High-strength molded septic tank

A high-strength, septic tank technology, used in anaerobic digestion treatment, biological sludge treatment, etc., can solve the problems of low-pollution drinking water sources and urban underground water supply pipelines, being susceptible to climate influence, and occupying a large space. Save transportation costs, easy to promote and implement, and the effect of large shipments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

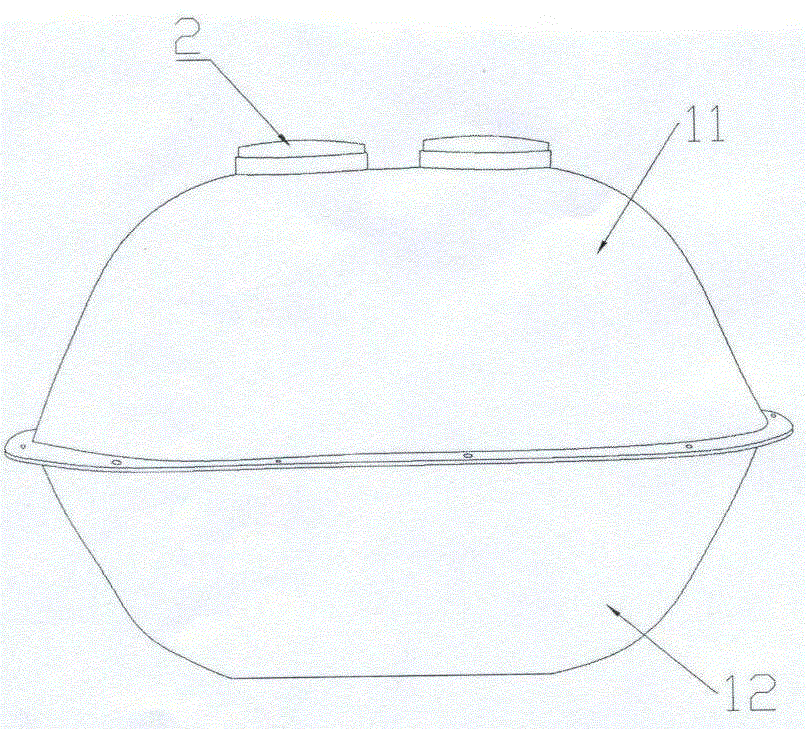

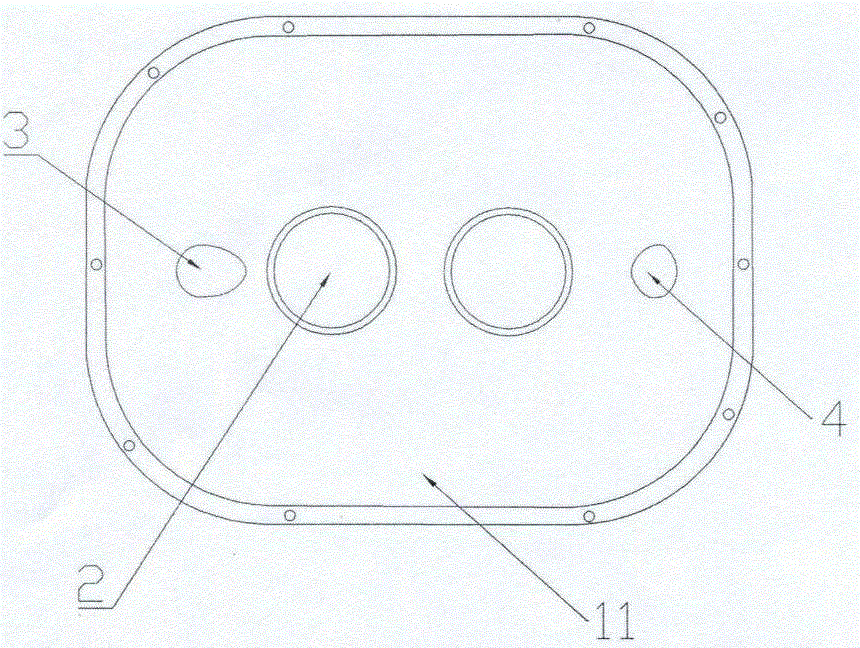

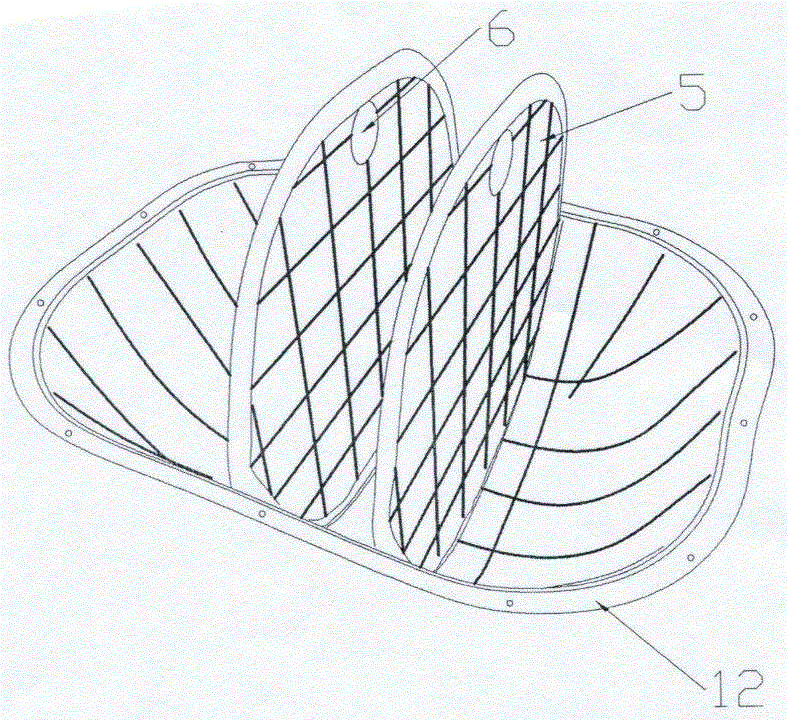

[0016] Embodiment one: see Figure 1~3 As shown, a high-strength molded septic tank includes a shell, an inspection slag outlet, a water inlet, a water outlet, and a partition arranged in the casing. The partition is provided with a flow hole, and the casing It includes an upper shell and a lower shell, the upper shell and the lower shell are provided with mounting flanges, and the mounting flanges are provided with mounting holes for bolt fastening, and the upper shell and the lower shell are connected by bolts. The fixed installation is an integrated structure. The water inlet, water outlet and inspection slag outlet are all set on the upper shell, and the lower shell is provided with an installation groove for fixing the partition plate. It is high-strength, durable and not easy to deform. Hand-laid glass fiber reinforced plastic septic tank It is easily deformed due to the limitation of the process; the unique stackable design of the upper and lower shells can be stacked m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com