Rubber composition including phenolic resin containing polysulfur structure, and application and tire thereof

A technology of rubber composition and phenolic resin, which is applied in special tires, tire parts, transportation and packaging, etc. It can solve the problems of high dynamic heat generation, poor flexural properties of rubber compounds, and lack of flexibility of cross-linking bonds. , to improve the mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

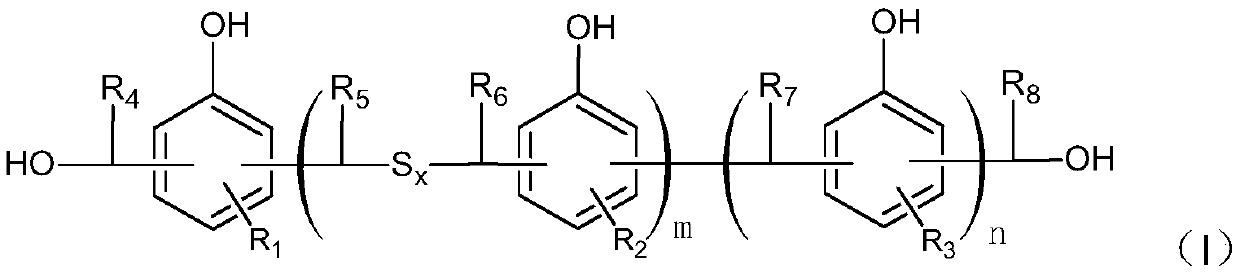

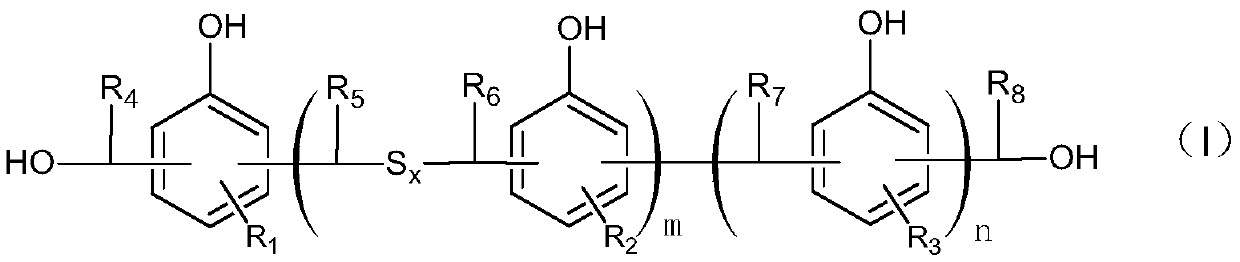

[0049] The phenolic resin containing methylene polysulfide structure shown in the formula (I) mentioned in the present invention can be prepared by the general method in the prior art, enumerate a kind of optional preparation method as example below, phenolic The preparation method of resin specifically comprises the following steps:

[0050] Step 1. Add sodium hydroxide or sodium sulfide, sulfur, and water into a reactor equipped with a stirring device, a thermometer and a back distillation device, raise the temperature to 80°C to 100°C, and react for 2 to 6 hours to obtain an aqueous solution of product A ;

[0051] Step 2, adding the product A aqueous solution, phenol or alkylphenol with a mass percent concentration of 10% to 50% into a reactor equipped with a stirring device, a thermometer and a back distillation device, and heating to 60°C to 100°C, After adding the aldehyde, stir the reaction at 60°C-100°C for 2-6 hours. After the reaction is completed, neutralize the r...

Embodiment 2

[0095] The phenolic resin that contains polysulfide structure among the embodiment 2 is shown in formula (VI),

[0096]

[0097] Wherein m=2-4, n=4-6.

Embodiment 3

[0098] The phenolic resin containing polysulfide structure in embodiment 3 is as shown in formula (VII),

[0099]

[0100] Wherein m=2-4, n=4-6.

[0101] The instruments and equipment adopted in each embodiment and comparative examples are as follows:

[0102] 1.6LBR1600 internal mixer, product of Farrel Company in the United States;

[0103] XK-160 open mill, product of Qingdao Xincheng Yiming Machinery Factory;

[0104] XLB-D600×600 flat vulcanizing machine, product of Zhejiang Huzhou Hongqiao Machinery Factory;

[0105] Model 3365 tensile machine, product of Instron Corporation of the United States;

[0106] Dynamic cutting test machine, a product of American Tap Company;

[0107] Compression heat generation instrument, the product of Alpha Company in the United States.

[0108] Table 1 comparative example and embodiment 1-3 formula table

[0109]

[0110] Table 2 Embodiment 4-6 formula table

[0111]

[0112] According to the formula shown in Table 1 and Ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com