Method for preparing sauced radish by fermentation

A technology for sauced radish and radish, which is applied in the field of preparing sauced radish by fermentation, can solve the problems of loss of viable bacteria, increase cost, and be difficult to preserve, and achieve the effects of low water content, reduced processing cost, and beneficial protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

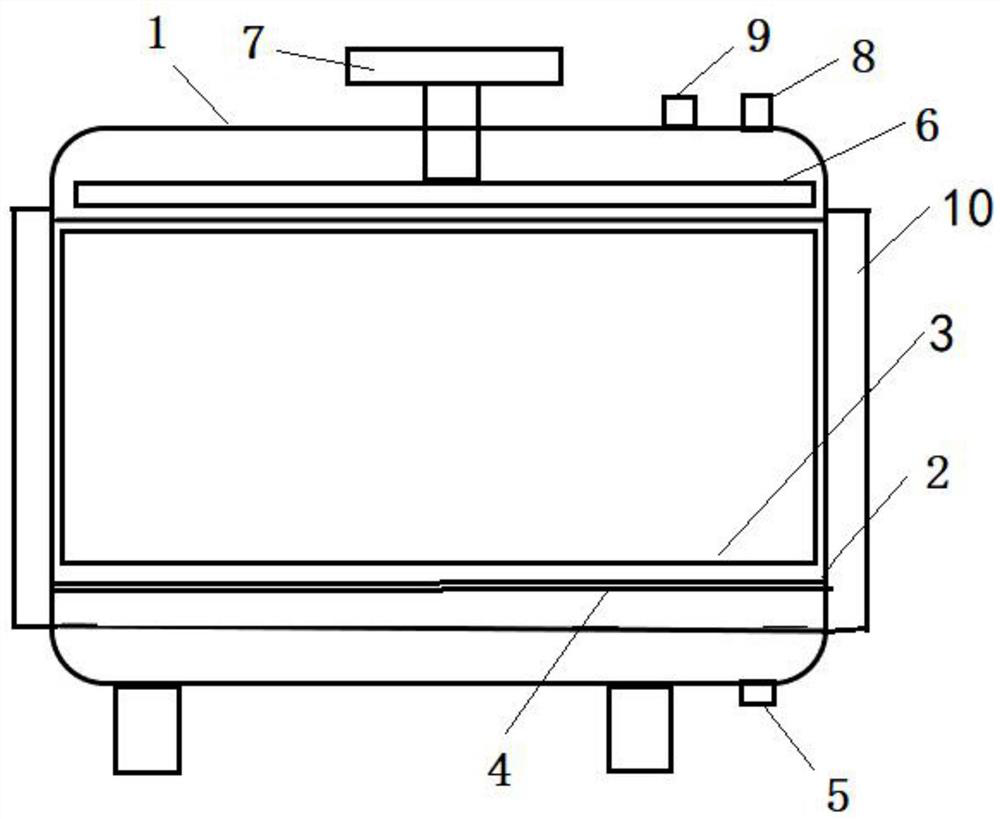

Image

Examples

Embodiment 1

[0035] A method for preparing pickled radish by fermentation, comprising the following steps:

[0036] (1) Pretreatment: Wash the radish and cut it into small pieces or strips, and dry it with hot air at a certain temperature and humidity until the moisture content of the radish is 60%, to obtain semi-dried radish. The temperature of the hot air is 50°C and the humidity is 20%; 100kg of fresh white radish can process 25kg of semi-dried radish with a water content of 60%.

[0037] (2) Mixing: get 0.01% bacterial powder of semi-dry radish weight, then add 20 times of cold boiled water to dissolve the bacterial powder, and take 15% soy sauce of semi-dry radish weight, soy sauce is no preservative, salt content Add about 16% low-salt solid-state fermented soy sauce to the dried radish in step (1), stir and mix until the liquid is completely absorbed by the radish; that is, weigh 2.5g of lactic acid bacteria powder for 25kg of semi-dried radish, and dissolve it in 50ml of water. S...

Embodiment 2

[0045] A method for preparing pickled radish by fermentation, comprising the following steps:

[0046] (1) Pretreatment: Wash the radish and cut it into small pieces or strips, and dry it with hot air at a certain temperature and humidity until the moisture content of the radish is 70%, to obtain semi-dried radish. The temperature of the hot air is 60°C and the humidity is 25%;

[0047] (2) Mixing: get 0.03% bacterium powder of semi-dry radish weight, then add 20 times of cold boiled water to dissolve the bacterium powder, and take by weighing 15-20% soy sauce of semi-dry radish weight, soy sauce is no preservative, contains Low-salt solid-state fermented soy sauce with a salt content of about 16%, is added to the dried radish in step (1), and fully stirred and mixed until the liquid is completely absorbed by the radish;

[0048] Bacteria powder is Lactobacillus weisnerii, Leuconostoc enterococci, Lactobacillus plantarum, Lactococcus lactis, Lactobacillus acidophilus, Lactoba...

Embodiment 3

[0055] A method for preparing pickled radish by fermentation, comprising the following steps:

[0056] (1) Pre-treatment: Cut the washed radish into about 15×12×12 mm in size, and dry it with hot air at 50° C. and 20% humidity until the water content of the diced radish is between 65% to obtain semi-dried radish.

[0057] (2) Mixing material: Lactobacillus weisnerii, Leuconostoc enterococci, Lactobacillus plantarum, Lactococcus lactis, Lactobacillus acidophilus, Lactobacillus brevis, Lactobacillus pentosus and cheese isolated from traditional fermented vegetables are selected. One or more mixed strains of Lactobacillus and the like are fermented strains. 1 ton of vegetables can be fermented per 100g of direct-sprayed bacterial powder. Dissolve 100g of fermented bacterial powder with 2kg of cold boiled water before use. Choose low-salt solid fermented soy sauce with no preservatives and a salt content of about 16%.

[0058] Add 1000kg of air-dried diced radish to 150-200kg of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com