Rubber nano short fiber composite material for automobile tire and preparation method thereof

A technology for automobile tires and composite materials, which is applied in the field of rubber nano-short fiber composite materials for automobile tires and its preparation, can solve the problem of low tensile strength and tensile stress of the composite materials, reducing the reinforcing effect of acicular silicate, and acicular Insufficient silicate modification and other problems, to achieve the effect of high tear strength and tensile stress, small deformation, and improved hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Nano-short fiber rubber composite material for automobile tire apex rubber, the mass parts of each component are:

[0037] 80 parts of natural rubber matrix;

[0038] 20 parts of epoxy natural rubber matrix;

[0039] 69.6 parts of modified palygorskite;

[0040] Soft carbon black N660 40 parts;

[0041] 2 parts paraffin oil;

[0042] 2 parts stearic acid;

[0044] 6 parts of sulfur;

[0045] Antiaging agent: 2 parts of 4010NA;

[0046] Vulcanization accelerator: NS 2 parts;

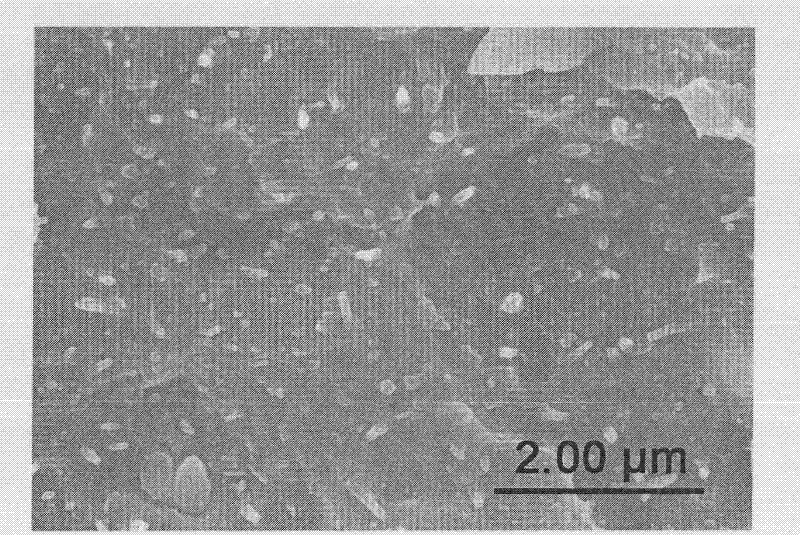

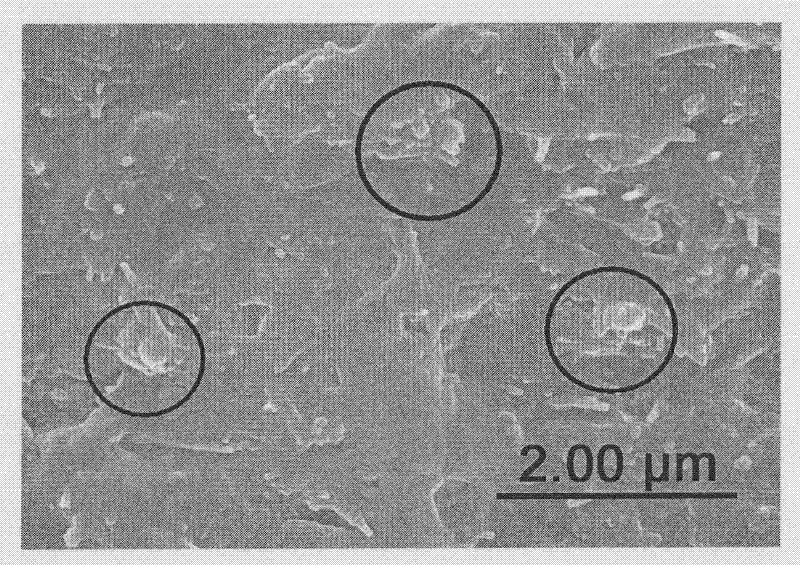

[0047] The modification method of palygorskite: 60 parts of 1250 mesh palygorskite, 7.2 parts of silane coupling agent γ-(2,3 glycidoxy) propyltrimethoxysilane and 2.4 parts of triethanolamine are added to the reactor, Then add dry ice and put a magnetic stirring bar at the same time. The reaction kettle is sealed and heated in a constant temperature oil bath at a temperature of 80°C until the pressure reaches 13MPa. Turn on the magnetic stirrer and stir for ...

Embodiment 2

[0050] Nano-short fiber rubber composite material for automobile tire apex rubber, the mass parts of each component are:

[0051] 85 parts of natural rubber matrix;

[0052] 15 parts of styrene-butadiene rubber matrix;

[0053] 92 parts of modified palygorskite;

[0054] Soft carbon black N642 30 parts;

[0055] 4 parts paraffin oil;

[0056] 3 parts of stearic acid;

[0058] 2 parts sulfur;

[0059] Antiaging agent: 4 parts of RD;

[0060] Vulcanization accelerator: 4 parts of CZ;

[0061] The modification method of palygorskite: add 80 parts of 1250 mesh palygorskite, 9 parts of vinyltriethoxysilane and 3 parts of triethanolamine into the reaction kettle, then add dry ice, and put a magnetic stirring bar at the same time, and the reaction kettle is sealed And heat it in a constant temperature oil bath at a temperature of 100°C until the pressure reaches 13.5 MPa. Turn on the magnetic stirrer and stir for 1.5 hours. After the reaction i...

Embodiment 3

[0064] Nano-short fiber rubber composite material for automobile tire apex rubber, the mass parts of each component are:

[0065] 90 parts of natural rubber matrix;

[0066] 10 parts of butadiene rubber matrix;

[0067] 38 parts of modified palygorskite;

[0068] Soft carbon black N539 60 parts;

[0069] 3 parts paraffin oil;

[0070] 2 parts stearic acid;

[0072] 5 parts of sulfur;

[0073] Anti-aging agent: 3 parts of 4020;

[0074] Vulcanization accelerator: 3 parts of DM;

[0075] The modification method of palygorskite: 30 parts of 1250 mesh palygorskites, 6 parts of bis-[γ (triethoxysilyl) propyl] tetrasulfide and 2 parts of triethanolamine are added to the reactor, and then dry ice is added. At the same time, put in a magnetic stirring rod, seal the reaction kettle and heat it in a constant temperature oil bath at a temperature of 40°C until the pressure reaches 10MPa. Turn on the magnetic stirrer and stir for 1.5 hours. After th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com