High-entropy ultrahigh-temperature zirconia-based thermal barrier coating material, preparation method and application thereof and zirconia-based thermal barrier coating

A thermal barrier coating, zirconia-based technology, applied in the coating, metal material coating process, fusion spraying, etc., can solve the problem of low thermal expansion coefficient and fracture toughness, reduced coating strain tolerance, coating thermal Short cycle life and other issues, to achieve the effect of alleviating thermal expansion mismatch, improving high temperature strain tolerance, and good resistance to CMAS penetration corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] As the first method (arc melting method) of the present invention, the present invention provides the preparation method of the zirconia-based thermal barrier coating material described in the above technical solution, comprising the following steps:

[0034] Mixing yttrium oxide, cerium oxide, and four rare earth oxides corresponding to the second rare earth element with molten zirconia, and smelting to obtain a ceramic molten liquid;

[0035] The ceramic melt is crushed to obtain a zirconia-based thermal barrier coating material.

[0036] In the present invention, unless otherwise specified, the required preparation raw materials are all commercially available products well known to those skilled in the art.

[0037] In the present invention, yttrium oxide, cerium oxide, and four rare earth oxides corresponding to the second rare earth element are mixed with molten zirconia, and smelted to obtain a ceramic molten liquid. In the present invention, the zirconia is prefer...

Embodiment 1

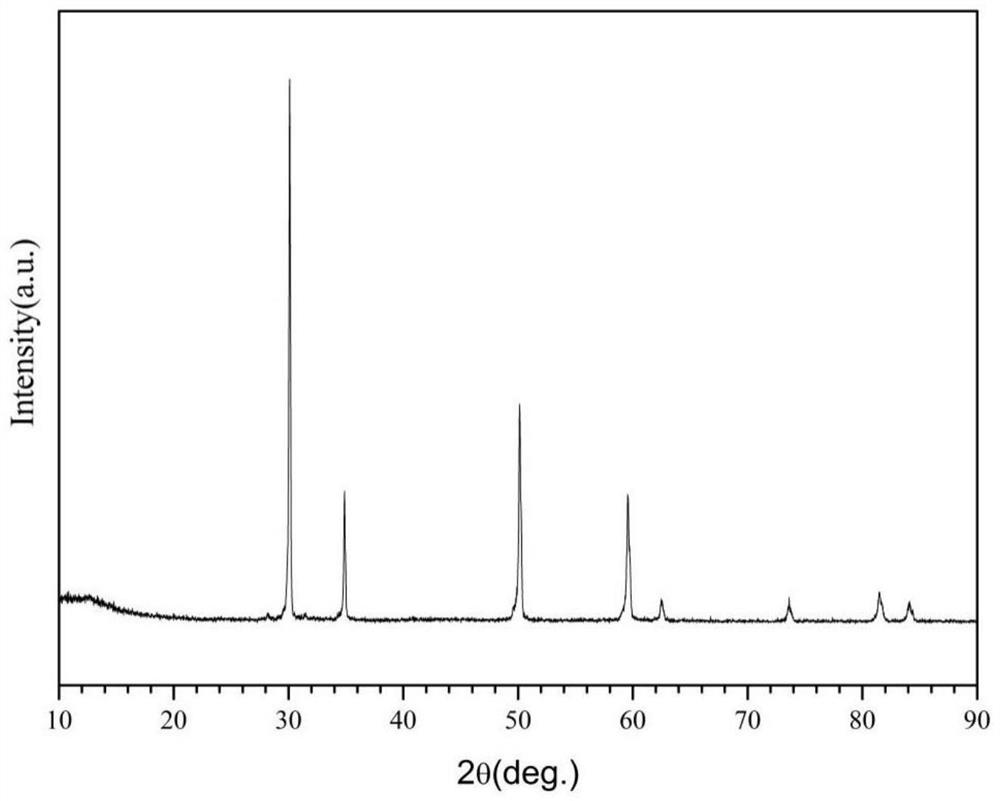

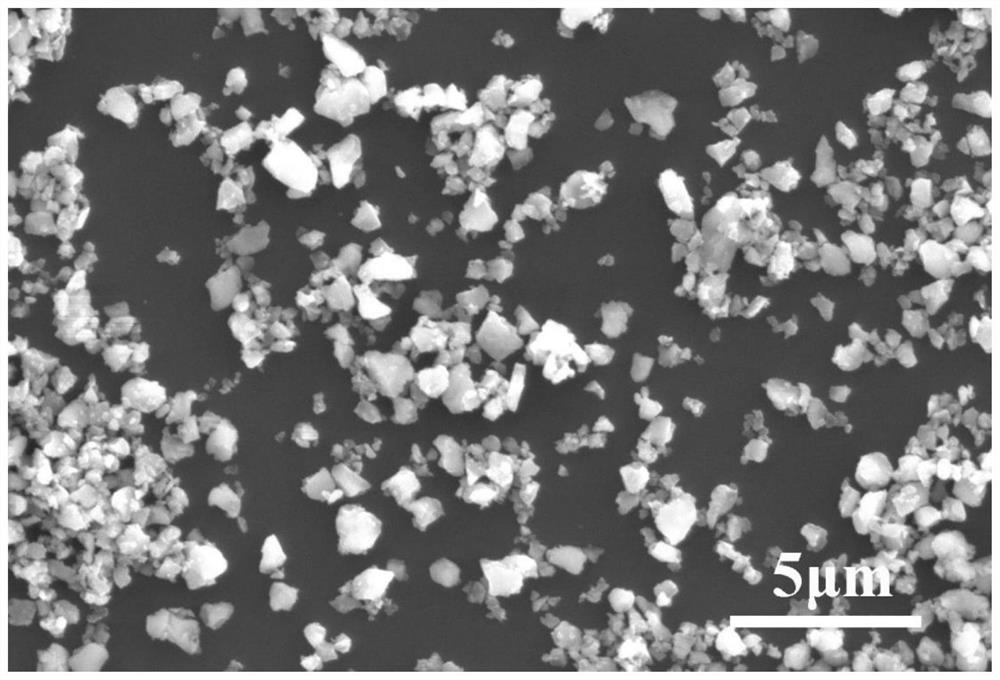

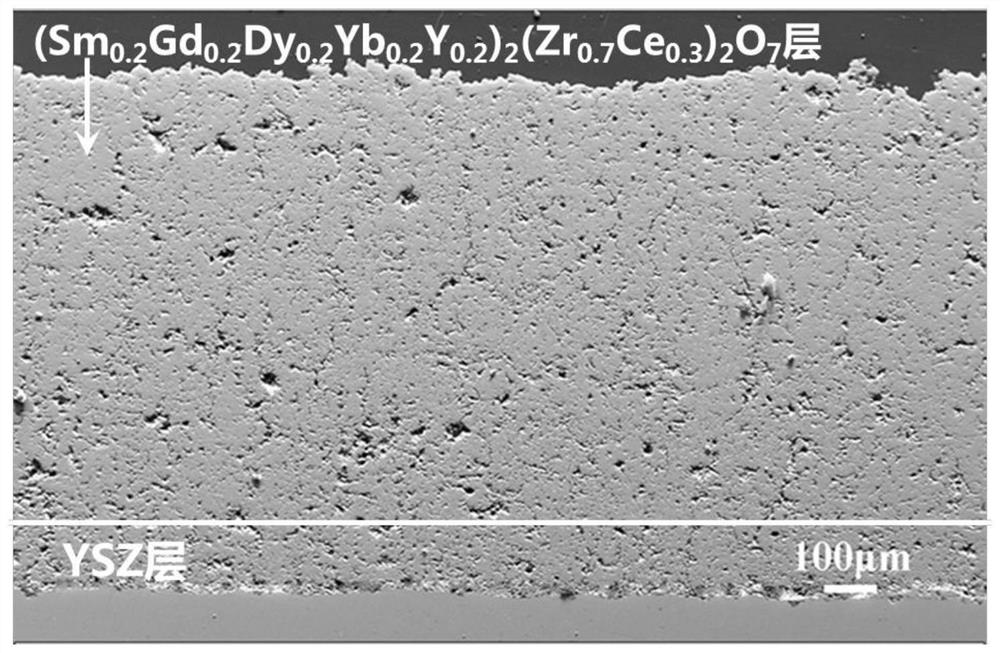

[0079] Preparation of zirconia-based thermal barrier coating materials (Sm 0.2 Gd 0.2 Dy 0.2 Yb 0.2 Y 0.2 ) 2 (Zr 0.7 Ce 0.3 ) 2 O 7 ;

[0080] According to the stoichiometric ratio determined by the chemical formula, the oxide powders corresponding to Sm, Gd, Dy, Yb and Y were calcined at 800 °C for 120 min, and the ZrO 2 The powder was put into the electric arc furnace, smelted at 2700 ℃ for 60min, and then added CeO 2 The powder is smelted at 2700℃ for 60min; the weighed Sm 2 O 3 , Gd 2 O 3 , Dy 2 O 3 , Yb 2 O 3 and Y 2 O 3 The powder is put into the electric arc furnace for smelting for 100min at the same time, and the inclined electric arc furnace is adopted. 2 The obtained ceramic melt is crushed to 200 μm~1mm with compressed air, and the powder is crushed to 200nm~5 μm by a mechanical crushing method, so as to obtain a zirconia-based thermal barrier coating material.

Embodiment 2

[0082] Zirconia-based thermal barrier coating materials (Nd 0.2 Gd 0.2 Eu 0.2 Tb 0.2 Y 0.2 ) 2 Zr 2 O 7 :

[0083] According to the stoichiometric ratio determined by the chemical formula, five rare earth oxide powders except Zr were calcined at 800 °C for 120 min; the five rare earth oxides were dissolved in concentrated nitric acid, and the liquid was evaporated to dryness to obtain water-soluble rare earth oxides. Nitrate crystals; five rare earth nitrates and ZrOCl 2 The crystals were dissolved in deionized water, stirred at room temperature for 30 min, and then mixed with five rare earth nitrate solutions and ZrOCl. 2 The solution was mixed and stirred for 1 h to obtain a mixed brine solution;

[0084] Add 1.5 mol / L ammonia water dropwise to the above mixed brine solution, and continue to stir rapidly until the pH of the solution as a whole is ≥ 12.5, stop adding ammonia water dropwise, and continue to stir and age for 2 hours; filter the precipitated suspension,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com