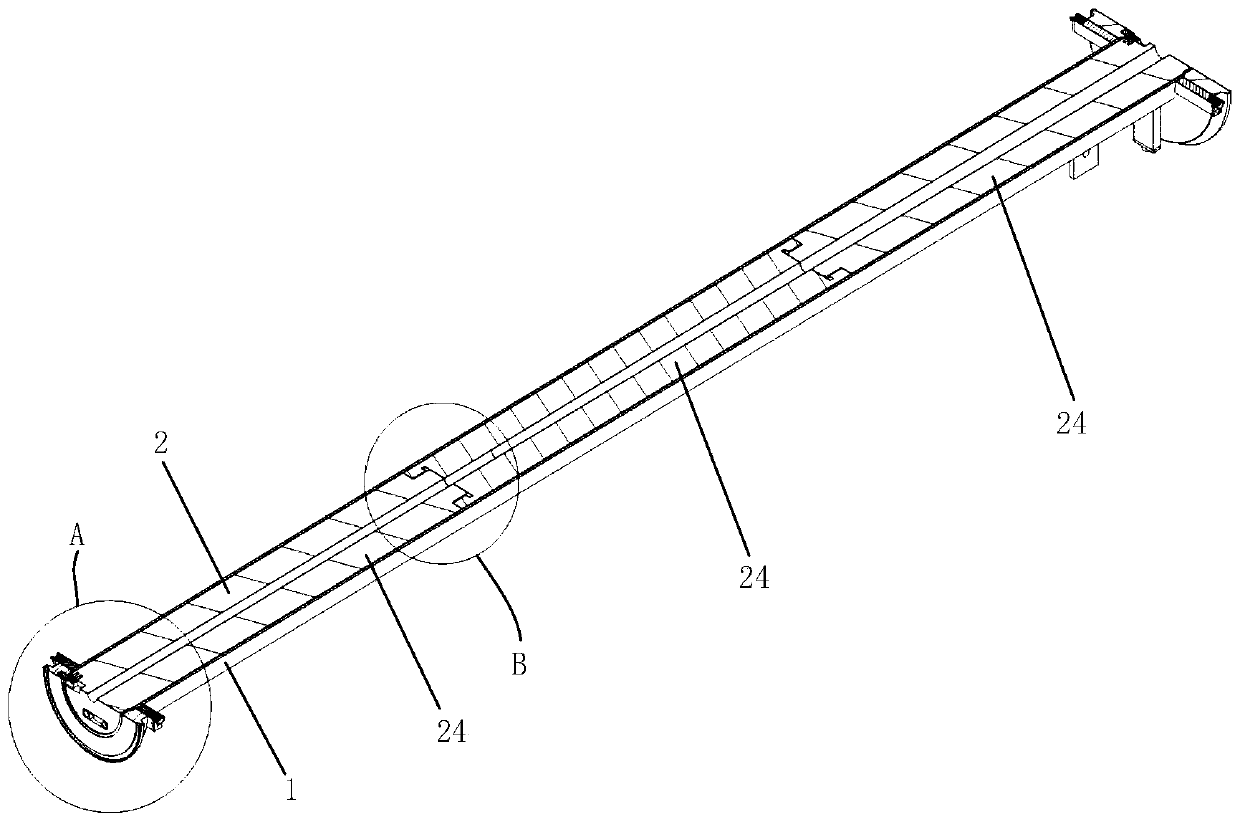

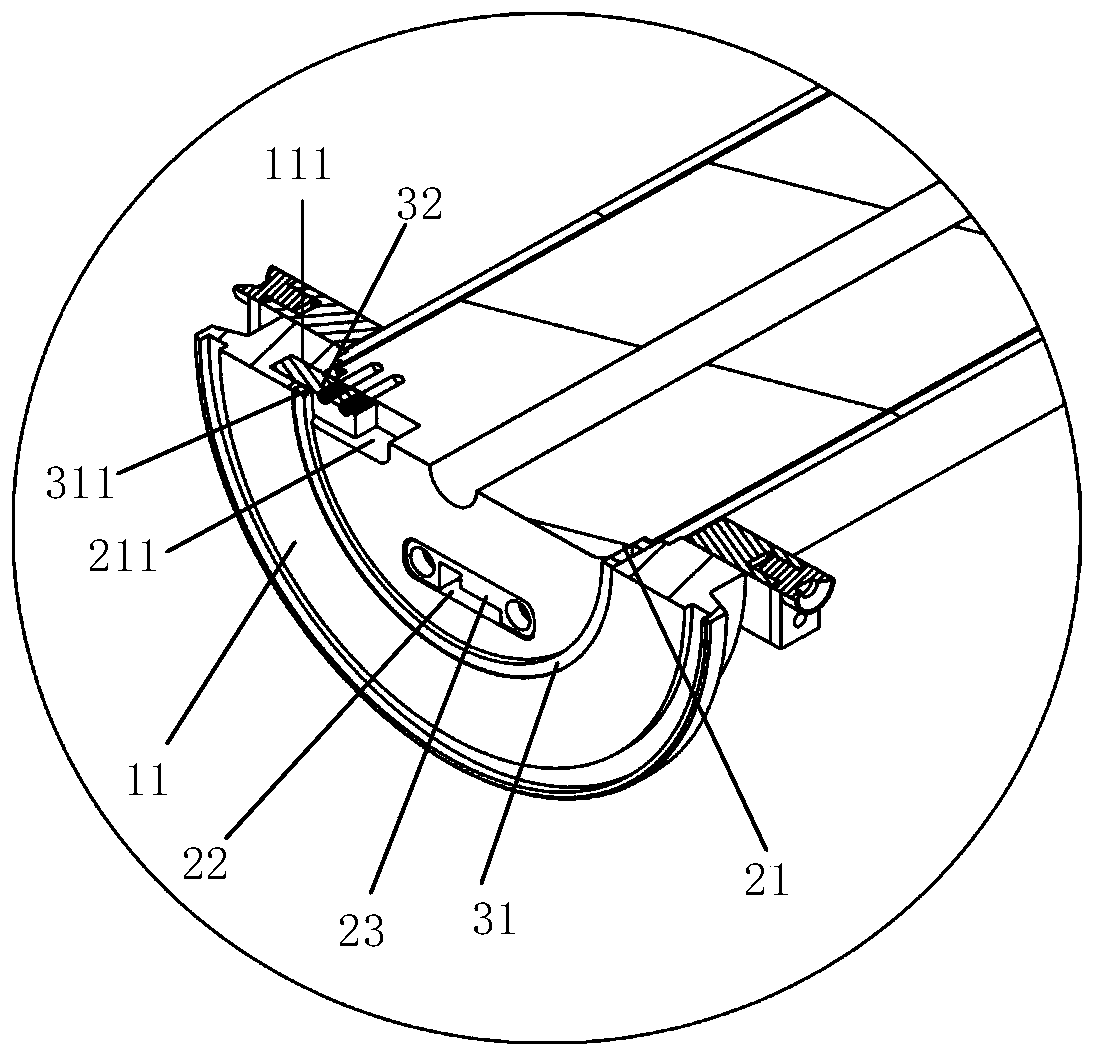

Neutron shielding pipeline used in high vacuum environment

PendingCN110767343AShielding effectLow outgassing rateNeutron sourcesNuclear radiationNuclear engineering

The invention discloses a neutron shielding pipeline used in a high vacuum environment. The neutron shielding pipeline comprises an inner pipe made of a shielding material and an outer pipe arranged on the outer wall of the inner pipe in a sleeving mode, wherein the outer diameter of the inner pipe is basically the same as the inner diameter of the outer pipe, and the extending direction and the extending length of the inner pipe are consistent with the extending direction and the extending length of the outer pipe respectively; the outer pipe is used for providing the vacuum environment for the inner pipe, and the inner wall of the inner pipe encloses a channel for conveying neutrons; the inner wall, the outer wall and the end face of the inner pipe are uniformly coated with coating layers with preset thicknesses respectively, and the coating layers are used for reducing the gas efficiency of the inner pipe. The inner pipe made of the shielding material not only can effectively shieldthe influence of nuclear radiation, but also can reduce the gas efficiency of the inner pipe under the action of the coating layers, has no influence on the vacuum environment, and can be used in thehigh vacuum environment.

Owner:CHINA SPALLATION NEUTRON SOURCE SCI CENT +1

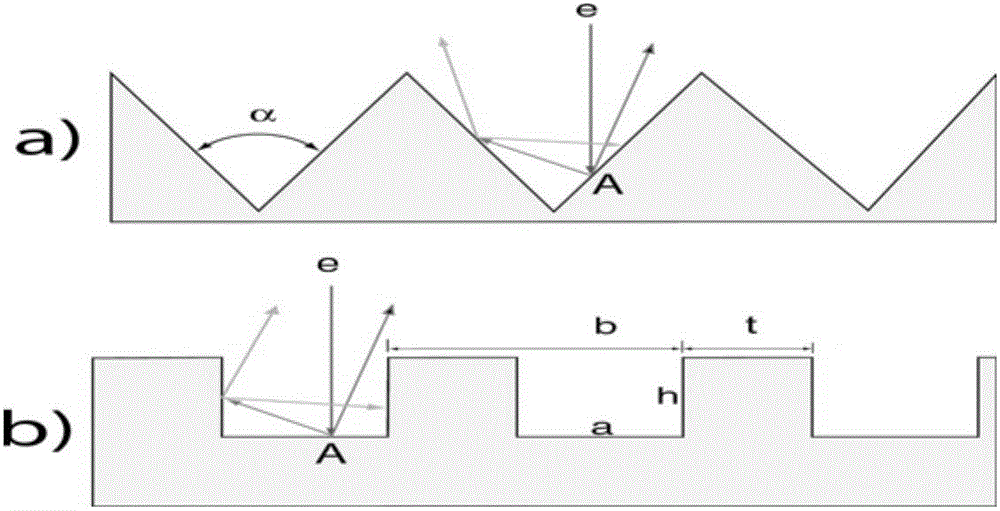

Rasterization dielectric lens with high power capacity

InactiveCN106450593AImprove thermal conductivityImprove conductivityWaveguide type devicesPower capabilityEmissivity

The invention relates to a rasterization dielectric lens used as a microwave output window in the technical field of high-power microwaves, in particular to a rasterization dielectric lens working with high power capacity. To overcome the defects that an existing high-power microwave transmitting antenna output window is prone to being punctured in medium output window-vacuum and medium output window-air interfaces, consequently, the transmission efficiency is not high enough, and the pulse is shortened, the rasterization dielectric lens high in power capacity, puncture threshold value and transmission efficiency and a manufacturing method of the rasterization dielectric lens are provided. The rasterization dielectric lens is composed of N metal grid bars and a medium output window. The N metal grid bars are periodically arranged in the medium output window at a certain interval p through a medium output window thickness direction penetrating manner. Due to the fact that the metal grid bars are adopted on the surface of the dielectric lens for partition, the secondary electron emissivity of the rasterization dielectric lens is smaller, the power capacity is greatly improved, the transmission efficiency is high, the phenomenon of pulse shortening is greatly reduced, and the rasterization dielectric lens can be applied to a high-power microwave output system.

Owner:NAT UNIV OF DEFENSE TECH

Fabrication process for molecular sieve bag

ActiveCN109896073AGuaranteed adsorption effectLow outgassing rateDispersed particle separationPackaging by pressurising/gasifyingMolecular sieveImpurity

The invention discloses a fabrication process for a molecular sieve bag. The fabrication process comprises the following steps of batching, molding, high sintering, vacuum activating, inner packagingand outer packaging. According to the molecular sieve bag fabricated adopting the fabrication process, a sealing bag will isolate air when the molecular sieve bag is not in use, a molecular sieve cannot absorb gases, and the adsorption property of the molecular sieve is guaranteed; the sealing bag needs to be torn and stripped when the molecular sieve bag is used, then the molecular sieve with a packaging bag is placed into an interlayer directly, when the sealing bag is torn, because of protection of the packaging bag, the molecular sieve will not be exposed to the air directly, so that the adsorption property of the molecular sieve is guaranteed; and meanwhile, because of the low air release rate and the high air permeability characteristics of the packaging bag, the excess gases will not be generated to destroy vacuum in use under the vacuum environment, and the effect of adsorbing impurity gases under the vacuum also will not be reduced because of isolation of the packaging bag.

Owner:张家港富瑞新能源科技有限公司

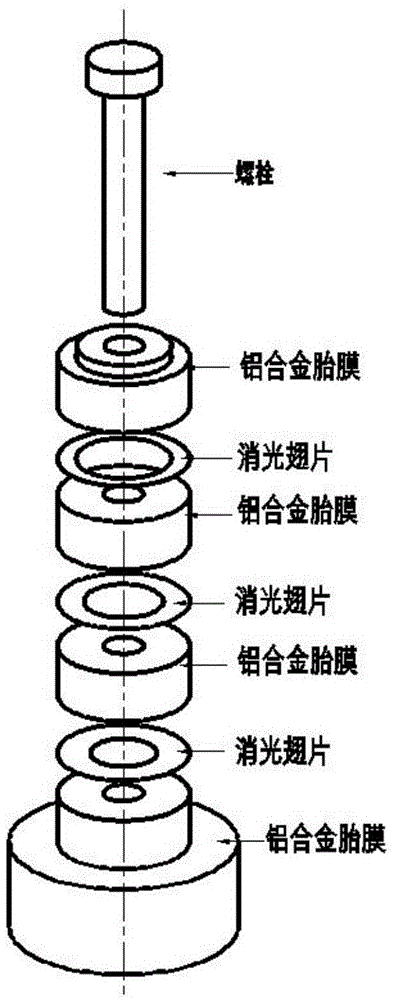

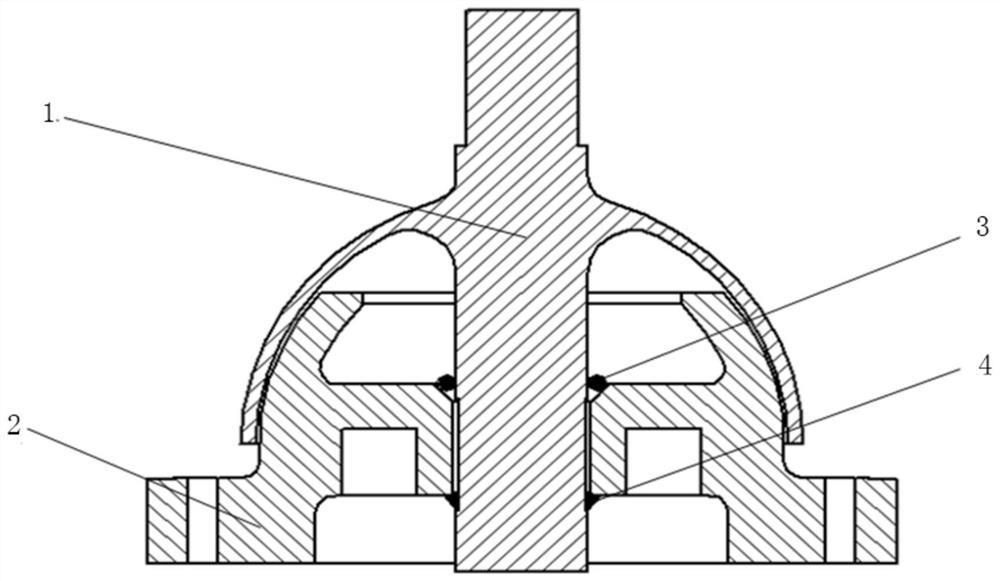

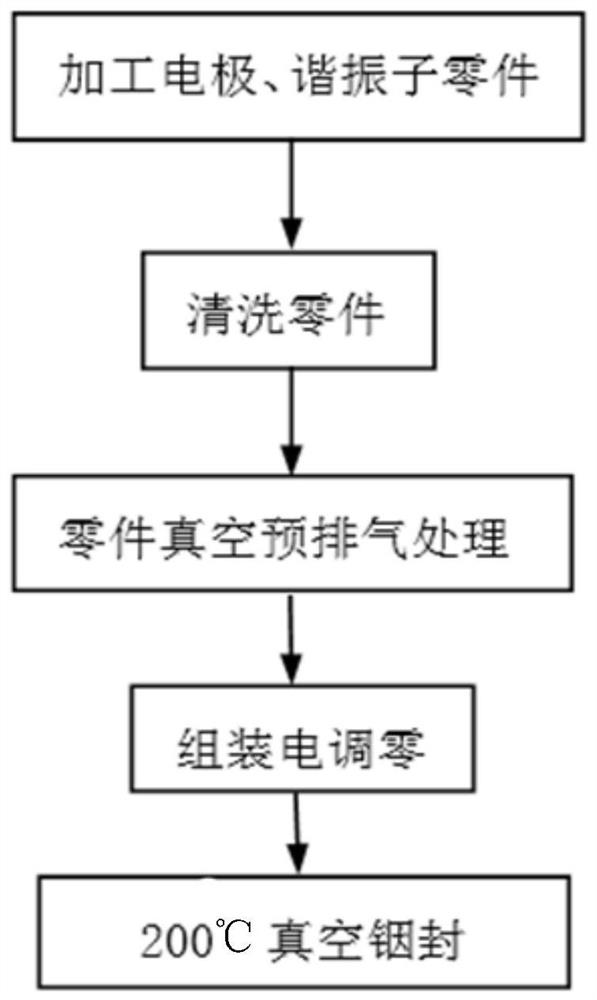

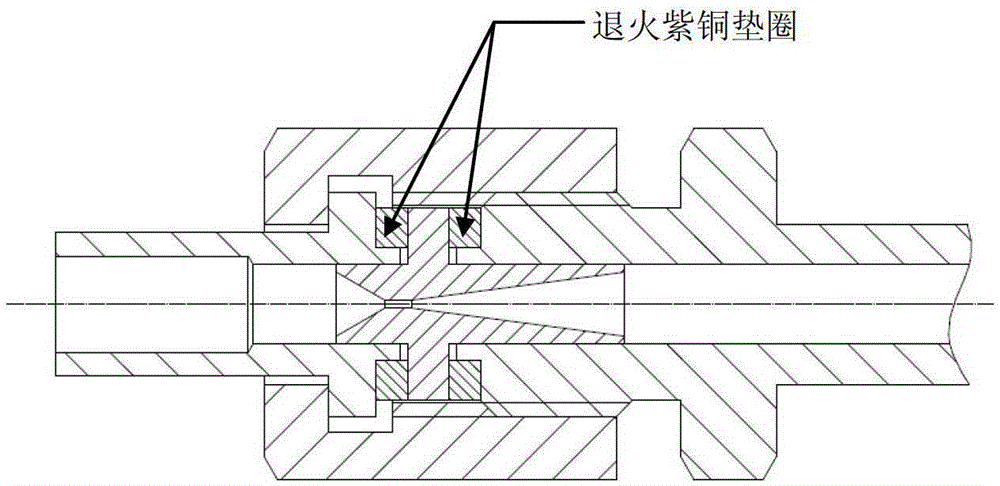

Harmonic oscillator and electrode fixed connection method suitable for high-vacuum environment

ActiveCN111854723AReduce exhaustImproved vacuum venting performanceSpeed measurement using gyroscopic effectsGyroscopes/turn-sensitive devicesIndiumEngineering

The invention relates to a harmonic oscillator and electrode fixed connection method suitable for a high vacuum environment. The method comprises the following steps that: 1, a harmonic oscillator part and an electrode part are processed and manufactured, the diameter of an electrode part center hole is larger than that of a harmonic oscillator part center rod, and a fit clearance is reserved between the electrode part center hole and the harmonic oscillator part center rod, and a chamfer surface is manufactured on the upper end opening of the electrode part center hole; 2, cleaning is performed so as to remove grease on the surface of the parts; 3, vacuum pre-exhausting treatment is performed; 4, assembling is performed, and electric zero setting is performed, an indium wire is arranged into the chamfer at the upper end of the electrode central hole before electric zero setting, silica gel is applied to the gap below the electrode after the zero setting, and the silica gel is solidified to form a silica gel sealing ring; and 5, after the silica gel is solidified, the assembly of the electrode and the oscillator, together with an adjusting fixture, is arranged into a vacuum furnace, and heating, insulating and cooling are sequentially performed to fill the fit clearance between the electrode and the oscillator with indium so as to realize the fixed connection of the electrode and the oscillator. According to the method of the invention, the reliable fixed connection of the harmonic oscillator and the electrode is realized, and the prepared assembly structure meets the high-vacuum use environment.

Owner:TIANJIN NAVIGATION INSTR RES INST

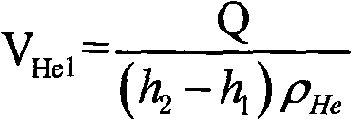

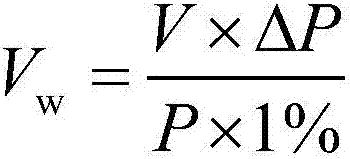

Full-metal small-volume container and volume determination system and method

ActiveCN106568630ALow outgassing rateExtended service lifePreparing sample for investigationMaterial analysis by electric/magnetic meansNoble gasCarbon dioxide gas cylinder E

The invention belongs to the fields of accurate determination of the composition and content of rare gas isotopes, and particularly discloses a full-metal small-volume container and a volume determination system and method. The container comprises a first normally closed type air cylinder, a first carbon steel driving rod, a first welding corrugated pipe, a stainless steel pipe gas outlet, a second normally closed type air cylinder, a second carbon steel driving rod, a second welding corrugated pipe, a stainless steel pipe gas inlet, a to-be-detected small-volume container and a base. The system includes a high-precision diaphragm gauge communicating with the stainless steel pipe gas inlet of the full-metal small-volume container, a stainless steel cold trap, a first metal valve, a second metal valve, a small-volume container with known size, a third metal valve, a fourth metal valve, a fifth metal valve, an oil-free molecular pump group, and a high-purity carbon dioxide gas bottle. The technical problems of large small-volume container measurement error and low sensitivity are solved.

Owner:BEIJING RES INST OF URANIUM GEOLOGY

Luminescent film and its preparation method and use

InactiveCN1304527CUniform surfaceControl thicknessImage/pattern display tubesLuminescent compositionsChemistryCoating

The invention include a lightening film and its preparing method and application. The chemical formula of lightening film: Y3(1-x-y)(AlzGa(1-z))5O12:Tb3x, A3y, 0.0001 C09K 11 / 80 H01J 31 / 12 0 4 2 2004 / 11 / 5 1632052 2005 / 6 / 29 1304527 2007 / 3 / 14 2007 / 3 / 14 2007 / 3 / 14 Tianjin University of Technology Tianjin 300191 Li Lan Zhang Xiaosong liao xiaorong 12002 The Patent Agency Subvision of Tianjin Prospecting and Designing Institute of the Ministry of Water Conservacy and Power No.60 Dongting Road, Hexi District, Tianjin 300222

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

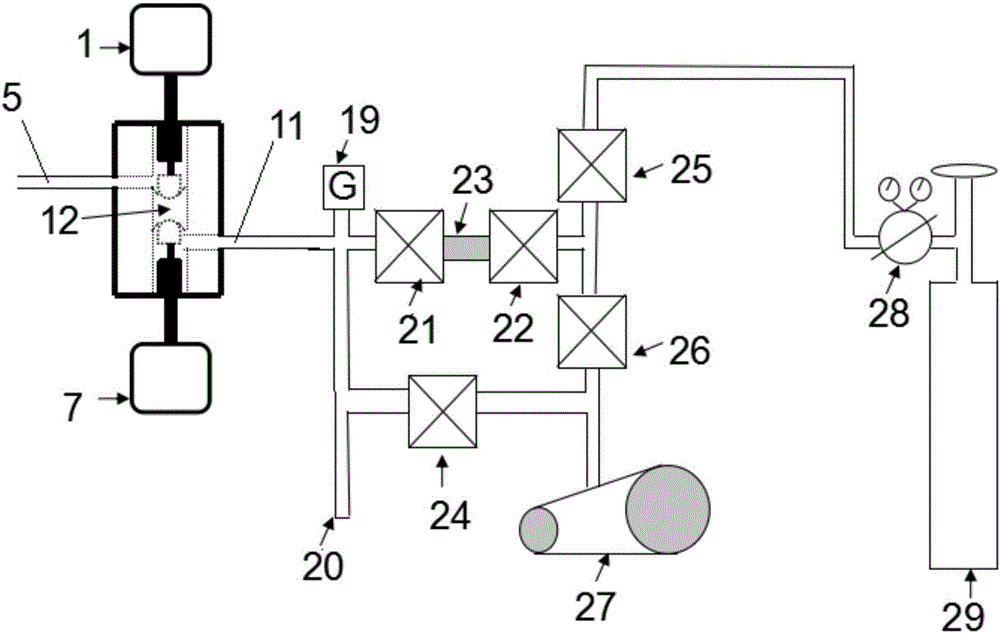

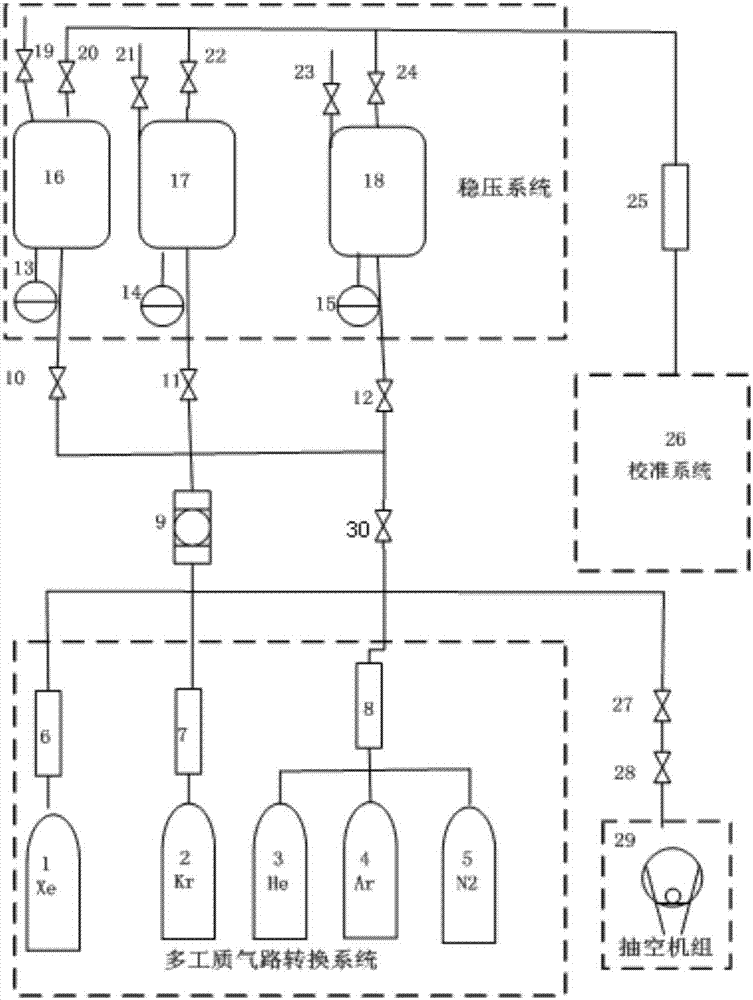

Gas supply device and method for multi-working-medium gas micro-flow calibration

ActiveCN107355681AAccurate CalibrationIn line with actual working conditionsPipeline systemsCalibration gasGas cylinder

The invention discloses a gas supply device and method for multi-working-medium gas micro-flow calibration. According to the gas supply device, a gas storage system formed by connecting a plurality of high-pressure gas bottles in parallel is used for providing multiple calibration gases, and the calibration gases conforming to the working medium actual gas can be provided. Through an electrical path converter and a pressure stabilizing system, the inlet and outlet pressure of the calibration gases is ensured, the pressure of the provided calibration gases is consistent with the actual pressure of the working medium gas, the actual work condition is better met, and working medium gas micro-flow calibration is more accurate. By means of the gas supply device and method, the calibration gases conforming to the working medium actual gas can be provided, and meanwhile the pressure of the provided calibration gases is consistent with the actual pressure of the working medium gas; and the gas supply method is simple, feasible and easy to operate.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

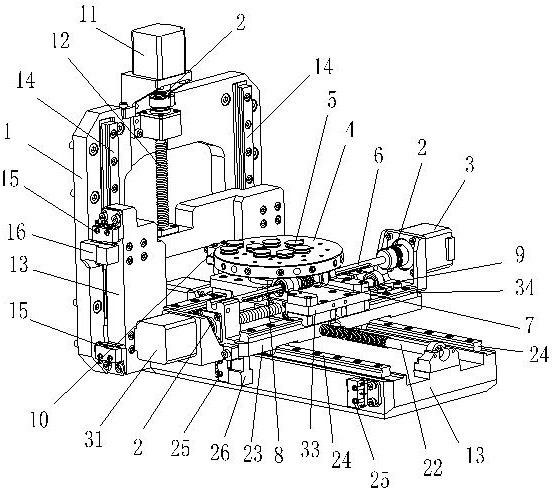

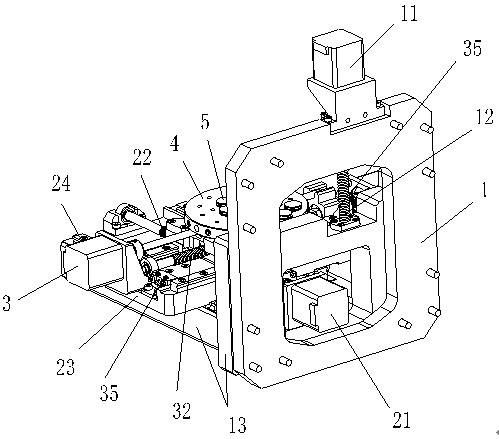

Vacuum four-axis motion platform structure for scanning electron microscope

PendingCN112362680AStable jobPrecise positioningMaterial analysis using wave/particle radiationRotary stageParticle physics

The invention discloses a vacuum four-axis motion platform structure for a scanning electron microscope. The vacuum four-axis motion platform structure for the scanning electron microscope not only can enable a sample support on a rotary table to move on an X axis, a Y axis and a Z axis, but also can enable the sample support to rotate by 360 degrees along with the rotary table, so that multi-dimensional rapid movement of a to-be-detected sample is realized, and the movement is more accurate and controllable due to the design of the travel switch. In conclusion, the vacuum four-axis motion platform for the scanning electron microscope is scientific and reasonable in structural design, capable of rapidly and reliably positioning a sample on the sample support, high in repeated positioning precision, compact in overall mechanism, long in linear travel distance of the sample on the X axis, the Y axis and the Z axis, capable of containing a large-size sample on the sample support and convenient to assemble and disassemble, is high in reliability and can be suitable for field emission electron microscopes and other high-vacuum environments.

Owner:无锡量子感知研究所

A kind of preparation method of secondary ion probe sample target

InactiveCN108375497BLow outgassing rateIncrease vacuumPreparing sample for investigationMaterial analysis by electric/magnetic meansEpoxyApatite

The invention belongs to the field of analysis and test of secondary ion probes, and particularly relates to a preparation method of a secondary ion probe sample target, for improving flatness of sample grains and reducing outgassing rate of the sample target. The sample target mainly comprises a glass sheet, epoxy resin and sample grains. The preparation method, based on a main body, namely a circular glass sheet, includes the steps of firstly, cutting to form a plurality of grooves on the glass sheet, placing the sample grains in the grooves, injecting the epoxy resin into the grooves to cure, and carrying out fine grinding and polishing on the sample target after finishing curing. The preparation method has the advantages that the outgassing rate of the sample target is low due to the fact that the epoxy resin is placed in the grooves of the glass sheet only, and accordingly vacuum keeping of a sample chamber is facilitated; since glass and mineral grains(such as zircon and apatite)have the similar hardness, the mineral grains, the epoxy resin and the glass sheet are kept at the same plane effectively during the polishing, and further flatness of edges of the mineral grains areimproved.

Owner:INST OF GEOLOGY & GEOPHYSICS CHINESE ACAD OF SCI

Vacuum seal welding method for window and optic window of low temperature metal Dewar

InactiveCN100364707CExcellent air leakage rateLow outgassing rateVacuum evaporation coatingSoldering apparatusIndiumInfrared window

The present invention discloses the method of low temperature vacuum sealing and welding between the window frame and the optical window of metal Dewar. In the welding between the window frame of kovar alloy material and the optical window of infrared transmitting material, the optical window is first vacuum plated to form Cr / Au coating as the transition layer in the parts to be welded, and the welding in performed with In as welding material at low temperature. The present invention has the outstanding advantage of low temperature welding producing no negative effect on the antireflective coating in the infrared window. Using soft In as the welding material can buffer the difference between the optical window material and the kovar alloy material in expansion coefficient. The metal Dewar has gas leakage rate superior to 3E(-12) torr.liter / sec and gas releasing rate far lower than that of traditional technological process.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

A method for forming an integrated cold screen for an infrared detector

ActiveCN105486411BGood for maintaining vacuum and long lifeLow outgassing rateRadiation pyrometryCold shieldEngineering

The invention discloses a molding method of an integrated cold shield for an infrared detector. Extinction fins of the cold shield are directly electro-casted with a cold shield body, secondary bonding is avoided, glue for packaging is effectively controlled, the vacuum service life of the detector can be maintained for long time; and design of the cold shield body is simplified, bonded fitting and positioning surfaces are not embodied in the cold shield body, the total weight of the cold shield is decreased, power requirement for a refrigerator is lowered, and work of the cold shield is higher.

Owner:11TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

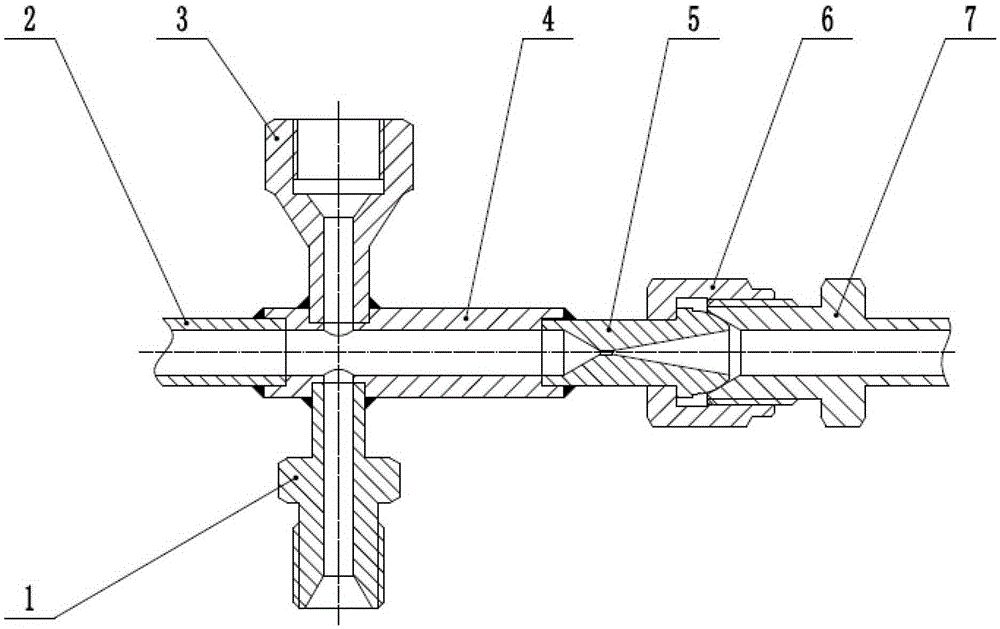

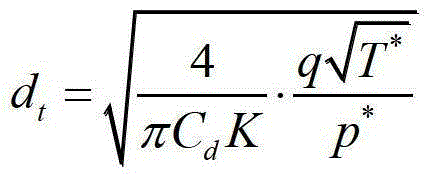

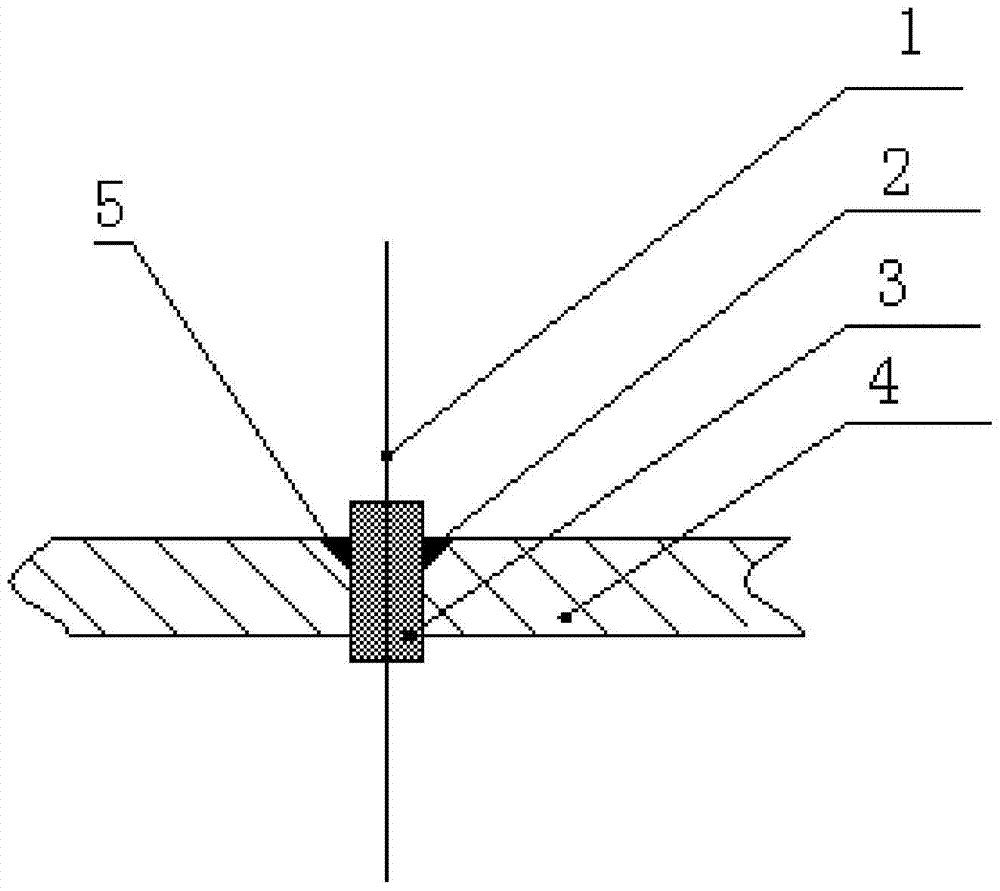

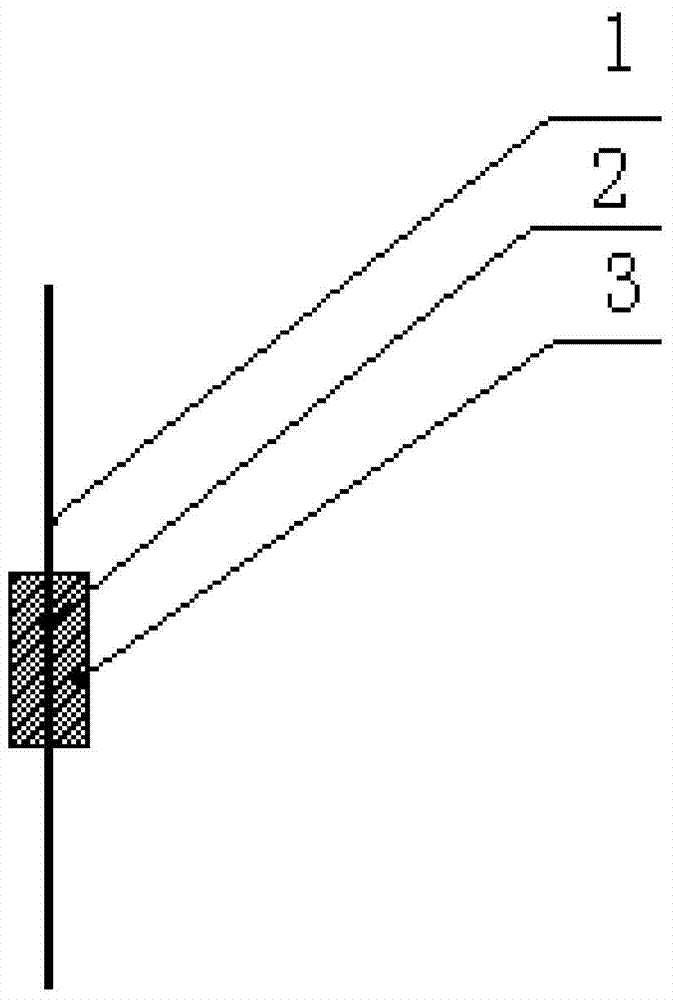

Sonic Nozzle Assemblies for Gas Flow Control in Vacuum Environments

The invention discloses a sound speed nozzle assembly applied to control gas flow in the vacuum environment. The sound speed nozzle assembly comprises an air inlet pipe, a temperature measurement nozzle, a pressure measurement nozzle, an air current stabilizing pipe, a sound speed nozzle spherical joint, an outer sleeved nut and a welding filler neck, wherein one end of the air current stabilizing pipe is fixedly connected with the air inlet pipe, the other end of the air current stabilizing pipe is fixedly connected with the sound speed nozzle spherical joint, a temperature measurement hole and a pressure measurement hole are formed in the air current stabilizing pipe, the temperature measurement nozzle and the pressure measurement nozzle are fixedly connected to the temperature measurement hole and the pressure measurement hole respectively, and the other end of the sound speed nozzle spherical joint is fixedly connected with the welding filler neck through the outer sleeved nut. The sound speed nozzle assembly is integrally made of stainless steel materials, and a sound speed nozzle and a spherical joint are integrally machined and formed. Compared with a conventional sound speed nozzle assembly, the sound speed nozzle assembly is simple in process, the number of sealed faces is decreased from four to one, the sphere of the spherical joint and the conical surface of the welding filler neck form line sealing, the reliability is greatly improved, and the sound speed nozzle assembly can be used in the vacuum and low-temperature environment in a continuous and long-term mode.

Owner:BEIHANG UNIV

Gd3Al5O12:Ce, Dy luminous film and preparing method

InactiveCN1775999AUniform surfaceControl thicknessVacuum evaporation coatingSputtering coatingCrazingField emission display

The invention relates to emitting film and the method to manufacture. The feature is that it adopts Na2CO3, LiCO3, Gd2O3, SiO2, Pr2O3, Eu2O3, Er2O3, Tm2O3, Ce2O3, Lu2O3, Nd2O3, Sm2O3 that the purity is 99.99% as raw material, and the solvent is water and alcohol. The invention has equal emitting film surface, compacting and no crazing, the particle is equal and the thickness could be controlled. The film has good emitting capability.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Electronics Vacuum Feedthrough

The invention relates to an electronic vacuum feed-through member. The electronic vacuum feed-through member comprises a flexible circuit board and a substrate with a through hole formed therein, and further comprises a holder clamping the flexible circuit board, wherein a sealing colloid is arranged between the flexible circuit board and the holder for integrally packaging the flexible circuit board and the holder to form a flexible circuit board-holder assembly, and the flexible circuit board-holder assembly is packaged in the through hole through the sealing colloid. The electronic vacuum feed-through member provided by the invention has the advantages of high density, high frequency, low noise, low outgassing rate and low leak rate and can realize high-speed low-noise electronic reading of 128 paths.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com