Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

63results about How to "Reduce dynamic heating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of silicon dioxide graft graphene oxide/rubber composite material

The invention relates to a preparation method of a silicon dioxide graft graphene oxide / rubber composite material, which comprises the following steps: by using natural rubber as a main material and superhigh-wear-resistance carbon black, high-dispersity silica white, silica white dispersing agent, silicon dioxide graft graphene oxide nanoparticles, silane coupling agent, heat stabilizer HS-80 and anti-reversion agent WK-901 as auxiliary materials, mixing according to certain parts by weight, compounding with a Banbury mixer to prepare compounded rubber, and extruding the compounded rubber with an extruder to prepare the semifinished product rubber. The composite material blended from the silicon dioxide graft graphene oxide and natural rubber has the characteristics of low heat generation, high tensile strength, high tearing strength, favorable abrasion resistance, favorable heat stability and the like. When being applied to aircraft tire tread rubber, compared with the traditional tread rubber, the rubber has the advantages of higher use safety and longer service life.

Owner:中国化工集团曙光橡胶工业研究设计院有限公司

Fatigue-resisting natural rubber nano composite material and preparation method thereof

The invention discloses a fatigue-resisting natural rubber nano composite material and a preparation method thereof. The preparation method is characterized by comprising the following steps of: carrying out mechanical intercalation on 100 parts of natural rubber and 1-7 parts of nano montmorillonoid, then adding 4-8 parts of vulcanizing activator, 1-4 parts of anti-aging agent, 15-50 parts of carbon black packing, 0.5-3 parts of vulcanizing accelerator and 0.5-3 parts of vulcanizing agent, then adding gelatine into a flat-plate vulcanizing machine, and carrying out mould pressing for 10-30 minutes with the temperature of 135-155 DEG C and the pressure of 10-15MPa to obtain the fatigue-resisting natural rubber nano composite material. The invention substitutes the traditional high-structure carbon black packing by adopting the organic nano montmorillonoid, reduces the thermogenesis of the material under the dynamic loading effect and the same hardness by adopting less packing usage amounts, effectively prevents internal cracks of the material from generating and expanding by utilizing the layered structure of the nano montmorillonoid, and obtains a series of natural rubber materials with excellent fatigue-resisting performance without sacrificing the tensile breaking strength and the breaking elongation ratio of the material at the same time.

Owner:SICHUAN UNIV

Anti-tear conveyer belt covering rubber with low rolling resistance and preparation method thereof

The invention relates to anti-tear conveyer belt covering rubber with low rolling resistance and a preparation method thereof. The formula of the covering rubber comprises the following components in parts by weight: 100 parts of raw rubber systems, 4-8 parts of activating systems, 38-55 parts of reinforcing agents, 2-5 parts of plasticizers, 1-3 parts of fibers, 3-9 parts of anti-aging systems, 1-3 parts of coupling agents and 3-7 parts of vulcanization systems. These components can be prepared into the anti-tear conveyer belt covering rubber with low rolling resistance by the procedures of plastifying, banburying, milling and vulcanizing. On the basis that main body rubber is natural rubber and adopts butadiene rubber, the reinforcing system is subjected to bridging action by adopting an aramid short fiber, the rolling resistance and dynamic heating of the covering rubber are obviously reduced, and meanwhile, the rubber has high tearing resistance, wear-resisting property and anti-fatigue performance.

Owner:中德(扬州)输送工程技术有限公司

Steel wire protective layer repair adhesive for retreading radial aircraft tire and application of steel wire protective layer repair adhesive

ActiveCN104262699AHigh tensile strengthHigh tear strengthNatural rubber adhesivesNon-macromolecular adhesive additivesAdhesive cementKetone

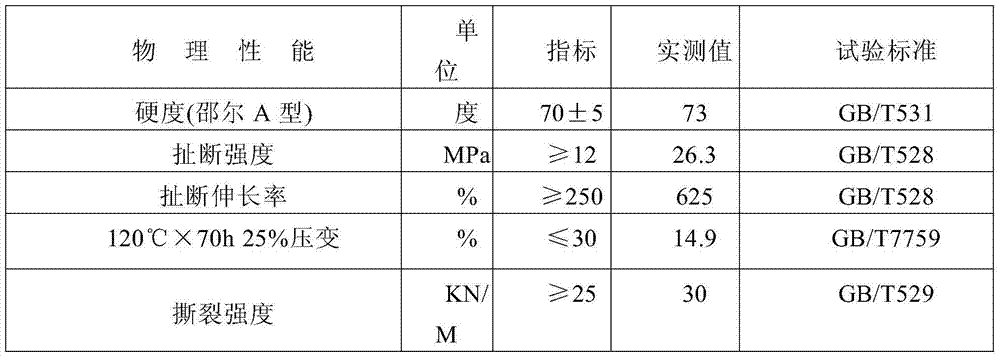

The invention discloses a steel wire protective layer repair adhesive for retreading a radial aircraft tire and application of the steel wire protective layer repair adhesive. The steel wire protective layer repair adhesive is prepared by taking natural rubber as a main material, taking styrene-butadiene rubber, an adhesive, cobalt boroacylate, phenolic resin, high-dispersion white carbon black, a silane coupling agent, carbon black with high wear resistance, a ketone amine type anti-aging agent, insoluble sulfur and a sulfonamide type accelerator as main auxiliary materials, and mixing by an open mill or an internal mixer. The application is that a rubber compound is mixed with a solvent, namely gasoline according to the mixture ratio of 1: (3-6) to prepare adhesive cement of the repair adhesive, and the rubber compound is additionally pressed into a slice on a tabletting machine and cut into a certain size to form a rubber piece which is used as the rubber piece of the repair adhesive. The adhesive has the advantages of relatively high tensile strength, tear strength and stress at definite elongation, good resistance to thermal aging and low dynamic heat production; furthermore, the adhesive has good adhesion performance with a steel wire, and the adhesion performance of the adhesive after thermal aging with the steel wire is not reduced significantly.

Owner:中国化工集团曙光橡胶工业研究设计院有限公司

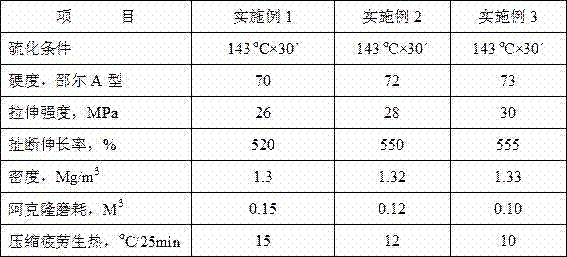

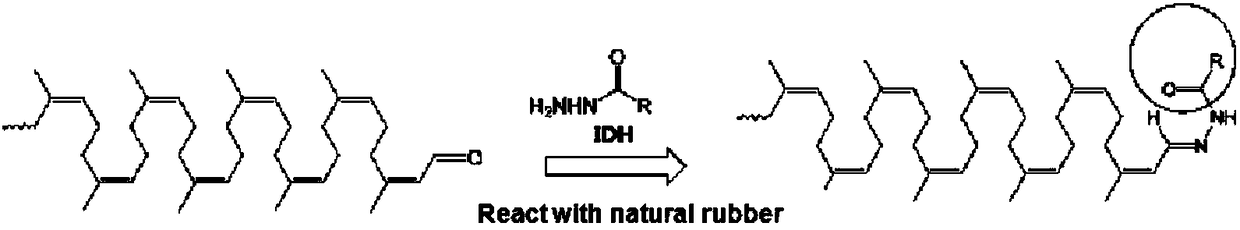

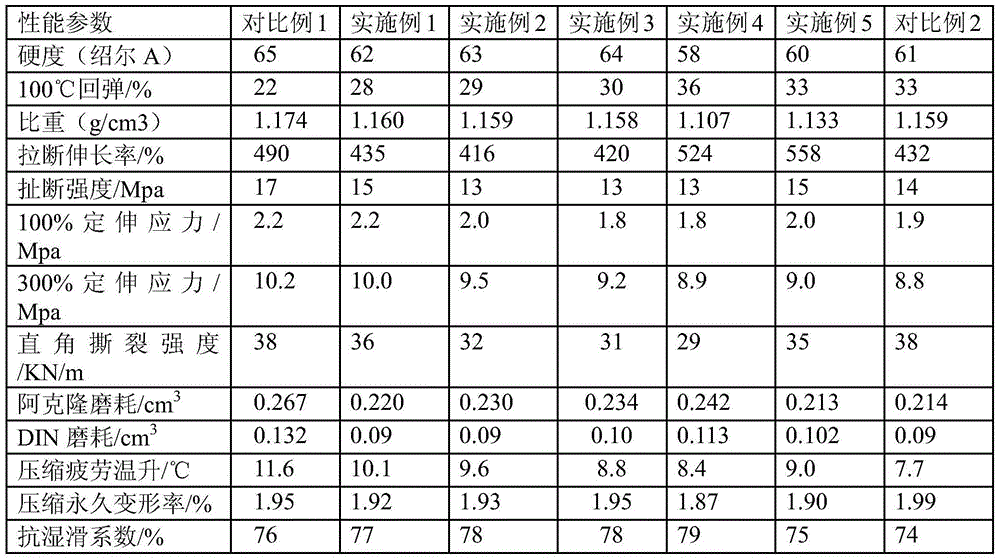

Isophthalic dihydrazide-contained tread rubber composition for radial tire and preparation method thereof

The invention relates to the technical field of tire rubber, and particularly discloses an isophthalic dihydrazide-contained tread rubber composition for a radial tire and a preparation method thereof. The isophthalic dihydrazide-contained tread rubber composition is prepared from the following raw materials in parts by weight: 100 parts of polyisoprene, 30 to 50 parts of carbon black, 2 to 10 parts of a petroleum plasticizer, 5 to 20 parts of silicon dioxide, 1 to 3 parts of stearic acid, 2 to 5 parts of zinc oxide, 1 to 4 parts of protective wax, 1 to 3 parts of a silane coupling agent, 0.2to 1 part of isophthalic dihydrazide, 0 to 3 parts of N-tert-butyl-2-benzothiazolyl sulfenamide, 1 to 3 parts of N,N'-dimethyl-p-phenylenediamine, 1 to 4 parts of sulfur powder and 0.1 to 1 part of ascorch retarder, and is prepared through mixing.

Owner:TRIANGLE TIRE

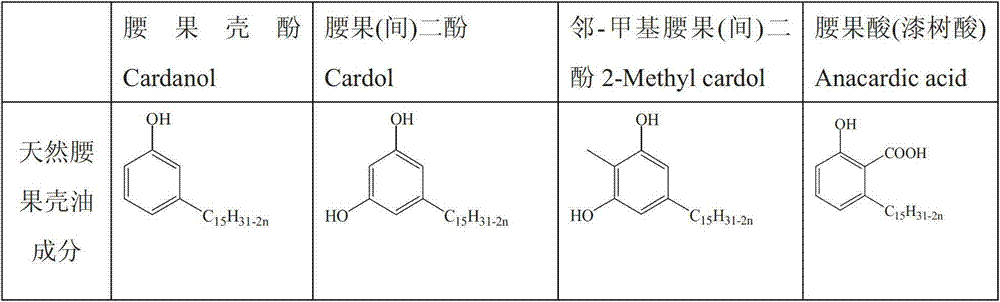

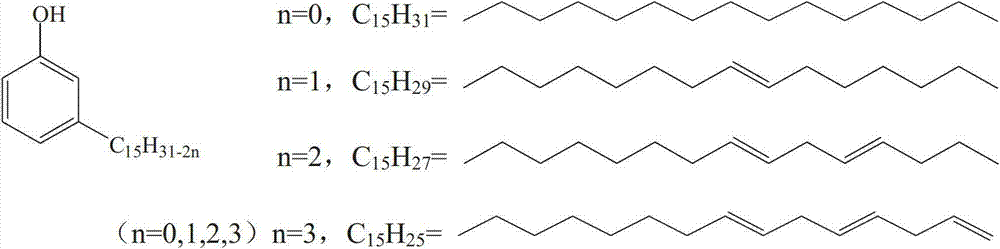

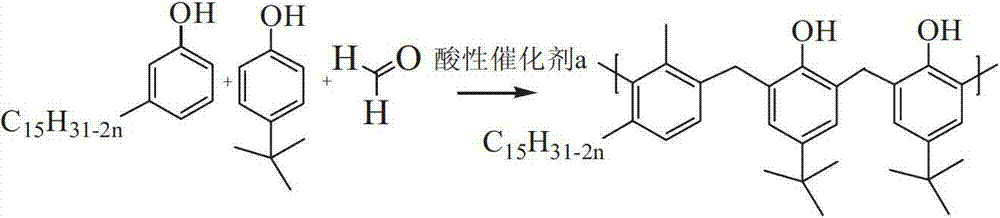

Cashew oil modified alkyl phenol-phenol formaldehyde tackifying resin, preparation method and application thereof

The present invention provides a cashew oil modified alkyl phenol-phenol formaldehyde tackifying resin, which is a cardanol and alkyl phenol formaldehyde copolymerized product, wherein the polymer side chain is a long carbon chain having unsaturated double bonds, and the softening point is 100-140 DEG C. The present invention further discloses a preparation method and an application of the cashew oil modified alkyl phenol-phenol formaldehyde tackifying resin, wherein the cashew oil modified alkyl phenol-phenol formaldehyde tackifying resin can be adopted as a rubber tackifier so as to provide good self-adhesion for the rubber material and reduce dynamic heat production of the rubber, and the rubber tackifier is particularly suitable for tire production.

Owner:SINO LEGEND CHINA CHEM +1

Tread rubber of radial tire

InactiveCN105418993AGood anti-aging performanceImprove cut resistanceSpecial tyresAging resistanceHeat resistance

The invention relates to tread rubber of a radial tire. The tread rubber disclosed by the invention is prepared by mixing natural rubber, butadiene styrene rubber and cis-1,4-polyisoprene rubber; due to the matching of other auxiliary materials, the tread rubber not only has good properties of cutting resistance, prickling resistance, crack extension resistance and tear and chipping resistance, but also has the characteristics of lower dynamic heat generation and better heat resistance; the tread rubber can be used for a long time and is not easy to age, and a prepared tire is good in abrasion resistance and aging resistance.

Owner:SHANDONG YONGTAI CHEM GROUP

All-steel radial tire combined rubber compound for improving shoulder separation and tread separation

ActiveCN107722379AHigh modulusReduce dynamic heatingSpecial tyresRolling resistance optimizationAging resistanceSulfur

The invention discloses an all-steel radial tire combined rubber compound for improving shoulder separation and tread separation. The all-steel radial tire combined rubber compound is respectively used for preparing shoulder pad rubber and base part rubber. The all-steel radial tire combined rubber compound comprises, by weight, 80.0-100.0 parts of natural rubber, 0-20.0 parts of cis-polybutadienerubber, 15.0-45.0 parts of carbon black, 8.0-15.0 parts of white carbon black, 3.0-6.0 parts of zinc oxide, 1.0-3.5 parts of an activator stearic acid, 1.0-2.0 parts of a carbon black dispersant, 0.5-2.0 parts of an antioxidant RD, 1.0-2.5 parts of an antioxidant 4020, 1.3-3.8 parts of a silane coupling agent, 1.5-3.0 parts of insoluble sulfur IS7020, 0.8-1.8 parts of an accelerator NS, 0.1-0.3 part of a scorch retarder and 0.5-2.0 parts of alkyl phenol disulfide. The above formula rubber compound has a high modulus at a given elongation, so the deformation of a tire under the same load is reduced, thereby heat generated by compression deformation and curling is reduced; and the rubber compound has the advantages of low dynamic heat, good aging resistance, improvement of the long-time high load driving resistance of the tire, and effective reduction of the shoulder separation, tread separation and other symptoms.

Owner:SAILUN GRP CO LTD

V belt capable of reducing dynamic heat build-up

The invention particularly relates to a V belt capable of reducing dynamic heat build-up and belongs to the technical field of rubber V belt production. According to a traditional V belt primer, viscose powder is added to the components, such as a chloroprene rubber adhesive, cis-butadiene rubber, magnesium oxide, stearic acid and carbon black, the viscose powder is an inert filler with relatively coarse particles, so that the distance between molecular chains can be increased in the rubber molecular chains, friction between the molecular chains is reduced and internal stress dispersion is facilitated, thereby reducing dynamic heat build-up and prolonging the service life of a product.

Owner:浙江保尔力橡塑股份有限公司

Zinc oxide special for natural rubber and preparation method of zinc oxide

The invention discloses zinc oxide special for natural rubber and a preparation method of the zinc oxide. The zinc oxide special for the natural rubber comprises, by weight, 50-70 parts of zinc oxide, 10-20 parts of zinc stearate, 15-25 parts of zinc p-toluate and 2-5 parts of dispersant. The preparation method of the zinc oxide comprises the following steps of 1, adding the dispersant to a zinc sulfate solution, and conducting stirring so that the dispersant can be uniformly dispersed in the solution; 2, adding p-toluylic acid and stearic acid to a sodium hydroxide solution, conducting stirring while the mixture is heated to 60 DEG C, and continuing with heat preservation and stirring till a reaction is conducted completely; 3, under the condition that stirring is conducted ceaselessly, adjusting the pH value of a mixed solution which is obtained in step 1 and step 2 after the reaction is conducted for a while with a sodium hydroxide solution, continuing stirring till the reaction is ended, and then conducting centrifugal separation; 4, drying filter cakes obtained after separation, so that the zinc oxide special for the natural rubber is obtained. The zinc oxide has the vulcanization activating function and can improve anti-vulcanization reversion performance of the natural rubber, and dispersibility of the zinc oxide in a rubber material is good.

Owner:JIANGSU ATE DONGTAI NEW MATERIALS TECH

Bicycle tire tread rubber

InactiveCN104292514ASmall deformabilityLight in massSpecial tyresRolling resistance optimizationRolling resistanceStearic acid

The invention relates to the technical field of tires, and discloses a bicycle tire tread rubber which comprises the following raw materials in parts by weight: 80-90 parts of natural rubber, 10-20 parts of cis-1,4-polybutadiene rubber, 15-30 parts of plasticizer, 25-58 parts of silica white, 1-10 parts of vulcanizing agent, 1-20 parts of accelerator, 1-9 parts of zinc oxide, 0.1-2 parts of calcium carbonate, 1-10 parts of reinforcing agent cb, 0.1-2 parts of stearic acid, 2-5 parts of anti-aging agent aw, 2-5 parts of anti-aging agent 4010, 1-2 parts of paraffin and 1-10 parts of silane coupling agent. The bicycle tire tread rubber has the advantages of tear resistance, fatigue resistance, heat resistance, abrasion resistance, aging resistance, small deformability, light weight, favorable water absorptivity, long service life, low compressive heat generation and dynamic heat generation, small permanent deformation, favorable anti-slip property and small rolling resistance, and can well absorb shock load.

Owner:MINGGUANG RUITAI IND

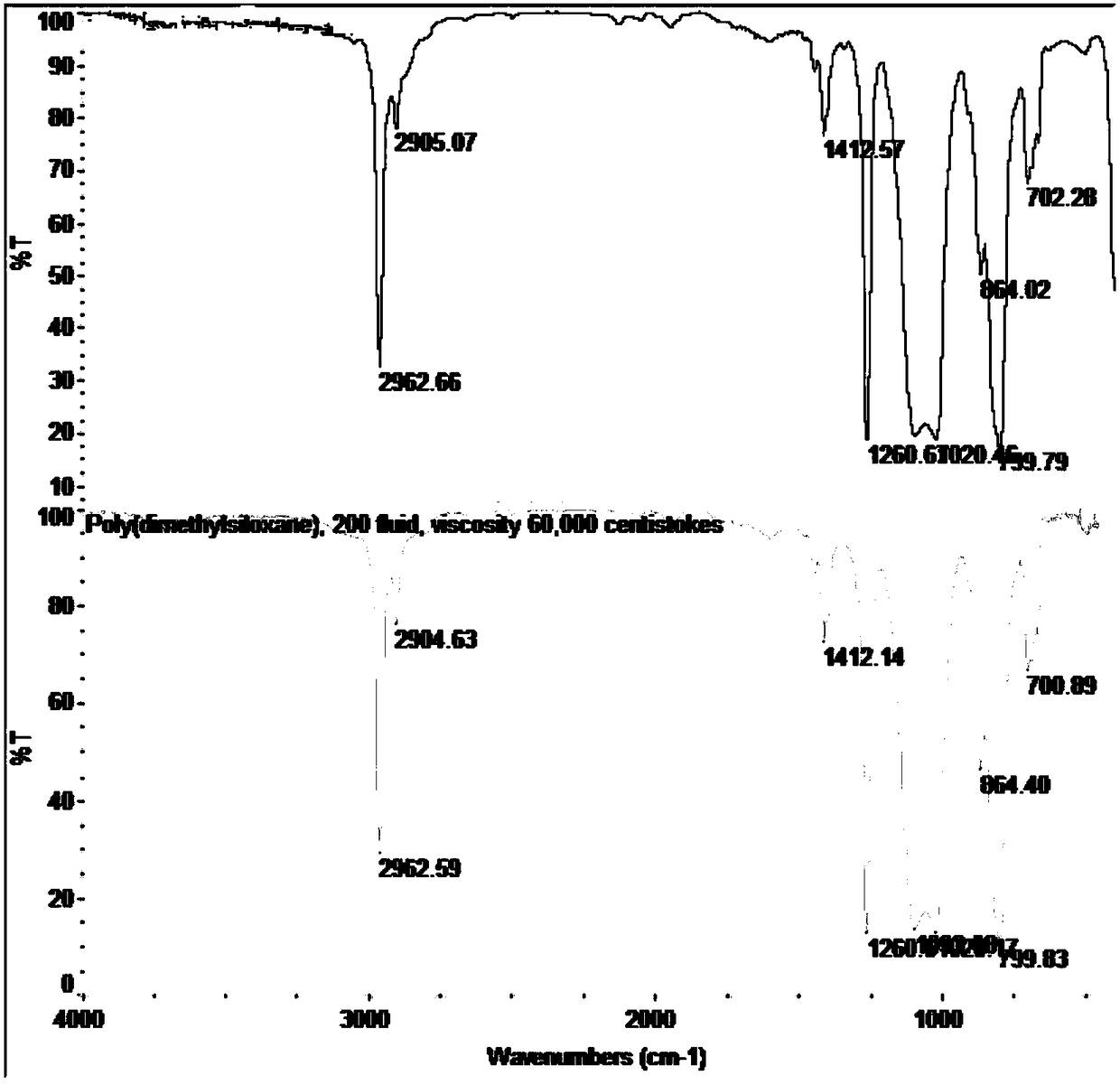

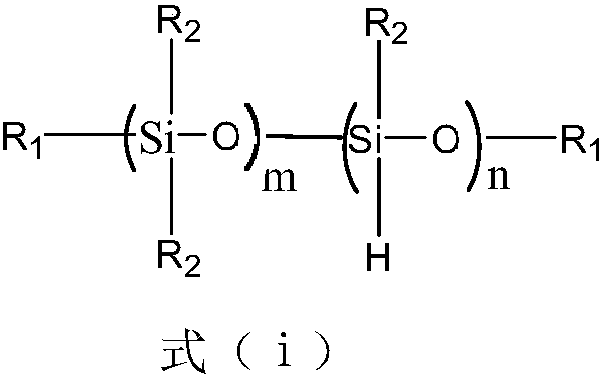

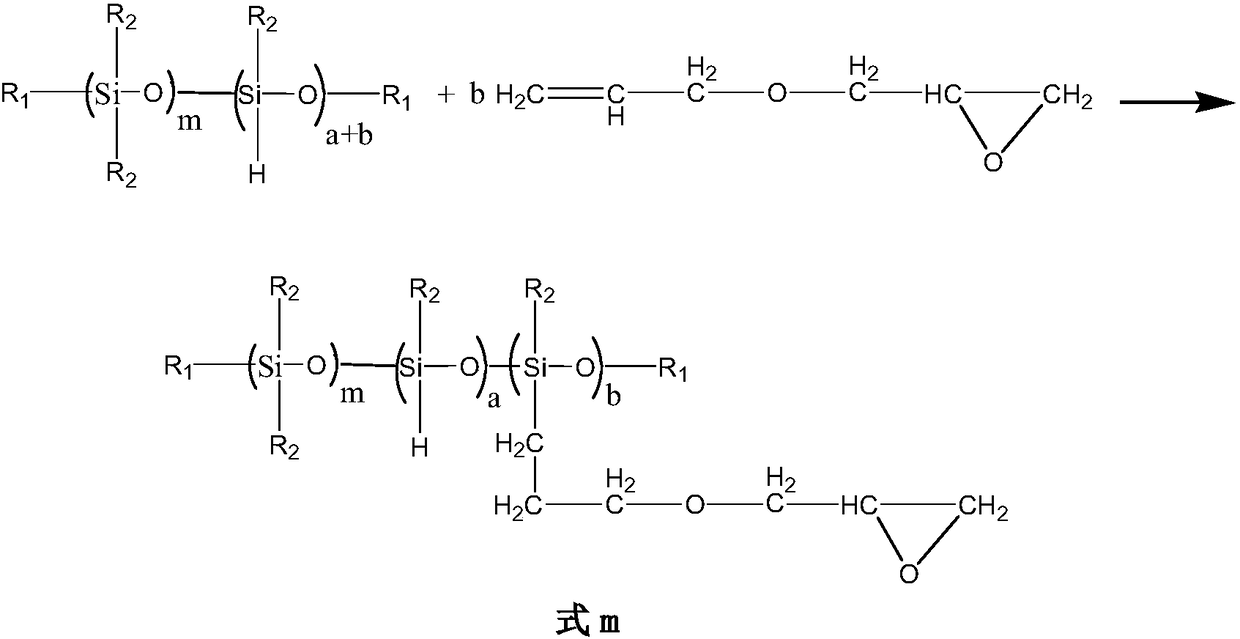

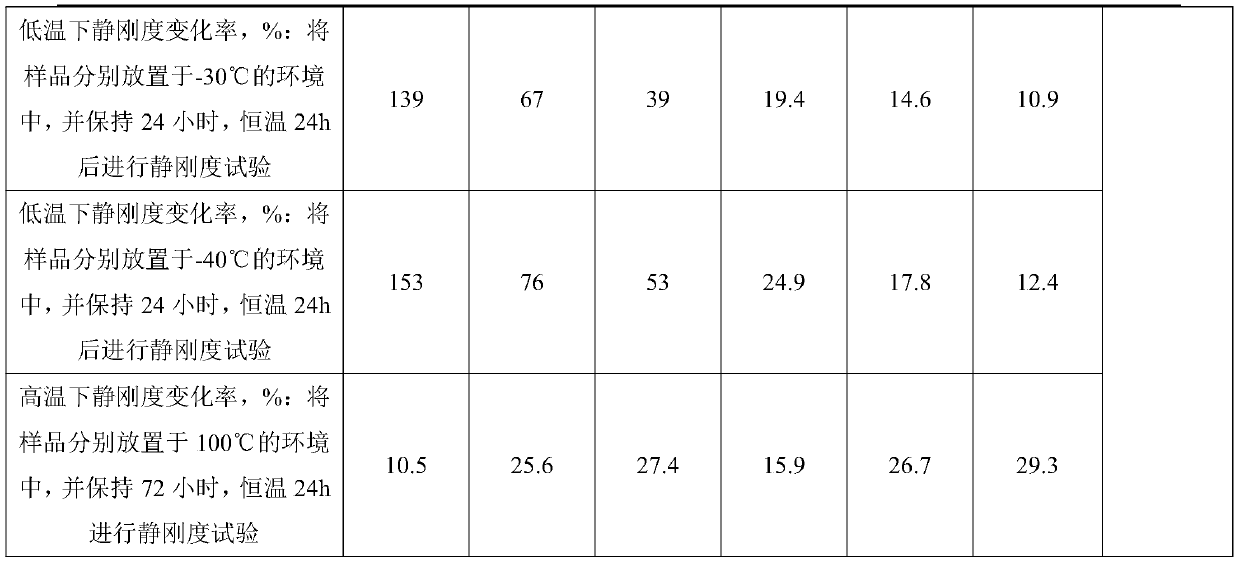

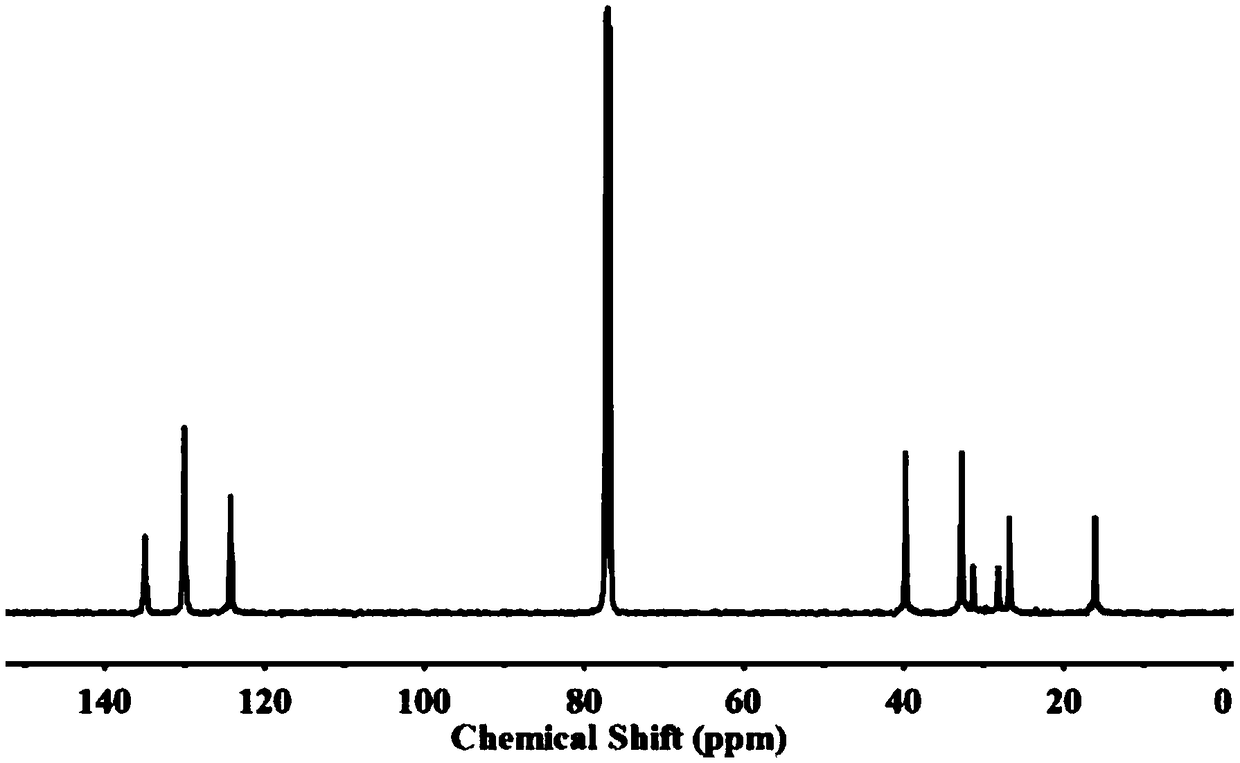

Unsaturated epoxidized polysiloxane, preparation method and applications thereof

The present invention relates to an unsaturated epoxidized polysiloxane, a preparation method and applications thereof, wherein the unsaturated epoxidized polysiloxane modifies a polybutadiene-styreneactive lithium polymer. According to the present invention, the unsaturated epoxidized polysiloxane contains an unsaturated double bond and a plurality of epoxy groups having high activity, does nothave active silicon-hydrogen bond, and can efficiently carrying out coupling or end capping reaction on an epoxy group and the terminal active lithium of a styrene-butadiene random copolymer to obtaina polyfunctionalized solution polymerized styrene-butadiene rubber, wherein the tire tread vulcanized rubber has low dynamic heat generation and the rolling resistance decrease rate is more than 28%by using the polyfunctionalized SSBR raw rubber as the radial semi-steel tire tread rubber. According to the present invention, whether the silicon-hydrogen addition reaction or the ammonia esterification reaction of the residual silicon-hydrogen and isocyanate is the homogeneous reaction, the preparation method is simple, the reaction is easy to control, and the method is suitable for industrialproduction.

Owner:CHINA PETROLEUM & CHEM CORP +1

Cold-resistant EPDM (ethylene propylene diene monomer) composite material and preparation method thereof

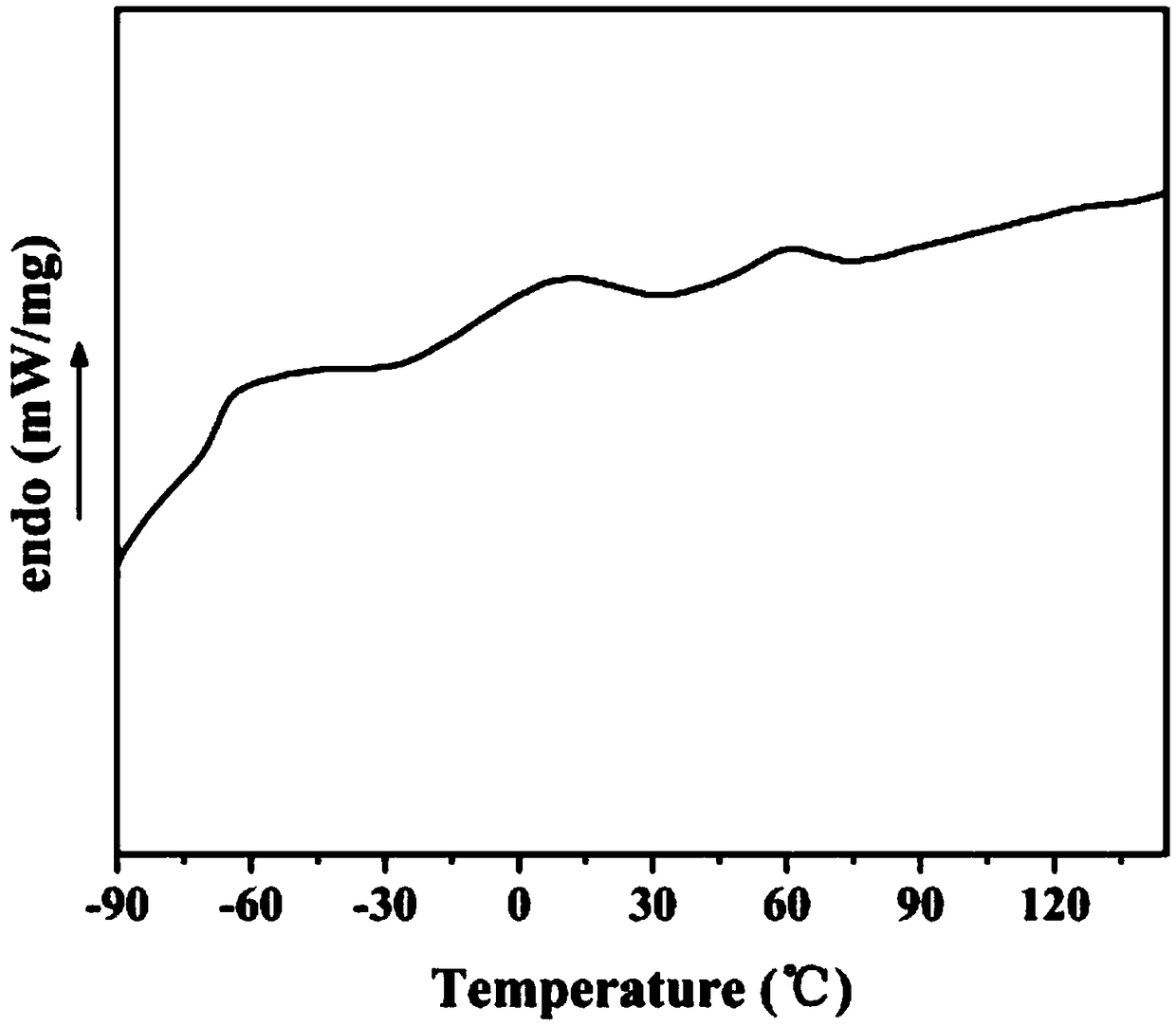

ActiveCN110183784ALower glass transition temperatureGood low temperatureRubber materialVitrification

The invention discloses a cold-resistant EPDM (ethylene propylene diene monomer) composite material which comprises the following components in parts by weight: 100 parts of crude rubber, 30-60 partsof a softening plasticizer, 90-140 parts of a reinforcing agent, 6-9 parts of a vulcanization accelerator and 2-4 parts of an anti-aging agent, wherein the crude rubber comprises an EPDM and an ethylene butene diene monomer; and the mass ratio of the EPDM to the ethylene butene diene monomer is (30:70)-((70:30). By optimizing constitution components of the crude rubber, the softening plasticizer,the vulcanization accelerator and the like, the glass-transition temperature of a rubber material can be reduced, and the rubber material has good low-temperature properties, is capable of maintainingthe elasticity and normal working capabilities at a low temperature and improving product reliability, and is applicable to working conditions at minus 40 DEG C or even minus 50 DEG C.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Preparation method of high trans-1,4-isoprene-butadiene copolymer

The invention discloses a preparation method of a high trans-1,4-isoprene-butadiene copolymer. By adopting a solution slurry method, isoprene and butadiene are catalyzed to be polymerized by a supported titanium catalyst and further the high trans-1,4-isoprene-butadiene copolymer is synthesized. The copolymer consists of an isoprene unit with the mole fraction of 42.8 to 89.9 percent and a butadiene unit with the mole fraction of 10.1 to 57.2 percent; the mole contents of trans-1,4-configurations of the isoprene unit and the butadiene unit are both greater than 97 percent. Compared with high trans-1,4-polyisoprene and high trans-1,4-polybutadiene, the copolymer as a novel trans-1,4-polydiolefin has the advantage that processing and blending properties are remarkably improved; meanwhile, the copolymer has excellent dynamic properties such as small rolling resistance, good flexural fatigue resistance and low dynamic heat build-up and provides an ideal sizing material for high-performancegreen tires.

Owner:QINGDAO UNIV OF SCI & TECH

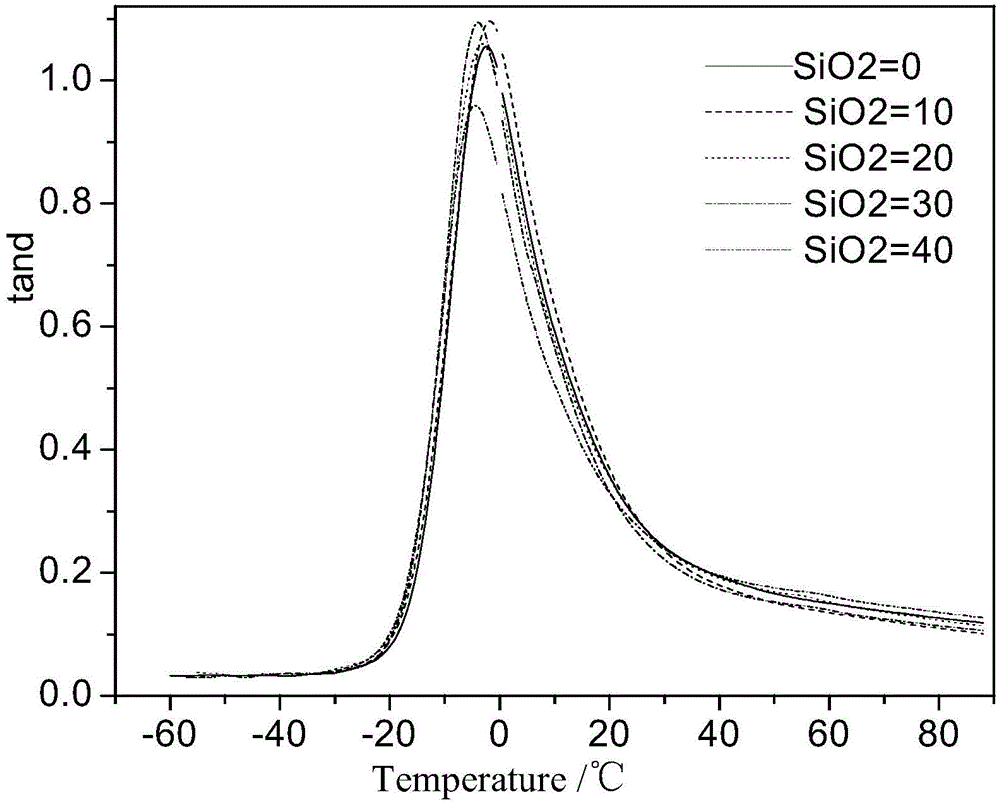

Rubber composition for high-speed energy-saving tire tread

ActiveCN105295128AImprove feedabilityImprove blending effectSpecial tyresRolling resistance optimizationRubber materialRolling resistance

The present invention relates to a rubber composition for a high-speed energy-saving tire tread, and belongs to the technical field of tire and rubber processing. The rubber composition comprises the following components: 100 parts by mass of HVPBR, 10-50 parts by mass of white carbon, 0-40 parts by mass of carbon black, and 0-2.7 parts by mass of a silane coupling agent, wherein a total amount of the white carbon and the carbon black is 50 parts by mass. Compared with the conventional rubber material for a tire tread, the rubber composition contains high vinyl polybutadiene with a branched structure, so that the consistency of the white carbon and a rubber material is improved, and the processability is improved. On the premise of ensuring excellent wet traction, the rolling resistance and dynamic heat build-up of the tread are reduced without causing obvious loss of traction force, thereby meeting a development concept of low-carbon economy that is currently advocated.

Owner:CHINA PETROLEUM & CHEM CORP

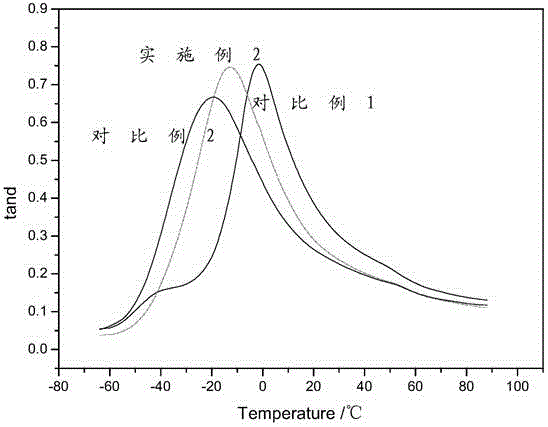

White carbon black reinforced rubber composition for semi-steel tire treads

InactiveCN105273250AReduce rolling resistanceLow heat generationSpecial tyresRolling resistance optimizationReinforced rubberSemi-steel

The invention relates to a white carbon black reinforced rubber composition for semi-steel tire treads, and belongs to the technical field of tire and rubber processing. The composition comprises, by mass, 50-60 parts of HVPBR, 40-50 parts of NR, and 50-70 parts of white carbon black; and a processing assistant and a filler can be added according to routine tread rubber performances. The high wet skid resistance and the low rolling resistance of the HVPBR containing a branched structure are used, the branched structure is in favor of realizing rubber and white carbon black blending and realizing processing performances and the mechanical strength of the NR, and the HVPBR, the NR and the white carbon black are compounded and are used in the production of tire treads. Compared with synthetic rubber materials for traditional semi-steel tire treads, high vinyl polybutadiene (HVPBR) has the advantages of low cost, improvement of the compatibility of the white carbon black and the rubber material, improvement of the processing performances, guaranteeing of excellent wet skid resistance, reduction of the rolling resistance and the dynamic heating of the treads, and no obvious traction loss.

Owner:CHINA PETROLEUM & CHEM CORP

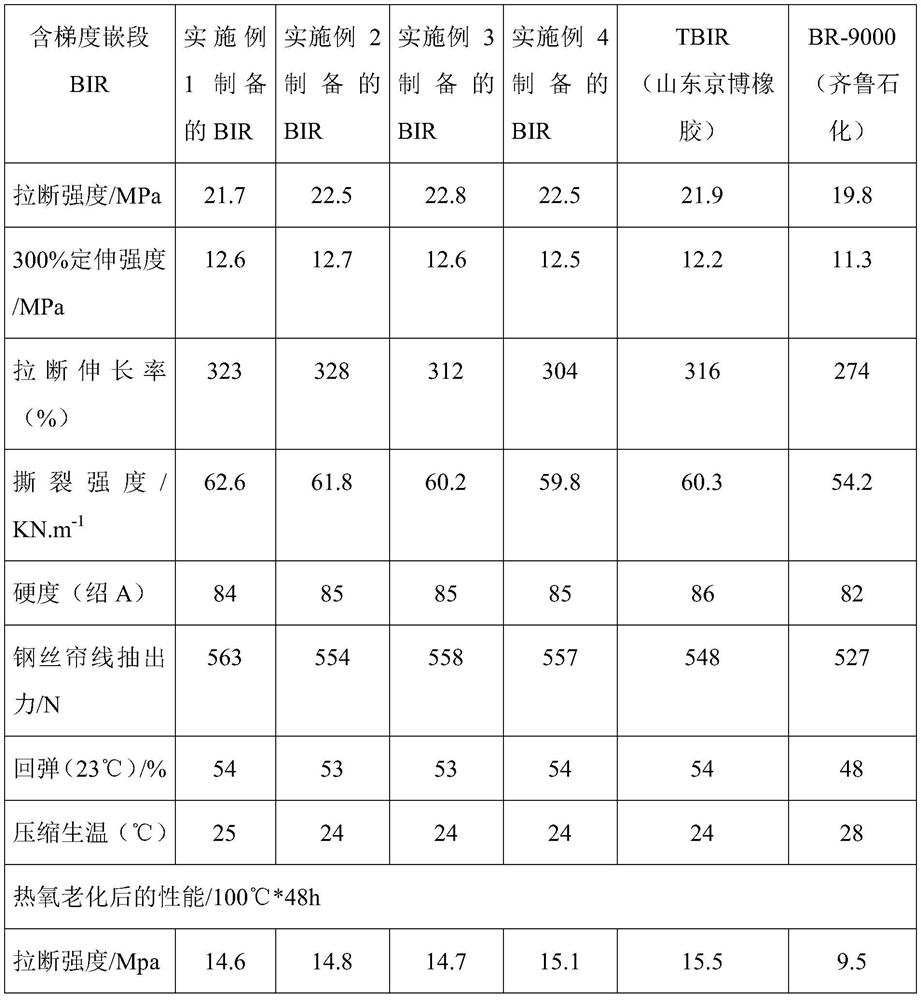

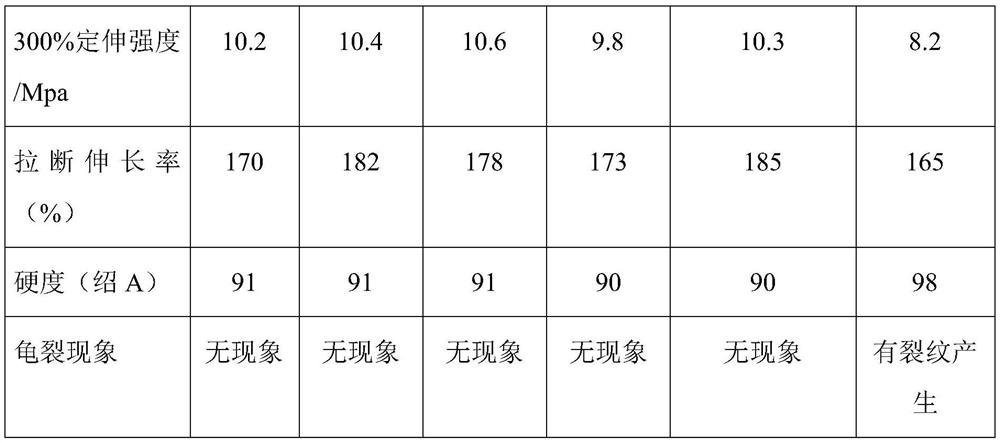

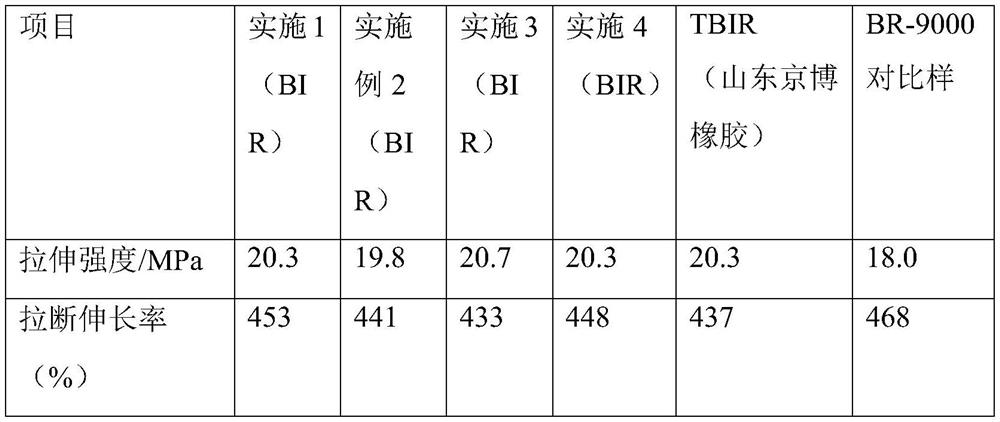

All-steel truck radial tire formula rubber material and preparation method thereof

PendingCN113563685AExcellent mutual adhesionCompatibleSpecial tyresRolling resistance optimizationRubber materialVulcanization

The invention discloses an all-steel truck radial tire formula rubber material and a preparation method thereof, and a tread rubber material, a sidewall rubber material and a tire base rubber material of the all-steel truck radial tire formula rubber material all use butadiene-isoprene copolymer rubber (BIR) with wide distribution, high melt elasticity, high branching and high trans 1, 4-addition unit content and multi-block units in gradient distribution, natural rubber or / and styrene butadiene rubber and the like, The matched composite material has excellent processability, and the composite vulcanized rubber material has the characteristics of good compatibility, high strength, low heat generation, flexing resistance, cracking resistance, aging resistance, wet skid resistance and low rolling resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of preparation method of silica grafted graphene oxide/rubber composite material

The invention relates to a preparation method of a silicon dioxide graft graphene oxide / rubber composite material, which comprises the following steps: by using natural rubber as a main material and superhigh-wear-resistance carbon black, high-dispersity silica white, silica white dispersing agent, silicon dioxide graft graphene oxide nanoparticles, silane coupling agent, heat stabilizer HS-80 and anti-reversion agent WK-901 as auxiliary materials, mixing according to certain parts by weight, compounding with a Banbury mixer to prepare compounded rubber, and extruding the compounded rubber with an extruder to prepare the semifinished product rubber. The composite material blended from the silicon dioxide graft graphene oxide and natural rubber has the characteristics of low heat generation, high tensile strength, high tearing strength, favorable abrasion resistance, favorable heat stability and the like. When being applied to aircraft tire tread rubber, compared with the traditional tread rubber, the rubber has the advantages of higher use safety and longer service life.

Owner:中国化工集团曙光橡胶工业研究设计院有限公司

Bridge damping support

The invention discloses a bridge damping support, and relates to the field of bridge construction. The bridge damping support sequentially comprises a top plate, a stainless steel plate, a polytetrafluoroethylene plate, a middle steel plate, a rubber block and a bottom basin, the rubber block is arranged in the bottom basin, and sealing rings are arranged between the rubber block and the middle steel plate. The rubber block comprises, by weight, 60-90 parts of natural rubber, 25-40 parts of butadiene rubber, 1-3 parts of sulfur, 3-6 parts of nano zinc oxide, 2-4 parts of stearic acid, 0.8-1.5parts of accelerant, 2-5 parts of silane coupling agent, 20-30 parts of reinforcing agent, 25-35 parts of carbon black and 1-3 parts of lecithin. The bridge damping support is mainly composed of the natural rubber and the butadiene rubber, has outstanding mechanical properties and is high in tensile strength and tearing strength, molecular chain breaking caused by the action of external mechanicalstress is not likely to happen, and the anti-seismic property is excellent. The lecithin serves as a modifier so that the carbon black can carry out in-situ grafting reaction, then the mechanical aging resistance of the rubber block is improved, and the service life is greatly prolonged.

Owner:浙江名博建设有限公司

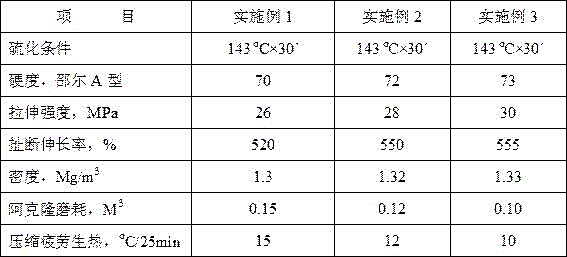

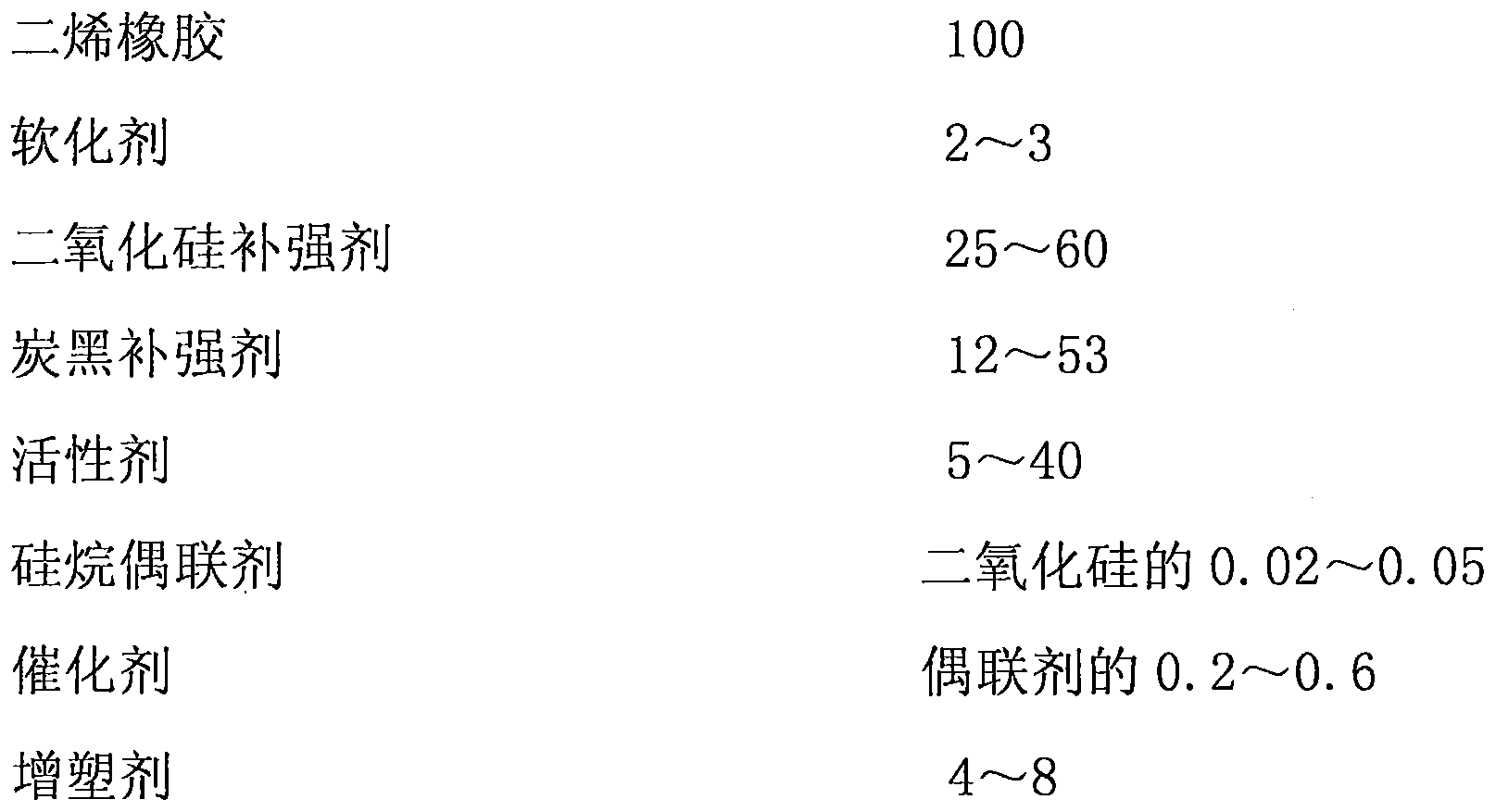

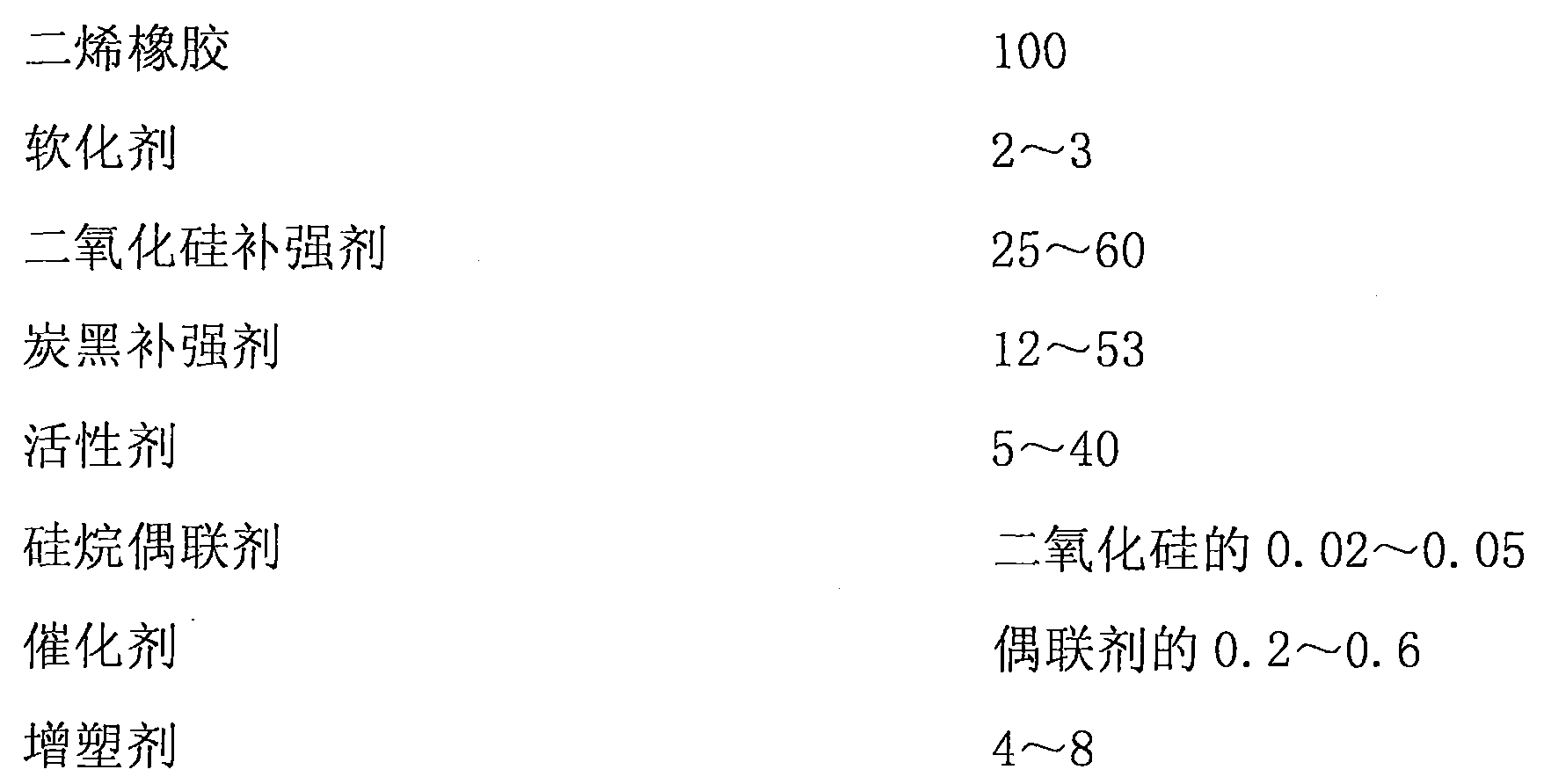

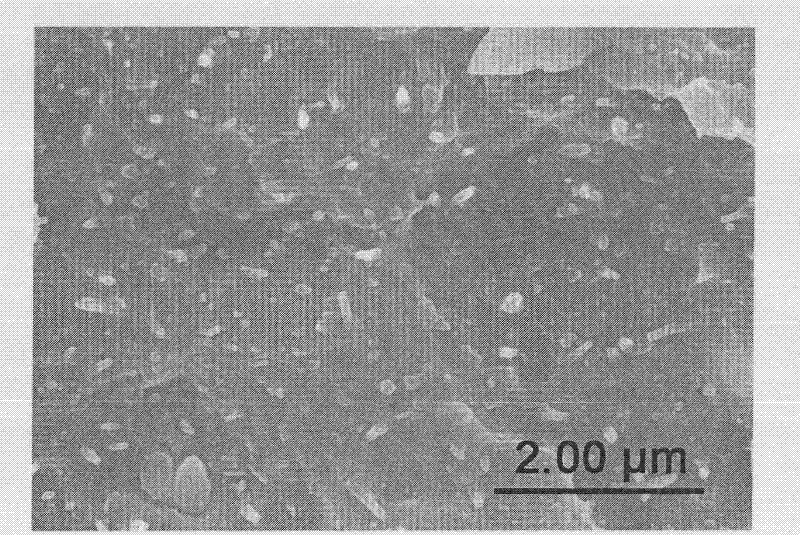

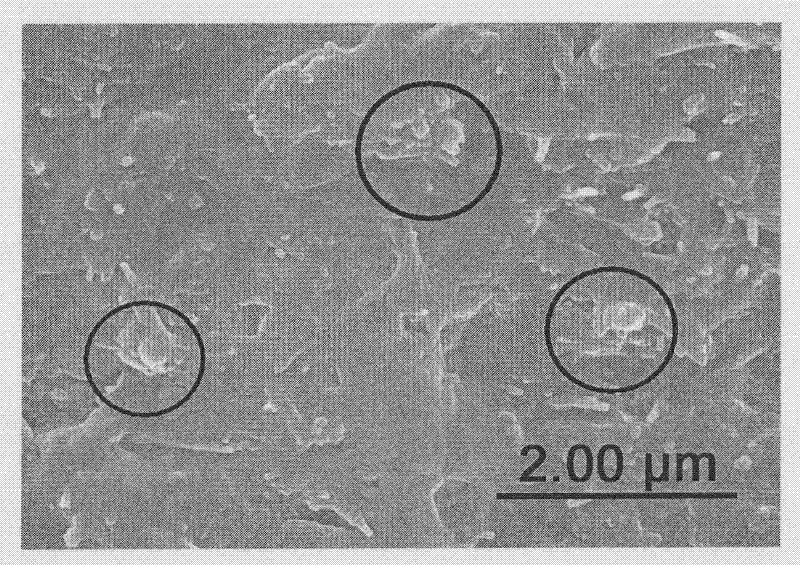

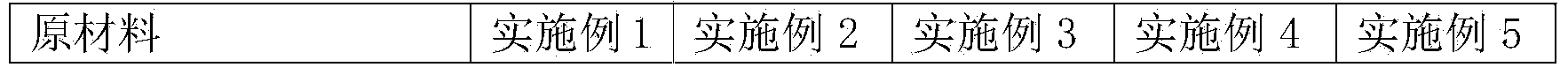

A kind of silica reinforced diene rubber

The invention belongs to the technical field of rubber materials, and relates to rubber materials and processing technology, in particular to the composition and processing technology of silica-reinforced diene rubber. The invention relates to a silica-reinforced diene rubber, which uses diene rubber as the main polymer, silica as the main reinforcing agent, silane as the coupling agent, zinc oxide as the active agent, and 2 -Mercaptobenzothiazole is used as a catalyst, especially related to the combined application of silicon dioxide and zinc oxide, and the rubber composition is prepared by adopting reactive mixing technology in a closed mixing equipment. The rubber composition has excellent comprehensive performance, especially low dynamic heat generation and good bonding performance.

Owner:NO 53 RES INST OF CHINA NORTH IND GRP

Rubber nano short fiber composite material for automobile tire and preparation method thereof

InactiveCN101885862BHigh hardnessHigh modulusSpecial tyresBulk chemical productionHardnessFibrous composites

The invention relates to a rubber nano short fiber composite material for an automobile tire and a preparation method thereof. By modifying needle-like silicate through a CO2 supercritical method, the needle-like silicate is dissociated into nano short fiber in the process of mixing with a rubber matrix, and soft carbon black is added. The prepared composite material is used as an automobile tireapex, and has the characteristics of high hardness, high modulus, low heat generation, and excellent processability.

Owner:BEIJING UNIV OF CHEM TECH

All-steel radial giant engineering tire sidewall filling rubber

The invention discloses an all-steel radial giant engineering tire sidewall filling rubber which is composed of the following components in parts by weight: 100 parts of natural rubber, 10-25 parts of white carbon black, 20-50 parts of hard carbon black, 6-15 parts of softening agent, 2-4 parts of resorcinol, 6-15 parts of zinc oxide, 1-3 parts of stearic acid, 2-7 parts of anti-aging system, 1.3-3.5 parts of vulcanization system, 0.8-1.5 parts of accelerator and 0.1-0.5 part of anti-scorching agent. The sidewall filling rubber prepared according to the formula has the advantages of low heat generation, excellent bending resistance, moderate hardness and moderate stress at definite elongation, and can obtain favorable balance between Mooney viscosity and tire adhesiveness.

Owner:HAOHUA SOUTH CHINAGUILIN RUBBER

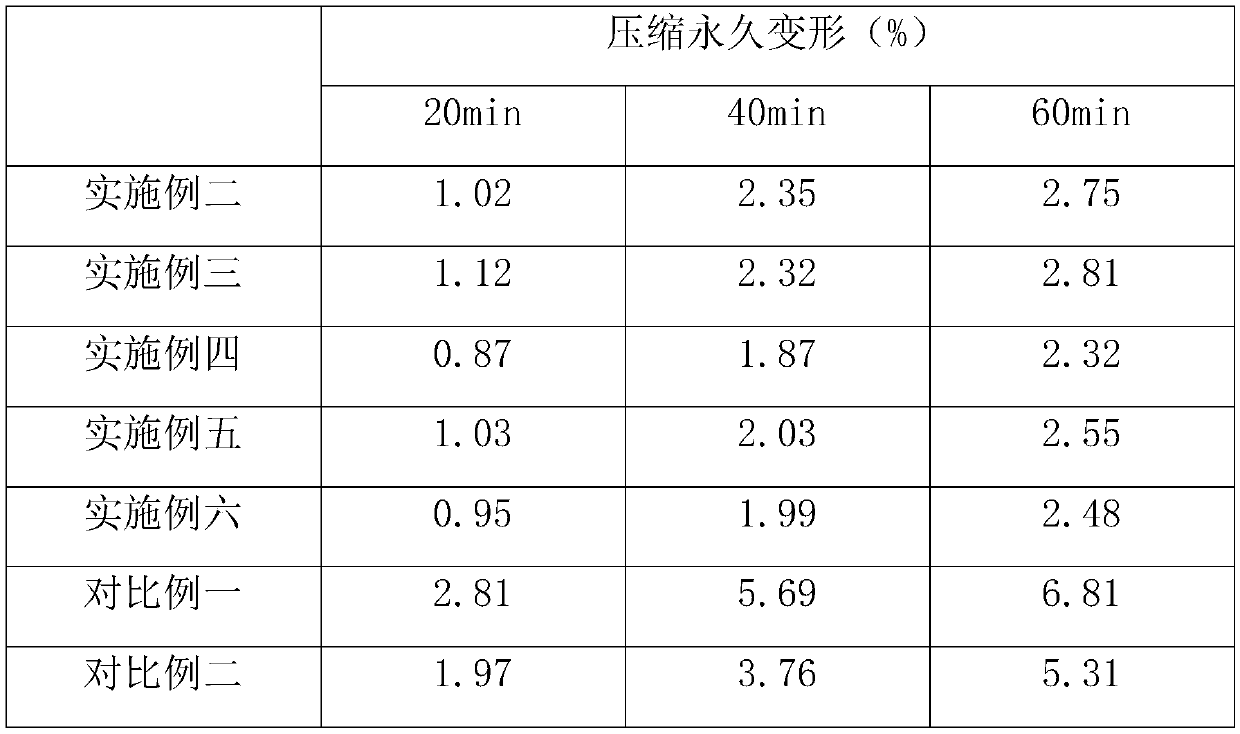

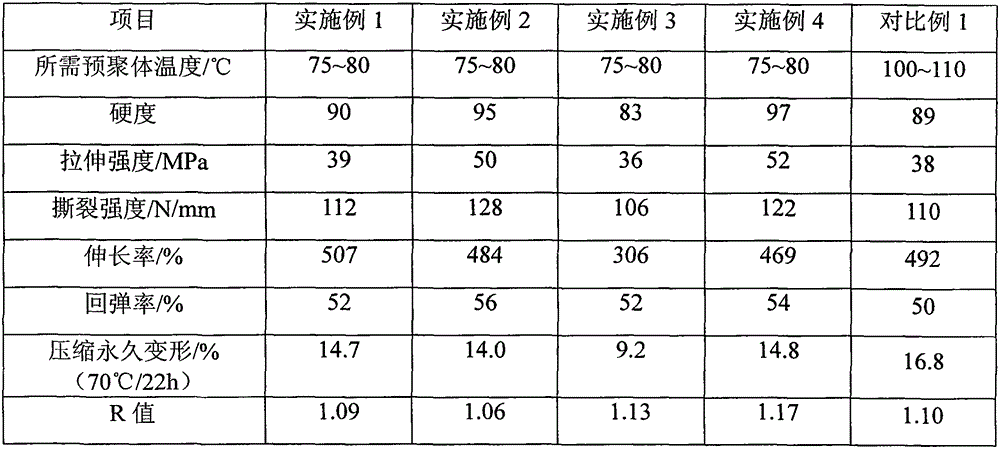

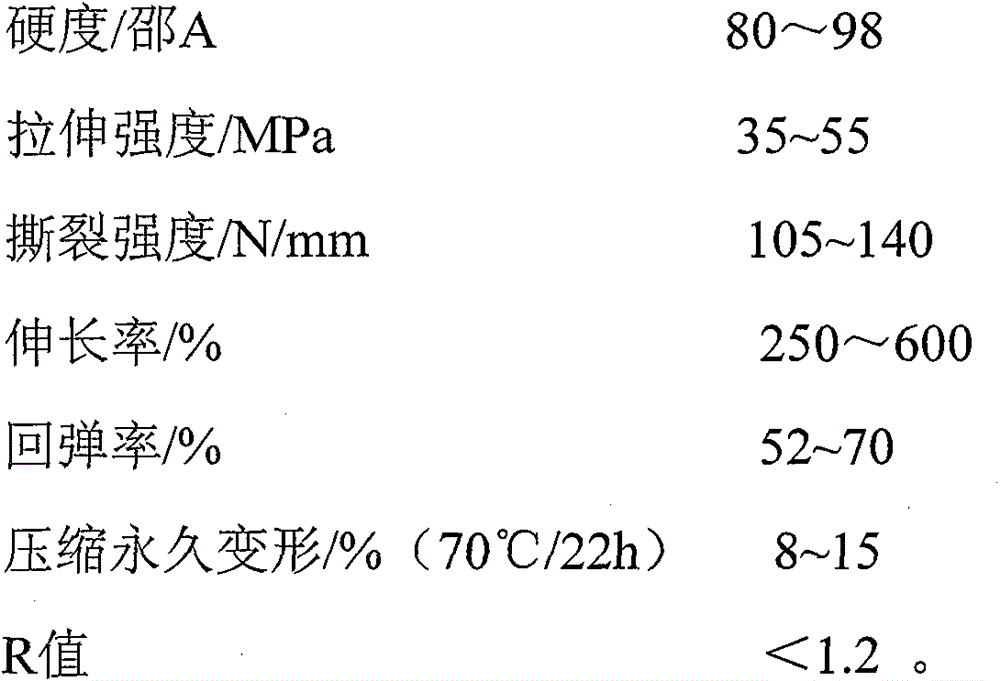

A kind of high-performance polyurethane elastomer and preparation method thereof

The invention discloses a high-performance polyurethane elastomer and a preparation method thereof. The high-performance polyurethane elastomer comprises two parts, i.e., a prepolymer component (component A) and a chain extender (component B), wherein the component A comprises the following materials in parts by weight: 100 parts of macromolecular dihydric alcohol and 14-35 parts of PPDI; the component B comprises the following materials in parts by weight: 100 parts of chain extender and 0.1-0.5 part of catalyst; the weight ratio of the component A to the component B is 100: 6-15; the chain extender is micromolecular dihydric alcohol, three-functionality-degree alcohol amine, three-functionality-degree alcohol or combination thereof; the micromolecular dihydric alcohol is selected from resorcinol-bi(beta-ethoxyl) ether (HER) or composition of the resorcinol-bi (beta-ethoxyl) ether (HER) and p-hydroquinone-bi(beta-ethoxyl) ether (HQEE) in the weight ratio of 1:0-2. The obtained elastomer material has the advantages that the permanent deformation is small, the resilience is excellent, the heat resistance and the mechanical performance are good and the temperature for the use and the operation of the prepolymer is low.

Owner:LIMING RES INST OF CHEM IND

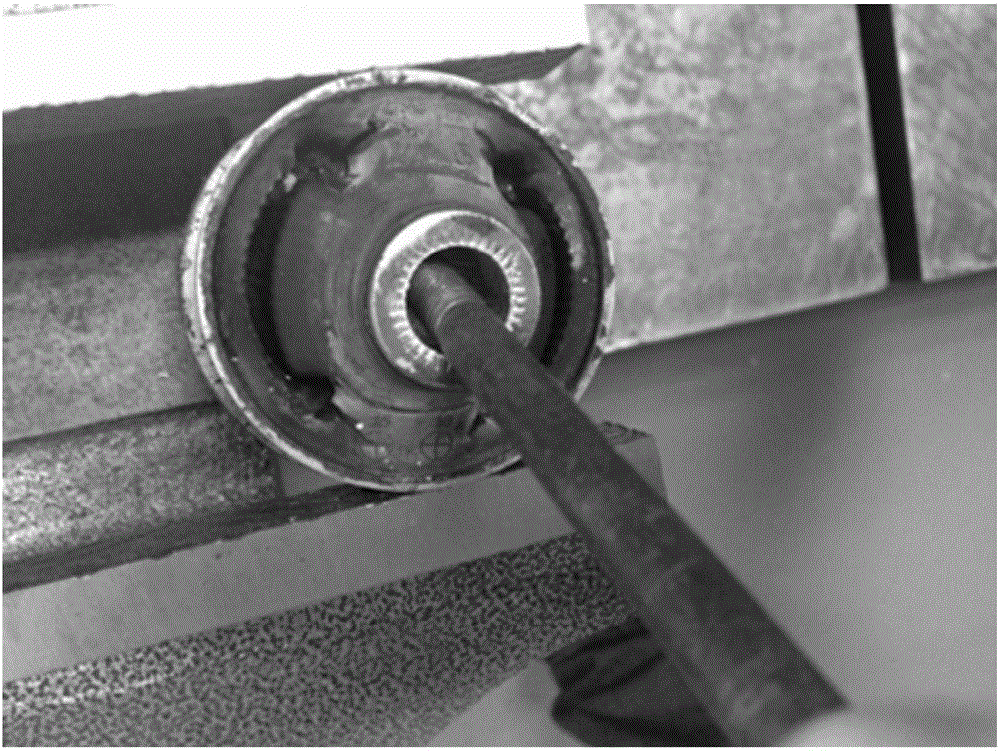

Rubber for swing arm liner bushings and preparation method for rubber

The invention relates to rubber for swing arm liner bushings. The rubber contains the following ingredients in percentage by mass: 10% to 30% of constant-viscose glue, 20% to 40% of cis-butadiene rubber, 30% to 40% of filler, 2% to 3.5% of plasticizer, 1% to 3% of accelerant, 1% to 4% of anti-aging agent 4010NA, 0.5% to 2% of anti-aging agent MB and 1.5% to 4% of antioxidant-1178, wherein the sum of mass percent of the constant-viscose glue and mass percent of the cis-butadiene rubber is 50% to 56%. A preparation method for the rubber for the swing arm liner bushings comprises the following steps: (1) carrying out plastication: firstly, weighing all the ingredients in percentage by mass; then, carrying out plastication on the constant-viscose glue and the cis-butadiene rubber, and then, carrying out standing for 22 to 48 hours; then, carrying out milling on the mixture and the other ingredients except for the accelerant; and then, carrying out standing for 22 to 48 hours, then, adding the accelerant to the mixture, and carrying out milling; and (2) carrying out curing for 9 to 14 minutes at the curing temperature of 155 DEG C to 165 DEG C and the mold-locking pressure of 15MPa to 25MPa. Compared with the prior art, the rubber for the swing arm liner bushings and the preparation method for the rubber have the characteristics that the service life is relatively long, and the stability in use is relatively good.

Owner:NINGBO YONGXIN AUTO COMPONENTS MFG

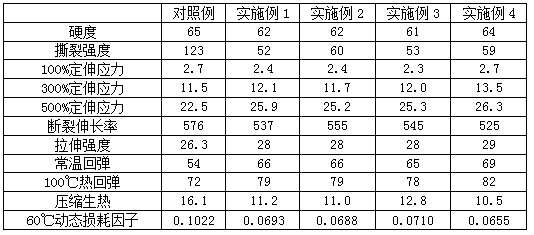

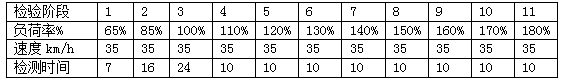

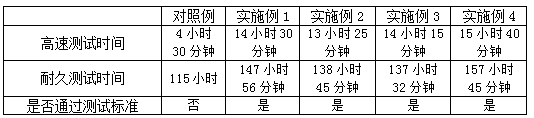

Special tyre-based rubber composition for engineering mechanical tire

InactiveCN108017807AImprove basic mechanical propertiesIncrease speedSpecial tyresRubber materialStearic acid

The invention relates to the technical field of tire rubber, and concretely relates to a special tire-based rubber composition for an engineering mechanical tire. The special tire-based rubber composition for the engineering mechanical tire is characterized by being prepraed from the following raw materials in parts by weight: 100 parts of natural rubber as a base, 35 to 45 parts of carbon black N330, 0 to 6 parts of white carbon black, 1.0 to 3.0 parts of stearic acid, 2.0 to 5.0 parts of zinc oxide, 0.7 to 1.0 part of N-tert-butyl-2-benzothiazole sulfenamide., 1.5 to 2.5 parts of sulphur, 0.5 to 1.0 part of anti-aging agent 4020, and 0.5 to 1.5 parts of anti-aging agent RD. According to the special tire-based rubber composition for the engineering mechanical tire, provided by the invention, the dynamic heating can be reduced by 30 percent or more, meanwhile, a basic mechanical property of a rubber material is improved, and standard requirements on high speed and durability tests of F-class tire products for a travelling crane are met.

Owner:TRIANGLE TIRE

Preparation method of aircraft tire

The invention discloses a preparation method of an aircraft tire. The aircraft tire comprises an airtight layer, a tire body layer, a tire crown layer and a tire tread which are sequentially arrangedfrom inside to outside, wherein the tire tread comprises a tire tread layer and tire side layers, the tire tread layer is provided with linear textures, and the tire side layers are arranged on the two sides of the tread layer; tire teeth are arranged between tire toes and tire heels of the tire body layer; the tire body layer comprises a tire body cord fabric layer and a buffer layer which are sequentially arranged from inside to outside, wherein the buffer layer is arranged between the tire body layer and the tire tread layer; and the tire body cord fabric layer is composed of a plurality ofcord fabric rubber layers and anti-wrapped cord fabric nylon net layers which are arranged alternately. According to the technical scheme, the method comprises the following steps of S1, preparing the tire crown layer; S2, preparing the tire teeth; S3, preparing a tire bag; S4, preparing tire side layers; S5, preparing the tire tread layer; S6, preparing the tire body; S7, preparing a green tiresemi-finished product; S8, preparing a green tire; and S9, forming. The preparation method has the advantages of being wide in raw material source, simple in preparation process, low in production cost, energy-saving and environment-friendly, easy to popularize and the like.

Owner:T RUBBER

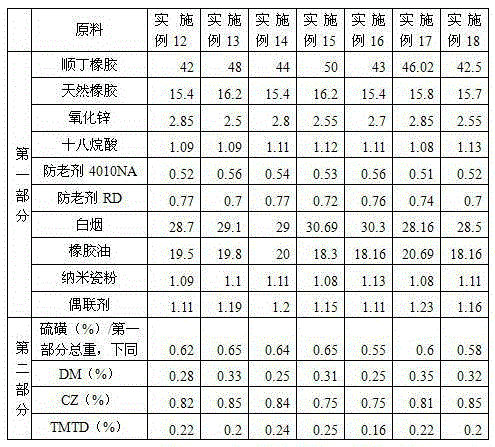

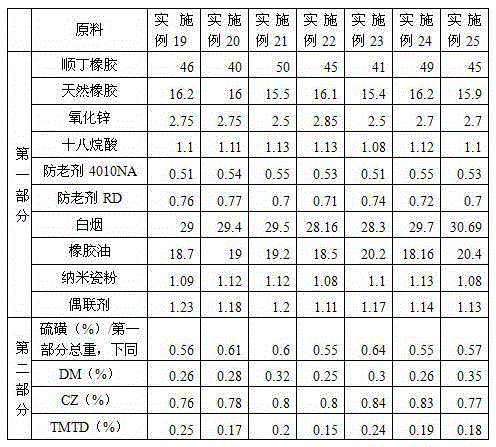

Novel traceless multifunctional training shoe rubber sole and preparation method thereof

The invention relates to a novel traceless multifunctional training shoe rubber sole and a preparation method thereof. The novel traceless multifunctional training shoe rubber sole consists of the following raw materials: butadiene rubber, natural rubber, zinc oxide, octadecanoic acid, an anti-aging agent, white smoke, rubber oil, nano ceramic powder, a coupling agent, sulfur and a vulcanization accelerator. When the traceless multifunctional training shoe rubber sole prepared by adopting the method is rubbed on a white ceramic tile, the surface of the white ceramic tile is clean and has no rubber sole scratch mark, and the resilience and abrasion resistance of the rubber also meet various property requirements of training shoes.

Owner:JIHUA 3515 LEATHER & SHOES

Tire rubber having cutting and abrasion resistance and low thermogenesis

InactiveCN105218880AExtended service lifeHigh tensile strengthSpecial tyresVulcanizationButadiene Dioxide

The invention relates to a development method of tire rubber having cutting resistance and abrasion resistance as well as low thermogenesis and solves the problem of early damage of tires traveling to and fro between paved roads and non-paved roads of mining areas in mid-short distance heavy-load regions, that is, requirements of the tires for puncturing resistance and cutting chipping resistance during traveling on the non-paved roads of the mining areas are met, requirements of the tires for abrasion resistance and low thermogenesis during traveling on the paved roads at high speeds are also met, so that the early damage of the tires is reduced, and the service lives of the tires are prolonged. According to the tire rubber, the rubber takes natural rubber as a main body and is synthesized with a small number of butadiene-styrene copolymers, and the basic abrasion resistance and cutting resistance of the tire rubber are guaranteed; a reinforcing system adopts both carbon black and white carbon black, in combination of a semi-efficient vulcanization system and a matched vulcanization technology, the excellent cutting resistance and abrasion resistance are acquired, and meanwhile, the thermogenesis of the rubber is also reduced.

Owner:AEOLUS TIRE

Nitrile rubber composition and crosslinked rubber product

Provided is a nitrile rubber composition characterized by containing carboxyl group-containing highly saturated nitrile rubber (a) that contains 5-60 wt% of alpha,beta-ethylenic unsaturated nitrile monomer units and has an iodine value of 120 or less, silica (b) having a specific surface area of 70 m2 / g or less, and a polyamine crosslinking agent (c), wherein the content of the polyamine crosslinking agent (c) is 0.1-20 parts by weight per 100 parts by weight of the carboxyl group-containing highly saturated nitrile rubber (a).

Owner:ZEON CORP

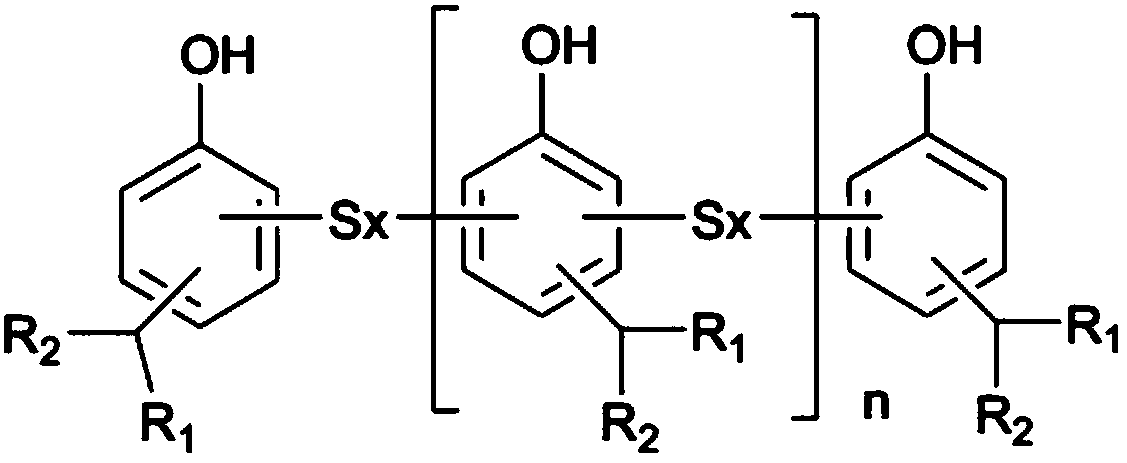

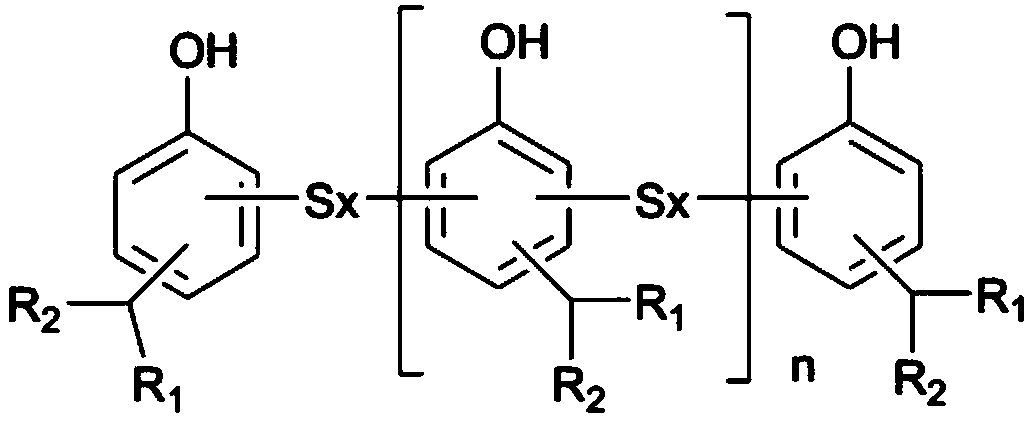

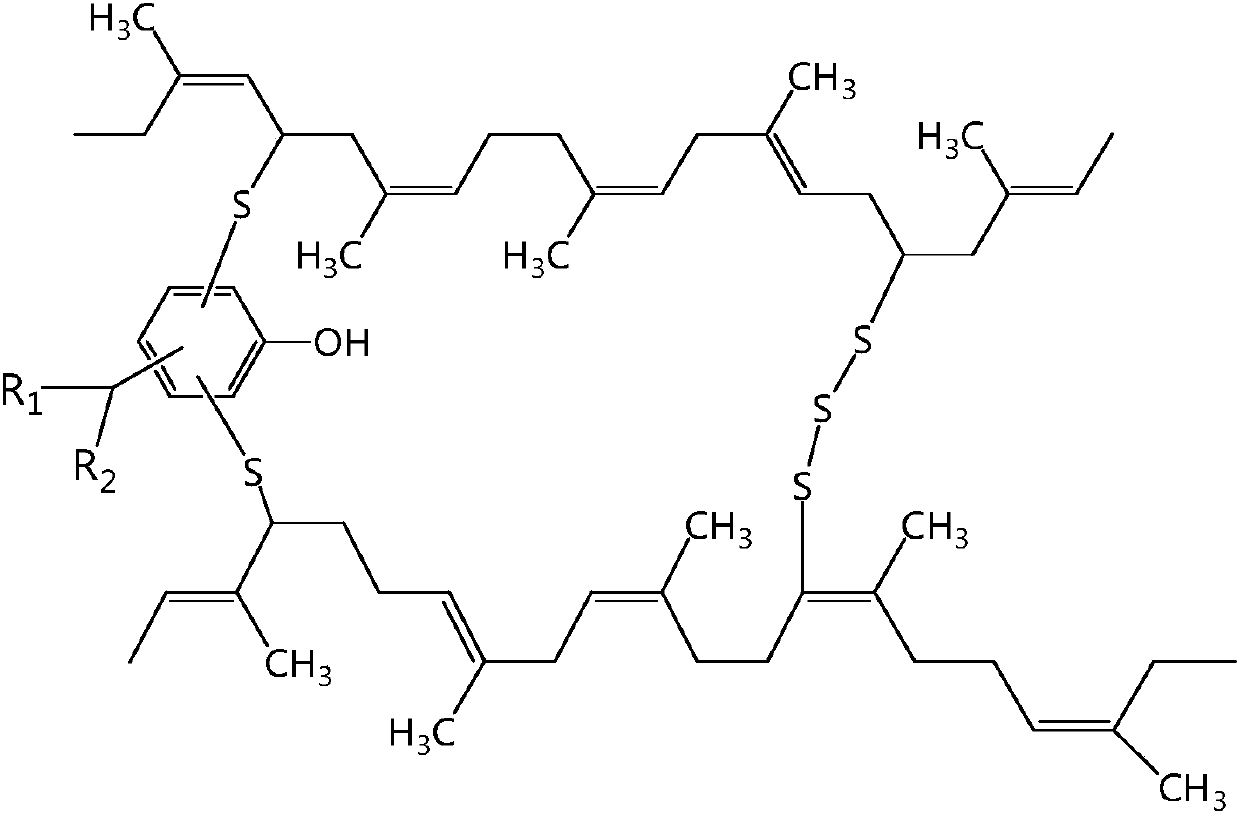

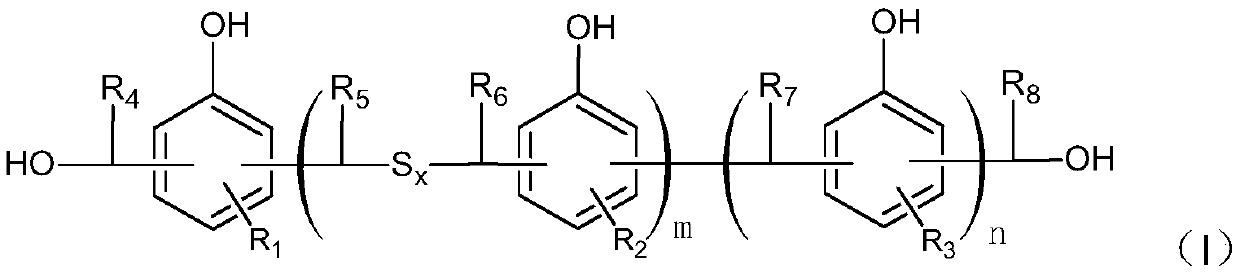

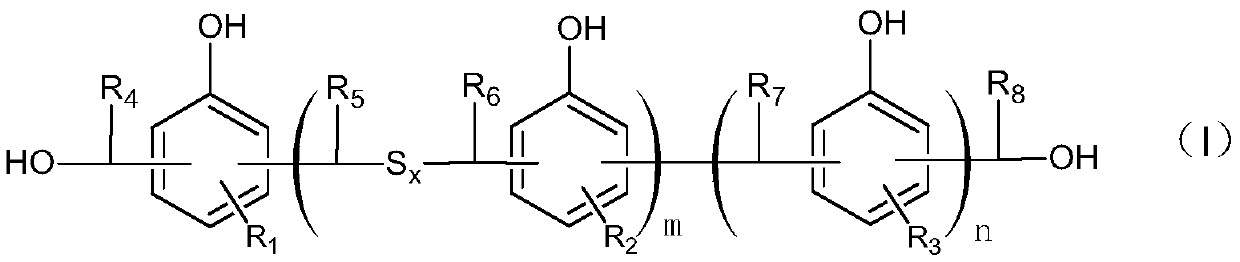

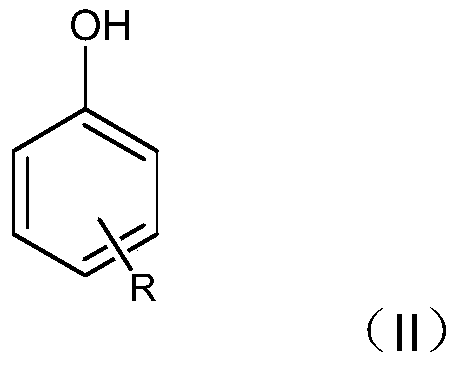

Rubber composition including phenolic resin containing polysulfur structure, and application and tire thereof

ActiveCN110878150AImprove flex propertiesImprove mechanical propertiesSpecial tyresRubber materialPolymer science

The invention relates to the technical field of rubber products, and concretely relates to a rubber composition including phenolic resin containing a polysulfur structure, an application of the rubbercomposition, and a tire produced by using the rubber composition. The rubber composition comprises 100 parts by weight of a rubber component and 1.0-20.0 parts by weight of the phenolic resin containing the polysulfur structure, and further comprises a methylene donor accounting for 3.0-25 wt% of the mass content of the phenolic resin containing the polysulfur structure. The rubber composition including phenolic resin containing the polysulfur structure can effectively improve the mechanical properties, the tear resistance, the cutting resistance and the puncture resistance of the rubber material under the same processing conditions, can reduce dynamic heat generation and improve the flexural property of the rubber compound, and is particularly suitable for the sidewall of the tire.

Owner:BEIJING RED AVENUE INNOVA +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com