Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

57results about How to "Large surface roughness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

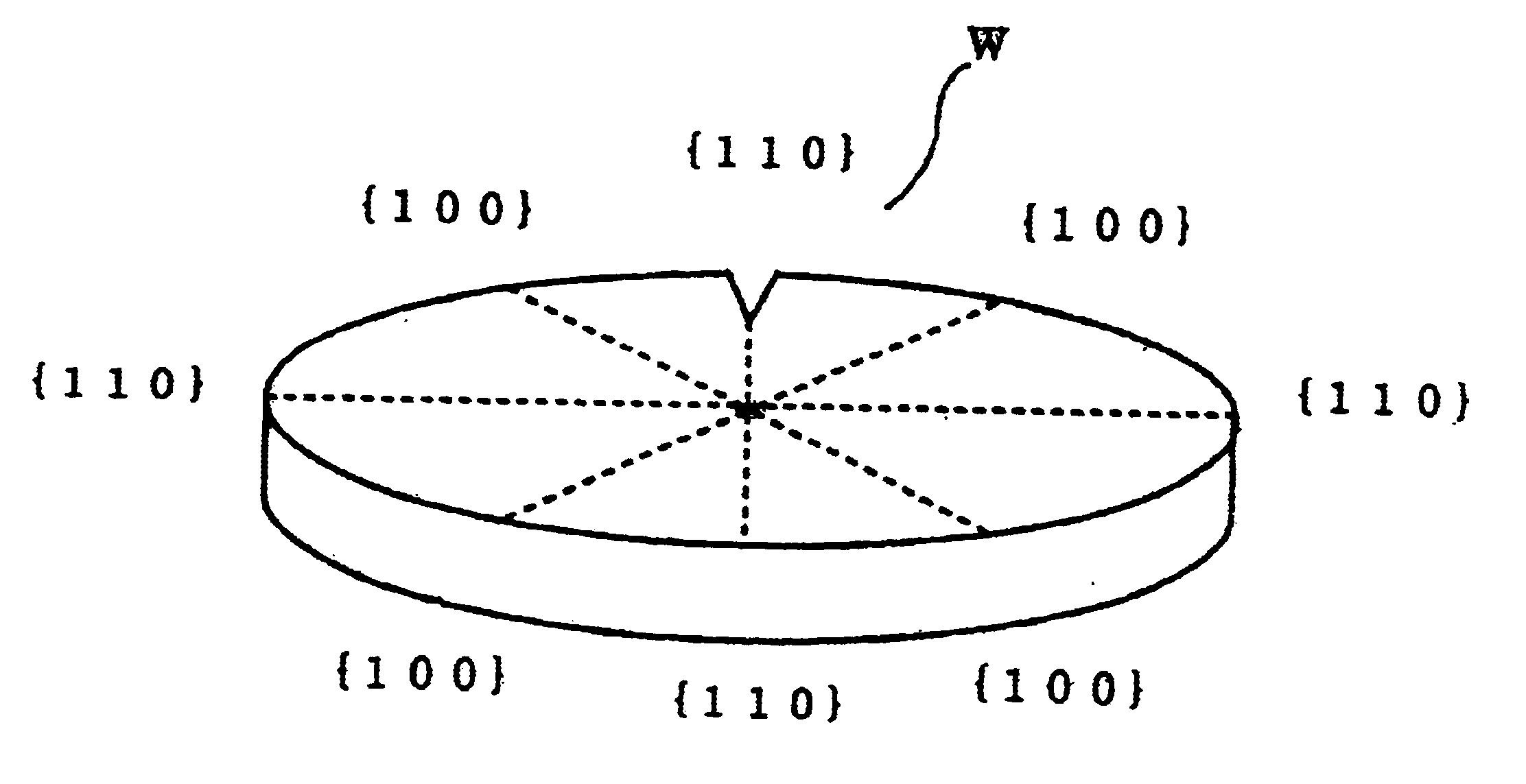

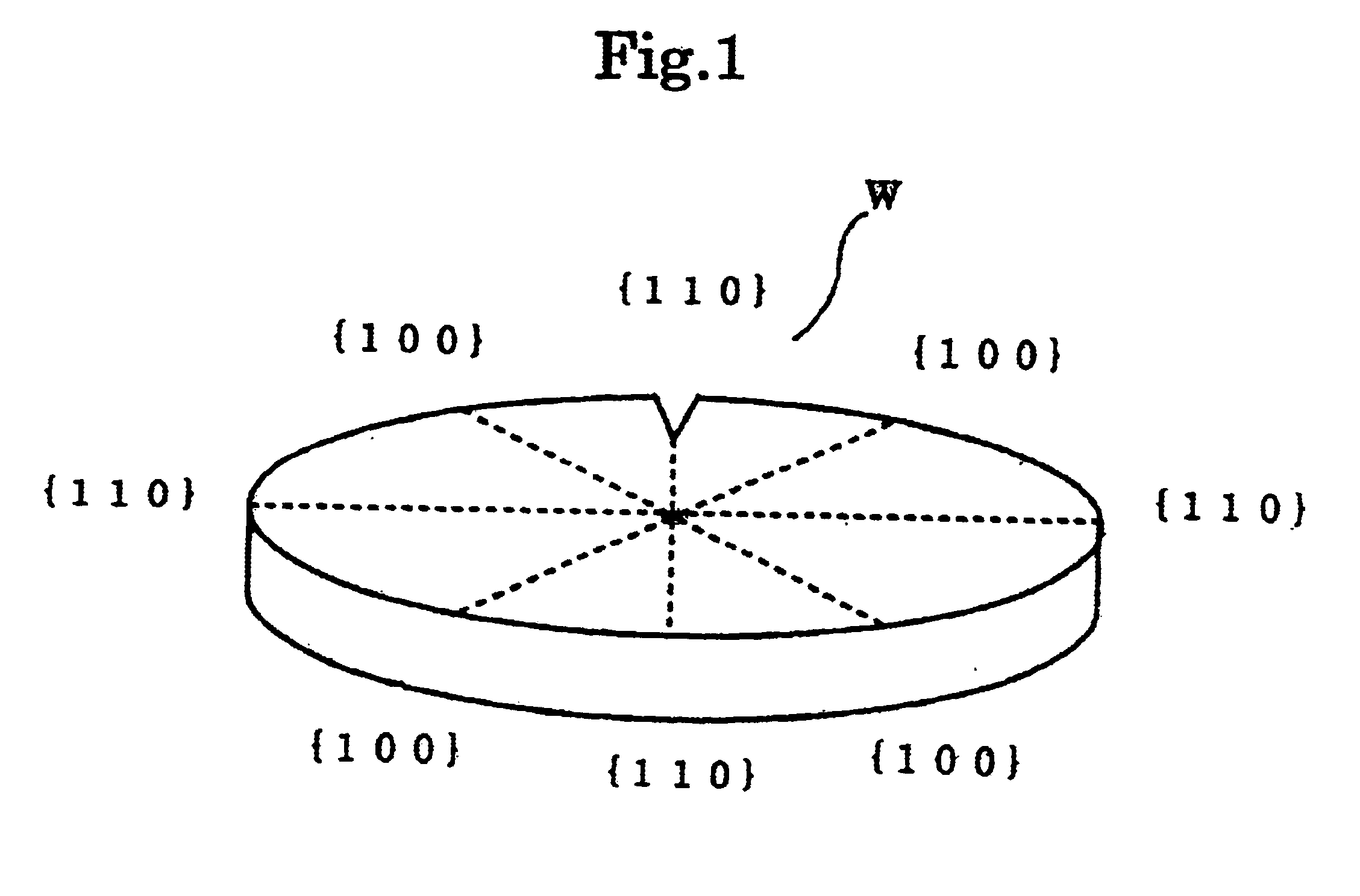

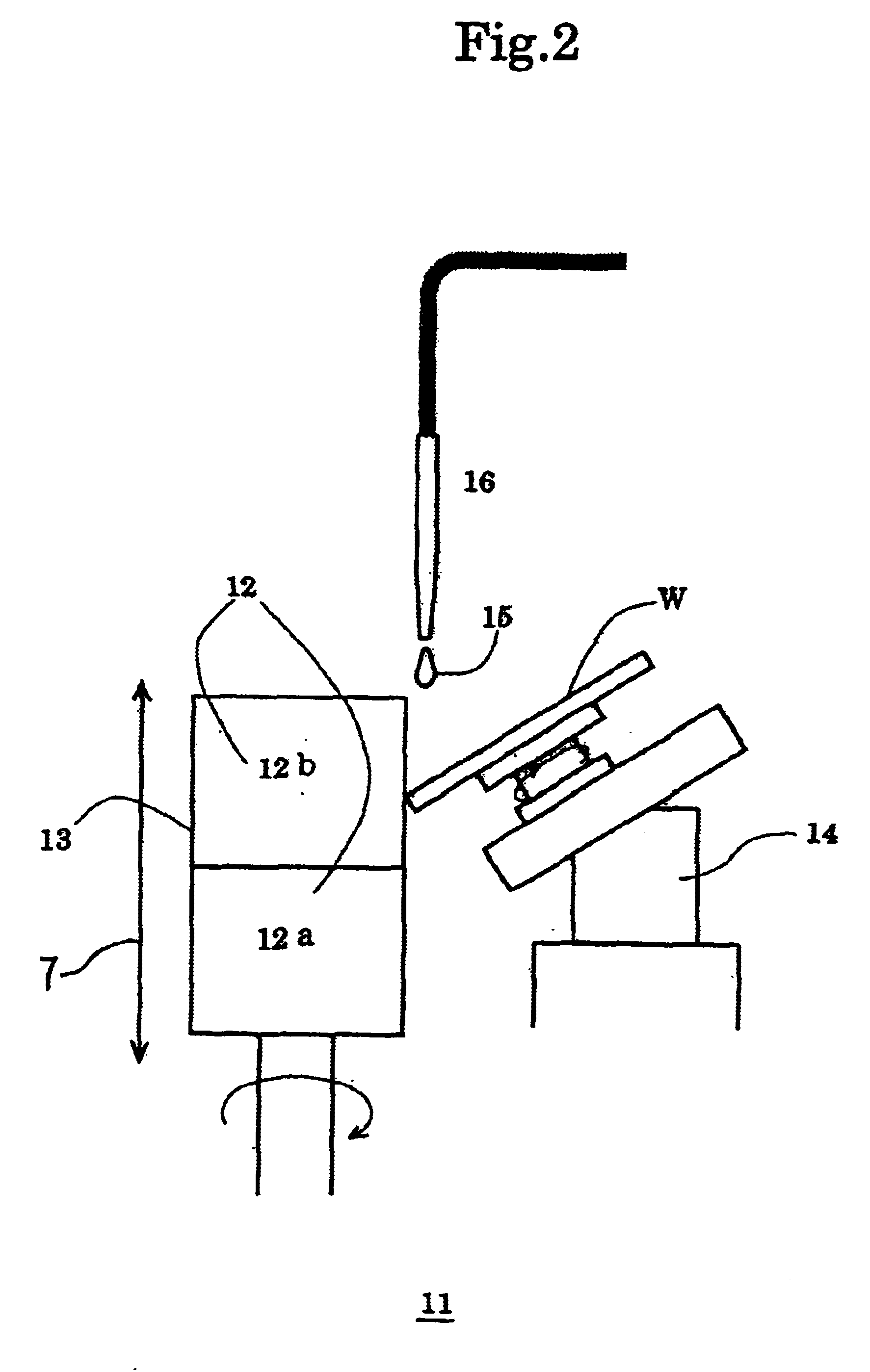

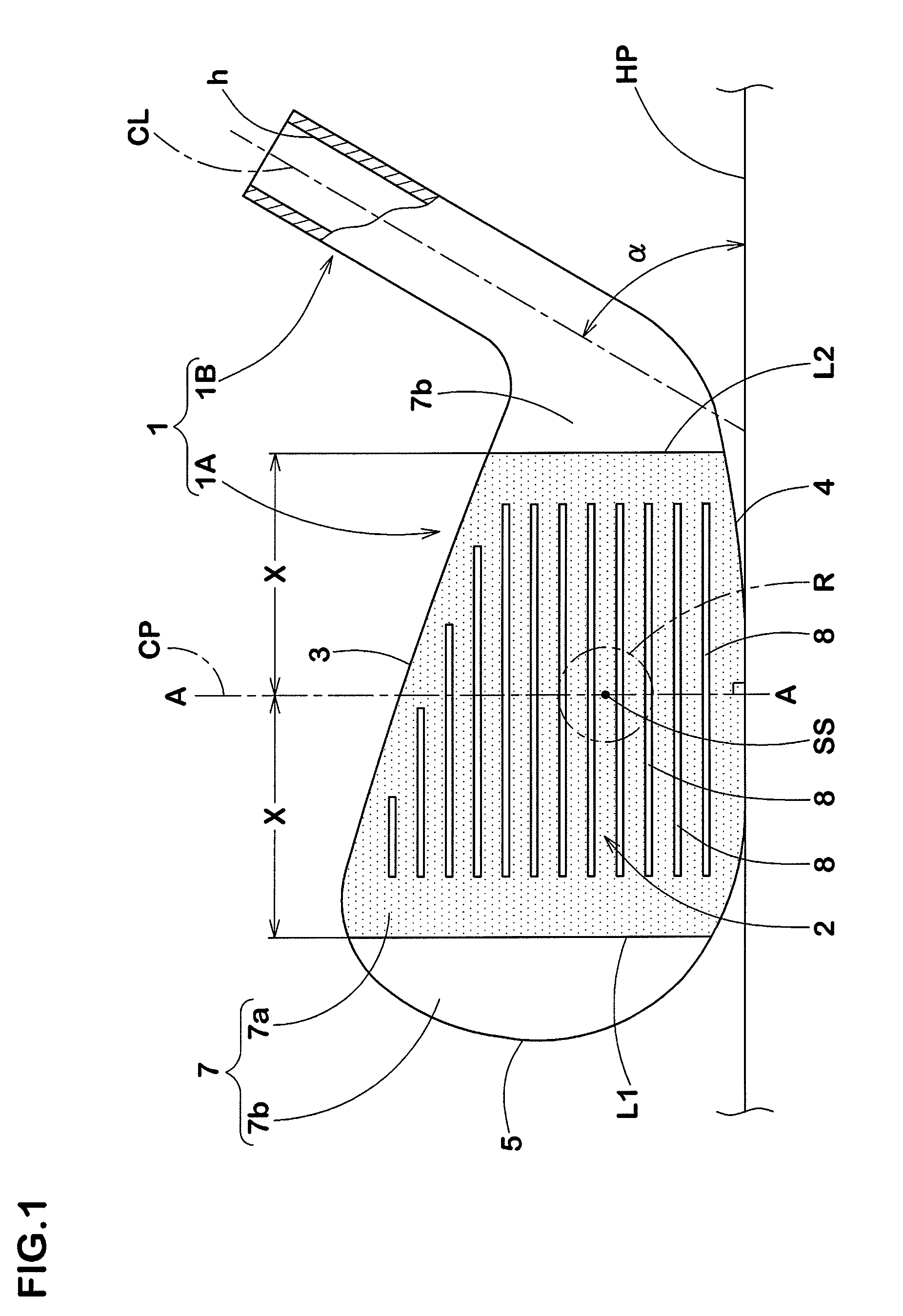

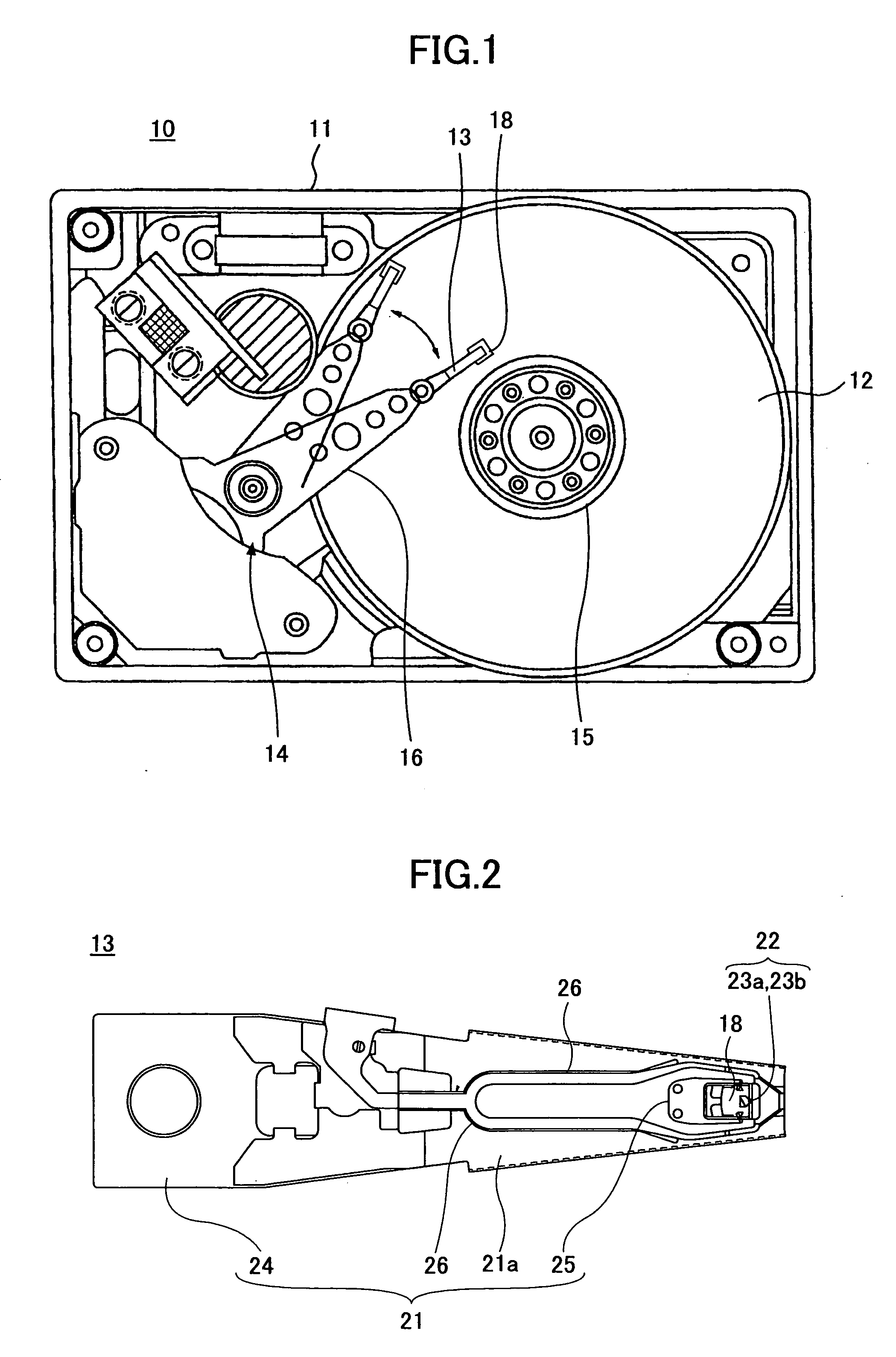

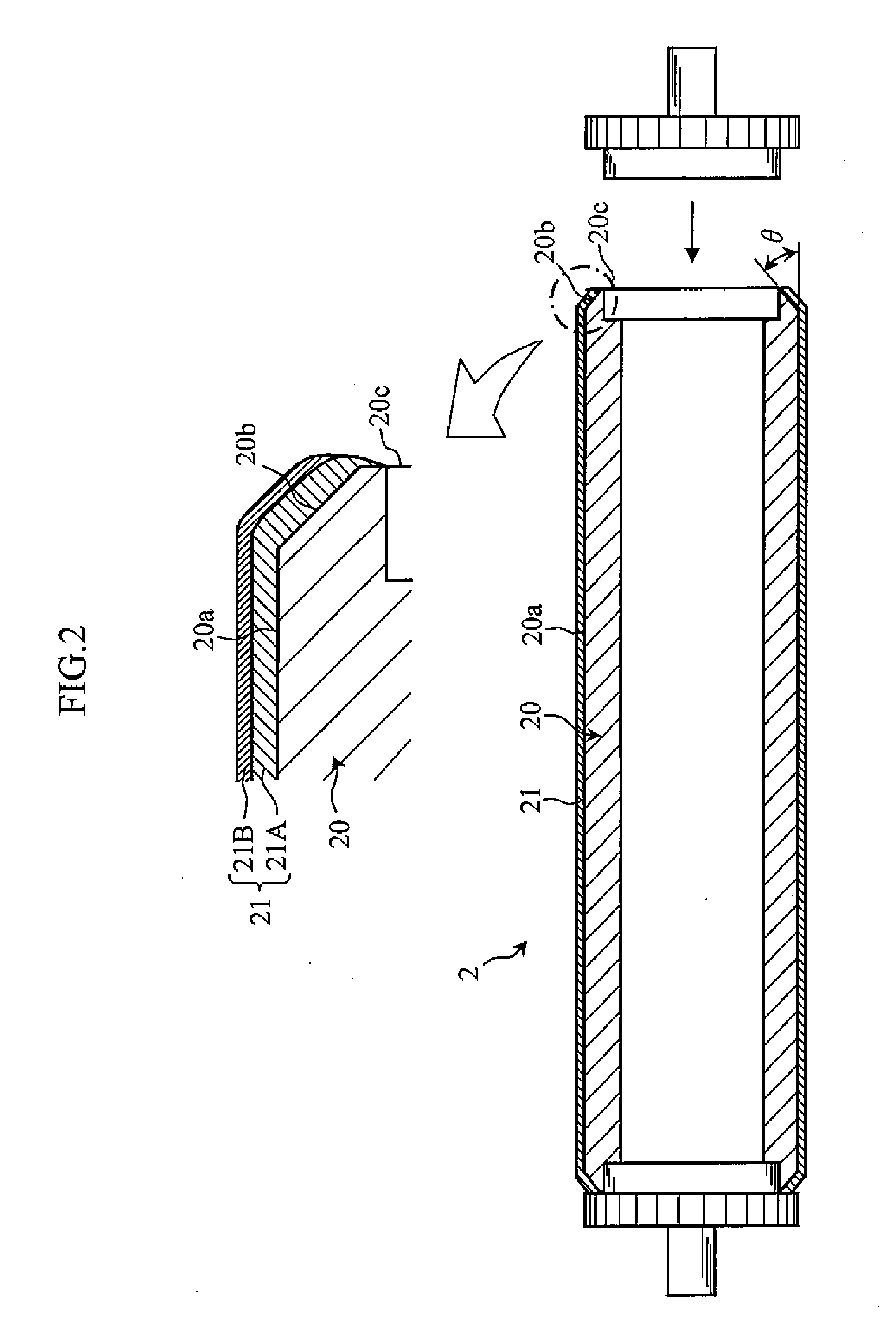

Method for apparatus for polishing outer peripheral chamfered part of wafer

InactiveUS6884154B2Improve productivityShorten polishing timeEdge grinding machinesPolishing machinesProduction rateHardness

In a process for polishing the chamfered peripheral part of a wafer using a polishing cloth while supplying a polishing slurry in order to improve productivity of the process by reducing a polishing time, at least two steps of polishing processes are performed in sequence. The process comprises a first polishing process to polish a particular part, e.g. the part corresponding to the {110} plane of a peripheral part of the wafer and a second polishing process in which the whole part of a peripheral part of the wafer is polished for finishing by means of varying a hardness of the polishing clothes and / or a particle size of abrasives in the slurry such as the hardness of the polishing cloth in the second polishing process being softer than that of in the first polishing process and a particle size of abrasives in the slurry in the second polishing process being finer than that of in the first polishing process.

Owner:SHIN-ETSU HANDOTAI CO LTD

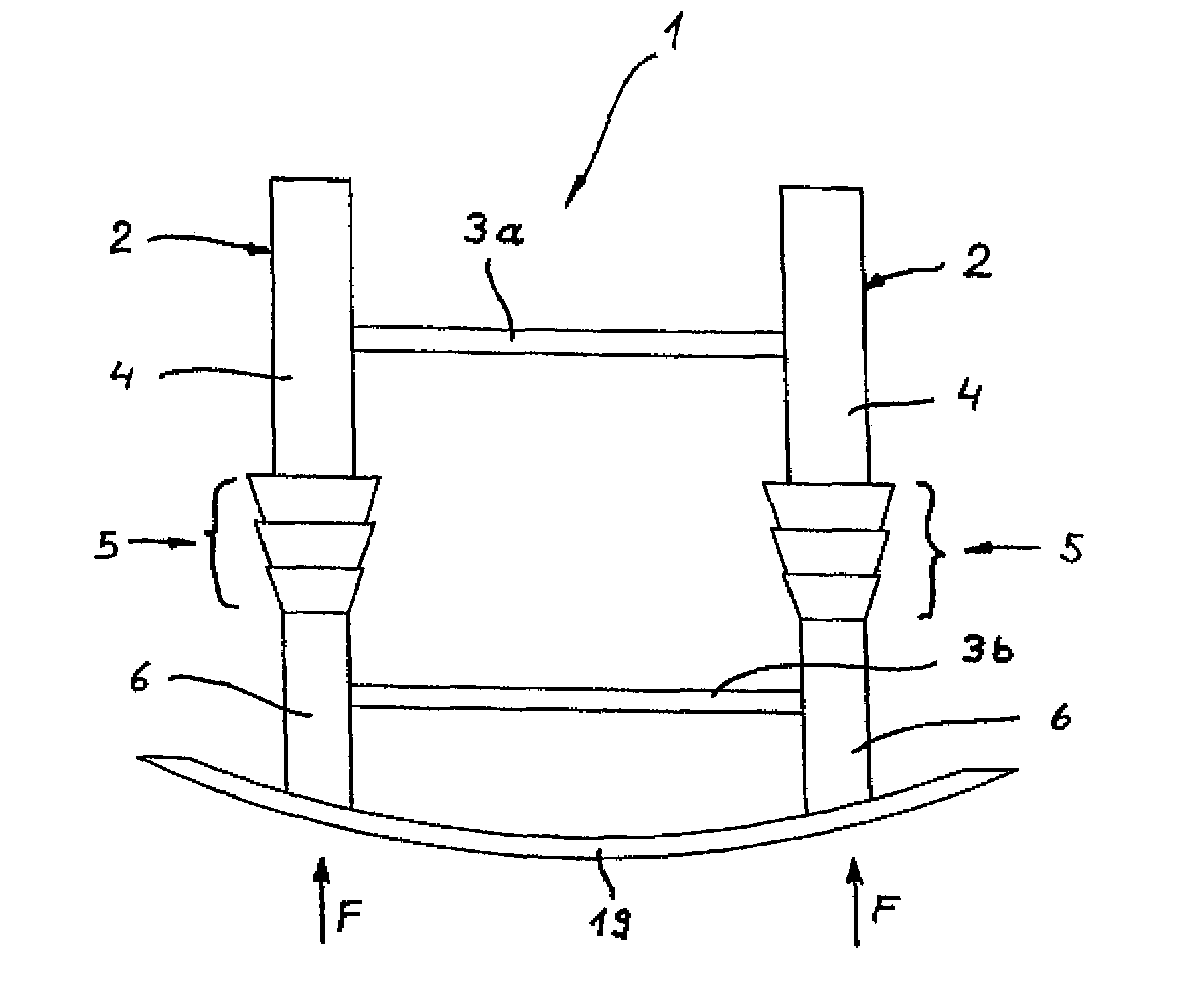

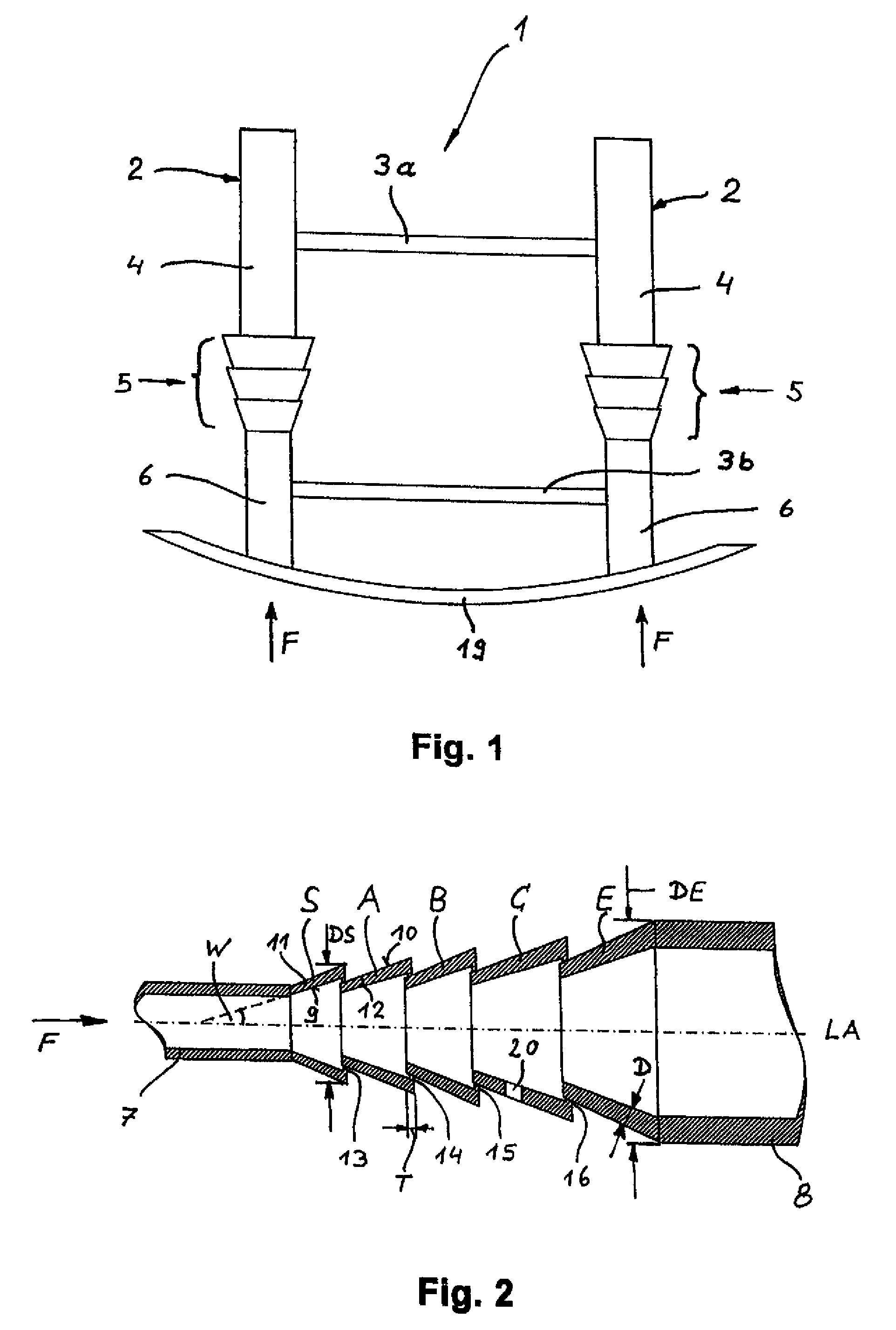

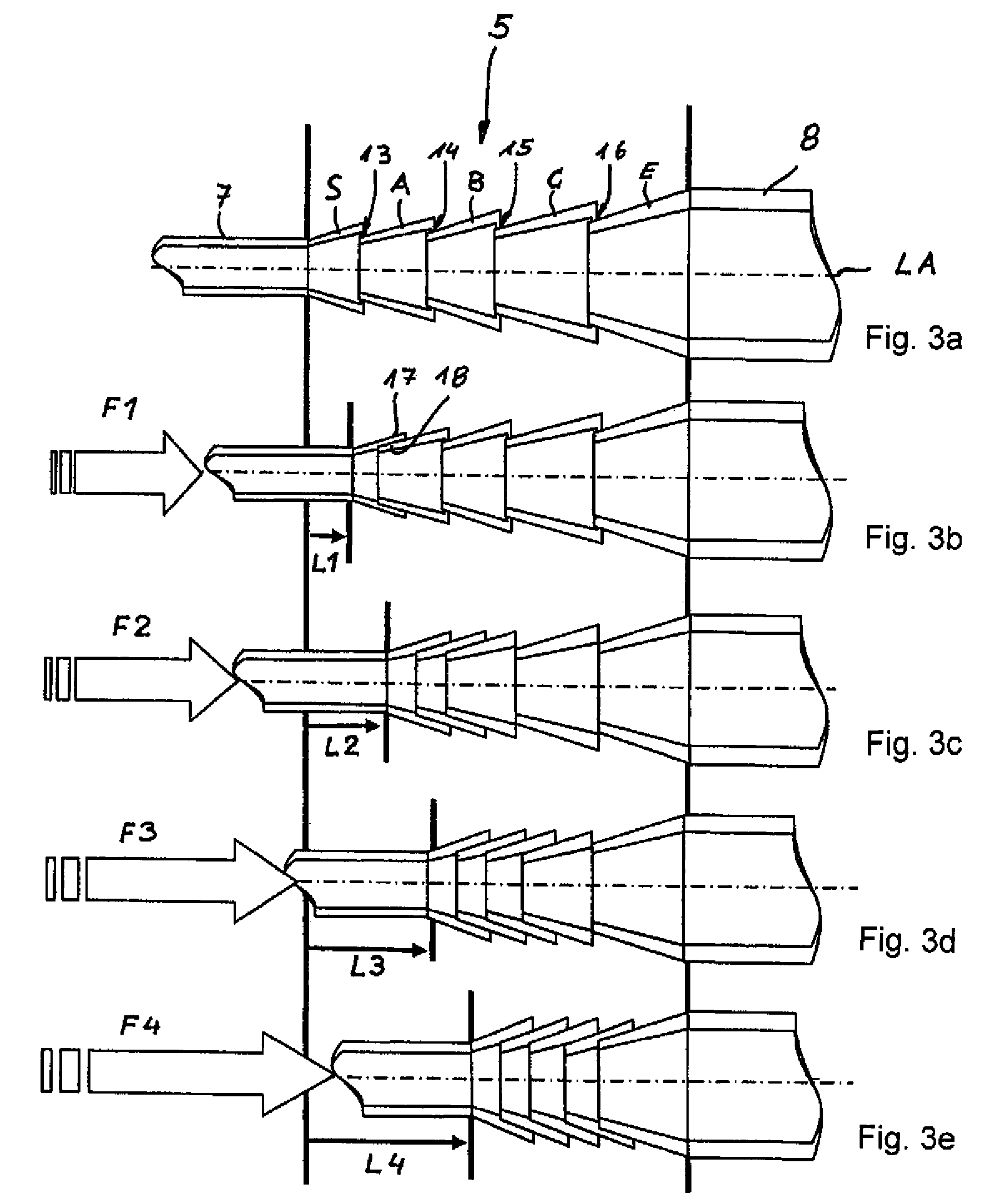

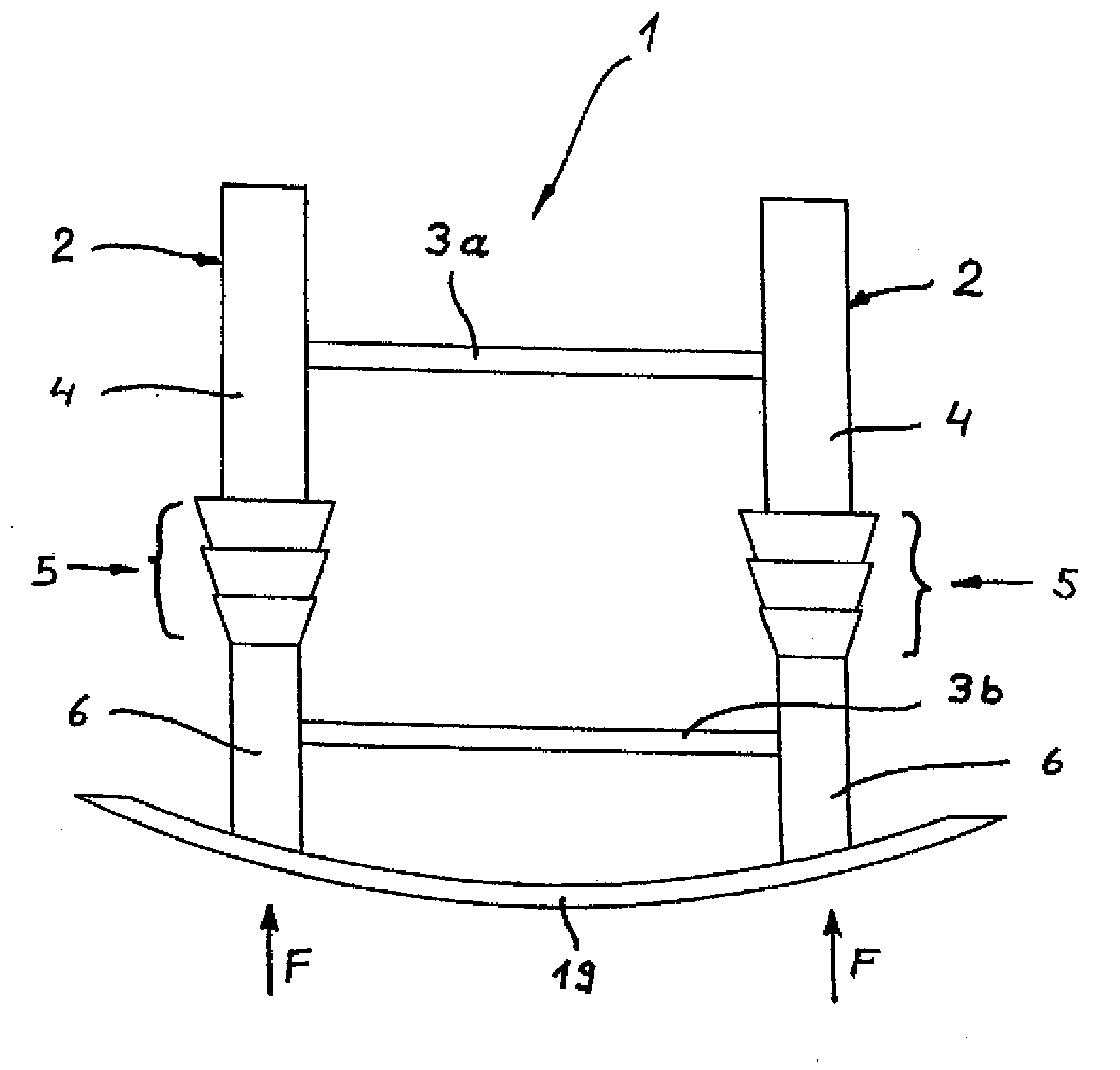

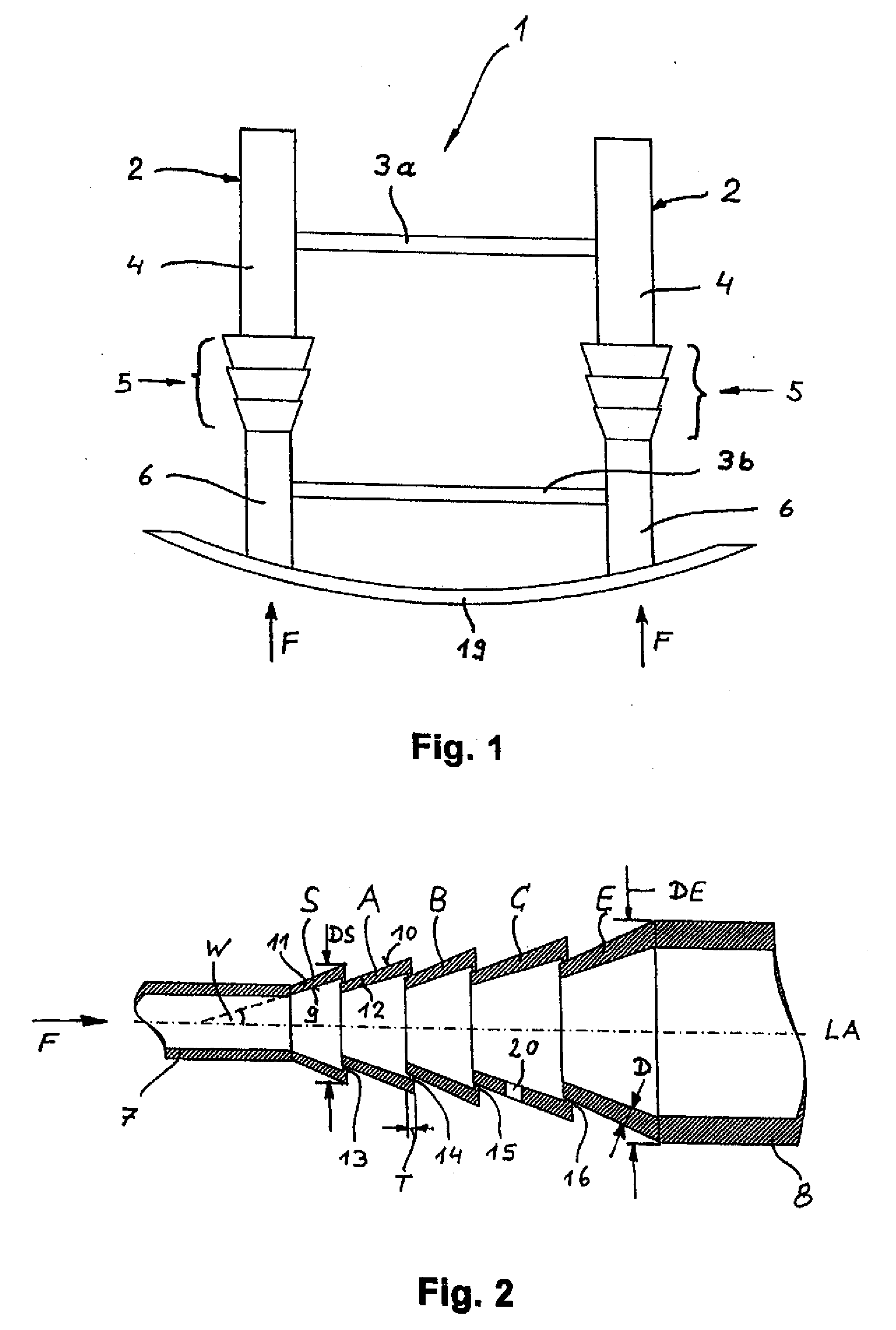

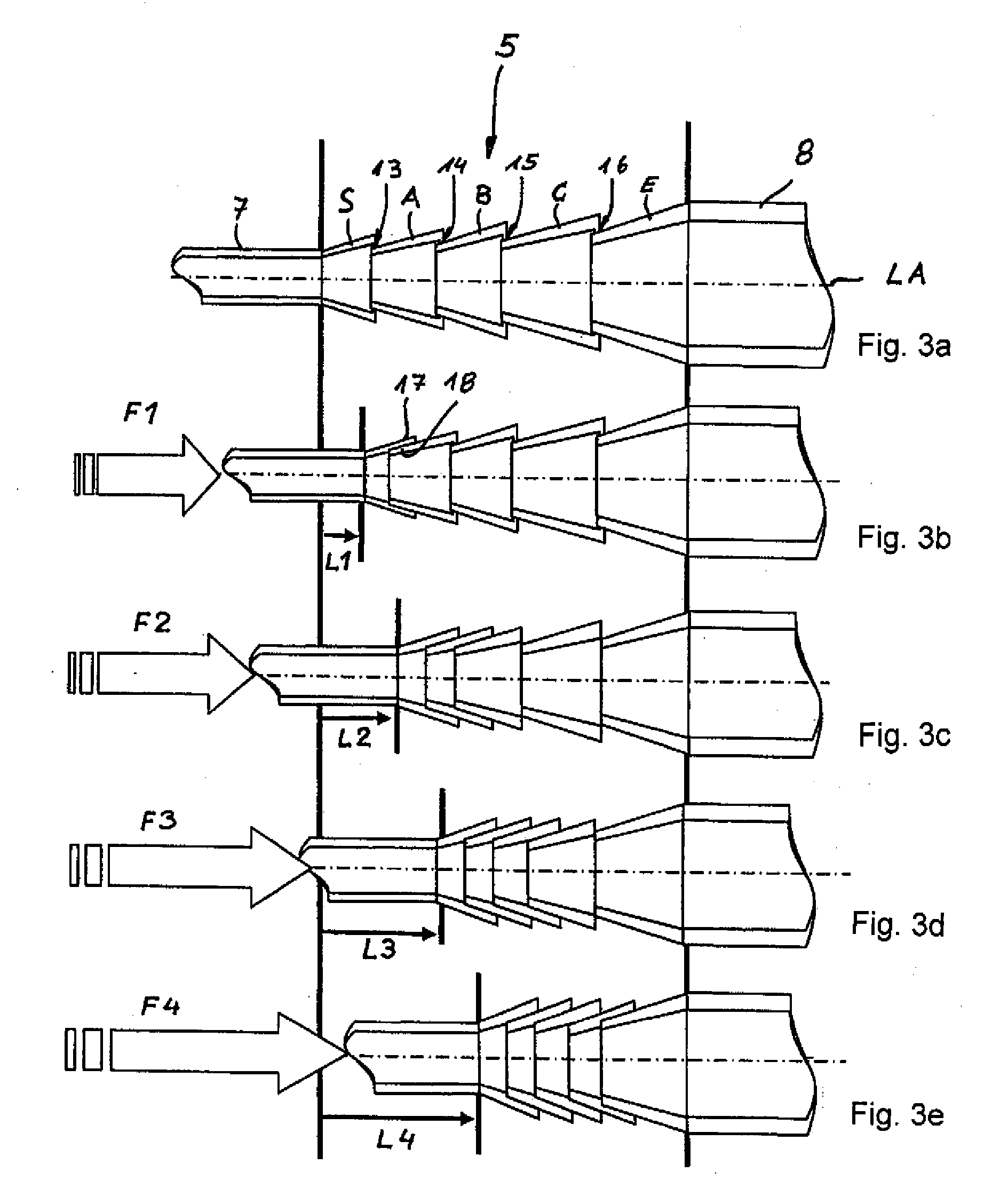

Adaptive crash structure for a vehicle body or chassis of a motor vehicle

InactiveUS7357445B2Reduce warpingAvoid accidental separationVehicle seatsUnderstructuresMobile vehicleMotor vehicle part

An adaptive crash structure of a vehicle body or chassis of a motor vehicle includes a first metal casting and a second metal casting. A deformation element in the form of a metal casting for absorbing energy interconnects and forms with the first and second metal castings a single piece construction through a casting process. The deformation element is comprised of a plurality of funnel-shaped wedge bodies which are disposed in succession, with neighboring wedge bodies being connected through intervention of a predetermined breaking web. Each wedge body is defined by a diameter, wherein the diameters of the wedge bodies are sized to allow the wedge bodies to move telescopically into one another when a limit stress is reached and the predetermined breaking webs rupture so as to effect a tight intergrip of the telescoping wedge bodies in a self-locking manner.

Owner:BENTELER AUTOMOBILTECHNIK GMBH

Adaptive crash structure for a vehicle body or chassis of a motor vehicle

InactiveUS20070114804A1Reduce warpingAvoid accidental separationUnderstructuresElastic dampersAbsorbed energySelf locking

An adaptive crash structure of a vehicle body or chassis of a motor vehicle includes a first metal casting and a second metal casting. A deformation element in the form of a metal casting for absorbing energy interconnects and forms with the first and second metal castings a single piece construction through a casting process. The deformation element is comprised of a plurality of funnel-shaped wedge bodies which are disposed in succession, with neighboring wedge bodies being connected through intervention of a predetermined breaking web. Each wedge body is defined by a diameter, wherein the diameters of the wedge bodies are sized to allow the wedge bodies to move telescopically into one another when a limit stress is reached and the predetermined breaking webs rupture so as to effect a tight intergrip of the telescoping wedge bodies in a self-locking manner.

Owner:BENTELER AUTOMOBILTECHNIK GMBH

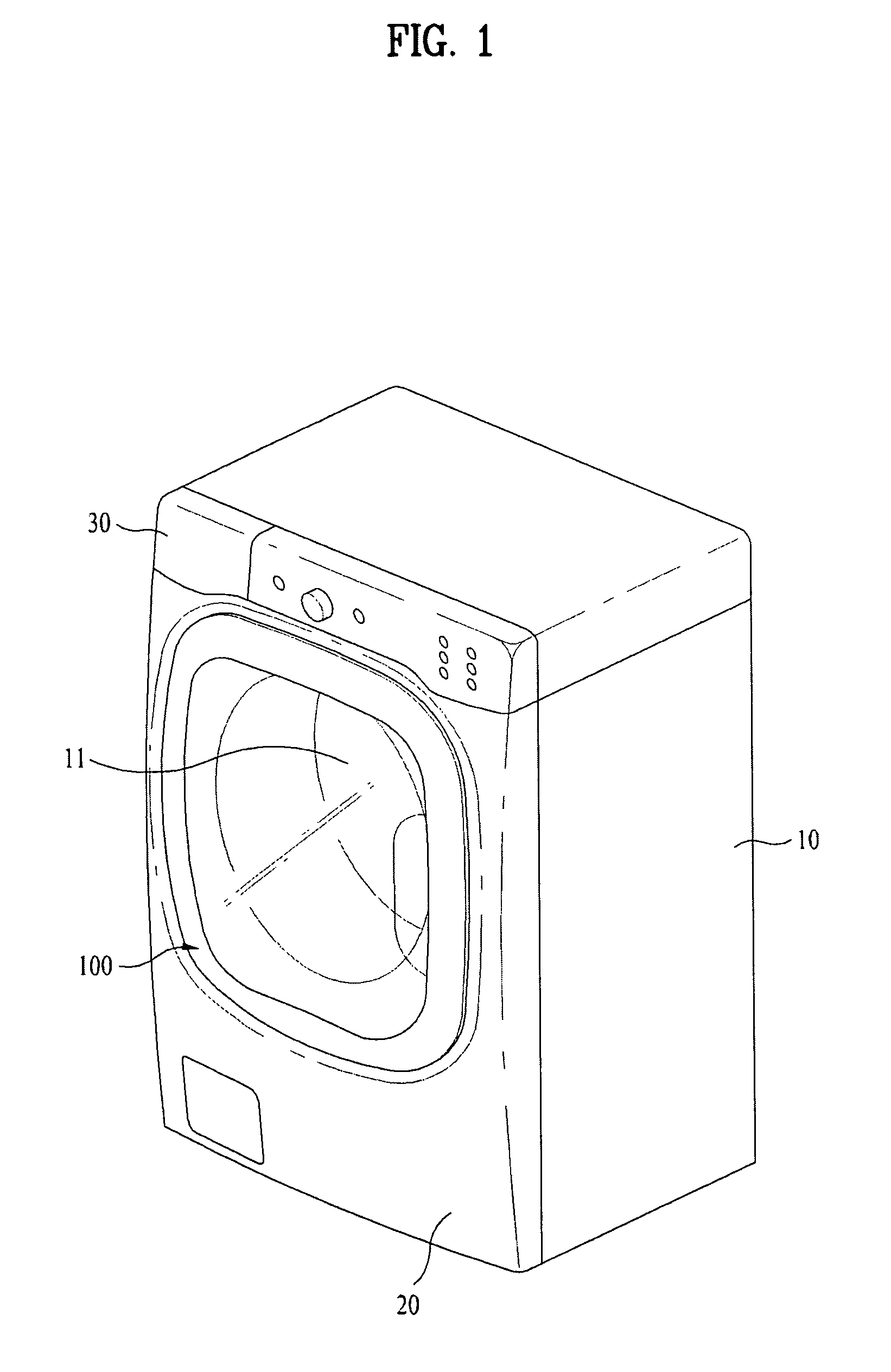

Door for washing machine

InactiveUS20100031581A1Improve productivityLarge surface roughnessWing accessoriesOther washing machinesEngineeringFront cover

A door for a washing machine is disclosed. A door for a washing machine includes an inner frame having an opening with a predetermined size, an outer frame provided at a front surface of the inner frame, having an opening in communication with the opening of the inner frame, a glass member fitted between the inner and outer frames, covering the openings of the inner and outer frames, a decorative member provided at a front surface of the outer frame, having an opening in communication with the openings, and a front cover fitted between the decorative member and the outer frame, covering the openings of the inner and outer frames and the decorative member, the front cover having a positioning portion determining a position of the front cover coupled to the outer frame.

Owner:LG ELECTRONICS INC

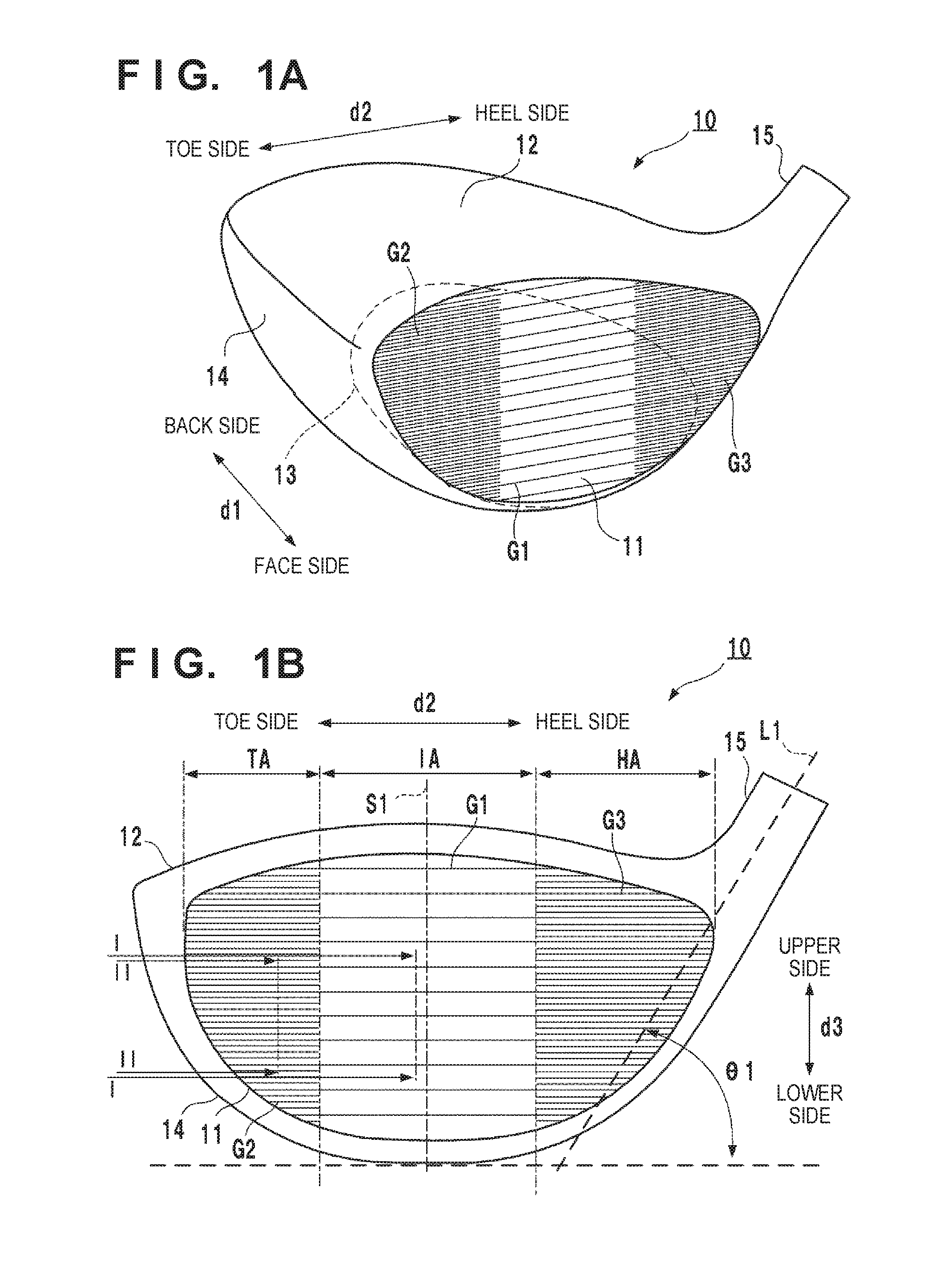

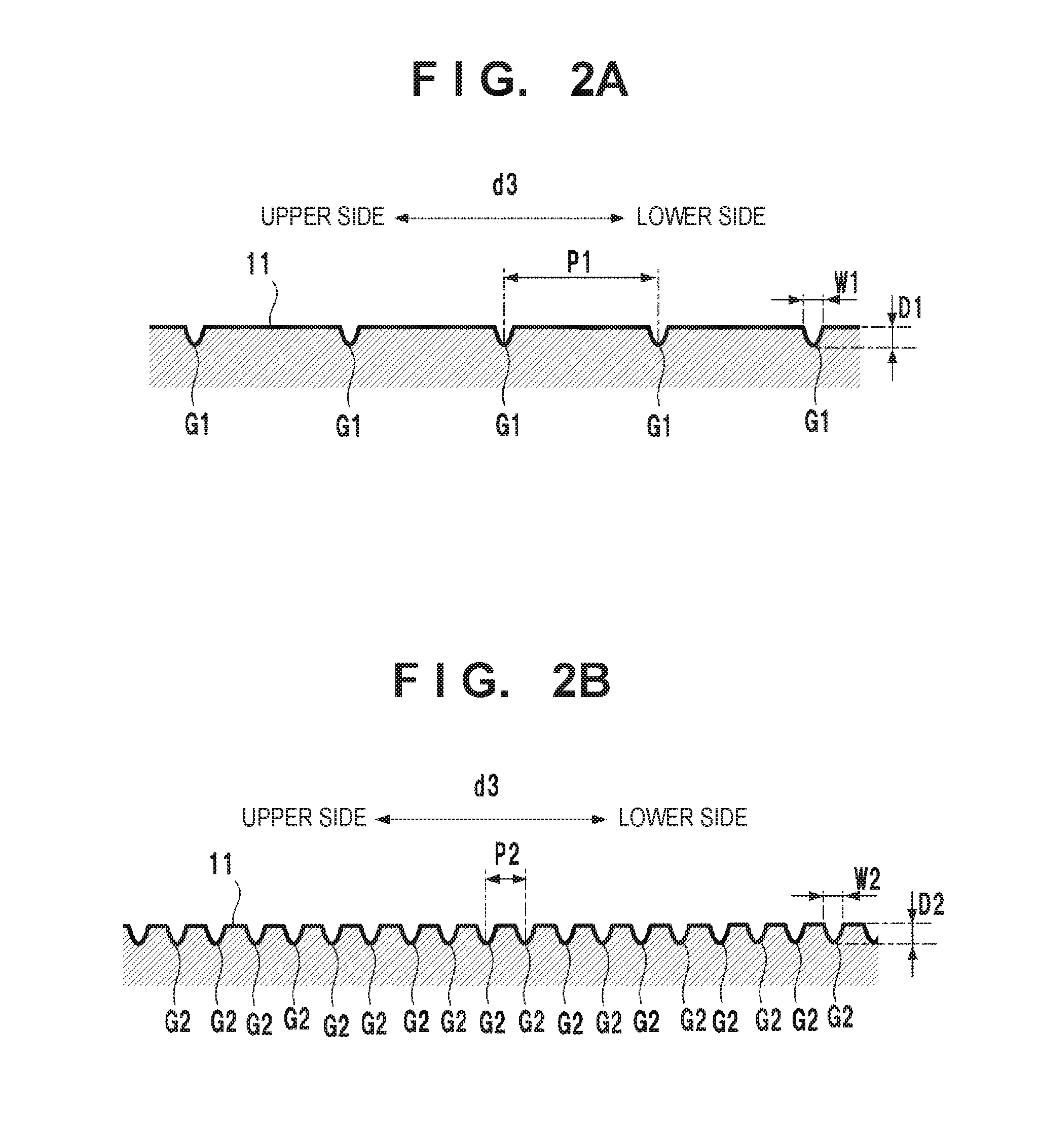

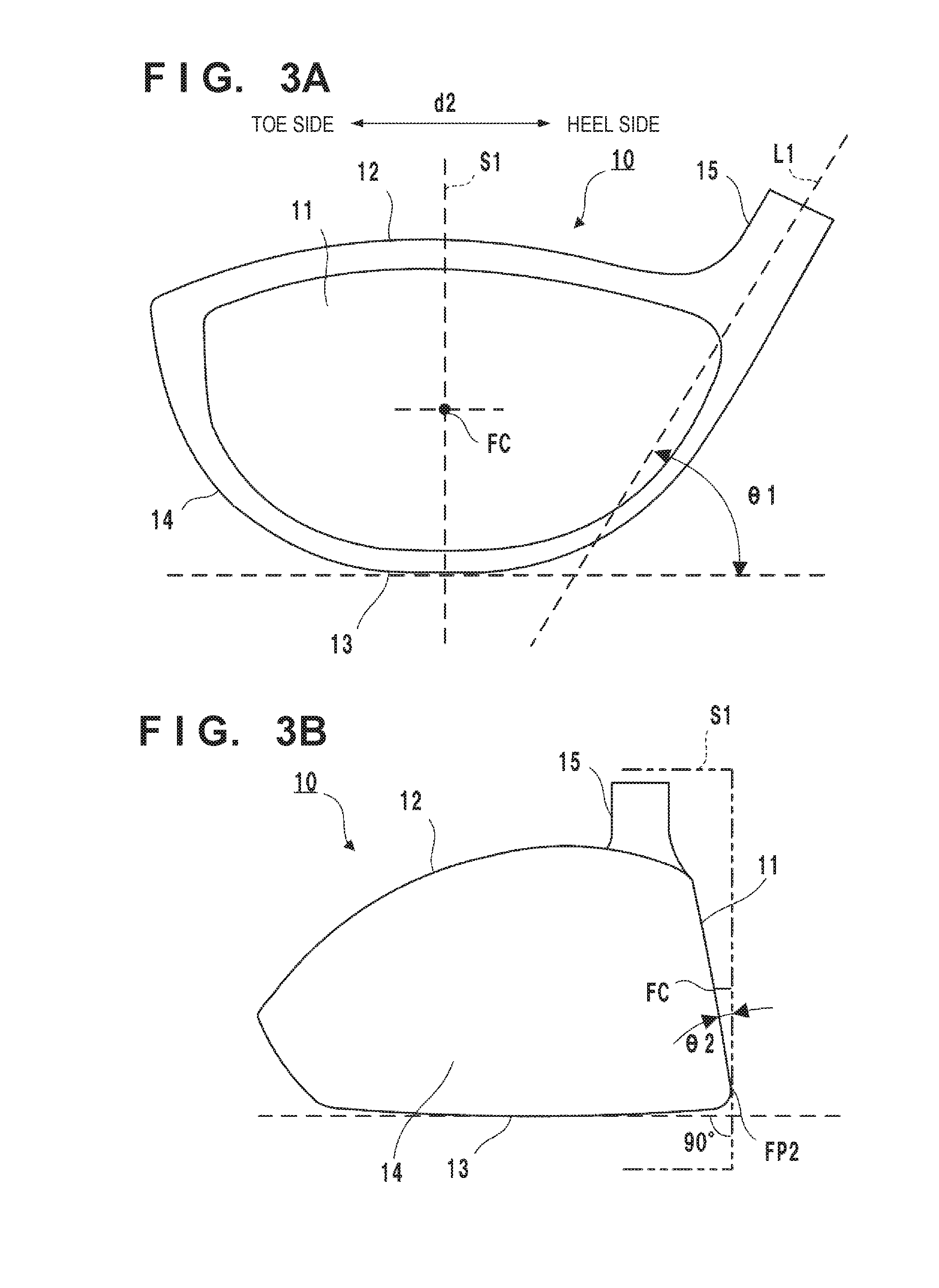

Golf club head and method for producing the same

ActiveUS20090305812A1Stable flight distanceLarge surface roughnessDomestic articlesGolf clubsBiomedical engineeringForeign matter

Owner:SUMITOMO RUBBER IND LTD

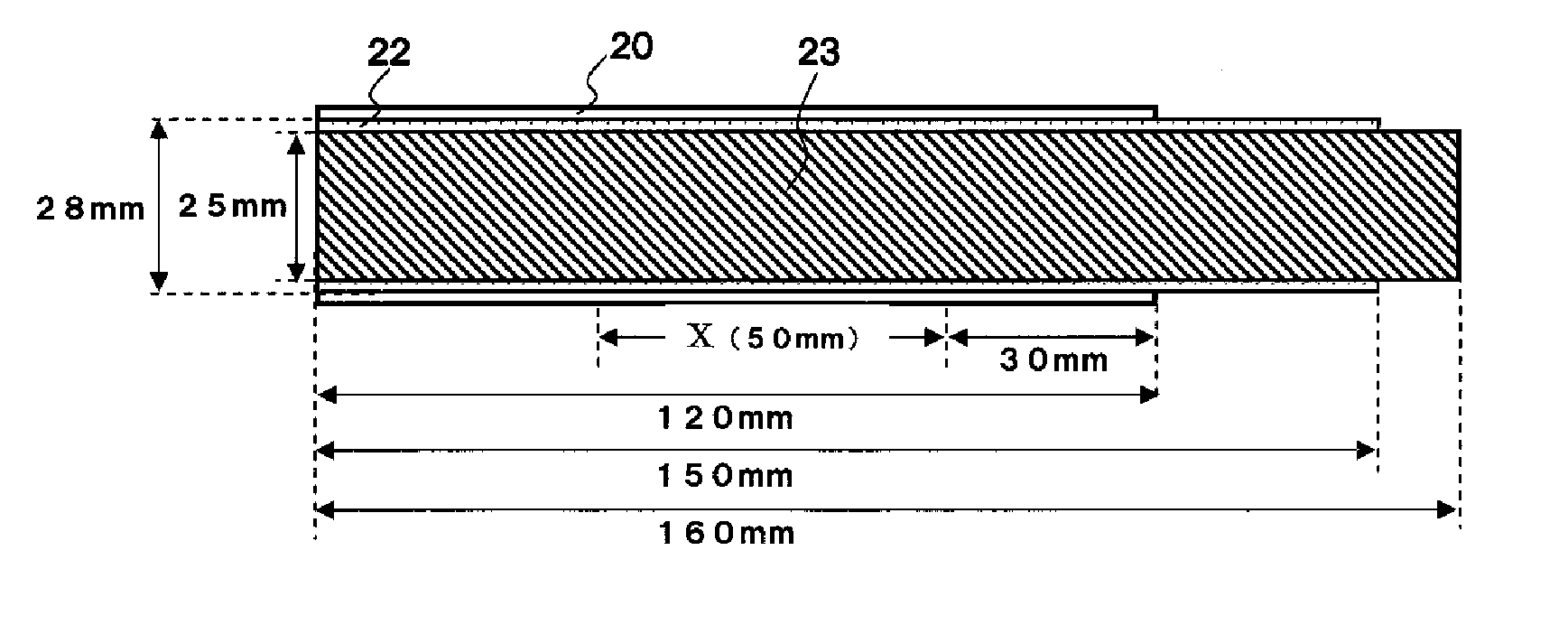

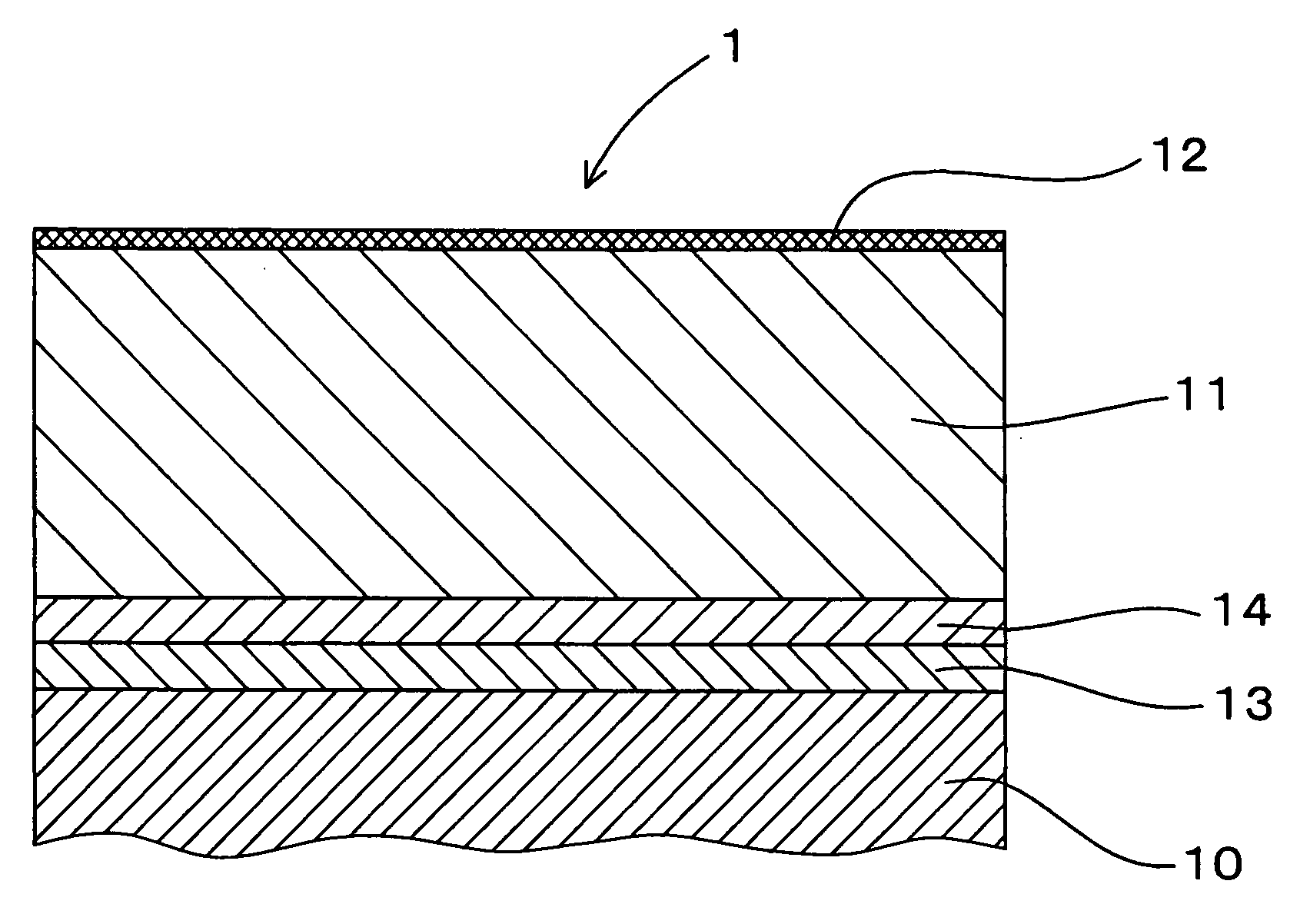

Nonaqueous electrolyte secondary battery and method for manufacturing the same

InactiveUS20110206962A1Increase productivityLarge surface roughnessElectrode manufacturing processesCell seperators/membranes/diaphragms/spacersSurface roughnessComposite oxide

An aspect of the invention provides a nonaqueous electrolyte secondary battery including a flattened electrode assembly in which a positive electrode plate containing lithium transition metal composite oxide as positive electrode active material, and a negative electrode plate containing carbon material able to insert and extract lithium ions as negative electrode active material, are stacked and wound with a separator interposed therebetween, and a protective layer constituted of inorganic oxide and an insulative binding agent provided on a surface of the negative electrode plate. The arithmetic mean surface roughness Ra of a face of the separator that contacts with the protective layer is 0.40 to 3.50 μm. With the invention, a nonaqueous electrolyte secondary battery is obtained that has enhanced formability of the flattened electrode assembly and superior output characteristics and other battery characteristics.

Owner:SANYO ELECTRIC CO LTD

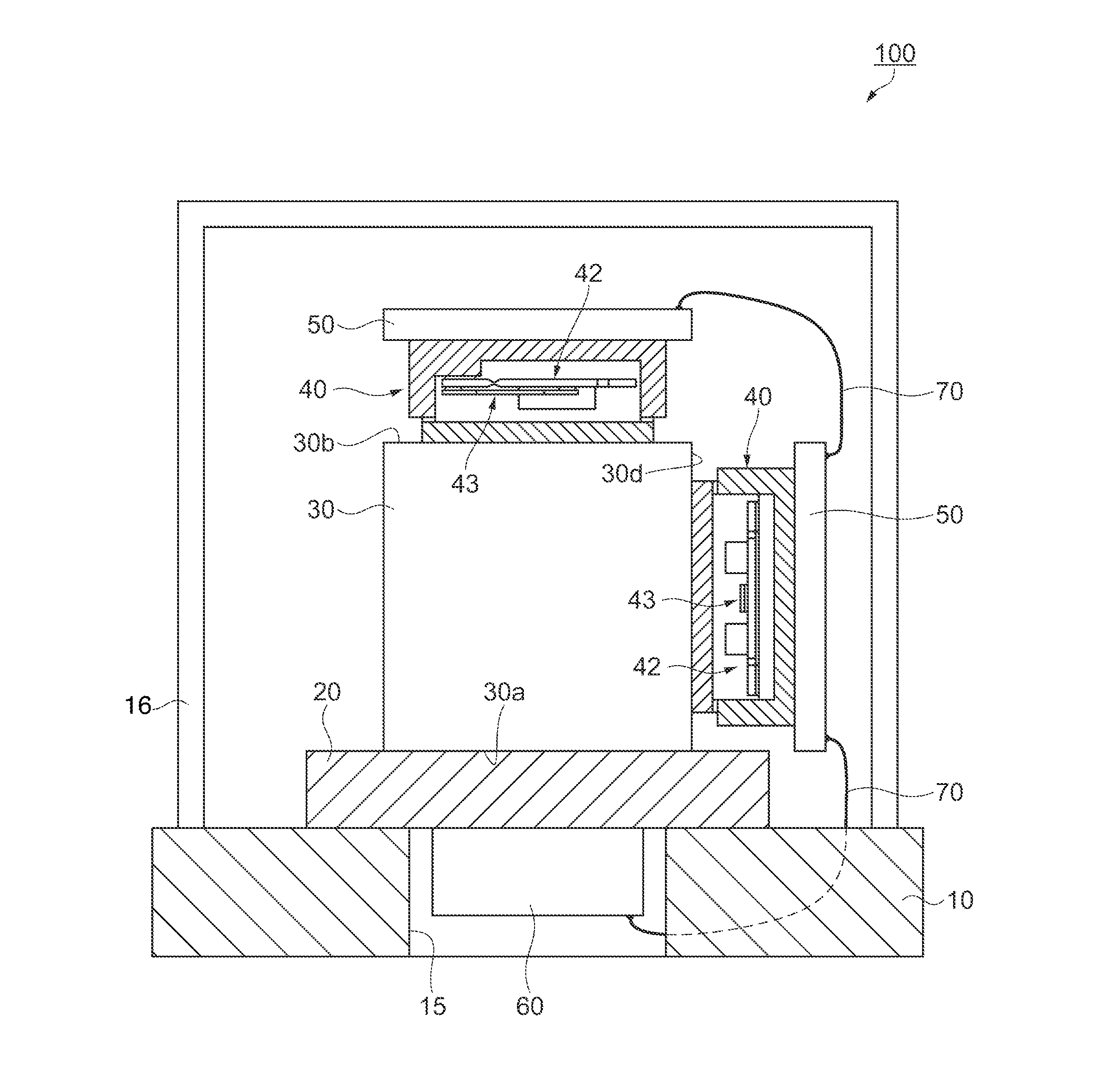

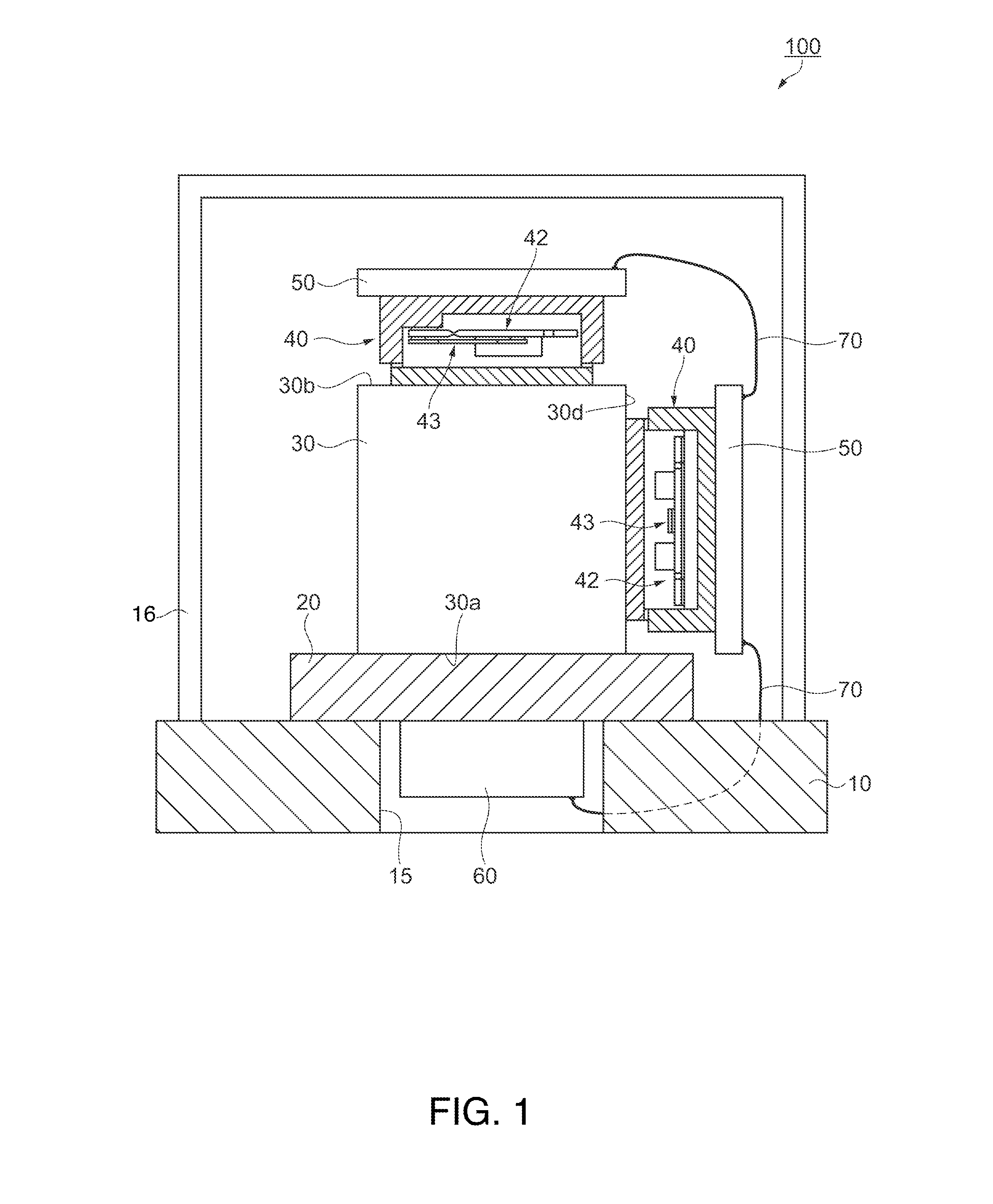

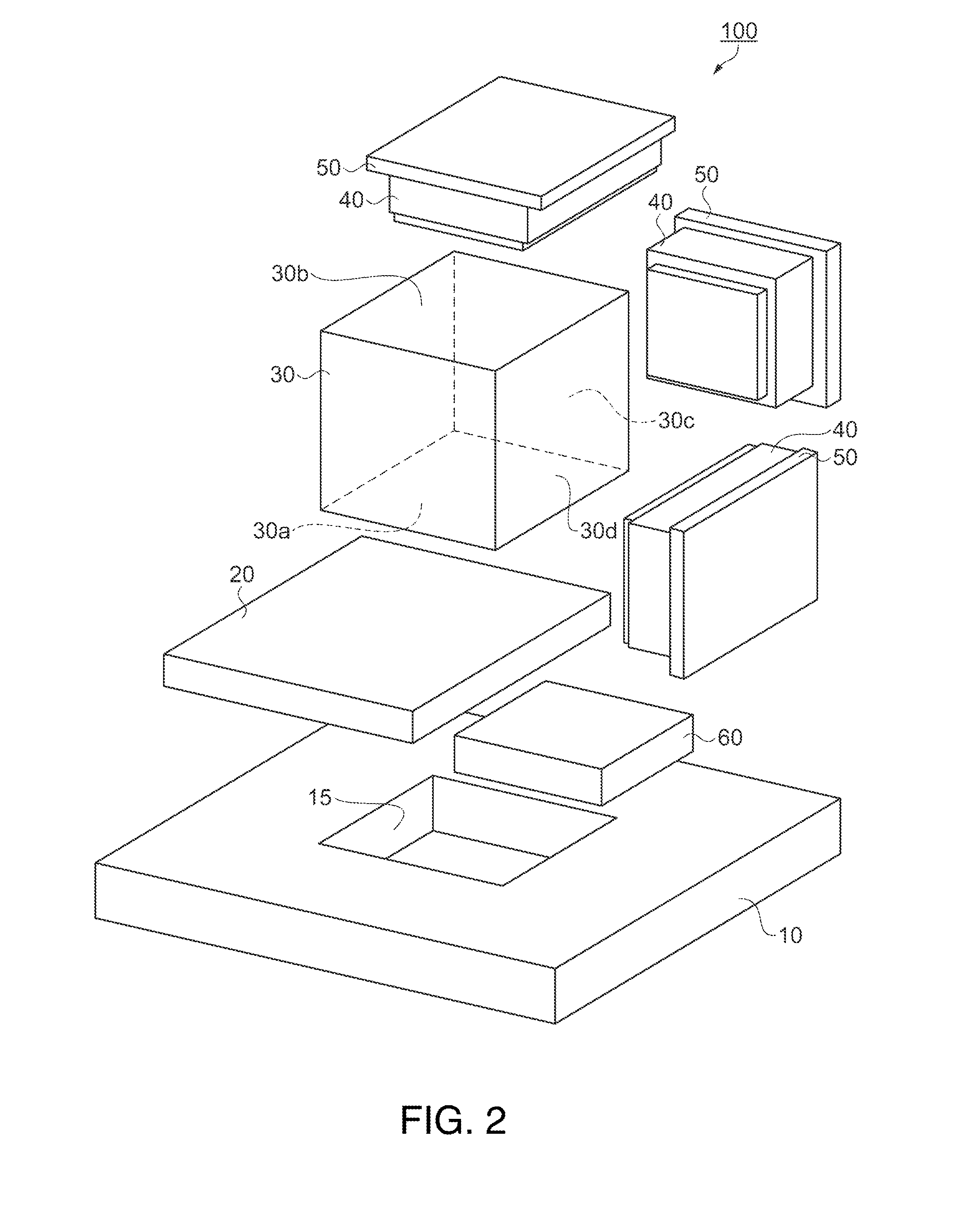

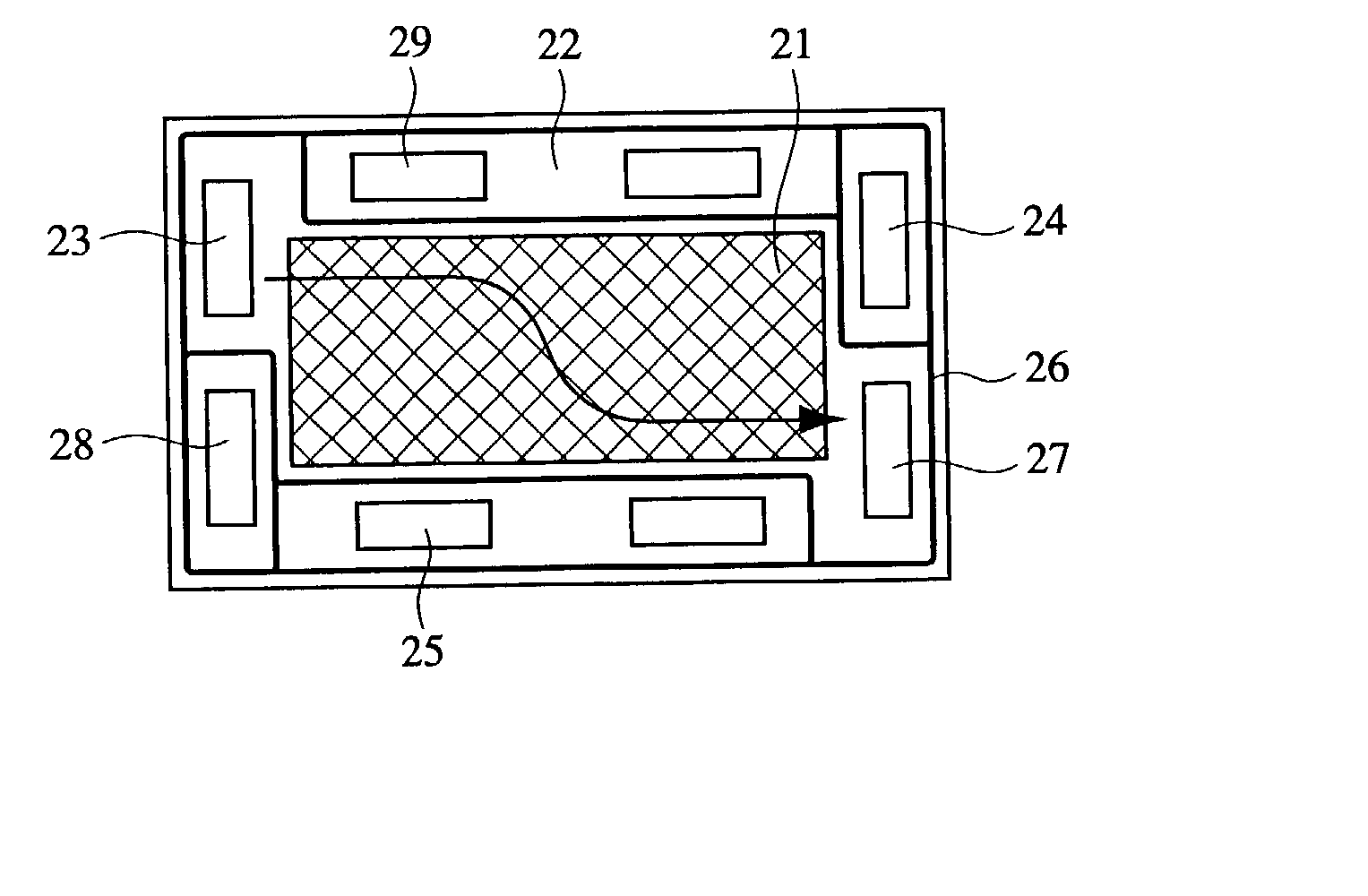

Physical quantity detecting device, electronic apparatus, and moving object

InactiveUS20140123754A1Excellent detection accuracyPerform safe and stable movementAcceleration measurement using interia forcesSpeed/acceleration/shock instrument detailsThermal transmittanceThermal conductivity

A physical quantity detecting device includes a metal block (a holding section) having six surfaces, inclination detectors (physical quantity detectors) respectively arranged on selected three surfaces among the six surfaces, an electronic component electrically connected to the inclination detectors, and a heat insulating material (a heat-conduction reducing section) present between the metal block and the electronic component and having thermal conductivity smaller than the thermal conductivity of the metal block.

Owner:SEIKO EPSON CORP

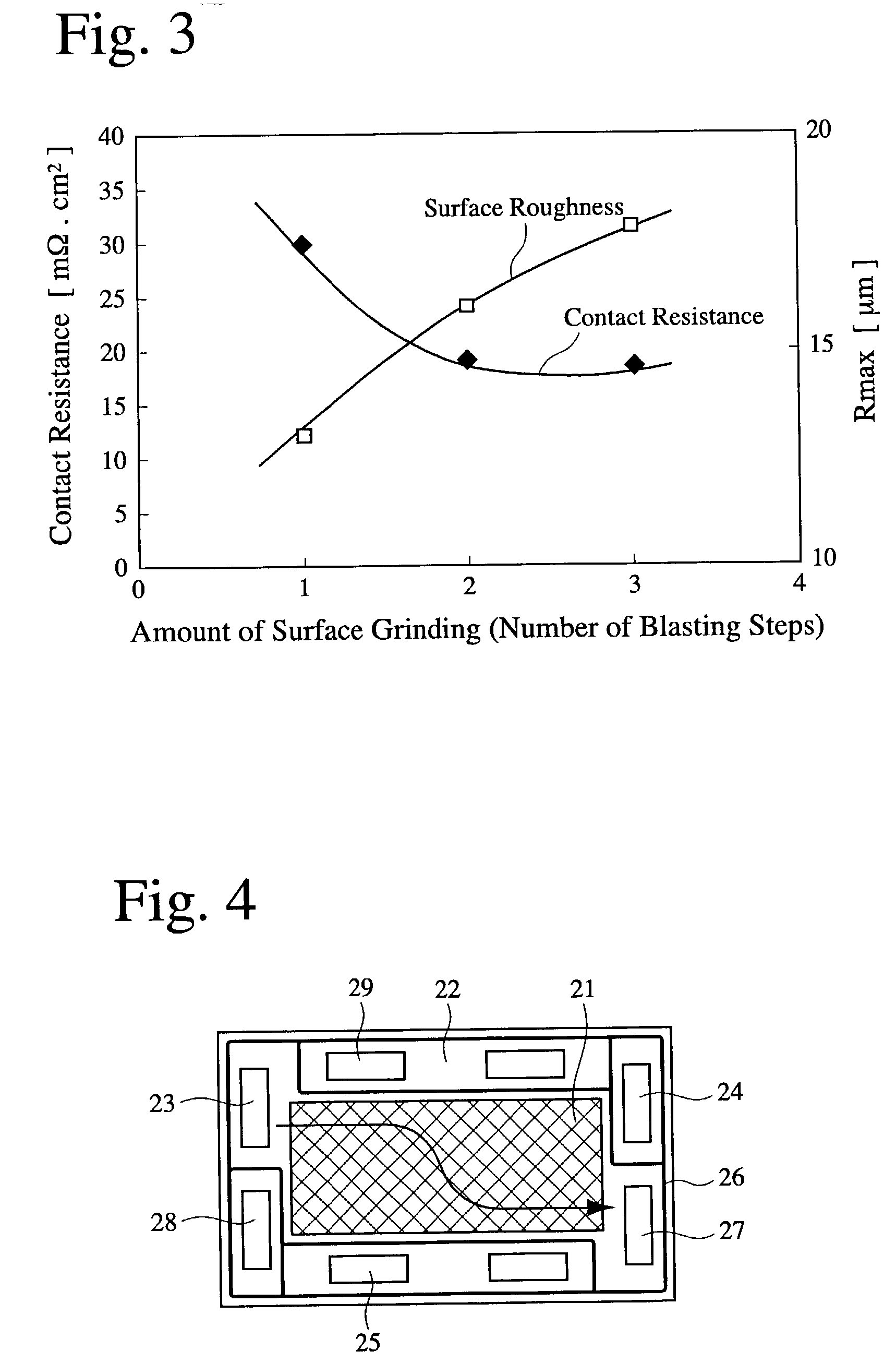

Fuel cell separator plate and method for producting it

ActiveUS20030087143A1Reduce contact resistanceImprove air tightnessFuel cells groupingFinal product manufactureFuel cellsSurface roughness

A fuel cell separator plate comprising a portion in contact with an electrode, and a sealing portion provided around the contact portion, the contact portion having a larger surface roughness (Rmax) than that of the sealing portion. It is preferably a molded separator plate made of a composite carbon material comprising carbon and a thermosetting resin.

Owner:HONDA MOTOR CO LTD

Door for washing machine

InactiveUS8151603B2Improve productivityLarge surface roughnessDoors/windowsWing accessoriesEngineeringFront cover

A door for a washing machine is disclosed. A door for a washing machine includes an inner frame having an opening with a predetermined size, an outer frame provided at a front surface of the inner frame, having an opening in communication with the opening of the inner frame, a glass member fitted between the inner and outer frames, covering the openings of the inner and outer frames, a decorative member provided at a front surface of the outer frame, having an opening in communication with the openings, and a front cover fitted between the decorative member and the outer frame, covering the openings of the inner and outer frames and the decorative member, the front cover having a positioning portion determining a position of the front cover coupled to the outer frame.

Owner:LG ELECTRONICS INC

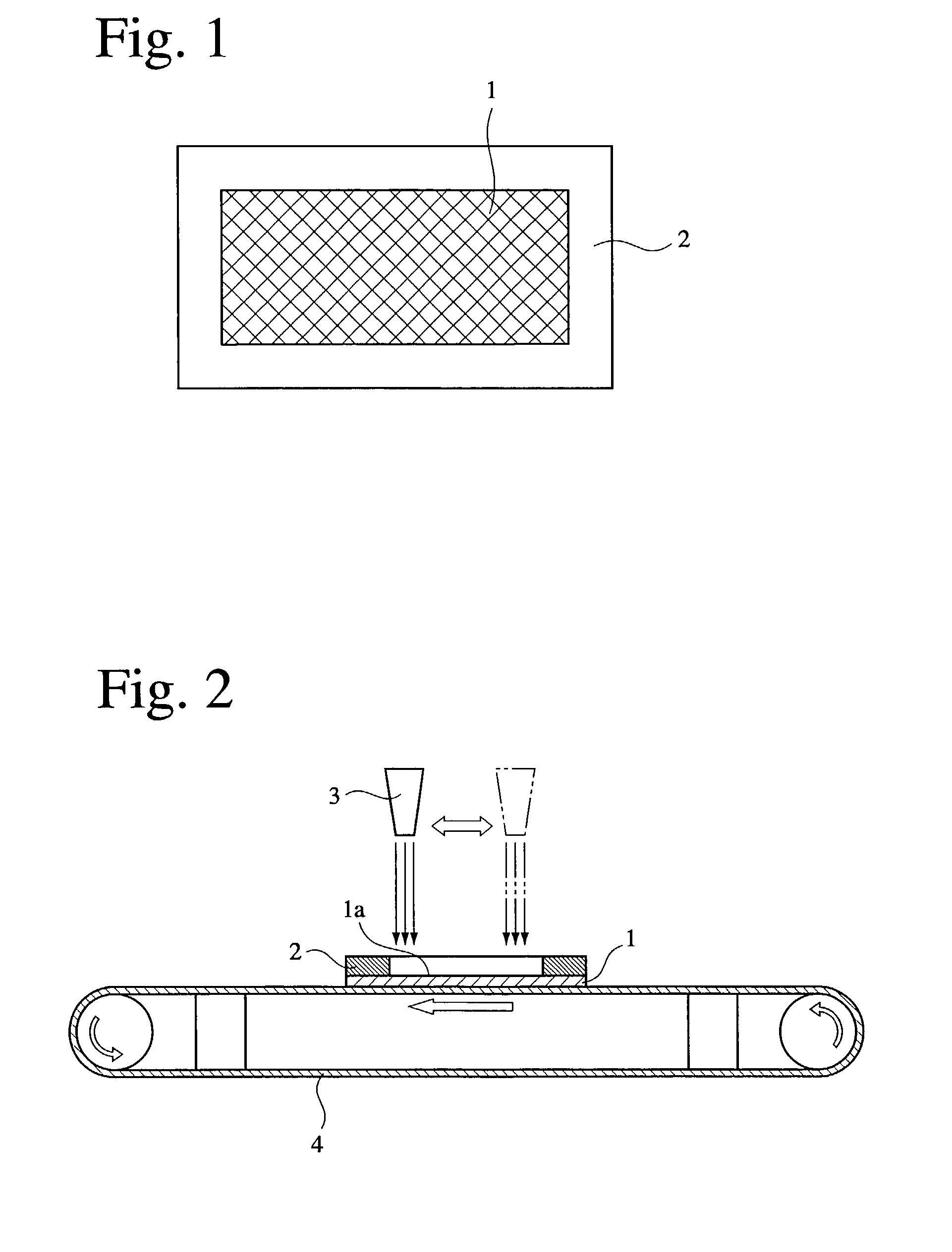

Magnetic recording medium, magnetic recording and reproducing apparatus, and method for manufacturing magnetic recording medium

InactiveUS20060292400A1Increase areal densityImprove reliabilityRecord information storageSpecial surfacesFilling materialsElectrical and Electronics engineering

A magnetic recording medium that includes a recording layer formed in a predetermined concavo-convex pattern in which recording elements are formed as convex portions, has high areal density, cannot cause crash of a magnetic head easily, and has high reliability, and a magnetic recording and reproducing apparatus including that magnetic recording medium are provided. The magnetic recording medium includes: the recording elements formed as the convex portions of the recording layer formed in a predetermined concavo-convex pattern over a substrate; and a filling material with which a concave portion between the recording elements is filled. The surface roughness of a portion of a surface of the medium above the filling material is larger than that of portions of the surface above the recording elements.

Owner:TDK CORPARATION

Laminated electronic component

ActiveUS20110122540A1Increased durabilityDeterioration of characteristicFixed capacitor electrodesFixed capacitor dielectricElectrical conductorEngineering

A laminated electronic component includes a component body including a plurality of laminated functional layers, a plurality of internal conductors provided inside the component body, and an external terminal electrode that is electrically connected to an internal conductor via an exposed portion of the internal conductor and that is defined by a direct plating film. An average grain diameter of metal grains defining the plating film is about 0.1 μm or less.

Owner:MURATA MFG CO LTD

Glass substrate and method of manufacturing the same

ActiveUS7320827B2Large surface roughnessLight trappingGlass rolling apparatusGlass/slag layered productsMetal chlorideThermal decomposition method

The present invention provides a glass substrate including a glass sheet, a thin film containing silica as its main component, and a group of metal oxide particles separated from one another, the metal oxide particles and the thin film being stacked on the glass sheet in that order from the glass sheet side, wherein the average height of the metal oxide particles is 10 to 100 nm. The present invention also provides a method of manufacturing the glass substrate, the method including forming a group of metal oxide particles by a thermal decomposition method including an inorganic metal chloride as a raw material.

Owner:NIPPON SHEET GLASS CO LTD

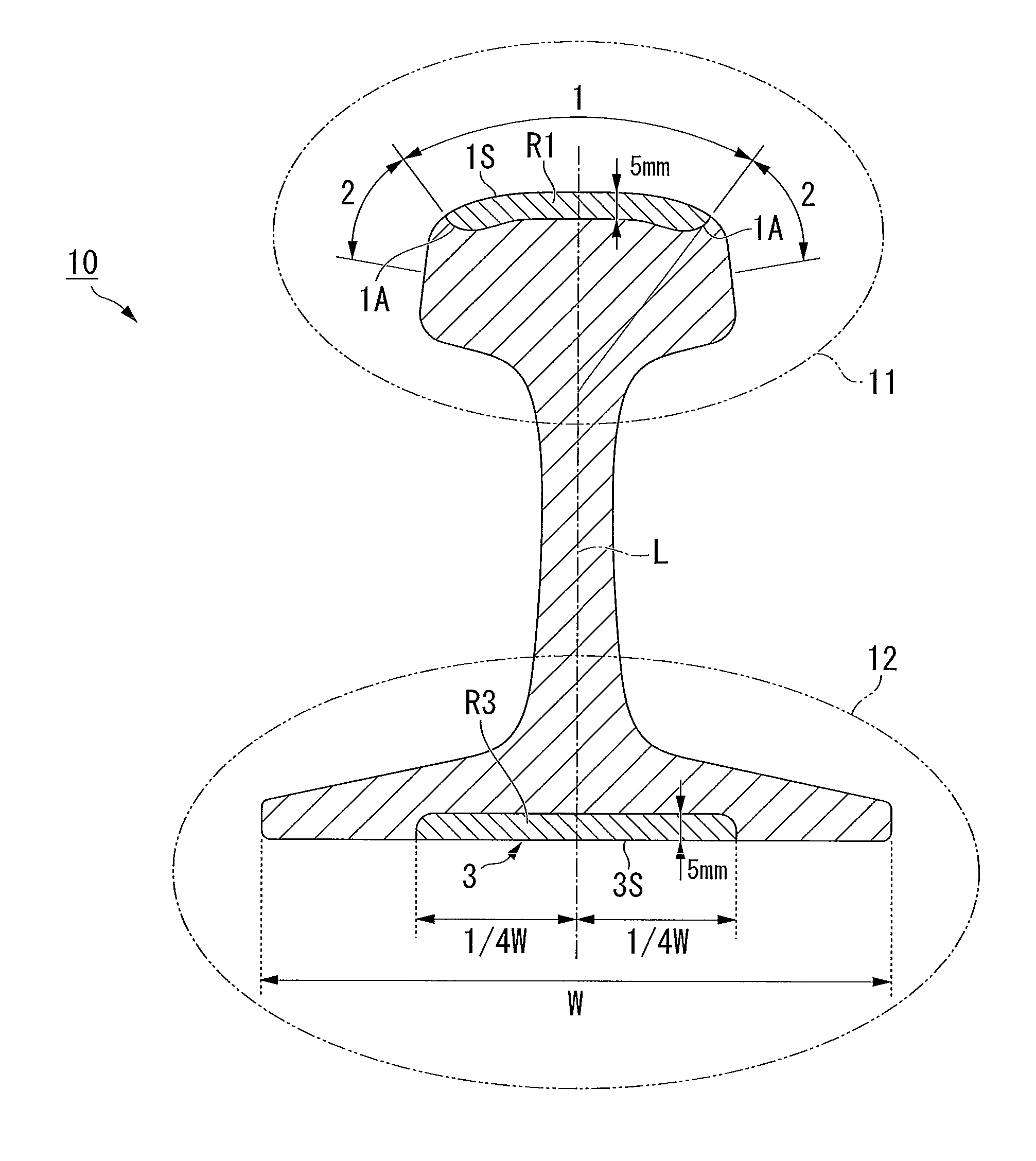

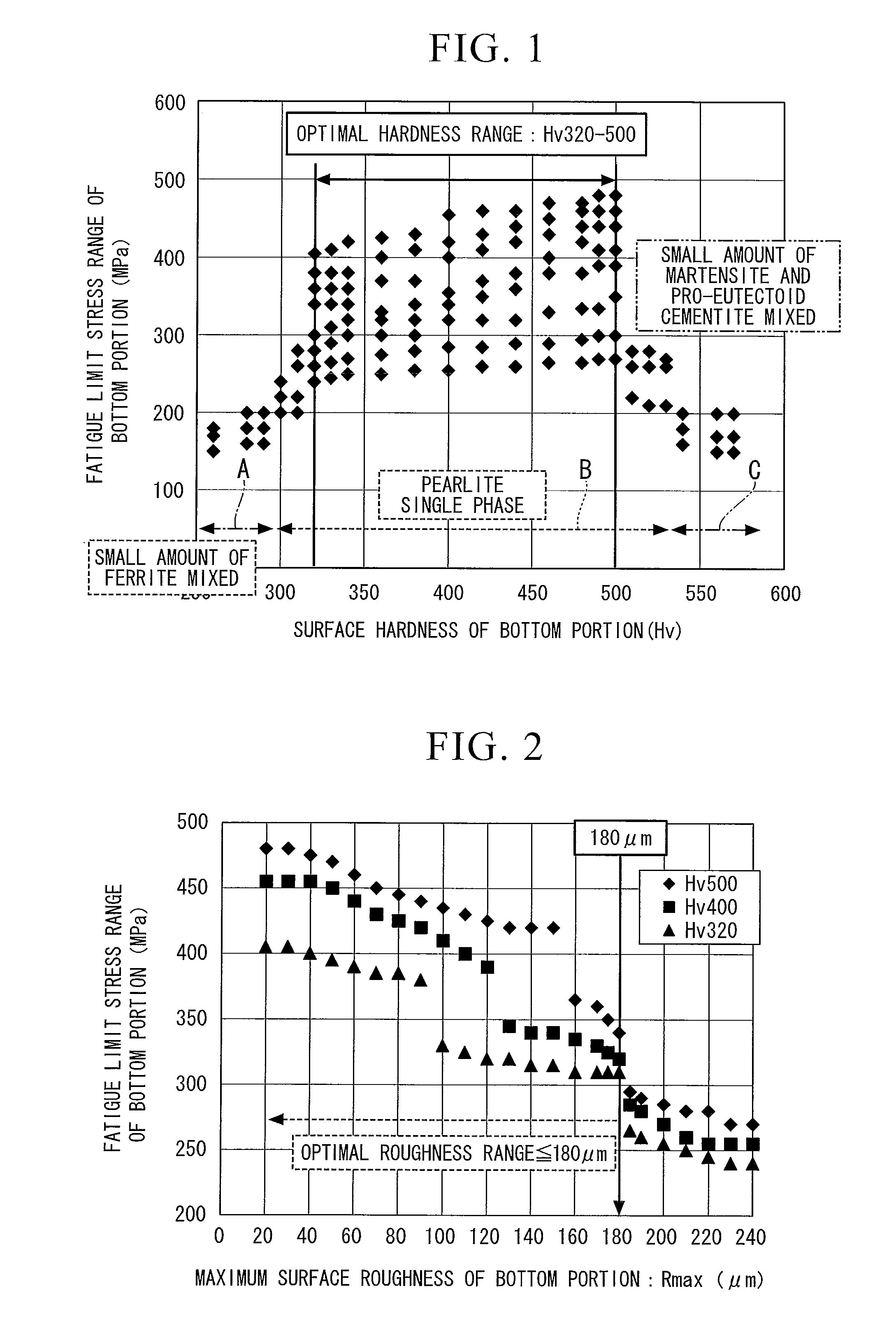

Pearlite rail

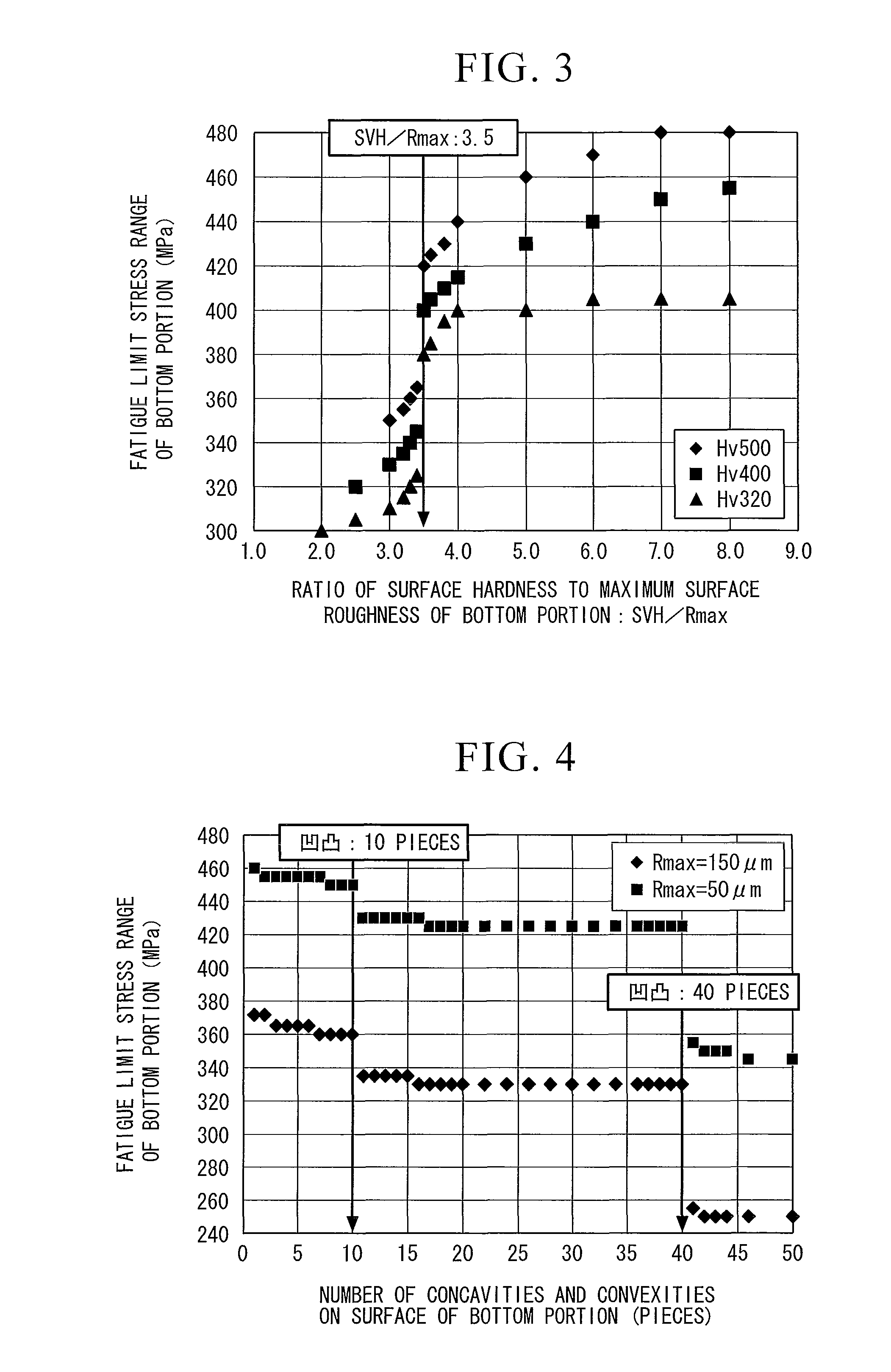

ActiveUS20110226389A1Maintain hardness (strength)Improve resistance to fatigue damageFurnace typesHeat treatment furnacesMetallurgySurface roughness

A pearlite rail contains, by mass %, 0.65 to 1.20% of C; 0.05 to 2.00% of Si; 0.05 to 2.00% of Mn; and the balance composed of Fe and inevitable impurities, wherein at least part of the head portion and at least part of the bottom portion has a pearlite structure, and the surface hardness of a portion of the pearlite structure is in a range of Hv320 to Hv500 and a maximum surface roughness of a portion of the pearlite structure is less than or equal to 180 μm.

Owner:NIPPON STEEL CORP

Multilayer substrate cleaning method, substrate bonding method, and bonded wafer manufacturing method

ActiveUS20070023066A1Avoid generatingPrevent surface rougheningElectrostatic cleaningSemiconductor/solid-state device manufacturingChemistrySingle crystal

The present invention is a method for cleaning a multilayer substrate, comprising steps of forming a protective film on a surface of the SiGe layer of an outermost surface layer in the multilayer substrate and then cleaning the protective film with a cleaning liquid capable of etching the protective film so that the protective film remains, a method for bonding substrates, wherein an outermost surface layer of the multilayer substrate cleaned by the cleaning method and a surface of another substrate are bonded, and a method for producing a bonded wafer, comprising steps of, forming a Si1-XGex layer and a protective layer on a surface of a Si single crystal bond wafer in order, performing ion implantation through the protective layer thereby to form an ion implanted layer, cleaning the bond wafer, superposing closely a surface of the protective layer and a base wafer, then performing delamination at the ion implanted layer, forming a thermal oxide film on a surface of the delaminated layer transferred to the base wafer side by the delamination, removing the thermal oxide film to expose a condensation SiGe layer, and performing epitaxial growth of a Si single crystal layer on the surface. Thereby, there is provided a cleaning method and a bonding method for preventing a SiGe layer of an outermost surface layer in a multilayer substrate from being roughening of the surface, and a method for producing a bonded wafer for preventing bonding defects along with ion implantation.

Owner:SHIN-ETSU HANDOTAI CO LTD

Manufacturing method, golf club head, and design method

InactiveUS20160354652A1Large surface roughnessSmall surface roughnessGolf clubsSurface roughnessEngineering

The present invention relates to a method of manufacturing a wood type golf club head including a face portion, a crown portion, and a sole portion. The method includes a setting step of setting a surface roughness of the face portion and a step of forming the face portion based on the surface roughness set in the setting step. In the setting step, the larger a moment of inertia of the golf club head is, the larger the surface roughness outside an impact area of the face portion is set, and the smaller the moment of inertia is, the smaller the surface roughness outside the impact area of the face portion is set.

Owner:BRIDGESTONE SPORTS

Coating structure and method for forming the same

InactiveUS20070264491A1Sufficient water-shedding propertyLarge surface roughnessWear reducing fuel injectionSynthetic resin layered productsFluorine containingMetal

A coating structure for a metal member includes a surface-smoothing layer formed on the metal member for smoothing a surface of the metal member, and a fluorine-based film formed on the surface-smoothing layer. The fluorine-based film can be formed by applying a fluorine-containing solution on the surface-smoothing layer, and by drying the fluorine-containing solution. The coating structure can be suitably used for a fuel injection nozzle.

Owner:DENSO CORP

Image forming method

InactiveUS20050053855A1High image definitionStably obtainElectrographic process apparatusSilver halide emulsionsChemistrySurface layer

Owner:FUJIFILM BUSINESS INNOVATION CORP

Magnetic recording medium and magnetic recording/reproducing apparatus

InactiveUS20070003799A1Suppress attractionSame surface roughnessMagnetic materials for record carriersRecord information storageSurface roughnessRecording media

Owner:KK TOSHIBA

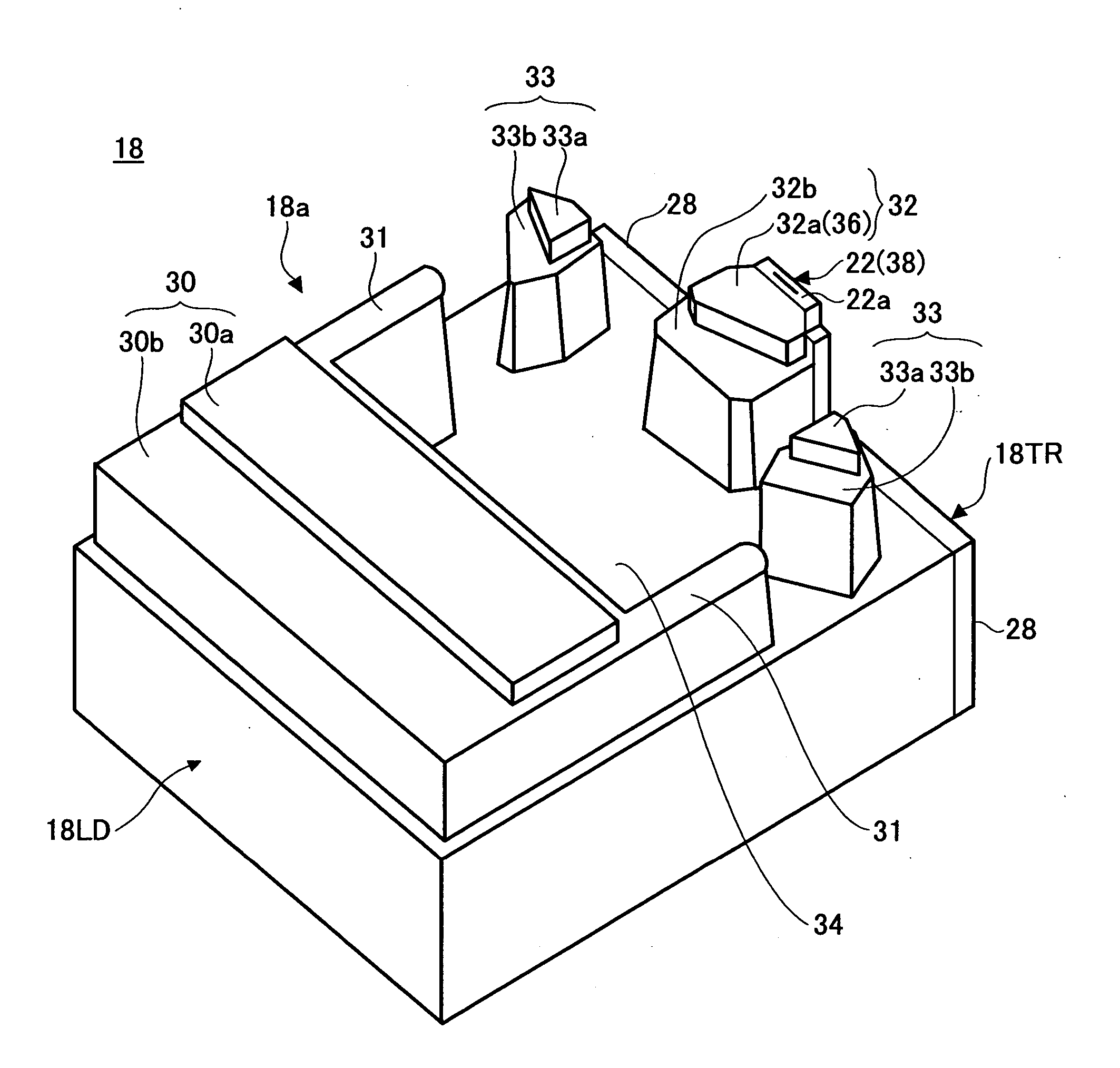

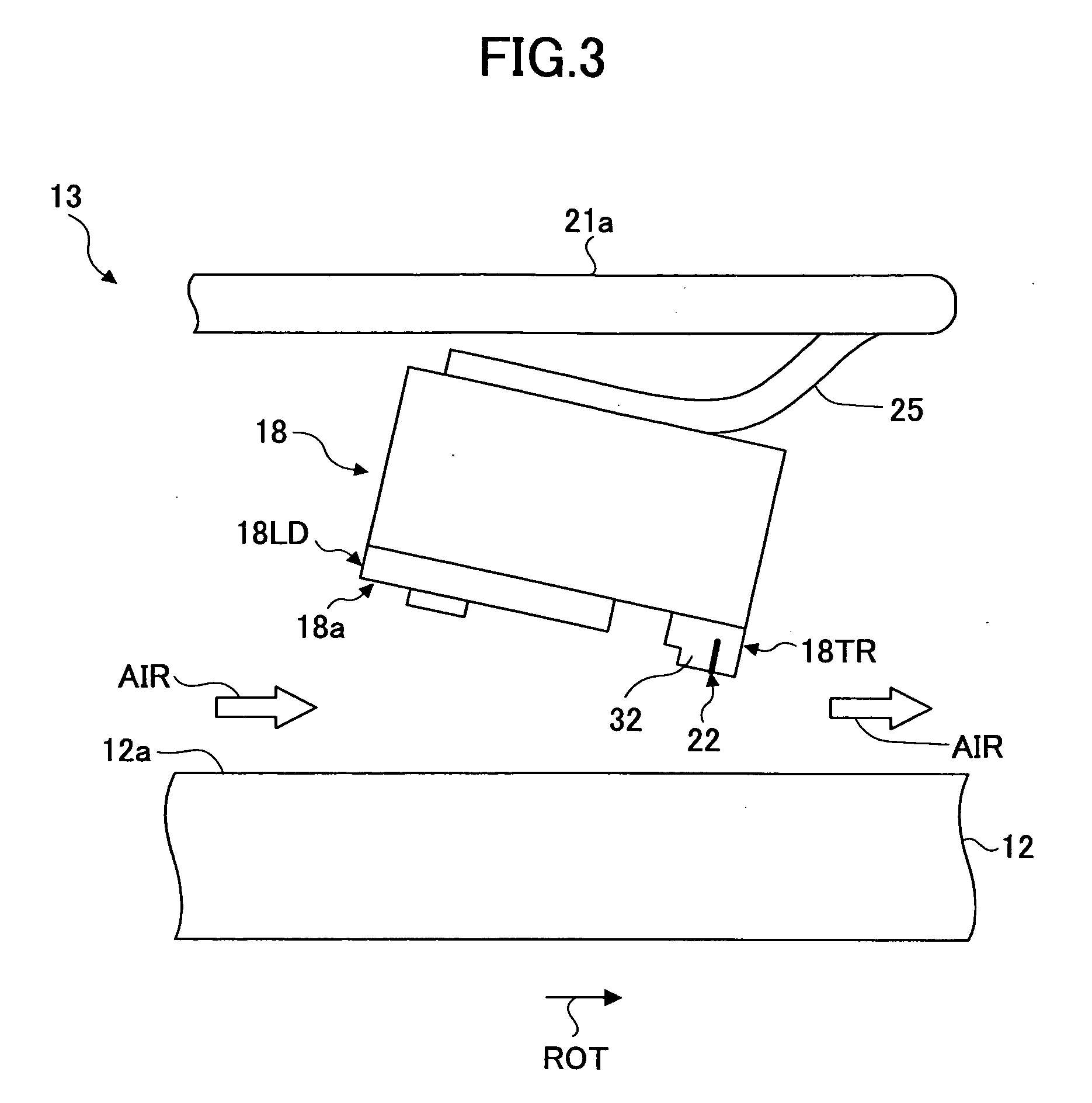

Magnetic head and manufacturing method of the same

InactiveUS20060221502A1Quality improvementImprove floating stabilityFluid-dynamic spacing of headsRecord information storageSurface roughnessWater repellent

A magnetic head includes a head slider configured to float above a recording medium and having an element part for recording to and reproducing from the recording medium, the element part being situated on a medium facing surface facing to the recording medium. The medium facing surface has a first air bearing surface situated in a vicinity of a side of an air flow-out end. The medium facing surface has a rear rail having the element part situated at the side of the air flow-out end of the first air bearing surface. The first air bearing surface is covered with a lubricating layer made of water repellent resin and has an average surface roughness larger than an average surface roughness of a surface of the element part.

Owner:FUJITSU LTD

Method of electroplating copper over a patterned dielectric layer to enhance process uniformity of a subsequent CMP process

InactiveUS6958247B2Improve uniformityLarge surface roughnessSemiconductor/solid-state device manufacturingCompound (substance)Electroplating

In a new method of plating metal onto dielectric layers including small diameter vias and large diameter trenches, a surface roughness is created at least on non-patterned regions of the dielectric layer to enhance the uniformity of material removal in a subsequent chemical mechanical polishing (CMP) process.

Owner:GLOBALFOUNDRIES INC

Electrophotographic Photosensitive Member, and Image Forming Apparatus Using Same

ActiveUS20070231719A1Prevent peelingAvoid problemsElectrographic process apparatusSurface roughnessEngineering

The present invention relates to an electrophotographic photosensitive member including a cylindrical body and a photosensitive layer. The cylindrical body has provided with an outer circumference, end surfaces and chamfers formed therebetween. and aThe photosensitive layer is formed on the outer circumference of the cylindrical body. The photosensitive layer covers the chamfers. The chamfers have a surface roughness larger than the outer circumference. Preferably, the end surfaces have a surface roughness larger than the outer circumference.

Owner:KYOCERA CORP

Composition for film formation, method for preparing the composition, and method for forming insulating film

InactiveUS20050112386A1Low dielectric constantImprove adhesionLiquid surface applicatorsLayered productsSilane compoundsOrganic film

A composition for film formation having low dielectric constant, excellent adhesion to a silica film and excellent adhesion to an organic film, a method for preparing the composition, and a method for forming a silica film using the composition are disclosed. The composition for film formation comprises (A) a product of hydrolysis and condensation obtained by hydrolyzing and condensing at least one specific silane compound, and (B) an oxygen-containing organic solvent, wherein the content of the product of hydrolysis and condensation (A) is less than 5% by weight based on the weight of the composition. The composition can form a silica film having improved dielectric constant characteristics and storage stability, and also improved adhesion to other silica films and organic films.

Owner:JSR CORPORATIOON

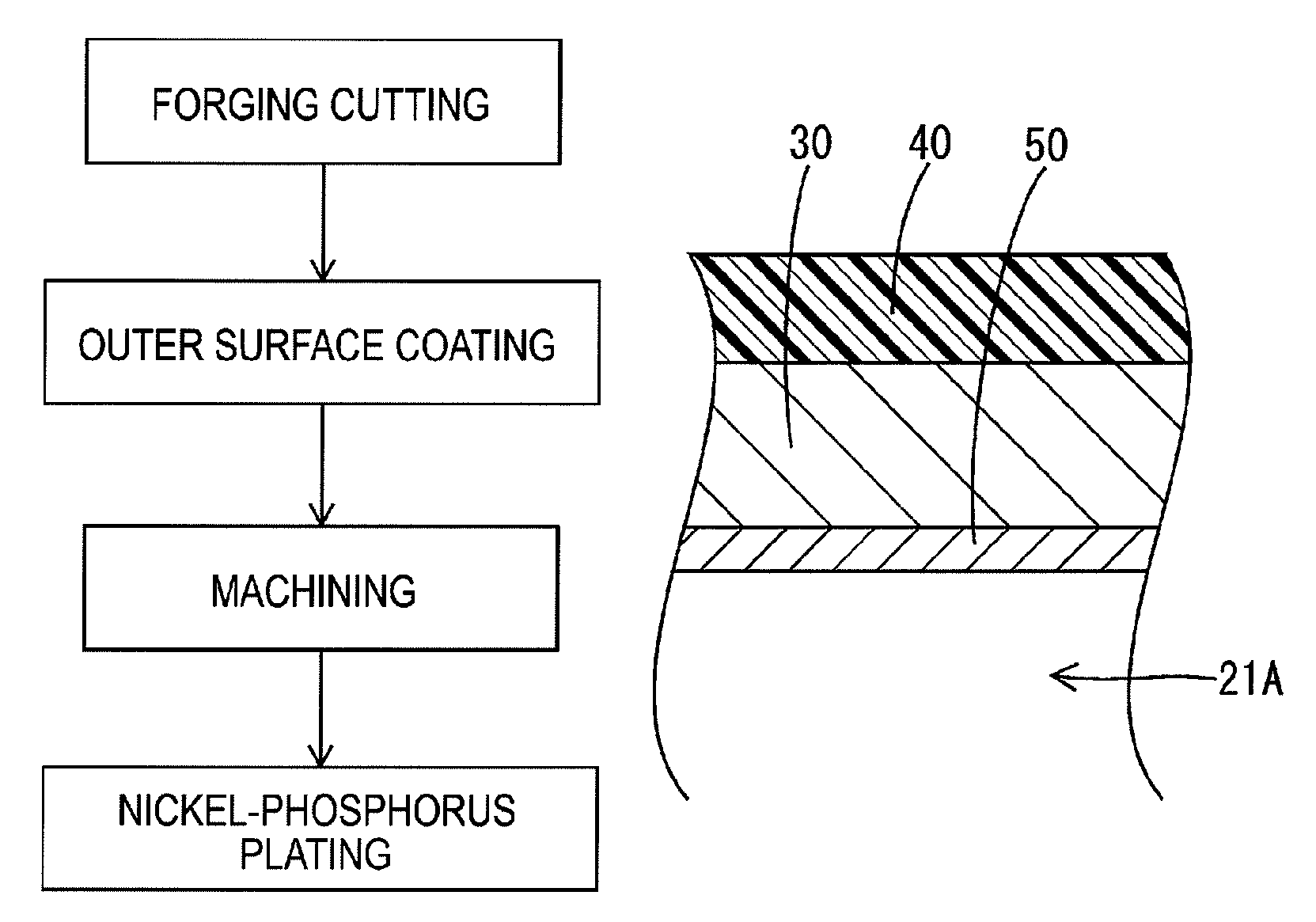

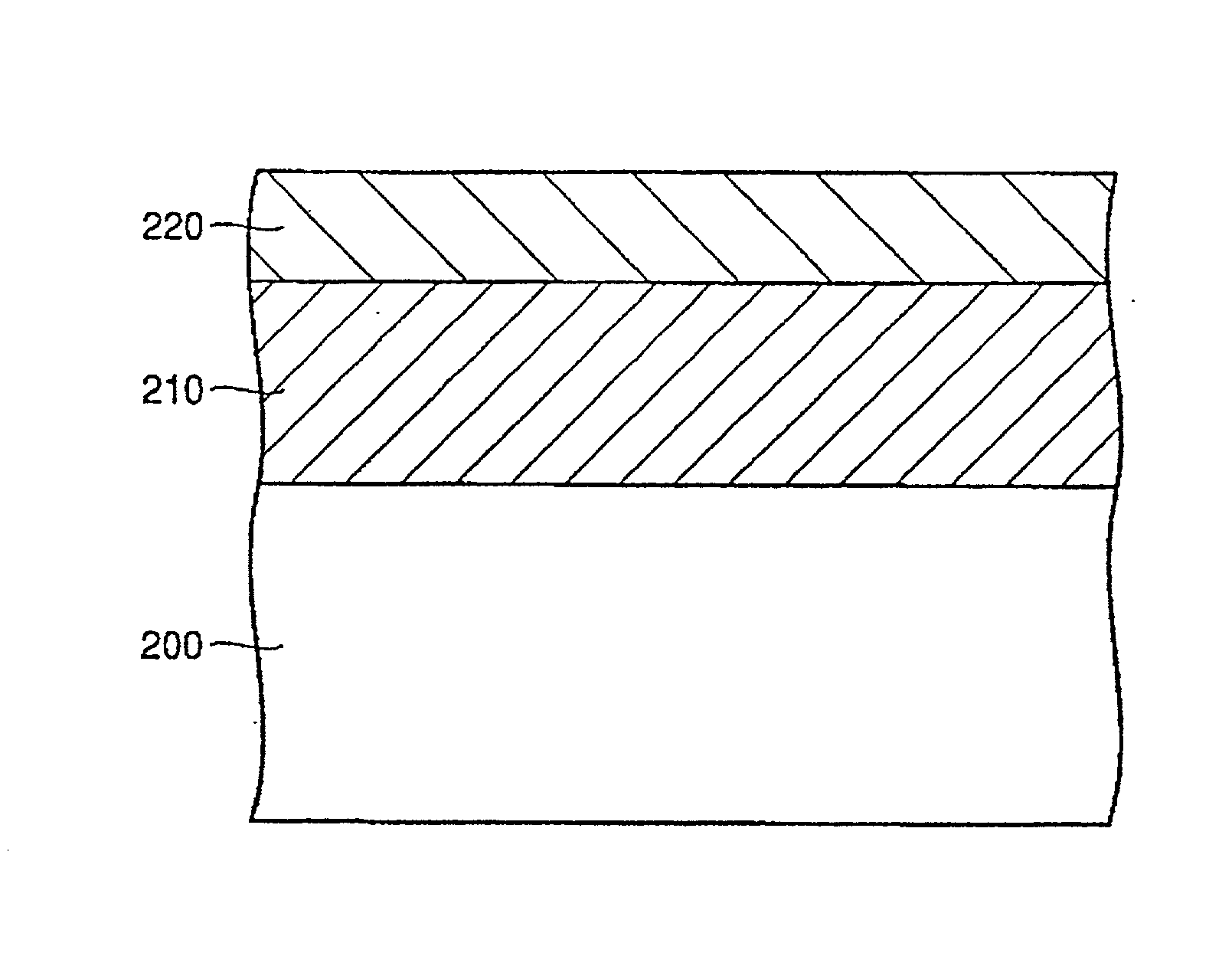

Method of manufacturing fuel system part and fuel system part

ActiveUS9371587B2Lower costLow quantityLow pressure fuel injectionCorrosion preventionElectroless platingNickel

A method manufactures a fuel delivery pipe including a crude metal made of forged iron, a nickel-phosphorus plating layer formed on an inner surface of the crude metal, and a nonmetal paint film formed on an outer surface of the crude metal. The method includes coating the outer surface of the crude metal with paint to form the paint film, machining the crude metal with the paint film formed thereon to form a machined surface inside the crude metal, and electroless plating the machined crude metal in nickel-phosphorus plating solution to form the nickel-phosphorus plating layer on the machined surface.

Owner:OTICS CORP

Window material for ultraviolet-ray-emitting element and method for producing same

InactiveUS20160096776A1Improve surface roughnessLarge surface roughnessOptical articlesRecord information storageUltraviolet lightsLength wave

A window material for an ultraviolet light emitting device for emitting an ultraviolet light having a wavelength of 300 nm or less is mounted on at least an ultraviolet light emitting side of the ultraviolet light emitting device. The window material for an ultraviolet light emitting device contains a translucent alumina substrate, and a surface of the window material has an average grain diameter of 6 to 60 μm.

Owner:NGK INSULATORS LTD

Infrared laser optical element and manufacturing method therefor

InactiveUS20020080843A1Increased durabilityImprove moisture resistanceMirrorsOptical filtersIon beamOptoelectronics

Owner:SUMITOMO ELECTRIC IND LTD

Gas-insulated electrical installation provided with a device for dissipating energy produced by an electric arc

ActiveUS20050174721A1Improve efficiencyPrevent spontaneous combustionSwitchgear arrangementsEmergency protective arrangement detailsSolid particleCheck valve

An electrical equipment containment is arranged on a cooling enclosure opening out onto the outside. An outlet orifice makes the containment communicate with the cooling enclosure. This orifice is closed by a membrane or a check valve. A grate separates the cooling enclosure into an upper volume and a lower volume. The grate supports a layer of solid granular material the upper surface whereof remains free. This material is preferably porous and also comprises dusts. In the event of an internal electric arc, the shock wave escaping from the containment is dampened by the surface deformation of the layer of solid material. The incandescent particles projected via the opening are stopped by the layer of solid material. The hot gases are cooled as they flow through the material, causing a cloud of dust contributing to preventing any post-combustion.

Owner:SCHNEIDER ELECTRIC IND SAS

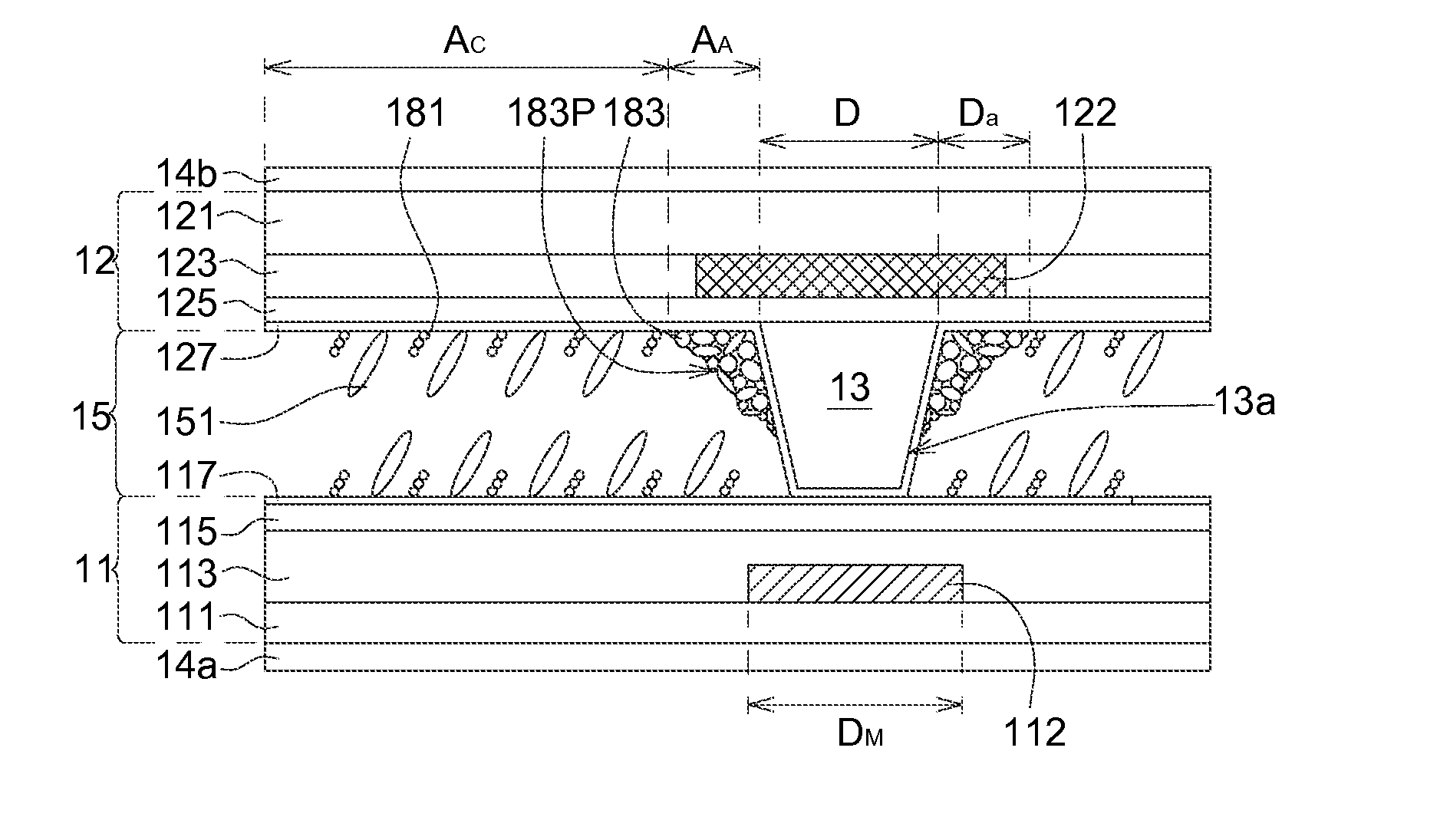

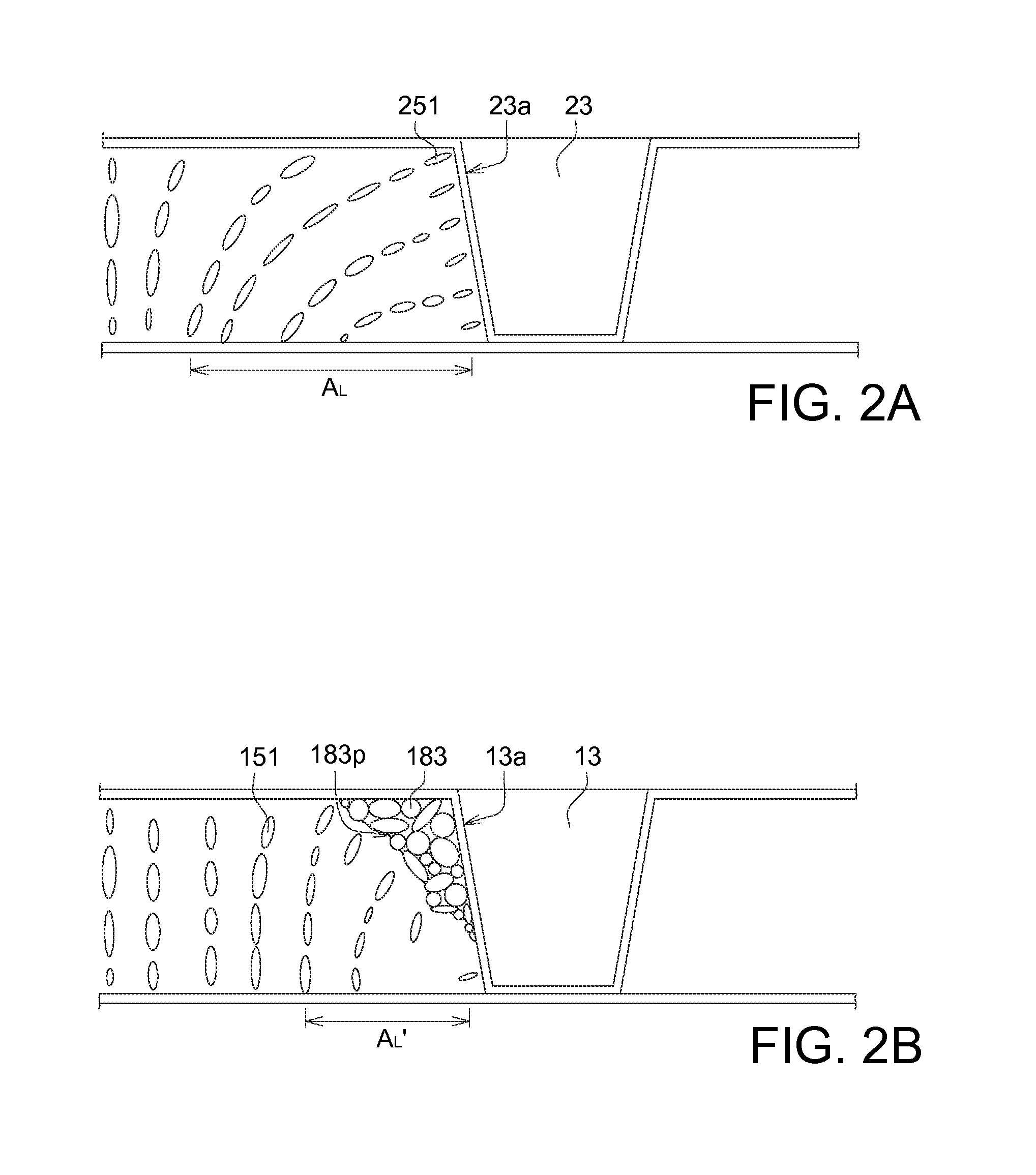

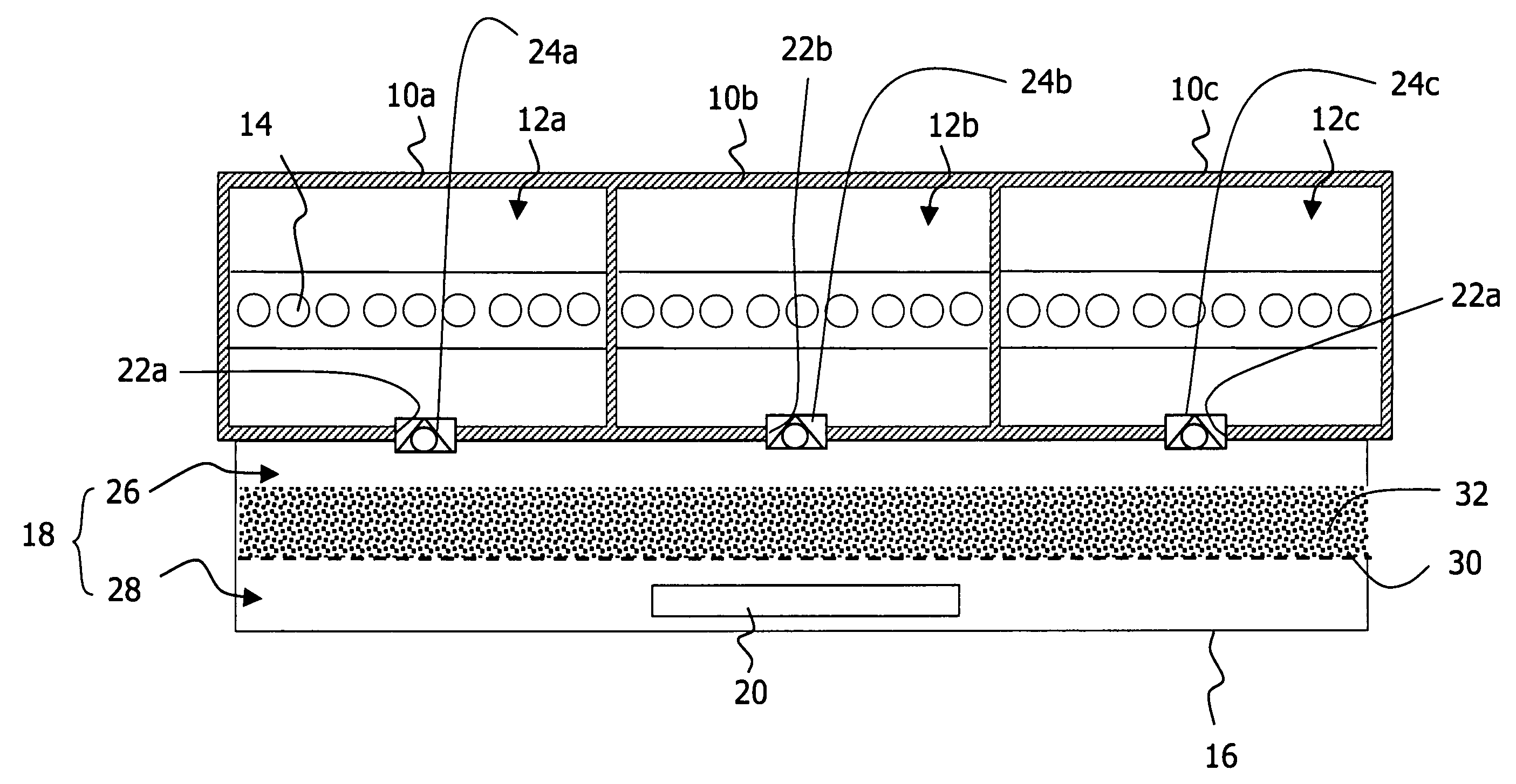

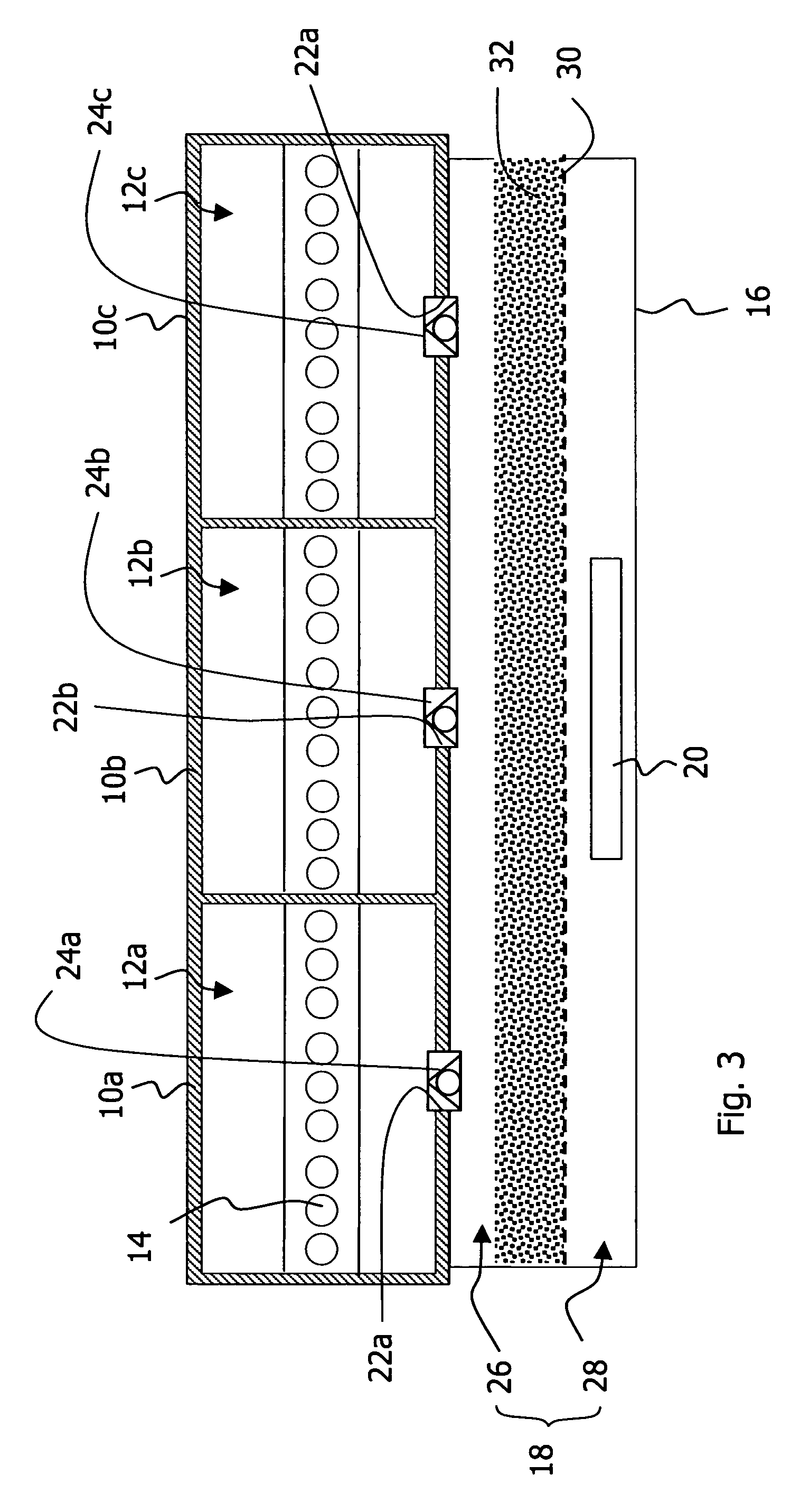

Display panel with agglomerates

A display panel comprises a first substrate having a first alignment film, a second substrate having a second alignment film and plural spacers, a liquid crystal layer disposed between the first and second substrates, and a plurality of agglomerates positioned between the first and second alignment films and further surrounding at least one of the spacers. The spaces maintain a uniform gap between the first and second substrates. The second alignment film is disposed oppositely to the first alignment film and covers the spacers. In one embodiment, sizes of the agglomerates are distributed in a range of 0.1 μm˜2 μm.

Owner:INNOLUX CORP

Gas-insulated electrical installation provided with a device for dissipating energy produced by an electric arc

ActiveUS7352551B2Improve efficiencyPrevent spontaneous combustionSwitchgear arrangementsEmergency protective arrangement detailsShock waveSolid particle

Owner:SCHNEIDER ELECTRIC IND SAS

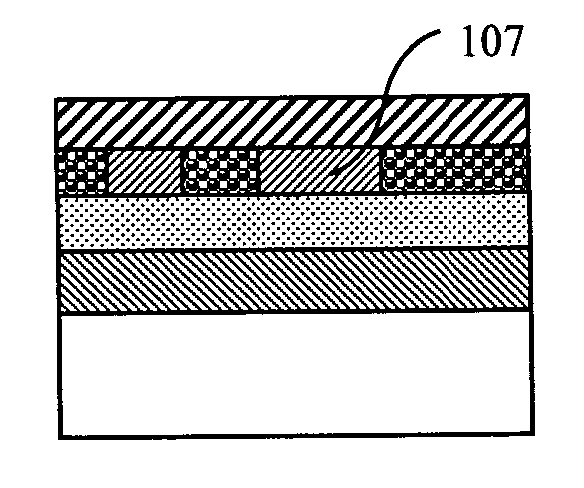

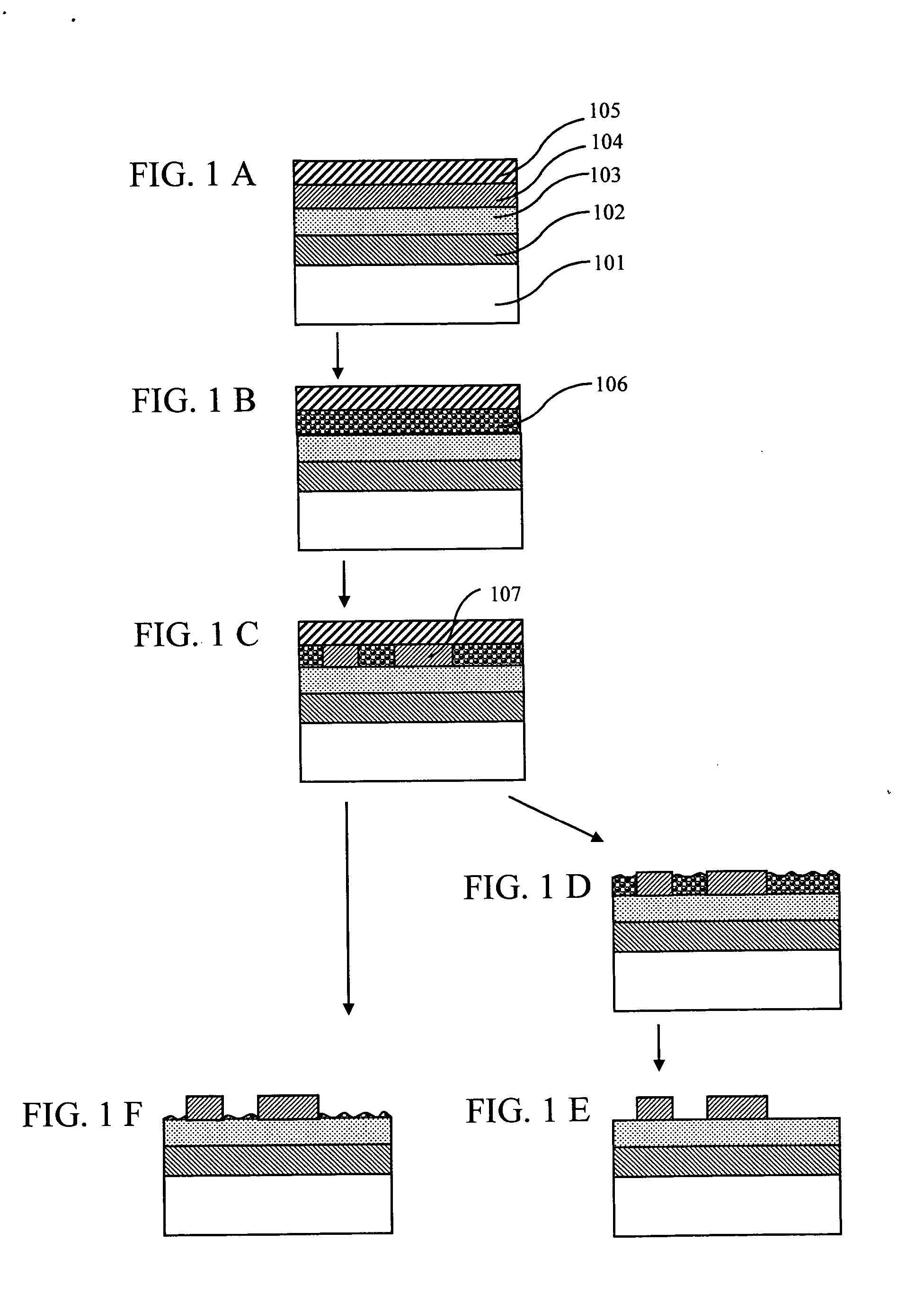

Method for fabrication of physical patterns and the method for fabrication of device using the same

InactiveUS20060275712A1Improve solubilityReduce solubilityPhotomechanical apparatusRecord information storageEtchingMedicine

Etching properties are improved in a processing method of a phase change material in which the regions of one state are removed by etching to form a fine physical pattern. The phase change film is subjected to an advance treatment conducted before the etching, and this advance treatment uses water, an alkaline solution, an acid solution, or a surface-active agent. The regions to be removed by the etching are treated in the advance treatment to facilitate penetration of the etchant in the etching step so that complete removal is accomplished with no film residue. The advance treatment also improves etching resistance of the regions to be left unremoved. The process is thereby stabilized.

Owner:HITACHI LTD

Pearlite rail

ActiveUS8361246B2Maintain hardness (strength)Improve resistance to fatigue damageFurnace typesHeat treatment furnacesMetallurgySurface roughness

A pearlite rail contains, by mass %, 0.65 to 1.20% of C; 0.05 to 2.00% of Si; 0.05 to 2.00% of Mn; and the balance composed of Fe and inevitable impurities, wherein at least part of the head portion and at least part of the bottom portion has a pearlite structure, and the surface hardness of a portion of the pearlite structure is in a range of Hv320 to Hv500 and a maximum surface roughness of a portion of the pearlite structure is less than or equal to 180 μm.

Owner:NIPPON STEEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com