Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

55results about How to "Improves reversion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

All-steel radial tire combined rubber compound for improving shoulder separation and tread separation

ActiveCN107722379AHigh modulusReduce dynamic heatingSpecial tyresRolling resistance optimizationAging resistanceSulfur

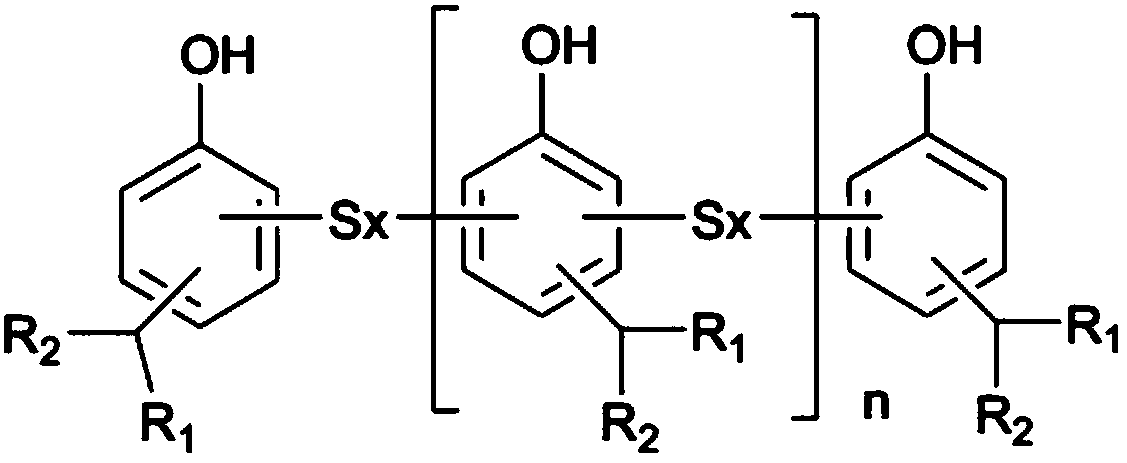

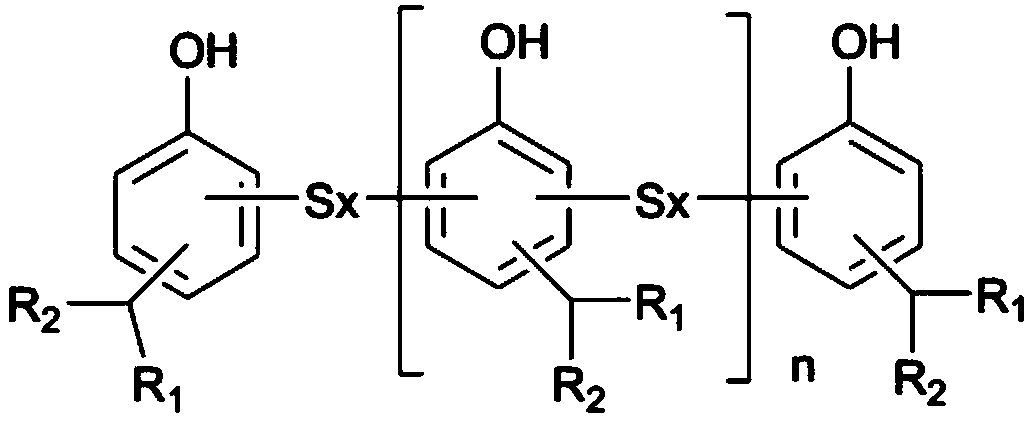

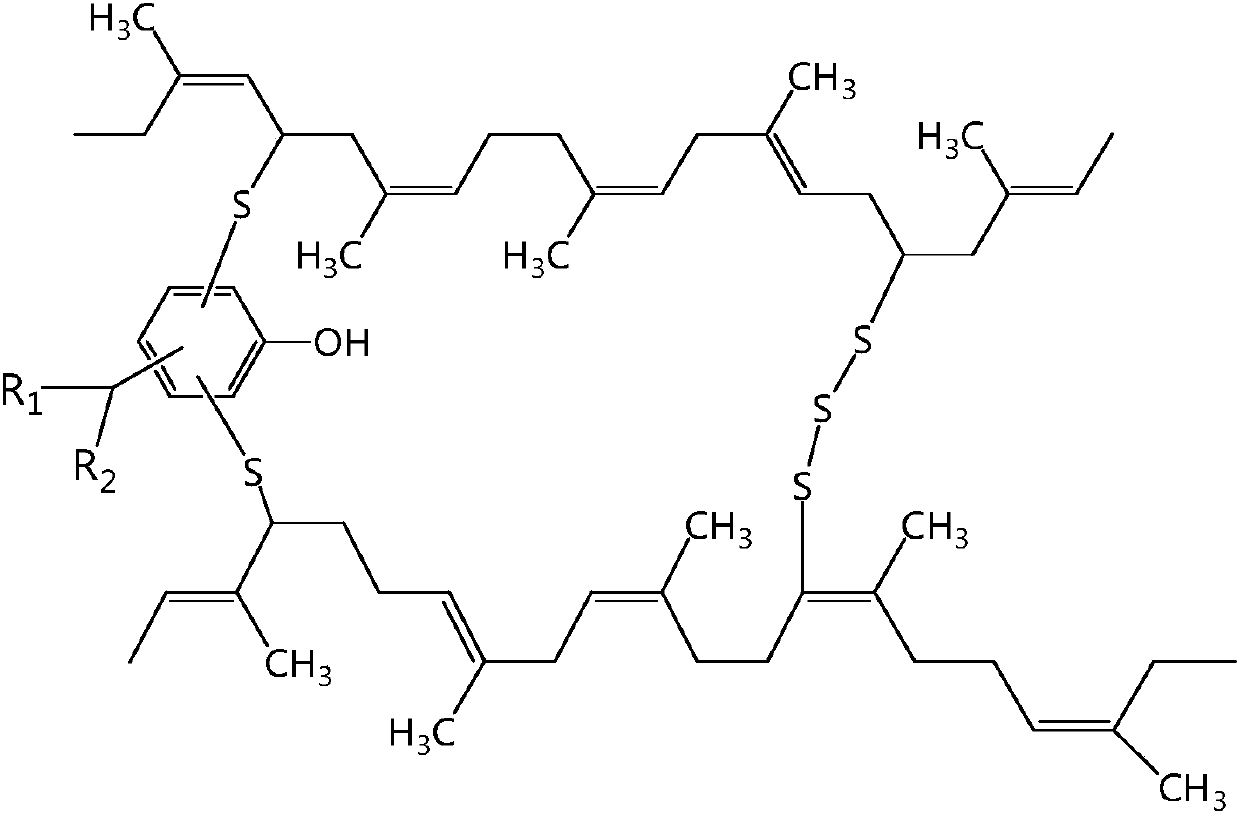

The invention discloses an all-steel radial tire combined rubber compound for improving shoulder separation and tread separation. The all-steel radial tire combined rubber compound is respectively used for preparing shoulder pad rubber and base part rubber. The all-steel radial tire combined rubber compound comprises, by weight, 80.0-100.0 parts of natural rubber, 0-20.0 parts of cis-polybutadienerubber, 15.0-45.0 parts of carbon black, 8.0-15.0 parts of white carbon black, 3.0-6.0 parts of zinc oxide, 1.0-3.5 parts of an activator stearic acid, 1.0-2.0 parts of a carbon black dispersant, 0.5-2.0 parts of an antioxidant RD, 1.0-2.5 parts of an antioxidant 4020, 1.3-3.8 parts of a silane coupling agent, 1.5-3.0 parts of insoluble sulfur IS7020, 0.8-1.8 parts of an accelerator NS, 0.1-0.3 part of a scorch retarder and 0.5-2.0 parts of alkyl phenol disulfide. The above formula rubber compound has a high modulus at a given elongation, so the deformation of a tire under the same load is reduced, thereby heat generated by compression deformation and curling is reduced; and the rubber compound has the advantages of low dynamic heat, good aging resistance, improvement of the long-time high load driving resistance of the tire, and effective reduction of the shoulder separation, tread separation and other symptoms.

Owner:SAILUN GRP CO LTD

Flame-retardant sealing ring for motors of range hoods

The invention discloses a flame-retardant sealing ring for motors of range hoods. The flame-retardant sealing ring is made from raw materials including nitrile rubber, zinc oxide, stearic acid, carbon black, white carbon black, sulphur powder, an accelerant CZ, an accelerant M, an accelerant TMTD, ETU-80, light magnesium oxide, pottery clay, chloroprene rubber adhesive, aluminum hydroxide, a silane coupling agent, zinc borate, antimonous oxide, modified flame retardant, dioctyl phthalate, carnauba wax, antiager 2246, antiager BZ and a processing agent WB-16. The flame-retardant sealing ring is good in high-temperature resistance and flame retardant performance, and meanwhile has the advantages of oil resistance, no halogen, low toxicity and environment friendliness.

Owner:NINGGUO ZOYE PLASTIC & RUBBER CO LTD

Flame-retardant ageing-resistant sealing ring rubber material

The invention discloses a flame-retardant ageing-resistant sealing ring rubber material which comprises the following raw materials in parts by weight: 80-100 parts of natural rubber, 20-40 parts of butadiene styrene rubber, 10-30 parts of ethylene propylene diene monomer, 10-30 parts of a phosphate modified polyurethane elastomer, 2-4 parts of dicumyl peroxide, 0.5-1 part of sulfur, 1-3 parts of an accelerant DM, 2-4 parts of an accelerant TAIC, 3-8 parts of zinc oxide, 1-3 parts of stearic acid, 6-10 parts of carbon black N660, 5-10 parts of titanium dioxide, 2-5 parts of quartz powder, 10-18 parts of calcite in powder, 6-15 parts of opal powder, 1-4 parts of a silane coupling agent, 2-8 parts of zinc borate, 1-4 parts of melamine, 1-2 parts of an anti-aging agent 4010NA, 2-4 parts of an anti-aging agent MB and 1-3 parts of an anti-aging agent AW. The rubber material disclosed by the invention has good flame-retardant property, ageing resistance and excellent weather resistance.

Owner:天长市康宁甘油科技有限公司

Low-temperature-resistant and aging-resistant chloroprene rubber composite material

The invention discloses a low temperature-resistant and aging-resistant chloroprene rubber composite material. The low temperature-resistant and aging-resistant chloroprene rubber composite material is prepared from the following raw materials: chloroprene rubber, natural rubber, butadiene rubber, styrene-isoprene segmented copolymer rubber, polybutylene terephthalate, maleic acid grafted modified natural rubber, nano zinc oxide, nano magnesium oxide, stearic acid, 2,5-dimethyl-2,5-di-tertiary-butyl peroxide hexane, trithiocyanuric acid, triallyl trimellitate, nano silica, precipitated silica, purple carbon black, nano microcrystalline cellulose, silane coupling agent KH-550 modified montmorillonoid, an anti-aging agent, an accelerant NA-22, an accelerant TE, an accelerant ZIP, vinyl tri(beta-methoxyl ethyoxyl) silane, dioctyl azelate, dioctyl sebacate and a titanate coupling agent NDZ-201. The low temperature-resistant and aging-resistant chloroprene rubber composite material disclosed by the invention has the advantages of high strength, good low temperature resistance and excellent aging resistance.

Owner:扬州市兴安橡塑制品有限公司

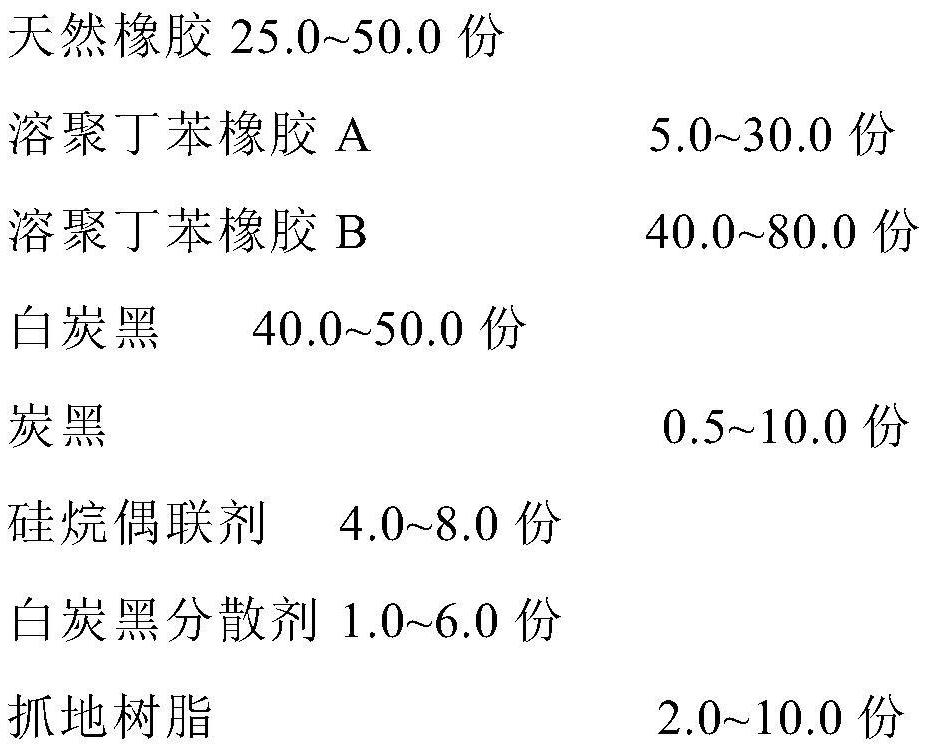

A kind of low filling high performance tire tread compound and tire

ActiveCN109251379BHigh strengthImprove thermal stabilitySpecial tyresRolling resistance optimizationRubber materialPolymer science

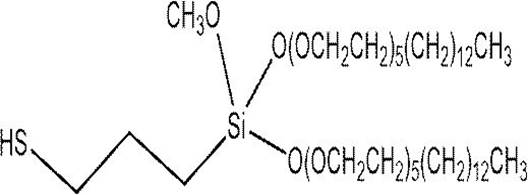

The invention belongs to the field of manufacturing of rubber tires, and relates to a low-filling high-performance tire tread rubber material and a tire, wherein the tire tread rubber material is formed by mixing the following raw materials by weight: 25.0-50.0 parts of natural rubber, 5.0-30.0 parts of a solution polymerized styrene-butadiene rubber A, 40.0-80.0 parts of a solution polymerized styrene-butadiene rubber B, 40.0-50.0 parts of white carbon black, 0.5-10.0 parts of carbon black, 4.0-10.0 parts of a silane coupling agent, 1.0-6.0 parts of a white carbon black dispersing agent, 2.0-10.0 parts of a road-holding resin, and 0.5-3.0 parts of an anti-reversion agent. According to the present invention, the tire tread rubber material uses a large amount of the natural rubber, is lessfilled with the filler, such that the high tensile strength and the high elongation at break can be achieved, the requirements of low rolling resistance and high wet gripping of the tire can be met, and the rolling resistance and the wet road-holding ability can meet the Class B stipulated by the EU Tire Labeling Regulation.

Owner:ZHONGCE RUBBER GRP CO LTD

Abrasion-resistant base compound for solid tyres of crane cars

The invention belongs to the technical field of rubber production, and particularly relates to an abrasion-resistant base compound for solid tyres of crane cars. The abrasion-resistant base compound for the solid tyres of the crane cars comprises raw materials in parts by weight as follows: natural rubber, liquid polybutadiene rubber, carbon black N234, white carbon black, a silicon coupling agent, poly-2,3,4-trimethyl-1,2-dihydroquinoline, N-(1,3-dimethyl)-N'-phenyl-p-phenylenediamine, zinc oxide, zinc stearate, N-tert-butylbenzothiazole-2-sulfenamide, tetramethyl-thiuram sulfide, sulfur, N-cyclohexylthiophthalimide and polyamide fibers. The base compound has the higher modulus and the good abrasion resistance, and meanwhile, the base compound is better in reversion resistance and low in hysteresis loss.

Owner:SHANDONG YONGTAI CHEM GROUP

Anti-aging cable with excellent toughness

The invention discloses an anti-aging cable with excellent toughness. The cable comprises a conductor and a sheath layer which coats the outer side of the conductor, wherein the sheath layer comprises the following raw materials in parts by weight: 25-45 parts of ethylene-propylene-diene-terpolymer rubber, 16-22 parts of EVA (ethylene-vinyl acetate copolymer) resin, 10-20 parts of natural rubber, 3-7 parts of nanometer hydroxyapatite micromist, 8-16 parts of kieselguhr, 15-25 parts of saw dust powder, 4-6 parts of ammonium polyphosphate, 16-20 parts of turf powder, 4-8 parts of sea-foam stone powder, 2-4 parts of yttrium oxide, 10-20 parts of composite microsphere, 4-8 parts of microcrystalline fiber, 4-6 parts of magnesium oxide, 2-4 parts of zinc oxide, 2-6 parts of tetrabutylammonium bromide, 2-4 parts of pentaerythritol ester, 12-16 parts of dimethyl mercaptopropionic acid isooctyl ester tin, 30-35 parts of tricresyl phosphate, 2-4 parts of zinc-ethylphenyl dithiocarbamate, 2-5 parts of dicumyl peroxide, 1.5-2.5 parts of antiager H and 1-1.8 parts of antiager D.

Owner:JINYUAN ELECTRIC GRP

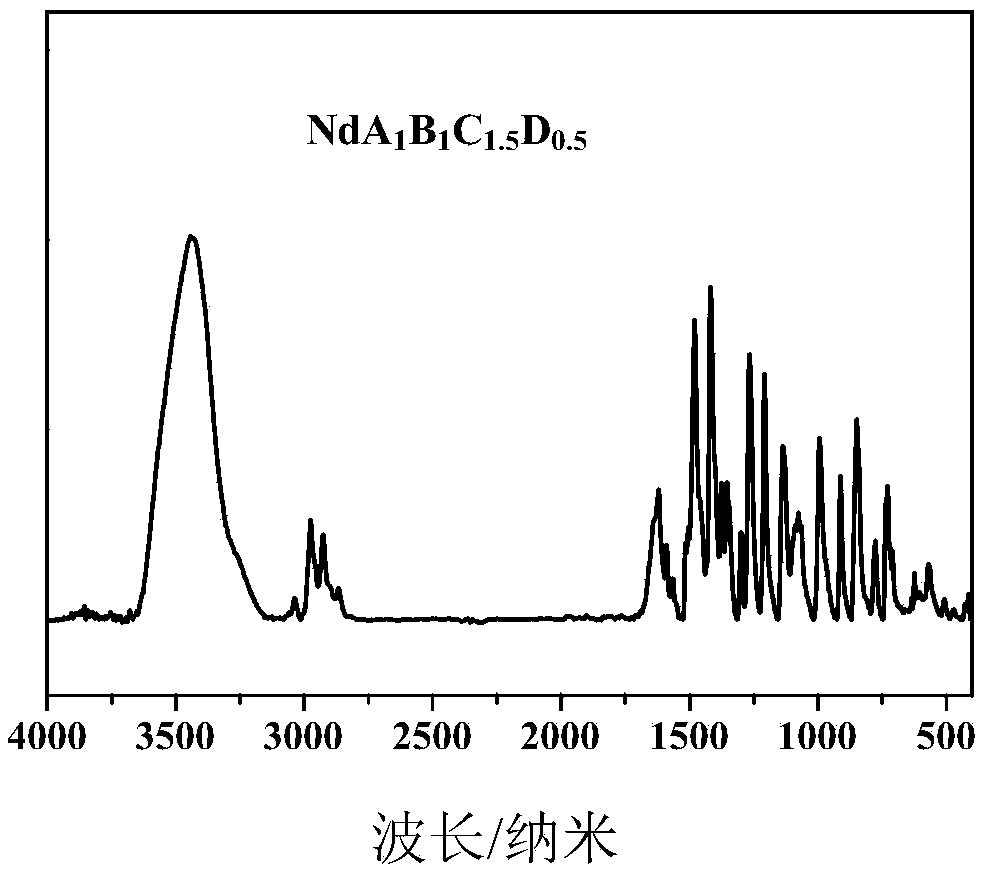

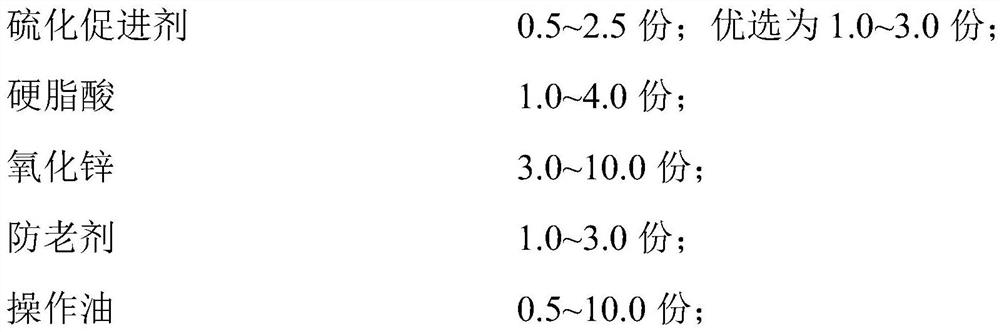

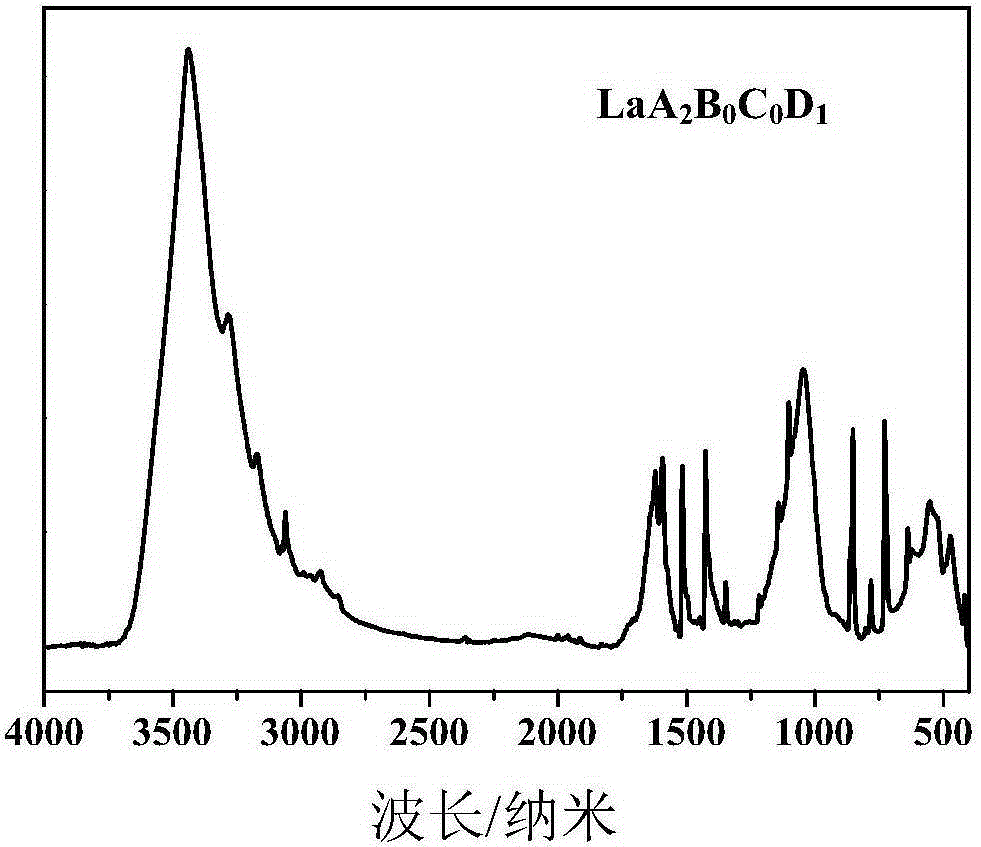

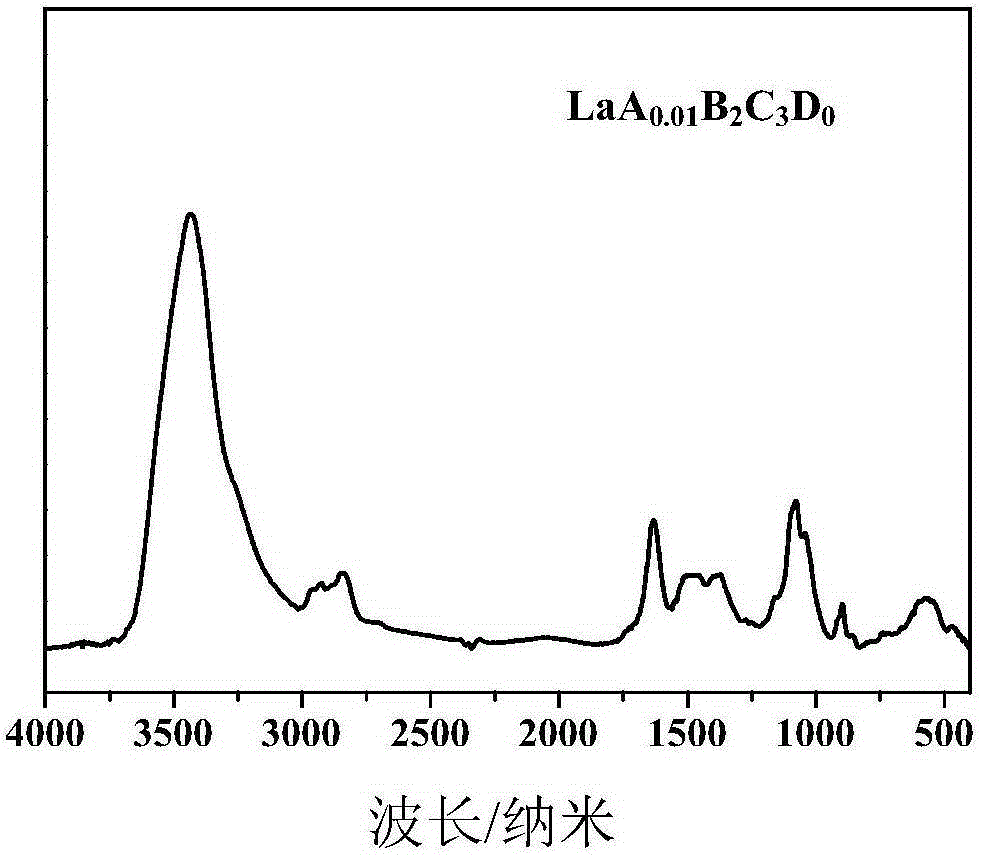

Preparation method of Nd-based multi-ligand vulcanization accelerator

ActiveCN103819716ABest promotion effectReduce dosageGroup 3/13 element organic compoundsRare-earth elementChemistry

The invention discloses an Nd-based multi-ligand vulcanization accelerator and a preparation method thereof. In synthesis, an Nd element is used as a rare earth element, and four ligands are contained; the ligand 1 and the ligand 2 are accelerator radicals with good vulcanization acceleration effects, the ligand 3 is phenanthroline capable of forming strong coordination with the rare earth element, and the ligand 4 is acrylic acid capable of improving the solubility of the accelerator in a sizing material. The preparation method is simple, convenient and feasible, does not need inert gas shielding, is mild in preparation process condition, and has no harmful gas generation. The multi-ligand rare earth vulcanization accelerator has good solubility in rubber, and is long in vulcanization and scorching time, good in vulcanization curve flatness, non-toxic, odorless and pollution-free. The vulcanization accelerator can replace a currently used zinc oxide, stearic acid and accelerator combination system, and is applicable to high performance tires and other rubber products.

Owner:BEIJING UNIV OF CHEM TECH

Abrasion-resistant base compound for solid tyres of heavy trucks

The invention belongs to the technical field of rubber production, and particularly relates to an abrasion-resistant base compound for solid tyres of heavy trucks. The abrasion-resistant base compound for the solid tyres of the heavy trucks comprises raw materials in parts by weight as follows: natural rubber, carbon black N339, aromatic oil, poly-2,3,4-trimethyl-1,2-dihydroquinoline, N-(1,3-dimethyl)-N'-phenyl-p-phenylenediamine, zinc stearate, N-tert-butylbenzothiazole-2-sulfenamide, tetramethyl-thiuram sulfide, sulfur, an anti-scorching agent and P-tert-butylphenol formaldehyde resin. The base compound has the higher modulus and the good abrasion resistance, and meanwhile, the base compound is better in reversion resistance and low in hysteresis loss.

Owner:盐城易宝路轮胎有限公司

Rubber composition for coating steel wire cord of radial tire for engineering machinery

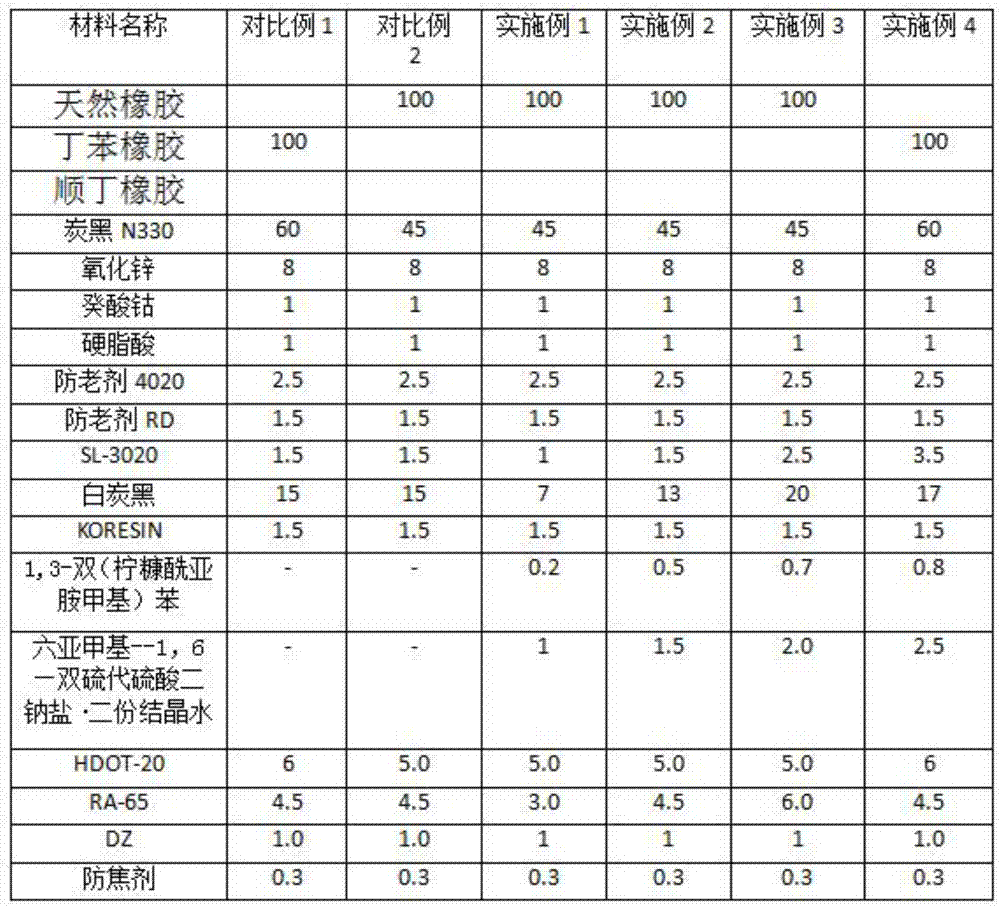

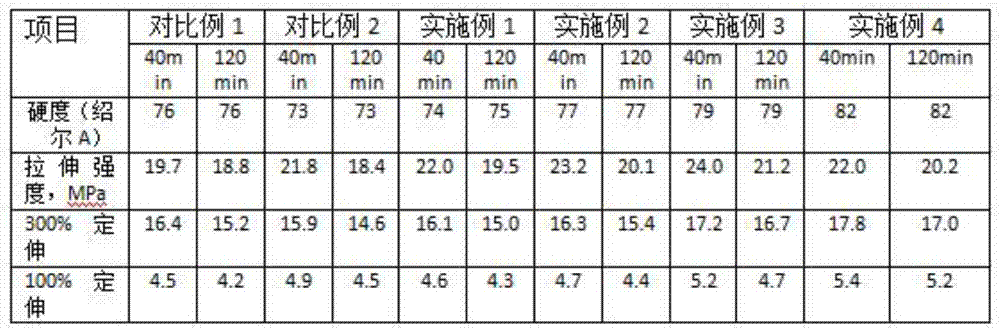

The invention relates to the technical field of rubber, in particular to a rubber composition for coating a steel wire cord of a radial tire for engineering machinery. The rubber composition is characterized by further comprising the following components in parts by weight by taking 100 parts by weight of a rubber component as the baseline: 5-20 parts of white carbon black, organic acid cobalt salt with the cobalt content of 0.03-1 parts by weight, 0.5-5 parts of an adhesive resorcinol capable of being replaced with a mixture of resorcinol and a carrier, 0.5-7 parts of an adhesive HMMMM capable of being replaced with a mixture of the adhesive HMMMM and a carrier, 1.0-3.0 parts of hexamethylene-1,6-bisthiosulfate disodium salt / two-part crystal water capable of being replaced with a mixture of hexamethylene-1,6-bisthiosulfate disodium salt / two-part crystal water and a carrier, 0.1-1 part of 1,3-bis9(3-methyl-2,5-dioxopyrrol-1-yl)methyl)benzol capable of being replaced with a mixture of 1,3-bis9(3-methyl-2,5-dioxopyrrol-1-yl)methyl)benzol and a carrier, 2-8 parts of insoluble sulfur and 0.5-1.5 parts of a sulfenamide accelerator DZ.

Owner:TRIANGLE TIRE

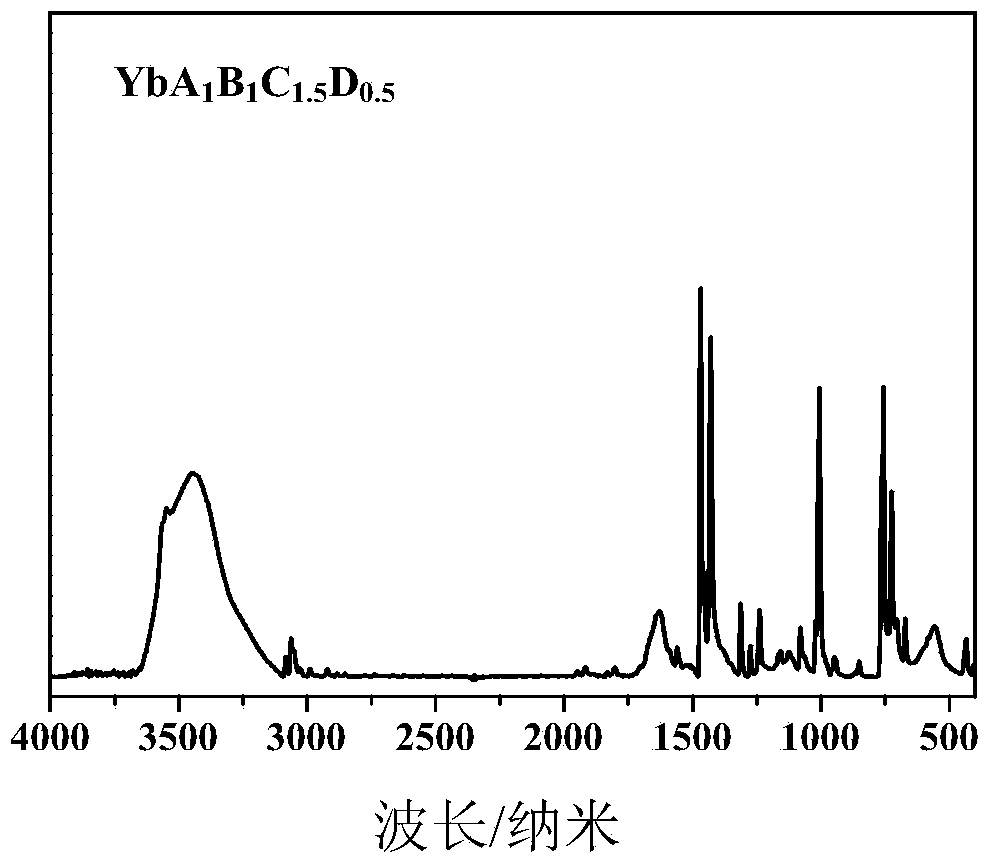

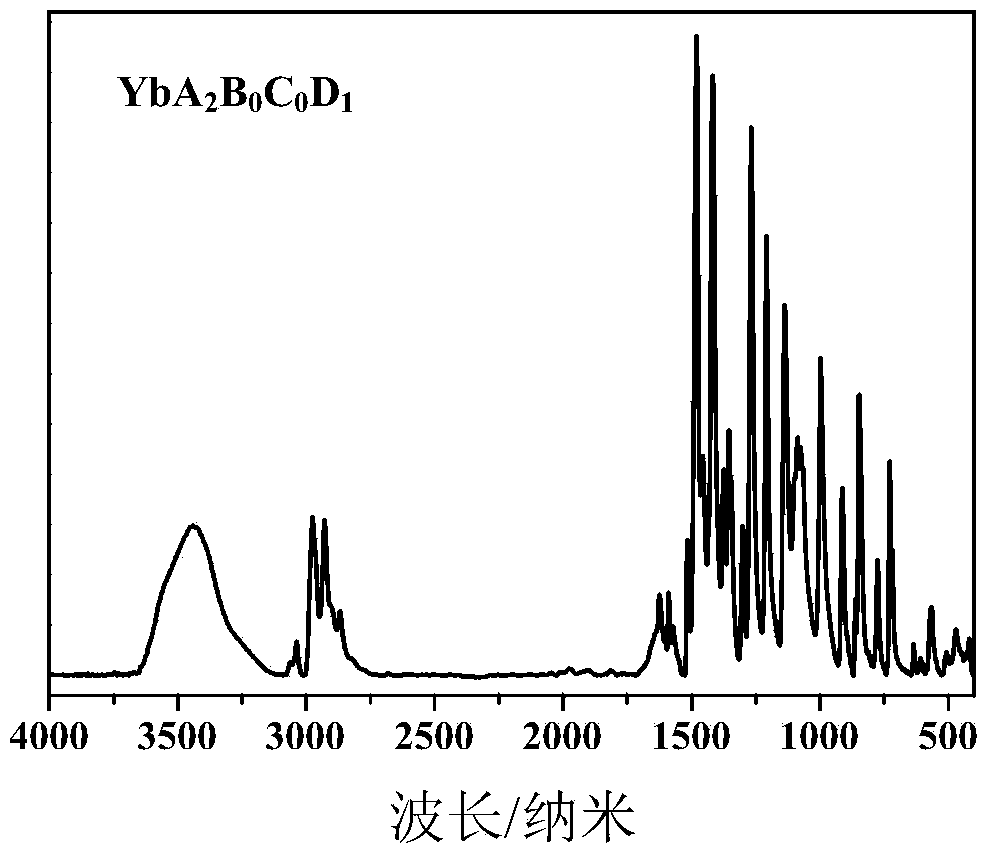

Ytterbium-based multi-ligand vulcanization accelerator and preparation method thereof

ActiveCN103819713AEasy to prepareMild conditionsGroup 3/13 element organic compoundsRare-earth elementSolubility

The invention discloses an ytterbium-based multi-ligand vulcanization accelerator and a preparation method thereof. During synthesis, ytterbium, a rare earth element, is adopted. The vulcanization accelerator comprises 4 ligands, wherein the first ligand and the second ligand are accelerator groups with good vulcanization accelerating effects; the third ligand is citric acid which can form good coordination with the rare earth element; the ligand 4 is dopamine which can improve the solubility of the vulcanization accelerator in rubber. According to the invention, the preparation method is simple and feasible, no inert gas shielding is needed, the preparation conditions are mild, and no harmful gas is generated. The vulcanization accelerator is high in solubility in rubber, can maintain a long vulcanization scorch time, is non-toxic and odorless, and generates no pollution; the flatness of the vulcanization curve is high. The vulcanization accelerator can replace the current commonly-used combined system of zinc oxide, stearic acid and accelerator. The vulcanization accelerator can be applied to high-performance tire and other rubber products.

Owner:BEIJING UNIV OF CHEM TECH

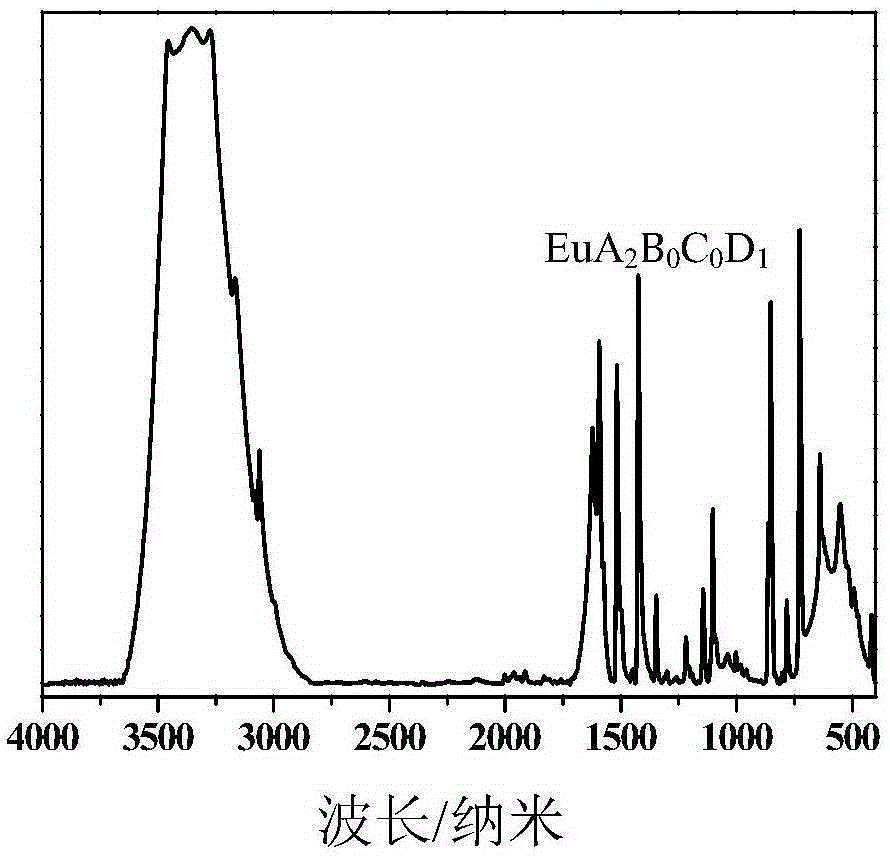

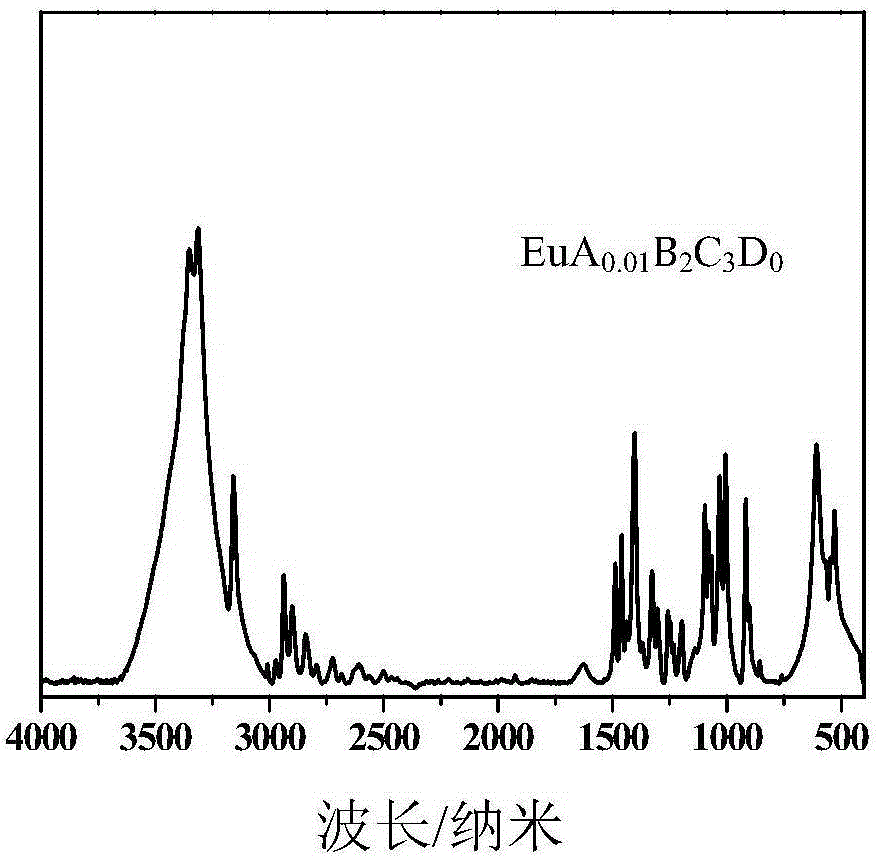

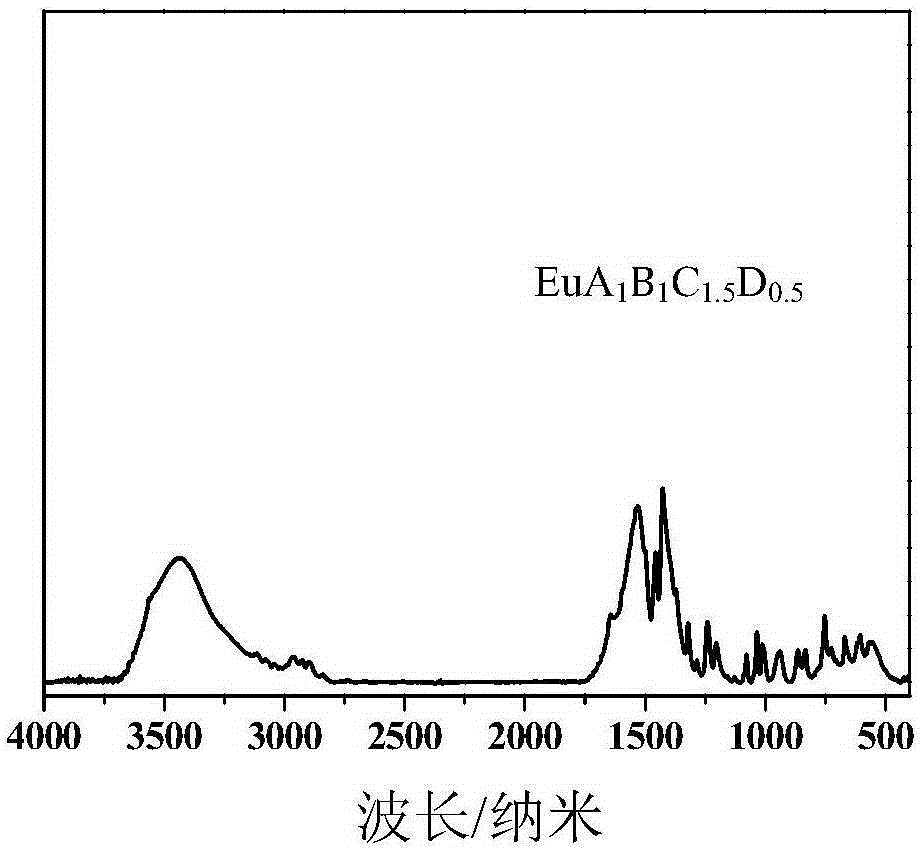

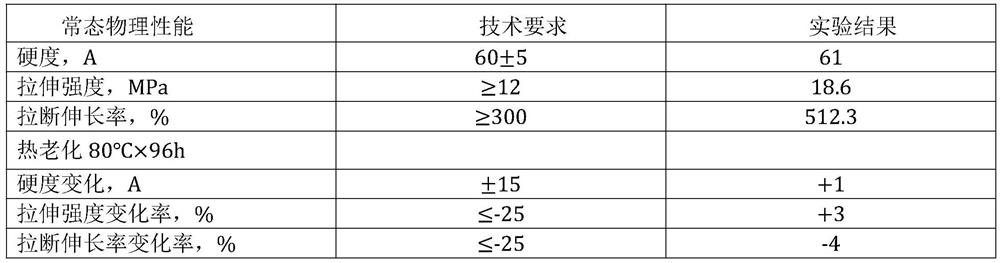

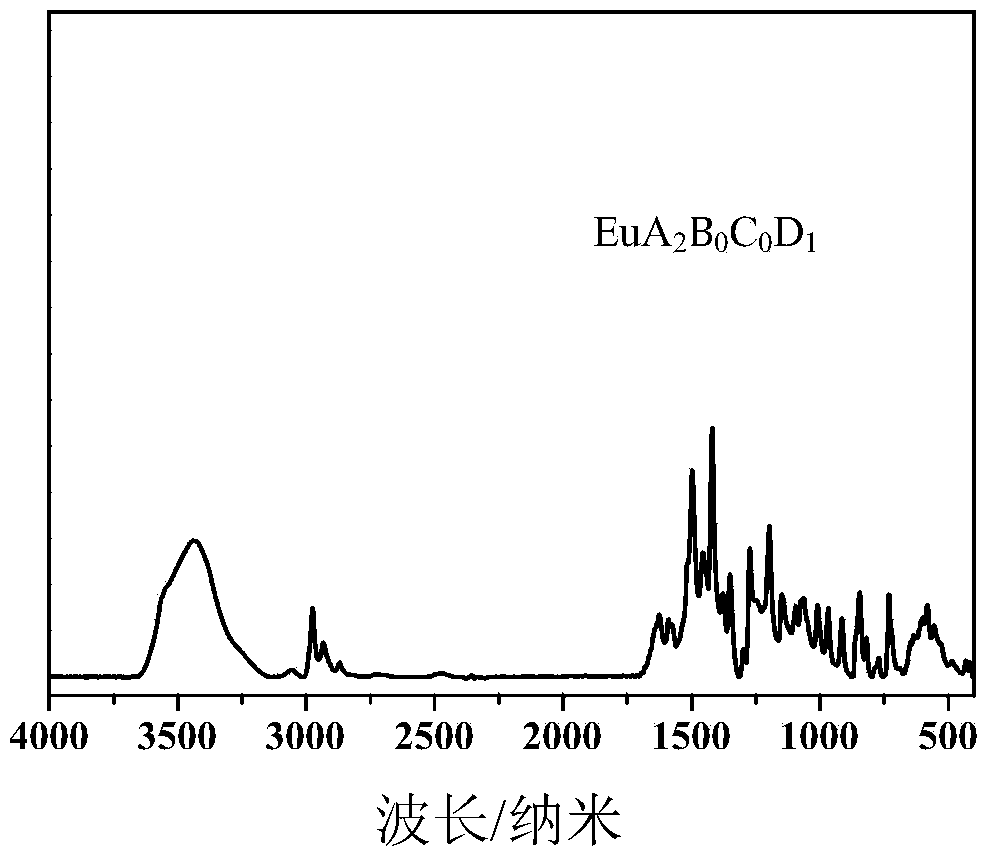

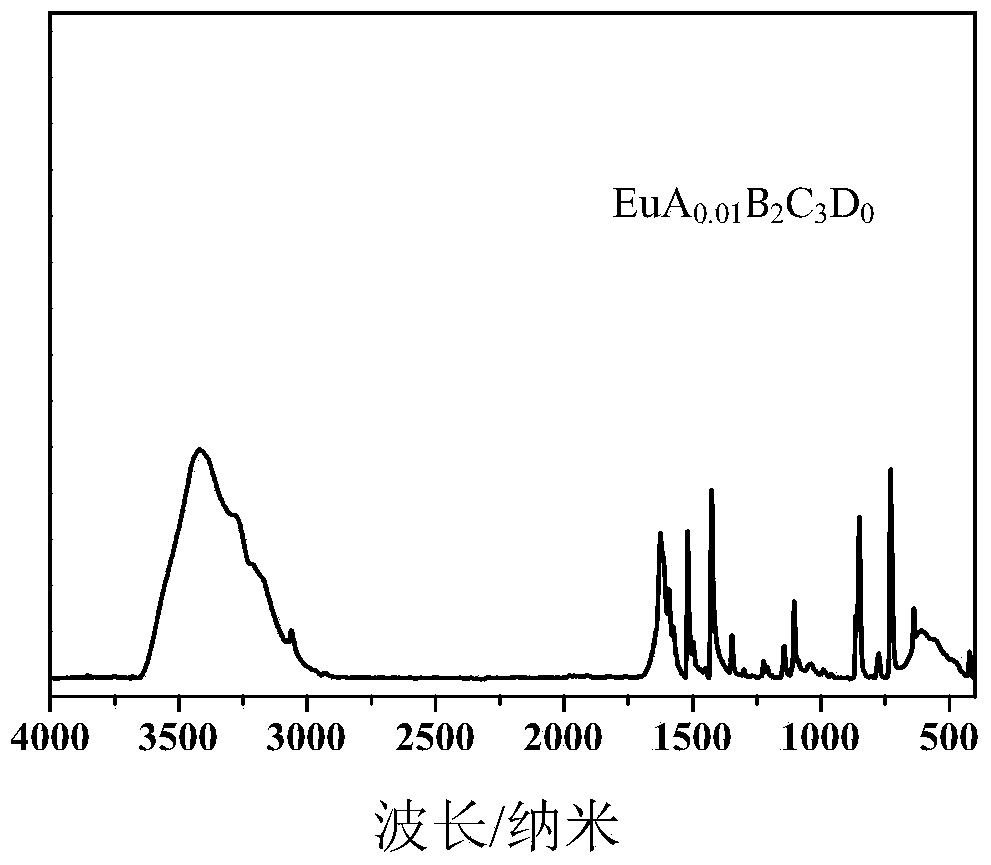

A kind of preparation method of europium-based multi-ligand rubber vulcanization accelerator

ActiveCN103819728BEasy to prepareMild conditionsGroup 3/13 element organic compoundsRubber materialRare-earth element

Owner:BEIJING UNIV OF CHEM TECH

Anti-revulcanization support rubber for run-flat tires

InactiveCN111234329ADecreased reversion rateImproved reversion resistanceSpecial tyresPolymer scienceSulfenamide

The invention discloses anti-revulcanization support rubber for run-flat tires, and relates to the technical field of rubber production. The anti-revulcanization supporting rubber for a run-flat tireis prepared from the following raw materials in parts by weight: 3# smoked sheet rubber, neodymium butadiene rubber, carbon black N550, TDAE oil, poly-2,2,4-trimethyl-1,2-dihydroquinoline, N-(1,3-dimethyl)butyl-N'-phenyl p-phenylenediamine, zinc oxide, stearic acid, sulfenamide accelerators, sulfur, scorch retarder and anti-revulcanization additives. The supporting rubber has good vulcanization revulcanization resistance, and meanwhile, the resilience, flexibility, tearing strength, low heat generation and other properties of vulcanized rubber can still be well maintained.

Owner:DONGYING FANGXING RUBBER CO LTD

Preparation method of anti-reversion sidewall rubber for run-flat tires

The invention discloses a preparation method of anti-reversion sidewall rubber for run-flat tires, and relates to the technical field of rubber production. The rubber is prepared from the following raw materials in parts by weight: natural rubber, ethylene propylene diene monomer, carbon black, an elastomer compatibilizer, zinc oxide, stearic acid, operating oil, an internal releasing agent, microcrystalline wax, an anti-aging agent RD, an accelerant, sulfur and an anti-reversion aid. The preparation method comprises the following steps: putting the natural rubber and the ethylene propylene diene monomer into an internal mixer, adding the carbon black, the elastomer compatibilizer, the zinc oxide, the stearic acid, the operating oil, the internal releasing agent, the microcrystalline wax and the anti-aging agent RD into the internal mixer, adding the accelerant, the sulfur and the anti-reversion assistant into the internal mixer, and finally vulcanizing. The sidewall rubber has good vulcanization reversion resistance, and the resilience, flexibility, tearing strength, low heat generation and other properties of vulcanized rubber can still be well maintained.

Owner:DONGYING FANGXING RUBBER CO LTD

Flexible energy-saving super-wear resistant covering glue for steel wire rope core conveyor belt and preparation method thereof

InactiveCN108641131AHigh strengthHigh tear performanceChemical industryMicrocrystalline waxHexamethylenetetramine

The invention discloses flexible energy-saving super-wear resistant cover rubber for a steel wire rope core conveyor belt and a preparation method thereof, and relates to the field of rubber conveyorbelts. The product comprises the following components in parts by weight: 60-80 parts of natural rubber, 20-40 parts of butadiene rubber, 0.2-0.3 parts of a peptizer, 2-5 parts of an anti-aging agent,0.5-1.5 parts of an antioxidant, 4-7 parts of nano zinc oxide, 1.5-2 parts of stearic acid, 1-1.5 parts of microcrystalline wax, 2-5 parts of a high performance rubber dispersant, 3-5 parts of an anti-wear agent, 5-10 parts of a phenolic reinforcing resin, 1-1.5 parts of an accelerator, 3-5 parts of aromatic oil, 40-70 parts of carbon black, 0.5-1.5 parts of hexamethylenetetramine, and 1.5-2.5 parts of sulfur. The product has the characteristics of wear resistance, tear resistance, high adhesion with core rubber adhesive layers, long service life, and the like.

Owner:江苏凯嘉橡胶科技股份有限公司

Medical silicone rubber and production process thereof

The invention relates to the technical field of silicone rubber, and discloses medical silicone rubber, which is prepared from the following raw materials in parts by weight: 100 parts of rubber raw materials; 45 to 55 parts of white carbon black; 3-8 parts of a vulcanizing agent; 2-3 parts of a control agent; 1-2 parts of hydrogen-containing silicone oil; 3-5 parts of a heat-resistant additive; 1-3 parts of an inhibitor; and 1-2 parts of a catalyst. According to the medical silicone rubber and the production process, the rubber raw materials are refined twice, a platinum complex is used as a catalyst, hydrogen-containing silicone oil is used as a cross-linking agent, vinyl at the tail end and in the middle of polysiloxane and the cross-linking agent are subjected to an addition reaction, and a silicone rubber product is free of generation of low-molecular substances, uniform in vulcanization and excellent in reversion resistance.

Owner:东莞市贝克摩尔高性能材料有限公司

Raw material for preparing high-temperature-resistant high-fatigue-resistance natural rubber

InactiveCN112080046AImprove fatigue resistanceImprove heat aging resistanceMicrocrystalline waxVulcanization

The invention relates to the technical field of rubber, in particular to a high-temperature-resistant high-fatigue-resistance natural rubber preparation raw material. The rubber is prepared from, by mass, 100 parts of smoke sheet rubber, 3-8 parts of zinc oxide, 1-2 parts of stearic acid, 1-3 parts of anti-aging agent RD, 1-2 parts of anti-aging agent 4010NA, 1-2 parts of anti-aging agent 4020, 2-5 parts of microcrystalline wax 9332F, 3-5 parts of silane coupling agent Si-669 / G, 0.5-1.5 parts of PAPI, 20-40 parts of carbon black N330, 30-60 parts of carbon blackN660, 10-30 parts of barium sulfate, 5-20 parts of aromatic oil Tudalen 84, 2-3 parts of sulphur, 1-2 parts of accelerant CZ, 0.5-1 parts of IDH, and 2-4 parts of Perkalink 900. By reasonably adjusting a formula system, the fatiguelife, the temperature resistance and the vulcanization reversion resistance of the natural rubber can be remarkably improved.

Owner:北威(重庆)科技股份有限公司

A wear-resistant base rubber for truck solid tires

Owner:盐城易宝路轮胎有限公司

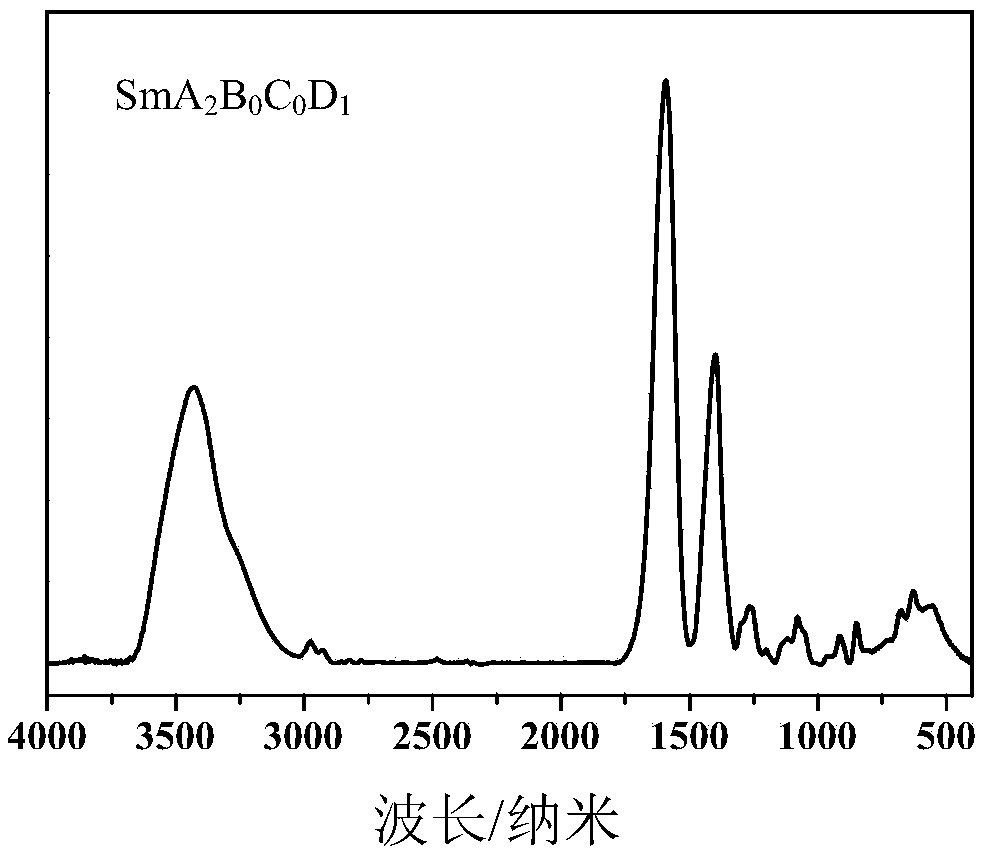

Preparation method for samarium-group multiple-ligand thiofide

ActiveCN103819718AEasy to prepareMild conditionsGroup 3/13 element organic compoundsRare-earth elementSolubility

The invention discloses a samarium-group multiple-ligand thiofide and a preparation method thereof. According to the preparation method, during synthesis, a rare earth element is a samarium element comprising four ligands. The ligand 1 and the ligand 2 are accelerating agent groups with an excellent vulcanization accelerating effect, the ligand 3 is acrylic acid capable of improving the dissolubility of an accelerator in a sizing material, and the ligand 4 is triethanolamine capable of forming strong coordination with the rare earth element. The preparation method for the samarium-group multiple-ligand thiofide is simple, convenient and feasible, and does not need inert gas for protection, conditions in the preparing process are mild, and production of harmful gas is prevented. The multiple-ligand rare earth thiofide has good dissolubility in rubber, and is long in sulfidation and scorching times, good in flatness of a sulfidation curve, nontoxic, odorless and free from contamination. The thiofide can substitute a conventionally frequently-used simultaneous-use system of zinc oxide, stearic acid and an accelerator, and is applied to high-performance tires and other rubber products.

Owner:BEIJING UNIV OF CHEM TECH

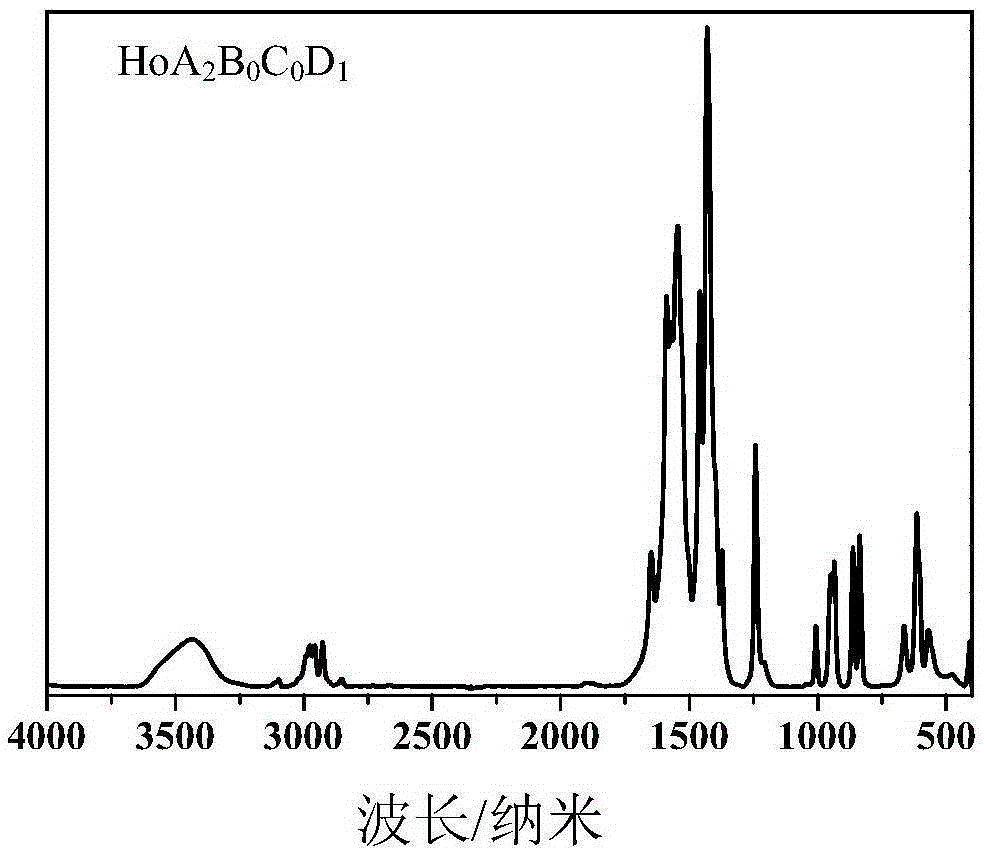

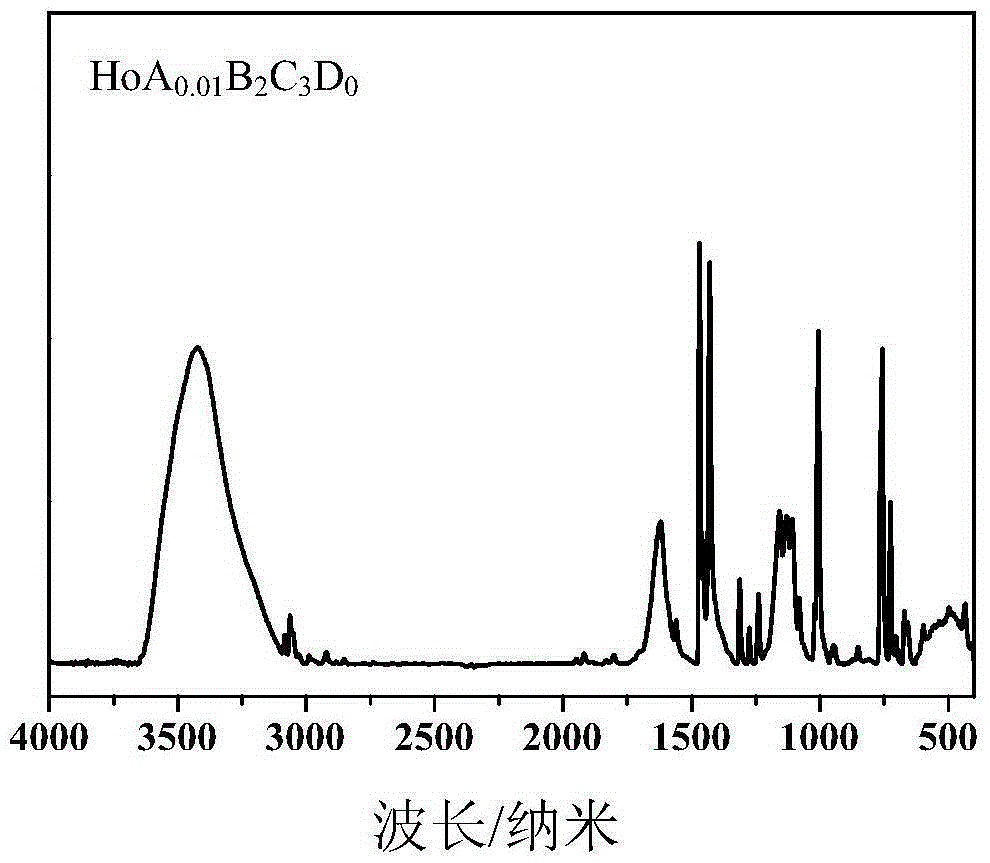

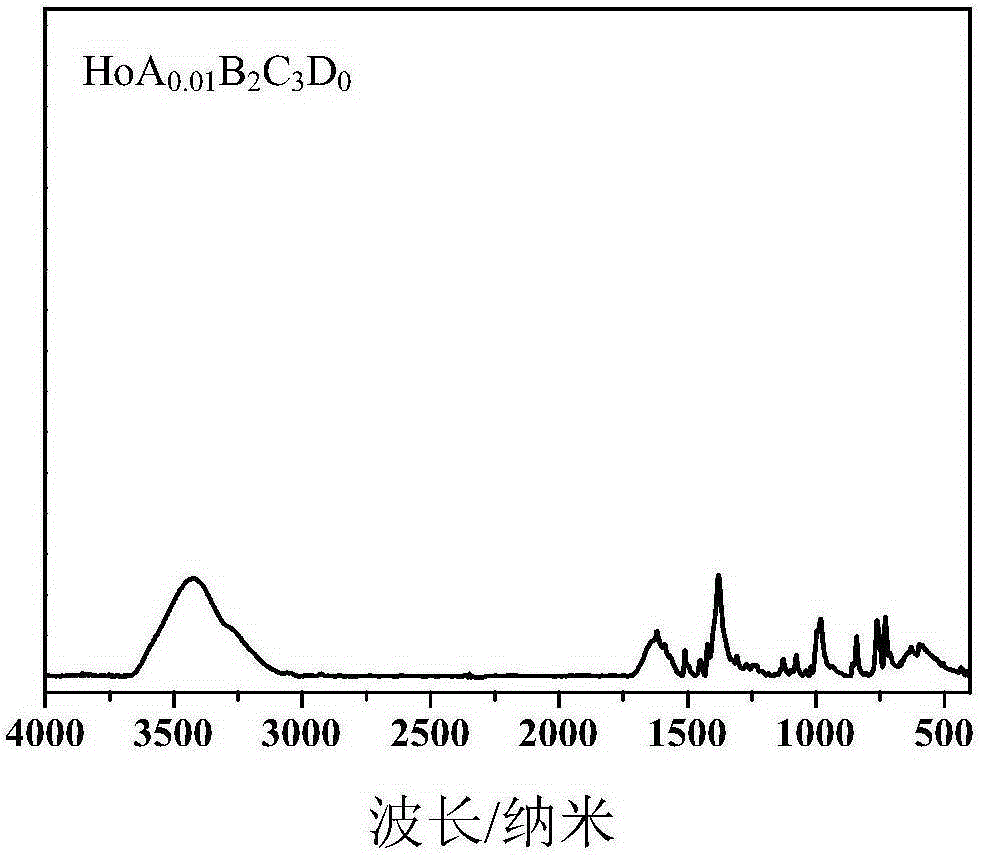

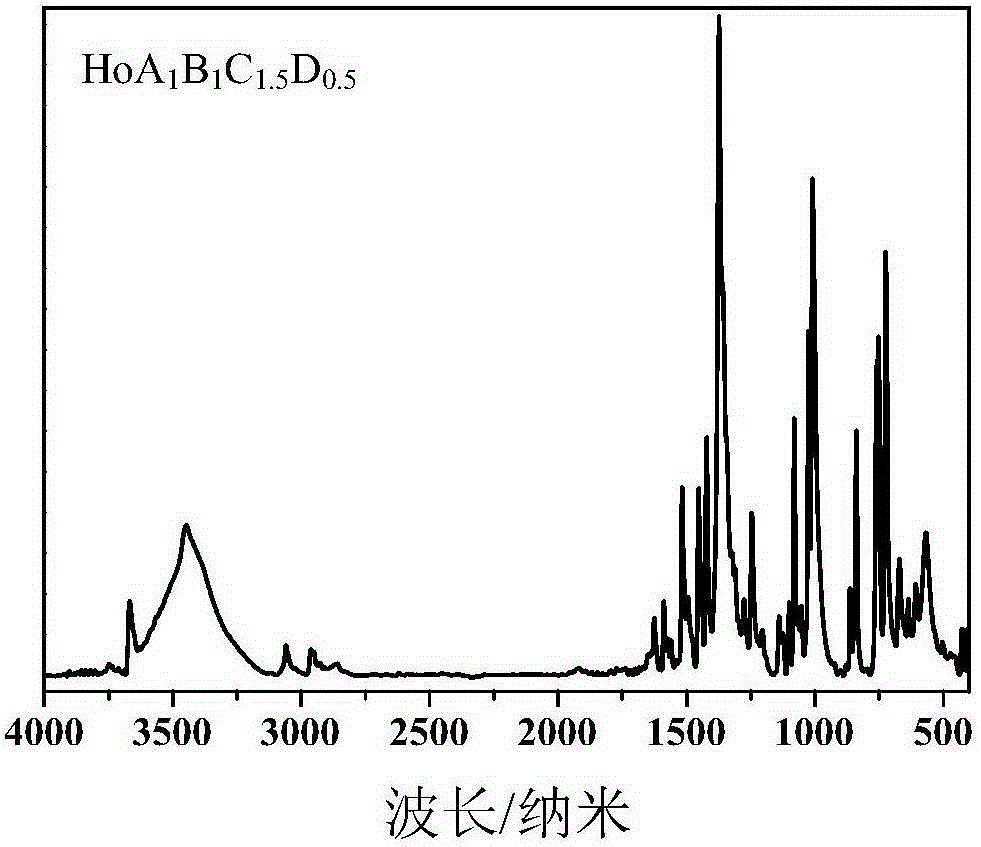

A kind of holmium-based multi-ligand rubber vulcanization accelerator and preparation method thereof

ActiveCN103819727BEasy to prepareMild conditionsGroup 3/13 element organic compoundsRare-earth elementSolubility

Owner:BEIJING UNIV OF CHEM TECH

Preparing method for europium-base multiple-ligand vulcanizing accelerator

ActiveCN103819729AEasy to prepareMild conditionsGroup 3/13 element organic compoundsRare-earth elementSolubility

The invention discloses a europium-base multiple-ligand vulcanizing accelerator and a preparing method thereof. Europium is the rare earth element in synthesis, and 4 kinds of ligands are included, wherein the ligands 1 and 2 are accelerator groups with excellent vulcanizing acceleration effects, the ligand 3 is stearic acid improving solubleness of the accelerator in a rubber material, and the ligand 4 is citric acid forming strong coordination with the rare earth element. The method is simple and feasible, requires no protection of inert gases, is mild in the preparation condition and generates no harmful gas; the multiple-ligand rare earth vulcanizing accelerator has excellent solubleness in rubber, the vulcanization and scorch time is long, the vulcanization curve is excellent in flatness, and no toxicity, odor or pollution is generated; the accelerator substituting the conventional frequently used system adopting zinc oxide, stearic acid and accelerator together can be applied to high-performance tires and other rubber products.

Owner:BEIJING UNIV OF CHEM TECH

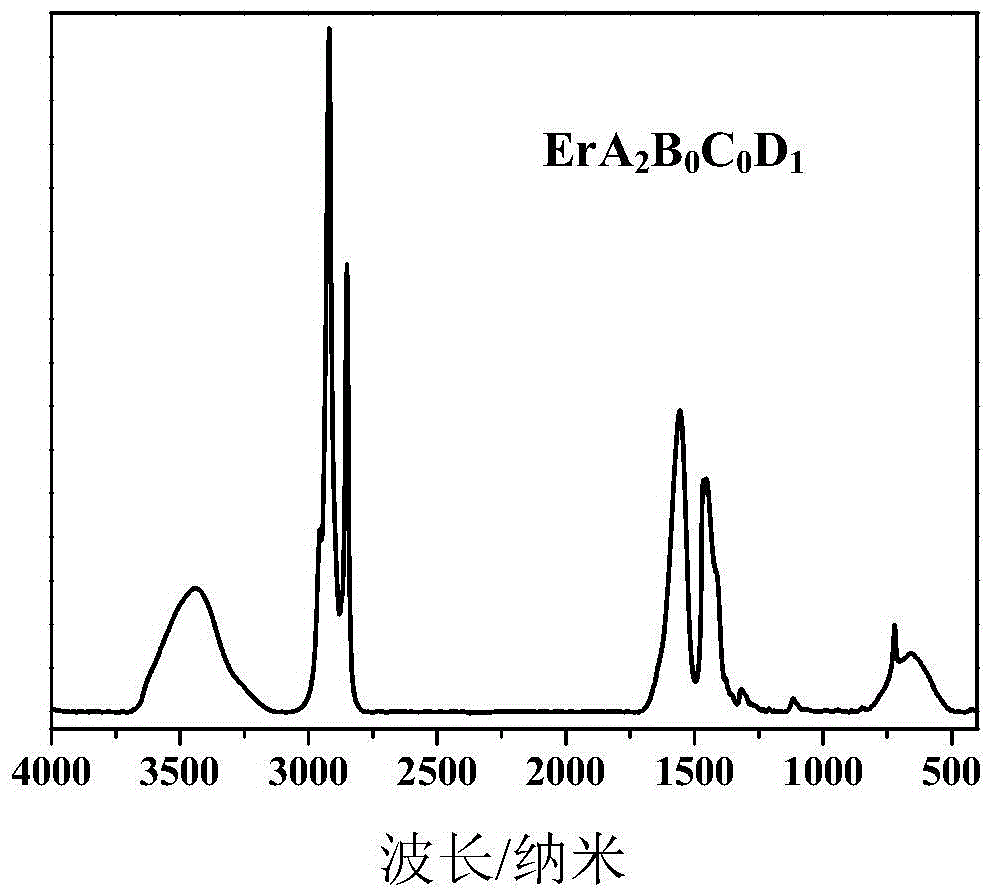

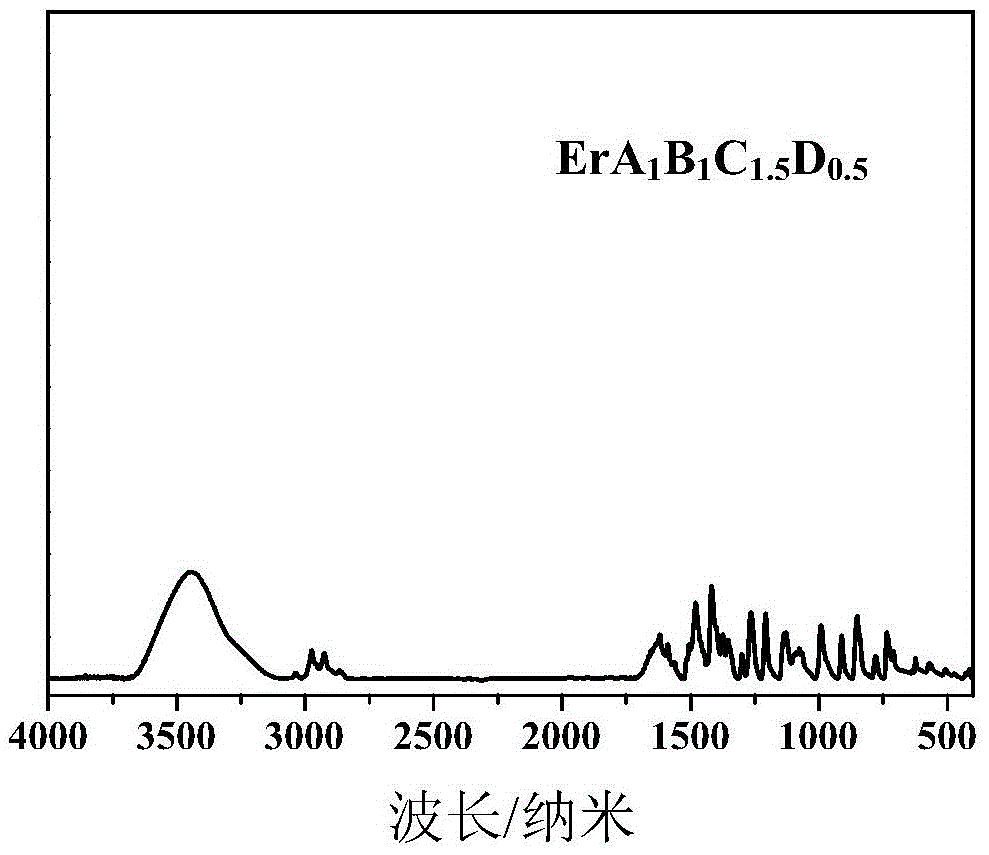

A kind of preparation method of erbium-based multi-ligand rubber vulcanization accelerator

ActiveCN103819730BEasy to prepareMild conditionsGroup 3/13 element organic compoundsSolubilityRare-earth element

The invention discloses an erbium-based multi-ligand vulcanization accelerator for rubber and a preparation method thereof. A rare earth element in the synthesis is erbium which contains 4 ligands, wherein a ligand 1 and a ligand 2 are accelerant groups with a good vulcanization accelerating effect; a ligand 3 is citric acid which can form strong coordination with the rare earth element; a ligand 4 is triethanolamine which can improve the solubility of the accelerator in rubber materials. The preparation method is simple, convenient and feasible, does not need inert gas shielding, is moderate in conditions of the preparation process, and generates no harmful gas. The multi-ligand rare earth vulcanization accelerator has good solubility in rubber,is long in vulcanization and scorching time and excellent in flatness of vulcanization curve, and is non-toxic, odorless and pollution-free. The accelerator can be applied to high performance tire and other rubber products instead of the conventional frequently-used blending system of zinc oxide, stearic acid and an accelerator.

Owner:BEIJING UNIV OF CHEM TECH

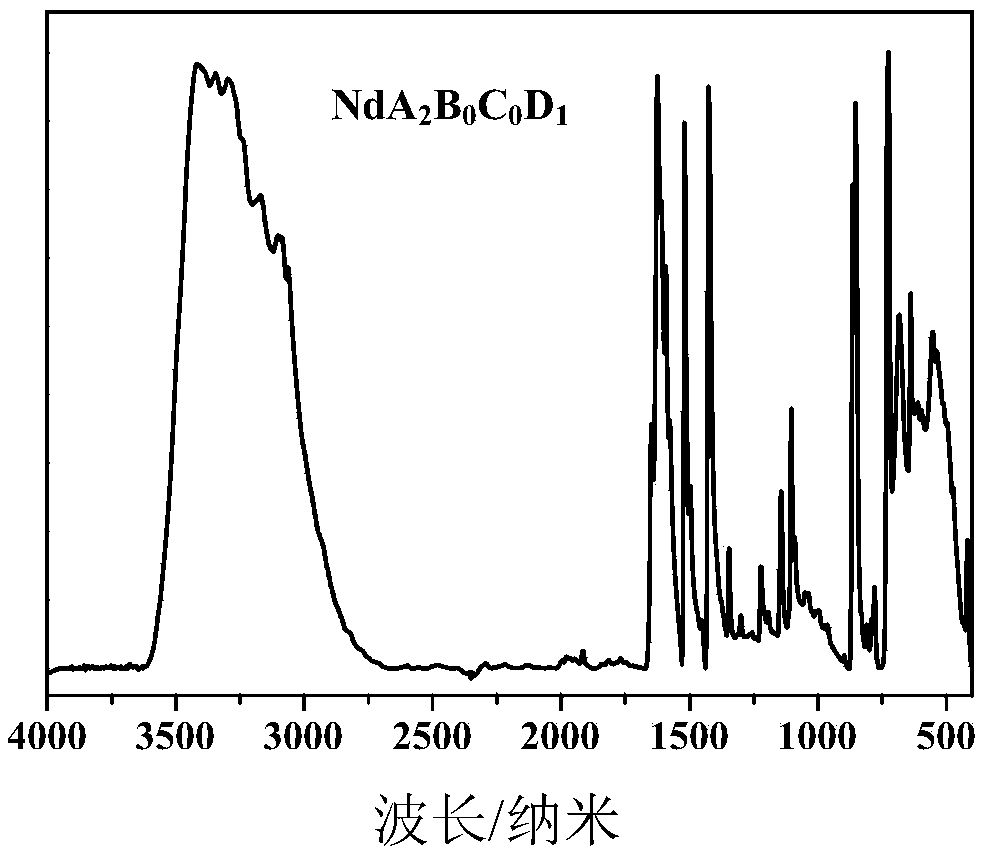

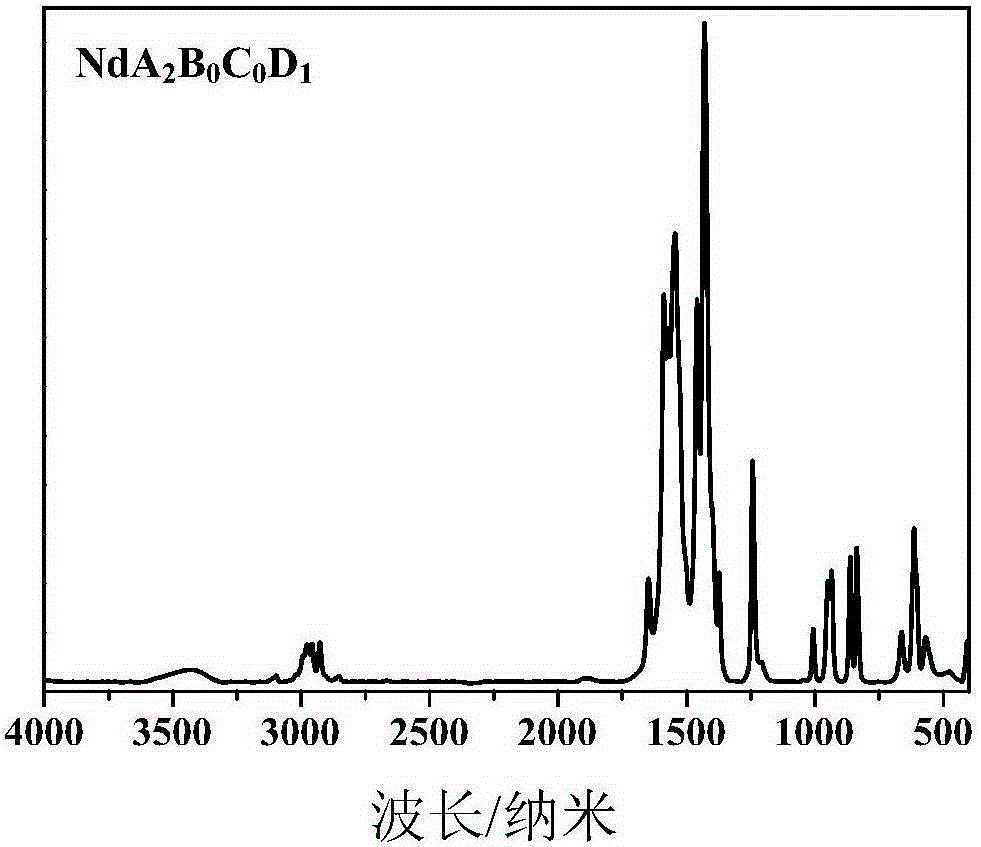

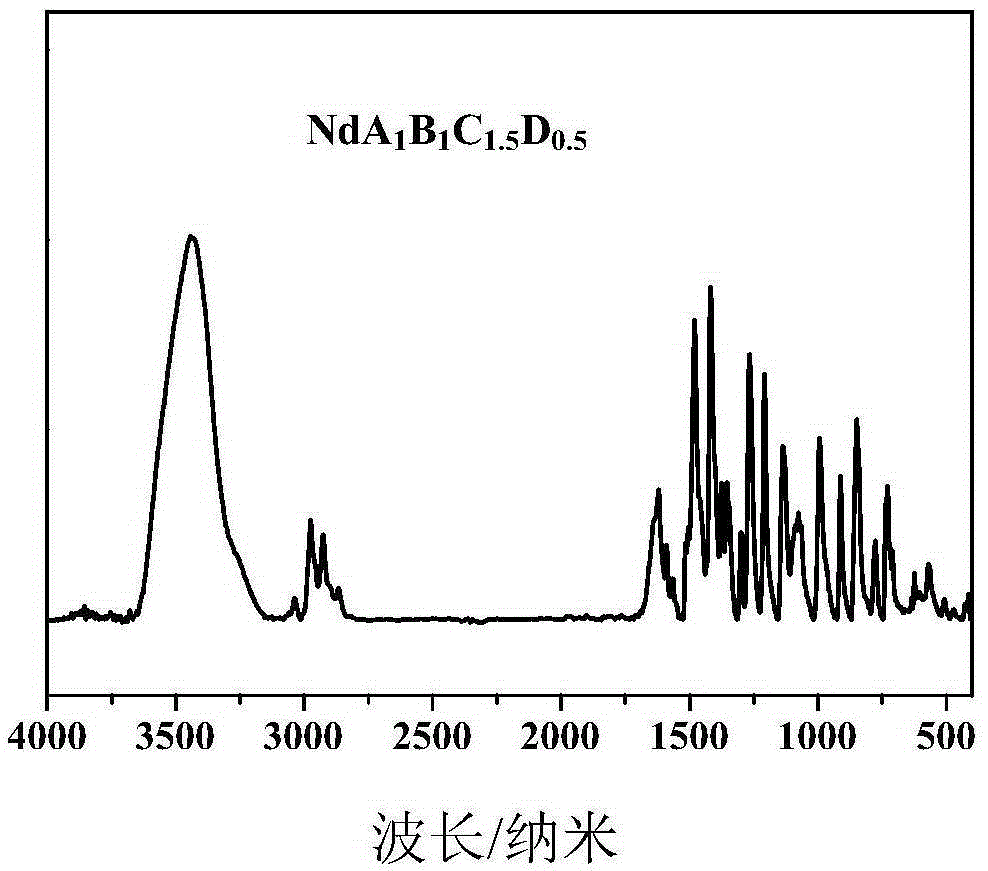

A kind of neodymium-based multi-ligand vulcanization accelerator and preparation method thereof

ActiveCN103819719BEasy to prepareMild conditionsGroup 3/13 element organic compoundsSolubilityRare-earth element

The invention discloses an Nd-based multi-ligand vulcanization accelerator and a preparation method thereof. In synthesis, an Nd element is used as a rare earth element, and four ligands are contained; the ligand 1 and the ligand 2 are accelerator radicals with good vulcanization acceleration effects, the ligand 3 is triethanolamine capable of improving the solubility of the accelerator in a sizing material, and the ligand 4 is acrylic acid capable of forming strong coordination with the rare earth element. The preparation method is simple, convenient and feasible, does not need inert gas shielding, is mild in preparation process condition, and has no harmful gas generation. The multi-ligand rare earth vulcanization accelerator has good solubility in rubber, and is long in vulcanization and scorching time, good in vulcanization curve flatness, non-toxic, odorless and pollution-free. The vulcanization accelerator can replace a currently used zinc oxide, stearic acid and accelerator combination system, and is applicable to high performance tires and other rubber products.

Owner:BEIJING UNIV OF CHEM TECH

Cable with good toughness and excellent thermal stability

InactiveCN106674709AImprove toughnessGood flexibilityPlastic/resin/waxes insulatorsElectrical conductorMicrosphere

The invention discloses a cable with good toughness and excellent thermal stability. The cable comprises a conductor and a protective jacket layer which covers the outer side of the conductor, wherein the protective jacket layer is prepared from the following raw materials in parts by weight: 20 to 40 parts of EVA (Ethylene Vinyl Acetate) resin, 5 to 15 parts of hydrogenated nitrile butadiene rubber, 12 to 15 parts of ABS (Acrylonitrile Butadiene Styrene) high-glue powder, 2 to 6 parts of microcrystalline cellulose, 5 to 15 parts of composite microsphere, 1 to 5 parts of nano hydroxyapatite powder, 5 to 12 parts of talcum powder, 2 to 6 parts of medical stone, 10 to 20 parts of oil shale, 12 to 15 parts of asbestos ash, 2 to 3 parts of ammonium polyphosphate, 1 to 2 parts of yttrium oxide, 1 to 3 parts of bis-2,4-dichlorobenzoyl peroxide, 1 to 2 parts of zinc dimethyldithioformate, 1 to 2 parts of butyl stearate, 1 to 3 parts of tetrabutylammonium bromide, 1 to 2 parts of zinc oxide, 2 to 3 parts of magnesium oxide, 24 to 28 parts of triethyl citrate, 8 to 10 parts of dimethyltin bis(isooctylmercaptoacetate), 25 to 30 parts of triethyl citrate, 1 to 2 parts of an anti-ageing agent AW and 0.8 to 1.2 parts of an anti-ageing agent A.

Owner:JINYUAN ELECTRIC GRP

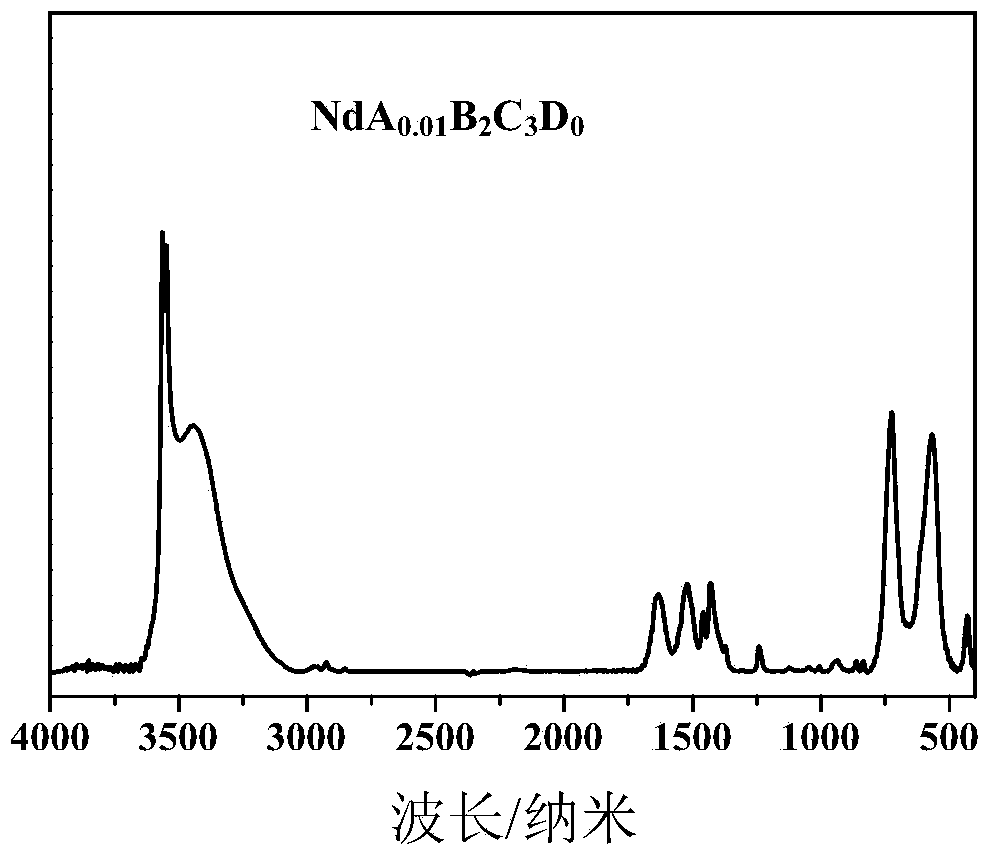

A kind of preparation method of neodymium-based multi-ligand rubber vulcanization accelerator

ActiveCN103819716BEasy to prepareMild conditionsGroup 3/13 element organic compoundsRare-earth elementSolubility

The invention discloses an Nd-based multi-ligand vulcanization accelerator and a preparation method thereof. In synthesis, an Nd element is used as a rare earth element, and four ligands are contained; the ligand 1 and the ligand 2 are accelerator radicals with good vulcanization acceleration effects, the ligand 3 is phenanthroline capable of forming strong coordination with the rare earth element, and the ligand 4 is acrylic acid capable of improving the solubility of the accelerator in a sizing material. The preparation method is simple, convenient and feasible, does not need inert gas shielding, is mild in preparation process condition, and has no harmful gas generation. The multi-ligand rare earth vulcanization accelerator has good solubility in rubber, and is long in vulcanization and scorching time, good in vulcanization curve flatness, non-toxic, odorless and pollution-free. The vulcanization accelerator can replace a currently used zinc oxide, stearic acid and accelerator combination system, and is applicable to high performance tires and other rubber products.

Owner:BEIJING UNIV OF CHEM TECH

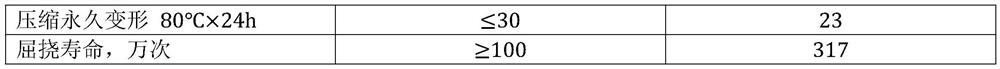

Bead wear-resistant rubber composition and mixing method thereof and tire

The invention relates to the technical field of new materials for manufacturing car tires, and in particular, relates to a bead wear-resistant rubber composition and a mixing method thereof and a tire. According to the bead wear-resistant rubber composition, the lagging loss of a rubber material is reduced by adopting butadiene rubber B; styrene butadiene rubber is adopted to improve carbon black dispersion so as to reduce lagging of the rubber material; the lagging of the rubber material is reduced by reducing the dosage of a filling reinforcing agent; the wear resistance is improved by adopting a high-wear-resistance carbon black reinforced rubber composition; by adopting the lignocellulose reinforced rubber composition, the modulus can be improved, and the permanent deformation can be reduced; and an organic sulfur donor is adopted to reinforce the bead wear-resistant rubber composition, so that the anti-reversion performance is improved, the modulus of the rubber material is improved, the compression permanent deformation is reduced, the compression temperature rise is reduced, the lag of bead wear-resistant rubber is reduced, the control of the tire is improved, and the rolling resistance of the tire is reduced.

Owner:ZHONGCE RUBBER GRP CO LTD

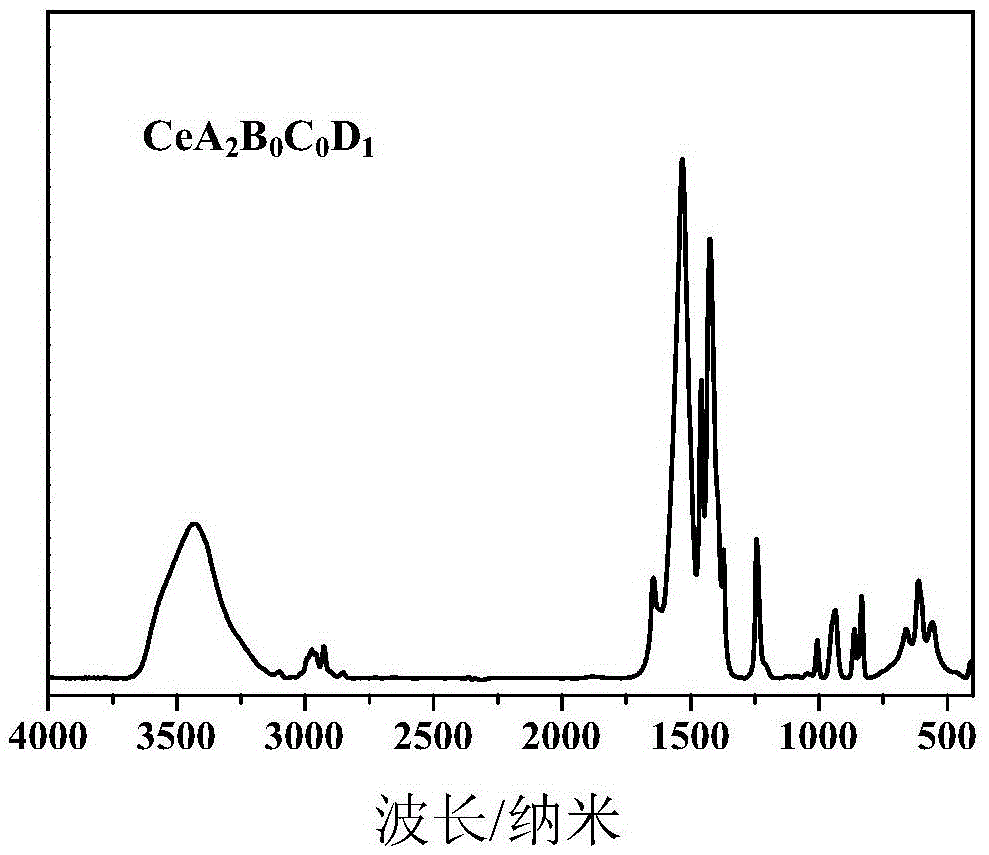

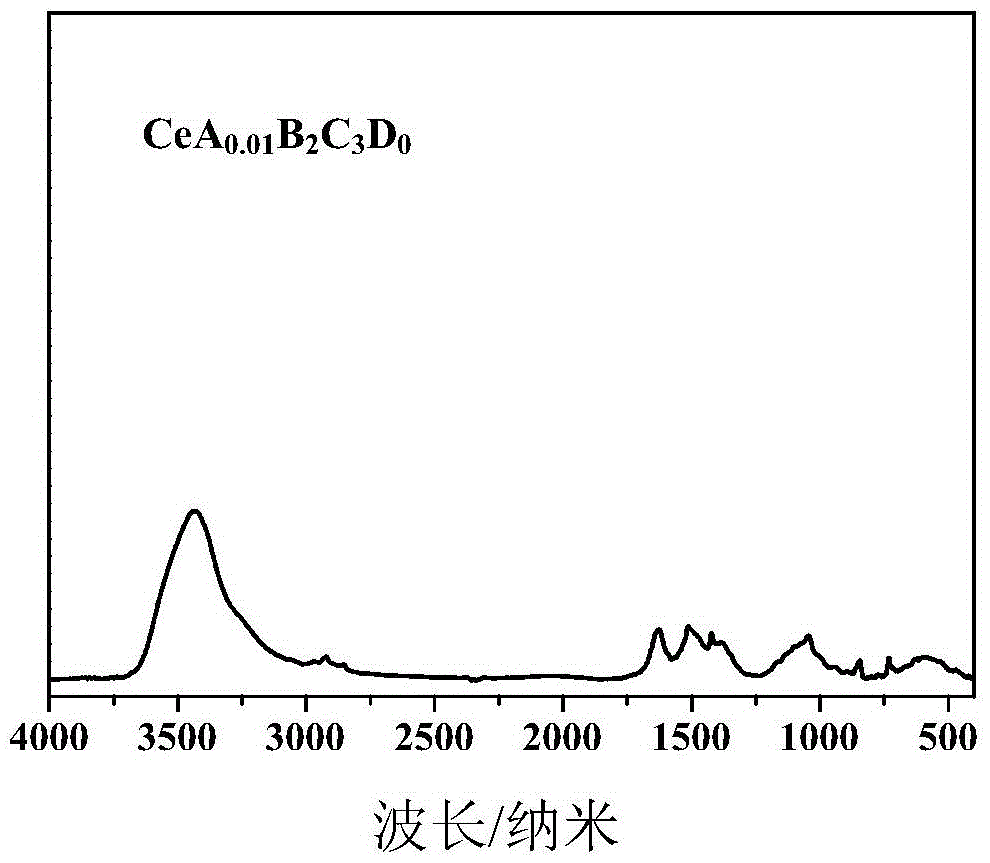

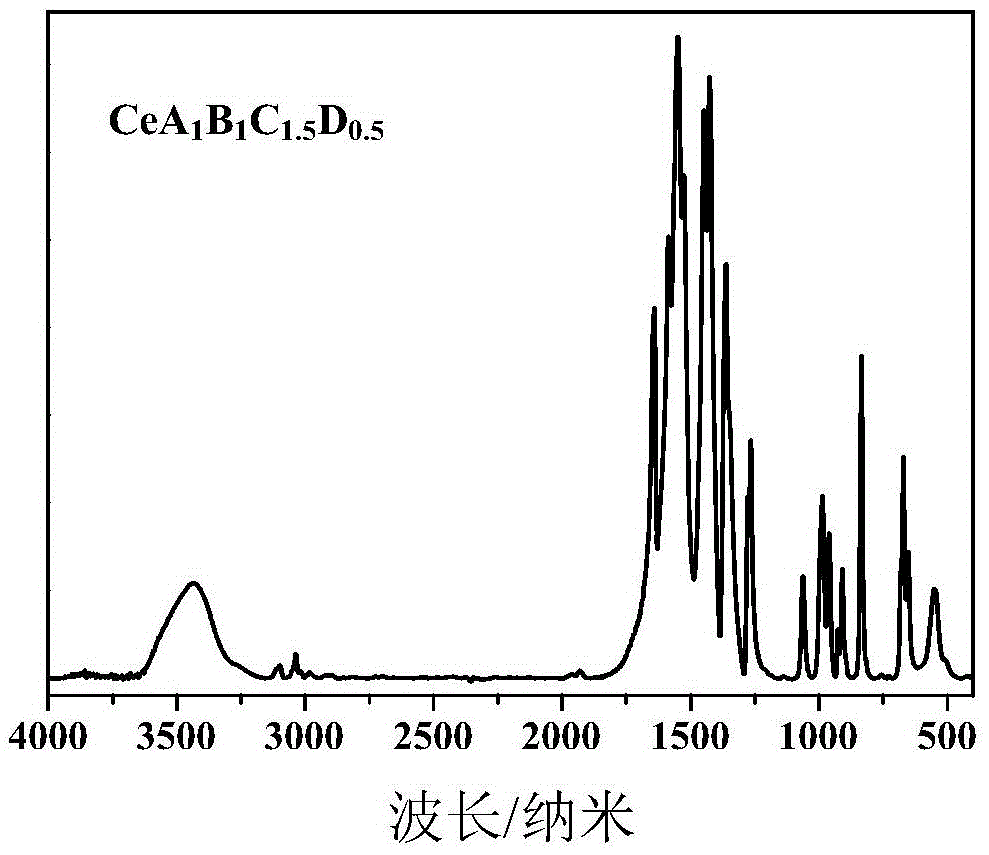

A kind of preparation method of cerium-based multi-ligand rubber vulcanization accelerator

ActiveCN103819722BEasy to prepareMild conditionsGroup 3/13 element organic compoundsSolubilityRare-earth element

The invention discloses a samarium-group multiple-ligand thiofide and a preparation method thereof. According to the preparation method, during synthesis, a rare earth element is a samarium element comprising four ligands. The ligand 1 and the ligand 2 are accelerating agent groups with an excellent vulcanization accelerating effect, the ligand 3 is phenanthroline capable of forming strong coordination with the rare earth element, and the ligand 4 is acrylic acid capable of improving the dissolubility of an accelerator in a sizing material. The preparation method for the samarium-group multiple-ligand thiofide is simple, convenient and feasible, and does not need inert gas for protection, conditions in the preparing process are mild, and production of harmful gas is prevented. The multiple-ligand rare earth thiofide has good dissolubility in rubber, and is long in sulfidation and scorching times, good in flatness of a sulfidation curve, nontoxic, odorless and free from contamination. The thiofide can substitute a conventionally frequently-used simultaneous-use system of zinc oxide, stearic acid and an accelerator, and is applied to high-performance tires and other rubber products.

Owner:BEIJING UNIV OF CHEM TECH

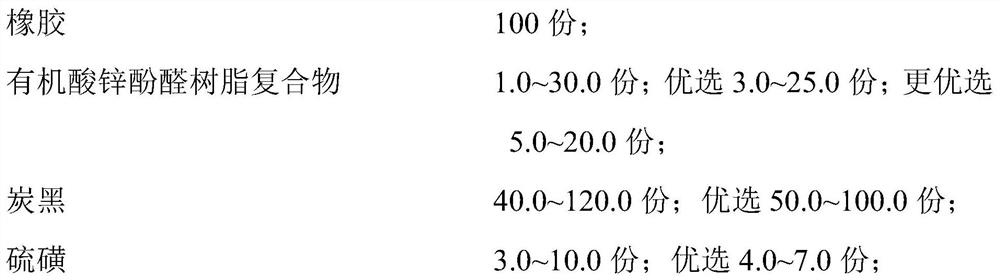

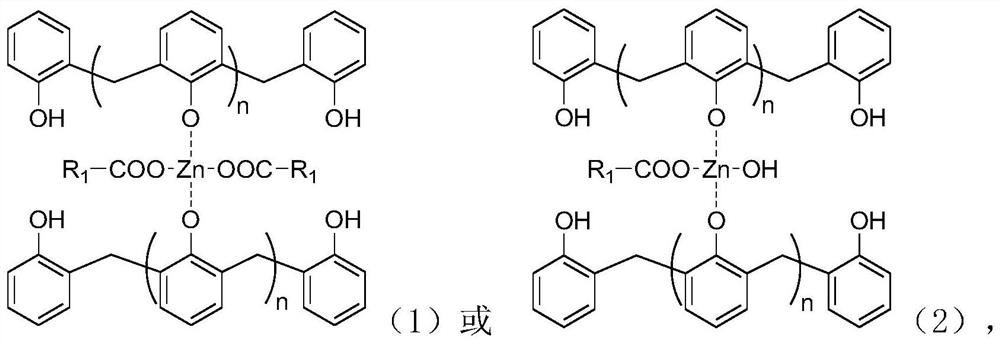

A kind of rubber composition containing organic acid zinc phenolic resin compound and its preparation method and application

The invention discloses a rubber composition containing an organic acid zinc phenolic resin compound, a preparation method and an application thereof. The rubber composition comprises 100 parts of rubber, 1.0 to 30.0 parts of organic acid zinc phenolic resin compound, 40.0 to 120.0 parts of carbon black and 3.0 to 10.0 parts of sulfur, and may also contain process oil, vulcanization accelerator, methylene donor and other additives. Among them, the coordination cross-linking bond formed by the organic acid zinc phenolic resin compound can increase the strength and heat resistance of the phenolic resin, and the structure of the organic acid can also increase the compatibility between the phenolic resin and rubber, and the compound will improve the phenolic resin. The rubber composition has the characteristics of high modulus, low initial Mooney viscosity, improved fatigue life, and outstanding mechanical properties after high temperature aging.

Owner:BEIJING RED AVENUE INNOVA +1

A kind of preparation method of lanthanum-based multi-ligand vulcanization accelerator

ActiveCN103819726BEasy to prepareMild conditionsGroup 3/13 element organic compoundsRare-earth elementSolubility

The invention discloses a lanthanum-base multiple-ligand vulcanization accelerant and a preparation method thereof. The rare earth element in synthesis is cerium element which contains 4 ligands; the ligand 1 and the ligand 2 are accelerant groups with favorable vulcanization accelerating effect; the ligand 3 is triethanolamine which can improve the solubility of the accelerant in rubber; the ligand 4 is phenanthroline which can form a strong coordination with the rare element; the preparation method is simple and feasible; inert gas shielding is not needed; conditions in the preparation process are mild; no harmful gas is generated in the preparation process; the multiple-ligand vulcanization accelerant has favorable solubility in rubber; vulcanization scorch time is long; the flatness of vulcanization curve is high; the multiple-ligand vulcanization accelerant is non-toxic, odourless and pollution-free; the accelerant can replace a blending system of zinc oxide, stearic acid and the accelerant; the accelerant can be applicable in high performance tires and other rubber products.

Owner:BEIJING UNIV OF CHEM TECH

A kind of holmium-based multi-ligand vulcanization accelerator and preparation method thereof

ActiveCN103819717BEasy to prepareMild conditionsGroup 3/13 element organic compoundsRare-earth elementSolubility

The invention discloses a holmium-based multiple-ligand vulcanization accelerator and a preparation method thereof. A rare earth element in synthesis is holmium comprising four ligands, wherein the ligands 1 and 2 are accelerator groups having excellent vulcanizing and accelerating effects, the ligand 3 is alpha-methylacrylic acid capable of forming strong ligands together with the rare earth element, and the ligand 4 is octadecanoic acid capable of improving the solubility of the accelerator in a sizing material. The method is simple, convenient and easy, and does not require protection of inert gas, conditions during the preparation process are moderate, and no harmful gases can be generated. The multiple-ligand rare earth vulcanization accelerator has a good solubility in rubber, the vulcanizing and scorching time is long, the vulcanization curve is excellent in flatness, and toxin, odour and pollution are avoided. The accelerator can replace a conventionally used zinc oxide, octadecanoic acid and accelerator combined-use system and can be applied to high-performance tires and other rubber products.

Owner:BEIJING UNIV OF CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com