Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52results about How to "Long service" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

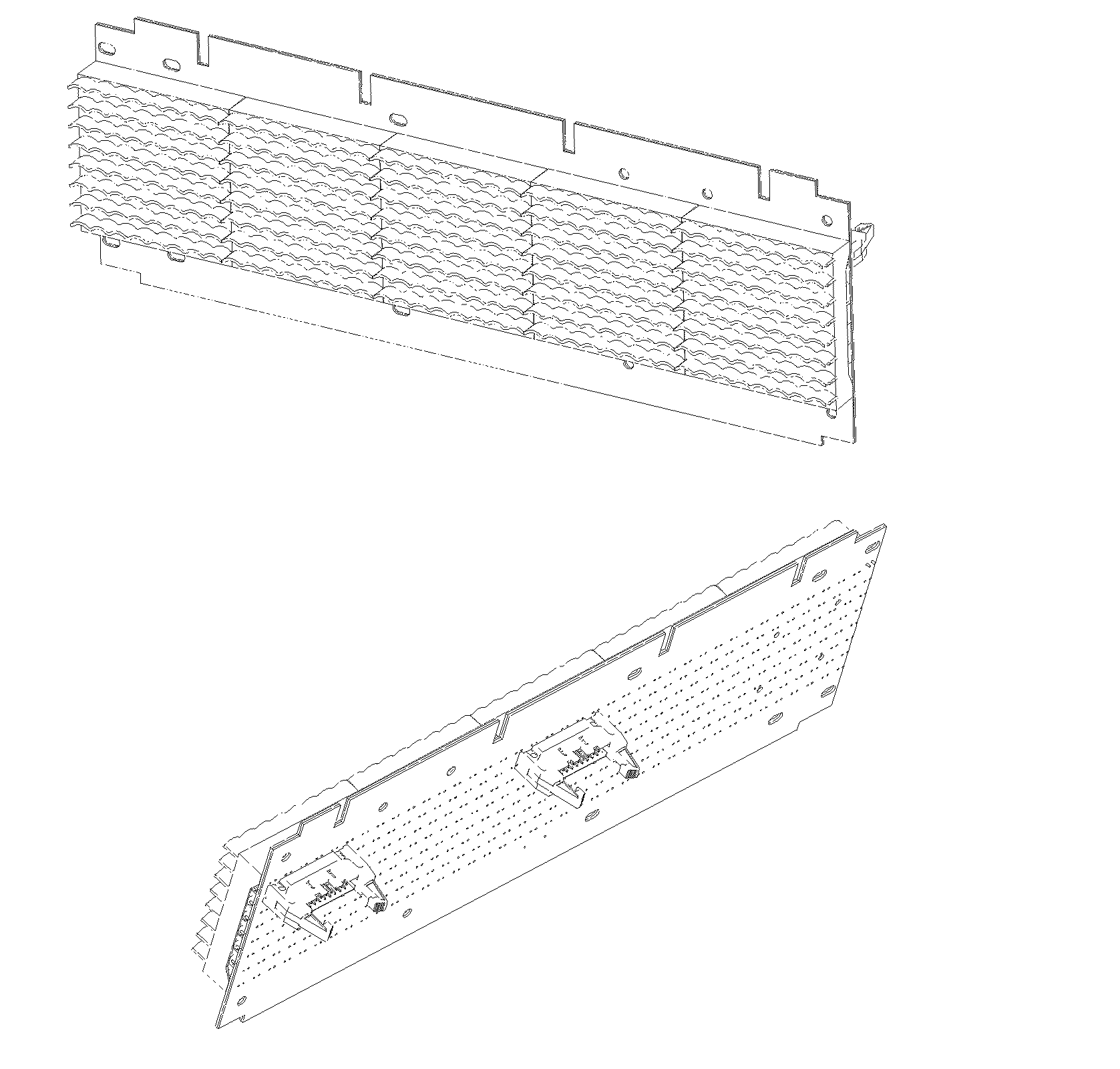

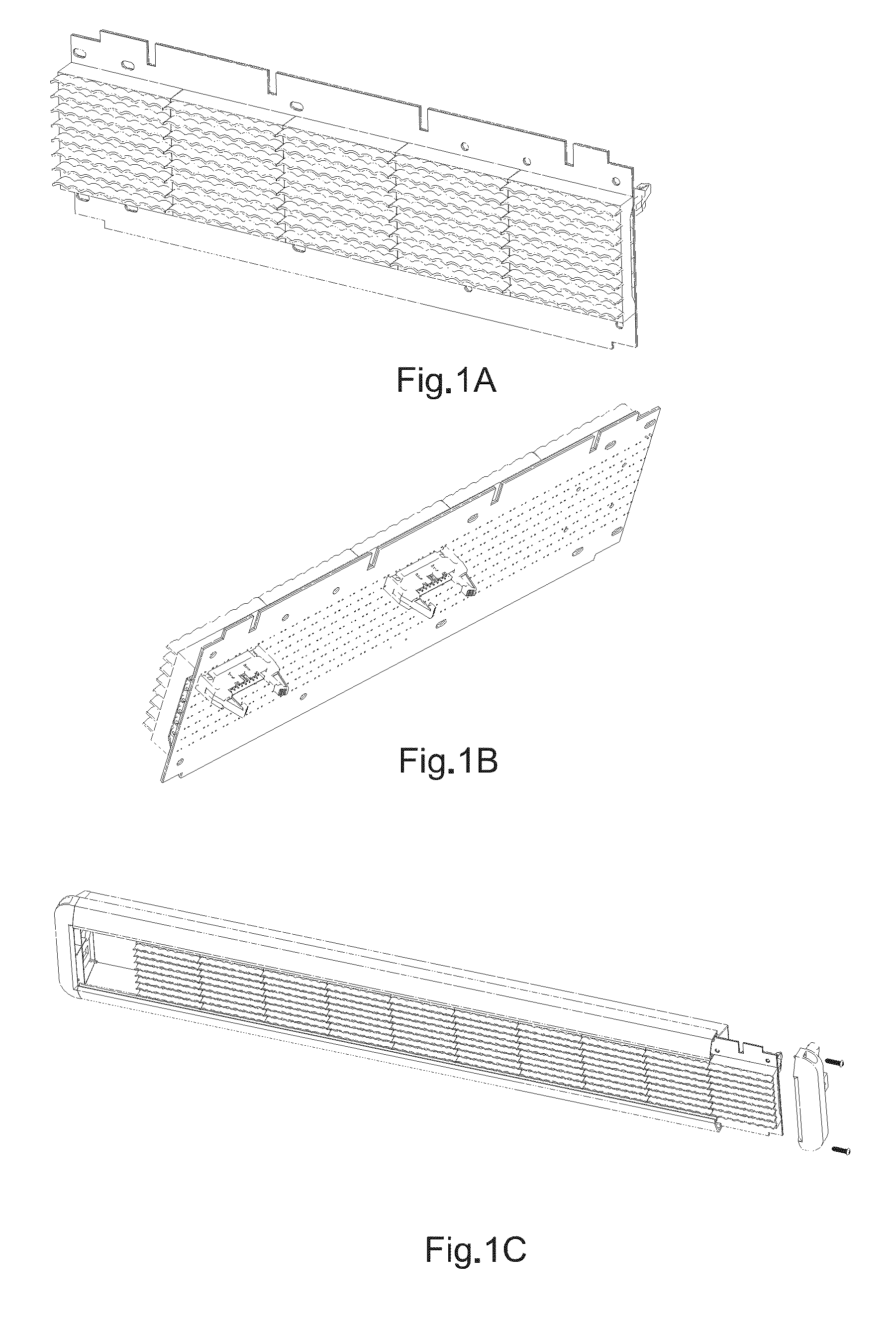

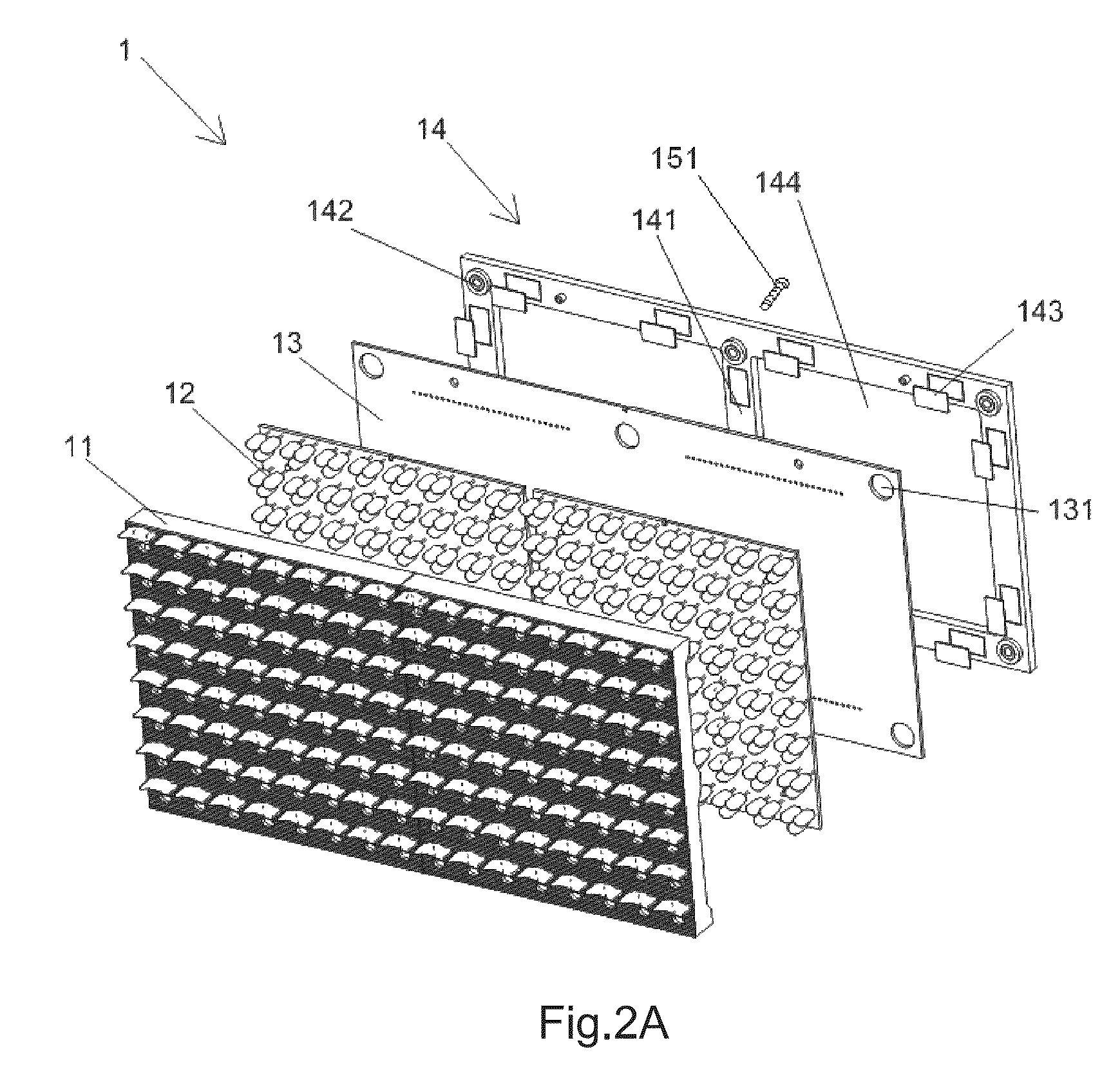

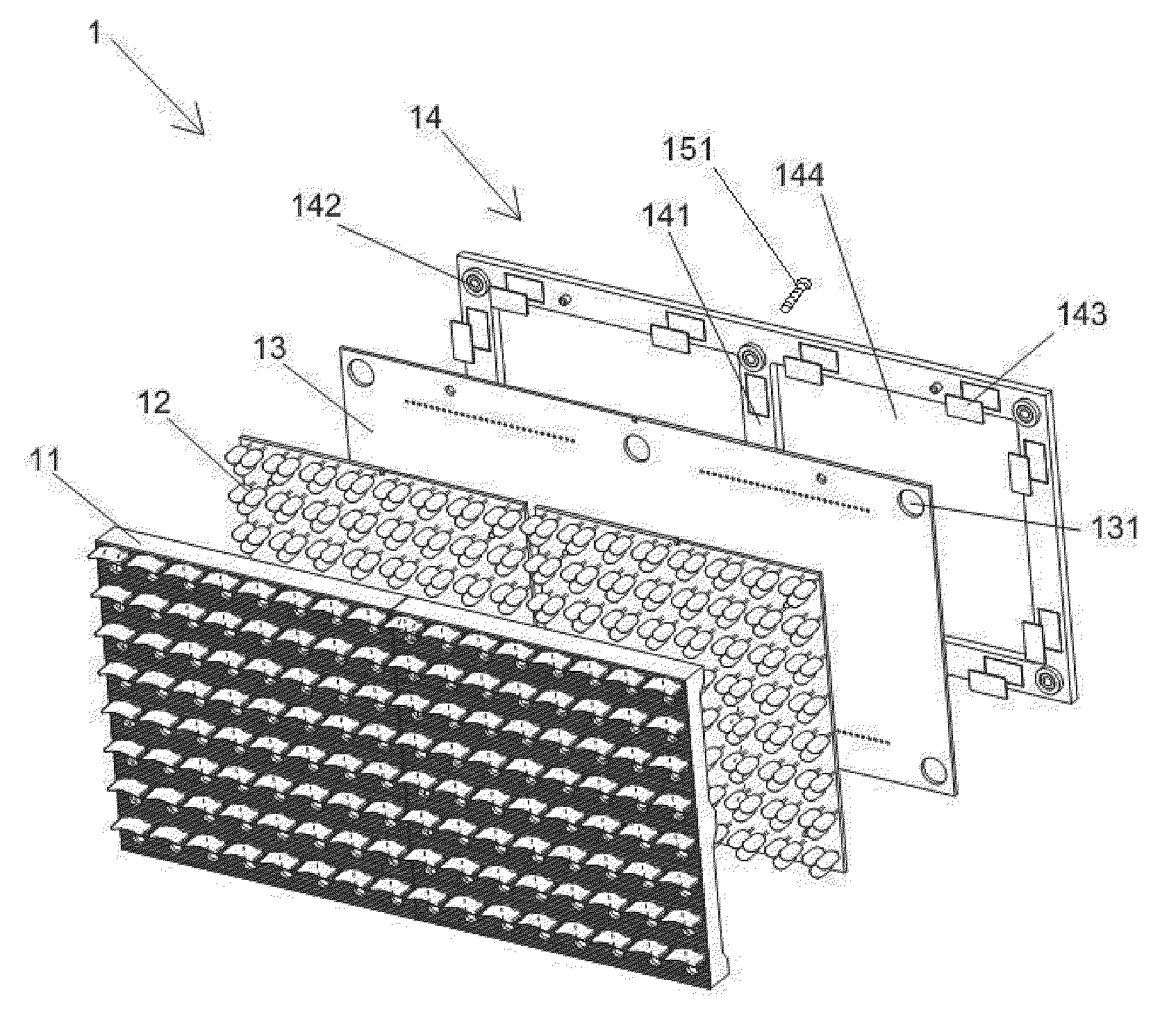

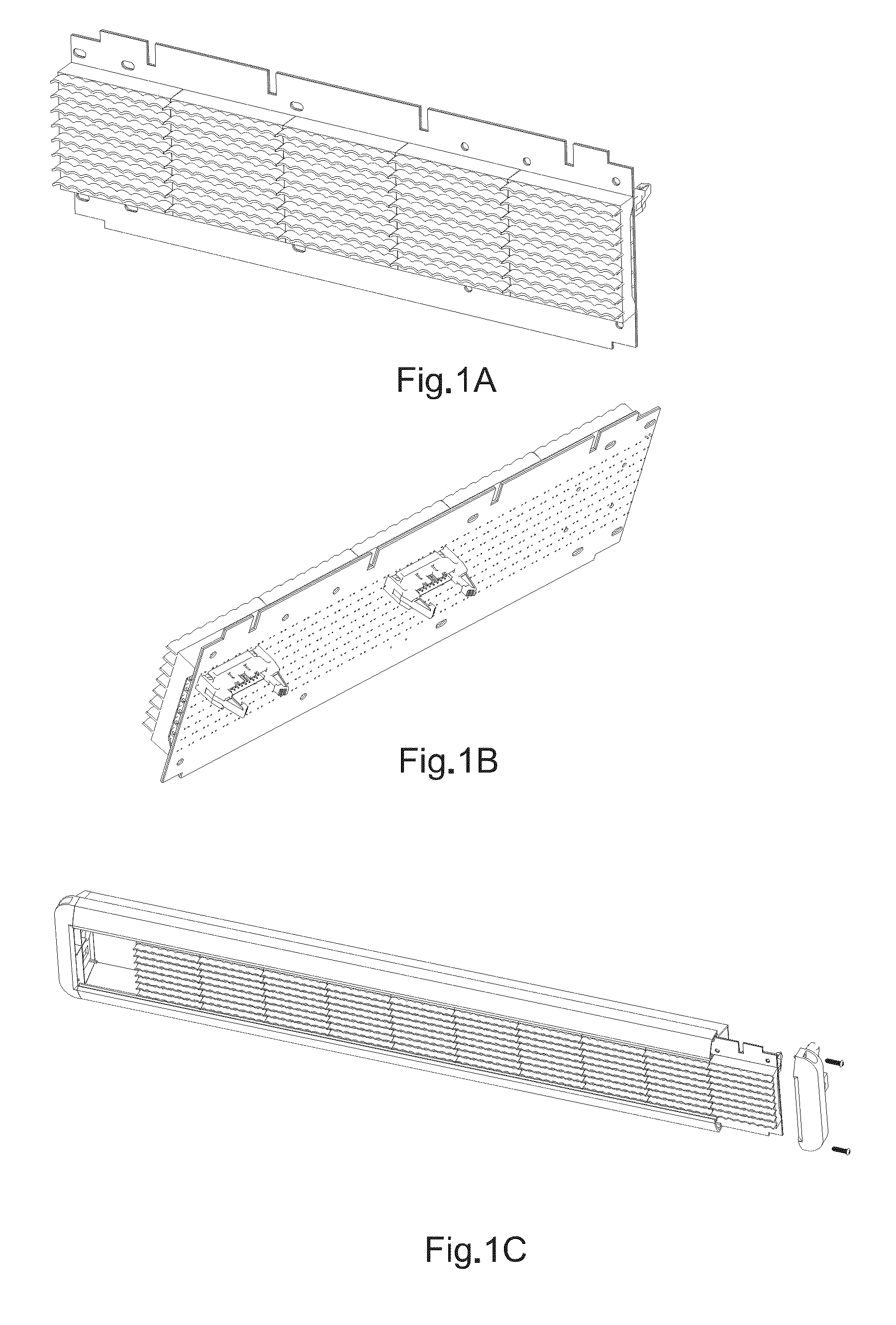

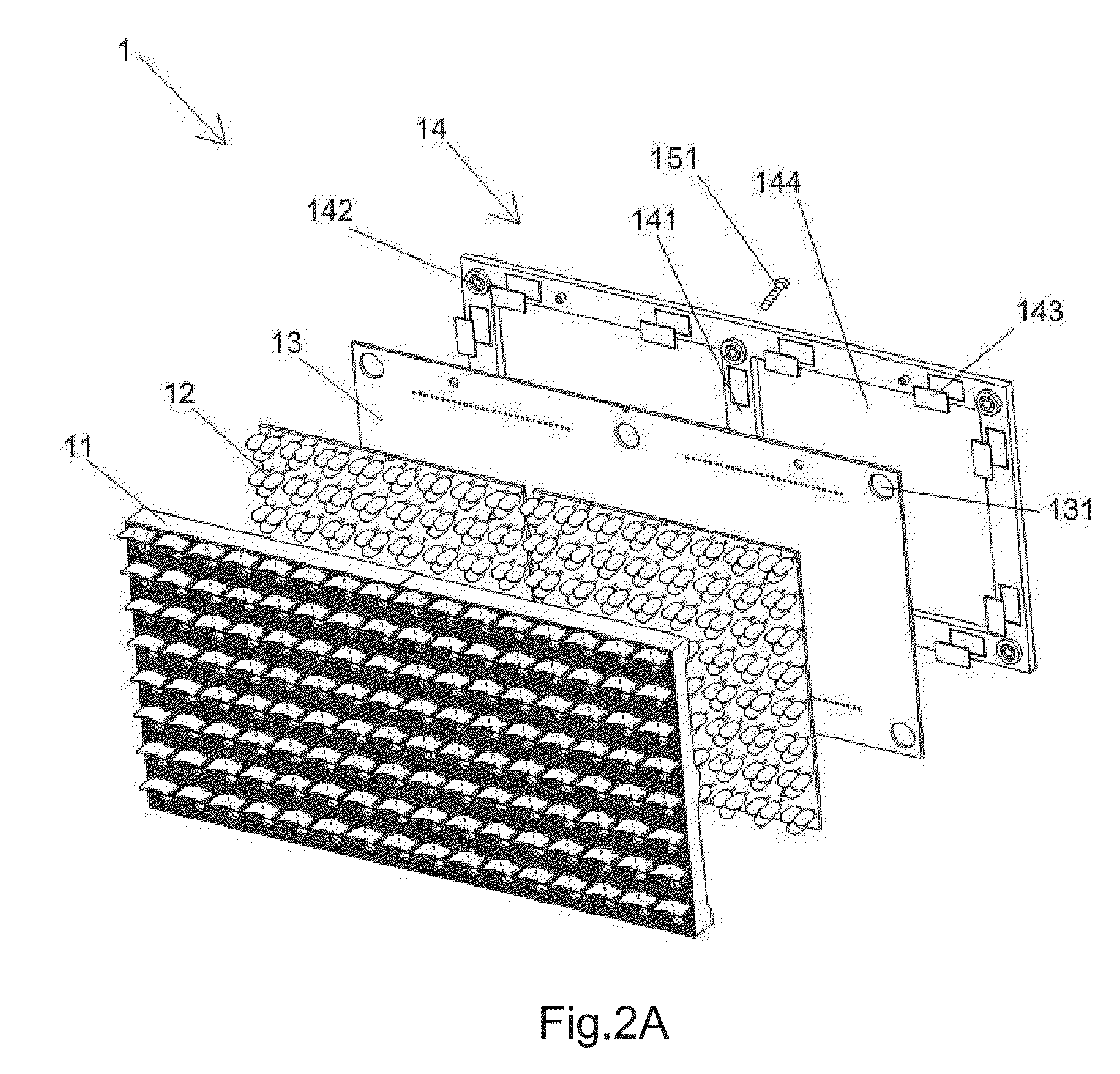

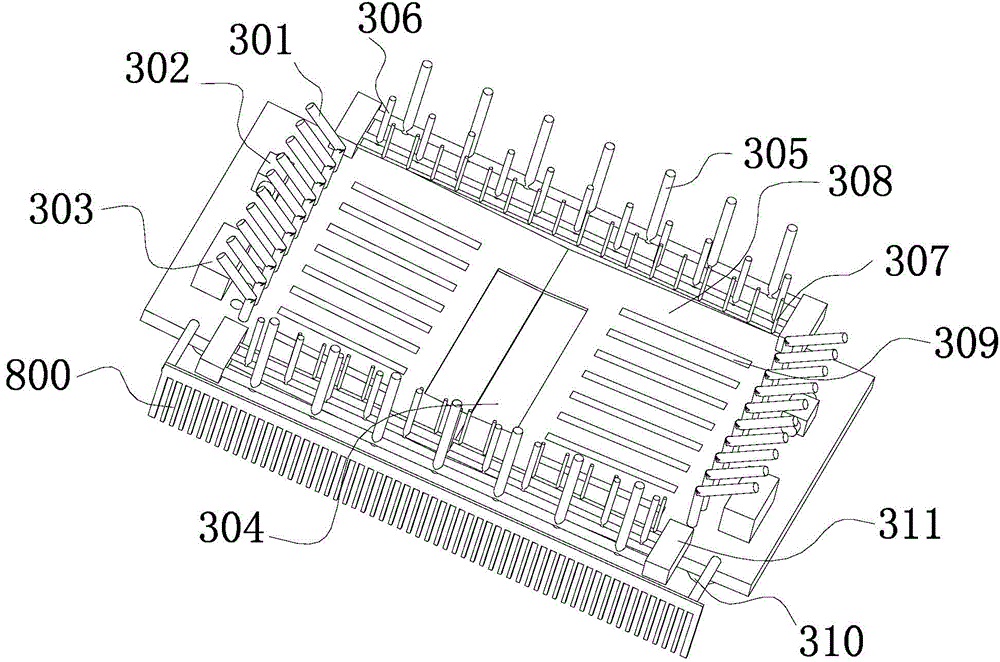

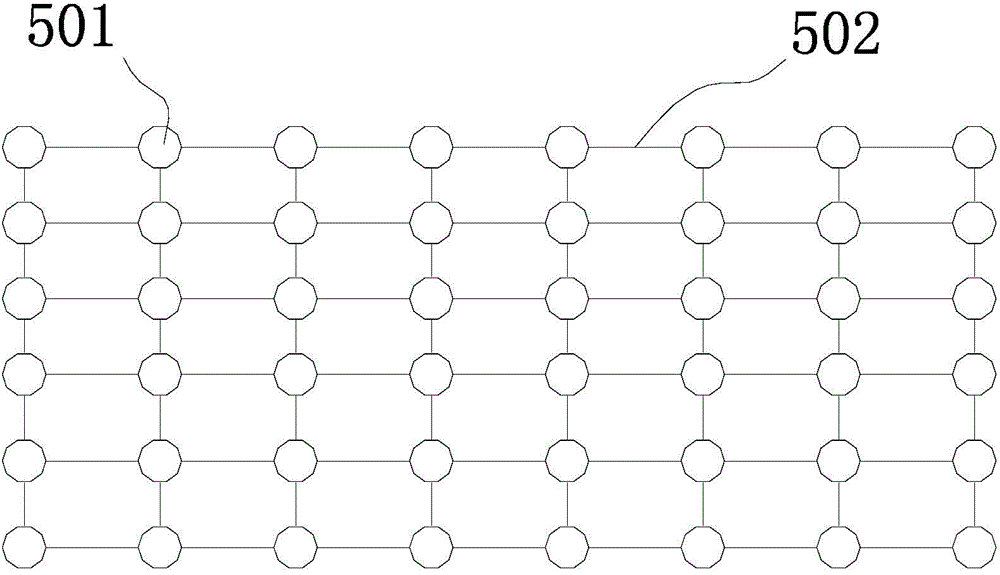

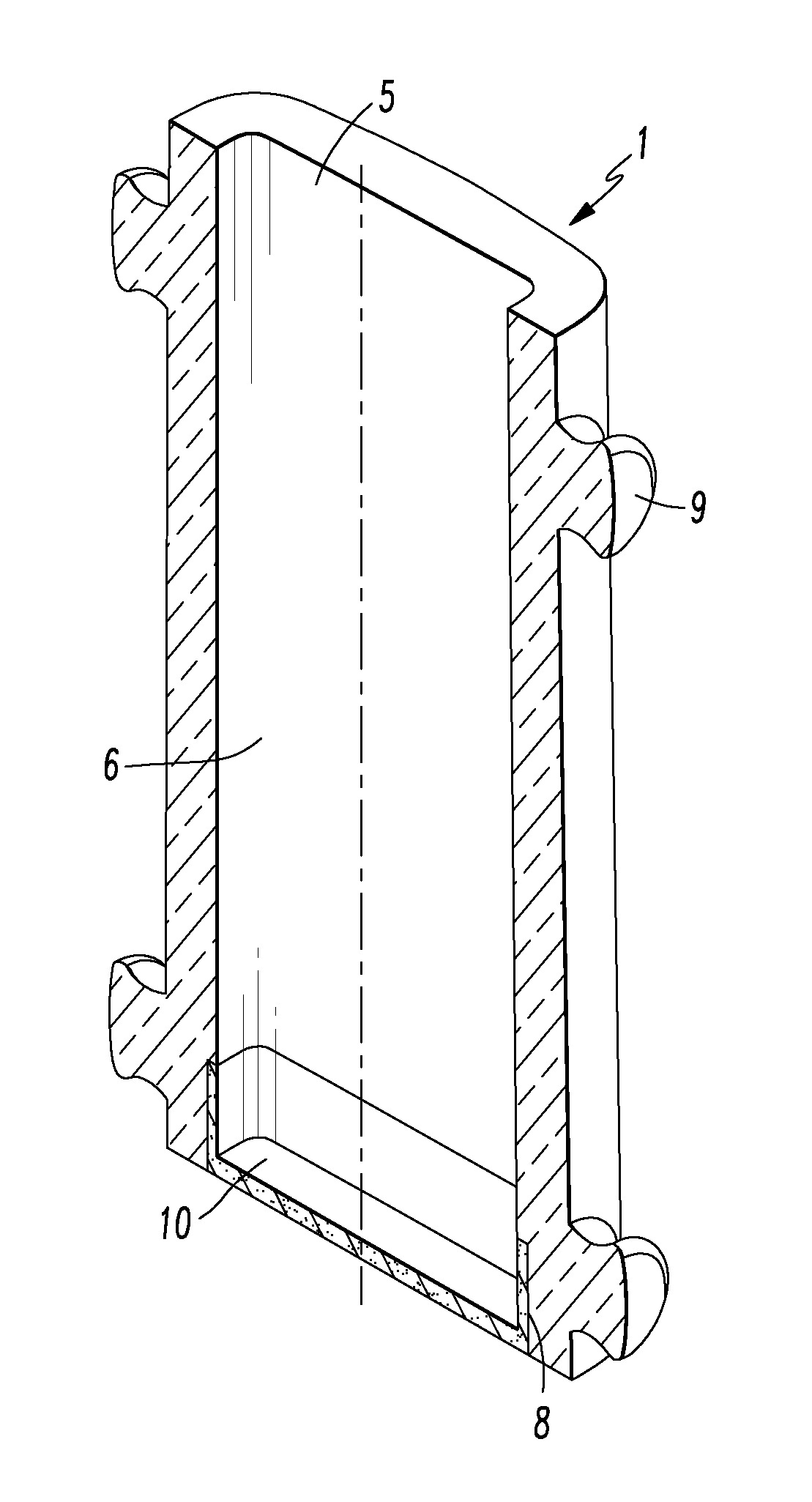

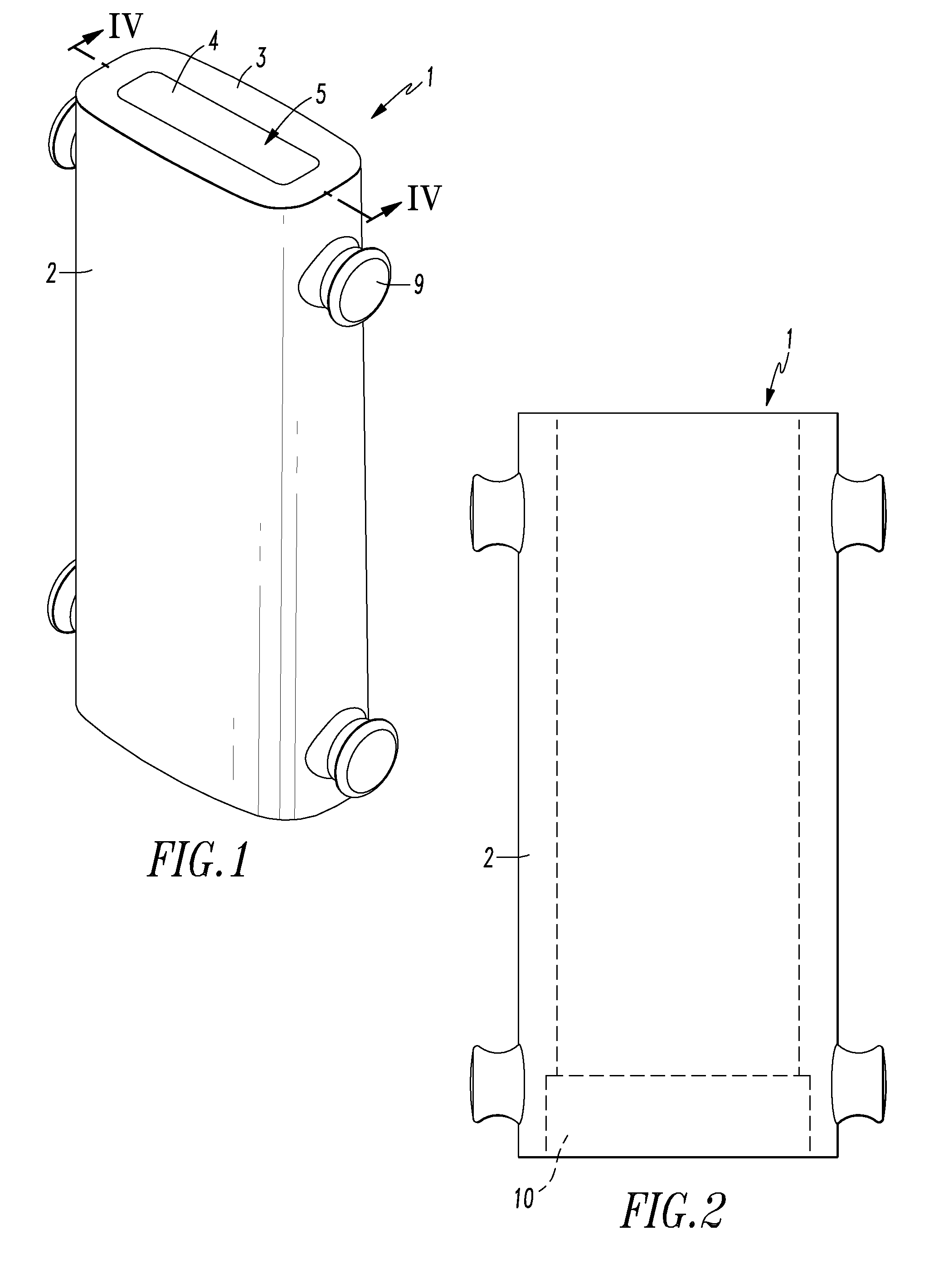

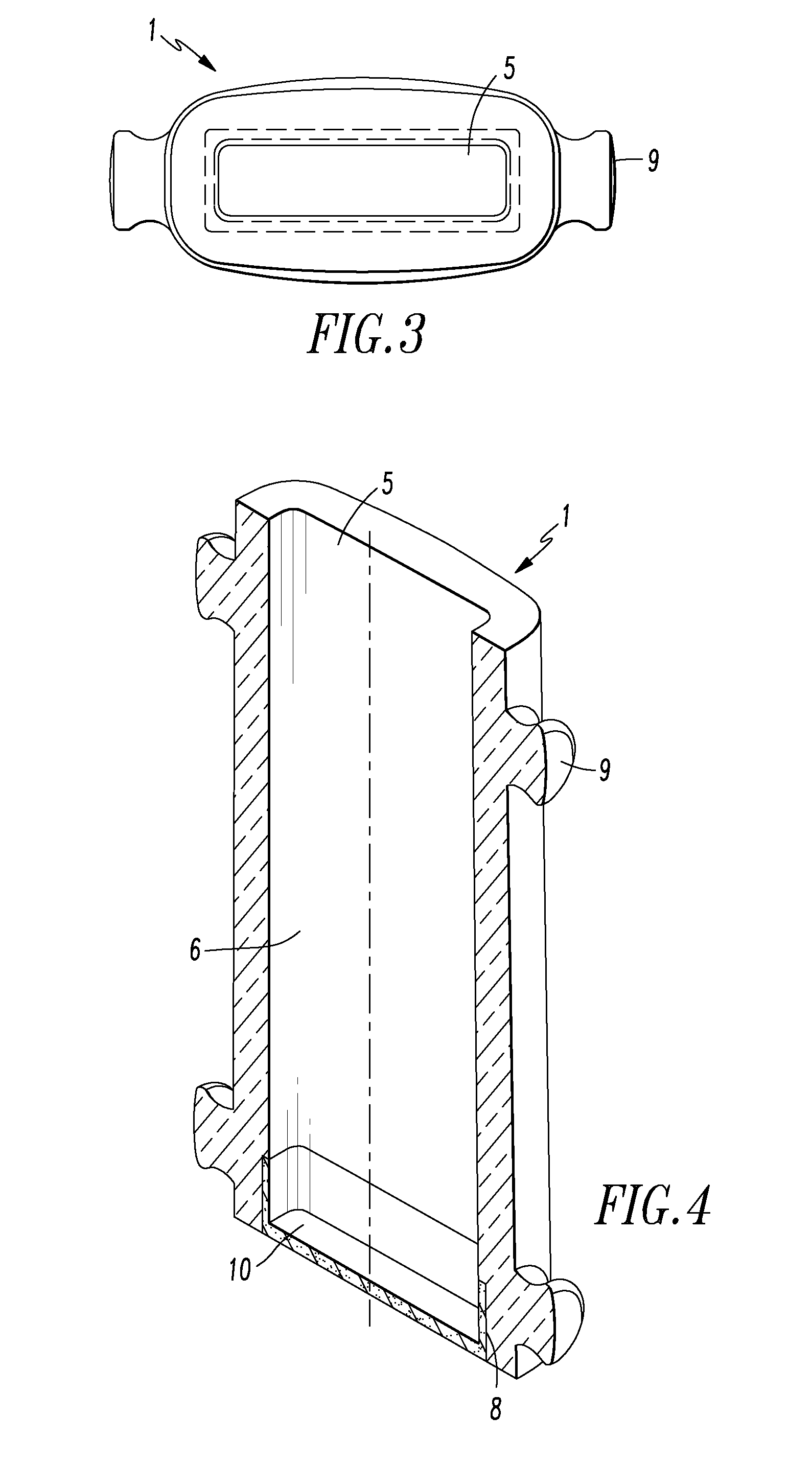

LED display screen assembly

ActiveUS8362696B2Easy to assembleLong serviceDischarge tube luminescnet screensLighting support devicesLED displayEngineering

Owner:ISIGN DISPLAY SYST HANGZHOU

LED display screen assembly

ActiveUS20110089824A1Easy to assembleLong serviceTube/lamp screens manufactureDischarge tube luminescnet screensEngineeringLED display

A LED display screen includes a case, a main board, and a plurality of LED display modules. The case has a front surface, a rear surface, and an opening provided between the front surface and the rear surface. The front surface has a window. The main board is inserted into the case via the opening, and has a front surface for displaying via the window. Each of the LED display module includes a LED display unit, a PCB driving board, and a supporting base. The LED display unit is connected electrically with the PCB driving board. The LED display unit mounts on the supporting base. The PCB driving board mounts on the supporting base. The PCB driving board is held between the LED display unit and the supporting base. The LED display modules mounts in formation on the front surface of the main board to form a united display screen.

Owner:ISIGN DISPLAY SYST HANGZHOU

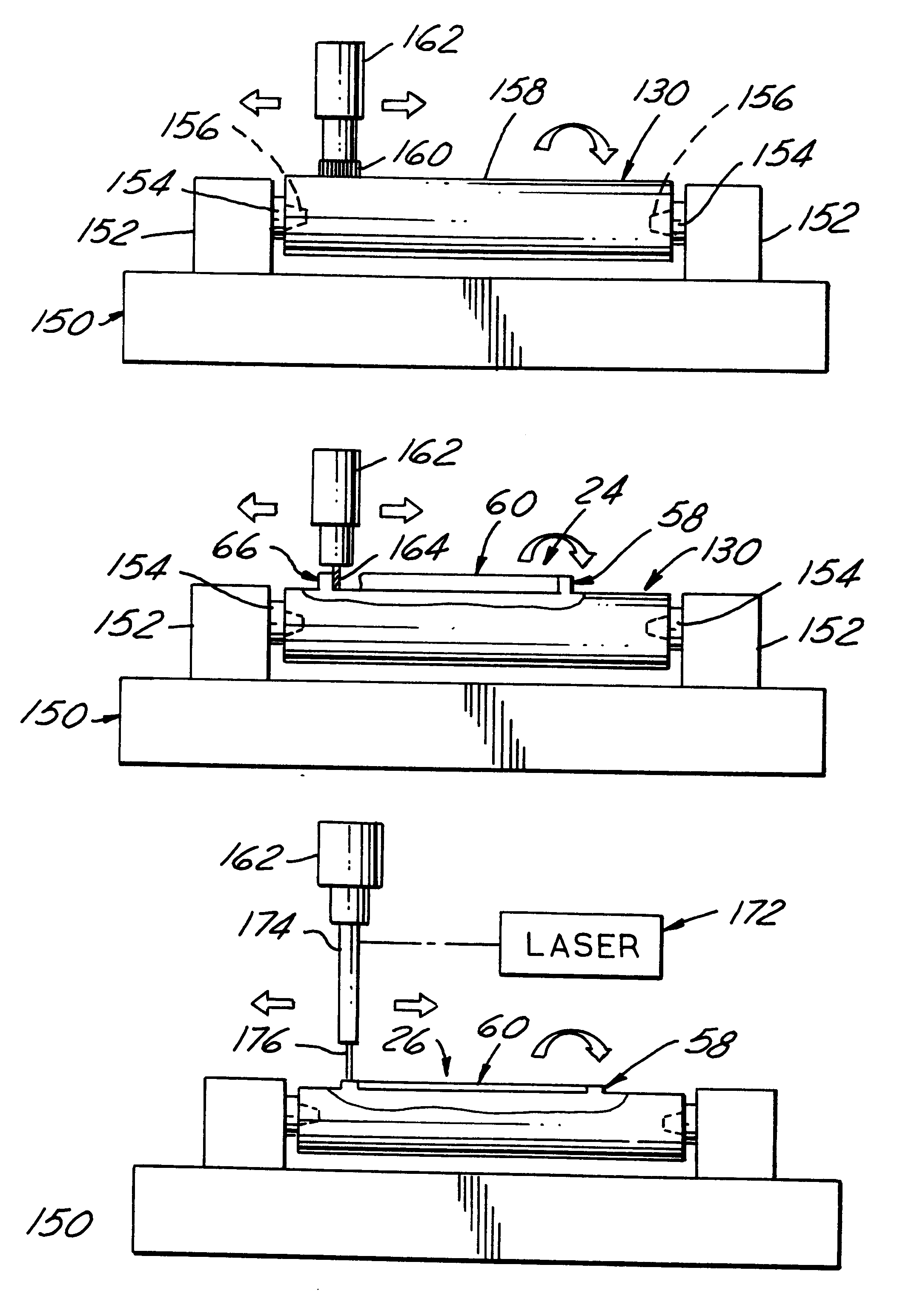

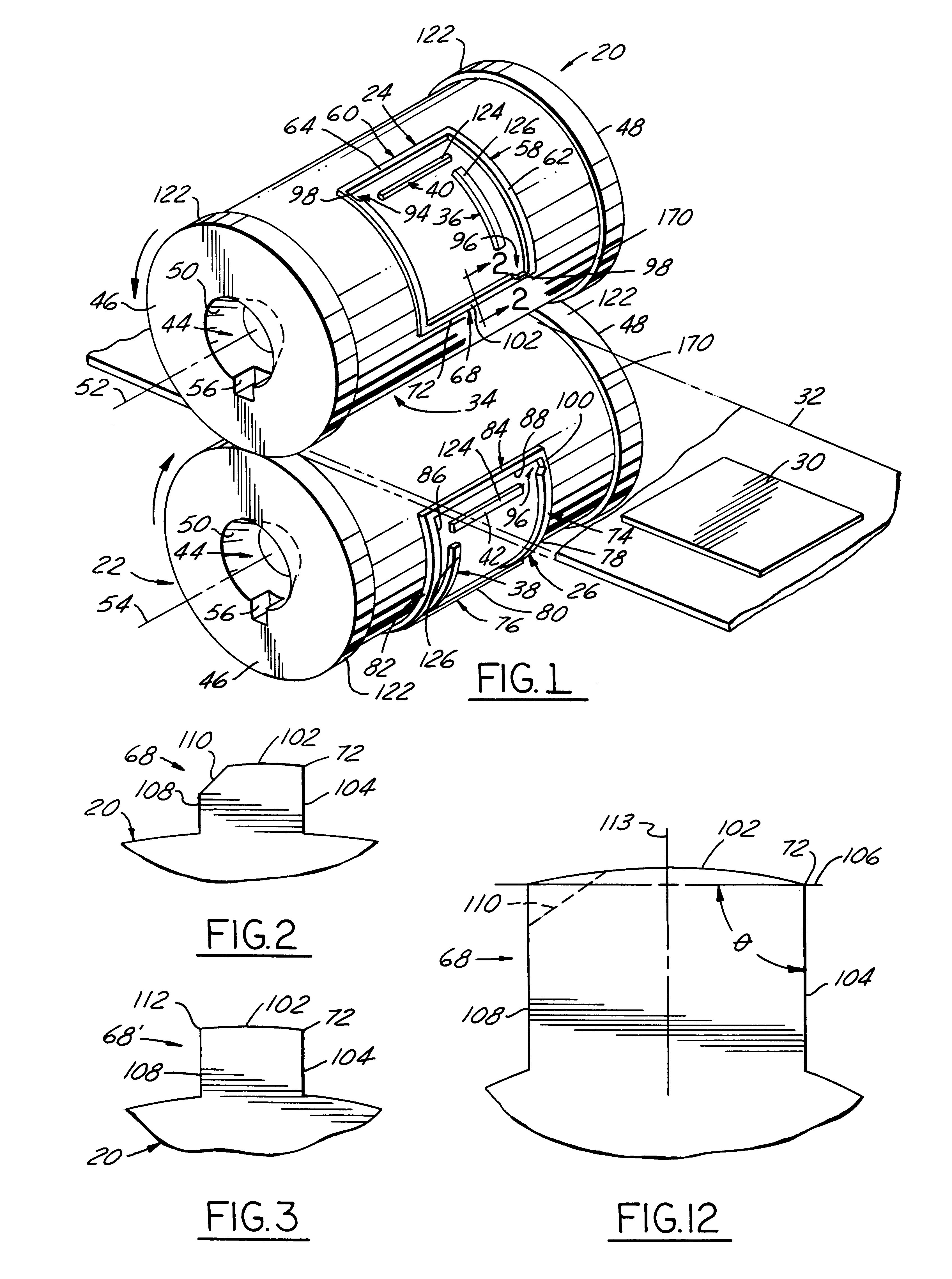

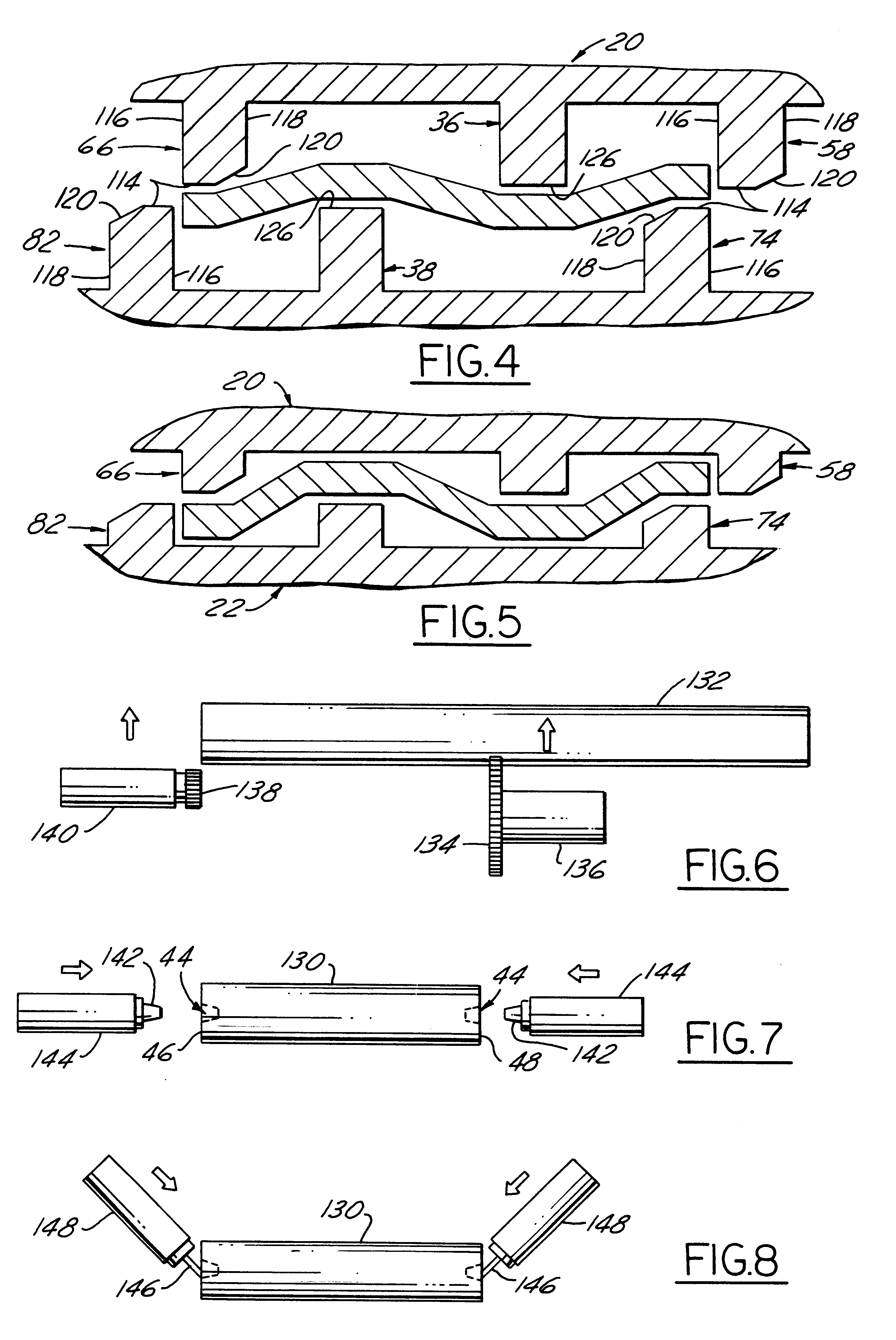

Method of making rotary cutting dies

InactiveUSRE37366E1Accurate locationExtended service lifeCutting toolsMetal rolling stand detailsEngineeringKnife blades

A method of making a pair of rotary die cylinders with lands having coacting cutting edges which cut blanks from a web of material passing through the nip of the rotating dies. In cross section each land has an outer face and a pair of spaced apart side faces which are parallel to each other and perpendicular to the chord of the outer face to provide a clean cut and facilitate release of the cut blank from the cutting blades as it emerges from the nip of the dies. The die cylinders are journalled for rotation by recesses with frusto conical locating surfaces in their opposed ends. Each die cylinder is made by machining the recesses in the opposed ends of a generally cylindrical workpiece of tool steel and then utilizing the recesses to locate and orient the workpiece relative to a cutting tool to produce a cylindrical surface on the workpiece concentric with the axis of the recesses and then to machine away portions of the periphery of the cylindrical surface to form the cutting blade lands thereon. After machining is completed the cutting blade lands may be hardened by heat treating utilizing a laser beam directed onto the lands to heat them at an elevated temperature so that upon quenching they are hardened without any substantial hardening and resulting distortion of the core or body of the workpiece.

Owner:BERNAL

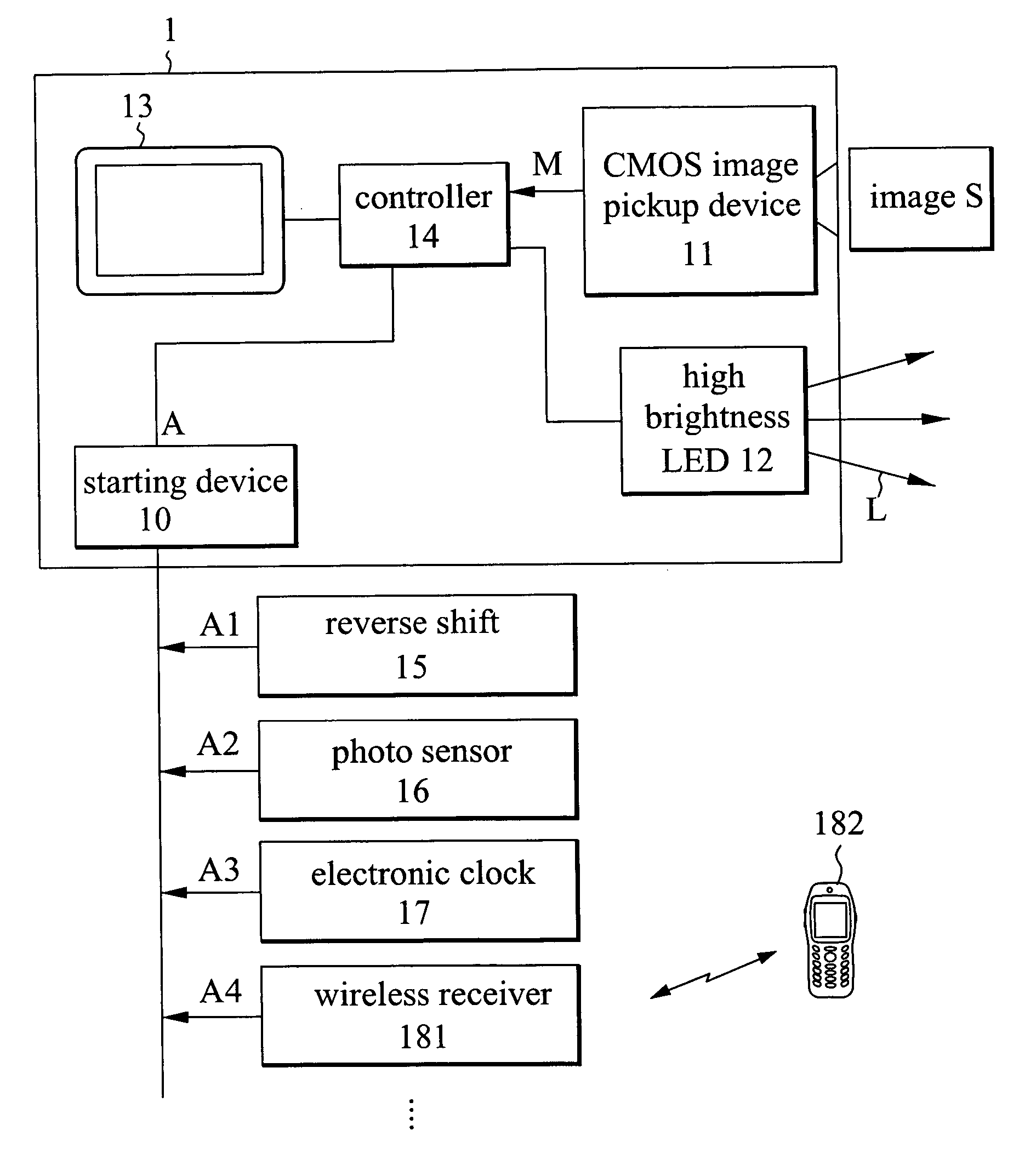

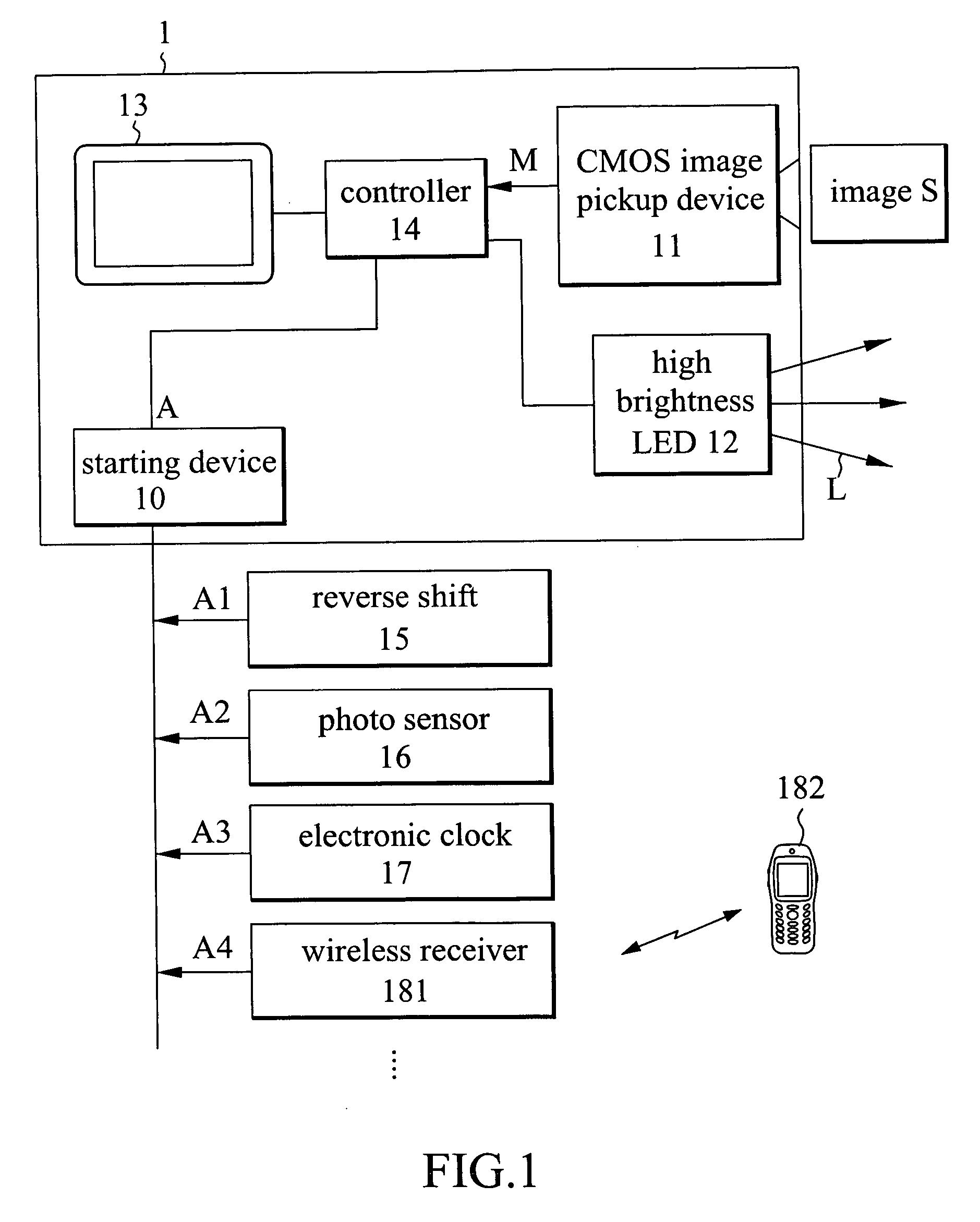

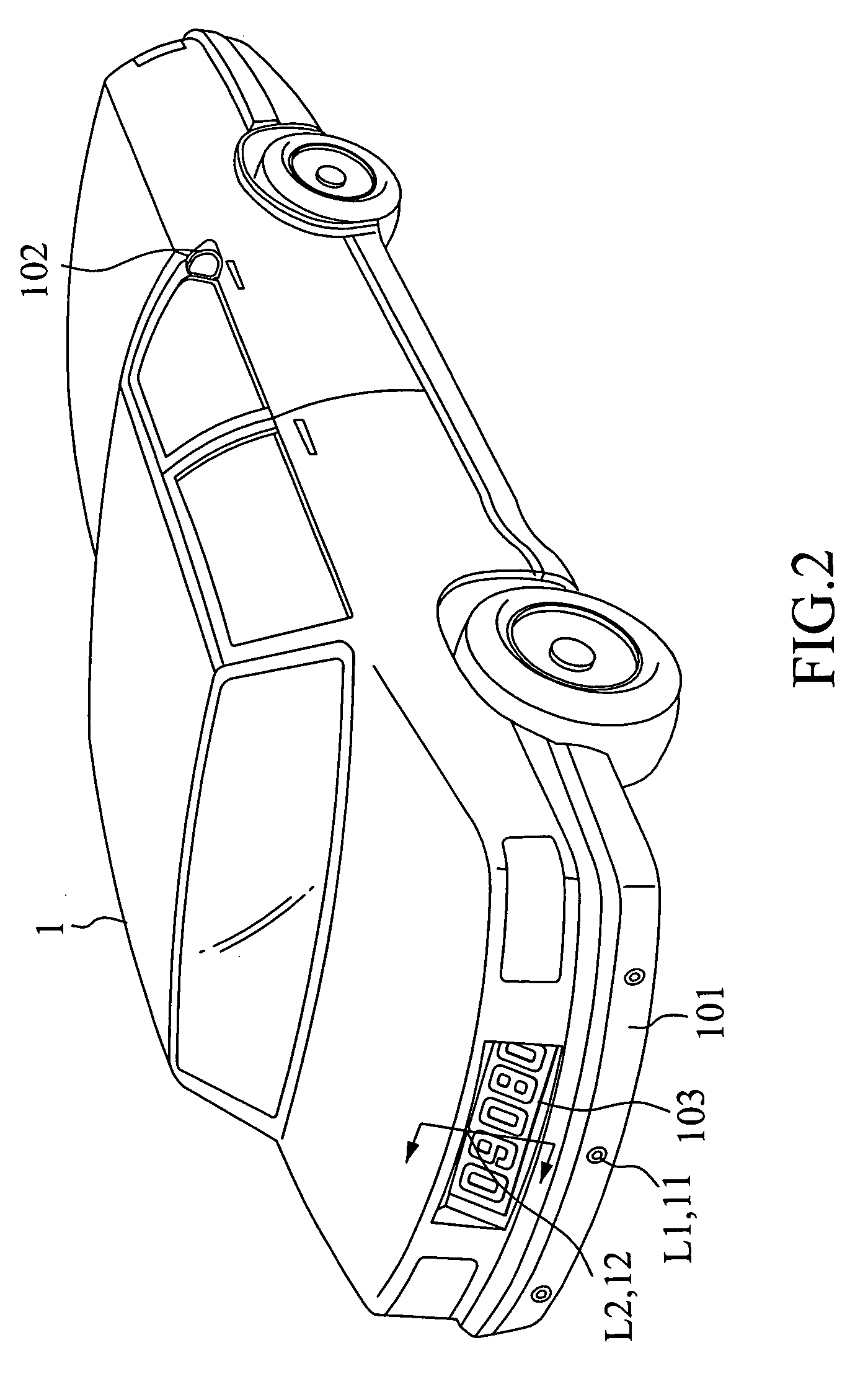

Vehicle rear side video monitoring system

InactiveUS20060176370A1Small sizeLight weightTelevision system detailsColor television detailsVideo monitoringCMOS

Disclosed is an inexpensive, easy-to-install, highly durable vehicle rear side video monitoring system, which uses a CMOS image pickup device to pick up the image of the scene behind the vehicle, and a high brightness LED to provide sufficient illumination for enabling the CMOS image pickup device to pick up the image clearly.

Owner:XINGYI SCI & TECH

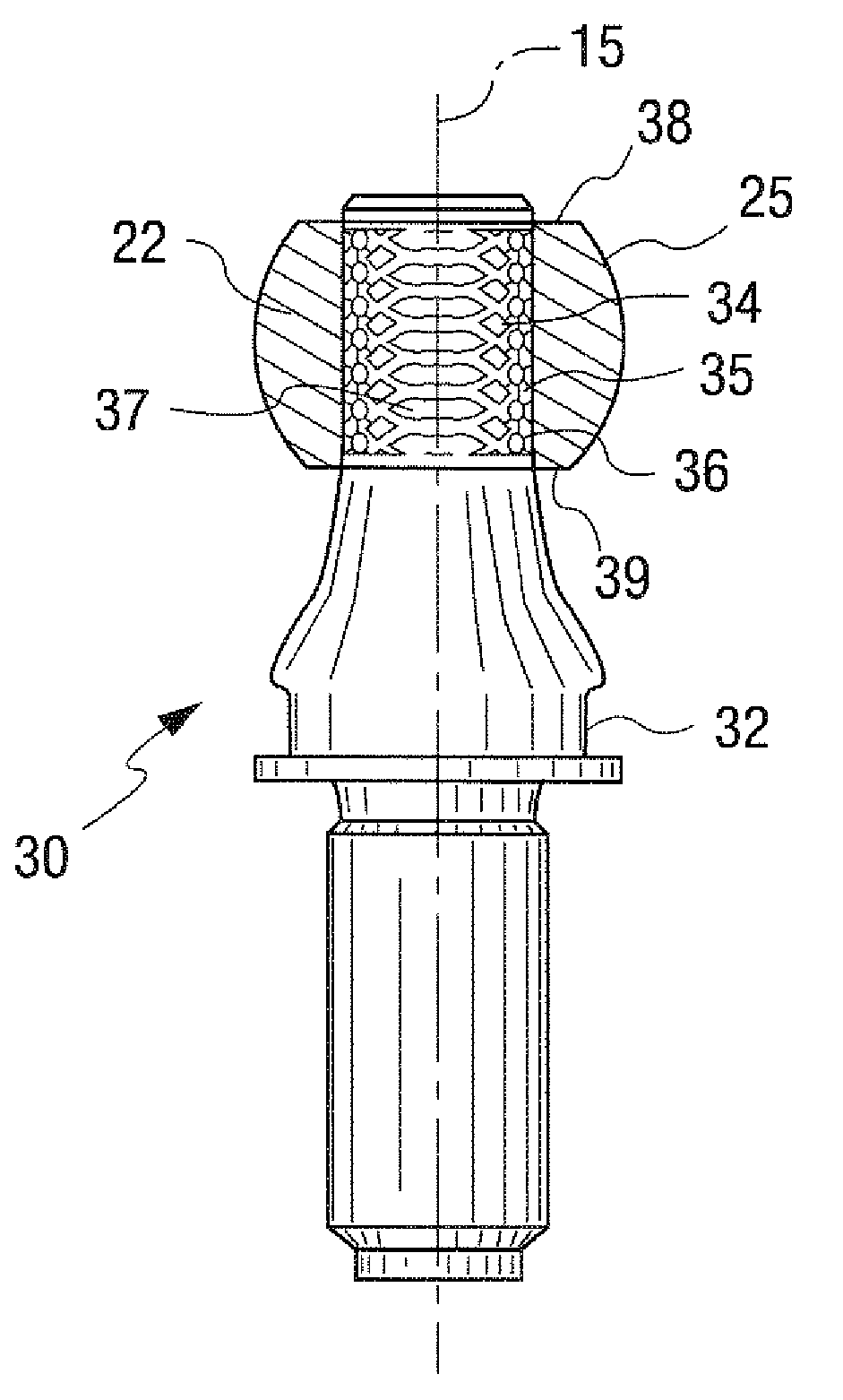

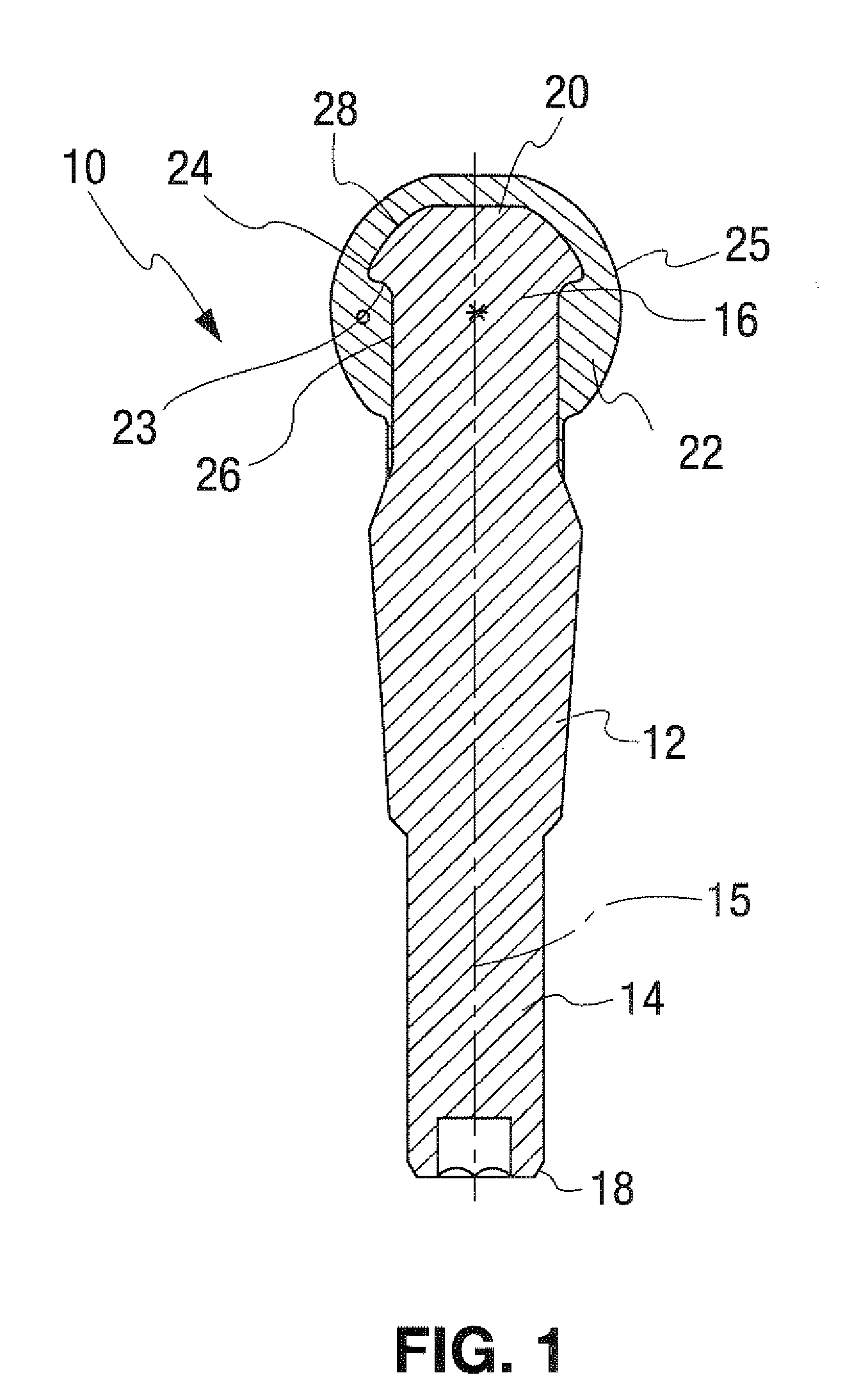

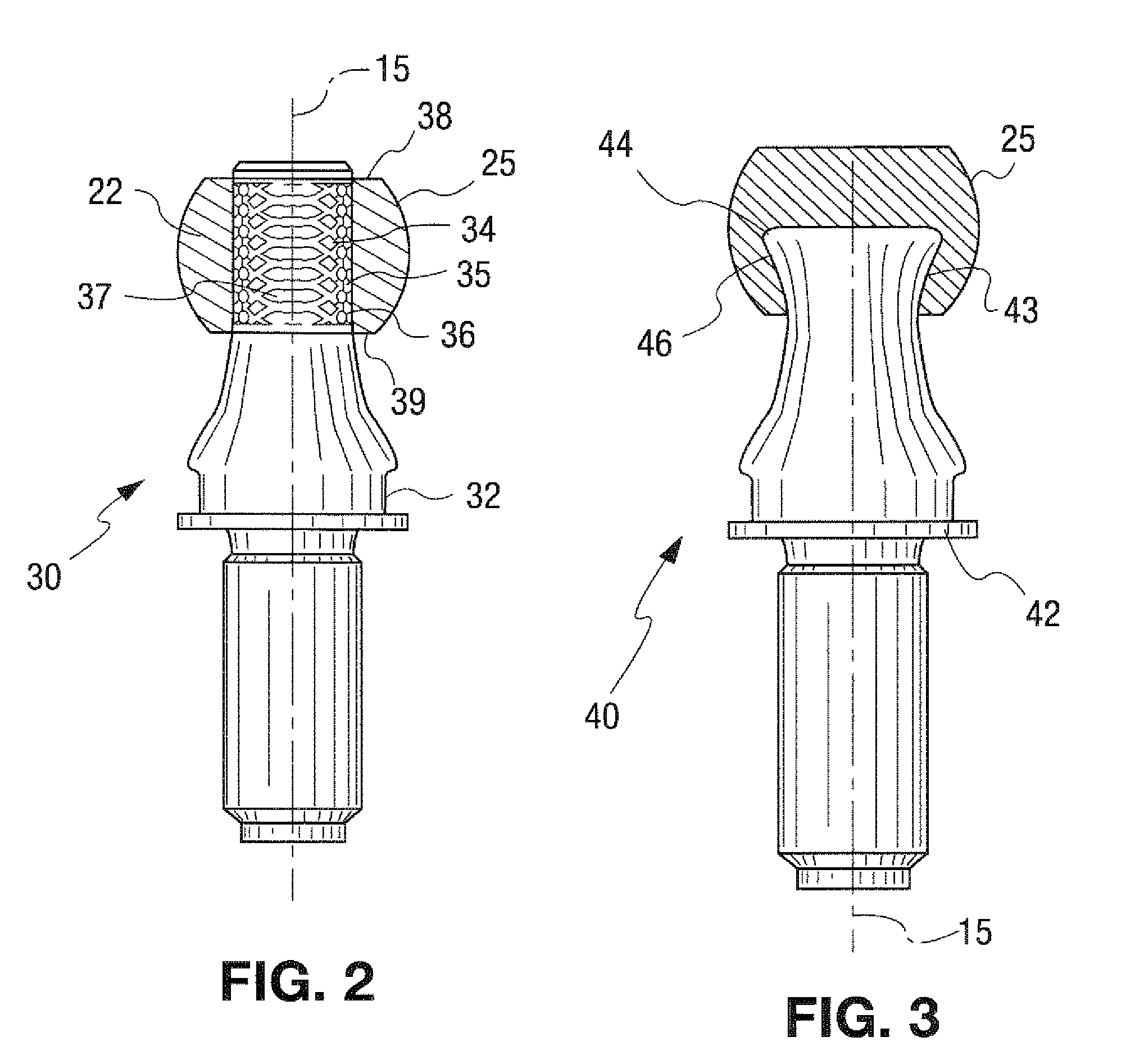

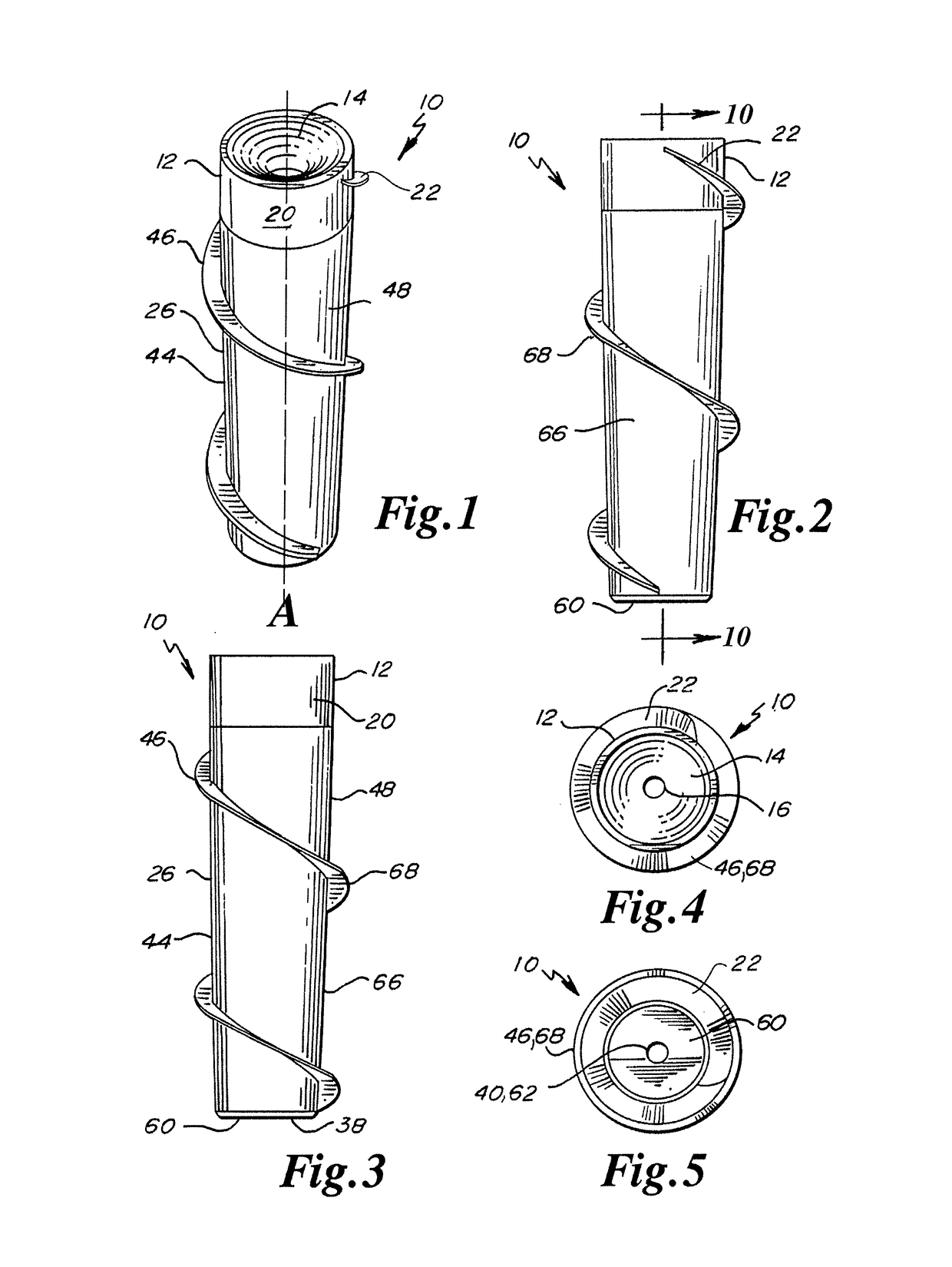

Ball-and-socket joint ball pin with injection molded metal ball

InactiveUS20090003927A1Improve carrying capacityLow costSteering linkagesCouplings for rigid shaftsEngineeringInjection molding process

A metallic ball pin of a ball-and-socket joint, preferably one with high load-bearing capacity, for motor vehicles with a surface ball part 22 containing grooves 60, 62 for receiving lubricant designed at one end of a pin member 10, 30, 40. To improve its functional properties and to reduce its manufacturing costs, a surface ball part 22 with a joint ball surface 25 is molded to a joint ball core portion 16 using an injection molding process.

Owner:ZF LEMFOERDER METALLWAREN AG

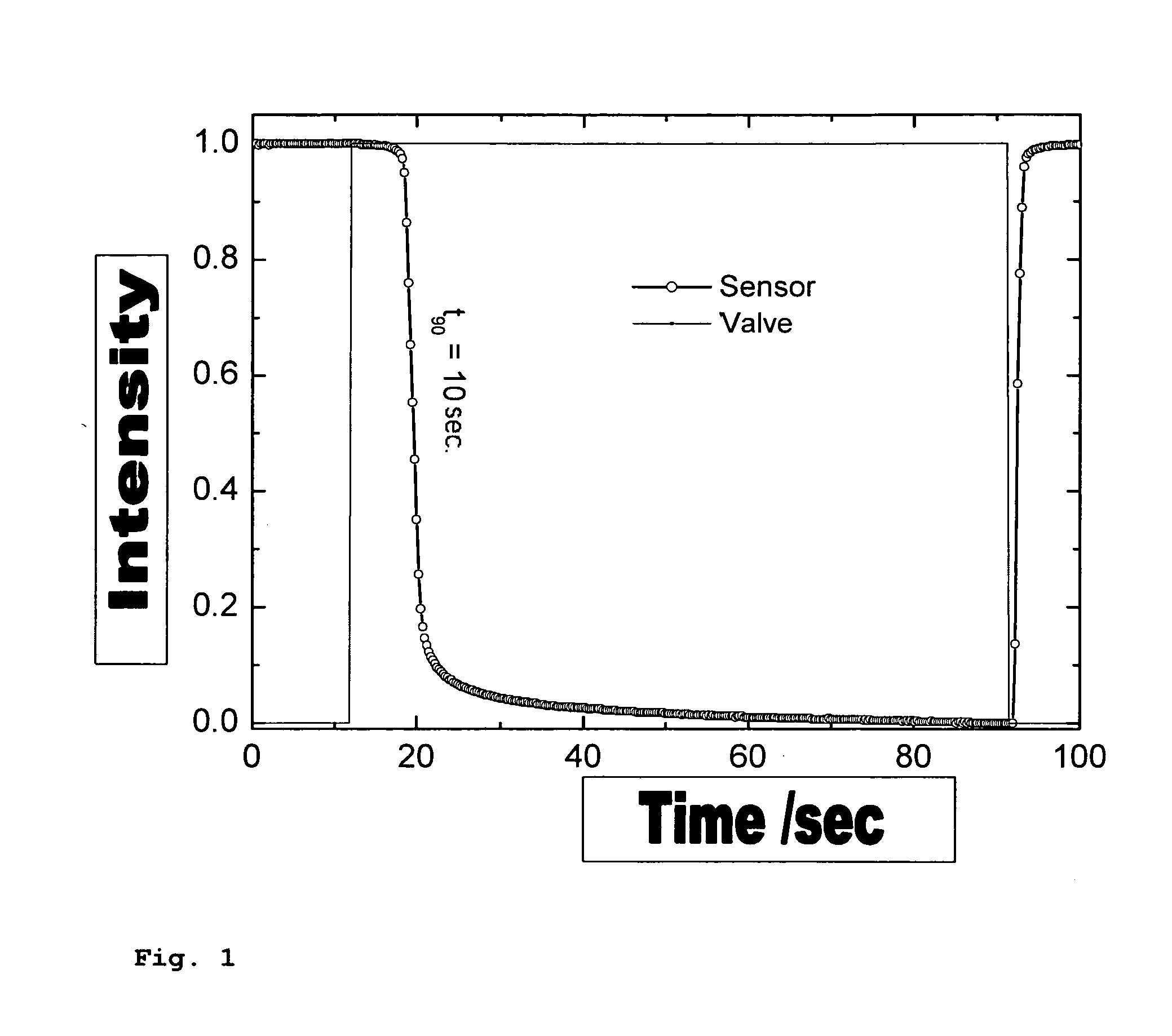

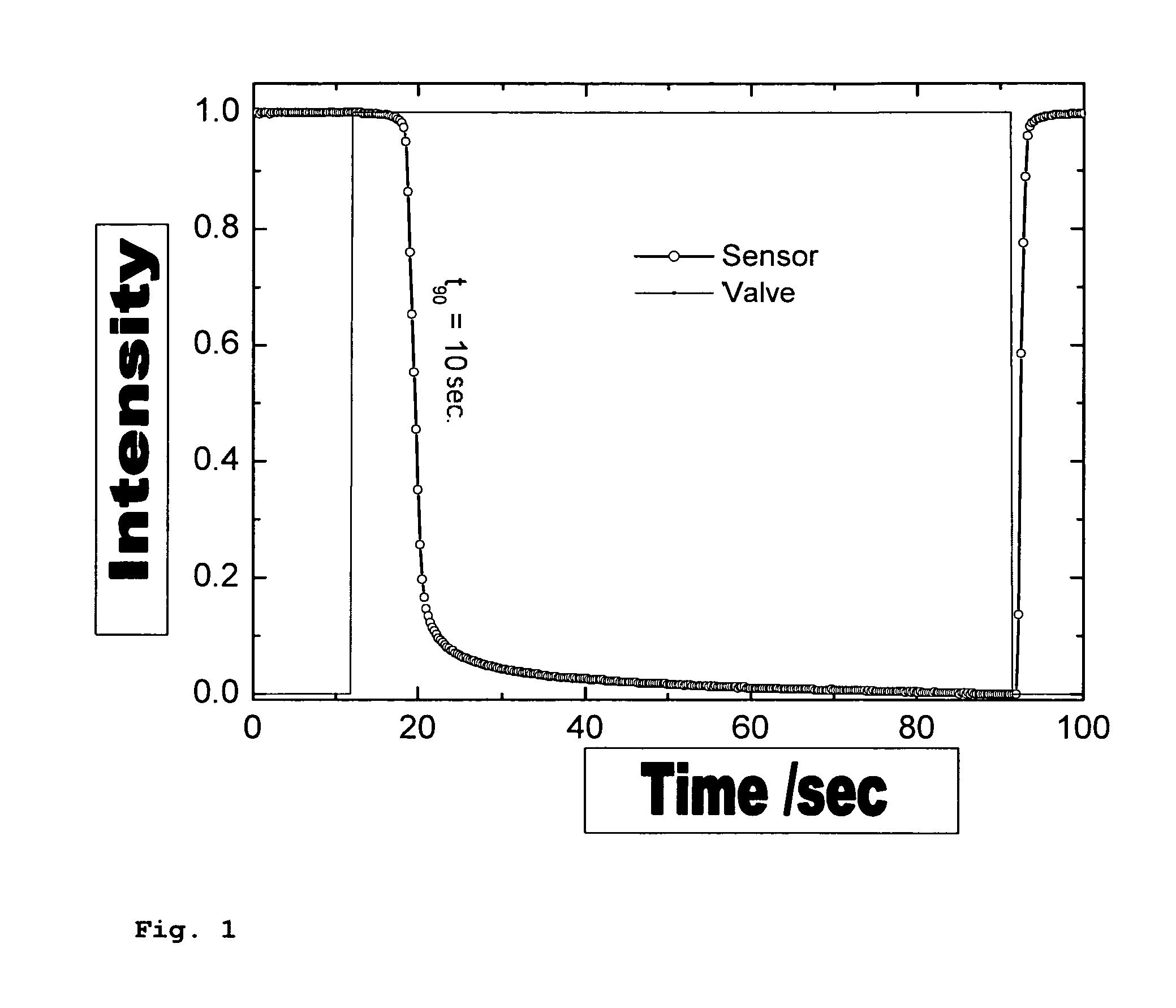

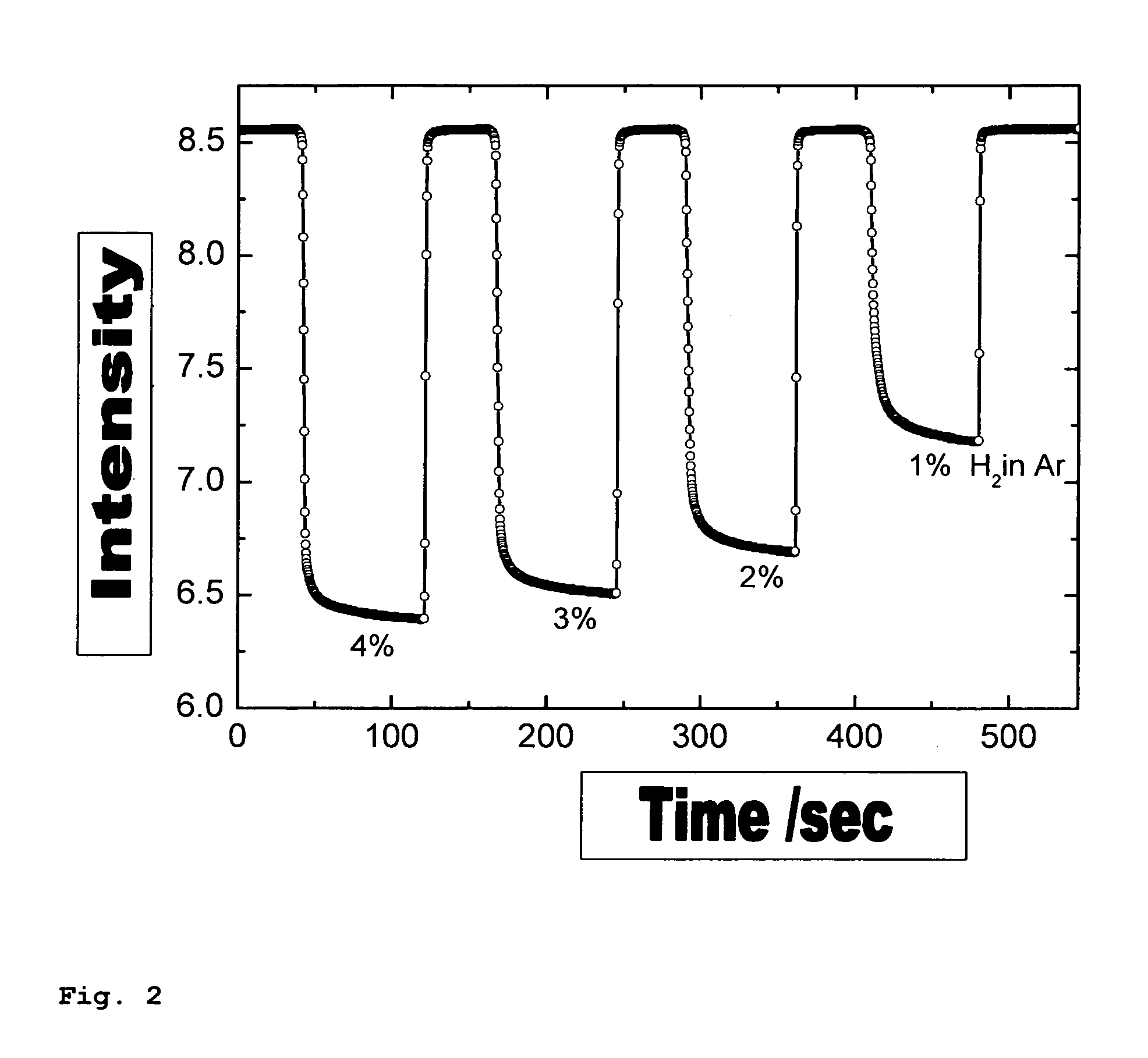

Invention Concerning Gas Sensors

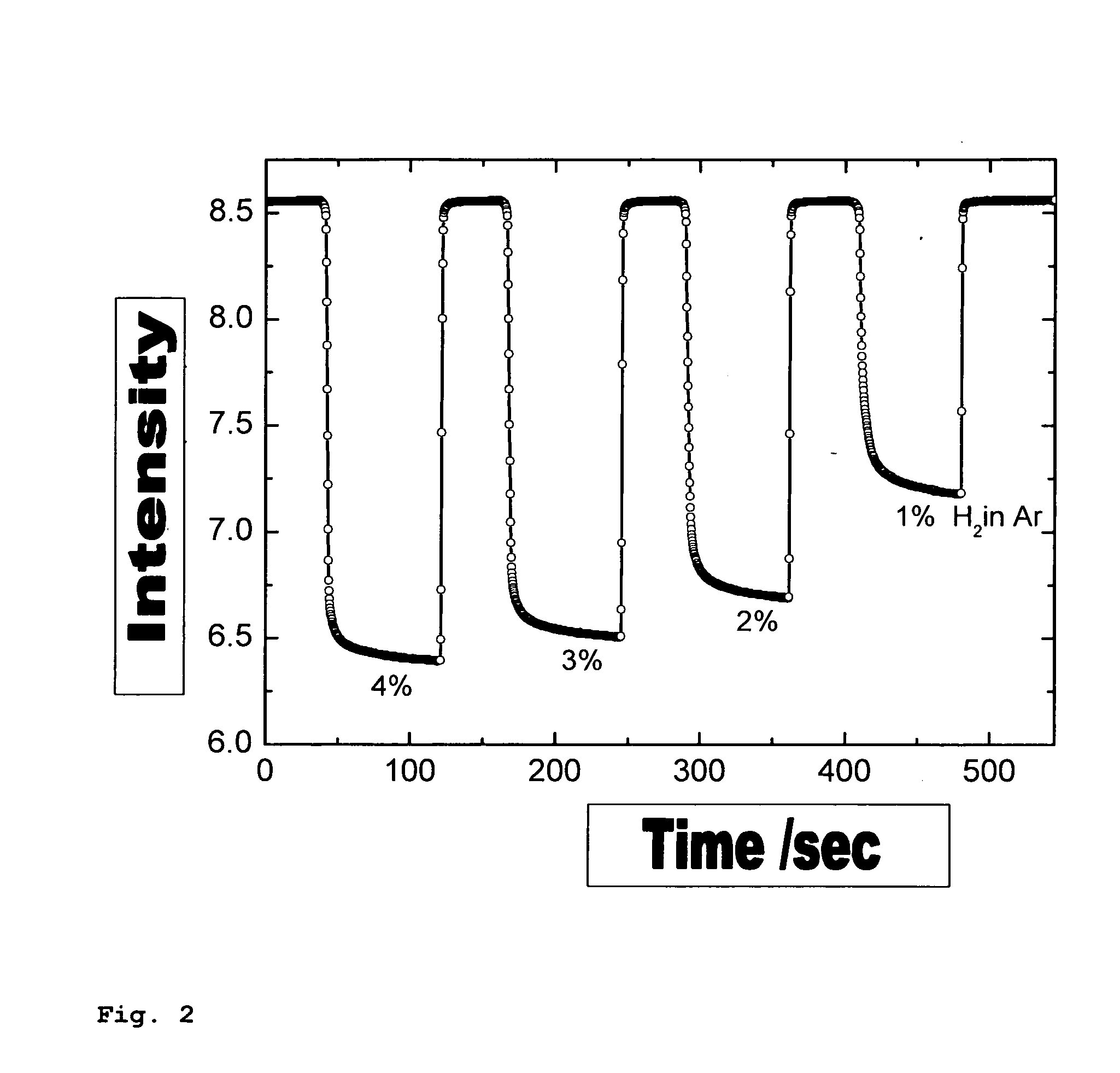

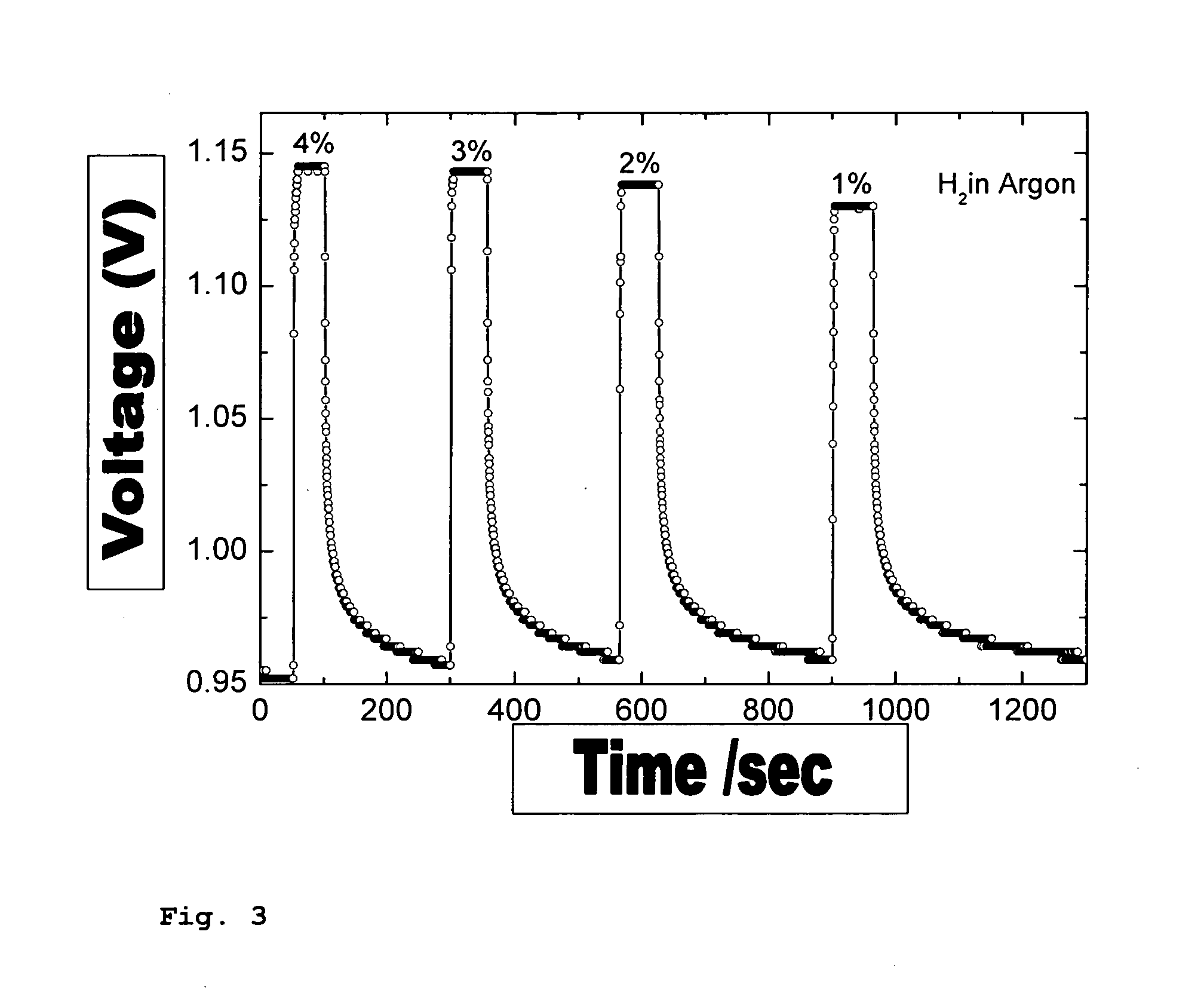

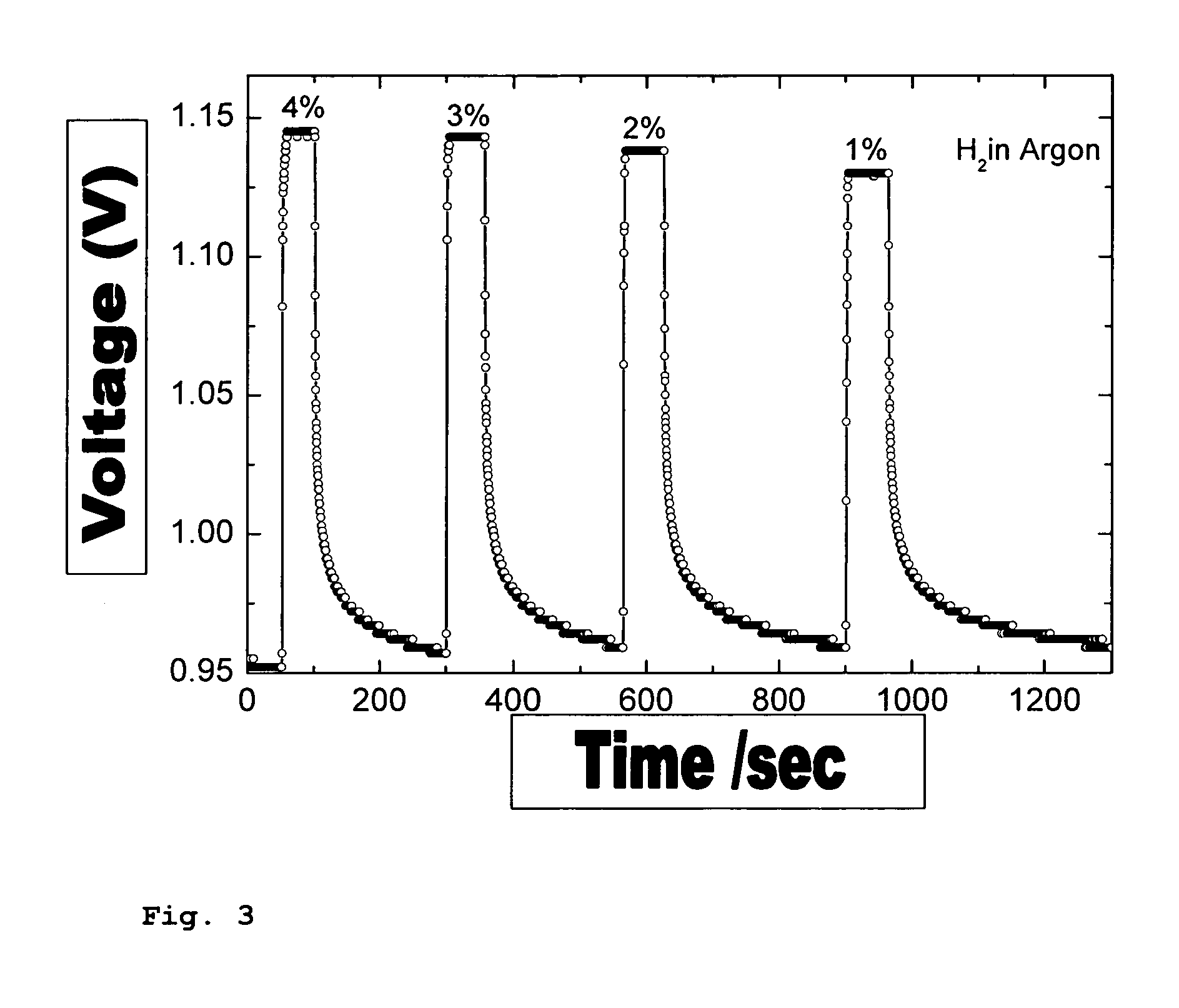

InactiveUS20090283421A1Short response timeLong serviceWeather/light/corrosion resistanceVolume/mass flow measurementHydrogenGas composition

The invention at hand concerns a novel class of gas sensors, in particular for hydrogen or hydrogen-containing fluids (gases or liquids), such as hydrocarbons, hydrogen sulphides or more complex gas mixtures or gas compositions which contain hydrogen or hydrogen compounds.

Owner:JUSTUS LIEBIG UNIV

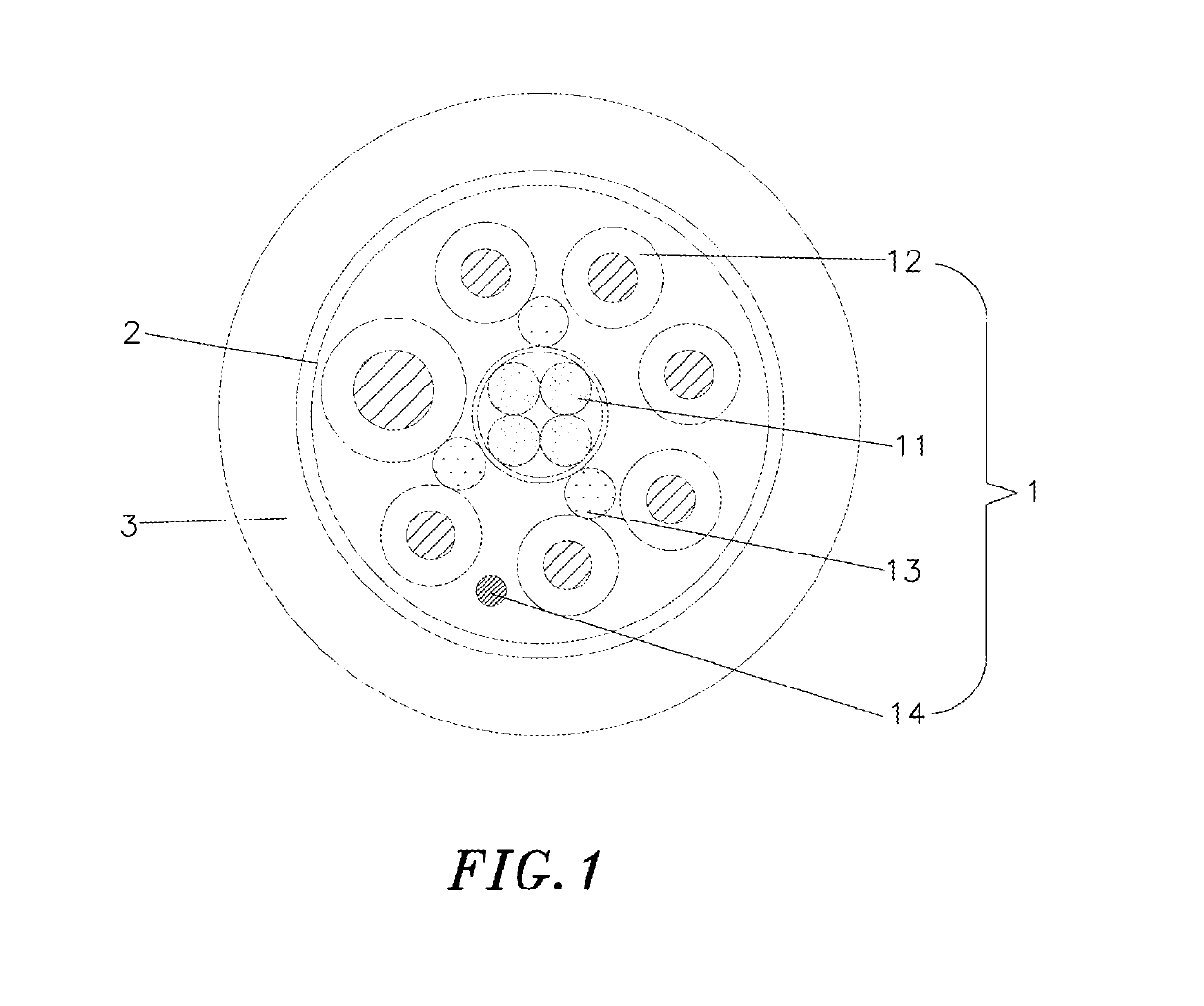

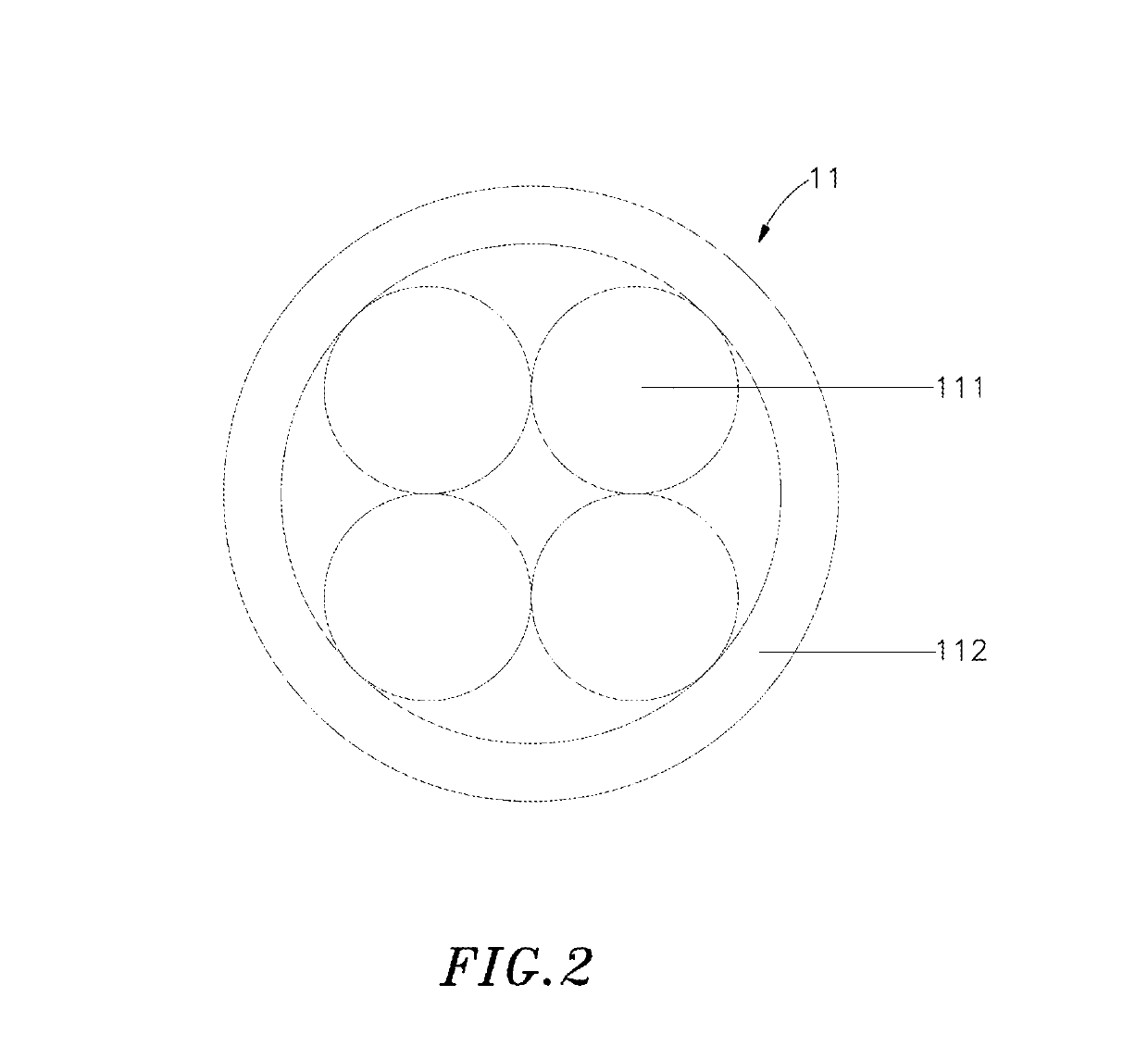

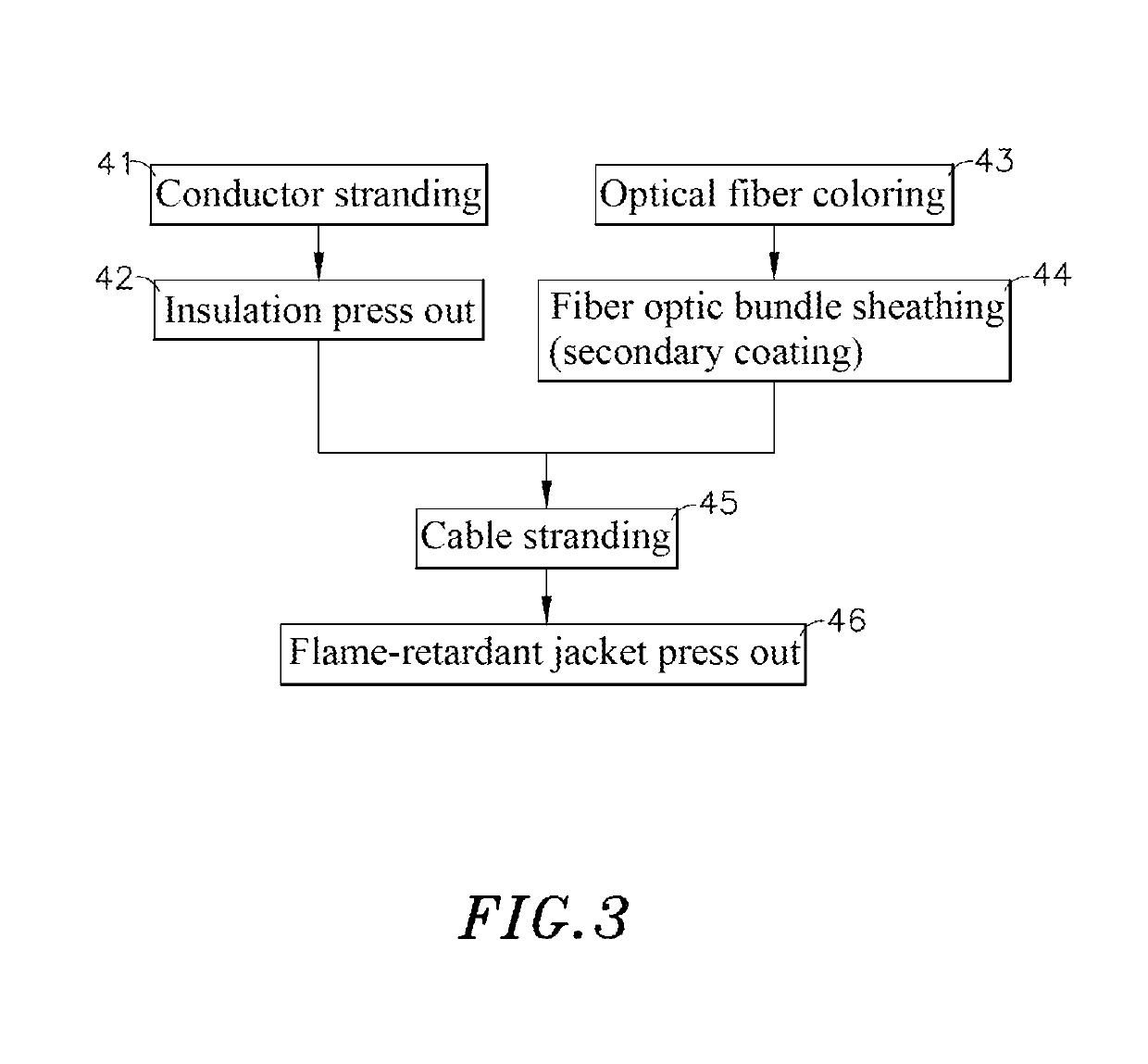

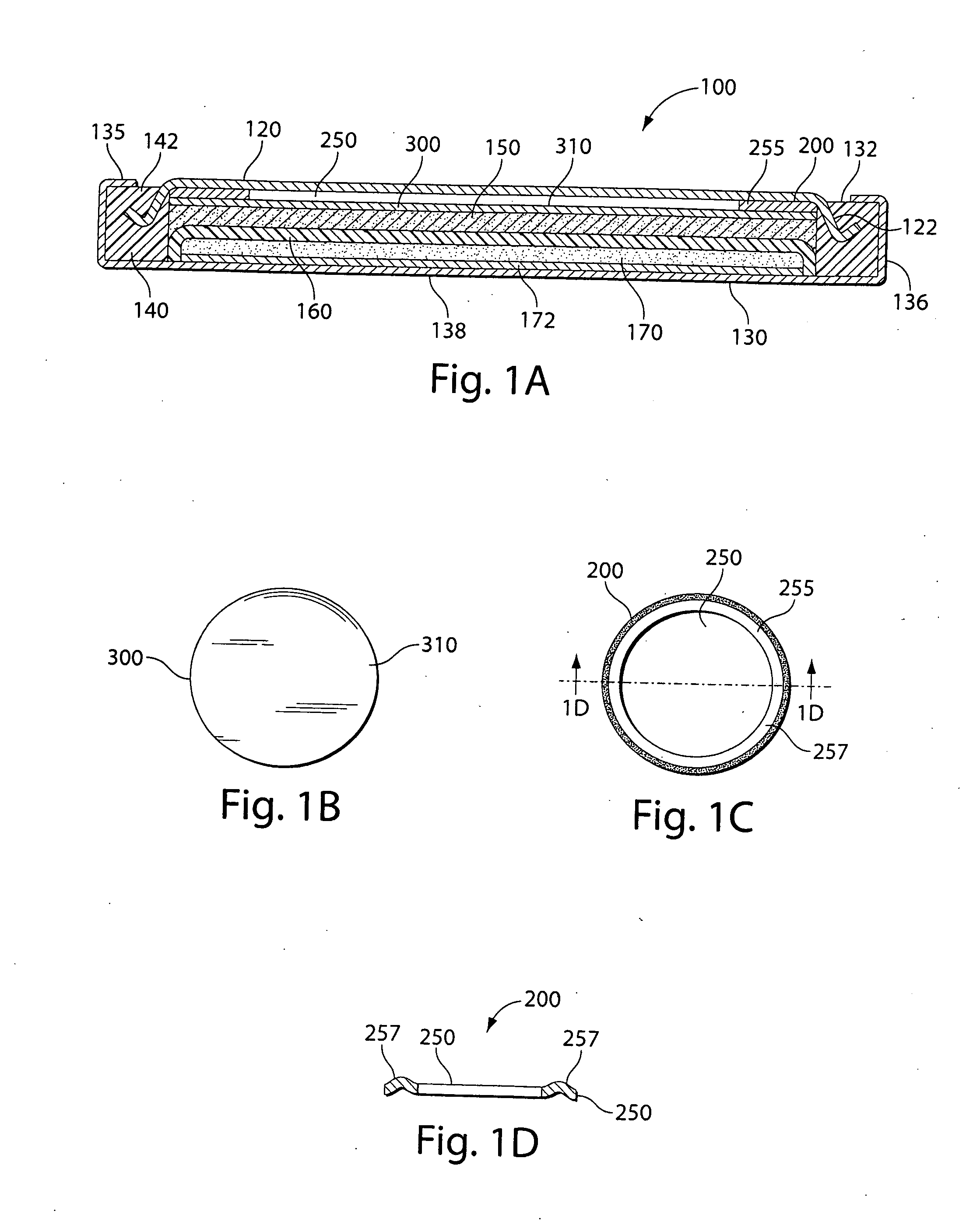

Composite optoelectronic HDMI cable

ActiveUS10345544B1Reduce signal attenuationLong distance applicationPlastic/resin/waxes insulatorsCommunication cablesUltrasound attenuationElectrical conductor

A composite optoelectronic HDMI cable having the advantages of low signal attenuation, long distance application, ease of installation and light weight is disclosed. Specifically, a fiber optic bundle unit is provided in the HDMI cable instead of the existing copper wire or alloy conductor, and the overall outer diameter is reduced by half and the weight is reduced by three quarters when compared to the copper wire or alloy conductor. It is very convenient for long-distance use or project laying.

Owner:SURE FIRE ELECTRICAL

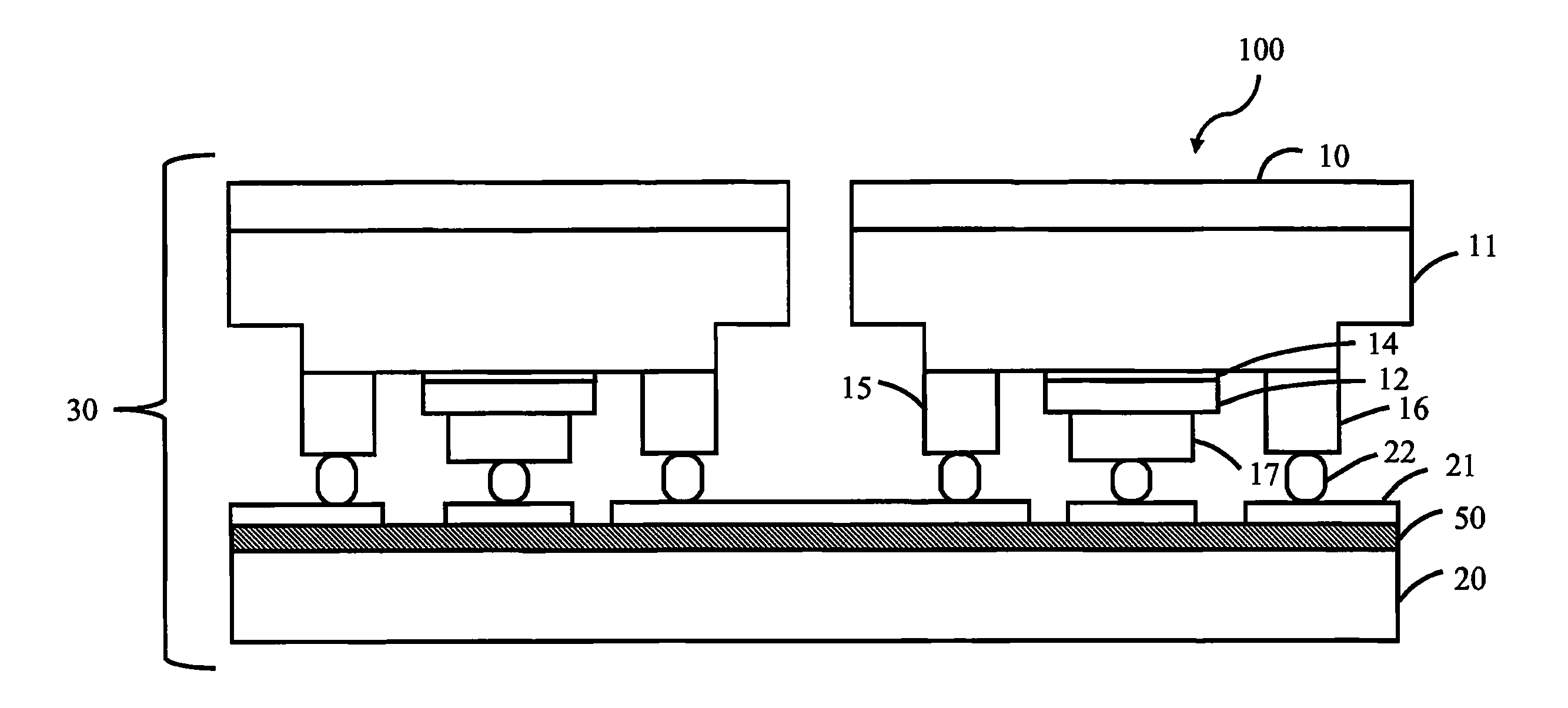

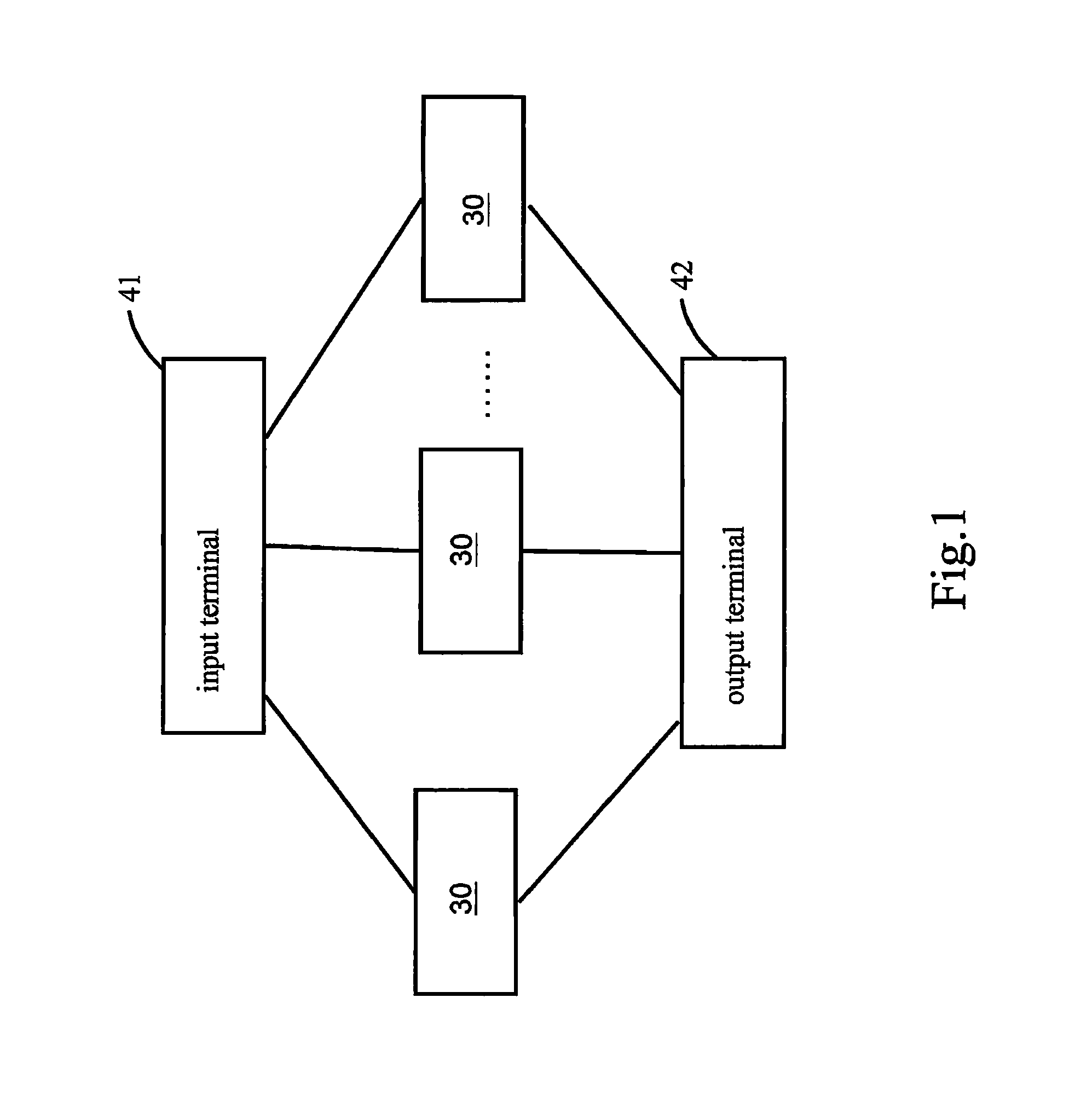

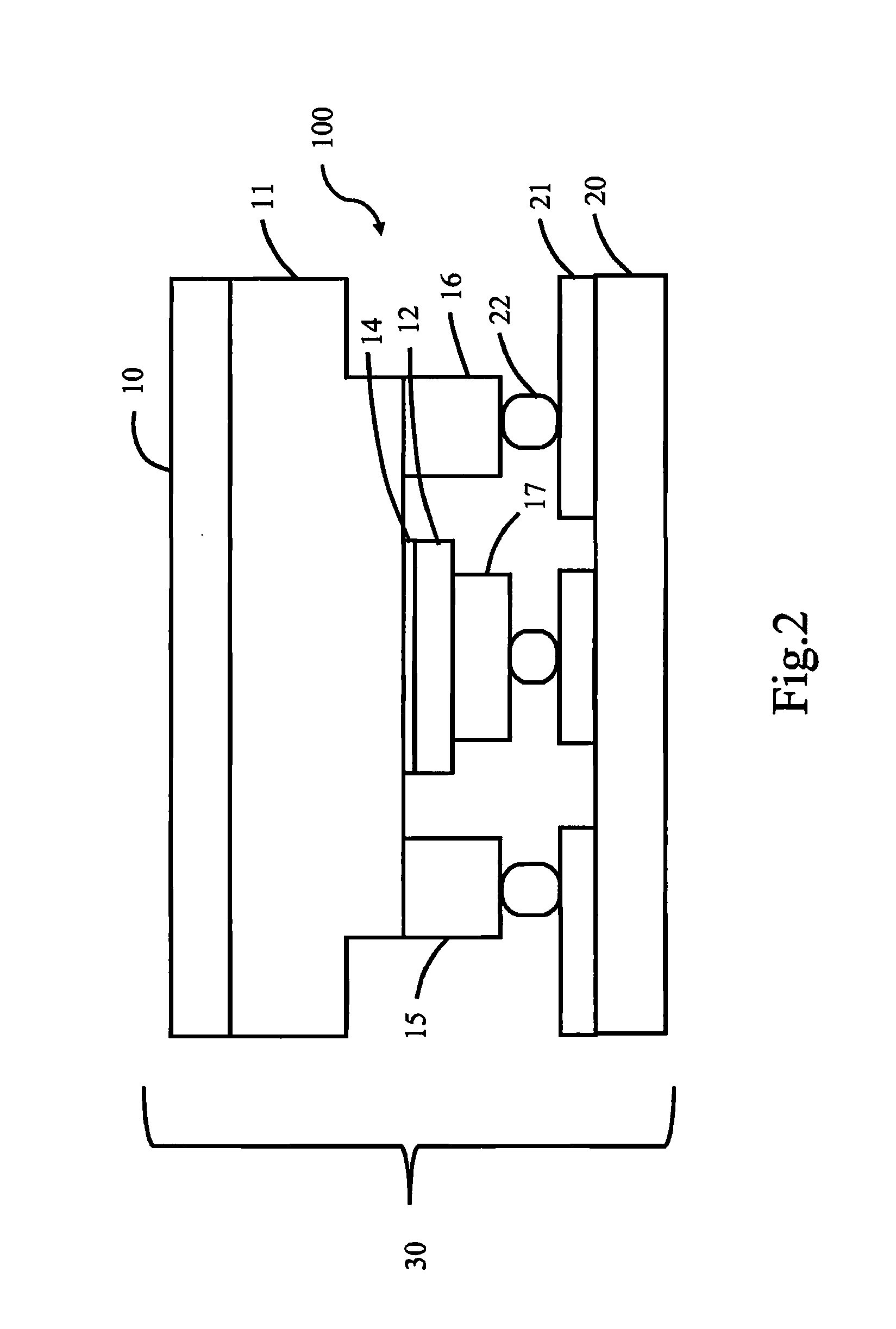

High electron mobility field effect transistor (HEMT) device

InactiveUS20100230722A1Increase heightBetter heat dissipation mechanismSolid-state devicesSemiconductor devicesHigh electronEngineering

A High Electron Mobility Transistor (HEMT) device, which is formed by connecting a plurality of low power flip-chip type High Electron Mobility Transistor (HEMT) elements in parallel, or connected them in parallel and in series in combination into a tree-shaped structure, and then connecting said structure to an input terminal and an output terminal. Distances between each of the flip-chip type HEMT elements, from each element to said input terminal, and from each element to said output terminal are designed to be equal, such that powers consumed by each of the flip-chip type HEMT elements are equal, currents flowing through are evenly distributed, and heat generated is liable to be dissipated. A spike leakage protection layer, such as zinc-oxide (ZnO) amorphous layer or poly-crystal layer, is further included, hereby further enhancing the efficiency of said flip-chip type HEMT element and prolonging its service life.

Owner:CHANG GUNG UNIVERSITY

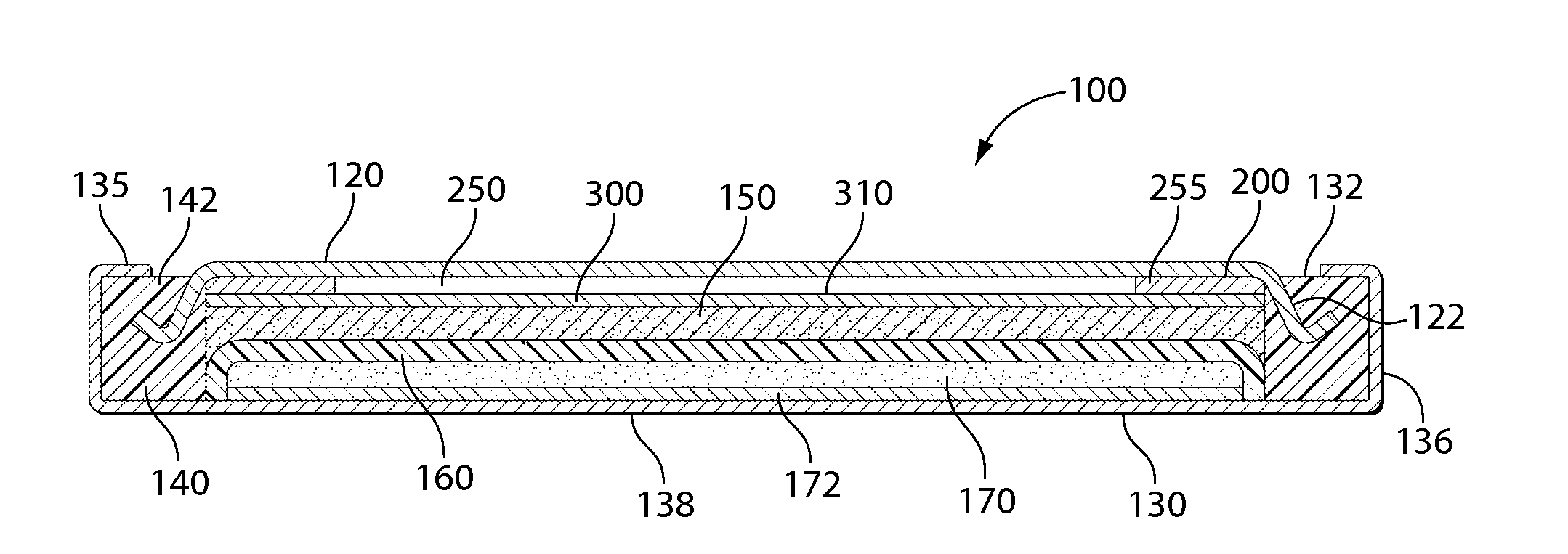

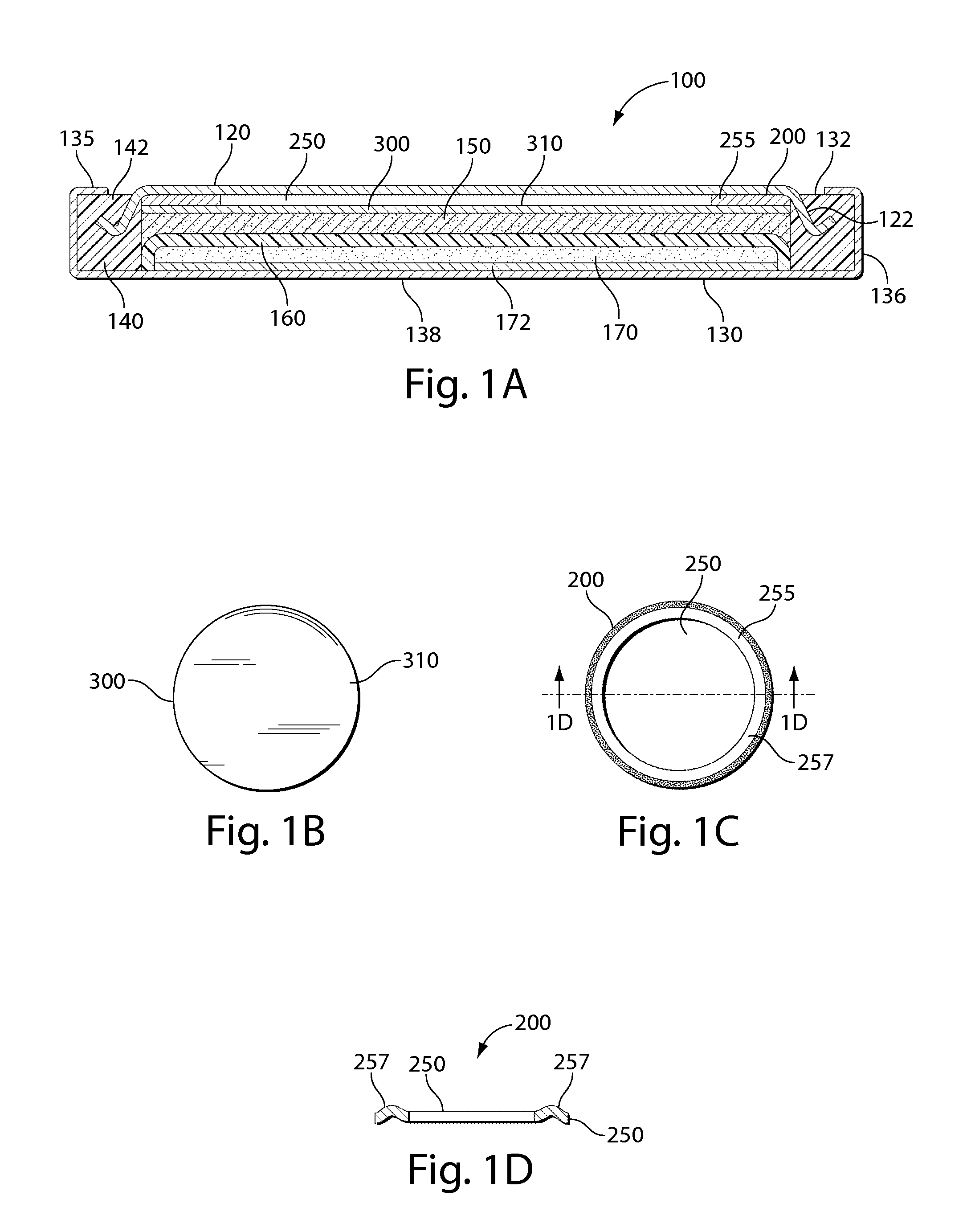

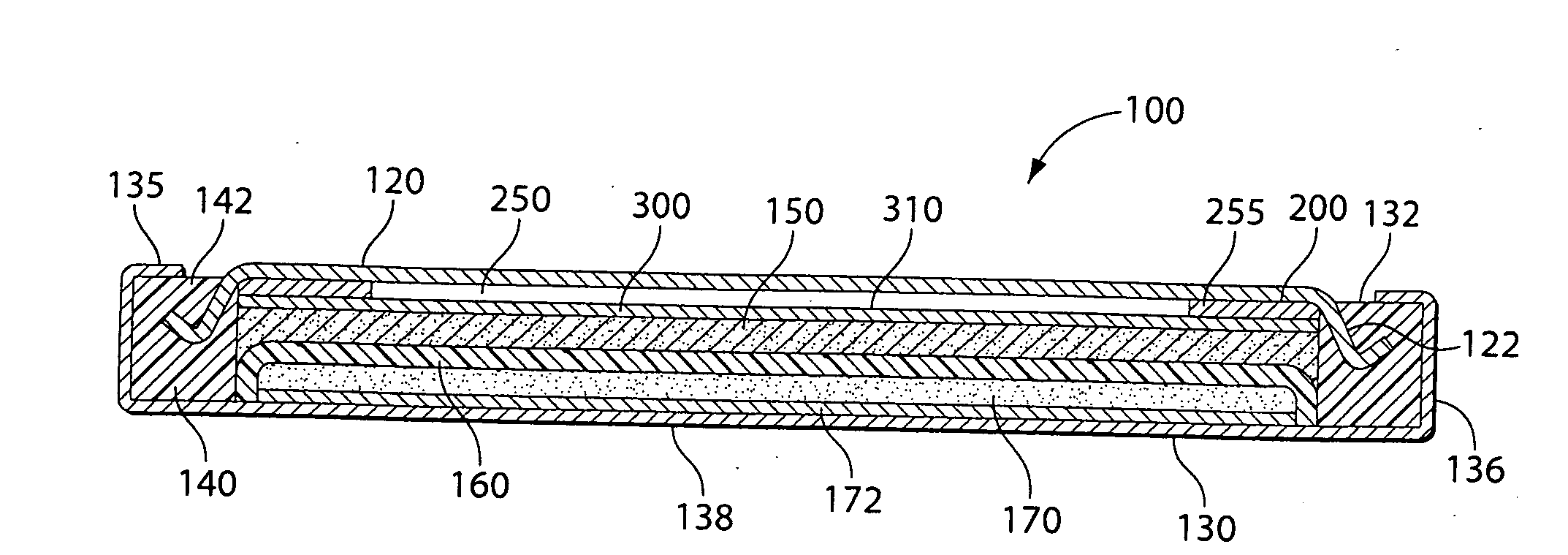

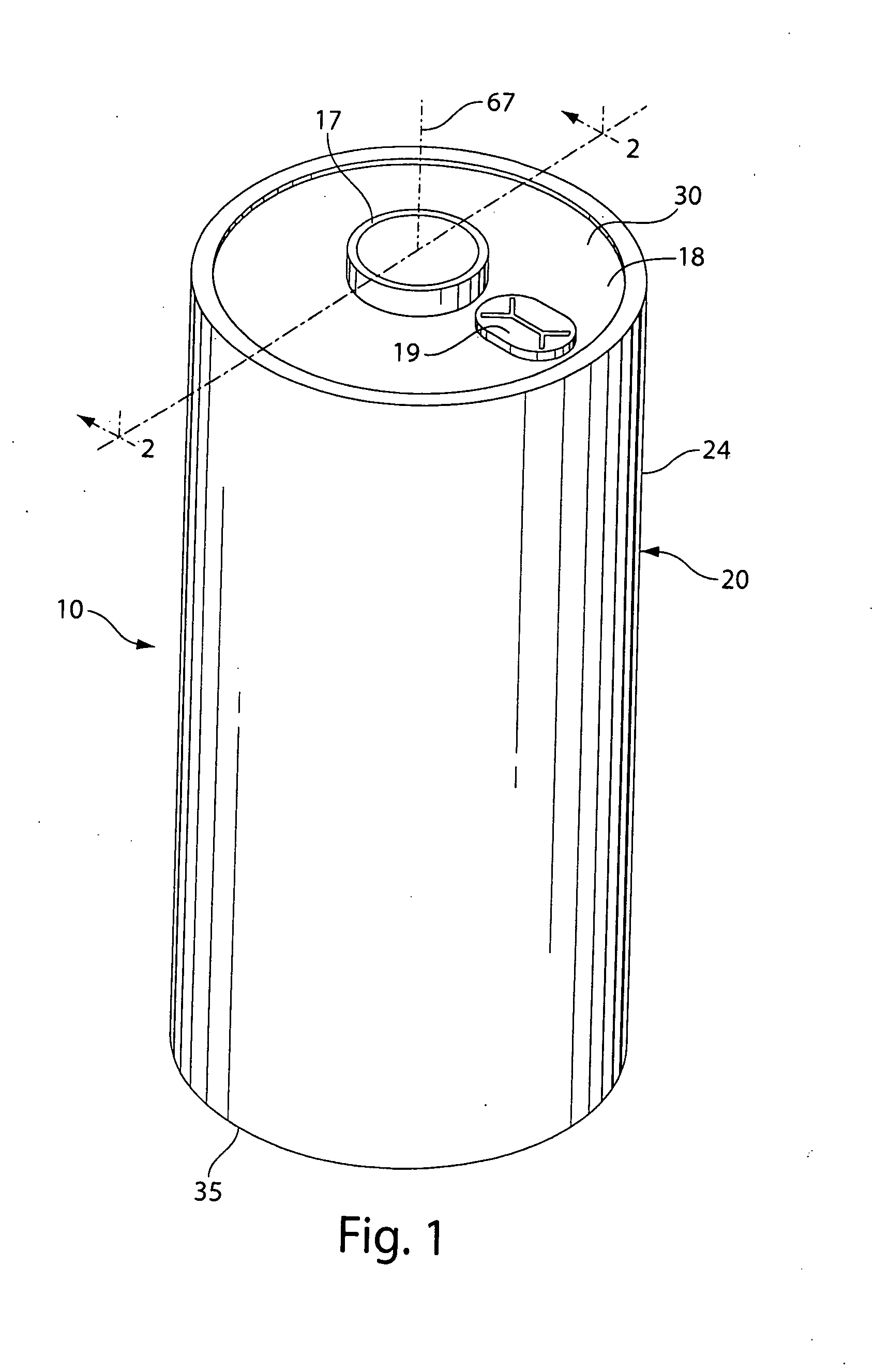

Lithium cell with cathode containing metal doped iron sulfide

ActiveUS8153296B2Improve discharge performanceLong serviceSulfur compoundsOrganic electrolyte cellsIron sulfidePrimary cell

A primary cell having an anode comprising lithium and a cathode comprising a metal doped iron sulfide and carbon particles. A cathode slurry is prepared comprising the metal doped iron sulfide powder, carbon, binder, and a liquid solvent. The mixture is coated onto a conductive substrate and solvent evaporated leaving a dry cathode coating on the substrate. The anode and cathode can be spirally wound with separator therebetween and inserted into the cell casing with electrolyte then added.

Owner:DURACELL U S OPERATIONS

System for capturing Asian carps

InactiveCN104855353ALong serviceHighly precise and specific trappingFishingSound barrierTreatment effect

The invention discloses a system for capturing Asian carps. The system comprises a tugboat, an acousto-optic generator arranged at the tail of the tugboat, and a floating fishing bed arranged at the rear of the tugboat, wherein sound and light production of the acousto-optic generator is controlled through an acousto-optic controller; the floating fishing bed is connected with the tugboat through a traction mooring rope; a sound barrier device is arranged at the front part of the floating fishing bed and is used for reflecting sound and light generated by the acousto-optic generator; during the proceeding process of the tugboat, the acousto-optic generator arranged at the tail of the tugboat is adopted to simulate sound and light rays of nature having a stimulation effect on different fish varieties of Asian Cyprinidae so as to stimulate the Asian carps in water, so that the Asian carps jump out of the water surface, naturally fall on the floating fishing bed on the condition that the floating fishing bed moves in a cooperative manner, and then are captured. According to the invention, the biological attributes of the fish varieties of Asian Cyprinidae are utilized to manually simulate sound and light illumination so as to induce the fish varieties of Asian Cyprinidae to jump out of the water surface in groups and be captured in batches, so that the ecological treatment effect of restraining biological invasion is realized.

Owner:罗康隆

Lithium cell with cathode containing metal doped iron sulfide

ActiveUS20100055574A1Improve battery performanceLow viscosityConductive materialSulfur compoundsMetallurgyIron sulfide

A primary cell having an anode comprising lithium and a cathode comprising a metal doped iron sulfide and carbon particles. A cathode slurry is prepared comprising the metal doped iron sulfide powder, carbon, binder, and a liquid solvent. The mixture is coated onto a conductive substrate and solvent evaporated leaving a dry cathode coating on the substrate. The anode and cathode can be spirally wound with separator therebetween and inserted into the cell casing with electrolyte then added.

Owner:DURACELL U S OPERATIONS

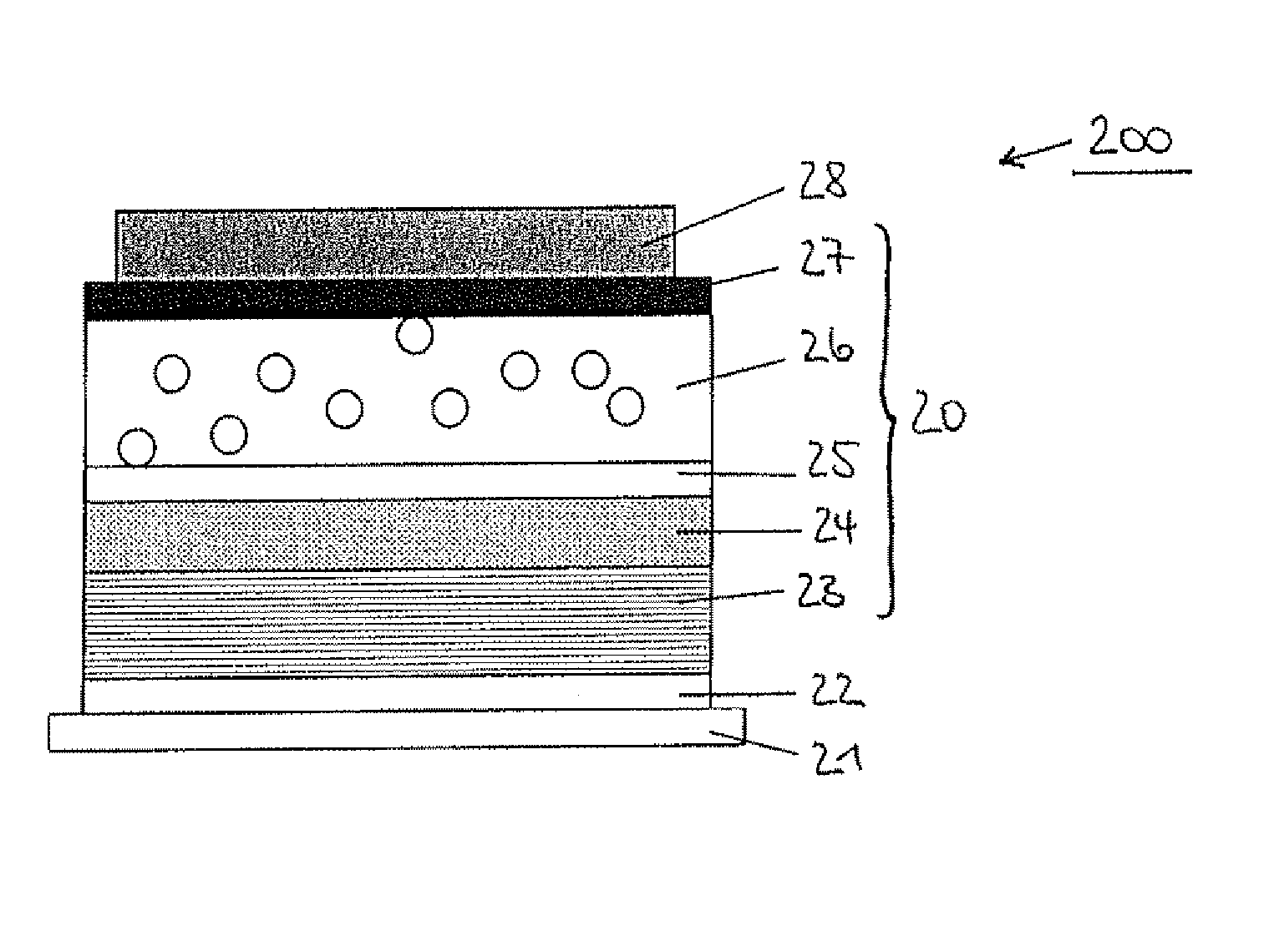

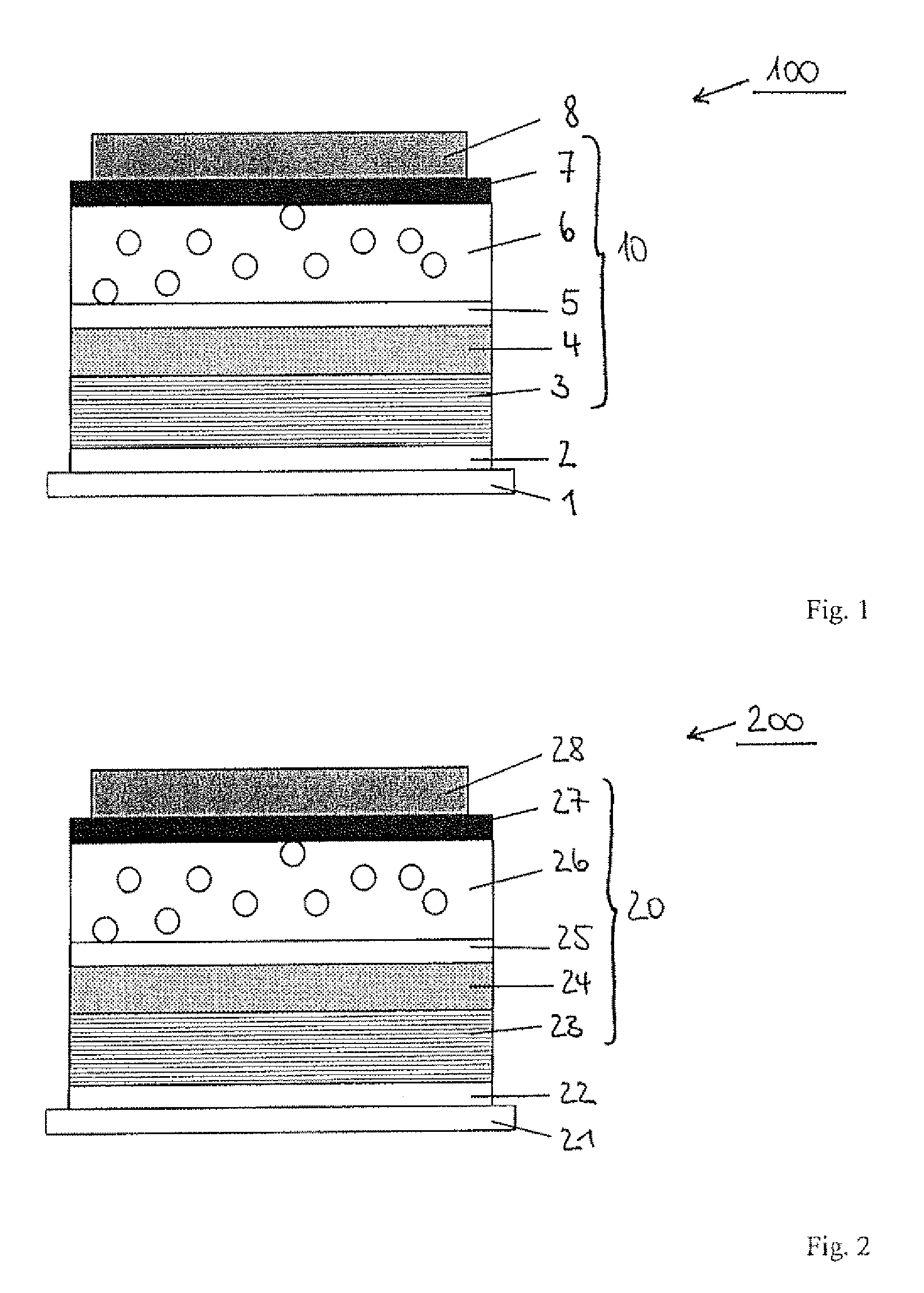

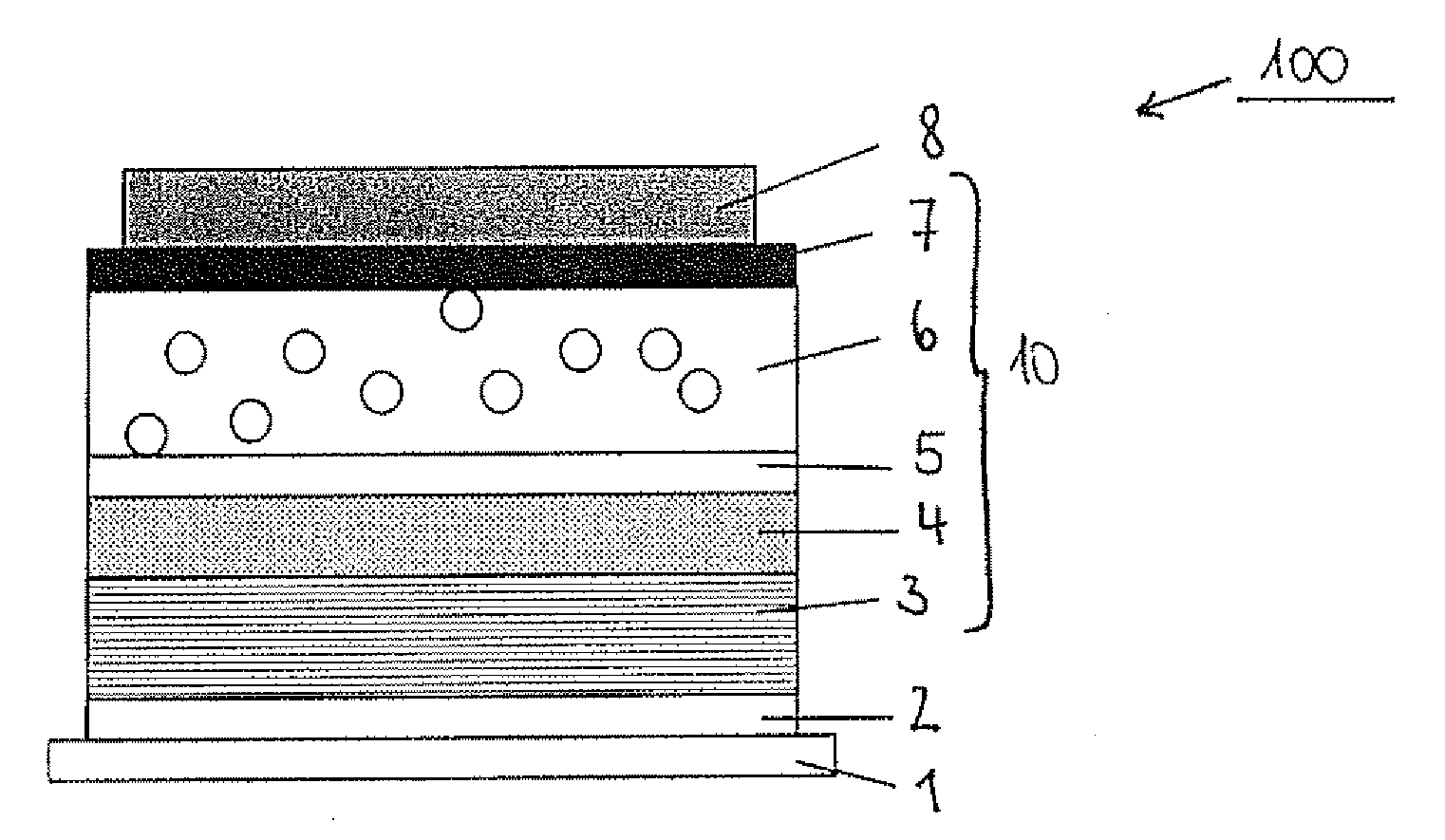

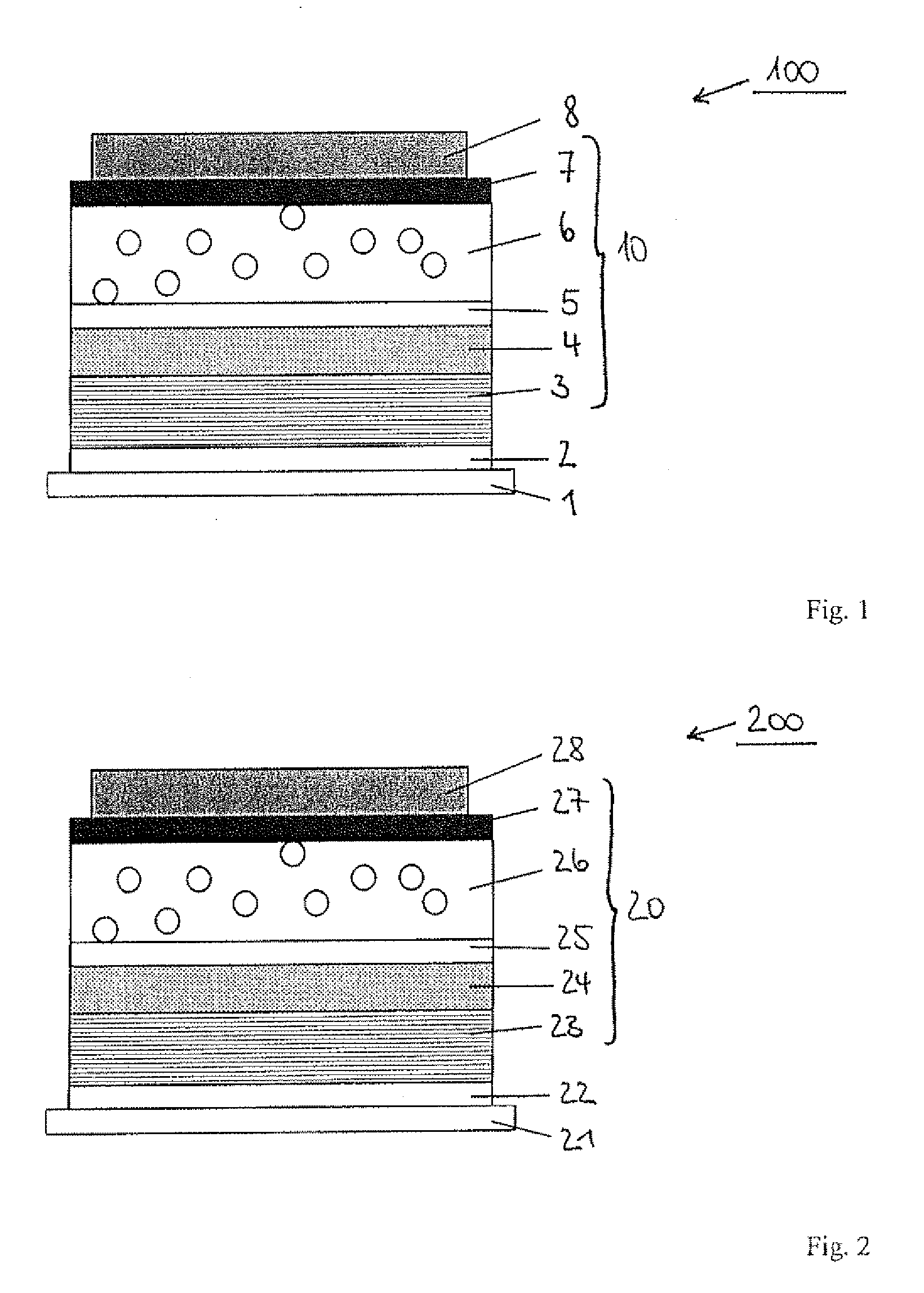

Light-emitting component

ActiveUS8569743B2Increase flexibilityImprove rendering capabilitiesElectroluminescent light sourcesSolid-state devicesLight-emitting diodeLight emitting device

The invention relates to a light-emitting device, in particular a light-emitting diode, with an arrangement of layers on a substrate, wherein the arrangement of layers has an anode contact and a cathode contact which are in electrical contact with a light-emitting layer stack arranged between the anode contact and the cathode contact which, on its part, comprises a polymer layer consisting of a polymer material and a low-molecular layer of vacuum-deposited small molecules of an organic material, and wherein the small molecules of the low-molecular layer are formed as donor molecules with an oxidation potential versus Fc / Fc+ (ferrocene / ferrocenium redox couple) of maximum approx. −1.5 V, if the low-molecular layer is arranged adjacent to the cathode contact, and as acceptor molecules with a reduction potential versus Fc / Fc+ (ferrocene / ferrocenium redox couple) of minimum approx. −0.3 V if the low-molecular layer is arranged adjacent to the anode contact.

Owner:NOVALED GMBH

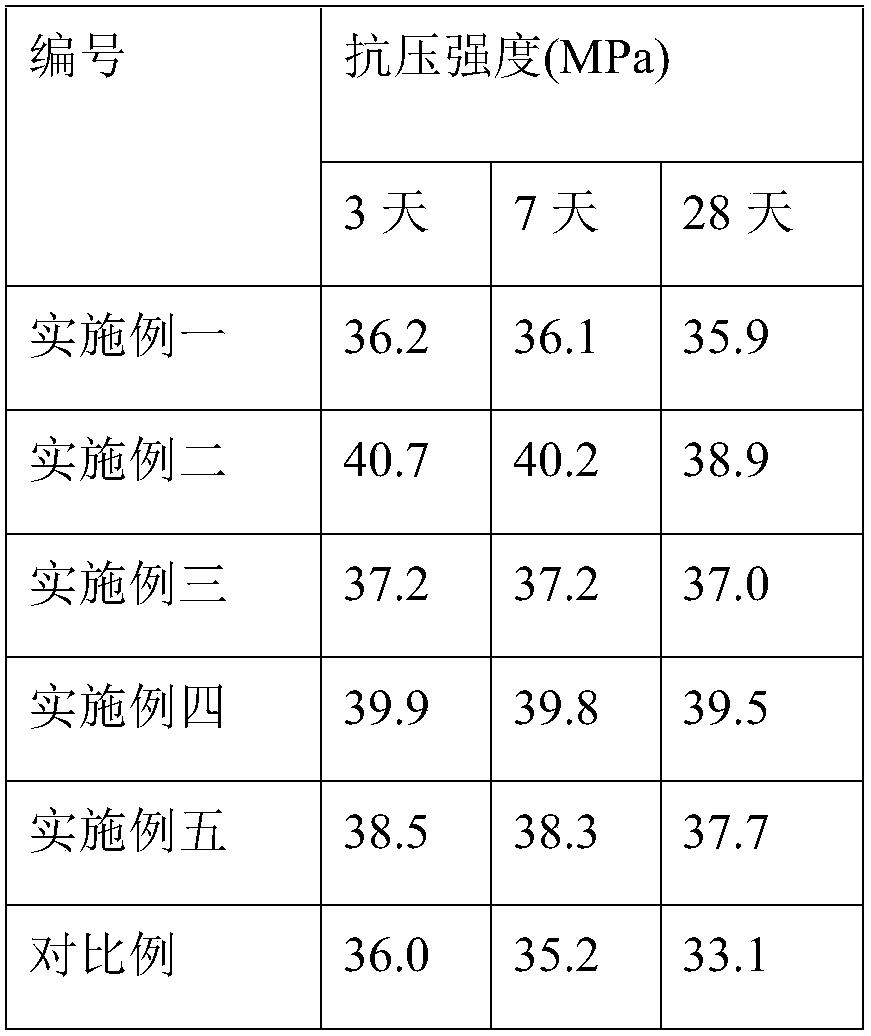

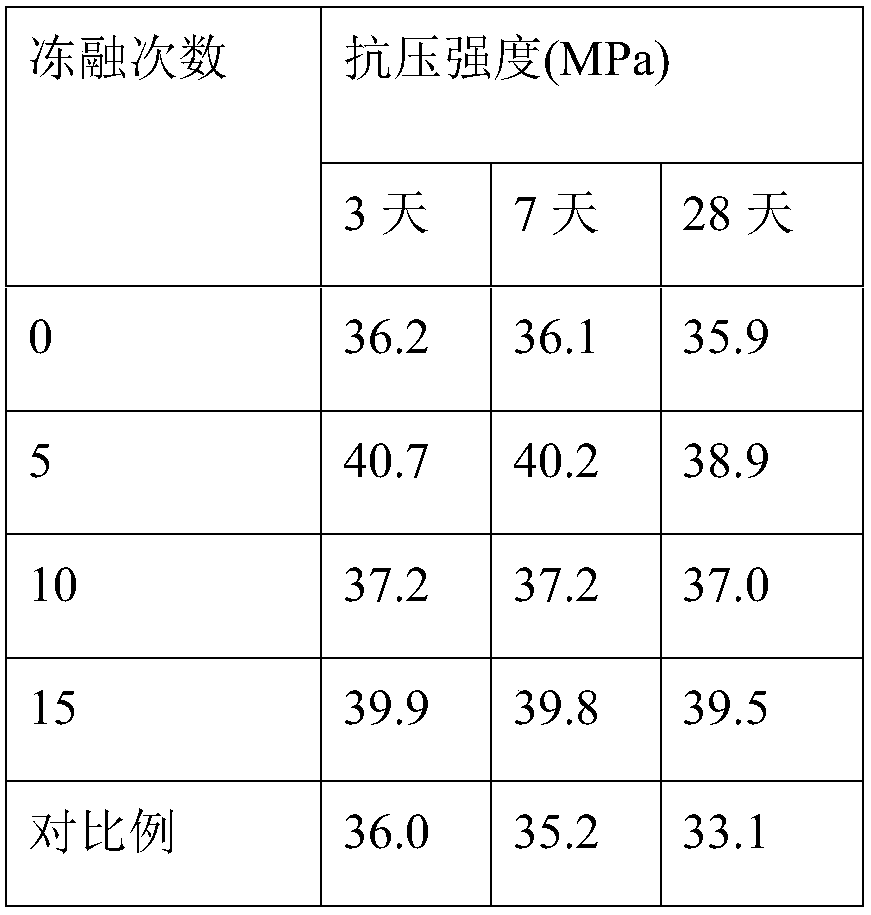

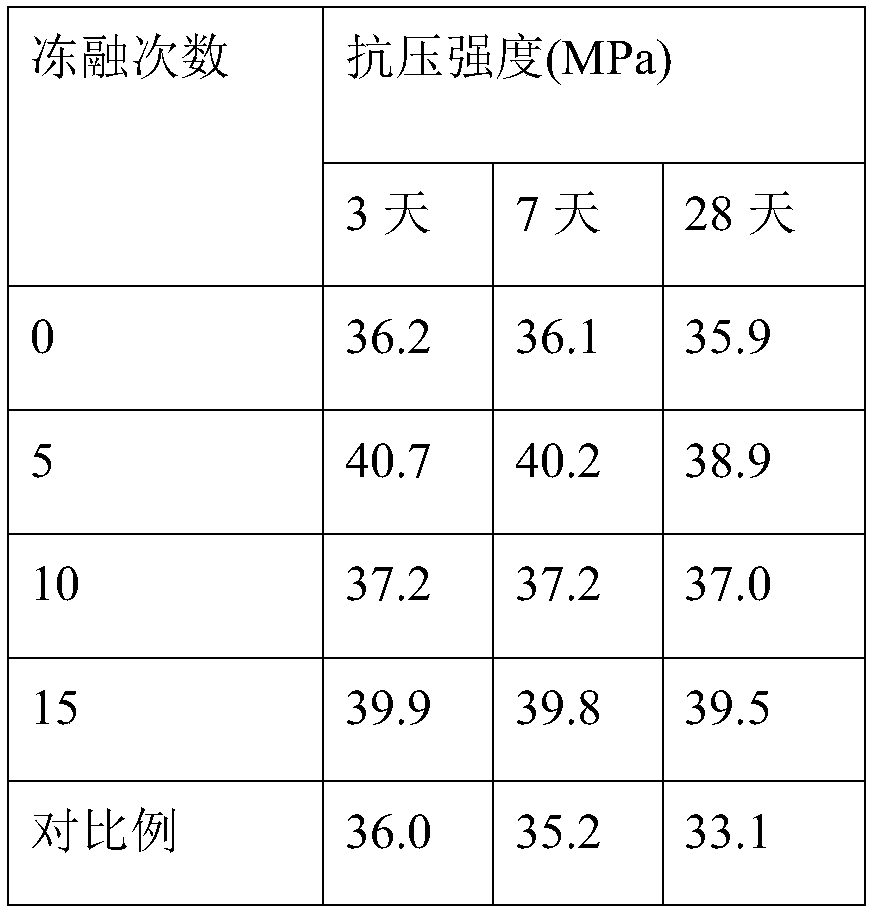

Marine environment concrete crack repair material and preparation method thereof

The invention discloses a marine environment concrete crack repair material which is prepared from the following components in parts by weight: 30-50 parts of Portland cement, 10-30 parts of desaltedsea sand, 5-15 parts of abandoned sea fish, 10-30 parts of crustacean exoskeleton, 4-10 parts of silica fume, 2-5 parts of a corrosion inhibitor, 0.5-2 parts of an early strength agent, 5-10 parts ofan expanding agent and 0.1-0.5 part of polypropylene fiber. The above materials are suitable for marine environment concrete crack repair and can ensure the long-term marine environmental concrete service after being filled.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

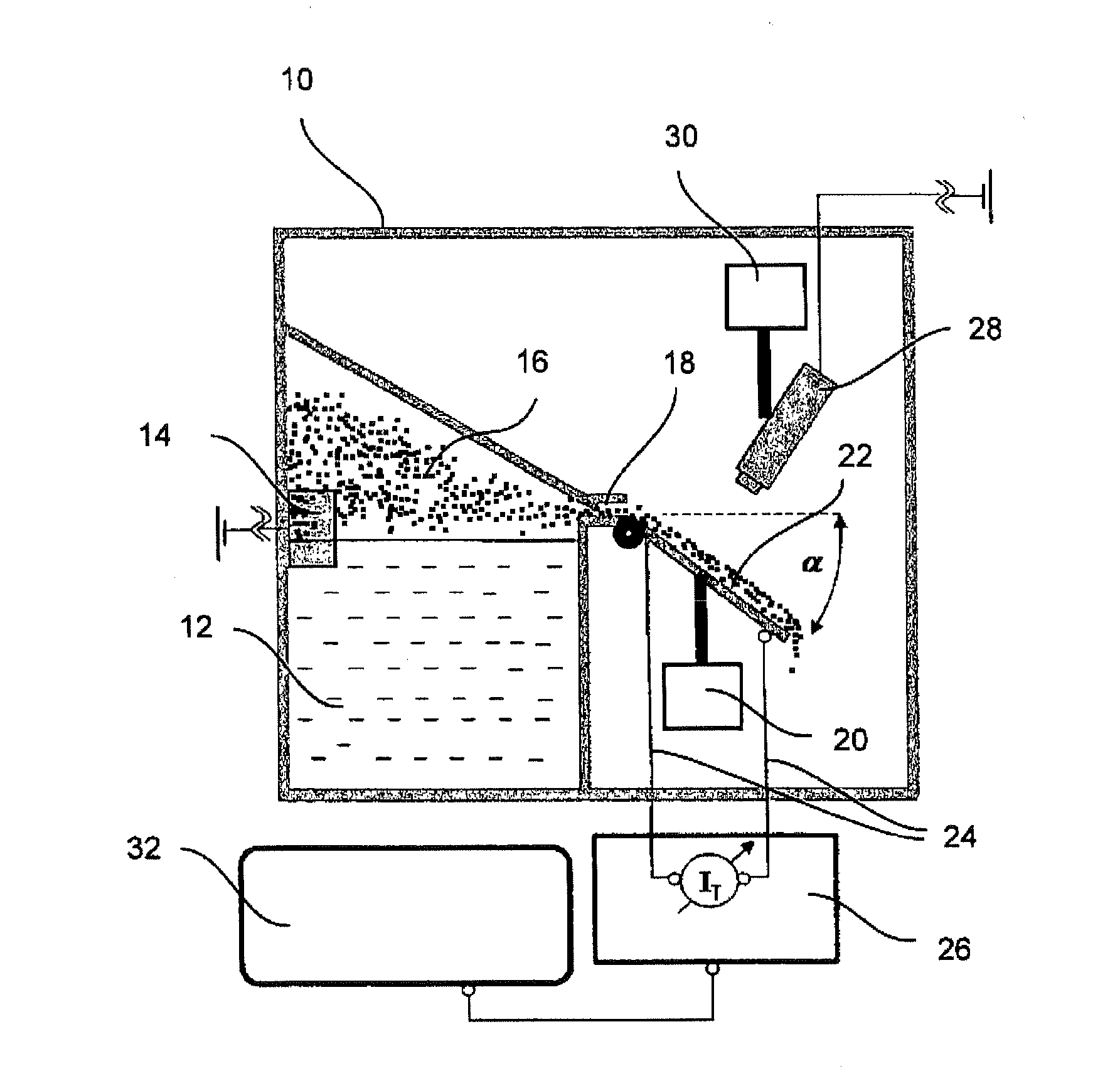

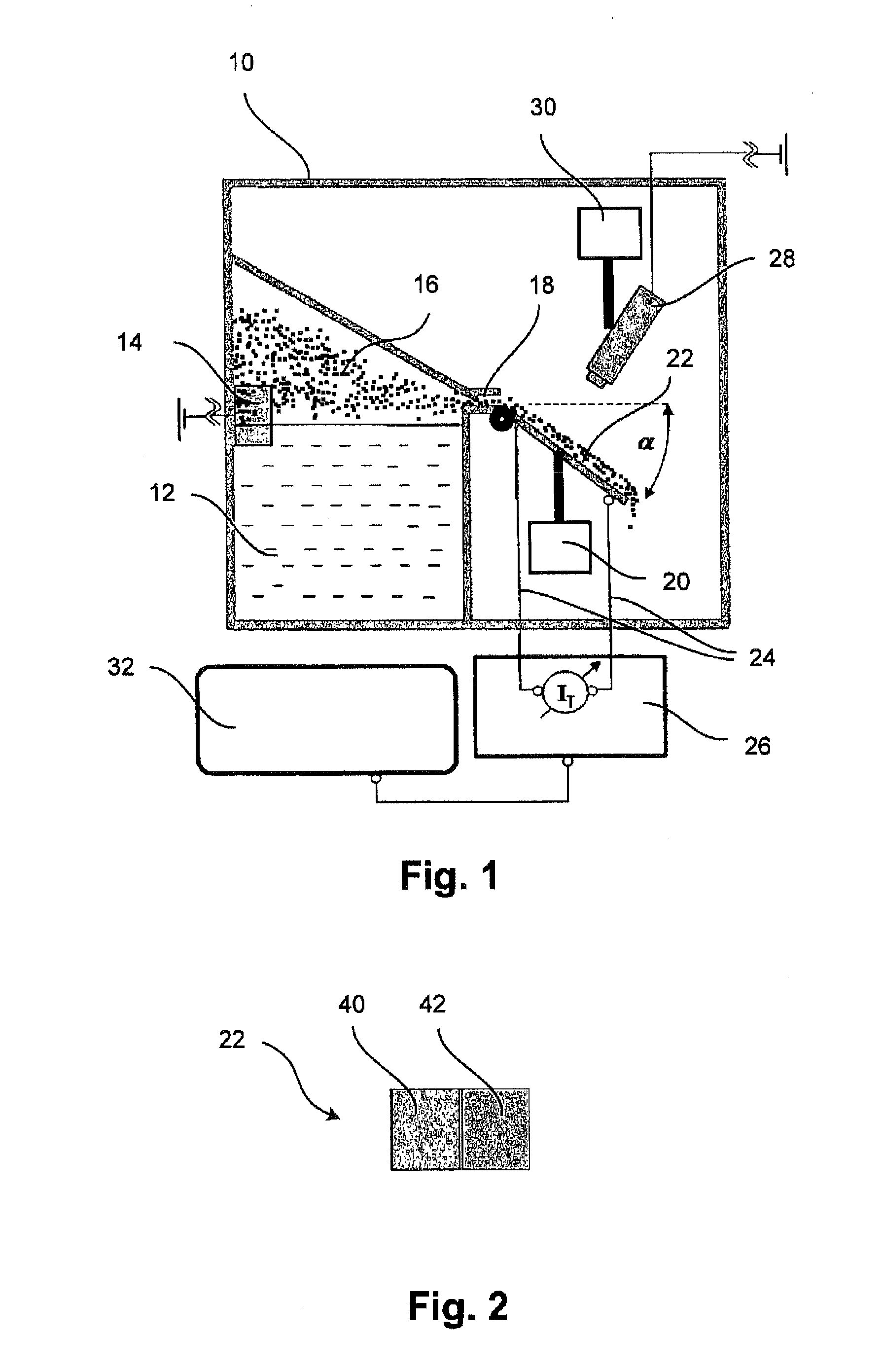

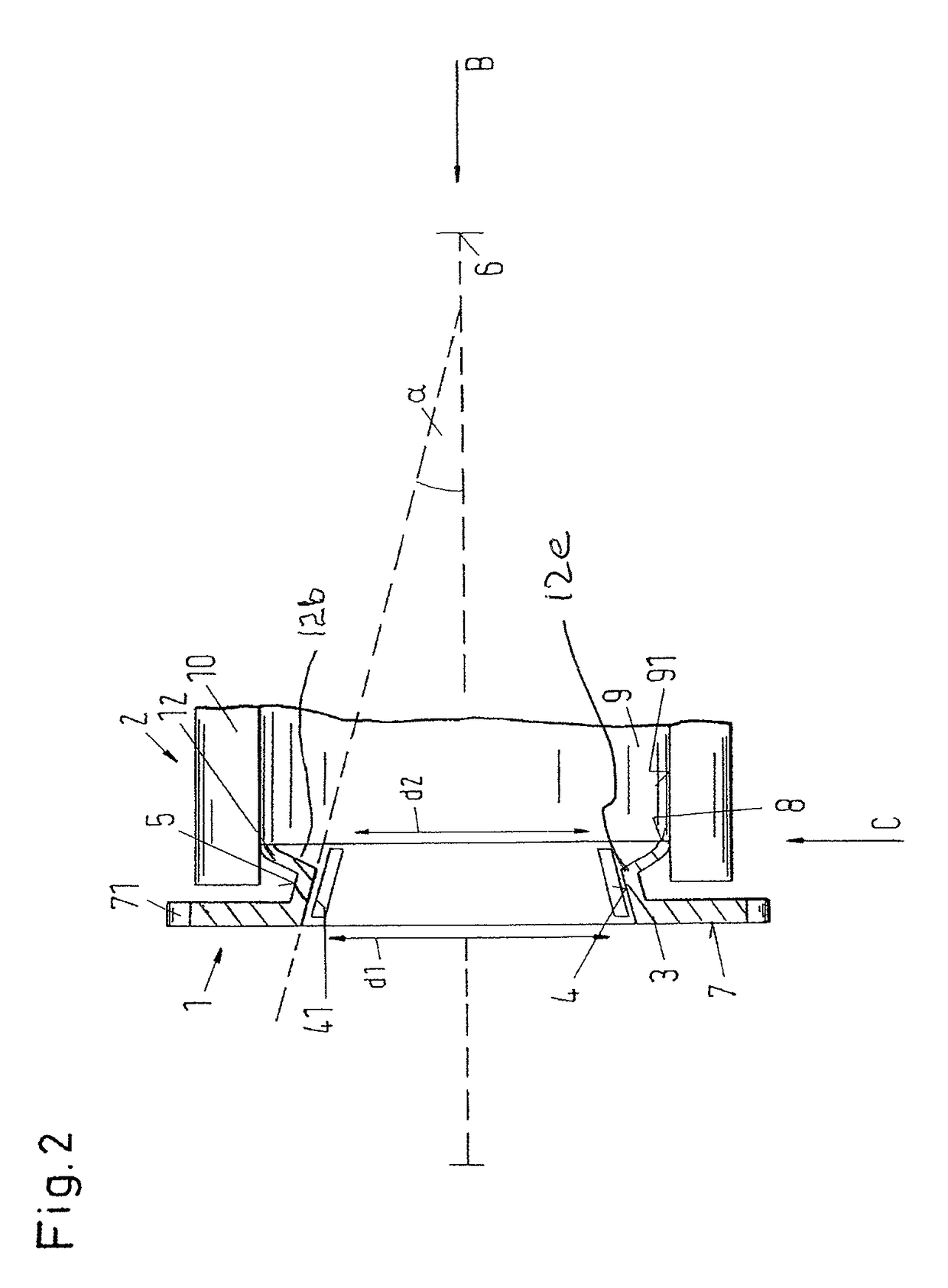

Method And Device For Forming An Electrolyte Film On An Electrode Surface

InactiveUS20130280416A1Reduce surface tensionIncreased formationWeather/light/corrosion resistanceElectrolyte layer coatingElectrolysisFluid electrolytes

In a method for forming an electrolyte film on an electrode surface, the liquid electrolyte is sprayed into a cavity to form an electrolyte mist; the electrolyte mist exits the cavity through an opening and then flows across the electrode surface, which is directed downward at an angle behind the opening, whereby an electrolyte film is formed on the electrode surface and wherein the thickness of the electrolyte film is set by means of the angle of inclination of the electrode surface. A corresponding device includes an electrolyte tank communicating with a mist chamber for accommodating sprayed electrolyte by means of a spraying apparatus, wherein the mist chamber comprises a mist outlet. Furthermore, a retainer for fixing the electrode surface at a specifiable angle of inclination is provided, so that electrolyte mist, which can exit through the mist outlet, flows across the electrode surface to form an electrolyte film.

Owner:AIRBUS OPERATIONS GMBH

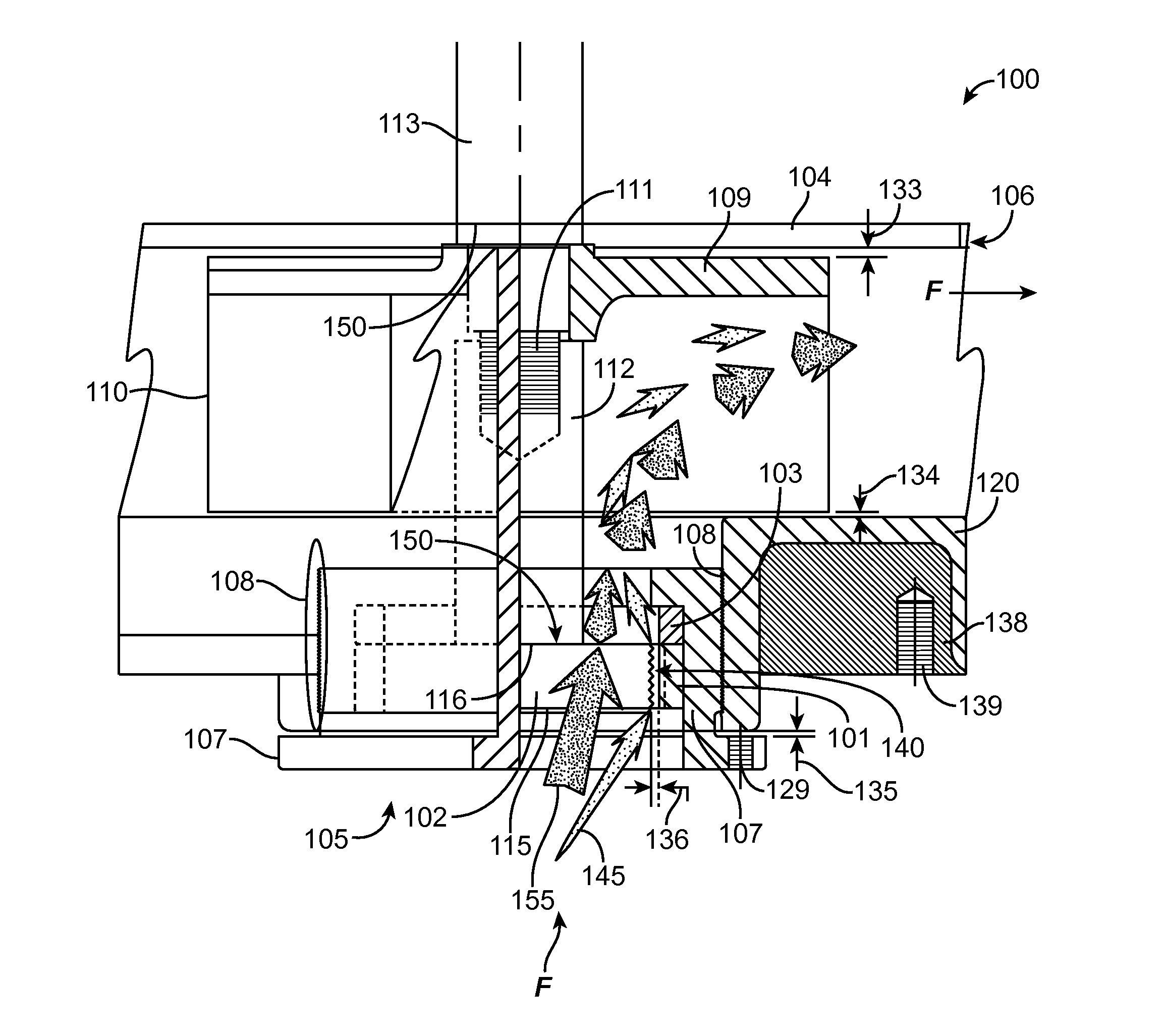

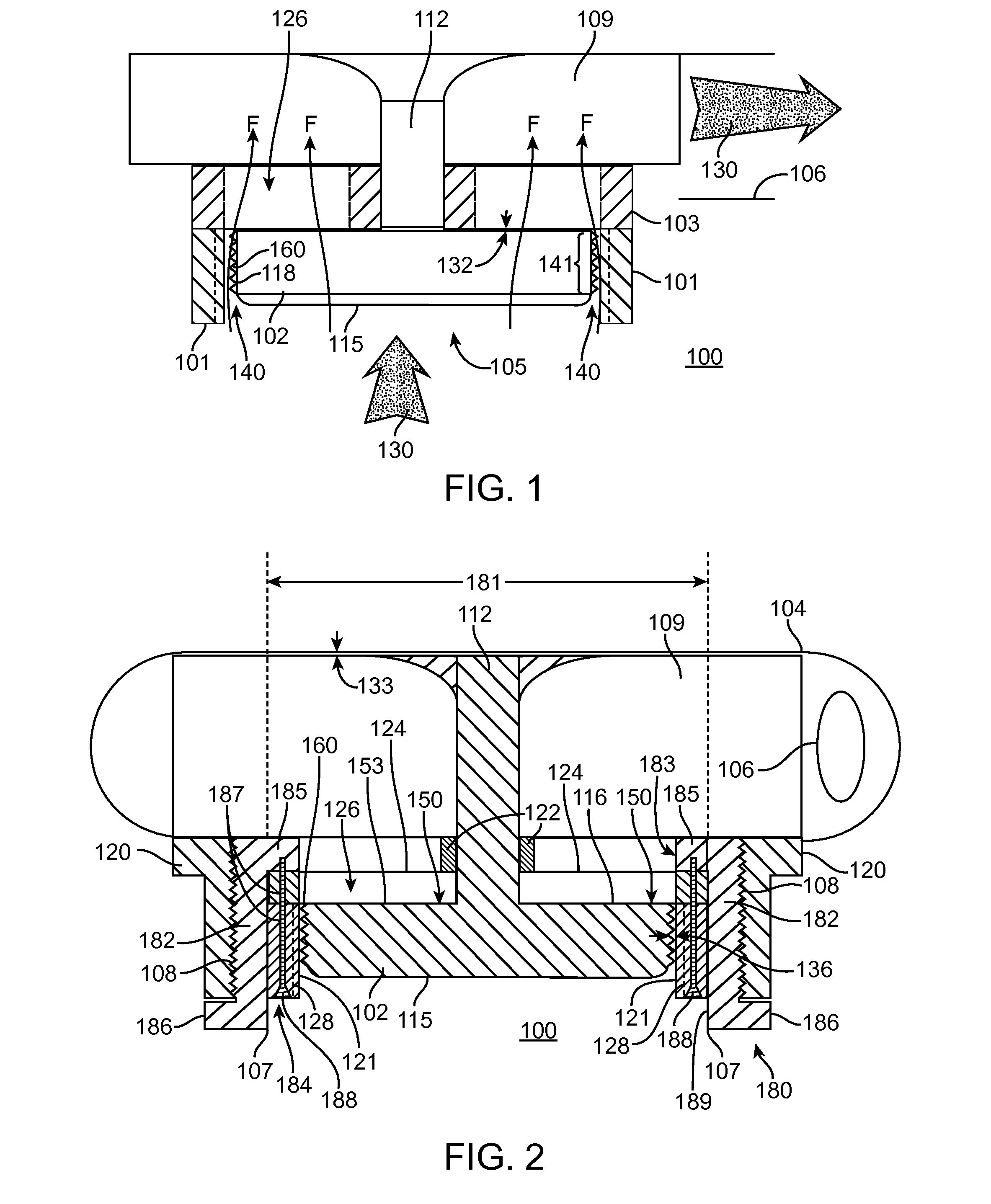

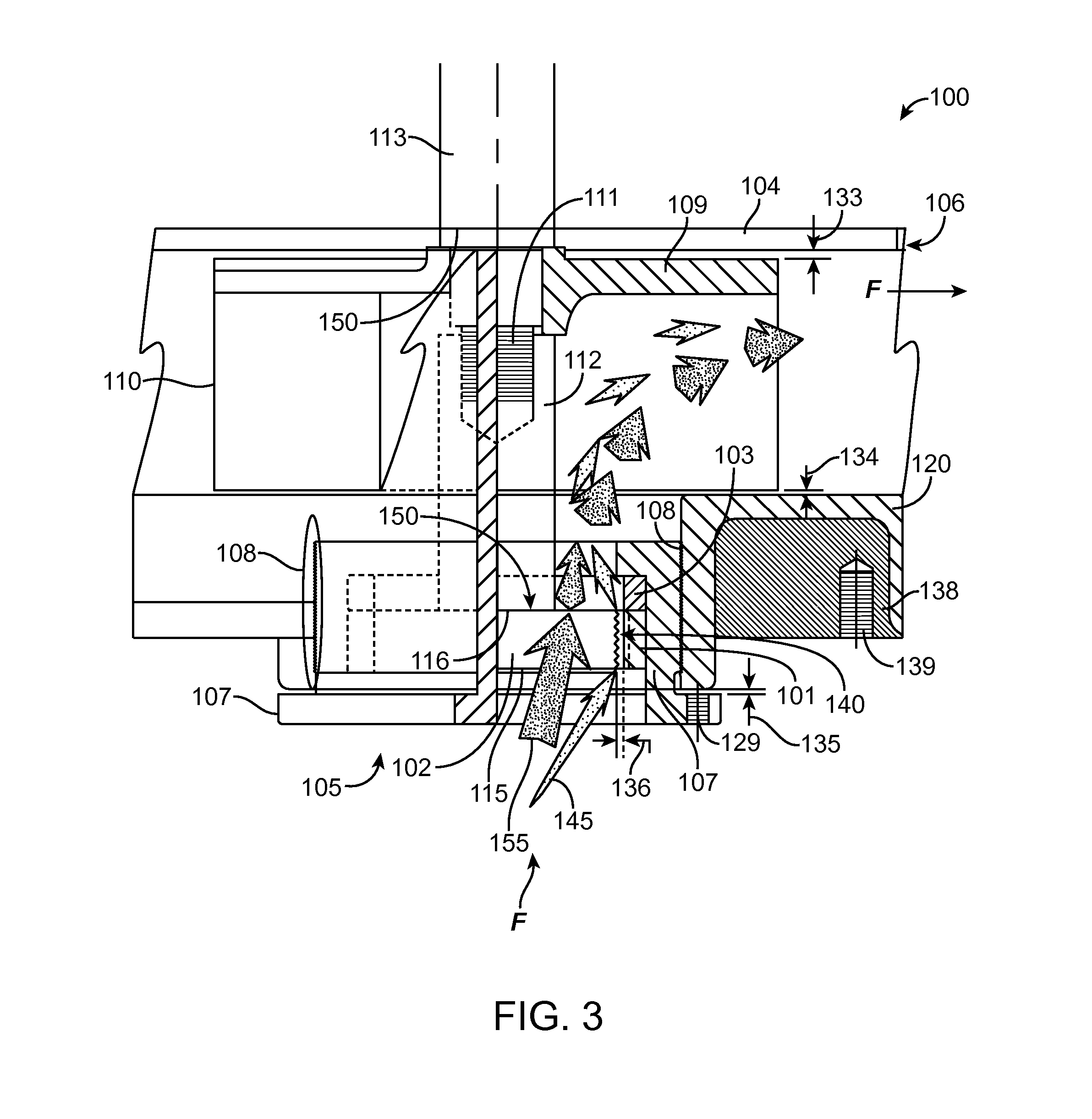

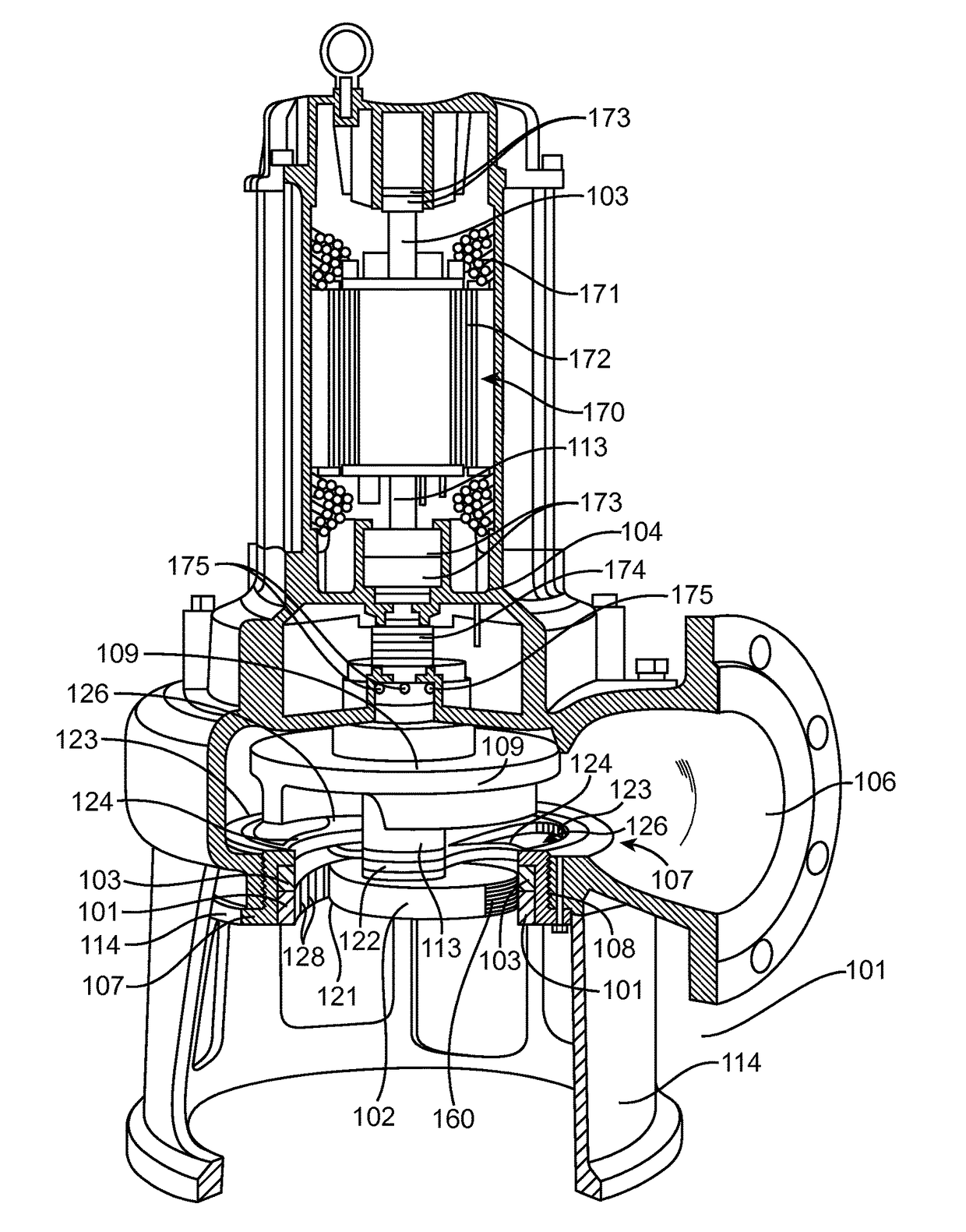

Shred and shear pump

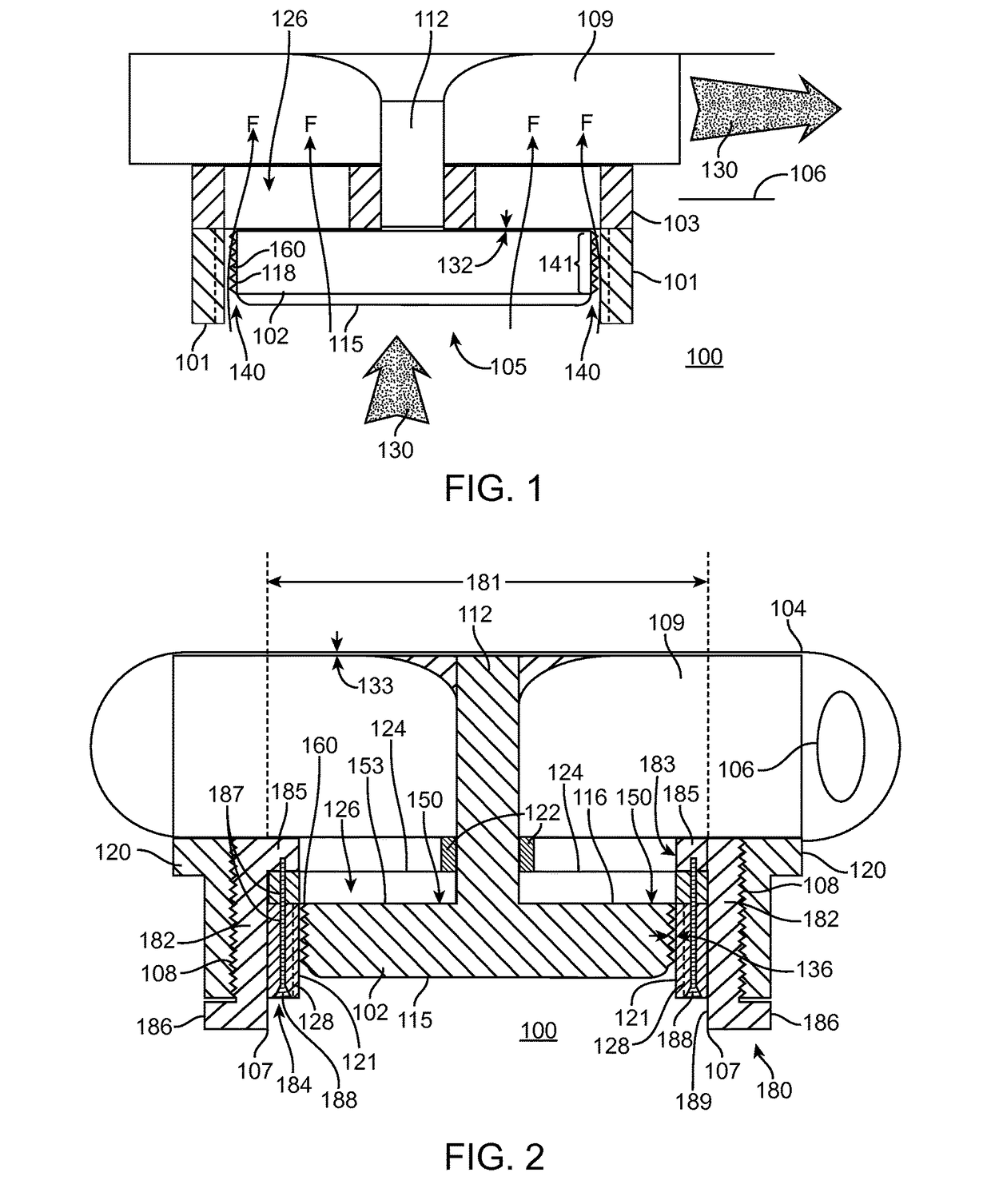

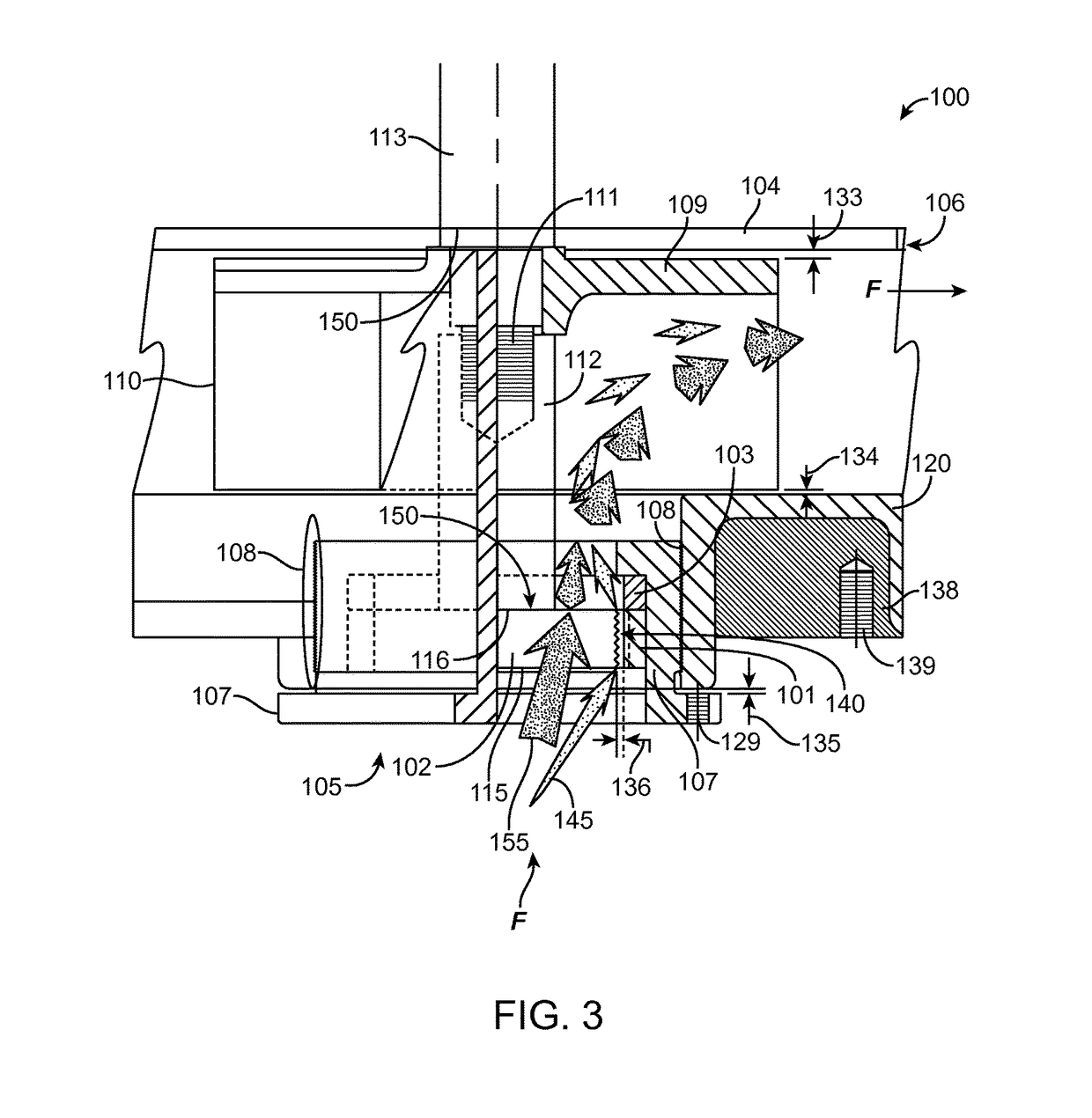

ActiveUS20150377255A1Increase heightLong serviceSpecific fluid pumpsPump componentsImpellerWastewater

The present invention is a pump (100) used for applications where a solid (130) is present in wastewater and other liquids that requires cutting and reduction in size so as to pass the solid (130) through the inlet (105) to the outlet (106) of the pump (100). The pump (100) has a pump casing (104) with an inlet (105) and an outlet (106) formed therein. A drive unit (170) rotates a drive shaft (113) extending axially through the pump casing (104) to an impeller (109) and a cutter bar (102). The pump (100) is further configured with a radial cutter ring assembly (101) positioned adjacent the cutter bar (102) and the inlet (105) providing a shredding cutting action (140) of solids (145) between the rotating cutter bar (102) sliding past a radial cutter ring assembly (101) held stationary, e.g. cutting blades (160) formed in an edge (118) of the cutter bar (102) rotate across an internal surface (121) of the radial cutter ring assembly (101). The pump (100) also has an axial cutter ring assembly (103) with one or more blades (124) forming openings (126) adapted for the passage of solids (155) from the inlet (105) to the outlet (106) to provide a shearing cutting action (150) of solids (155) by a rotation of an upper surface (116) of the cutter bar (102) sliding past an axial cutting surface (153) of the blades (124) of the axial cutter ring assembly (103). The shred and shear pump (100) may be configured with a plurality of slots (128) on the internal surface (121) of the radial cutter ring assembly (101) to hold woven fibrous material for the shredding cutting action (140). The pump (100) also features improved optimized flow, cutting and reducing solids in the form of woven fibrous materials, and adjustability of the cutter housing (107) for precision and wear adjustment.

Owner:IND FLOW SOLUTIONS OPERATING LLC

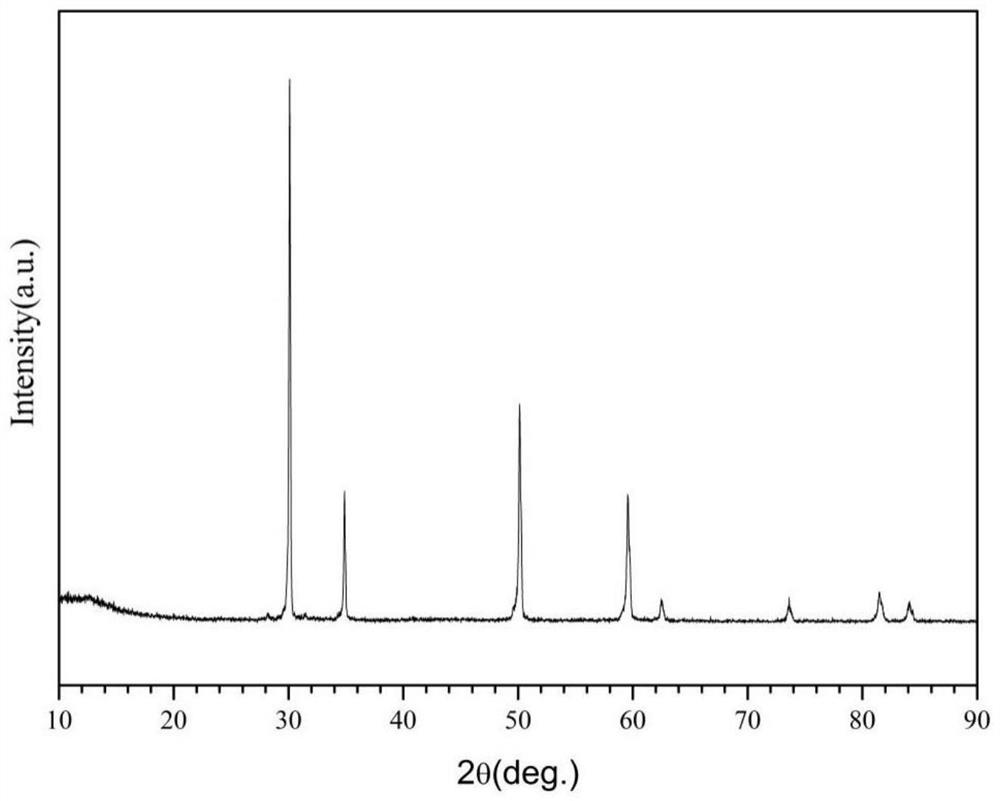

Chromium-free catalyst for gas-phase fluorination and application thereof

ActiveUS20160311736A1Environmentally friendlyStrong oxygen storage abilityPreparation by hydrogen halide split-offPreparation by halogen replacementChromium freeHydrofluoroolefin

Disclosed in the present invention is a chromium-free catalyst for gas-phase fluorination and an application thereof. The precursor of the related chromium-free catalyst for gas-phase fluorination consists of a compound containing iron element, a compound containing rare earth metal element and a compound containing element A, wherein element A is one selected from Ca, Al, Mg and Ti, the precursor is subjected to calcination and fluorination treatment to obtain the chromium-free catalyst for gas-phase fluorination. The precursor of the catalyst is calcined at 400-500° C. and fluorinated with hydrogen fluoride at 350-450° C. to obtain the chromium-free fluorinated catalyst. The catalyst has characteristics of being chromium-free and environment-friendly, good catalytic activity and long life etc. The catalyst can be used for preparing hydrofluoroolefins or hydrochlorofluoroolefins from halohydrocarbons.

Owner:XIAN MODERN CHEM RES INST

Shred and shear pump

ActiveUS9719527B2Long serviceImprove cutting effectSpecific fluid pumpsPump componentsImpellerDrive shaft

The present invention is a pump used for applications where a solid is present in wastewater and other liquids that requires cutting and reduction in size so as to pass the solid through the inlet to the outlet of the pump. The pump has a pump casing with an inlet and an outlet formed therein. A drive unit rotates a drive shaft extending axially through the pump casing to an impeller and a cutter bar. The pump is further configured with a radial cutter ring assembly positioned adjacent the cutter bar and the inlet providing a shredding cutting action of solids between the rotating cutter bar sliding past a radial cutter ring assembly held stationary, e.g. cutting blades formed in an edge of the cutter bar rotate across an internal surface of the radial cutter ring assembly. The pump also has an axial cutter ring assembly with one or more blades forming openings adapted for the passage of solids from the inlet to the outlet to provide a shearing cutting action of solids by a rotation of an upper surface of the cutter bar sliding past an axial cutting surface of the blades of the axial cutter ring assembly. The shred and shear pump may be configured with a plurality of slots on the internal surface of the radial cutter ring assembly to hold woven fibrous material for the shredding cutting action. The pump also features improved optimized flow, cutting and reducing solids in the form of woven fibrous materials, and adjustability of the cutter housing for precision and wear adjustment.

Owner:IND FLOW SOLUTIONS OPERATING LLC

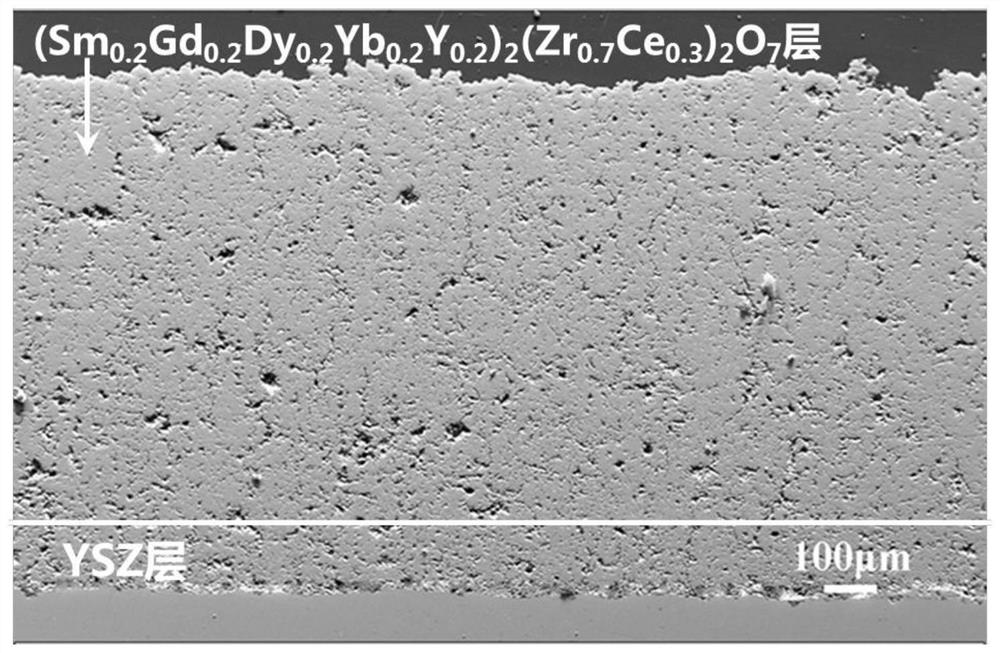

High-entropy ultrahigh-temperature zirconia-based thermal barrier coating material, preparation method and application thereof and zirconia-based thermal barrier coating

PendingCN114672756AGuaranteed high temperature lifeMitigation of Thermal Expansion MismatchMolten spray coatingEfficient propulsion technologiesThermal dilatationThermal growth

The invention provides a high-entropy ultrahigh-temperature zirconia-based thermal barrier coating material, a preparation method and application thereof and a zirconia-based thermal barrier coating, and belongs to the technical field of high-temperature coating materials. The zirconia-based thermal barrier coating material has the advantages of no phase change, low thermal conductivity, high thermal expansion coefficient, high fracture toughness, low sintering rate and good CMAS corrosion resistance, the zirconia-based thermal barrier coating material is used for a thermal barrier coating, a double-ceramic-layer structure is adopted, YSZ is used as a bottom layer, the zirconia-based thermal barrier coating material is used as a surface thermal barrier ceramic layer, and the thermal barrier coating material has the advantages of high thermal conductivity, high thermal expansion coefficient, high fracture toughness and good CMAS corrosion resistance. The thermal expansion mismatching between the high-entropy thermal barrier ceramic top layer and the metal bonding layer and the high-temperature chemical stability compatibility between the high-entropy thermal barrier ceramic top layer and the thermal growth oxide layer TGO layer can be effectively relieved, so that the long-life service of the thermal barrier coating within the temperature range of 1300-1600 DEG C is achieved, the thermal shock resistance cycle life is long, and the CMAS permeation corrosion resistance is good. Therefore, the material can be used for high-temperature hot end components of aero-engines or gas turbines.

Owner:EAST CHINA UNIV OF SCI & TECH +2

Light-Emitting Component

ActiveUS20100065825A1Increase flexibilityImprove rendering capabilitiesElectroluminescent light sourcesSolid-state devicesLight-emitting diodeLight emitting device

The invention relates to a light-emitting device, in particular a light-emitting diode, with an arrangement of layers on a substrate, wherein the arrangement of layers has an anode contact and a cathode contact which are in electrical contact with a light-emitting layer stack arranged between the anode contact and the cathode contact which, on its part, comprises a polymer layer consisting of a polymer material and a low-molecular layer of vacuum-deposited small molecules of an organic material, and wherein the small molecules of the low-molecular layer are formed as donor molecules with an oxidation potential versus Fc / Fc+ (ferrocene / ferrocenium redox couple) of maximum approx. −1.5 V, if the low-molecular layer is arranged adjacent to the cathode contact, and as acceptor molecules with a reduction potential versus Fc / Fc+ (ferrocene / ferrocenium redox couple) of minimum approx. −0.3 V if the low-molecular layer is arranged adjacent to the anode contact.

Owner:NOVALED GMBH

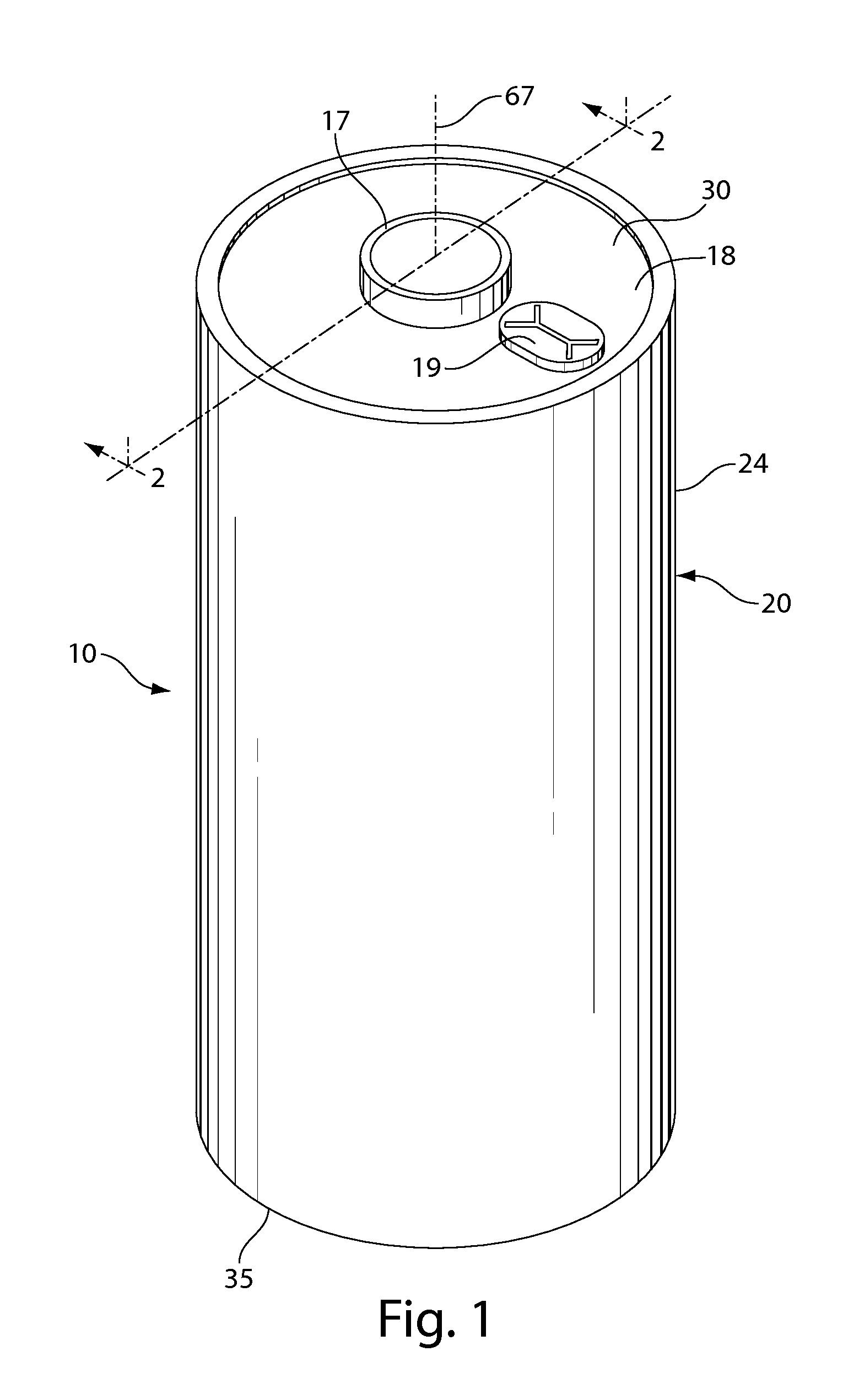

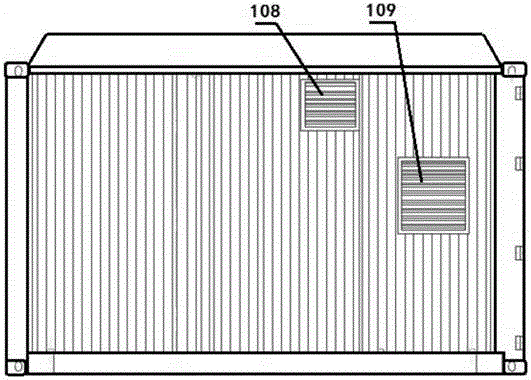

Terrestrial digital television station system

ActiveCN106160834AEasy to installAdapt to field operationsTelevision system detailsClimate change adaptationTelevision stationRadio frequency

The invention relates to a terrestrial digital television station system and belongs to the technical field of television signal transmitting and receiving. The terrestrial digital television station system comprises a signal processing subsystem, wherein the signal processing subsystem comprises a satellite receiving antenna, a satellite receiving decoder, an encoder, a digital exciter, a transmitter and a transmitting antenna; the satellite receiving decoder completes satellite signal receiving and decoding; the obtained video and audio signals are sent to the encoder, sent to the exciter by virtue of an ASI (asynchronous serial interface) interface, modulated into an RF (radio frequency) signal by the exciter and then transmitted to the transmitter; and the signals are subjected to power amplification by virtue of the transmitter and then are connected to a feeder by virtue of a rigid feedback element, an elbow and a flange and sent to the transmitting antenna to be transmitted out. The terrestrial digital television station system is easy to mount and can adapt to field operation tasks; meanwhile, the system is good in anti-seismic property, has good rainproof, dustproof, heat insulation, heat preservation and anticorrosion properties and can serve for a long time in wicked environments such as the wild, a mountainous area and salty air.

Owner:中仪英斯泰克进口有限公司

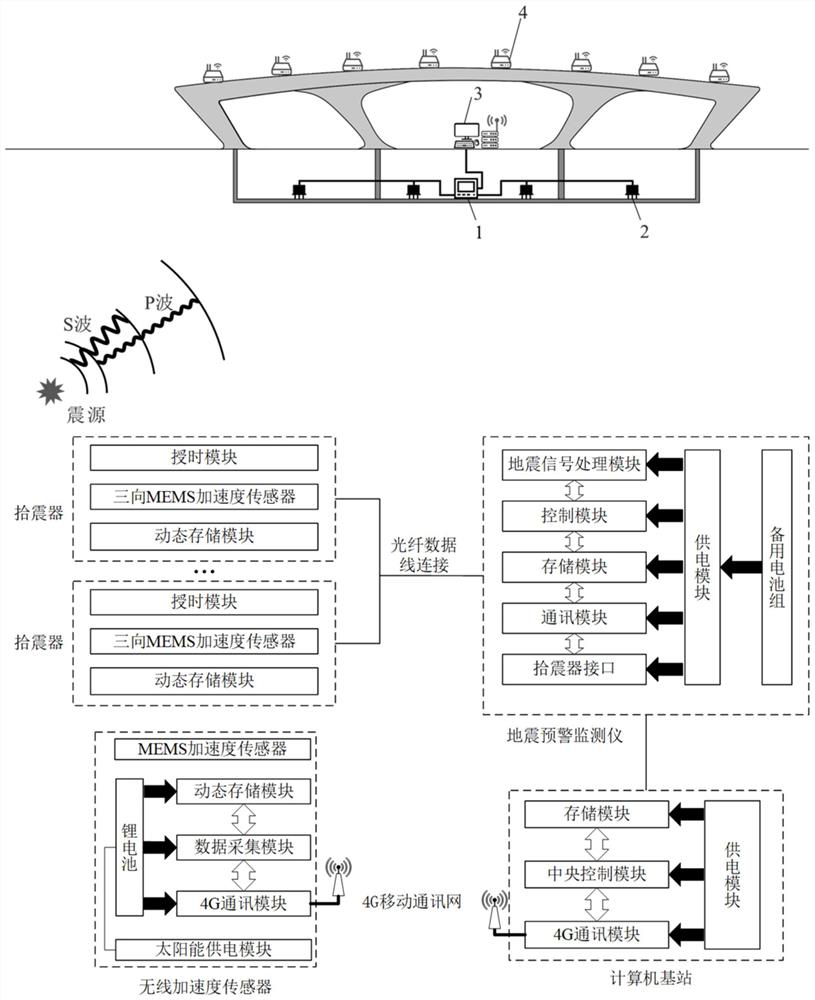

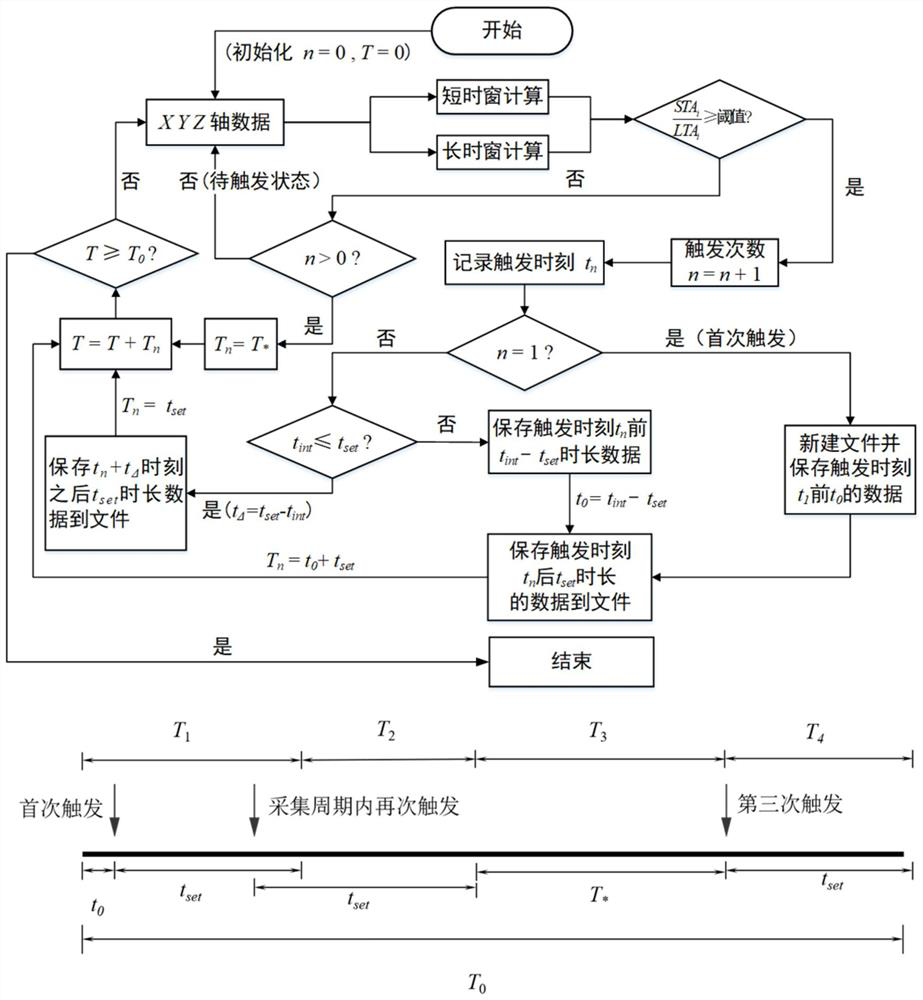

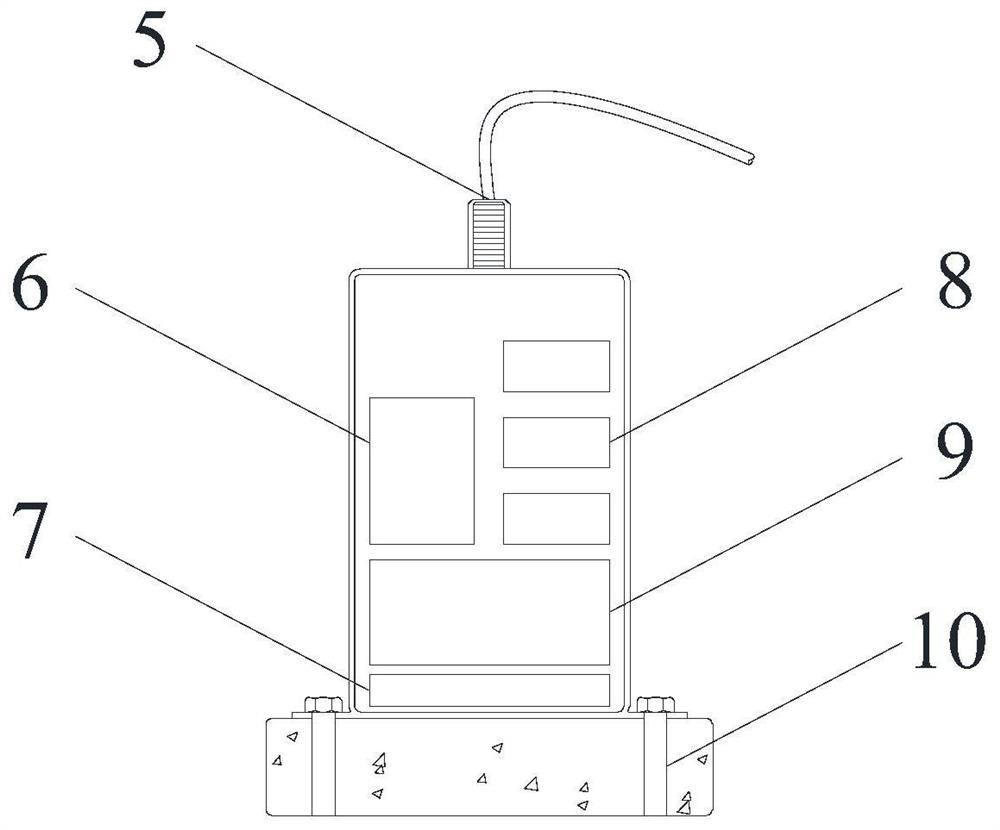

Spatial structure vibration response capturing and monitoring system based on earthquake early warning

PendingCN113031055AReal-time transmissionEasy to installSubsonic/sonic/ultrasonic wave measurementSeismic signal receiversVibration accelerationS-wave

The invention discloses a spatial structure vibration response capturing and monitoring system based on earthquake early warning. The spatial structure vibration response capturing and monitoring system is composed of an earthquake early warning monitor, a seismometer, a computer working base station and a magnetic type wireless vibration acceleration sensor. The earthquake early warning monitor captures earthquake P-wave signals and sends earthquake triggering information picked up by the seismometer to the working base station, and the base station issues a series of commands such as vibration response data acquisition, recording, compression and return to the wireless vibration acceleration sensor. Finally, the base station uploads site vibration and steel structure response data to the cloud platform, and building safety assessment analysis is carried out. According to the characteristics of different propagation speeds of earthquake P waves and S waves and large span and wide distribution of a large-span building, by combining an earthquake P wave pickup technology and wireless communication, long-term and all-weather monitoring of the ground vibration condition of the position where a large-span space structure is located is functionally realized, and comprehensive capture of the vibration response of the large-span space steel structure after an earthquake is realized.

Owner:ZHEJIANG UNIV

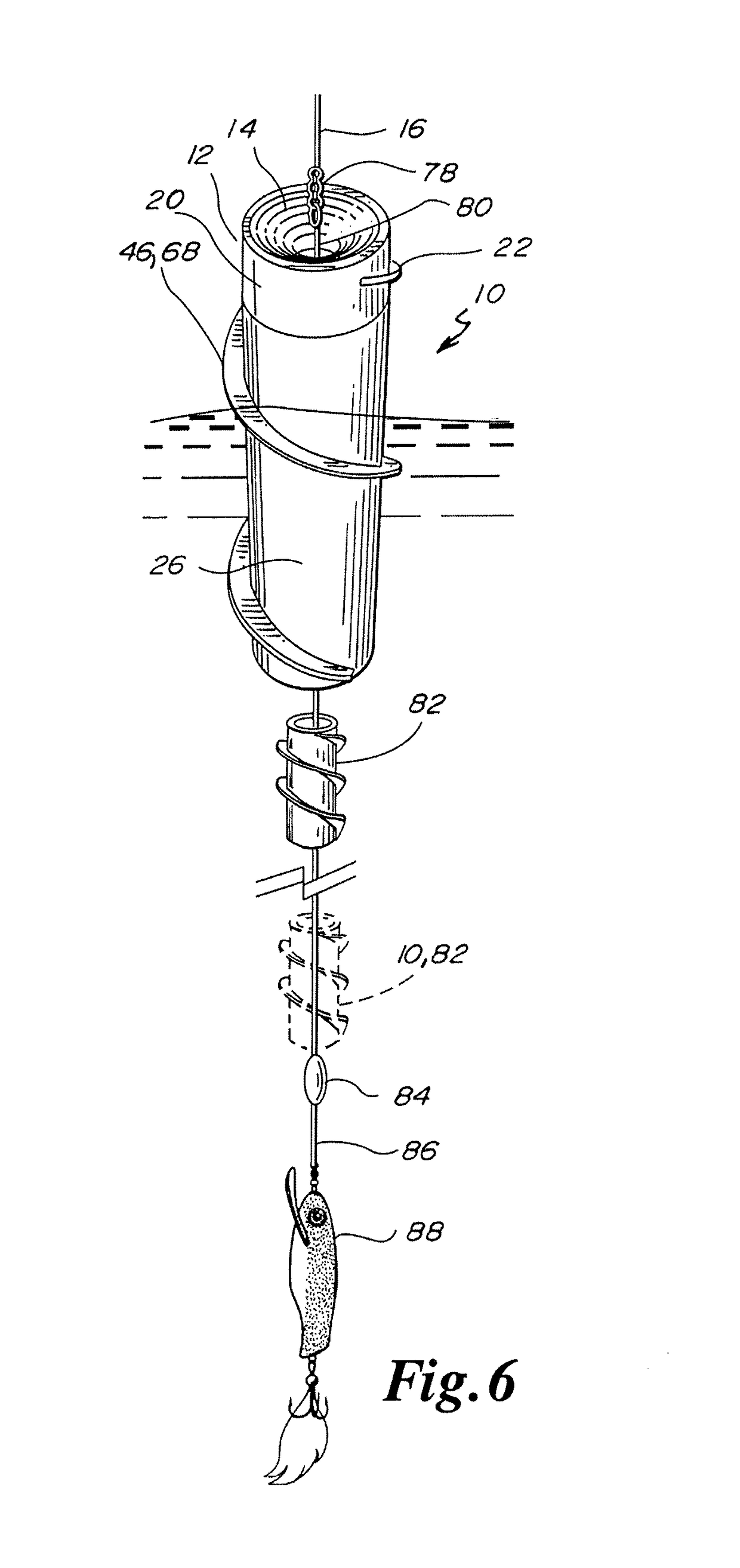

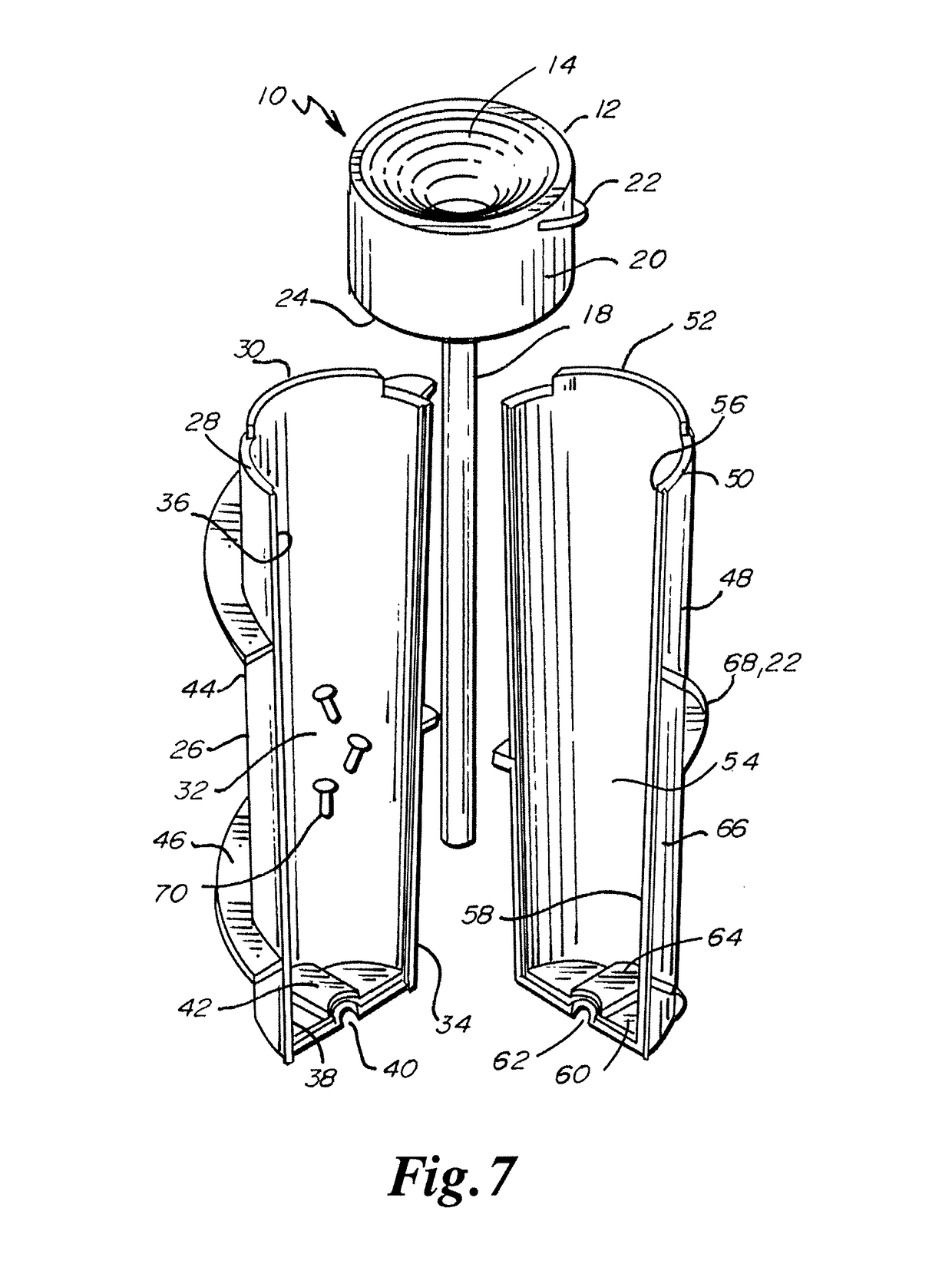

Fishing bobber

A hollow-bodied frustoconical fishing bobber has a top section with a semi-spherical, concave top surface with a line aperture in the bottom of the semi-spherical top surface and a depending tube through which a fishing line may extend. Below the top section are two hollow semi-cylindrical halves with bottom walls that are joinable together and connectable to the bottom of the top section with the depending tube passing through and ending at the joinable bottom walls. A continuous helical fin in three sections is on the outer surface of the top section and two semi-cylindrical halves which causes the fishing bobber to spin about it radial axis. Weights are locating with the hollow body.

Owner:BARNETT ROBERT H

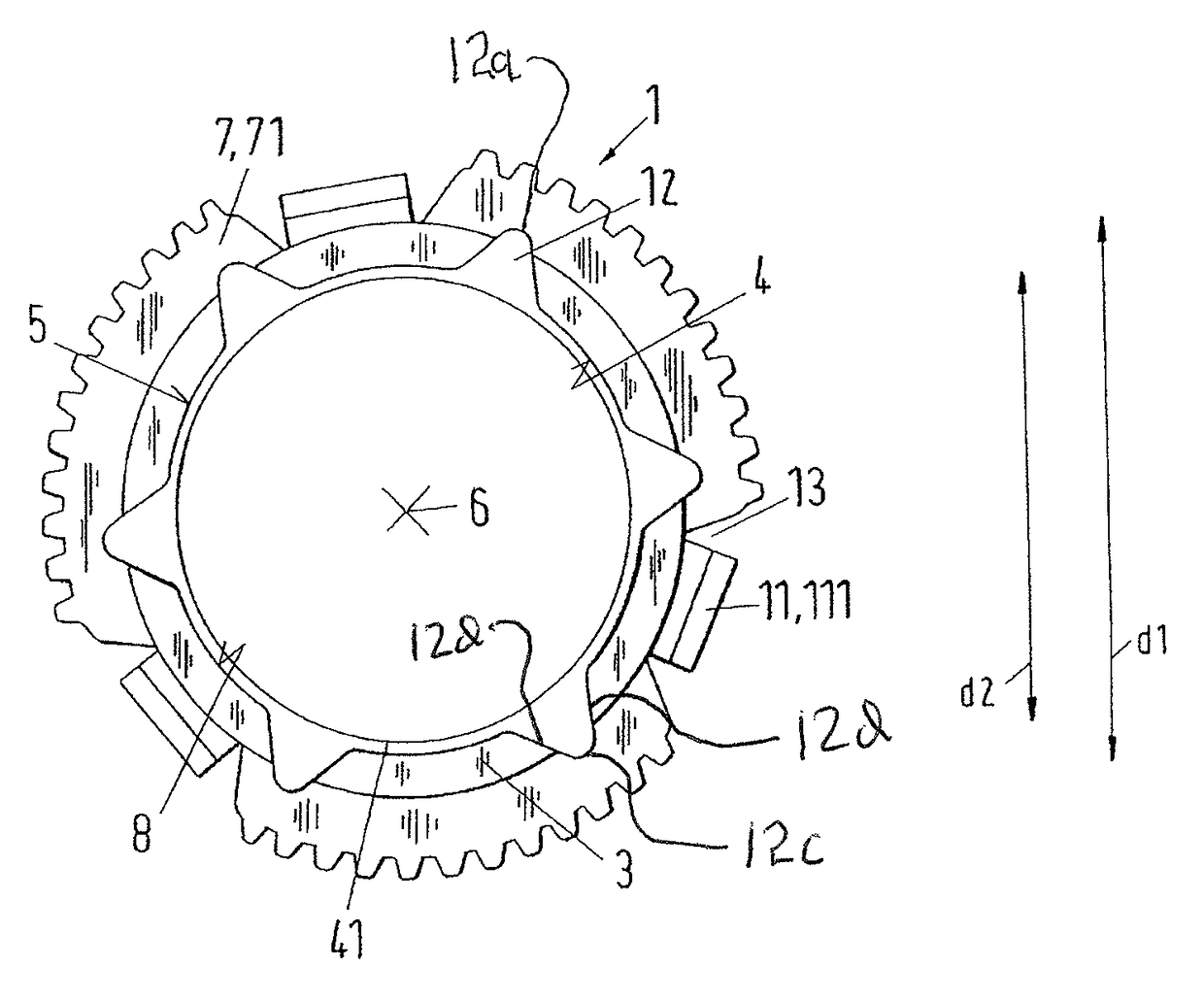

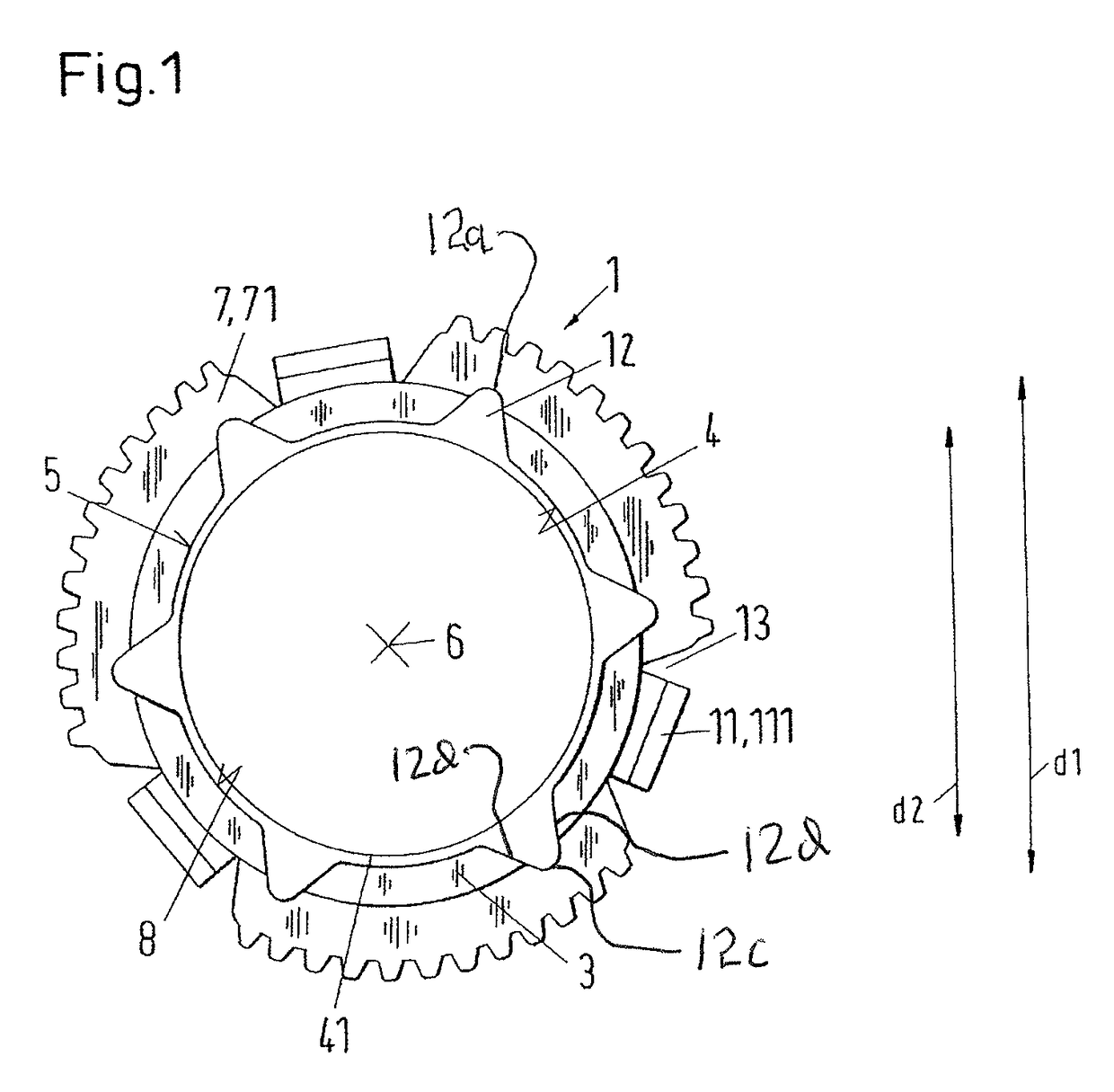

Synchronizer ring

ActiveUS9777800B2Easy to guideReliability and precision of synchronisationMechanical actuated clutchesToothed gearingsBody axisMechanical engineering

Synchronizer ring made of deep-drawable sheet metal. The ring includes a ring-shaped sheet metal body having a conical section arranged between a wall and a hub surface. One or more radially outwardly projecting guide elements are defined by radially outwardly projecting tapered indentations integrally formed with the ring-shaped sheet metal body. The wall is located at a largest conical diameter side of the ring-shaped sheet metal body and extends substantially perpendicular to a ring body axis. Gear teeth are arranged on a radially outer end of the wall. The one or more guide elements are configured to provide centering guidance relative to a hollow cylindrical surface of a synchronizer ring hub.

Owner:OERLIKON FRICTION SYST GERMANY

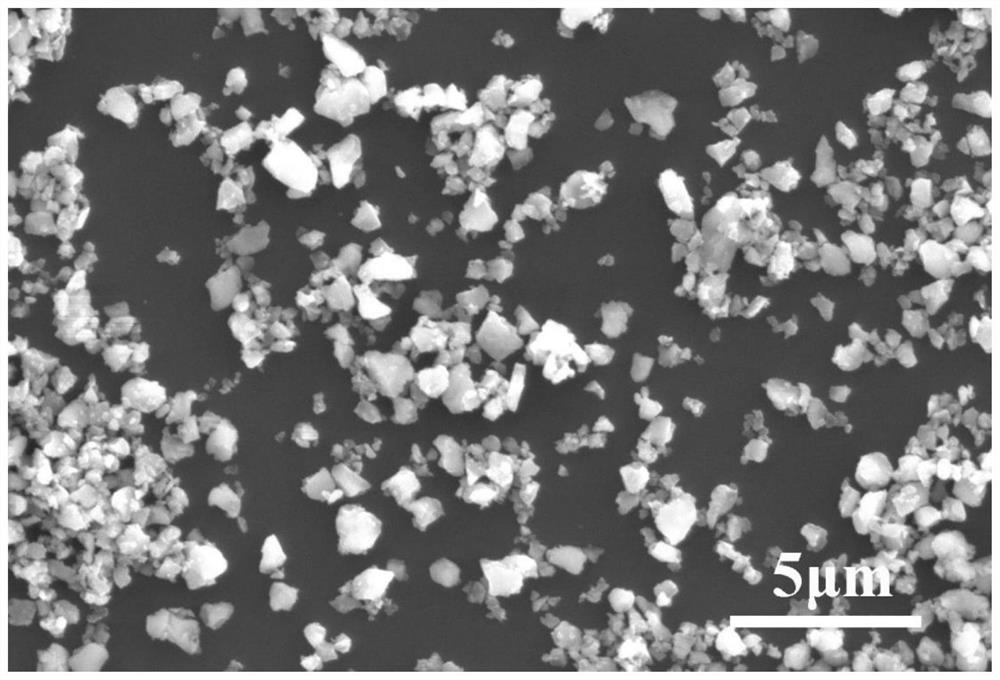

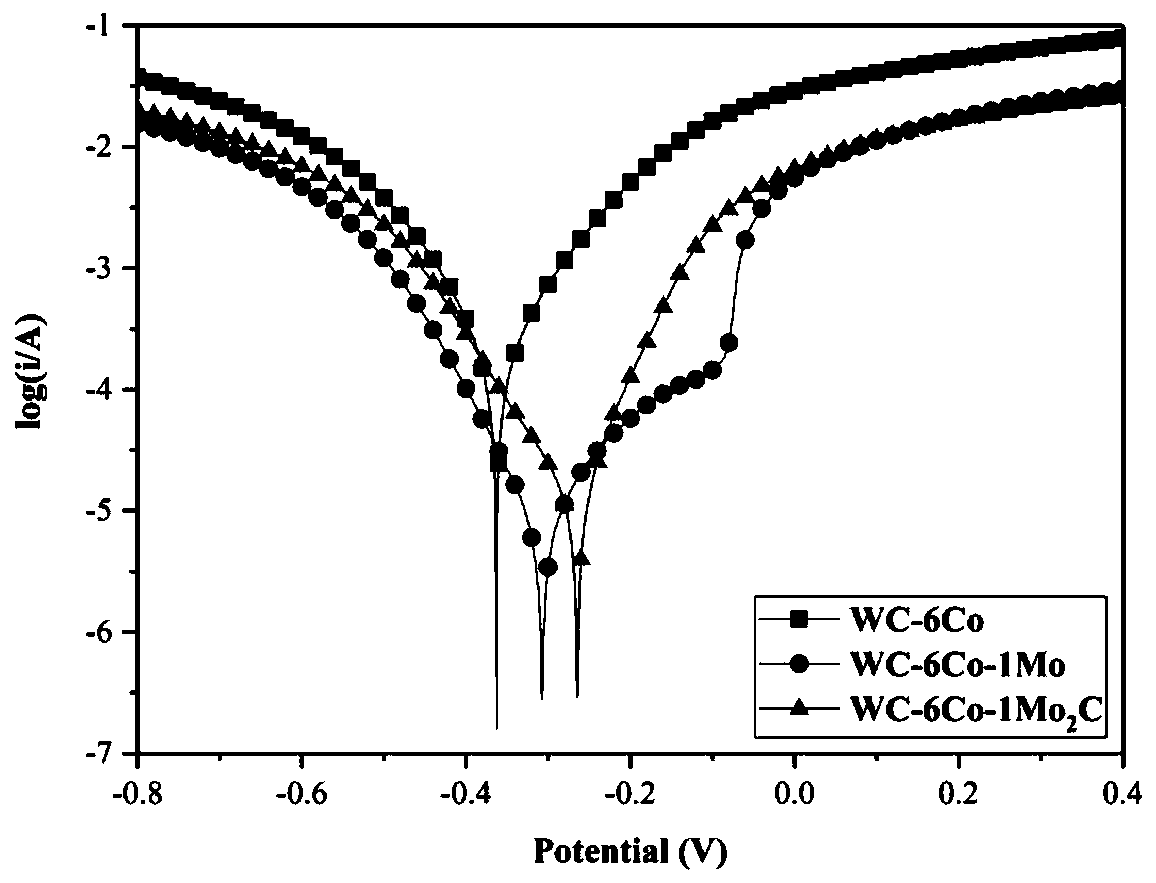

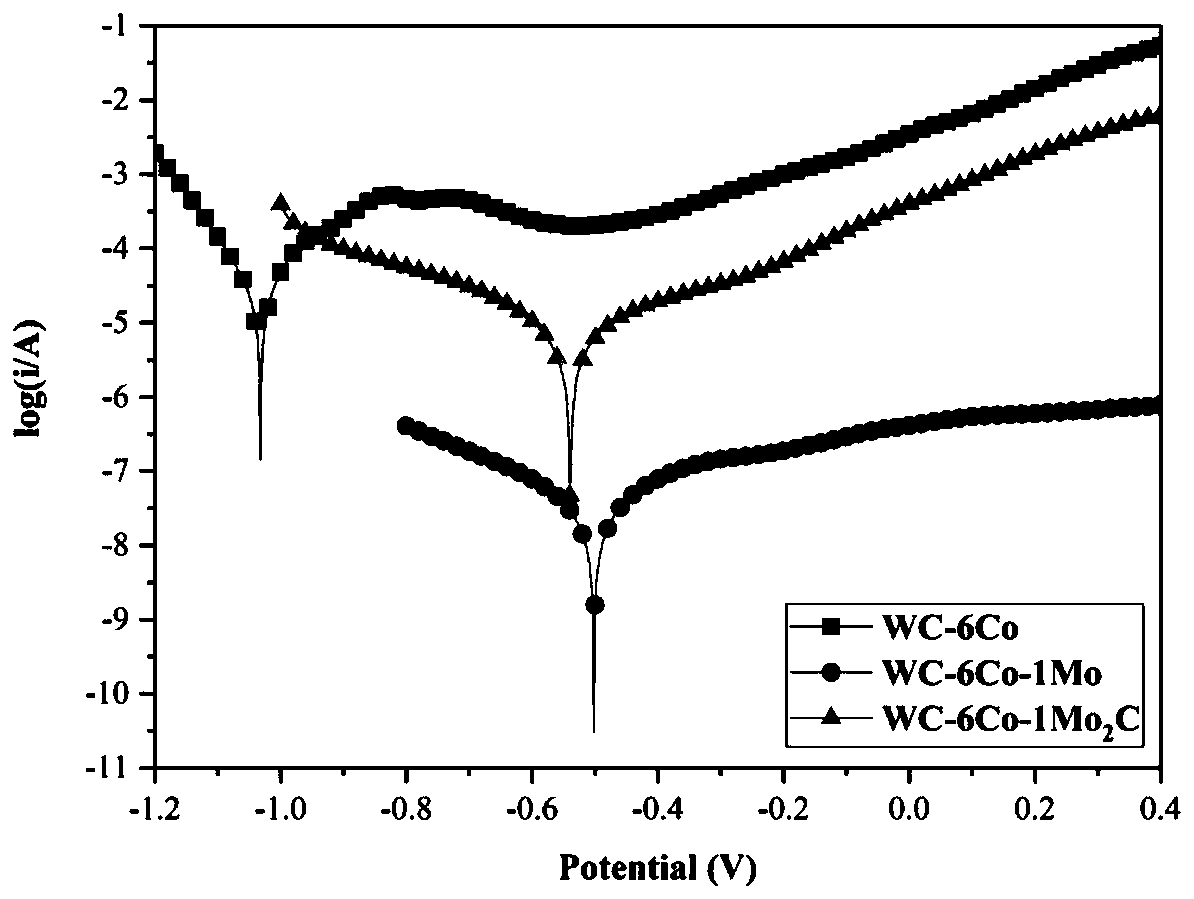

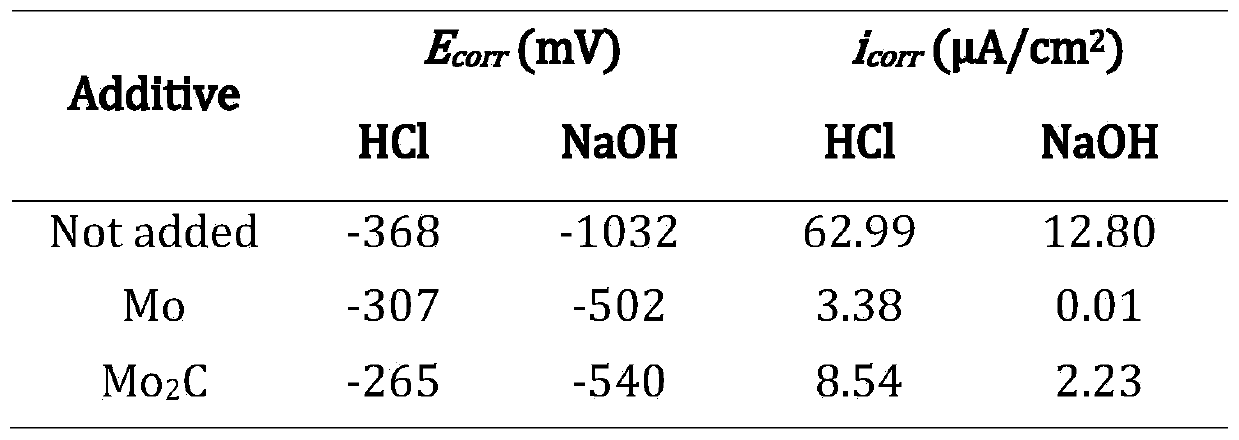

Tungsten-cobalt hard alloy resistant to acid and alkali environment and preparation method of tungsten-cobalt hard alloy

The invention provides a tungsten-cobalt hard alloy resistant to an acid and alkali environment and a preparation method of the tungsten-cobalt hard alloy. The tungsten-cobalt hard alloy is prepared from 96%-97.5% of WC-Co composite powder, 0.5%-2.0% of an additive and 2% of paraffin. The preparation method comprises the following steps of preparing WC-Co composite powder by adopting spray dryingand reduction carbonization methods; carrying out ball-milling mixing on the WC-Co composite powder and an additive to obtain mixed powder; drying the mixed powder in a vacuum drying oven, and sievingto obtain mixed powder; mixing the mixed powder with paraffin, drying, and granulating; and a pressed blank is prepared into the final hard alloy through an SPS sintering method. The corrosion resistance of the WC-Co hard alloy in an acidic or alkaline environment is improved while it is guaranteed that the WC-Co hard alloy has high hardness, high wear resistance and good toughness.

Owner:GANZHOU HAICHUANG TUNGSTEN

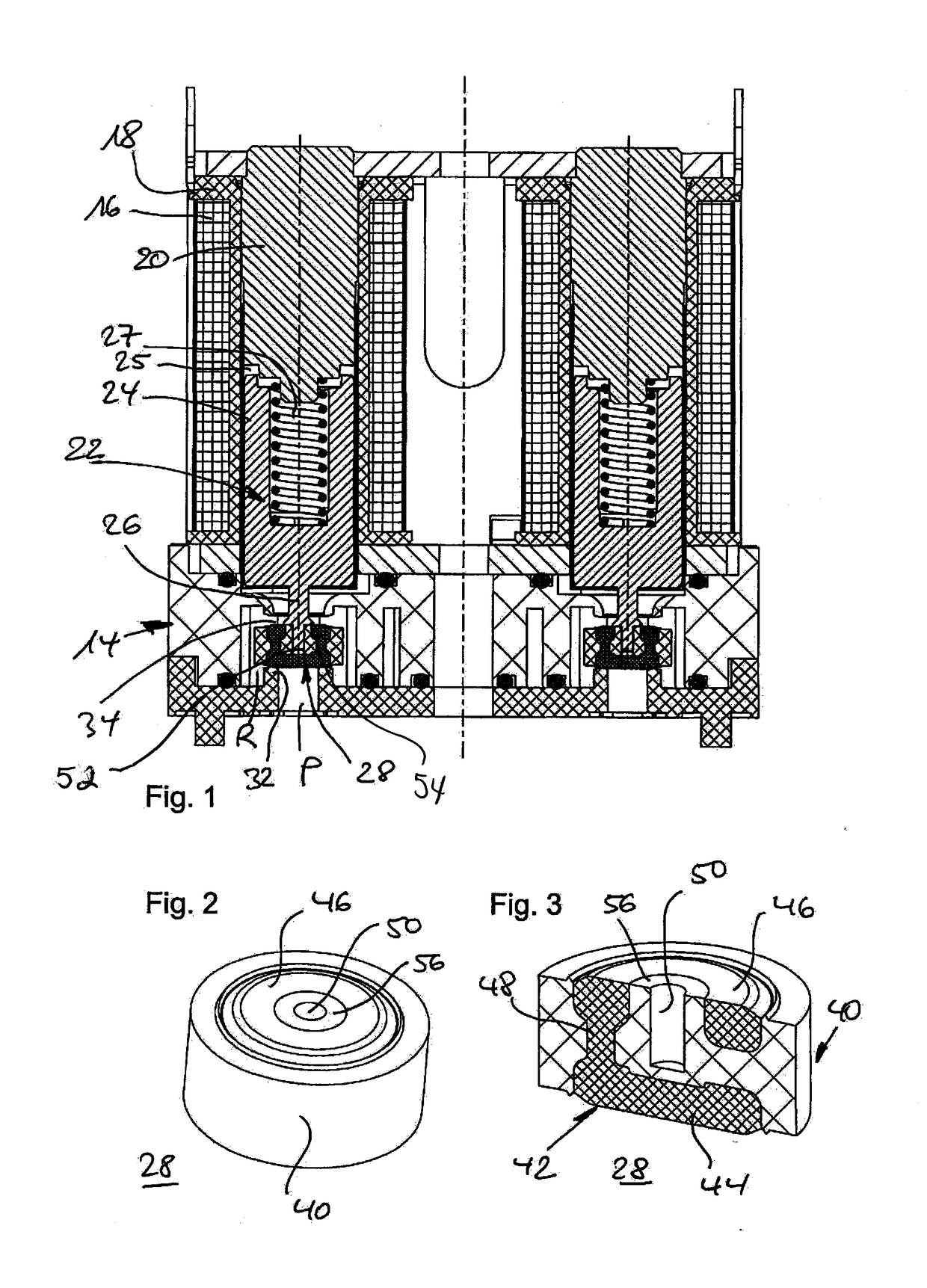

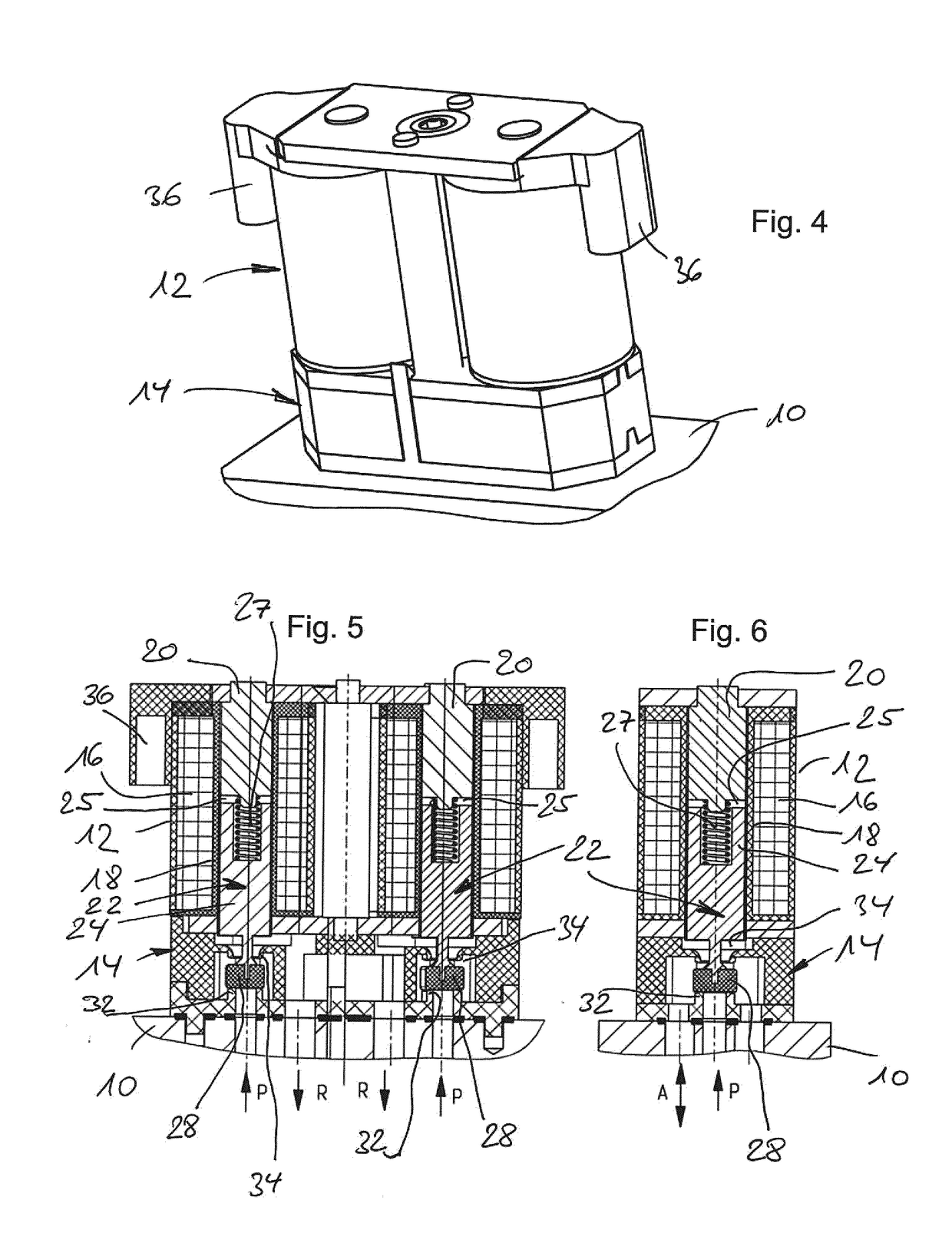

Electromagnetic valve and use thereof

ActiveUS20190024817A1Improve sealingEasy to manufactureOperating means/releasing devices for valvesLift valveRubber materialEngineering

The invention relates to an electromagnetic valve with armature means (22) which are designed to be movable along an axial direction in a valve housing (14) as a reaction to current flowing through stationary coil means (16) and which at one axial end have sealing means (28) designed to interact with a valve seat (32) assigned to a first valve inlet (P), wherein at least one second valve inlet and / or outlet (A, R) in the valve housing can be opened to the first valve inlet (P) by action of the armature means, and wherein the sealing means are provided as sealing bodies (28) on a portion (26) of the armature means of narrowed diameter, such that the sealing body having a larger diameter compared to the narrowed portion can be moved by the movement of the armature means between sealing positions formed at both axial ends of the sealing body, wherein the sealing body (28) designed as a component separate from the narrowed portion and / or designed to be releasable therefrom has a sealing portion (42), made of a polymer and / or rubber material, and also a support portion (40) which is made of a material different than and in particular harder than the material of the sealing portion, and which is designed for force-fit connection to the armature means.

Owner:ETO MAGNETIC GMBH

High-wear-resistance high-accident-resistance secondary intermediate roll

InactiveCN112111692ALong serviceLong-term accident resistanceFurnace typesRollsChemical compositionHardness

The invention relates to a high-wear-resistance high-accident-resistance secondary intermediate roll. The secondary intermediate roll is prepared from (1) 12-15 parts of C, (2) 2-6 parts of Si, (3) 2-5 parts of Mn, (4) 100-110 parts of Cr, (5) 8-12 parts of Mo, (6) 7-10 parts of V, (7) 3-5 parts of Co, (8) 1-3 parts of silicon-copper master batch wear-resistant agents, (9) 0.2-0.3 part of P, (10)0.2-0.3 part of S, and (11) 800-1000 parts of Fe and inevitable impurities. The preparation method of the secondary intermediate roll comprises the steps of (1) performing refining, pouring into ingots, electroslag remelting, forging forming according to chemical composition and weight fraction to make a rough billet, (2) conducting forging and spheroidizing annealing treatment on the rough billetto obtain a steel billet; (3) conducting rough turning and modulation treatment on the steel billet; (4) conducting quenching heat treatment on the steel billet; (5) conducting tempering treatment onthe steel billet; (6) performing refining; and (7) performing surface acoustic wave detection. According to the high-wear-resistance high-accident-resistance secondary intermediate roll, the overallhardness can reach 80-83 HSD, the overall hardness uniformity is smaller than or equal to 1 HSD, the service life is long, and the accident resistance is improved by 1.5 times or above compared with that of a traditional roll.

Owner:宜兴市鑫源辊业有限公司

Gas sensor for determining hydrogen or hydrogen compounds

InactiveUS8491766B2Short response timeLong serviceWeather/light/corrosion resistanceVolume/mass flow measurementHydrogenGas composition

The invention at hand concerns a novel class of gas sensors, in particular for hydrogen or hydrogen-containing fluids (gases or liquids), such as hydrocarbons, hydrogen sulphides or more complex gas mixtures or gas compositions which contain hydrogen or hydrogen compounds.

Owner:JUSTUS LIEBIG UNIV

A high temperature oxidation resistant austenitic stainless steel

ActiveCN112899568BImprove high temperature oxidation resistanceLong serviceSS - Stainless steelOxidation resistant

The invention provides a high-temperature oxidation-resistant austenitic stainless steel, which is characterized in that, in terms of weight percentage, it comprises: C≤0.080%, Si≤1.50%, Mn≤2.00%, P≤0.045%, S≤0.030%, Ni 19.00-22.00%, Cr 24.00-26.00%, B 0.20-0.40%, N≤0.03%, and the balance is Fe and unavoidable impurities. The high-temperature oxidation resistance of the austenitic stainless steel of the invention is improved, and it can serve for a long time in a high-temperature environment, and the service time is at least 2-3 times that of the current common austenitic stainless steel.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Mold having ceramic insert

An ingot mold has a body having an open top, a bottom with an opening, and a longitudinal cavity passing through the body. The cavity is defined by a cavity wall extending from the top to the bottom. The cavity wall has a recess adjacent the opening in the bottom of the body. A ceramic insert is positioned within the cavity such that the sidewalls of the ceramic insert are in The recess in the cavity wall.

Owner:HAYNES INTERNATIONAL

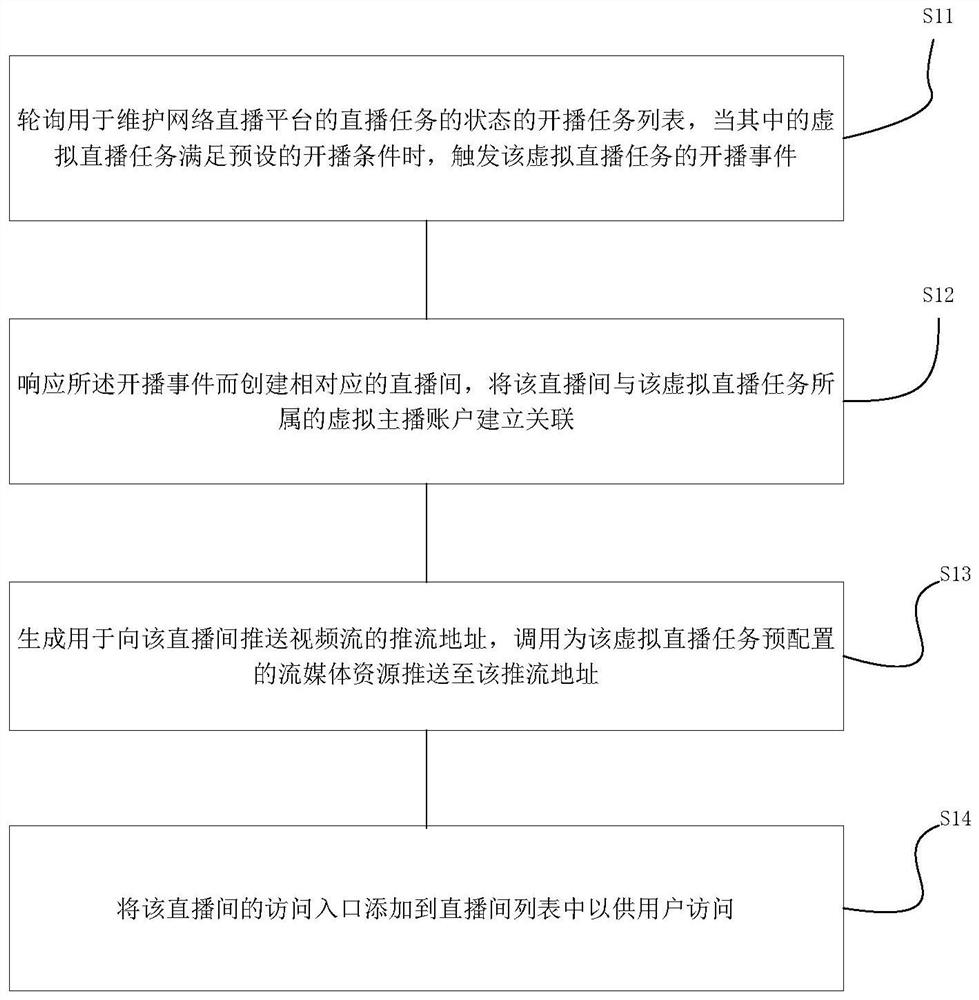

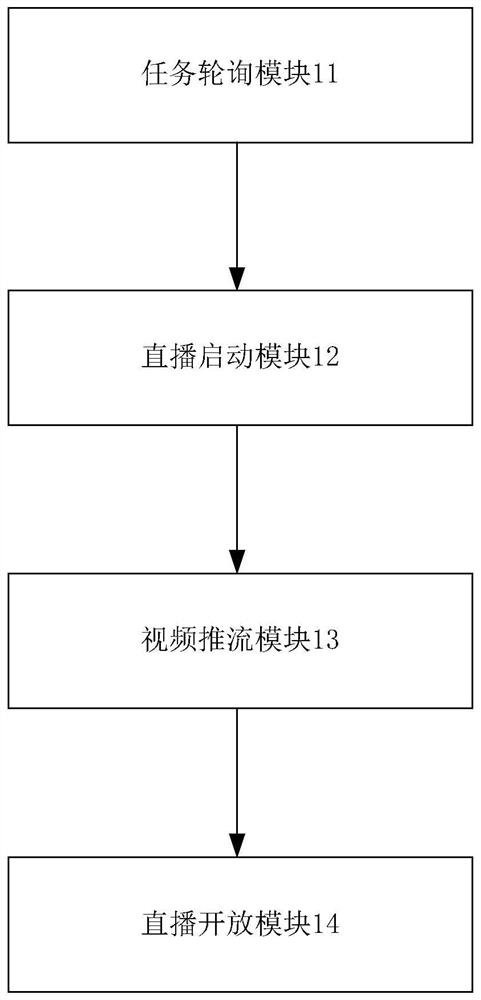

Virtual live broadcast method, device, equipment and storage medium

ActiveCN112218127BRealize reasonable planningFlow maximizationSelective content distributionSpecial service provision for substationEngineeringComputer science

The present application discloses a virtual live broadcast method, device, device, and storage medium. The method includes: polling the list of live broadcast tasks used to maintain the status of the live broadcast tasks of the network live broadcast platform, when the virtual live broadcast tasks in it meet the preset broadcast start conditions , trigger the start broadcast event of the virtual live broadcast task; create a corresponding live broadcast room in response to the start broadcast event, and associate the live broadcast room with the virtual anchor account to which the virtual live broadcast task belongs; The push stream address of the stream, call the streaming media resources preconfigured for the virtual live broadcast task to push to the stream push address; add the access entry of the live room to the live room list for user access. This application realizes the seamless access of virtual live broadcasting tasks in the webcasting platform, which is especially helpful to increase the overall active user traffic of the webcasting platform during non-prime time, and to improve the traffic monetization effect.

Owner:广州方硅信息技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com