Raw material for preparing high-temperature-resistant high-fatigue-resistance natural rubber

A technology of natural rubber and high temperature resistance, applied in the rubber field, can solve the problems of improper selection of natural rubber preparation components, difficulty in meeting the technical requirements of automobile vibration damping products in anti-vulcanization reversion, and damage to natural rubber properties, and achieve anti-vulcanization. The effect of improving the reversion performance, improving the anti-reversion performance and improving the fatigue resistance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] A raw material for preparing high-temperature-resistant and high-fatigue-resistant natural rubber, which is composed of the following raw materials in parts by mass: 100 parts of smoked sheet rubber, 3-8 parts of zinc oxide, 1-2 parts of stearic acid, 1-3 parts of anti-aging agent RD, anti-aging agent 1-2 parts of 4010NA, 1-2 parts of anti-aging agent 40201-2 parts, 2-5 parts of microcrystalline wax 9332F, 3-5 parts of silane coupling agent Si-669 / G, 0.5-1.5 parts of PAPI, 0-40 parts of carbon black N33020, carbon 30-60 parts of black N6600, 10-30 parts of barium sulfate, 845-20 parts of aromatic oil Tudalen, 2-3 parts of sulfur, 1-2 parts of accelerator CZ, 0.5-1 part of IDH, 2-4 parts of Perkalink 9000.

[0016] The above-mentioned natural rubber preparation raw materials are further limited, including the following mass components: 100 parts of smoked sheet rubber, 5-7 parts of zinc oxide, 1-2 parts of stearic acid, 1-3 parts of anti-aging agent RD, and 1 part of anti...

Embodiment 2

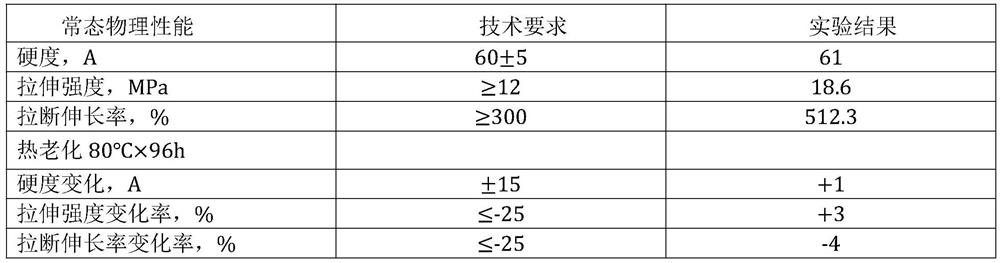

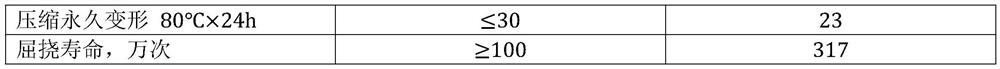

[0034]Embodiment 2 is a kind of preferred scheme selected on the basis of embodiment 1, selects definite weight part value from each batching weight part range in embodiment 1, carries out the refining of natural rubber then, with The natural rubber of natural rubber is carried out physical property test, with every physical property test result that draws, demonstrates in embodiment 1, and each raw material weight portion proportioning is as follows:

[0035] Including the following raw materials by mass, 100 parts of smoked sheet glue, 3 parts of zinc oxide, 1 part of stearic acid, 1 part of anti-aging agent RD, 2 parts of anti-aging agent 4010NA, 1.5 parts of anti-aging agent 40201, 5 parts of microcrystalline wax 9332F, silane di 3 parts of joint agent Si-669 / G, 0.5 parts of PAPI, 20 parts of carbon black N33020 parts, 60 parts of carbon black N66060, 10 parts of barium sulfate, 845 parts of aromatic oil Tudalen, 2 parts of sulfur, 1 part of accelerator CZ, 0.5 parts of IDH...

Embodiment 3

[0039] Embodiment 3 is the second preferred scheme selected on the basis of Example 1, select certain parts by weight from the range of parts by weight of the ingredients in Example 1, then carry out refining of natural rubber, use The natural rubber that obtains carries out physical performance test, with the various physical performance test results that draw, demonstrates in embodiment 1, and each raw material weight portion proportioning is as follows:

[0040] Including the following raw materials by mass, 100 parts of smoked sheet glue, 5 parts of zinc oxide, 1.5 parts of stearic acid, 2 parts of anti-aging agent RD, 2 parts of anti-aging agent 4010NA, 1.5 parts of anti-aging agent 40201, 4 parts of microcrystalline wax 9332F, silane coupling Joint agent Si-669 / G 3 parts, PAPI 0.5 parts, carbon black N33025 parts, carbon black N66050 parts, barium sulfate 15 parts, aromatic hydrocarbon oil Tudalen 8420 parts, sulfur 2 parts, accelerator CZ 1 part, IDH 0.6 parts, Perkalink...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com