Semi-automatic detection assembly line of starting motor electromagnetic switch

An electromagnetic switch, semi-automatic technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of low detection efficiency, transfer and disassembly time occupation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The preferred embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

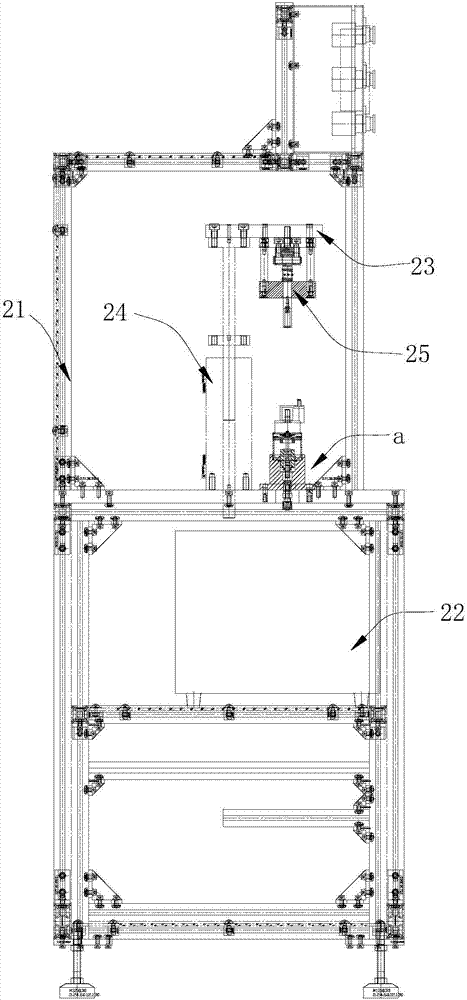

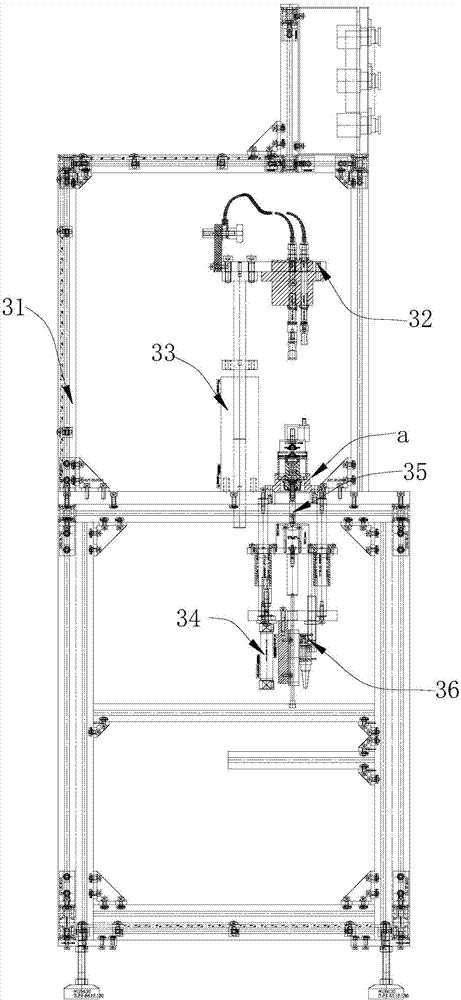

[0023] Such as Figure 1~8 The shown semi-automatic detection assembly line for the electromagnetic switch of the starter motor includes a central control mechanism, a transmission mechanism controlled and driven by the central control mechanism, an air tightness test box 2, a hook size test box 3, an additional stroke test box 4, a suction Closing and release voltage test box 5, coil current balance test box 6, contact drop and run-in test box 7 and withstand voltage test box 8. The transmission mechanism includes a first transmission belt 11 and a second transmission belt 12 , and a tool positioning platform 13 that is moved on the first transmission belt 11 and the second transmission belt 12 . The second conveyor belt 12 is below the first conveyor belt 11, and the starting end of the second conveyor belt 12 is received on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com