Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

62results about How to "Increase shipments" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

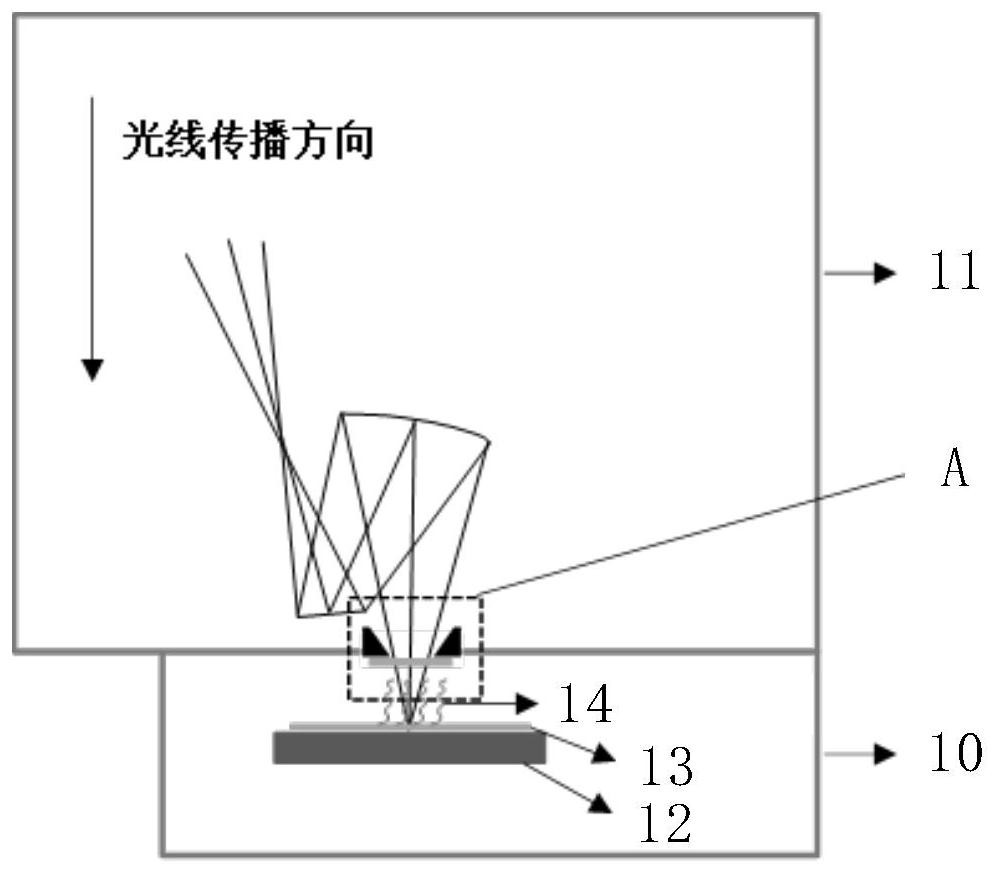

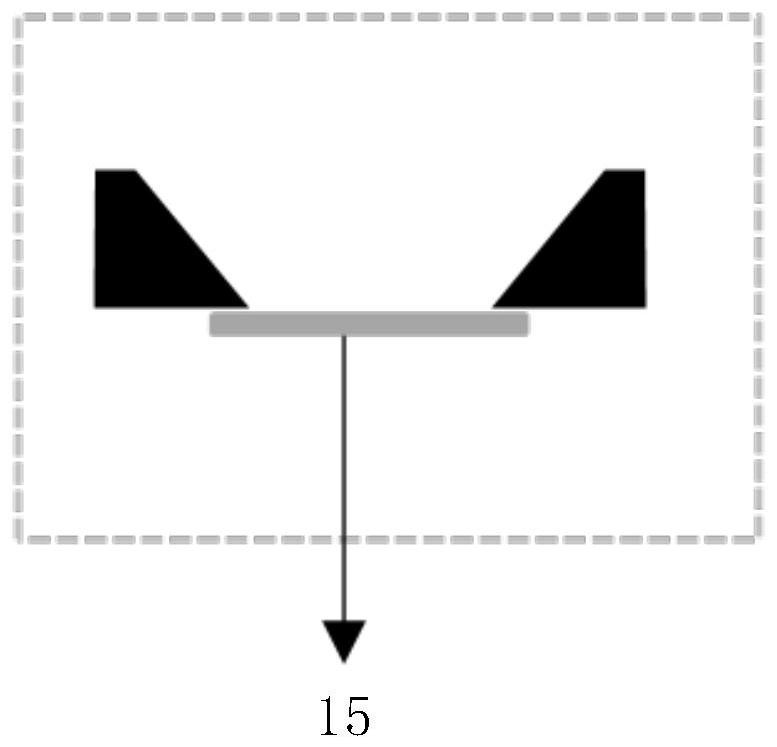

Carbonaceous Materials

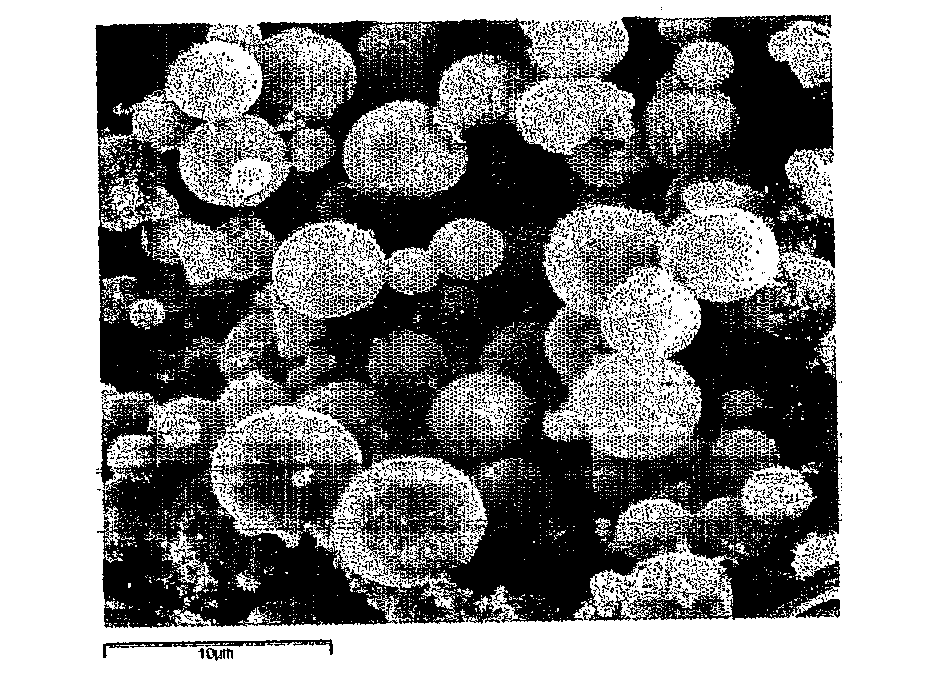

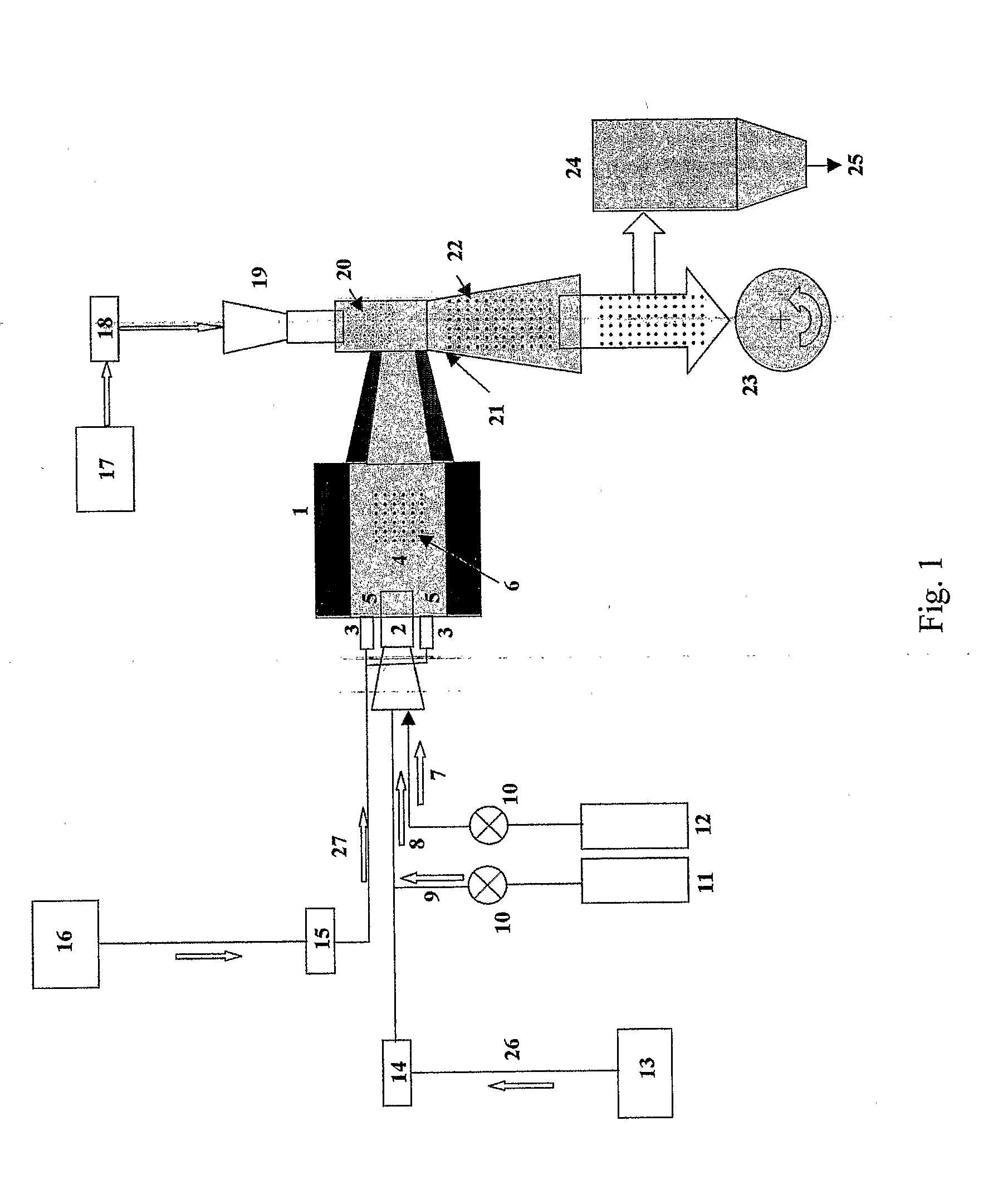

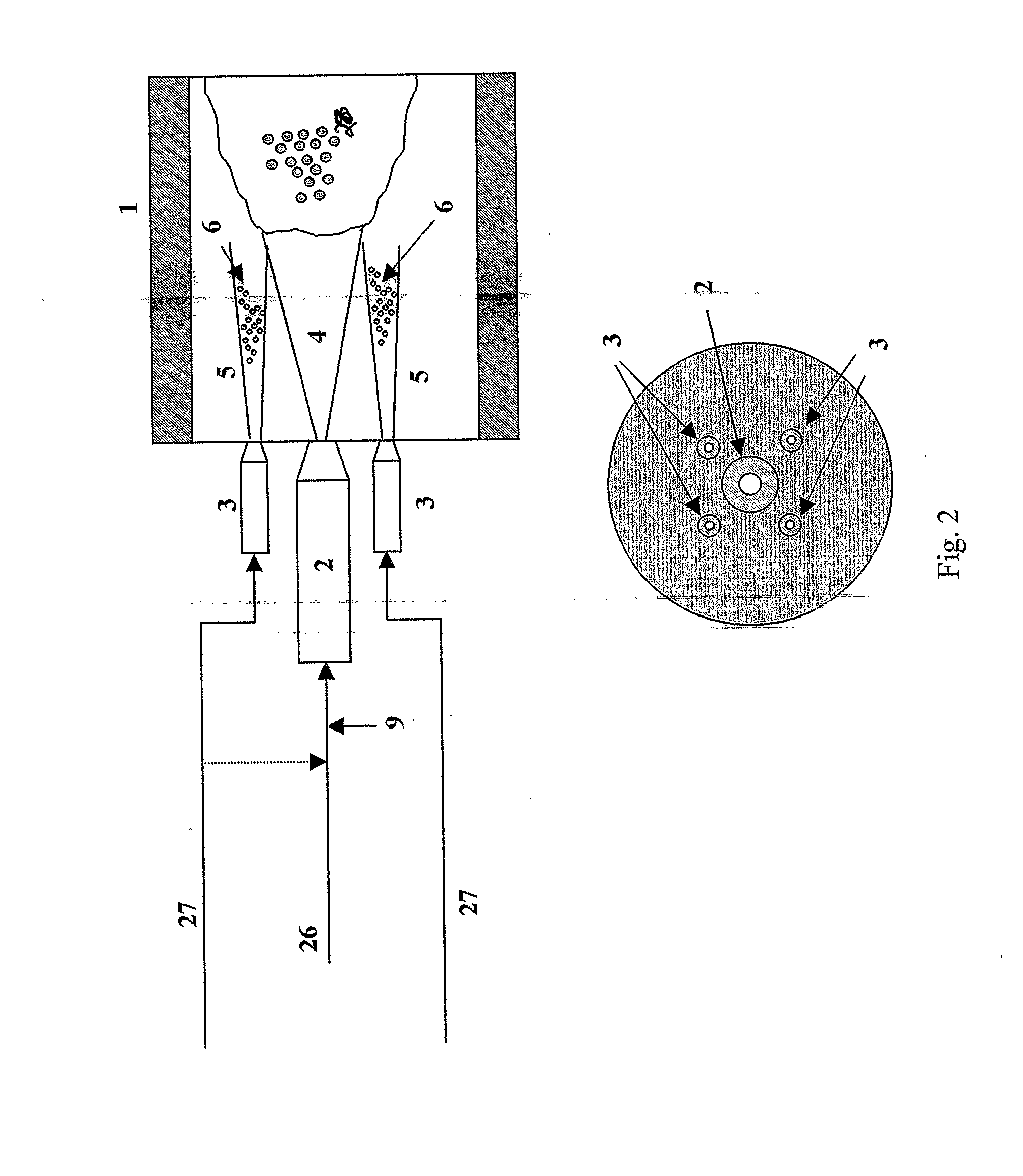

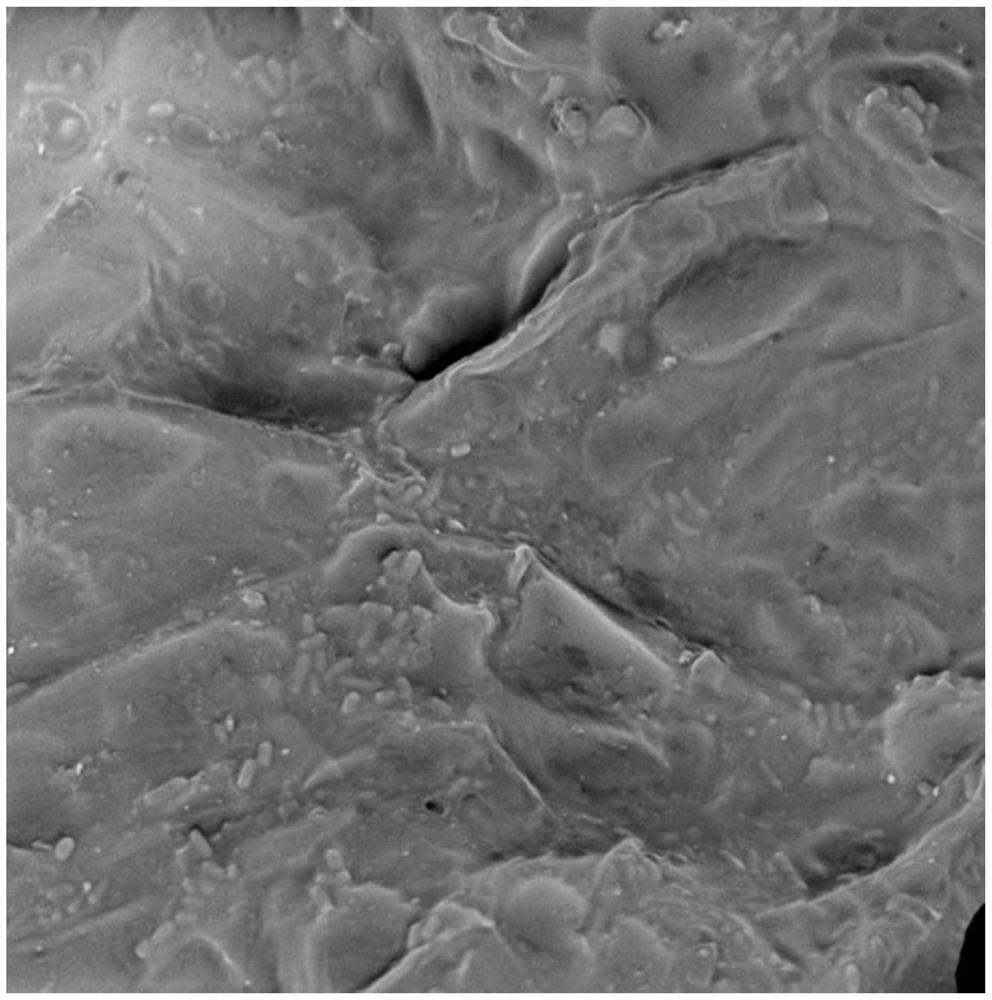

InactiveUS20080193763A1High sensitivityImprove conductivityPigmenting treatmentData processing applicationsPerformance enhancementInorganic materials

The present invention is directed to the formation of unique carbonaceous materials and a new segregated manufacturing business of carbonaceous material. In particular, the invention is directed to using a flexible reactor (1) in which spray or vapor can be used to form carbonaceous materials (28) and also in combination with inorganic material (6) to enable performance enhancement of products made using these materials.

Owner:MICROCOATING TECH

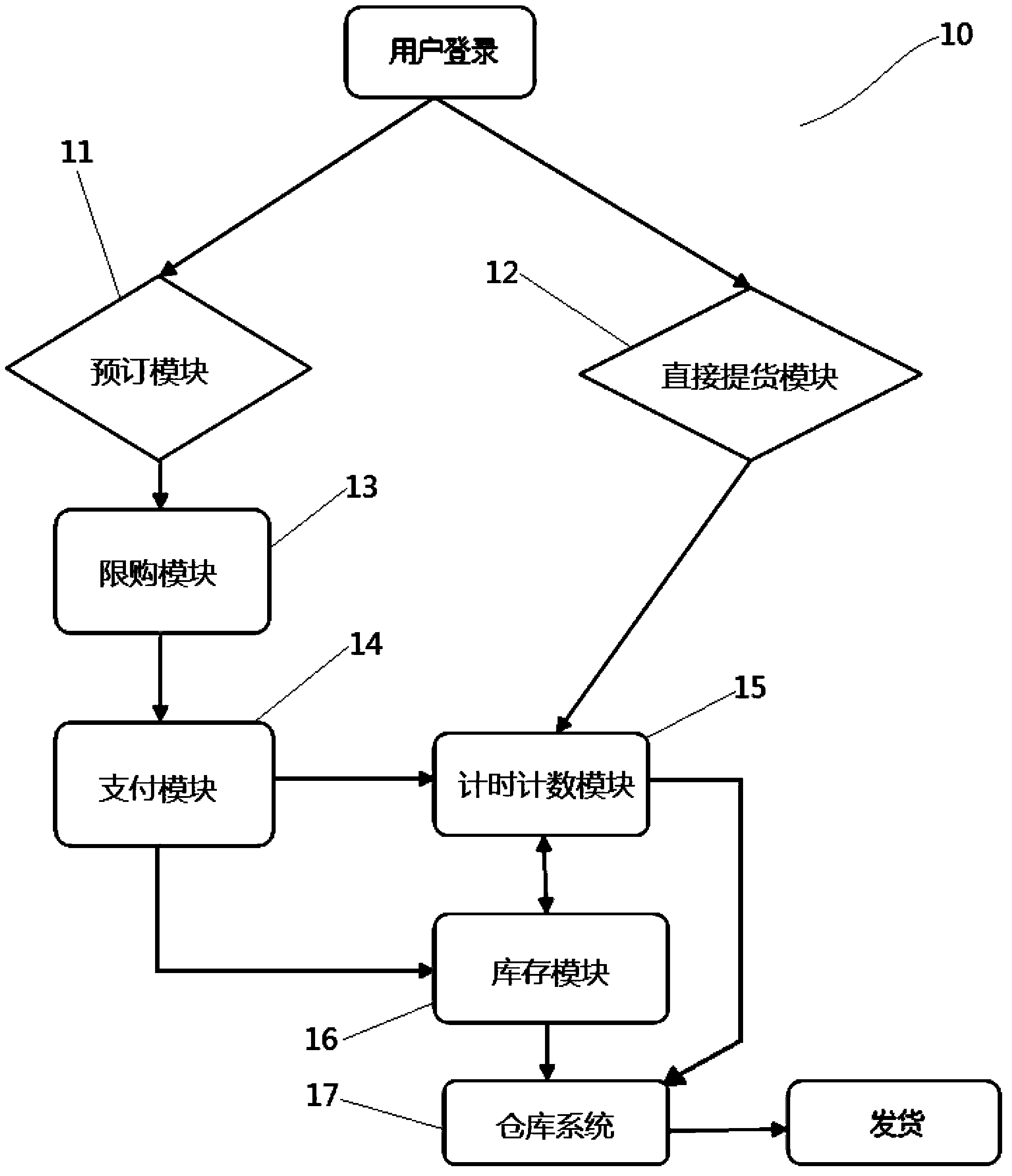

Commodity pre-purchasing system

InactiveCN103854213AIncrease shipmentsReduce churnBuying/selling/leasing transactionsPaymentDelayed time

This invention discloses a commodity pre-purchasing system, comprising a reservation module, a payment module, a timing counting module, and a warehousing module. This reservation module accepts the purchases reservation from users and transmits all the reservation commodity information to the payment module. The payment module transmits the user payment good information to the timing and counting module and the warehousing module. The timing and counting module provides selections of delay delivery and delivery quantity, and sends delivery instructions before the delay time set by the user according to the selection of the delivery quantity and updates the good quantity in the stock module. By adopting the technical scheme of the invention, the pre-order of the consumer can be received by using a pre-order mode and the potential consumption requirement of the user can be developed through the commodity discount. The commodity pre-purchasing system obtains the pre-order of the consumer, provides the consumer with cheap commodities, deliveries the newest commodities to the user right before the reservation time comes, provides convenience, increases shipment and reduces user wastage rate.

Owner:BEIJING JINGDONG SHANGKE INFORMATION TECH CO LTD

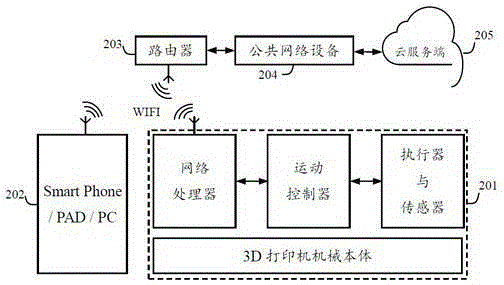

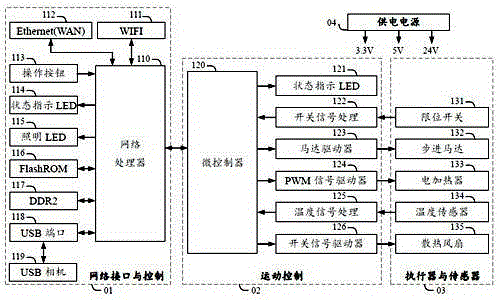

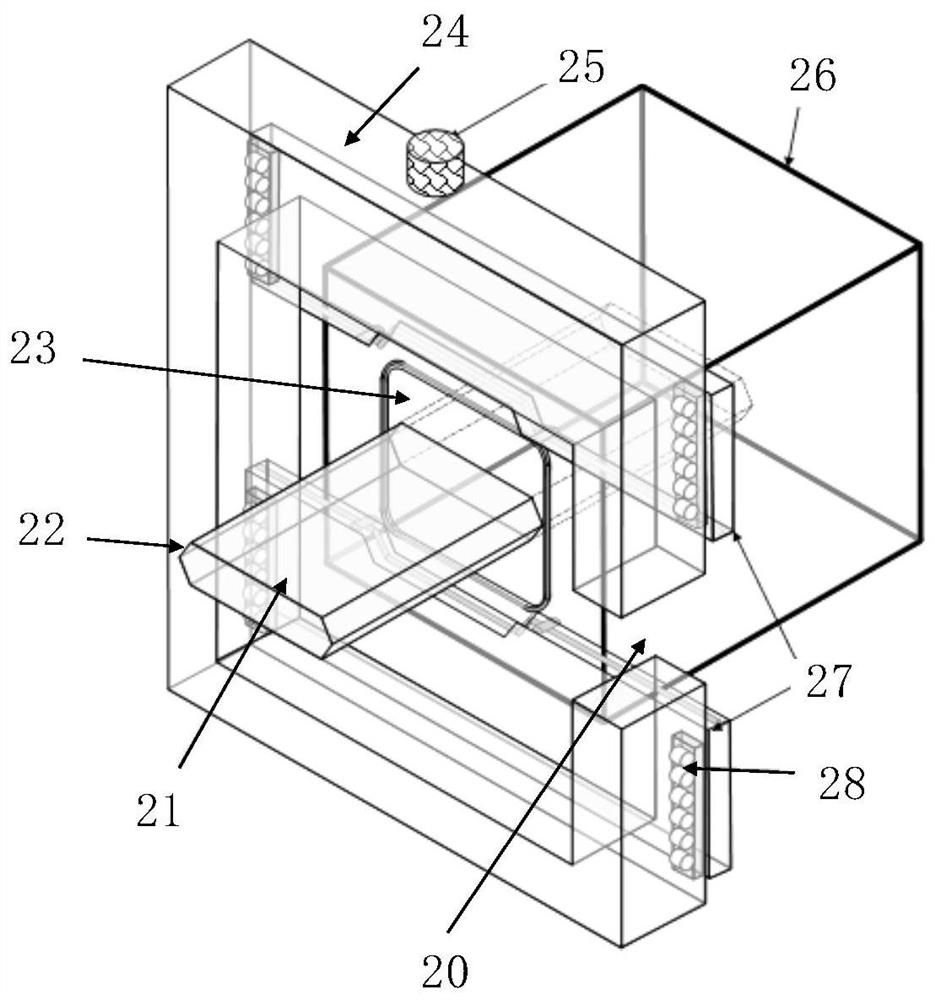

3D printer controller supporting cloud services

ActiveCN105224267AStrong network and switching capabilitiesLow costDigital output to print unitsReal Time KinematicNetwork interface

The invention provides a 3D printer controller supporting cloud services. The 3D printer controller mainly comprises a network interface and control unit and a motion control unit. The network interface and control unit comprises an Ethernet interface, a WIFI interface, a network processor and a data caching control device, and can independently communicate with a cloud server side and the motion control unit, and then exchange of 3D printing data and state and other information is achieved. The motion control unit adopts a high-real-time-performance microcontroller as a central processing unit to achieve real-time control and the like of real-time motion, feeding and extrusion of a printing head. The motion control unit and the network interface and control unit conduct two-way information exchange through synchronous serial or asynchronous serial interfaces. A double-CPU framework is adopted, 3D printing of the cloud services is achieved coordinately, and file transmission of a non-real-time network and 3D printing control with high real-time-performance requirements are effectively achieved.

Owner:ZHEJIANG UNIV OF TECH

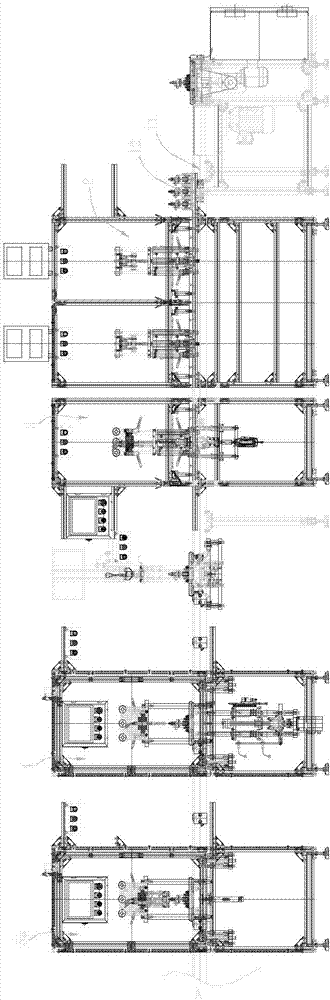

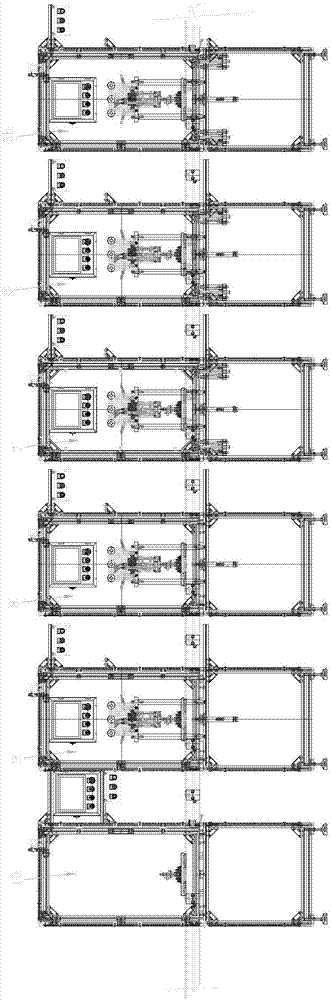

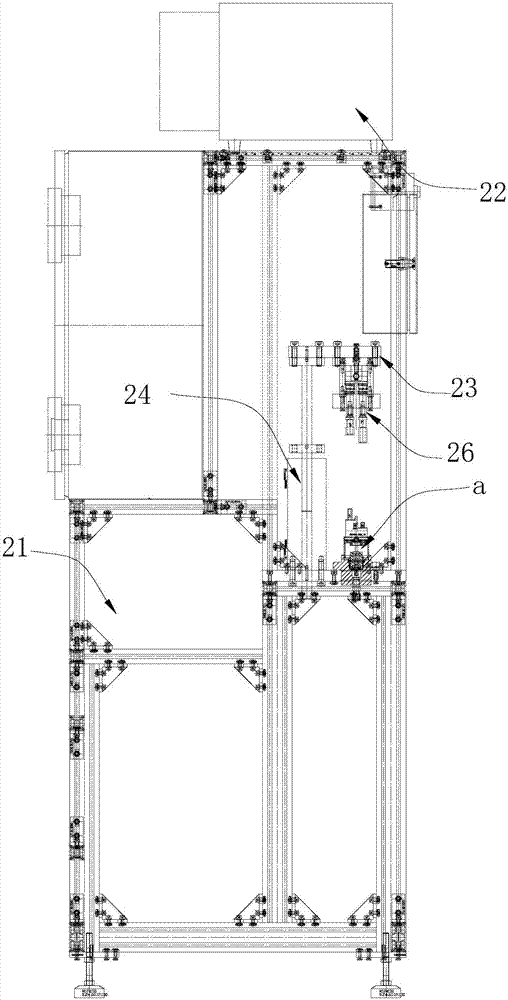

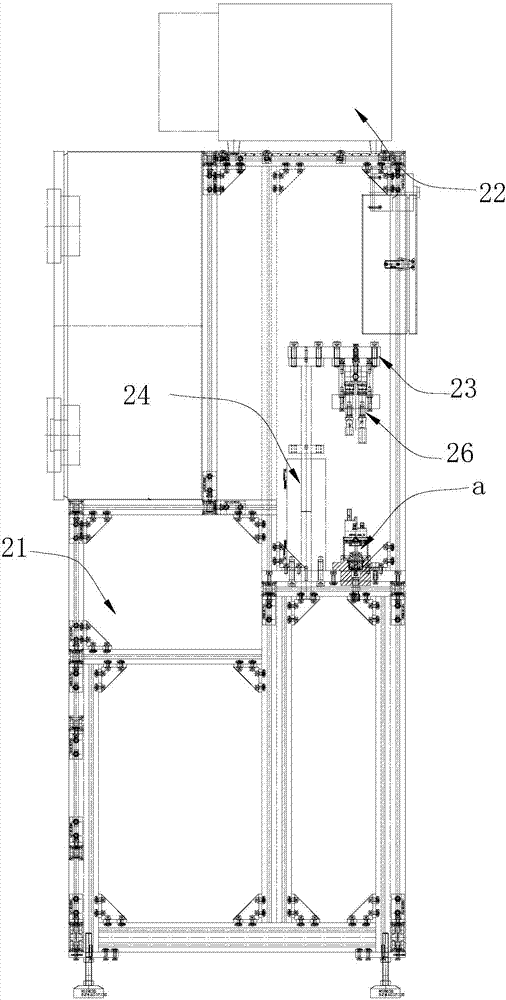

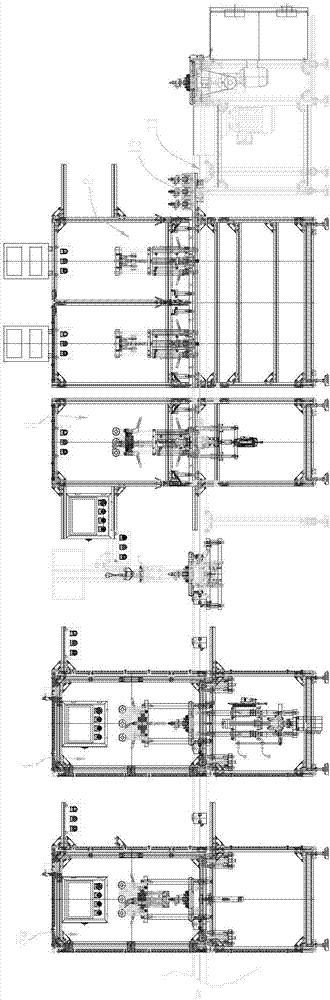

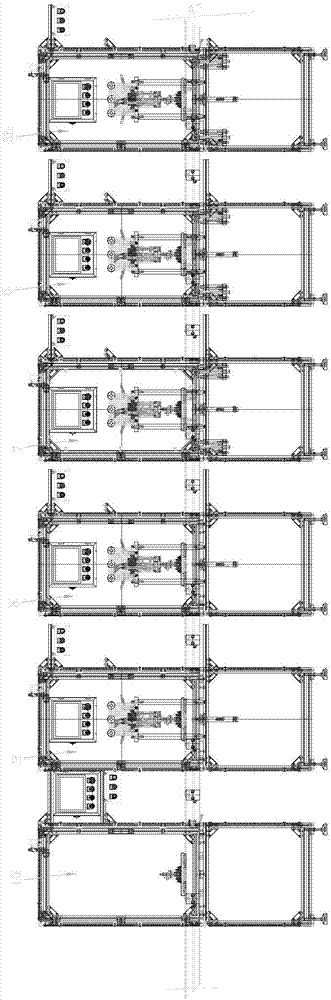

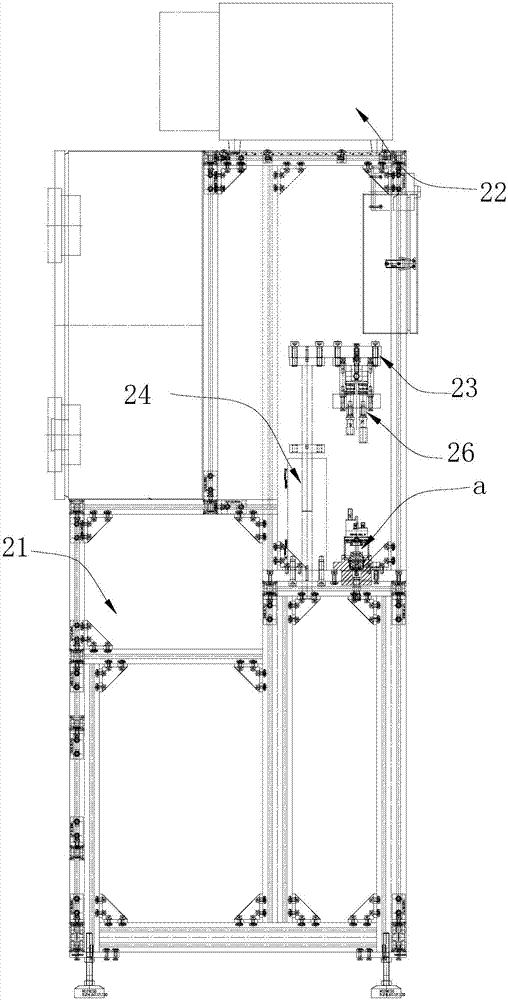

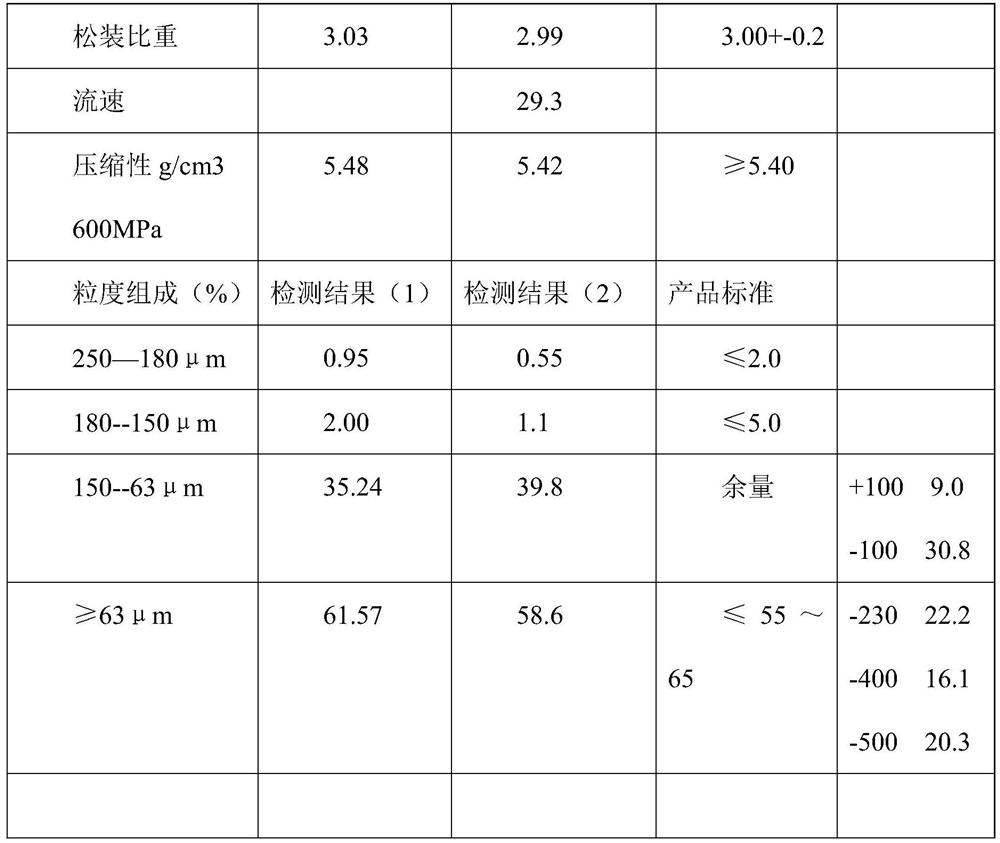

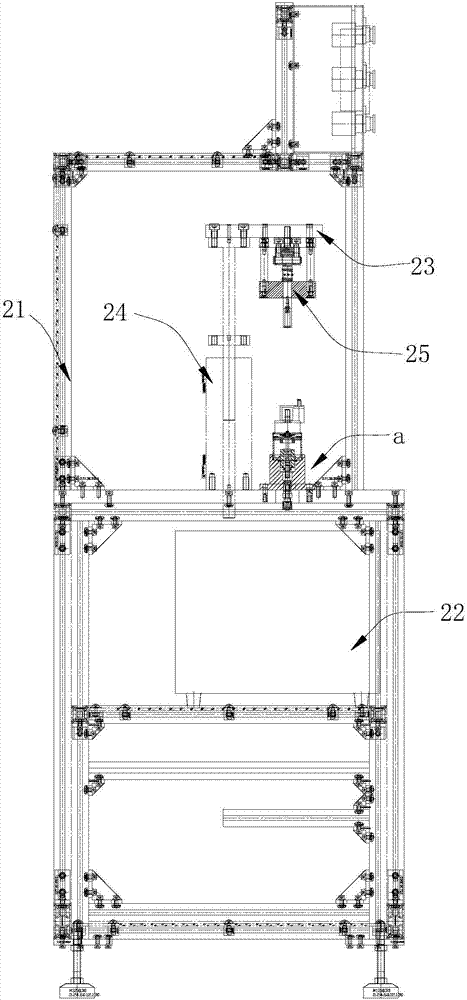

Full-automatic detection processing line

InactiveCN107192415AIncrease shipmentsLow costFluid-tightness measurementUsing optical meansPull in voltageEngineering

The invention relates to a full-automatic detection processing line, and belongs to the production field of electromagnetic switches of start motors. The full-automatic detection processing line comprises a middle control mechanism, as well as a transmission mechanism, an airtightness test box, a hook size test box, a switch cover direction confirmation mechanism, an additional stroke test box, a pull-in voltage test box, a release voltage test box, a coil current balance test box, a running-in test box, a measuring contact step-down and withstand voltage test box and an automatic ink jet box driven by the middle control mechanism; and the transmission mechanism comprises a cyclic feeding belt and a tool positioning platform arranged on the cyclic feeding belt. In the full-automatic detection processing line, the test boxes are arranged sequentially along the cyclic feeding belt, and during detection, the tool positioning platform is pushed manually and conveyed along the cyclic feeding belt, and undergoes different data detection successively; and via a processing line detection manner, the detection efficiency is improved greatly, the outgoing amount of an enterprise is increased, and the enterprise cost is reduced.

Owner:宁波铭富汽车零部件有限公司

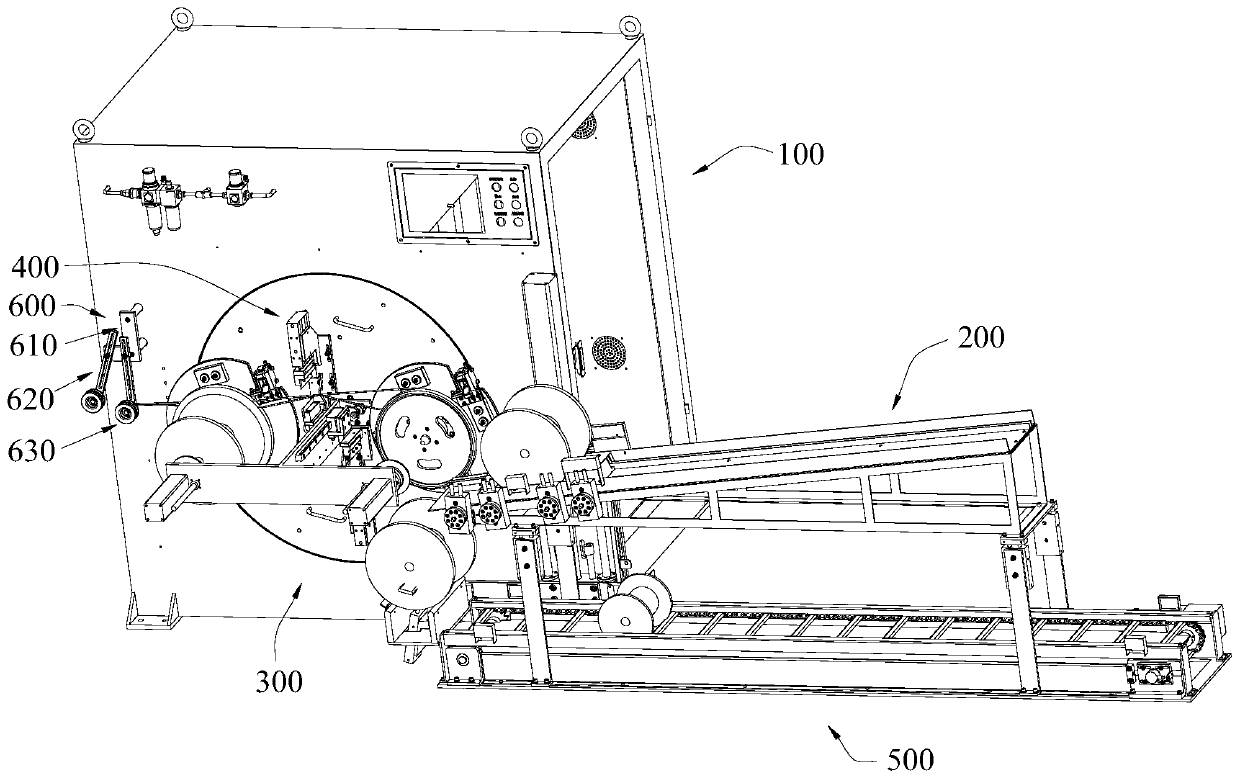

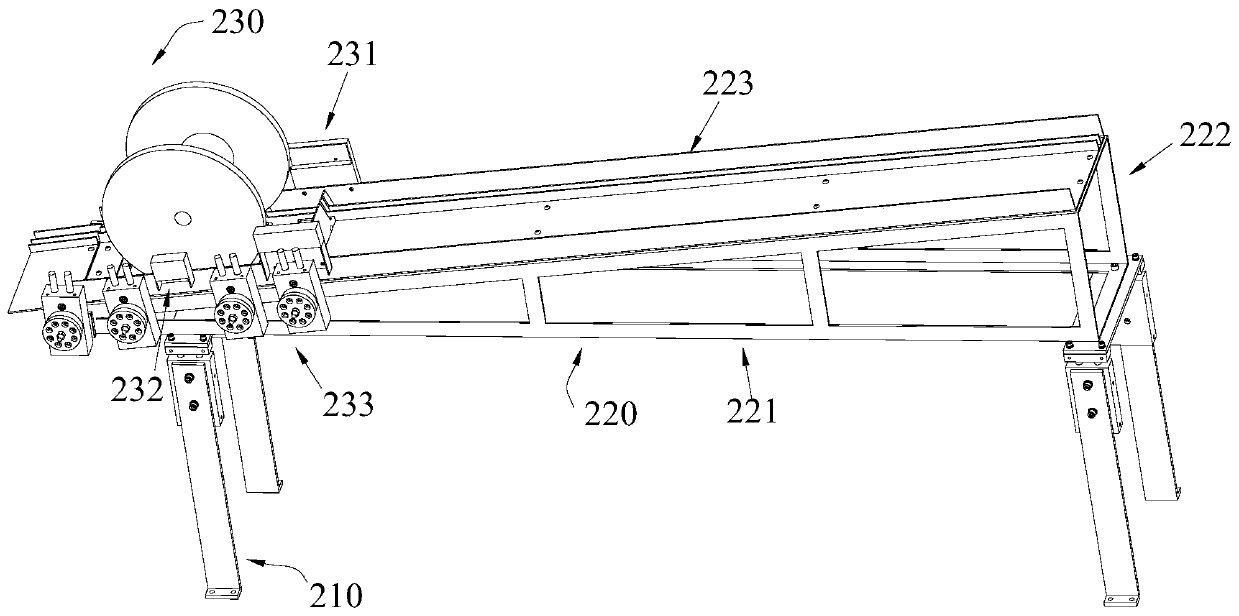

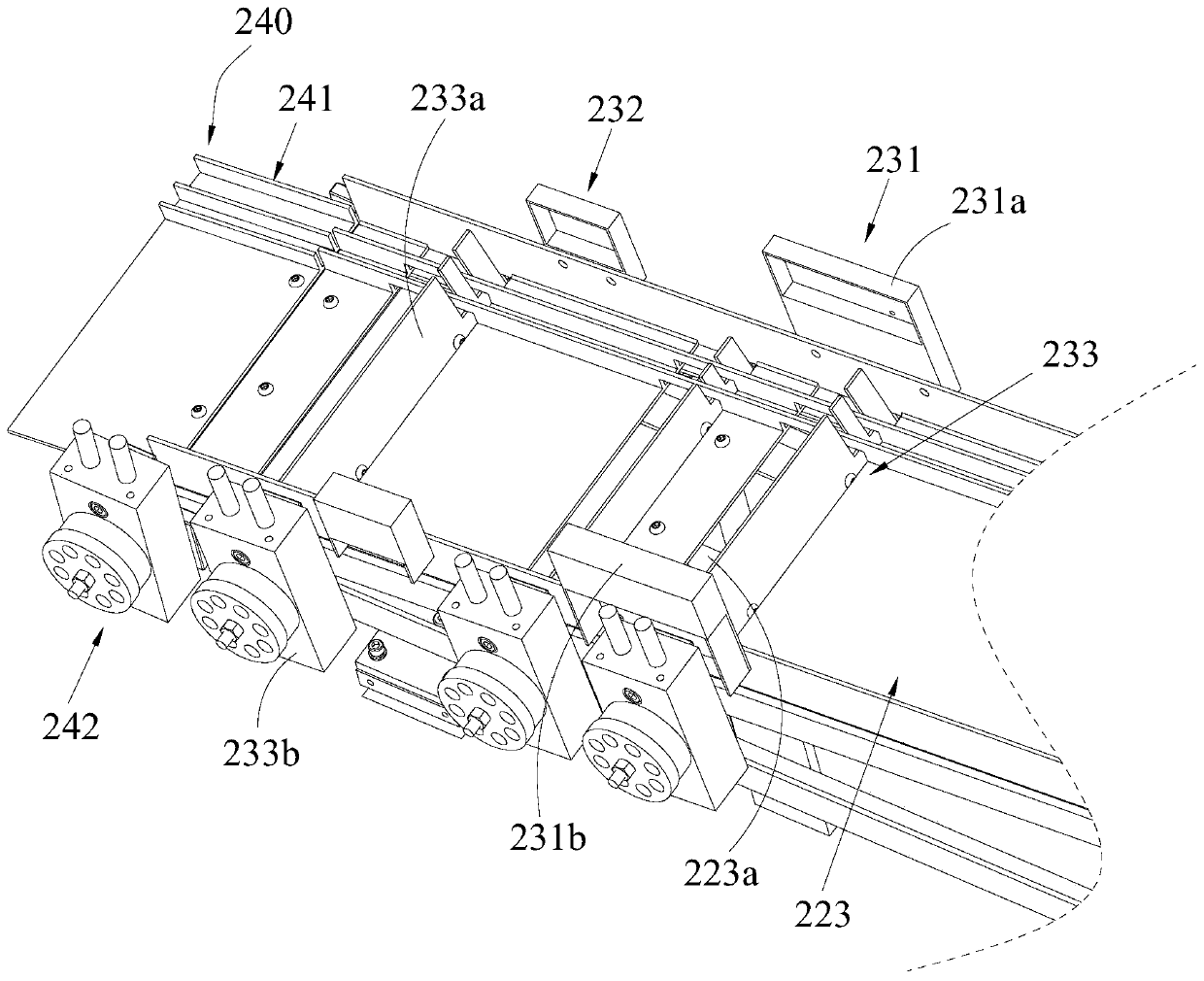

Full-automatic shaft winding equipment

The invention discloses full-automatic shaft winding equipment. The full-automatic shaft winding equipment comprises a base, an upper shaft device, a shaft changing device, a thread cutting device anda lower shaft device; the upper shaft device, the shaft changing device, the thread cutting device and the lower shaft device are respectively arranged on the base; the shaft changing device comprises a rotating fixing assembly and an shaft changing group; the rotating fixing assembly is arranged on the base; the rotating fixing assembly comprises a rotating fixing disc and a mounting frame; themounting frame is arranged on the rotating fixing disc; the shaft changing group comprises two winding rotating assemblies symmetrically arranged on the rotating fixing disc; the winding rotating assemblies comprise rotating discs, clamping manipulators and rotating drivers; the rotating discs are arranged on the rotating fixing discs; the clamping manipulators are arranged on the rotating discs;and the rotating drivers are connected with the rotating discs. Shaft changing and winding operation can be performed automatically instead of manually, so that the operation flow is simplified, the winding and shaft changing efficiency is improved, the production yield of bobbins is further increased, and the shipment quantity of wires is increased.

Owner:LTK INDS HUIZHOU +3

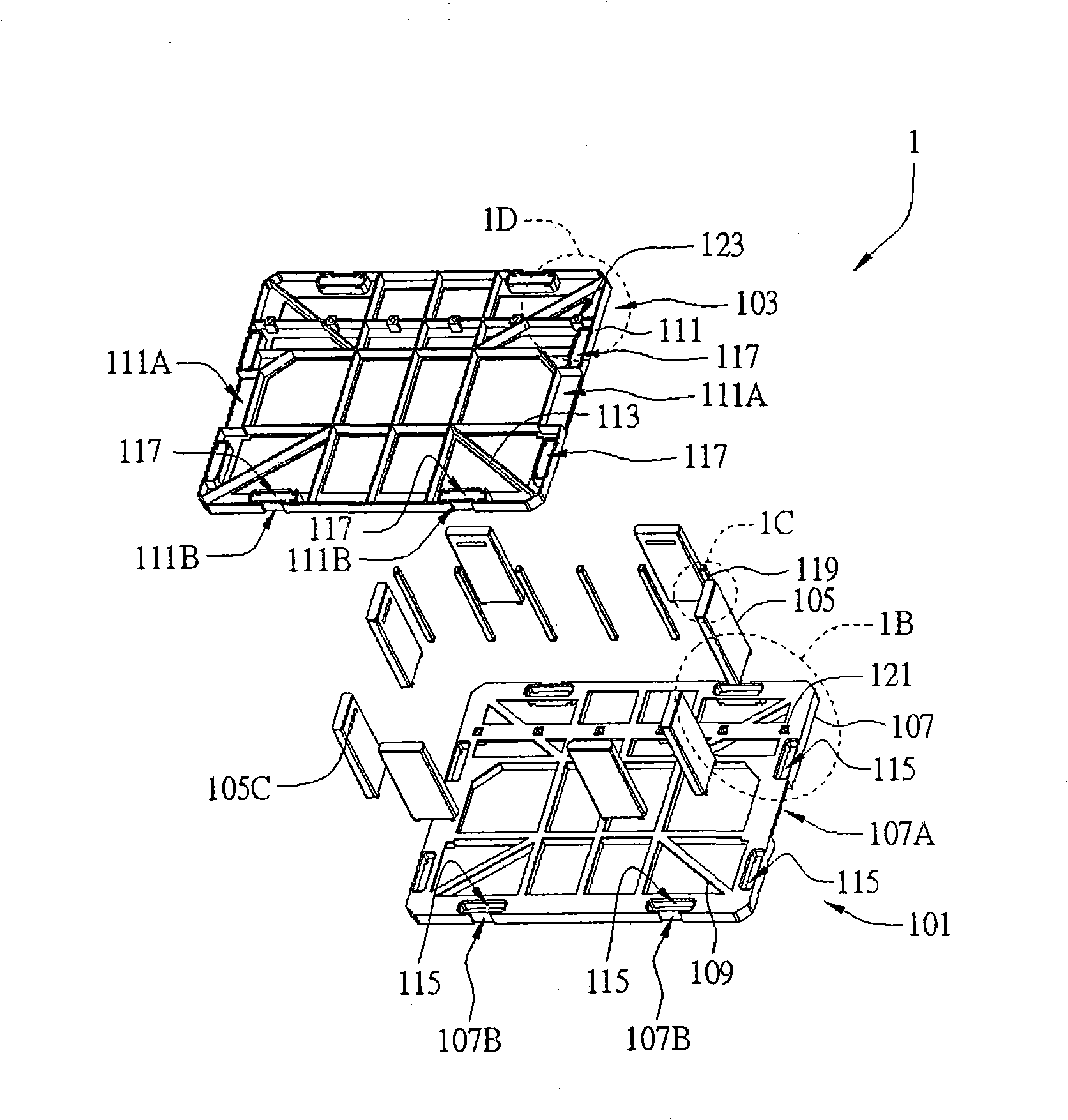

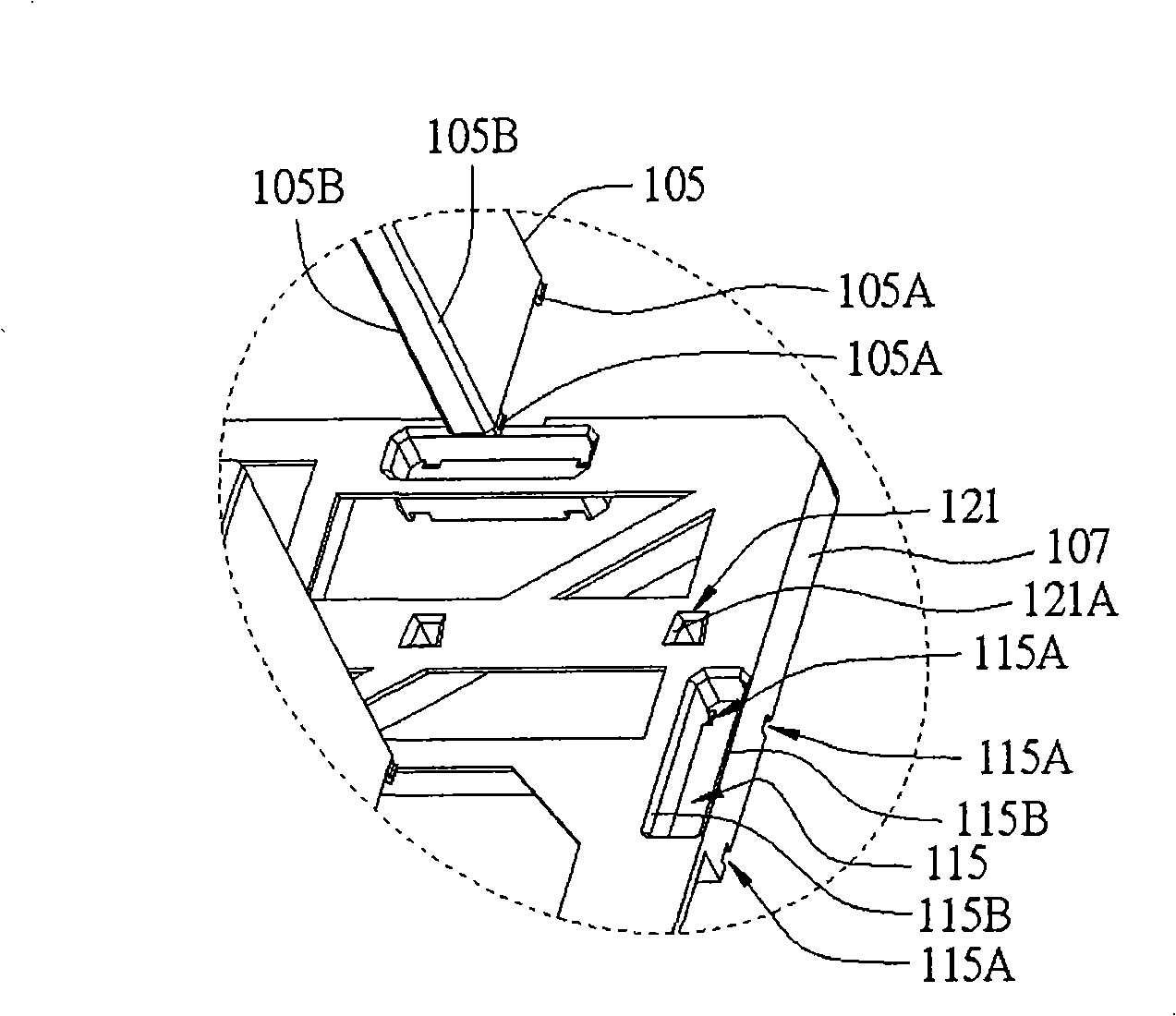

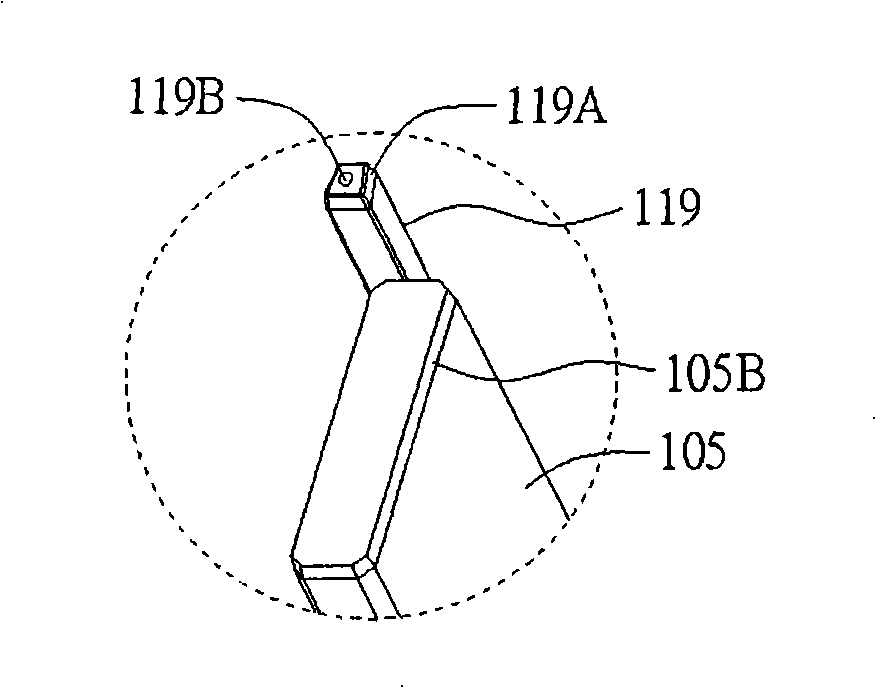

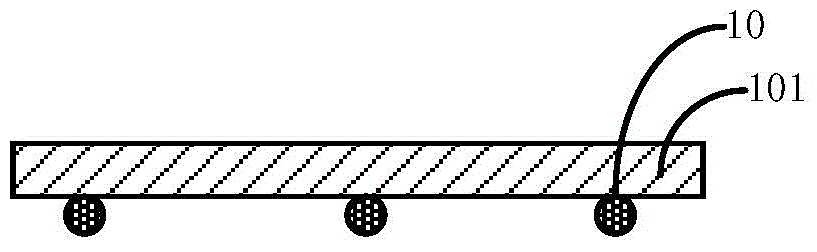

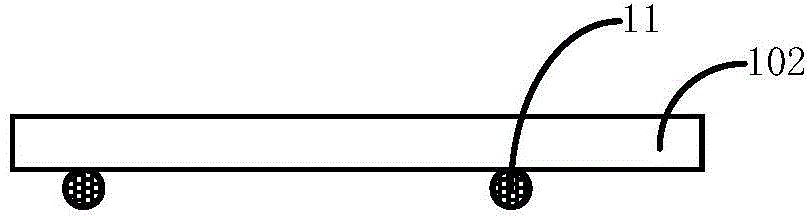

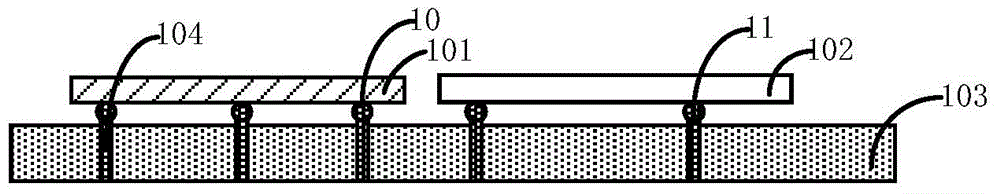

Method and apparatus for packing semi knock down

ActiveCN101301938AHigh speedEasy to useContainers to prevent mechanical damageRigid containersEngineeringMechanical engineering

The invention discloses a packing device and a corresponding packing method used for semi knocked down (SKD). The packing device comprises a first bracket mechanism, a second bracket mechanism and a plurality of supporting chock blocks. The first bracket mechanism is provided with a first outer frame and a plurality of first ribs which are arranged on an inner side of the first outer frame and share the same plane with the first outer frame. The second bracket mechanism has the same or similar form with the first bracket mechanism. The supporting chock blocks are arranged between the first bracket mechanism and the second bracket mechanism. The packing method adopting the packing device includes the following steps: the supporting chock blocks are inverted into the first bracket mechanism to form a containing chamber; the semi knocked down are arranged in the containing chamber; the semi knocked down are covered by the second bracket mechanism and the supporting chock blocks are also inverted into the second bracket mechanism.

Owner:AU OPTRONICS CORP

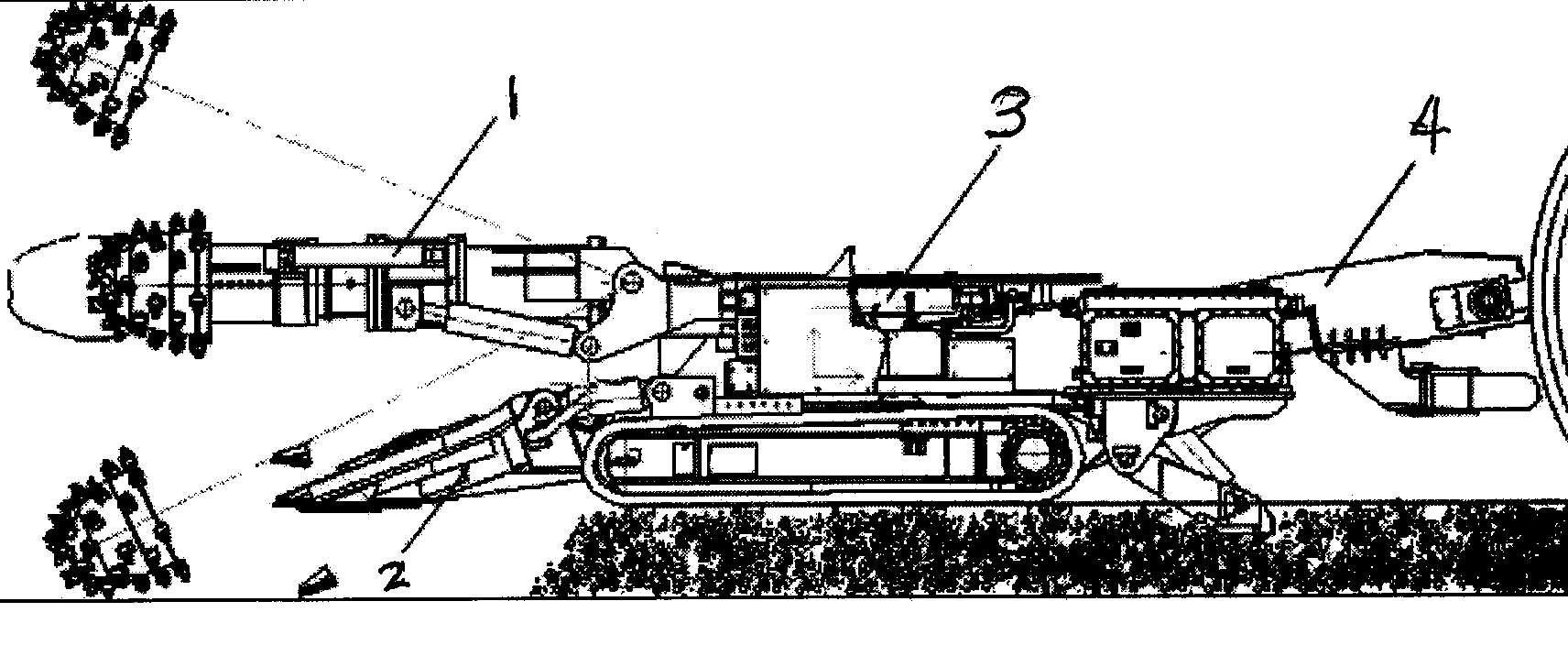

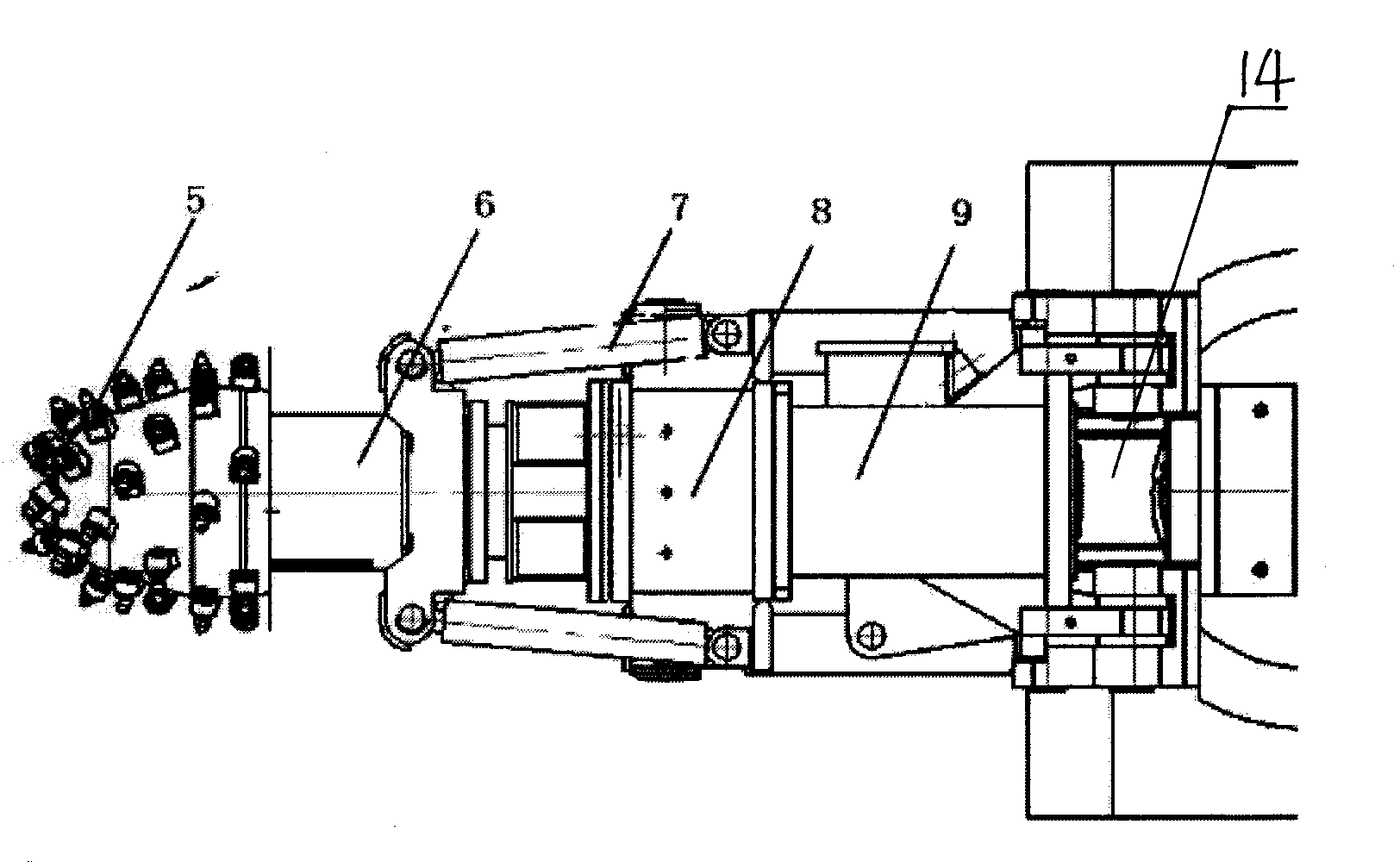

Tunneling machine

The invention relates to a tunneling machine, which is characterized in that a cutting head and a cutting speed reducer form hinge connections on both ends of a stretching bush though high strength bolts, a cutting motor forms a hinge connection behind the cutting speed reducer, a cutting portion is connected with a body frame through a connection pin, a stretching cylinder drives the cutting head to move forward along the stretching bush, a shovel plate and a first conveyor are connected with a shovel plate stretching frame through pins, the shovel plate stretching frame slides along a sliding box on the body frame, and a second conveyor connection frame forms a hinge connection on a first conveyor rear groove through a high strength bolt. The tunneling machine has the following advantages that: stretching degree and dinting depth of the cutting portion of the tunneling machine are increased to improve cutting rate so as to achieve stretching of the shovel plate portion; by matching with the increase of the stretching degree of cutting portion, shipment is increased, such that the first conveyor and the second conveyor can synchronously perform stretching movements along with the shovel plate so as to significantly improve the unloading condition of the first conveyor.

Owner:LIAONING GENERAL MINING MACHINERY EQUIP MFG

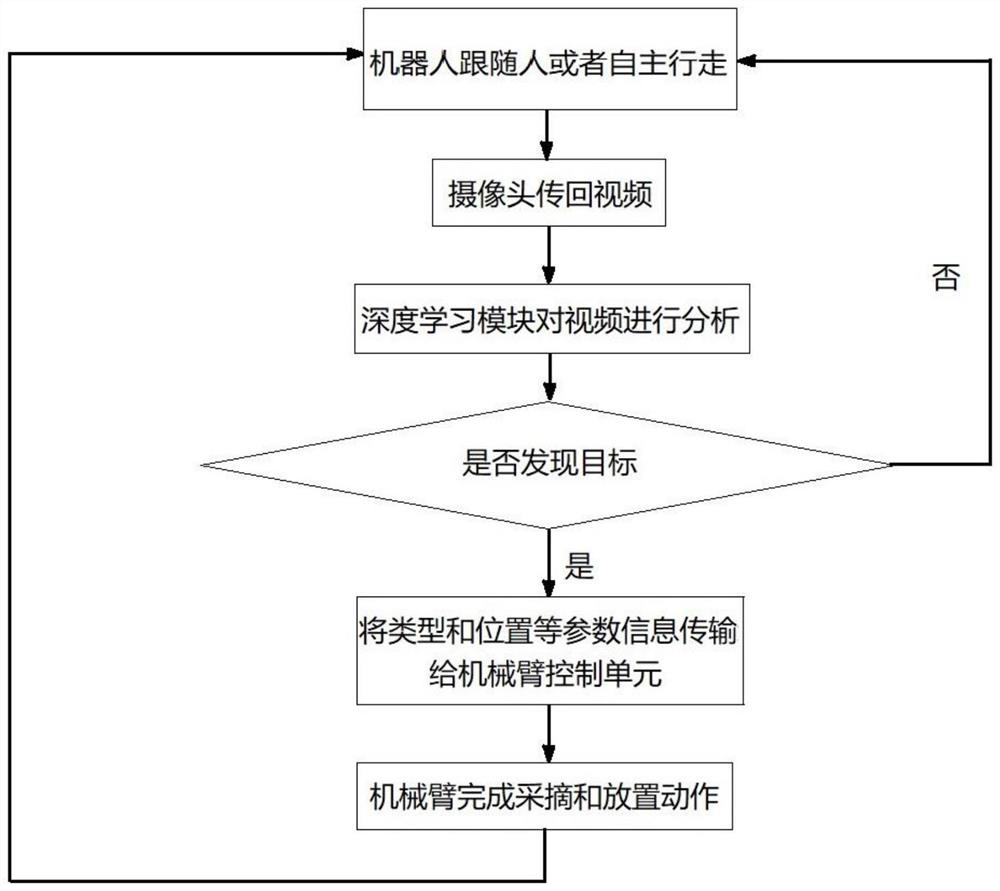

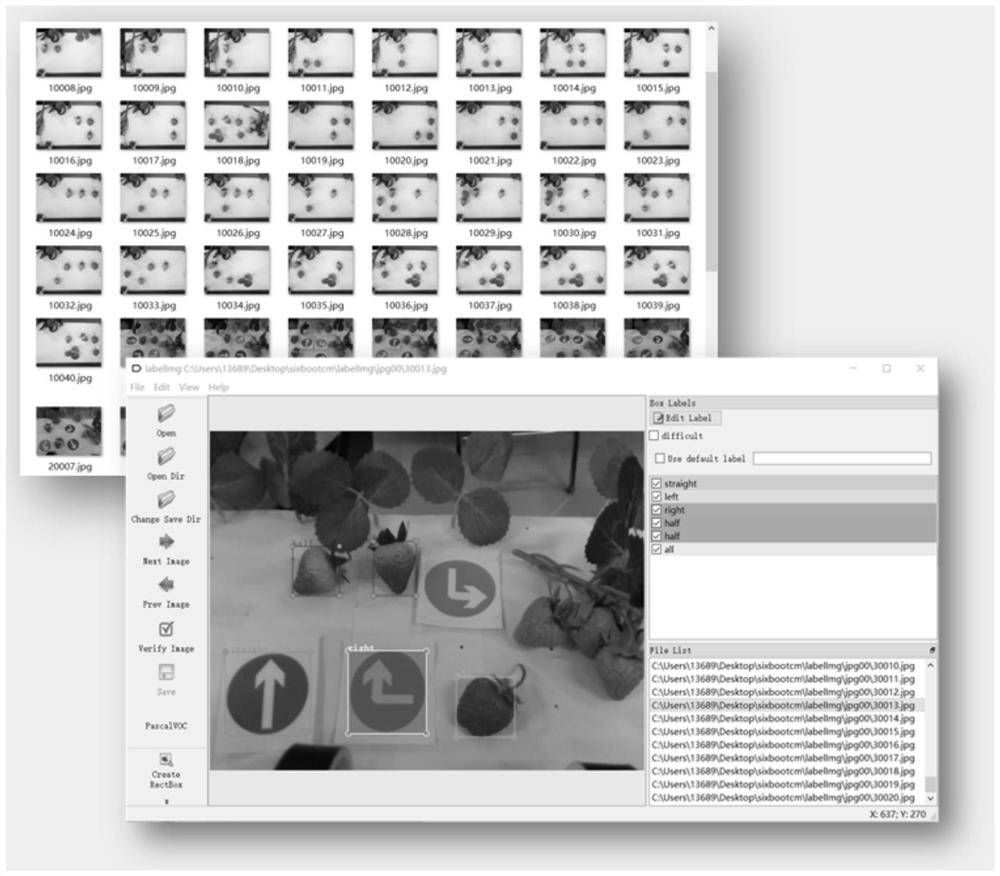

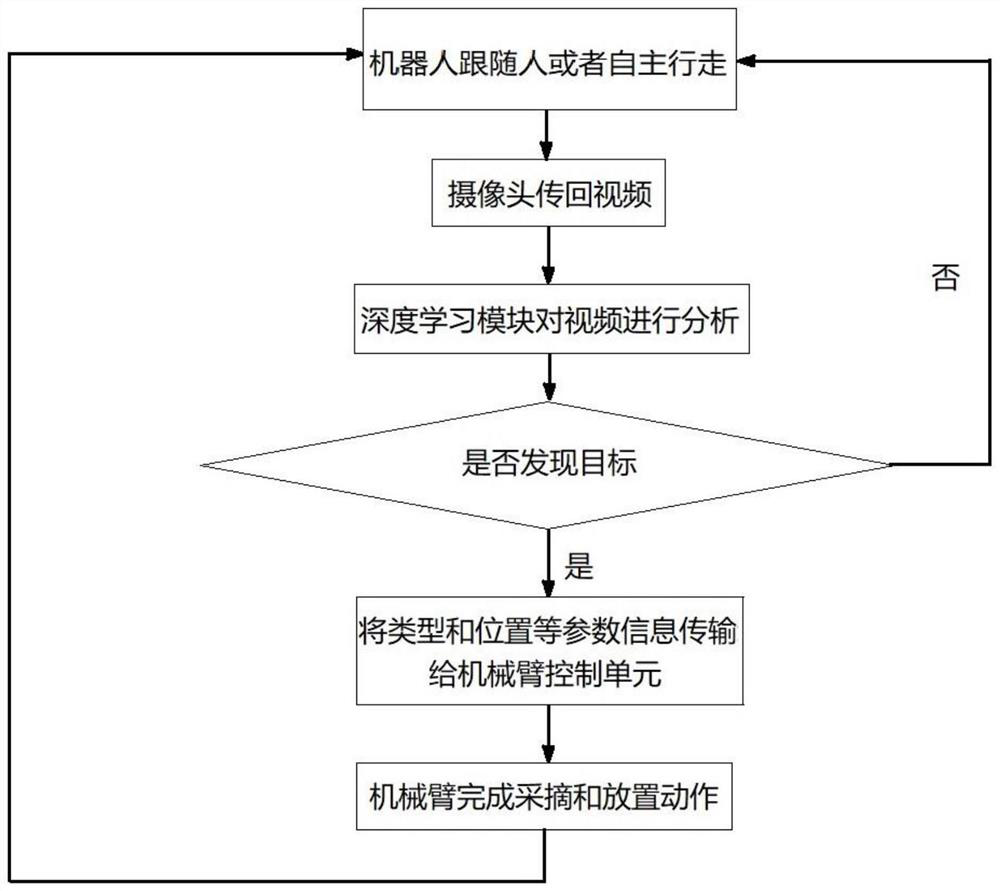

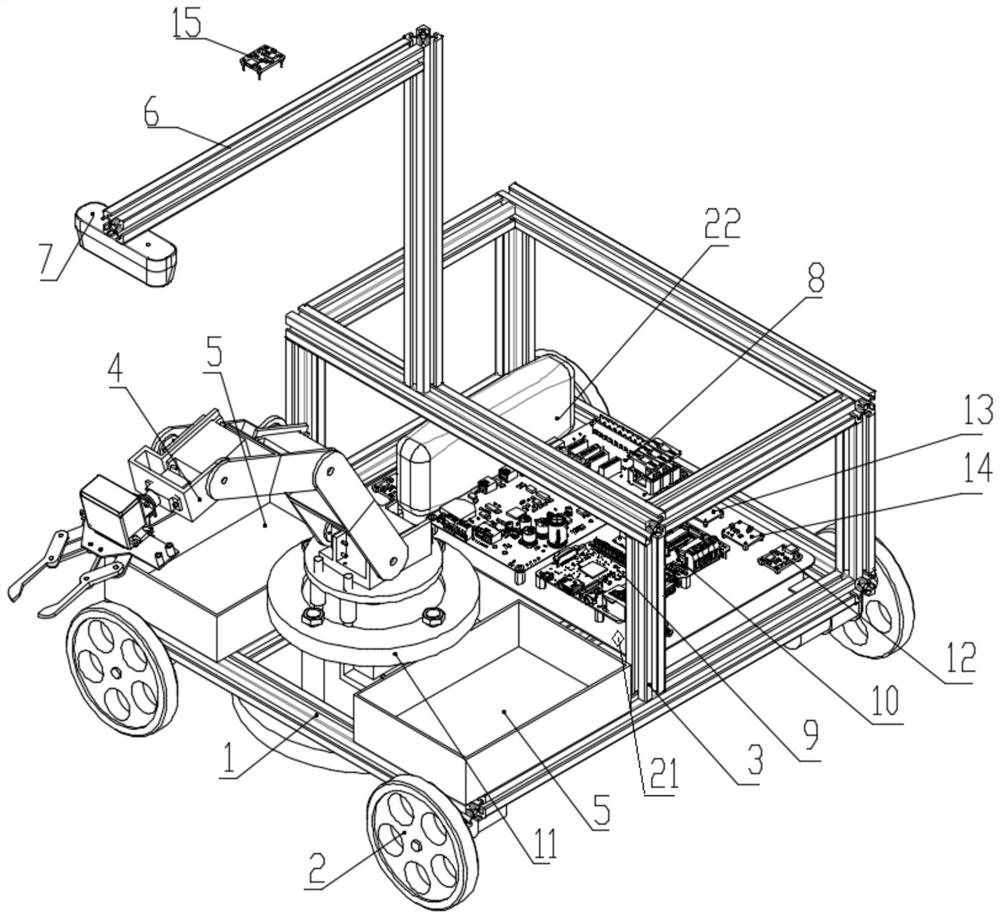

Agricultural picked object recognition algorithm based on database

PendingCN114429310AReduce lossImprove sales product qualityDatabase management systemsOffice automationFragariaAgricultural engineering

The invention belongs to the technical field of image recognition, and particularly relates to an agricultural picked object recognition algorithm based on a database, which is characterized in that a computer sets a maturity index according to a plurality of indexes such as colors, sizes and wrinkles of fruits to be picked and characteristics associated with maturity height, and establishes a model for the maturity degree and storage time of the fruits; the computer carries out artificial intelligence recognition on fruit pictures collected by the picking robot and transmits fruit types and coordinate information to a motion control unit of the picking robot, and finally grabbing, sorting and obstacle-avoiding walking are achieved. Compared with the prior art, the method has the beneficial effects that the maturity of strawberries can be divided into multiple grades according to market requirements, the maturity of picked strawberries with long storage time or long transportation distance is slightly lower, so that the distance of mailing and selling areas can be selected according to the maturity, the loss of the strawberries in transportation is reduced, and the economic benefit is increased. Sales areas are expanded, and economic benefits are improved.

Owner:UNIV OF SCI & TECH LIAONING

Full-automatic detection pipeline of start-up motor electromagnetic switches

The present invention belongs to the start-up motor electromagnetic switch production field and relates to a full-automatic detection pipeline. The full-automatic detection pipeline includes a central control mechanism, a transmission mechanism which is controlled to perform driving by the central control mechanism, an airtightness test box, an hanging hook size test box, a switch cover direction confirmation mechanism, an additional stroke test box, a pull-in voltage test box, a release voltage test box, a coil current balance test box, a run-in test box, a contact point voltage drop detection assembly, a voltage withstand test box and an automatic code spraying box; and the transmission mechanism comprises a circulation feeding belt and a tool positioning platform arranged on the circulation feeding belt. According to the full-automatic detection pipeline, the boxes are sequentially arranged along the circulation feeding belt; when detection is performed, the tool positioning platform is manually pushed to be conveyed along the circulation feeding belt and pass through various data detection stations; and a pipeline type detection mode is adopted, and therefore, detection efficiency can be greatly improved, the shipment quantity of enterprises can be improved, and the costs of the enterprises can be reduced.

Owner:NINGBO JIAHONG MOTOR

Intelligent unmanned-selling fresh food cabinet based on big data

PendingCN113327373AIncrease shipmentsImprove shopping experienceEpidemiological alert systemsLavatory sanitoryFresh foodEngineering

The invention discloses an intelligent unmanned-selling fresh food cabinet based on big data, wherein the fresh food cabinet comprises a cabinet body, the cabinet body is provided with a cabinet door, and the cabinet door is provided with a handle; the fresh food cabinet further comprises an image recognition assembly and a man-machine interaction component; the image recognition assembly is used for obtaining an infrared image of the face of a user and obtaining the body temperature and face feature information of the user; a user inputs personal information through the man-machine interaction assembly; and the man-machine interaction component recommends and displays fresh products suitable for the user to eat to the user according to the personal information input by the user. According to the fresh food cabinet, products beneficial to health of the user can be recommended to the user in combination with the personal health condition (obtained in combination with personal information of the user) of the user, so that the shopping experience of the user is improved, and the shipment amount of the fresh food cabinet is increased; and according to the fresh food cabinet, the facial feature information and the body temperature information of the user are obtained through the image recognition assembly, if the body temperature of the user is higher than the preset value, the user cannot open the cabinet door, and thus the risk that the epidemic situation is further spread is reduced.

Owner:深圳市哈哈零兽科技有限公司

Full-automatic detection assembly line of starting motor electromagnetic switch

InactiveCN107197621AIncrease shipmentsLow costCircuit interrupters testingElectrical componentsVoltage dropAssembly line

The invention relates to the field of production of a starting motor electromagnetic switch, in particular to a full-automatic detection assembly line. The full-automatic detection assembly line comprises a central control mechanism and a transmission mechanism, an air tightness test box, a hook size test box, a switch cover direction determination mechanism, an additive range test box, a suction voltage test box, a release voltage test box, a coil current balancing test box, a running-in test box, a contact voltage drop test and voltage-resistant test box and an automatic code spraying box which are controlled and driven by the central control mechanism, wherein the transmission mechanism comprises a cycle feeding belt and a tool positioning platform, and the tool positioning platform is arranged on the cycle feeding belt. In the full-automatic detection assembly line, each test box is arranged along a sequence of the cycle feeding belt, the tool positioning platform is manually pushed to be transmitted along the cycle feeding belt during detection, and detection of each data is sequentially performed; and by a detection mode of the assembly line, the detection efficiency is greatly improved, the yield of an enterprise is improved, and the enterprise cost is reduced.

Owner:宁波铭富汽车零部件有限公司

Semiconductor device, manufacturing method therefor, and electronic device

InactiveCN105390434AReduce process costIncrease shipmentsSolid-state devicesSemiconductor/solid-state device manufacturingPower semiconductor deviceEngineering

The invention relates to a semiconductor device, a manufacturing method therefor, and an electronic device. The method comprises the steps: S1, providing a bottom wafer; S2, forming an insulating layer on the bottom wafer, and forming a plurality of interconnection through holes in the insulating layer, so as to connect the bottom wafer; S3, providing a top wafer, and forming a plurality of convex points, matched with the interconnection through holes, on the top wafer; S4, enabling the interconnection through holes to be connected with the convex points, so as to form a flip chip. The method is advantageous in that (1) the method reduces the technology of one-time Bump, and reduces the technological cost; (2) the method reduces one wafer serving as an interlayer (Interposer) and the interlayer technology, and increases the output; (3) the method takes organic matters as insulating materials, reduces the risks of electric leakage, and improves the capability of breakdown resistance.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Detection assembly line for electromagnetic switch of start motor

ActiveCN107300449AIncrease shipmentsLow costTesting dielectric strengthMeasurement of fluid loss/gain ratePull in voltageVoltage drop

The invention relates to the production field of electromagnetic switches of start motors, and relates to a full-automatic detection assembly line. The full-automatic detection assembly line comprises a centralized control mechanism, a transmission mechanism, an airtightness testing box, a hook size testing box, a cover opening and closing direction confirmation mechanism, an additional travel testing box, a pull-in voltage testing box, a release voltage testing box, a coil current balance testing box, a running-in testing box, a measurement contact voltage drop and withstand voltage testing box, and an automatic code spraying box, wherein the transmission mechanism, the airtightness testing box, the hook size testing box, the cover opening and closing direction confirmation mechanism, the additional travel testing box, the pull-in voltage testing box, the release voltage testing box, the coil current balance testing box, the running-in testing box, the measurement contact voltage drop and withstand voltage testing box and the automatic code spraying box are controlled and driven by the centralized control mechanism to operate . The transmission mechanism comprises a circulating feeding belt, and a tool positioning platform disposed on the circulating feeding belt. According to the invention, all detection boxes in the assembly line are sequentially set along the circulating feeding belt, and the tool positioning platform is manually pushed to carry out the conveying along the circulating feeding belt during detection, and sequentially passes each data detection. The assembly line provided by the invention greatly improves the detection efficiency in an assembly line detection mode, improves the output of an enterprise, and reduces the cost for the enterprise.

Owner:宁波铭富汽车零部件有限公司

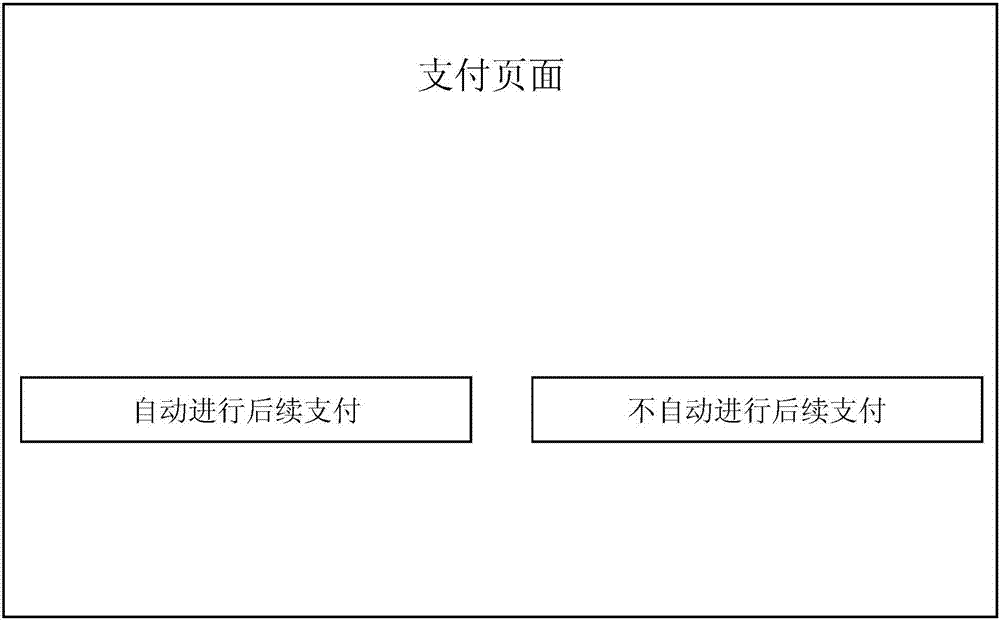

Method and device for payment

ActiveCN107122963AImprove efficiencyMeet different needsPayment schemes/modelsPayments involving neutral partyFinancial transactionOnline payment

The embodiments of the invention relate to the technical field of online payment, and particularly relate to a method and a device for payment. The method and the device are provided to solve the problem that buyers need to make multiple payments and the payment process is complicated for the deposit-based payment method in the prior art. According to the embodiments of the invention, for a transaction needing at least two payments, if a user chooses automatic subsequent payment after first payment, the amount of money needed for next payment is paid through a payment account set by the user upon the arrival of the automatic payment time. As the amount of money needed for next payment can be paid through the payment account set by the user upon the arrival of the automatic payment time for a transaction needing at least two payments, there is no need for buyers to make multiple payments manually, and the payment process is simplified.

Owner:ALIBABA GRP HLDG LTD

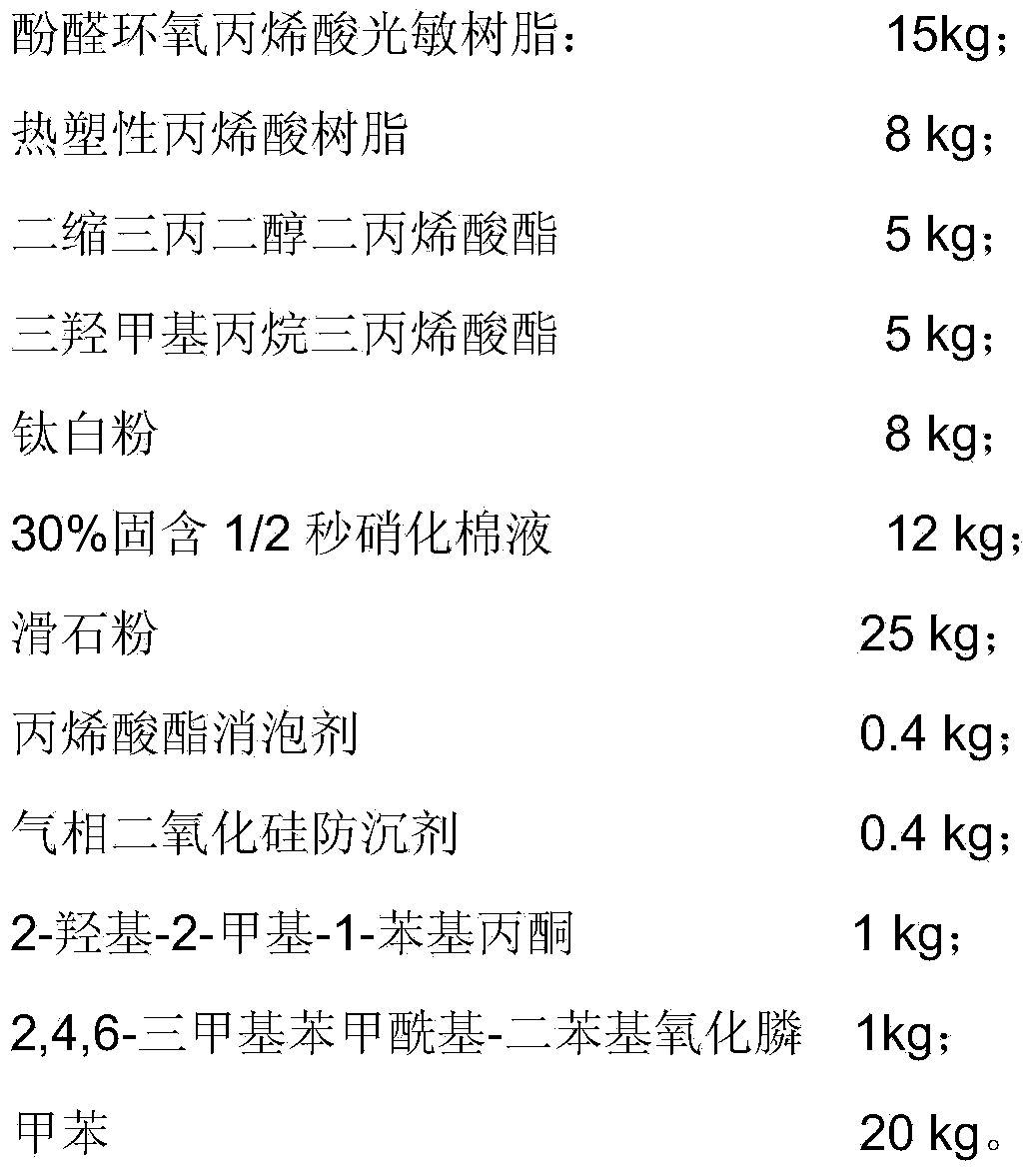

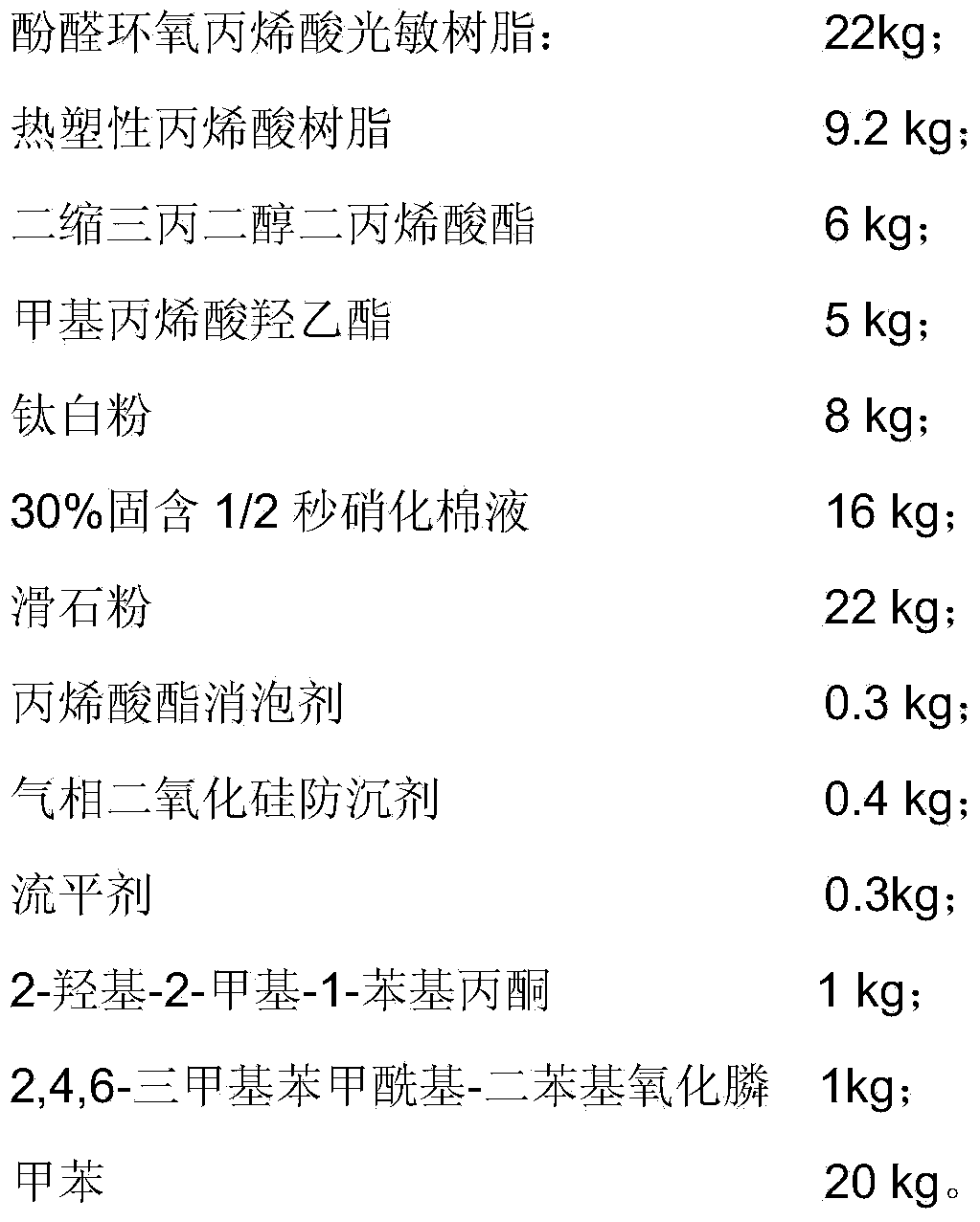

Open white priming paint sprayed by UV

ActiveCN103642367AOverfillSolve the problem of poor opening effectEpoxy resin coatingsOrganic solventAcrylic resin

The invention provides an open white priming paint sprayed by UV, wherein the open white priming paint is composed of the following components of: a photosensitive novolac epoxy acrylate resin, a thermoplastic acrylic resin, an active diluents, a white pigment, a nitrocotton liquid, a filler, a photoinitiator and an organic solvent. The invention provides an open white priming paint sprayed by UV having fast spraying, curing and dry speeds; obtained paint film has advantages of good adhesive force on a substrate, excellent sagging prevention performance and excellent open effect; solves problems of overgood filling effect and bad open effect for the UV white priming paint; the preparation technology of the open white priming paint is greatly simplified, construction efficiency is substantially raised, and a qualified rate of the product and a shipment amount of a furniture factory is greatly raised by using machine spraying.

Owner:SHANGHAI CHANGRUNFA PAINT

Method for preparing sauced radish by fermentation

PendingCN111743119AReduce moisture contentIncrease shipmentsFood freezingFood dryingBiotechnologyIcing sugar

The invention discloses a method for preparing sauced radishes by fermentation. The method comprises the following steps: cleaning radishes, cutting and air-drying; adding fungus powder and soy sauce,and mixing until the radish completely absorbs a mixture; putting the radishes into a vegetable basket of a fermentation tank for vacuum fermentation, pressurizing an upper pressing plate to the maximum degree one day before the fermentation is finished to enable marinade of the radishes to completely flow out, relieving the vacuum state, and opening a tank cover to take out the radishes after the marinade is completely discharged; putting the radishes into a vacuum tumbling machine, adding a flavoring agent, and performing vacuum tumbling until the powdered sugar and the monosodium glutamateare completely absorbed by the radishes; freezing the dried radishes in a freezing tray until the central temperature of the dried radishes is minus 40 DEG C, and transferring the dried radishes intoa freeze dryer for freeze drying; and bagging and packaging the freeze-dried radishes in a certain temperature and humidity environment. The method provided by the invention can realize low salt content of the freeze-dried sauced radish, reduce processing links such as rinsing and desalting and shorten the technological process, thereby reduce the processing cost and keep the product containing alarge amount of viable bacteria and rich sauced flavor.

Owner:GUANGXI UNIV

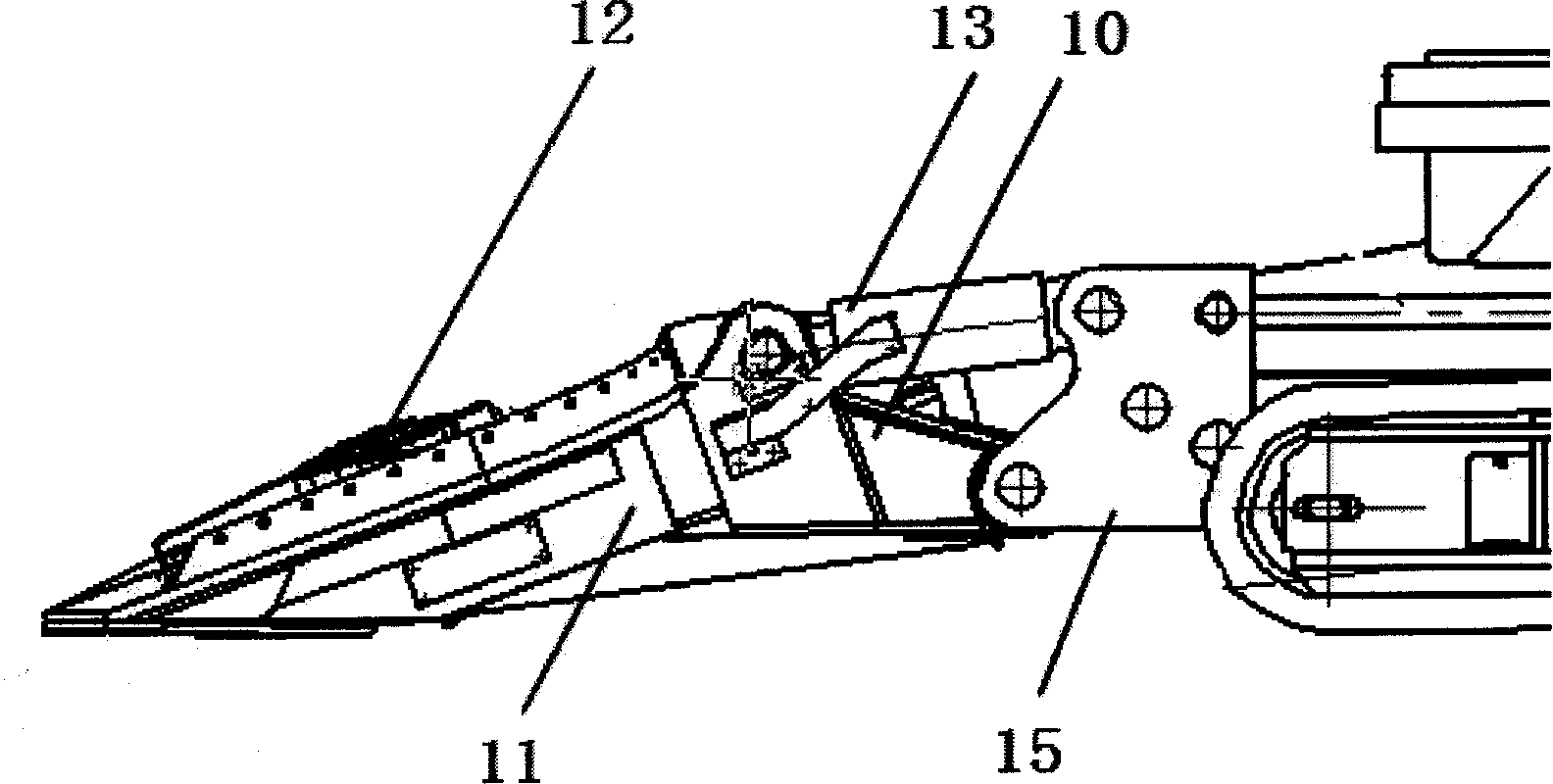

Agricultural picking robot target maturity judgment and classified storage method

ActiveCN114375689AReduce lossExpand sales areaProgramme-controlled manipulatorPicking devicesFragariaAgricultural science

The invention belongs to the technical field of image recognition, and particularly relates to an agricultural picking robot target maturity judgment and classified storage method which is characterized in that in an agricultural planting area, a picking robot inspects along a set route and collects pictures of picking targets; the control computer sets maturity indexes according to characteristics associated with maturity height and a plurality of indexes such as colors, sizes and wrinkles of fruits to be picked, establishes a model for the maturity degree and storage time of strawberries, and performs artificial intelligence recognition on strawberry pictures collected by the picking robot. And strawberry categories and coordinate information are transmitted to an artificial intelligence identification control panel, a picking and sorting control panel and a vehicle body moving control panel of the picking robot, and finally grabbing and sorting of the mechanical arm and obstacle avoidance walking of wheels are achieved. The method has the advantages that the strawberries can be picked, classified and packaged according to long storage time or long transportation distance, so that the loss of the strawberries in transportation is reduced, the sales area is expanded, and the economic benefit is improved.

Owner:UNIV OF SCI & TECH LIAONING

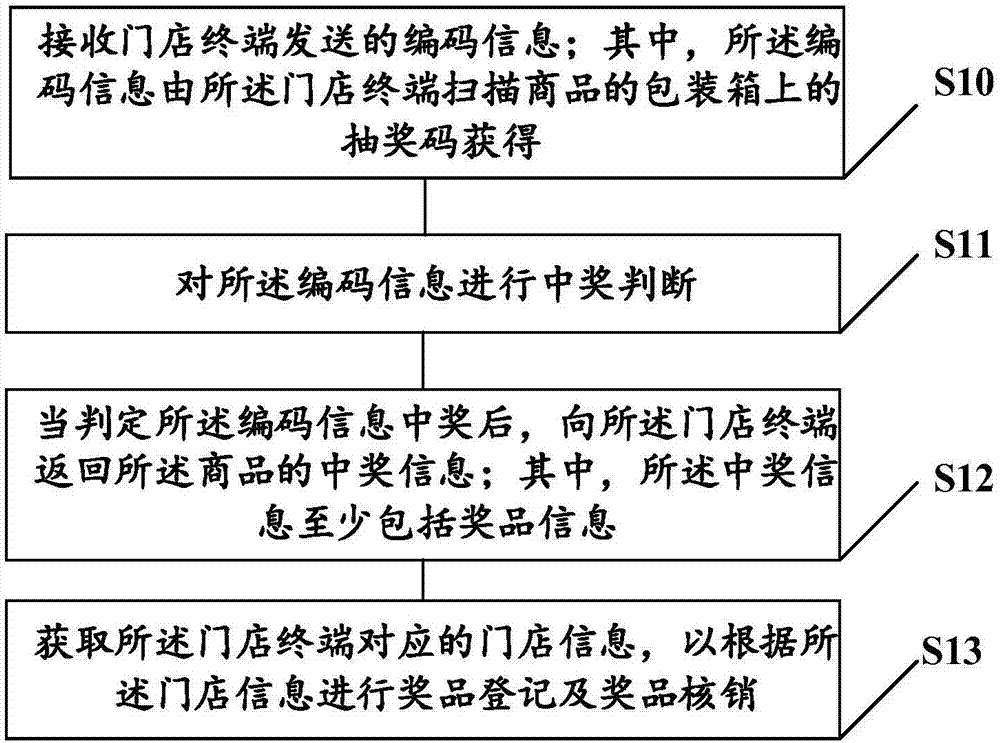

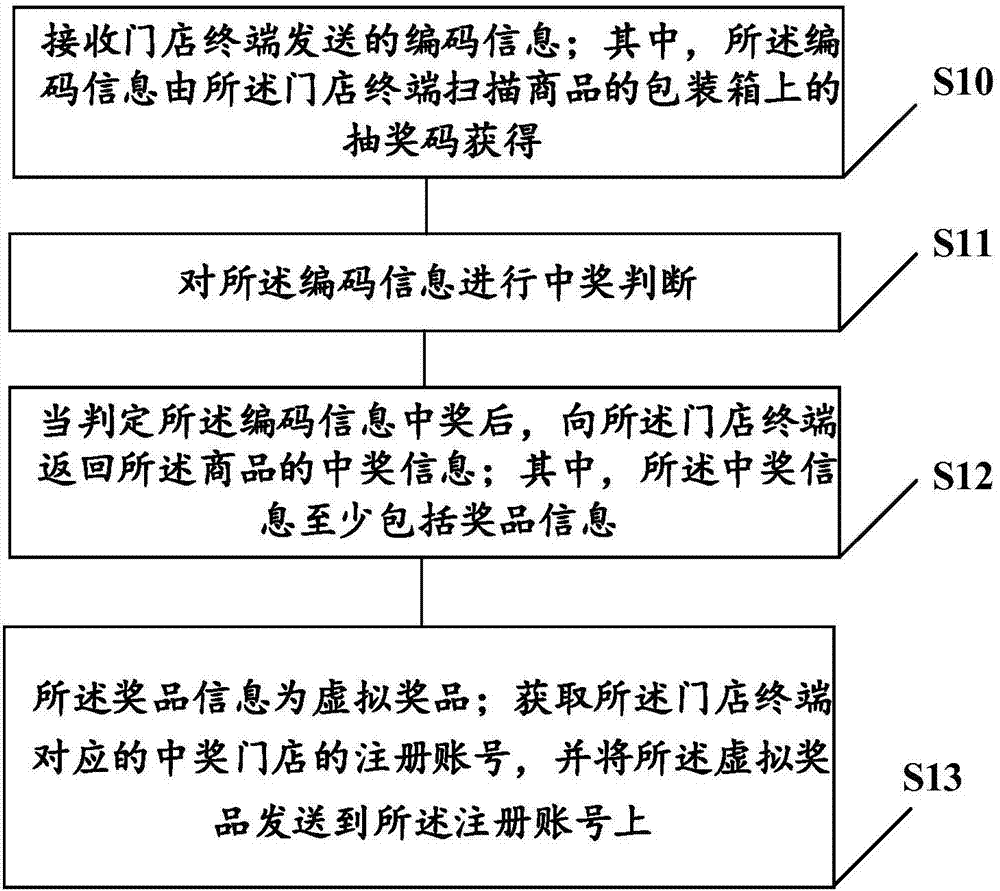

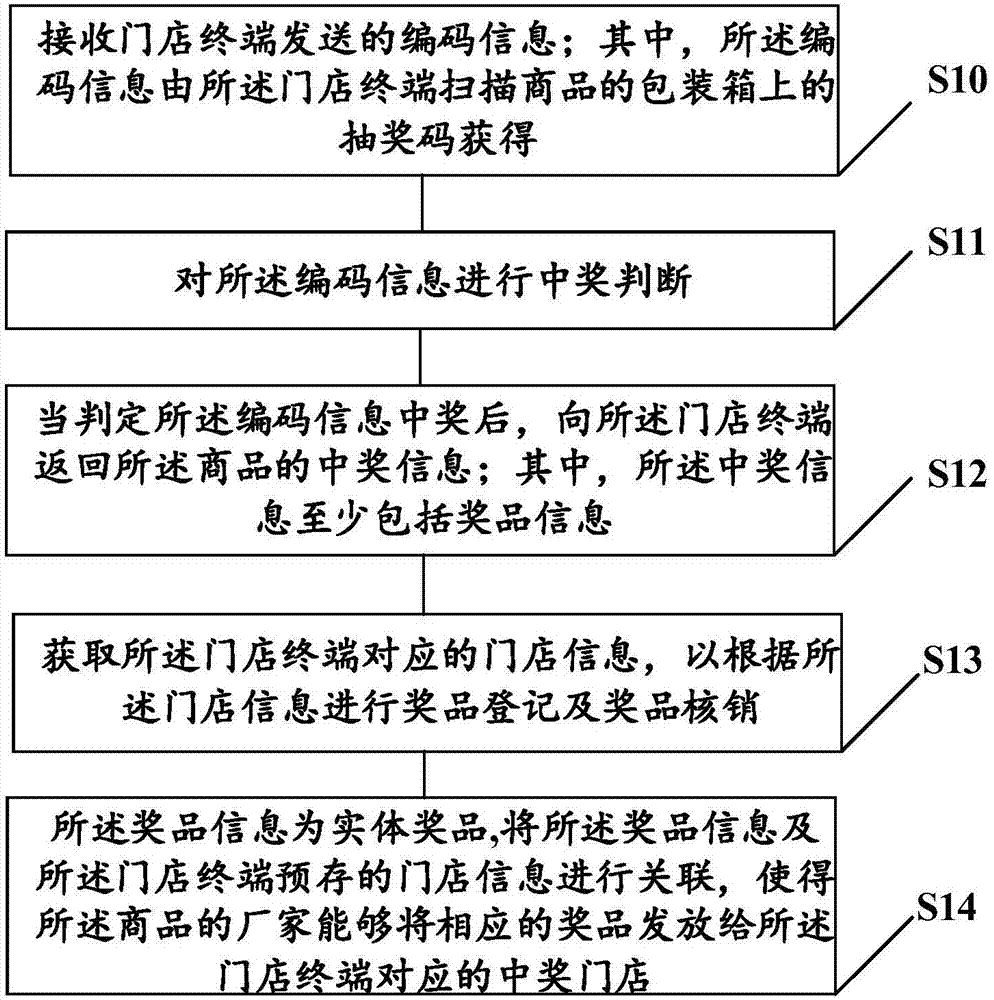

Winning prize registration and verification method, server and system

InactiveCN107545463AImprove safety and convenienceIncrease production and shipmentsMarketingComputer engineering

The invention discloses a prize registration and verification method, which comprises the following steps of receiving encoding information sent by a store terminal, wherein the encoding information is obtained by scanning a lottery code on a packing box of a commodity through the store terminal; carrying out winning judgment on the encoding information; after the encoding information is judged towin a prize, returning winning information of the commodity to the store terminal, wherein the winning information at least includes prize information; and obtaining store information corresponding to the store terminal in order to carry out prize registration and verification according to the store information. The invention discloses a prize registration and verification server and system, so that a manufacturer can carry out prize registration and verification on the prize, a cashing process is simplified and the cashing efficiency is improved.

Owner:广州基正投资有限公司

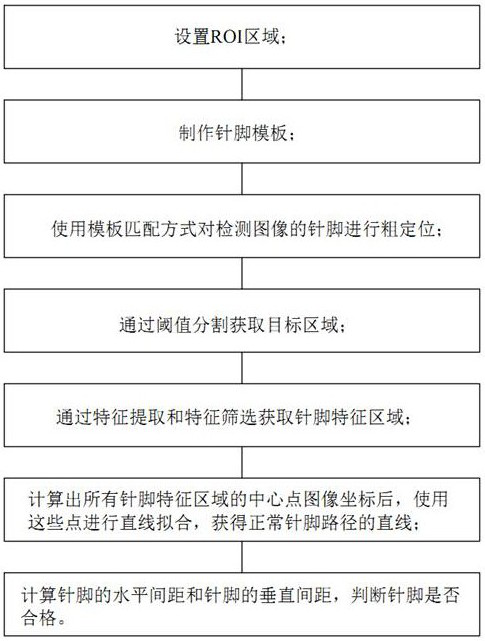

Visual inspection method for connector pins

InactiveCN114708262AHigh accuracy and stabilityLow costImage enhancementImage analysisAlgorithmTemplate match

The invention discloses a visual detection method for connector pins, and the method comprises a detection algorithm which comprises the following steps: 1, setting an ROI region; 2, a pin template is manufactured; step 3, performing coarse positioning on the pins of the detection image by using a template matching mode; 4, obtaining a target area through threshold segmentation; step 5, obtaining a pin feature region through feature extraction and feature screening; 6, after central point image coordinates of all the pin feature areas are calculated, straight line fitting is carried out by using the points, and a straight line of a normal pin path is obtained; and 7, calculating the horizontal distance and the vertical distance of the pins, and judging whether the pins are qualified or not. The beneficial effects of the invention lie in that the detection method can be used in cooperation with automatic equipment to rapidly detect products, the detection result is high in accuracy and stable, the shipment quantity of the products is greatly improved, and corresponding parameters can be adjusted according to the quality inspection standard of shipment requirements, and the shipment quality can be controlled.

Owner:深圳市海蓝智能科技有限公司

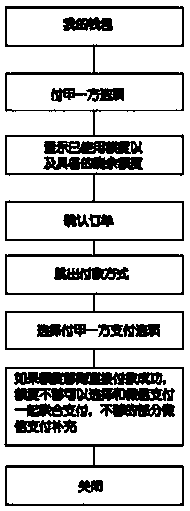

Transaction platform with no need for principal and transaction method thereof

InactiveCN107944974AFlexible transactionIncrease shipmentsBuying/selling/leasing transactionsProtocol authorisationPayment transactionFinancial transaction

The present invention discloses a transaction platform with no need for principal and a transaction method thereof. The transaction platform with no need for principal comprises a payment transactionplatform which has a non-principal purchasing mode, the non-principal purchasing mode mainly comprises a payment option of payment of a first party, and the payment transaction platform selects a payment option of payment of the first party to complete the non-principal transaction purchasing when the purchasing is performed. The transaction platform with no need for principal and the transactionmethod thereof can provide non-principal business transaction for merchants with no need for (excessive) preparation of funds to perform freight source purchase (buying), is flexible to transact, canincrease the sales quantity and can solve the problem of offline transaction outstanding accounts; and moreover, the transaction platform employs the mode combination technology to perform transactionso as to ensure turnover of capital of each merchant and perform maximum benefit solution of the outstanding account problem, and more business creation personnel utilize the least funds to create more values.

Owner:大维营科技(深圳)有限责任公司

Fragrant blend tea and preparation method

InactiveCN110100929AReasonable ratioAvoid physical burdenTea extractionAcute hyperglycaemiaVegetable oil

The embodiment of the invention provides fragrant blended tea and a preparation method. The blend tea is prepared from base tea liquid, a sweetening agent, brulee and prepared cheese. The fragrant blend tea contains the base tea liquid, the sweetening agent, the brulee and the prefabricated cheese and does not contain additives such as vegetable fat powder, hydrogenated vegetable oil and trans fatty acids which are harmful to the human body, the base tea liquid, the sweetening agent and the prefabricated cheese are reasonable in proportion, only a basic content of sugar and fat are provided, abody burden possibly generated due to too high sugar and fat is avoided, and the body burden does not exist after people drink the tea for a long time; the brulee is soft and smooth, heating or freezing can be conducted as needed, contrast is formed with the temperature of the base tea liquid, and the taste level and richness degree are increased. The risk of hyperglycemia and hyperlipidemia doesnot exist in long-term drinking. The preparation method is simple, selling is facilitated, the output volume is increased, and the workload of dispatching staff is reduced.

Owner:文彦然

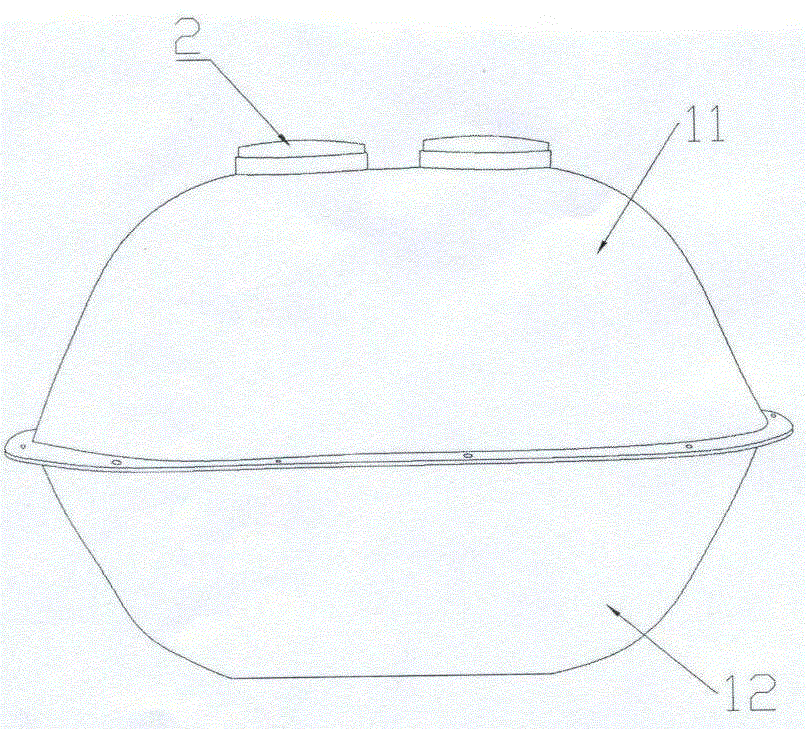

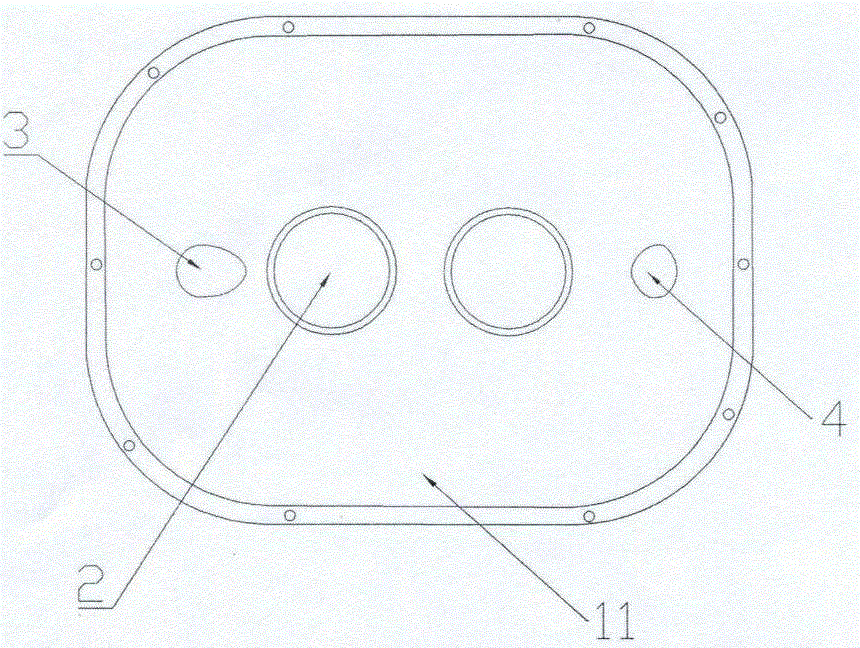

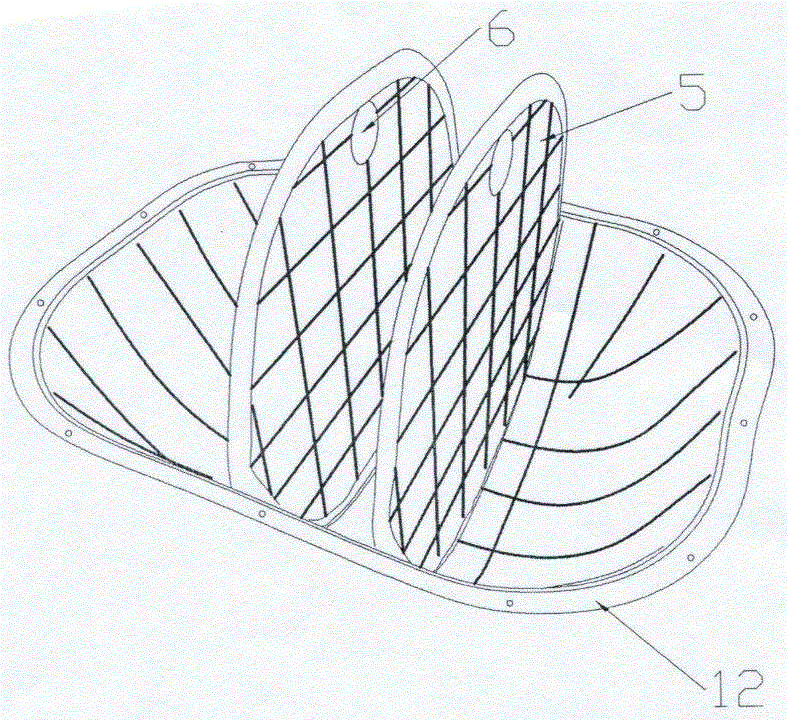

High-strength molded septic tank

InactiveCN106565068AIncrease shipmentsSimple structureTreatment with anaerobic digestion processesBiological sludge treatmentHigh densityHigh intensity

The invention relates to a high-strength molded septic tank. The high-strength molded septic tank comprises a shell, inspection residue outlets, a water inlet, a water outlet and separator plates arranged in the shell, every separator plate is provided with an opening, the shell comprises an upper shell and a lower shell, each of the upper shell and the lower shell is provided with a mounting edge, every mounting edge is provided with mounting holes used for bolt fastening, the upper shell and the lower shell are fixed and mounted through bolts to form an integral structure, the water inlet, the water outlet and the inspection residue outlets are arranged on the upper shell, and mounting slots used for fixing the separator plates are arranged in the lower shell. The high-strength molded septic tank adopting an SMC molding technology and a high temperature and high pressure forming technology has high density, has comparable strength with metal products, has smooth and clean surface, has no pores or joints, does not seep, and has light weight; the upper shell and the lower shell can be transported in a stacked manner, so the shipped quantity per truck is large, the septic tank is convenient to transport, and the transportation cost is saved; and the upper shell and the lower shell are connected through adopting glass cement (or a sealing ring) and the bolts, so the septic tank can be easily mounted in the construction field.

Owner:HENAN PENGXIANG MOLDING CO LTD

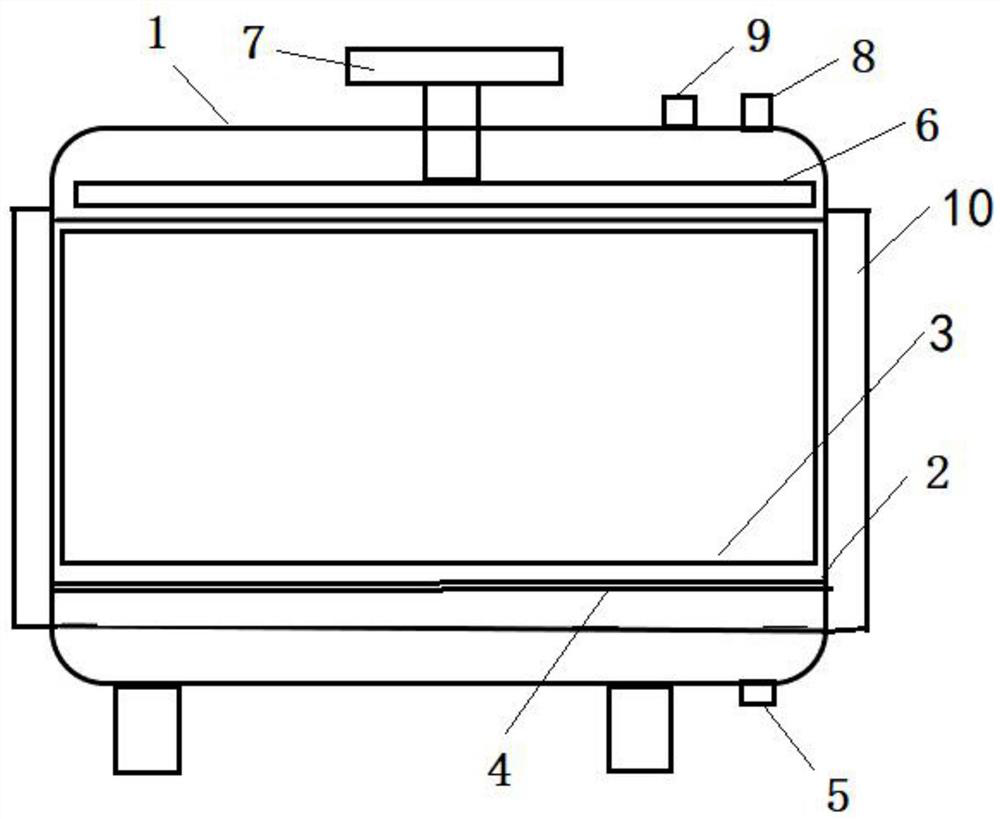

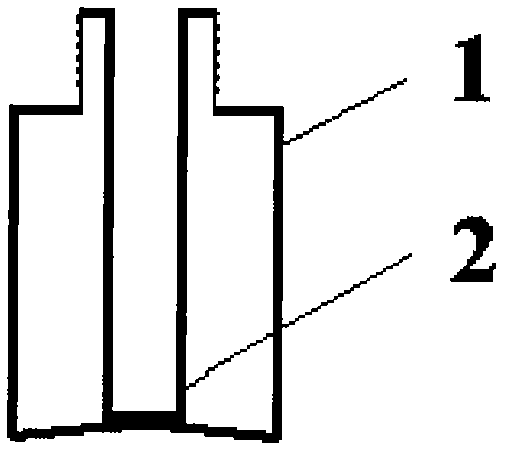

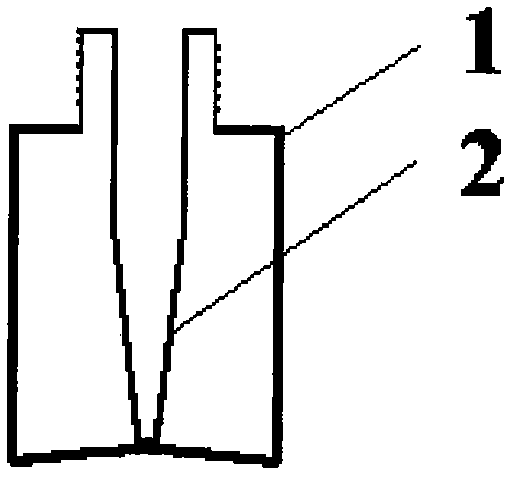

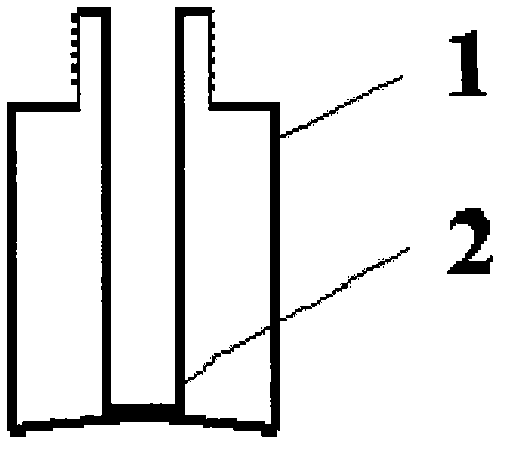

Metoclopramide nasal spray

InactiveCN103285470AReduced filling equipment requirementsIncrease shipmentsMedical atomisersMedicineMetoclopramide

The invention provides a metoclopramide nasal spray. A used spraying device comprises a spray bottle and a spray head, and is characterized in that the spray bottle comprises a casing (1) and a liner (2) with 3.0 ml volume; the liner of the spray bottle is in a shape of a cylinder, the combination of a cylinder and a conoidcone, or the combination of a cylinder, a conoidcone and a cylinder with a smaller diameter; the casing of the spray bottle is provided with the same shape, size and interface part with a spray bottle of a 10 ml spraying agent device sold in the market presently; and the spray head adopts a spray head of the 10 ml spraying agent device sold in the market presently. The metoclopramide nasal spray provided by the invention has the advantages of few residues, high safety and multiple times of effective spraying, the production cost can be reduced, and the medicine waste is prevented.

Owner:北京天衡药物研究院有限公司

Device for replacing dynamic gas lock online

ActiveCN111856887AIncrease shipmentsShorten the timePhotomechanical exposure apparatusMicrolithography exposure apparatusEngineeringMechanical engineering

The invention discloses a device for replacing a dynamic gas lock online, and the device comprises a buffering cavity which is used for temporarily storing a new dynamic gas lock connected from the exterior of a vacuum cavity under the isolation from the interior of the vacuum cavity, and temporarily storing an old dynamic gas lock fed from the interior of the vacuum cavity under the isolation from the exterior of the vacuum cavity; a conveying and loading and unloading mechanism which is used for accessing a new dynamic gas lock through the buffer cavity, conveying the new dynamic gas lock toa mounting point in the vacuum chamber for mounting, and conveying an old dynamic gas lock dismounted from the mounting point out of the vacuum cavity through the buffer cavity; and a sealing mechanism which is used for sealing a matching surface between the conveying and loading and unloading mechanism and the buffer cavity after one end part of the conveying, loading and unloading mechanism enters the buffer cavity. According to the invention, the dynamic gas lock can be replaced online in a non-stop manner, so that the time is greatly saved, and the shipment quantity of a photoetching machine is increased.

Owner:SHANGHAI INTEGRATED CIRCUIT RES & DEV CENT +1

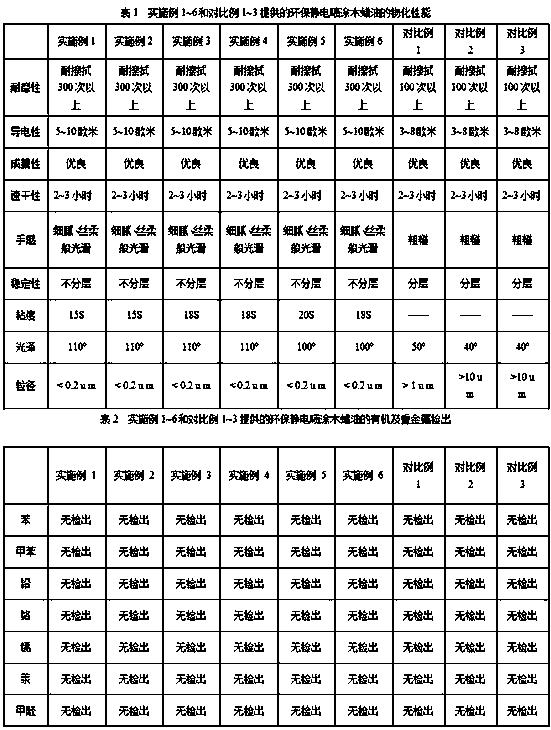

Environment-friendly electrostatic spraying wax oil as well as preparation method and application thereof

ActiveCN108753170AImprove conductivityImprove wear resistanceLiquid surface applicatorsWax coatingsEnvironmental resistanceSolvent based

The invention relates to environment-friendly electrostatic spraying wax oil as well as a preparation method and application thereof. The environment-friendly electrostatic spraying wax oil is prepared from the following components in parts by mass: 19 to 37 parts of an environment-friendly solvent, 15 to 20 parts of celluloid, 10 to 15 parts of maleic resin, 20 to 30 parts of blow castor oil, 20to 30 parts of linseed oil, 3 to 5 parts of carnauba wax, 3 to 5 parts of beewax and 1 to 2 parts of an electrostatic additive. According to the environment-friendly electrostatic spraying wax oil provided by the invention, the wax oil is applied to a wood product by a method of forming a film through electrostatic spraying; the electrostatic spraying has the advantages that on one hand, the quickdryness of the wax oil can be improved, and the actual drying speed can be increased by 50 percent, so that only 2 to 3 hours are spent from spraying to packaging, while common spraying wax oil or solvent type coating is generally packaged after 6 to 12 hours; on the other hand, the electrostatic spraying wax oil can save the labor and the cost and increase the shipment quantity of products, so that the wax oil has relatively high popularization and application value.

Owner:邱平亮 +1

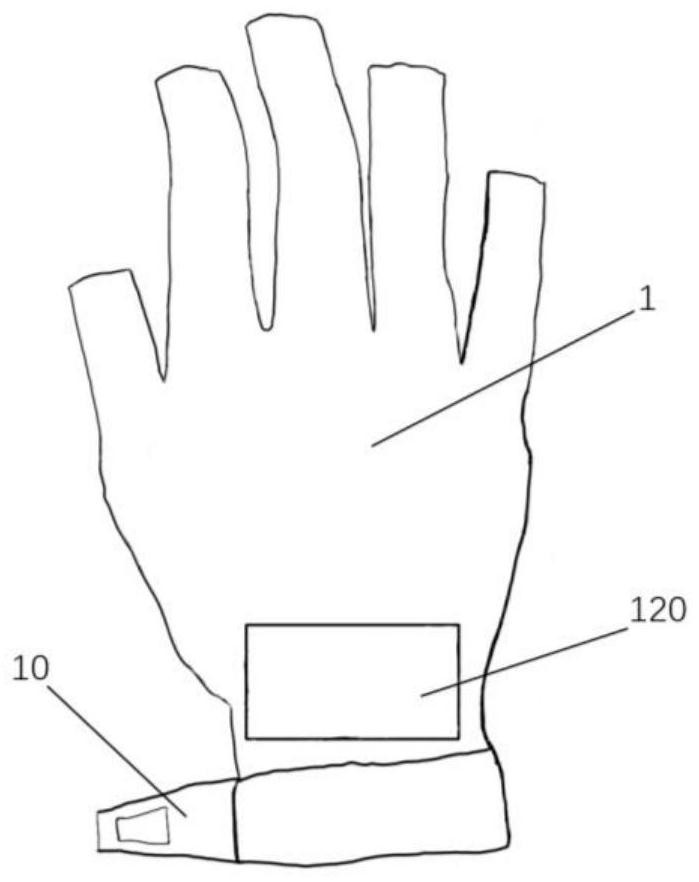

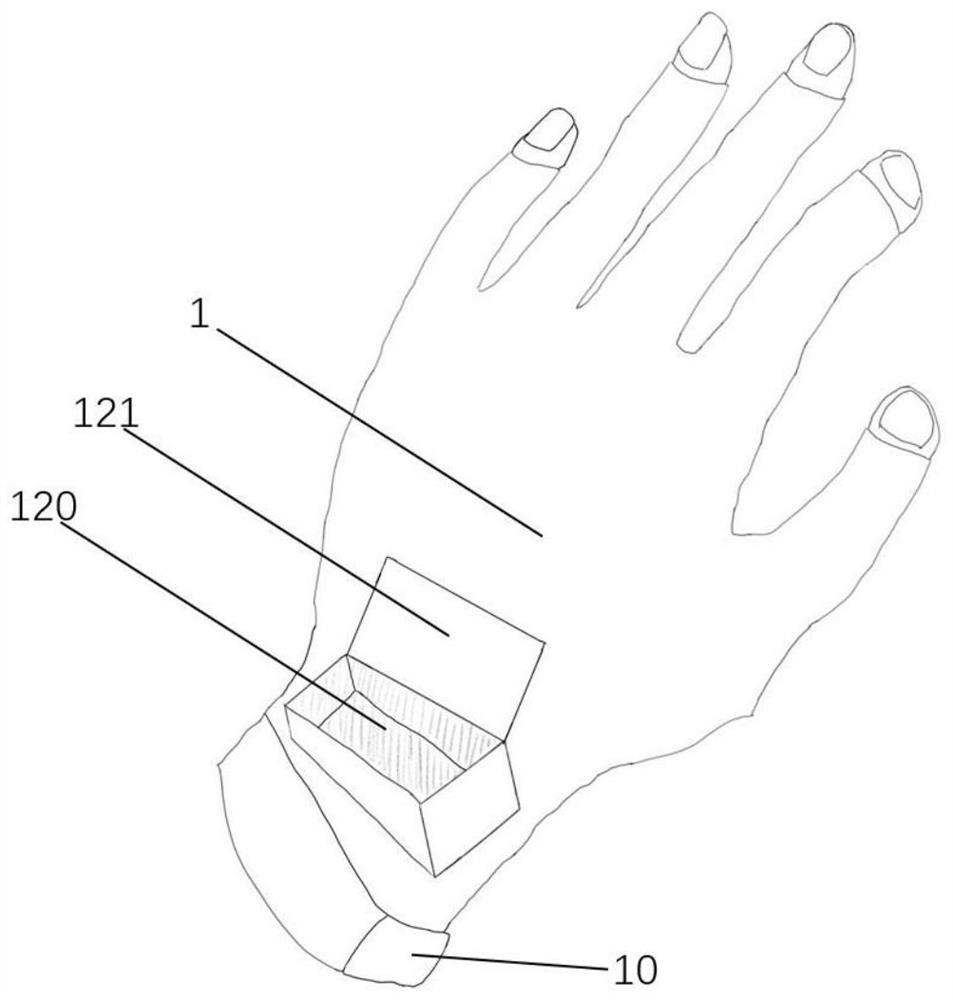

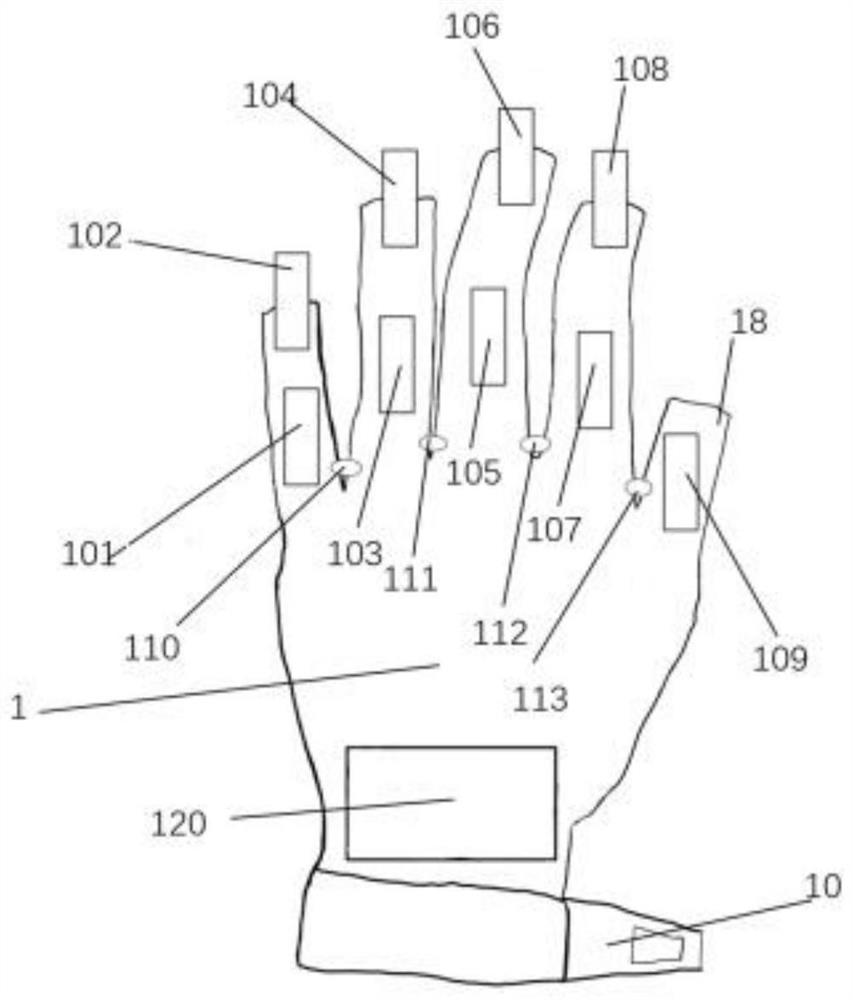

Comprehensive system glove capable of feeding back simultaneously

PendingCN113625875AHigh feasibilityLow costInput/output for user-computer interactionBody temperature measurementHand partsFinger-stall

The invention discloses a comprehensive VR system glove capable of achieving simultaneous feedback. The glove comprises a half-finger glove main body worn on a hand, a hand posture acquisition system arranged on the surface of the hand back part of the half-finger glove main body, an exoskeleton resistance system sleeving each fingertip, and a temperature / touch feedback system arranged on the half-finger glove main body and the exoskeleton resistance system. Each finger stall in the half-finger glove does not cover the fingertip, and each finger is exposed to the first joint from the fingertip.

Owner:SHENYANG POLYTECHNIC UNIV

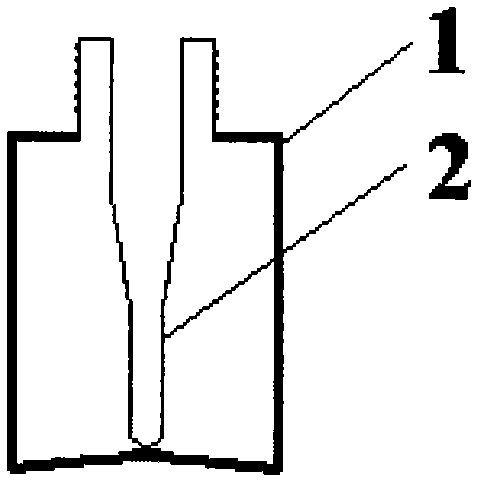

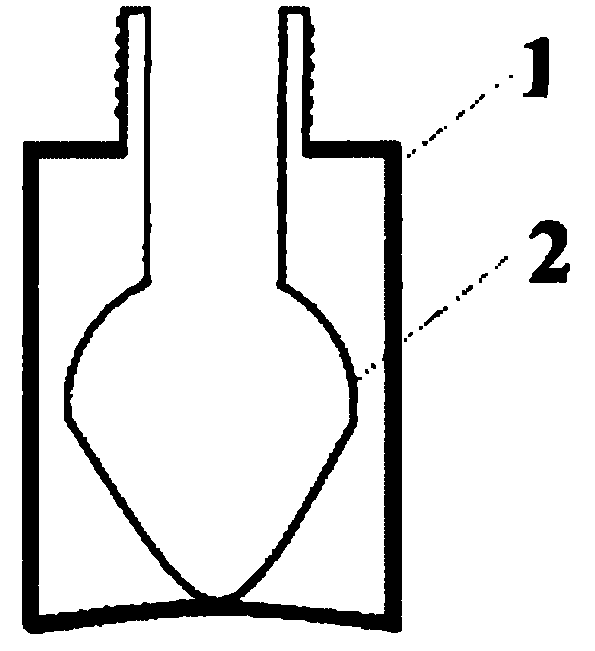

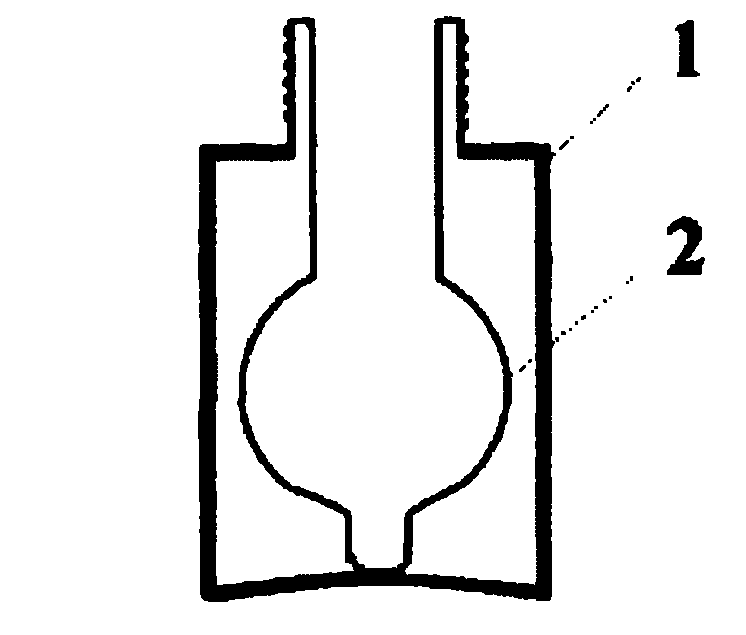

Oxytocin nasal spray

InactiveCN103285473AReduced filling equipment requirementsIncrease shipmentsPharmaceutical containersMedical packagingMedicineNasal spray

The invention provides an oxytocin nasal spray. A spraying device comprises a spraying bottle and a spraying head, and is characterized in that the spraying bottle comprises a casing (1) and a liner (2) with the volume of 6.0 ml; the liner of the spraying bottle is in a shape of a cylinder, the combination of a cylinder and an eggplant shape, or the combination of a cylinder, a sphere and a cylinder with a smaller diameter; the casing of the spraying bottle has the same appearance, size and connector part as those of a conventional 10 ml spray sold in the market; and the spraying head adopts a praying head of the conventional 10 ml spray sold in the market. The oxytocin nasal spray has the advantages of few residues, high safety and multiple effective spraying times, the production cost can be reduced, and the medicine waste is prevented.

Owner:北京天衡药物研究院有限公司

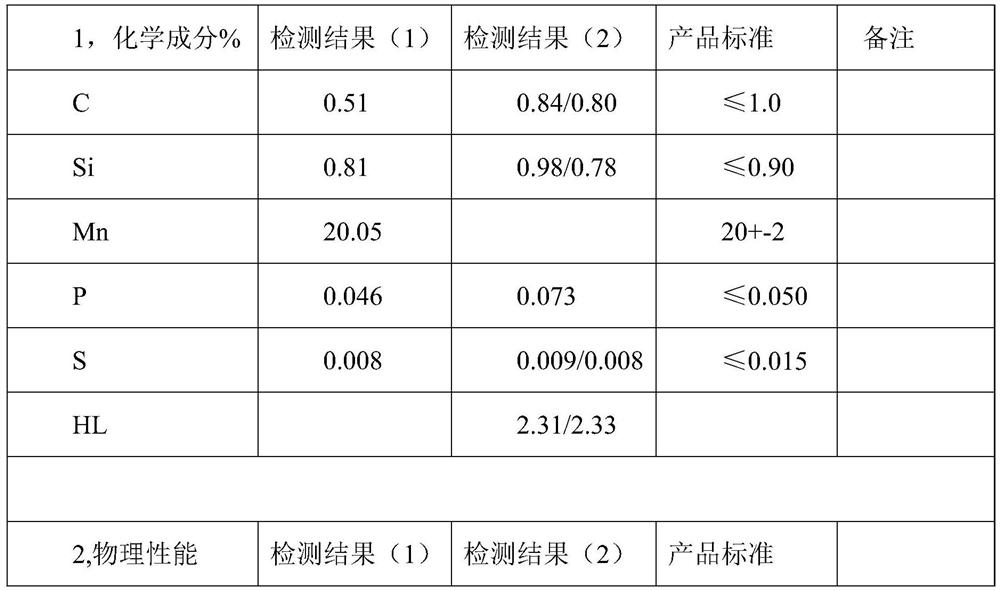

Method for manufacturing non-magnetic steel fine powder through water atomization

PendingCN114871437AImprove YieldIncrease shipmentsProcess efficiency improvementEconomic benefitsProcess engineering

The invention belongs to the technical field of non-magnetic steel materials, and particularly relates to a water atomization non-magnetic steel fine powder manufacturing method which comprises the following steps: step 1, market investigation: firstly analyzing market prospects, determining necessity of market investigation, analyzing market at the present stage, analyzing demand space of the current market, and investigating production conditions at the present stage; investigating and surveying product manufacturers of the same type, sorting and analyzing investigation and surveying data, and writing an investigation and surveying report; 2, designing a production scale according to an investigation report written according to a market investigation result, including selection of an address, establishment of an independent assembly line and formulation of a production shift changing system; step 3, formulating a production standard of the product; and 4, production process design including smelting, atomization, dehydration, drying, crushing and screening and warehousing preservation is conducted, the structure is reasonable, in the production process, the production efficiency is improved, the shipment amount is increased, the production cost is reduced, and economic benefits are high.

Owner:辽宁晟钰新材料科技有限公司

Semi-automatic detection assembly line of starting motor electromagnetic switch

The present invention relates to the production field of a starting motor electromagnetic switch. A semi-automatic detection assembly line comprises a central control mechanism, and a transmission mechanism, an airtightness test box, a hook size test box, an additional stroke test box, a pull-in and release voltage test box, a coil current balance test box, a contact voltage drop and running-in measurement test box and a withstand voltage test box which are controlled and driven by the central control mechanism. The detection box bodies in the semi-automatic detection assembly line are arranged orderly along a first conveyer belt, at detection, a tooling positioning platform is manually pushed to convey along the first conveyer belt, and the data is detected orderly. By an assembly line detection mode, the detection efficiency is improved substantially, the enterprise yield is improved, and the enterprise cost is reduced.

Owner:宁波铭富汽车零部件有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com