Isophthalic dihydrazide-contained tread rubber composition for radial tire and preparation method thereof

A technology of isophthalic hydrazide and rubber composition, applied in the field of tire rubber, can solve the problems of high energy loss, large dynamic heat generation, unsatisfactory tire service life, etc., to reduce energy loss, improve service life, reduce The effect of small dynamic heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The IDH has a high-efficiency active group, a melting point of 224° C., and a specific gravity of 1.344 g / cm, which can significantly improve the elasticity of the rubber material and reduce the heat generation of the rubber material.

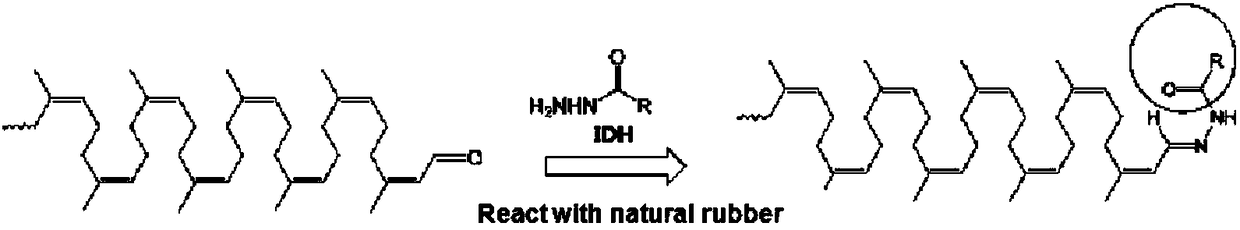

[0015] The reaction mechanism between IDH and natural rubber is as follows:

[0016]

[0017] The preparation steps of the present invention are as follows:

[0018] One-stage mixing: Start the internal mixer (GK400), set the rotor speed of the internal mixer to 50-55rpm, add rubber, stearic acid, zinc oxide, IDH and mix for 10-60s; raise the bolt, add carbon black to press the bolt, Mix for 20-150s, raise the plug, add petroleum-based plasticizer, press the plug, knead for 30-70s; knead for 30-160s, control the temperature at 155-165°C to remove glue;

[0019] Parking for the first time: put a section of masterbatch obtained by mixing in the air, and cool it down to room temperature naturally;

[0020] Two-stage mixing: Start the i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com