Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "Improve anti-reversion performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

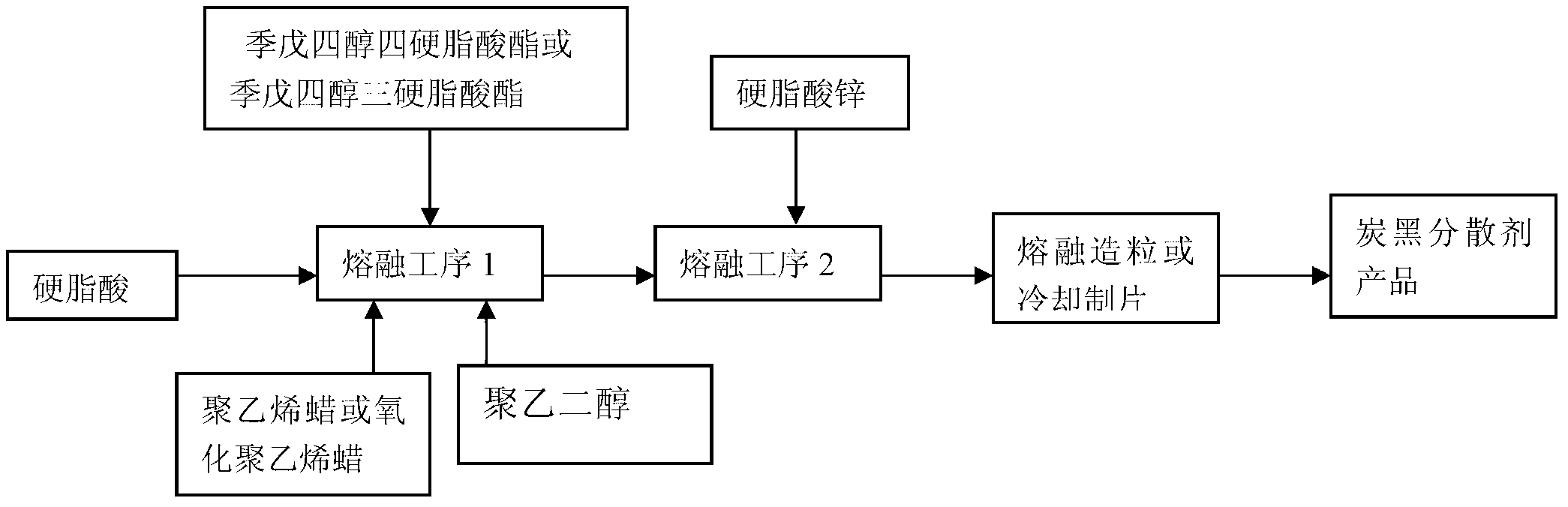

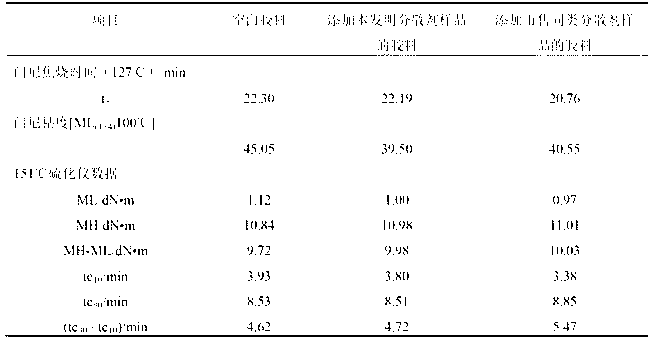

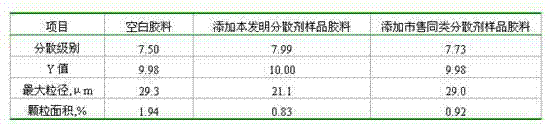

Novel carbon black dispersing agent for rubber and preparation method thereof

ActiveCN103304881AIncreased process safetyImprove mechanical propertiesPigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsRubber materialPolymer science

The invention relates to a preparation method of a novel carbon black dispersing agent for rubber. The novel carbon black dispersing agent comprises the following raw materials in parts by weight: 10-30 parts of polyethylene waxes or oxidized polyethlene waxes, 10-20 parts of zinc stearate, 10-30 parts of stearic acid, 10-30 parts of polyethylene glycol and 30-80 parts of pentaerythritol stearate. The novel carbon black dispersing agent disclosed by the invention can enhance the processing safety property, physical and mechanical property and vulcanizing rate of a rubber material, has multiple functions of dispersion, lubrication and physical plasticizing, is used for the mixing process of natural rubber and synthetic rubber, and can enhance the dispersibility of a filler and other powdery auxiliary agents in the rubber material, reduce the viscosity of the rubber material and enhance the flowability and extrusion rate of the rubber material, thereby reducing the energy consumption of tire or product processing, increasing the mixing efficiency, facilitating the demoulding of a vulcanized product and keeping the mould clean; and the novel carbon black dispersing agent disclosed by the invention can enhance the vulcanization reversion resistance and heat resistance of vulcanized rubber after being applied to the natural rubber.

Owner:SHANDONG YANGGU HUATAI CHEM

Method for preparing multifunctional rubber assistant by recycling alkali-weight-reduction processing discharged liquor

ActiveCN104829879AFast plasticizing speedImprove anti-reversion performanceSocial benefitsActivated carbon filtration

The invention discloses a method for preparing a multifunctional rubber assistant by recycling alkali-weight-reduction processing discharged liquor. The method comprises the following steps: sequentially passing alkali-weight-reduction wastewater through a laminar-flow precipitation tank and an activated carbon filter to enter an acid precipitation tank, adding sulfuric acid or hydrochloric acid while stirring, and precipitating terephthalic acid when the wastewater becomes acidic; and adding the terephthalic acid and stearic acid into a reaction kettle, adding water and sodium hydroxide to dissolve the terephthalic acid and stearic acid into a sodium solution, adding a zinc chloride solution to crystallize and precipitate a zinc terephthalate-zinc stearate crystal mixture, centrifuging, filtering, washing and drying to obtain the multifunctional rubber assistant finished product. By using the alkali-weight-reduction processing wastewater as the raw material, the method reduces the wastewater discharge and implements resource reutilization on the premise of preparing the novel rubber assistant, and thus, has obvious economic benefit and social benefit.

Owner:江苏爱特恩高分子材料有限公司

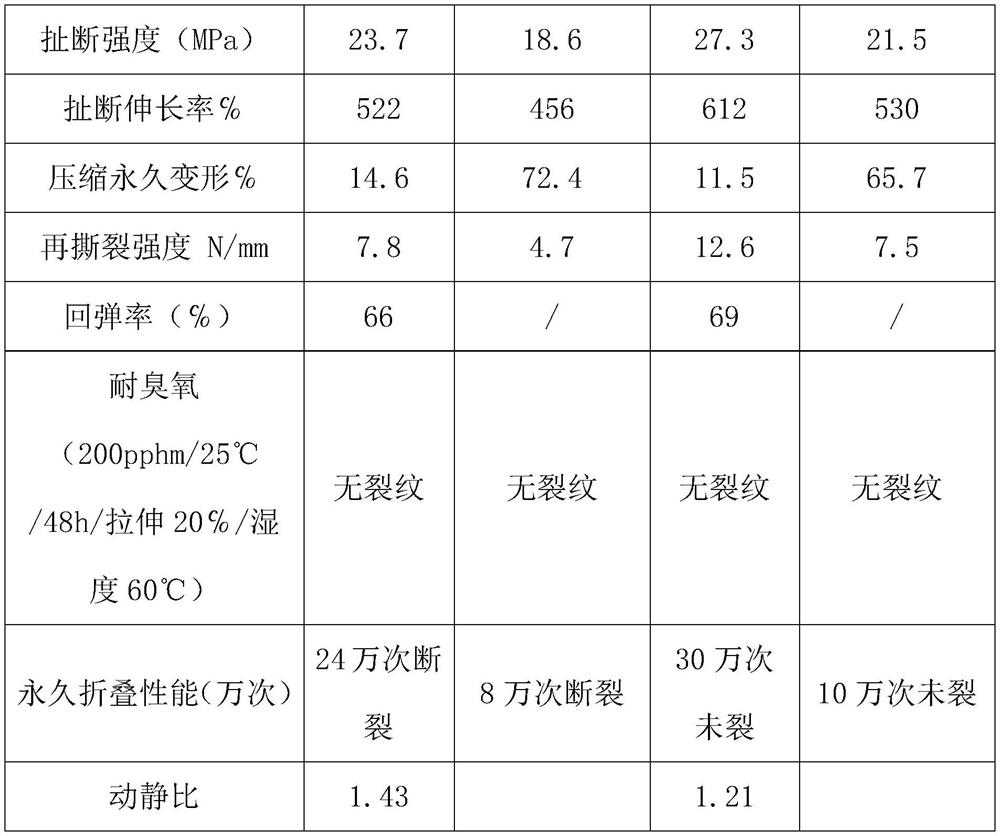

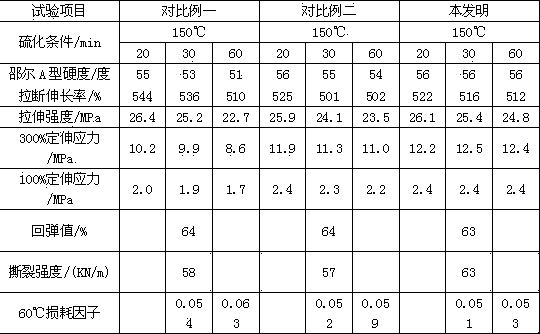

Rubber composition improving anti-reversion performance and application thereof

ActiveCN105348573AImprove anti-reversion performanceImprove dynamic performanceRubber materialPolymer science

Owner:BEIJING RED AVENUE INNOVA

All-steel radial tire combined rubber compound for improving shoulder separation and tread separation

ActiveCN107722379AHigh modulusReduce dynamic heatingSpecial tyresRolling resistance optimizationAging resistanceSulfur

The invention discloses an all-steel radial tire combined rubber compound for improving shoulder separation and tread separation. The all-steel radial tire combined rubber compound is respectively used for preparing shoulder pad rubber and base part rubber. The all-steel radial tire combined rubber compound comprises, by weight, 80.0-100.0 parts of natural rubber, 0-20.0 parts of cis-polybutadienerubber, 15.0-45.0 parts of carbon black, 8.0-15.0 parts of white carbon black, 3.0-6.0 parts of zinc oxide, 1.0-3.5 parts of an activator stearic acid, 1.0-2.0 parts of a carbon black dispersant, 0.5-2.0 parts of an antioxidant RD, 1.0-2.5 parts of an antioxidant 4020, 1.3-3.8 parts of a silane coupling agent, 1.5-3.0 parts of insoluble sulfur IS7020, 0.8-1.8 parts of an accelerator NS, 0.1-0.3 part of a scorch retarder and 0.5-2.0 parts of alkyl phenol disulfide. The above formula rubber compound has a high modulus at a given elongation, so the deformation of a tire under the same load is reduced, thereby heat generated by compression deformation and curling is reduced; and the rubber compound has the advantages of low dynamic heat, good aging resistance, improvement of the long-time high load driving resistance of the tire, and effective reduction of the shoulder separation, tread separation and other symptoms.

Owner:SAILUN GRP CO LTD

All-steel radial tyre bead chafer, and preparation method thereof

The invention relates to an all-steel radial tyre bead chafer, and a preparation method thereof, and belongs to the technical field of rubber. The preparation method comprises following steps: naturalrubber, high cis butadiene rubber, low cis butadiene rubber, carbon black, an anti-aging agent, a tackifying resin, aramid staple fiber, a rubber filling oil, zinc oxide, stearic acid, a protective wax, a promoter, sulfur, an anti-reversion agent and an anti-scorching agent are subjected to first-stage mixing, second-stage mixing, and third-stage mixing so as to obtain the all-steel radial tyre bead chafer. The preparation method is capable of improving the high temperature aging resistance, wear resistance, flexing resistance, and cure reversion resistance of bead chafer of tyres in using process, reducing bead chafer heat generation, and prolonging the service life of tyres.

Owner:JIANGSU GENERAL SCI TECH

Rubber material for supporting rubber of run-flat tire, preparation method of rubber material, and run-flat tire

InactiveCN110746661AImprove flexibilityImprove anti-reversion performanceTyre partsRubber technologyActive agent

The invention relates to the technical field of rubber, and in particular relates to a rubber material for supporting rubber of a run-flat tire, a preparation method of the rubber material, and the run-flat tire. The rubber material for the supporting rubber of the run-flat tire disclosed by the invention includes the following components: base rubber, a filler, an active agent, an anti-aging agent, resin, a vulcanizing agent, an accelerator and a multifunctional crosslinking auxiliary agent, wherein the base rubber comprises natural rubber and cis-polybutadiene. According to the rubber material, the resin and the multifunctional crosslinking auxiliary agent are added, so that the use amount of the vulcanizing agent and the accelerator is reduced, and the rubber material for the supportingrubber of the run-flat tire provided by the invention has excellent processability and reversion resistance while having high stretching strength, high modulus and high-temperature resistance.

Owner:GUANGZHOU FENGLI RUBBER TIRE

Piercing-resistant and tear-resistant tread base rubber and preparing method thereof

InactiveCN110408088AHigh softening pointHigh hysteresis at the side of the moleculeSpecial tyresPolymer scienceAging resistance

The invention belongs to the technical field of rubber, and particularly relates to piercing-resistant and tear-resistant tread base rubber and a preparing method thereof. The piercing-resistant and tear-resistant tread base rubber is prepared by conducting primary mixing, secondary mixing and third mixing on natural rubber, carbon black, white carbon black, a silane coupling agent, an anti-ageingagent, graphene oxide, modified DCPD resin, zinc oxide, stearic acid, an accelerant, sulfur, an anti-reversion agent and a scorch retarder through an internal mixer. By applying the modified DCPD resin, the graphene oxide and the anti-reversion agent to the all-steel tire tread base rubber in proper proportion, the respective characteristics are complementary, the tear resistance, piercing resistance, ageing resistance and reversion resistance of the tread trench bottom base rubber in the use process of an all-steel tire can be improved, and therefore the service life of the all-steel tire isprolonged.

Owner:JIANGSU GENERAL SCI TECH

Rubber vibration reduction device with high anti-aging performance and preparation method thereof

The invention discloses a rubber vibration reduction device with high anti-aging performance. The rubber vibration reduction device is applied to the technical field of anti-aging rubber reduction device preparation. The rubber vibration reduction device is prepared from 80 to 100 parts of natural rubber, 1 to 6 parts of modified chlorosulfonated polyethylene rubber, 0.5 to 3 parts of sulphur, 1 to 2.5 parts of a vulcanizing agent, 6 to 12 parts of an anti-aging agent, 4 to 10 parts of zinc oxide, 1 to 12.5 parts of white carbon black, 10 to 30 parts of carbon black, 12 to 16 parts of a softening agent, 10 to 19 parts of proportioning rubber, 25 to 45 parts of a filling material, 6 to 8 parts of ore fiber, 1 to 5 parts of an aluminum-zirconium coupling agent, 2 to 4 parts of polyoxyethylene glycol monostearate, 0.5 to 1.5 parts of a crosslinking agent, 1 to 2 parts of an antioxidant, 1 to 3 parts of an accelerant and 3 to 7 parts of magnesium oxide. By using the embodiment, the stability of the natural rubber vulcanization crosslinked bond structure under the high-temperature condition can be improved; the high-temperature heat oxidization aging resistance, ozone resistance and weather resistance performance of the rubber vibration reduction device and the anti-vulcanization reversion resistance performance of the natural rubber are improved.

Owner:ANHUI DFSEAL RUBBER SHOCK ABSORBER TECH CO LTD

Carcass layer tread rubber of aviation radial tire

The invention discloses a carcass layer tread rubber of an aviation radial tire. A crude rubber system of the carcass layer tread rubber jointly adopts natural rubber and butadiene rubber; a reinforcement system adopts STERLIN V (SV) carbon black and adopts parts of white carbon black; accessory ingredients, including silane coupling agent KH-560, binding agent SL-3090, adhesion promoter AIR-201, adhesion promoter AIR-1 and the like, are added into a formula. The carcass layer tread rubber disclosed by the invention has the advantages of low hardness and stress at definite elongation, soft rubber material and small possibility of generating gaps during repeated deformation; the carcass layer tread rubber can be suitable for the performance requirements of high speed, high load and high refurbishment frequency of a novel tire in the future; before and after ageing, the carcass layer tread rubber has the advantages of high bonding strength of the rubber material and a nylon cord, good fatigue durability, low heat generation, high rebound value and small hysteresis loss; a carcass layer of the tire can be protected from delamination, swelling and tire side puncturing, and the service life and the safe performance of the aviation radial tire are improved.

Owner:中国化工集团曙光橡胶工业研究设计院有限公司

Tread rubber for all-steel snow tire and preparation method of tread rubber

InactiveCN110343298AImprove wet skid resistanceImprove tear resistanceSpecial tyresPolymer scienceStearic acid

The invention belongs to the technical field of rubber, and particularly relates to tread rubber for an all-steel snow tire and a preparation method of the tread rubber. The method comprises the stepsof performing first-stage mixing on natural rubber, styrene-butadiene rubber, trans isoprene rubber, carbon black, graphene oxide, white carbon black, a silane coupling agent, an anti-aging agent, rubber protecting wax, modified DCPD resin, zinc oxide, stearic acid, an accelerator, sulfur and a scorch retarder by an internal mixer, performing second-stage mixing and performing third-stage mixingto prepare the tread rubber for the snow tire. The tread rubber prepared by deploying the usage amount of raw materials such as the modified DCPD resin, the graphite oxide material, the trans isoprenerubber and the anti-reversion agent can improve and enhance chipping resistance, wet skid resistance, aging resistance and reversion resistance of tread, thereby improving the safety performance andservice life of the snow tire.

Owner:JIANGSU GENERAL SCI TECH

Bifunctional organic thiosulfate and preparation method thereof

ActiveCN103626685AImprove thermal stabilityIncrease crosslink densityOrganic chemistryCross-linkPolymer science

The invention relates to a bifunctional organic thiosulfate of an anti-reversion agent for rubber industry and a preparation method thereof. The bifunctional organic thiosulfate provided by the invention has two active groups, a sulfur-containing active group generates a cross-linking reaction with rubber macromolecules in a rubber vulcanization process to insert a thermostable alkyl into a sulfur crosslinking bond; in addition, when reversion occurs in an over-vulcanization or application process of vulcanized rubber, the unsaturated double bond groups of the bifunctional organic thiosulfate would generate a Diels-Adel reaction with the C=C bond in the rubber so as to generate a thermostable C-C crosslinking bond to maintain the crosslinking density of the vulcanized rubber, improve the vulcanized reversion of the vulcanized rubber and enhance the service performance and service life of the products.

Owner:BEIJING RED AVENUE INNOVA

Modified carbon black and preparation method thereof

InactiveCN103819945ASolve the way outRealize comprehensive utilizationPigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsRubber materialGutter oil

The invention discloses a modified carbon black and a preparation method thereof. Gutter oil and waste engine oil are refined to be made into standard raw oil, and the standard raw oil is fully mixed with terephthalic acid metal salt and carbon black according to a certain proportion. The method adopts the gutter oil and the waste engine oil as raw materials, not only realizes the comprehensive utilization of wastes, but also solves the utilization problem of the gutter oil and the waste engine oil, turns waste into wealth, and brings good social benefits. As the standard raw oil, which is low in cost, is used, the production cost of an enterprise can be reduced, and the modified carbon black has a considerable economic value. The prepared carbon black is convenient to use, and tests prove that the mechanical property of a product can be improved after the carbon black is added into the product. The carbon black is applied to natural rubber, and can improve the vulcanization reversion resistance and heat resistance of rubber materials.

Owner:JIANGSU ATE DONGTAI NEW MATERIALS TECH

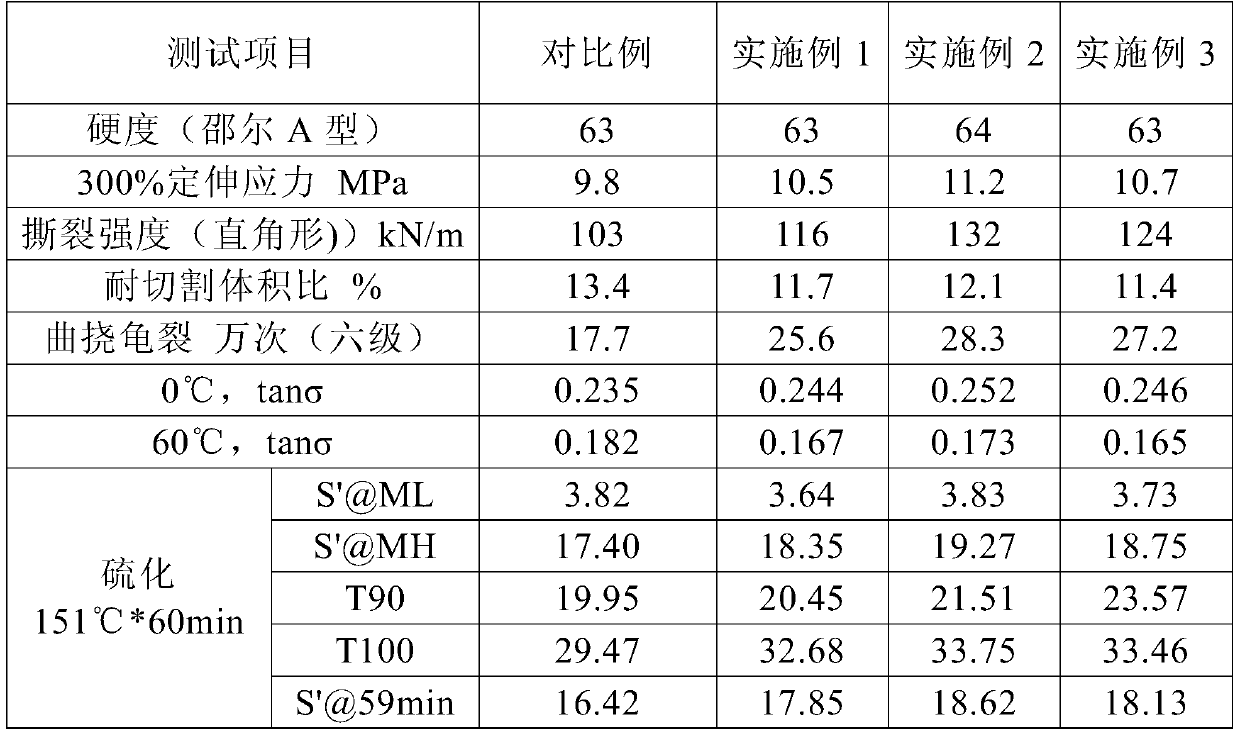

Tire bead protective rubber and preparation method thereof

The invention provides tire bead protective rubber, which comprises the following components: 15-45 parts of natural rubber, 55-85 parts of high cis-butadiene rubber, 1-10 parts of carbon nanotubes, 50-70 parts of carbon black, 3-6 parts of zinc oxide, 2-4 parts of stearic acid, 2-5 parts of an anti-aging agent, 2-6 parts of tackifying resin, 2-8 parts of rubber filling oil, 1-2 parts of rubber protective wax, 1-3 parts of an accelerant, 1-3.5 parts of insoluble sulfur, 0.2-1 part of an anti-reversion agent and 0.1-0.5 part of a scorch retarder CTP. According to the tire bead protective rubberdisclosed by the invention, the carbon nanotubes are added, so that the heat generation of the bead protective rubber can be reduced, and meanwhile, the rigidity and tear resistance of the bead protective rubber can be improved; by adding the anti-reversion agent, the anti-reversion performance and fatigue resistance of the rubber can be improved; and a relatively proper process route is exploredfor industrial application and production of the carbon nanotubes in tires.

Owner:JIANGSU GENERAL SCI TECH

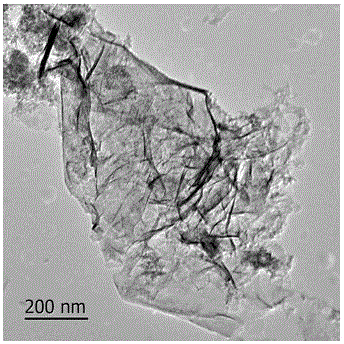

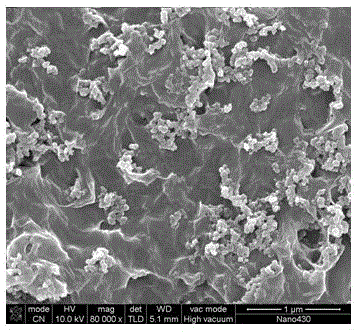

Preparation method of hydrotalcite-carbon black hybrid material as well as hydrotalcite-carbon black hybrid material/rubber composite material and application thereof

The invention discloses a preparation method of a hydrotalcite-carbon black hybrid material as well as a hydrotalcite-carbon black hybrid material / rubber composite material and application thereof. Firstly amino silane is used for performing surface modification on carbon black, so that the surface of the carbon black is aminated, meanwhile, an acid anhydride-forming modifier is adopted to perform surface functionalization on hydrotalcite, and then the aminated carbon black and the hydrotalcite subjected to acid anhydride forming are uniformly mixed and are subjected to cosedimentation, so as to obtain a zinc-aluminium hydrotalcite-carbon black hybrid material. Further, a conventional method is adopted to add the hydrotalcite-carbon black hybrid material into rubber, so as to obtain the rubber composite material. The hydrotalcite-carbon black hybrid material used for natural rubber can endow the composite material with excellent properties such as mechanical property, ageing property and air barrier property, and more importantly can improve sulfuration resisting reversion property of the composite material.

Owner:山东轻化致远新材料科技有限公司

Rubber anti-reversion agent composition

The invention discloses a rubber anti-reversion agent composition. The composition is prepared by using the following raw materials, by weight, 50-100 parts of natural rubber, 20-50 parts of carbon black, 15-45 parts of white carbon black, 3-7 parts of zinc fatty acid, 5-8 parts of disodium dithiosulfate, 8-12 parts of zinc aromatic acid, 7-15 parts of citraconyl imine, 2-5 parts of an accelerant NS, and 4-8 parts of propanethiol. The rubber anti-reversion agent composition has the advantages of stable performances, good quality, improvement of the anti-reversion capability of rubber, and guarantee of the stress at definite elongation of the rubber compound under over vulcanization conditions.

Owner:QINGDAO SHUAIWANG OIL CHEM

Insulating-layer semiconductive shielding material for ethylene propylene rubber cable

InactiveCN105218894AEvenly dispersedGood dispersionNon-conductive material with dispersed conductive materialStearic acidEthylene propylene rubber

The invention discloses an insulating-layer semiconductive shielding material for an ethylene propylene rubber cable. The material is characterized by being prepared from, by weight, 60-70 parts of nitrile butadiene rubber, 30-40 parts of chlorinated polyethylene, 30-50 parts of cable powder, 50-70 parts of conductive carbon black A, 10-30 parts of conductive carbon black B, 5-10 parts of magnesium oxide, 2-4 parts of paraffin, 2-8 parts of anti-aging agents, 20-30 parts of dioctyl phthalate, 0.5-1 part of dispersants, 2-5 parts of stearic acid and 1-8 parts of vulcanizing agents. The insulating-layer semiconductive shielding material for the ethylene propylene rubber cable has the advantages of good heat oxygen aging resistance, ozone aging resistance, acid-base resistance and chemical resistance performance, excellent oil resistance performance, good removability and glue liquidity, low cost and the like.

Owner:山东太平洋橡缆股份有限公司

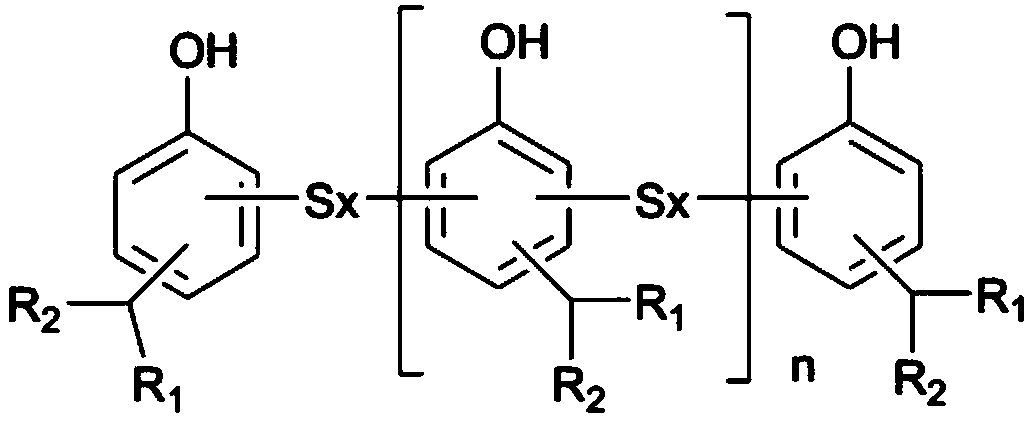

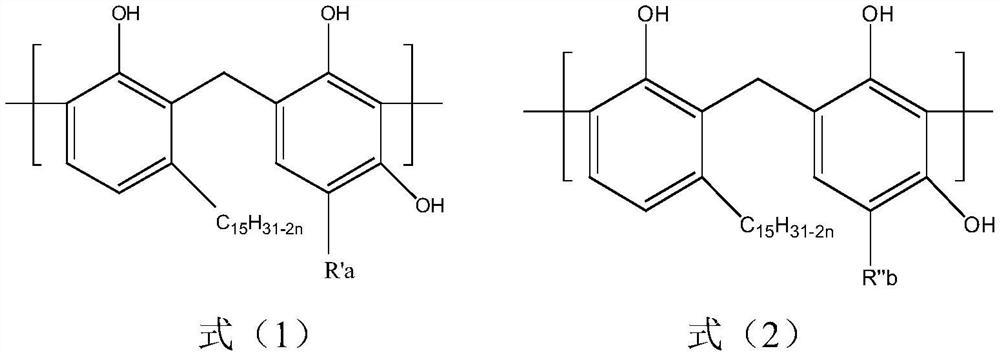

Rubber composition, preparation method thereof and rubber product

The invention relates to the technical field of rubber products, and particularly discloses a rubber composition, a preparation method thereof and a rubber product. The rubber composition comprises the following components in parts by weight: 100 parts of rubber, 20-80 parts of carbon black, 0.5-5 part of vulcanizing agent and 1-10 parts of mixed alkyl resorcinol modified cardanol formaldehyde bonding resin, and the mixed alkyl resorcinol modified cardanol formaldehyde bonding resin comprises a formula (1) and a formula (2), the mixed alkyl resorcinol modified cardanol formaldehyde adhesive resin is terminated by alkyl resorcinol; the preparation method of the rubber composition comprises the following steps: mixing rubber and carbon black, heating to 140-160 DEG C, cooling to 80-95 DEG C,adding the vulcanizing agent and the mixed alkyl resorcinol modified cardanol formaldehyde adhesive resin, and mixing at 40-50 DEG C for 4-10 minutes to obtain the rubber composition. The rubber composition of the present application has excellent adhesion properties.

Owner:BEIJING RED AVENUE INNOVA +1

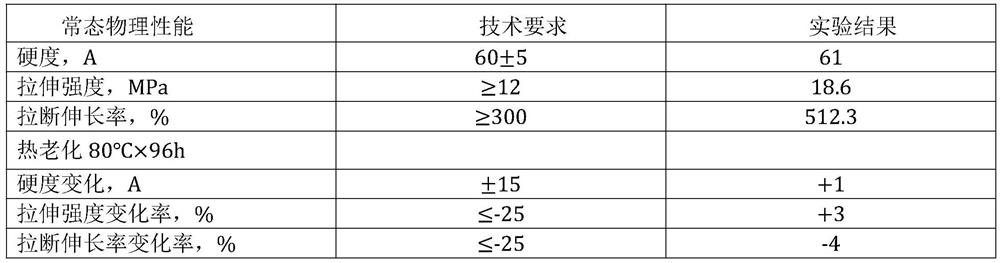

Marine mechanical high elastic coupler rubber and vulcanization preparation method thereof

InactiveCN108948447AGood vibration reduction effectGood consistency of mechanical propertiesVulcanizationWear resistant

The invention relates to a manufacturing process of a high-elastic coupler, in particular to marine mechanical high-elastic coupler rubber and a vulcanization preparation method thereof, and mainly solves the technical problems that the vulcanization process method existing in the prior art has low vulcanization degree, low comprehensive vibration damping performance, poor high temperature resistance, poor fatigue resistance, poor weather resistance, poor rubber mechanical properties, incapability of mass production and processing, and the like. The marine mechanical high-elastic coupler rubber comprises 90-110 parts by weight of natural rubber, 4-6 parts by weight of zinc oxide, 0.5-2 parts by weight of stearic acid, 10-35 parts by weight of high wear-resistant carbon black, 20-45 parts by weight of universal carbon black, 0-6 parts by weight of white carbon black, 1-2 parts by weight of sulfur, 1-2 parts by weight of an accelerator, 2-4 parts by weight of an anti-aging agent, 0.1-1 part by weight of a a scorch retarder, 0.5-2 parts by weight of a dispersing agent and 0-10 parts by weight of a softener, and can be obtained by first vulcanization by hot air, second vulcanization bypressurization, and third vulcanization at room temperature.

Owner:HANGZHOU ADVANCE COUPLING

High-aging-resistance rubber material and preparation method thereof

The invention discloses a high-aging-resistance rubber material and a preparation method thereof. The rubber material is characterized by mainly comprising natural rubber and modified chlorosulfonated polyethylene rubber, wherein the modified chlorosulfonated polyethylene rubber accounts for 0.1-5 wt% of the total amount of the natural rubber and modified chlorosulfonated polyethylene rubber. By fully utilizing the characteristic of heat oxidation aging resistance of the chlorosulfonated polyethylene rubber and the characteristic that sulfur can be adopted for vulcanization after modification, after the MCSM-120 is doped into the natural rubber, a vulcanization crosslinked network structure can be generated between the two rubber molecules, and the chlorosulfonated polyethylene rubber molecular chain is connected into the natural rubber molecular chain, thereby improving the stability of the natural rubber vulcanization crosslinked bond structure under high-temperature conditions, and enhancing the high temperature resistance, heat oxidation aging resistance, ozone resistance and weather resistance of the rubber shock absorber and nti-reversion property of the natural rubber.

Owner:建新赵氏科技股份有限公司

Anti-reversion rubber composition

InactiveCN103881158AImprove anti-reversion performanceGuaranteed tensile stressPolymer scienceHardness

The invention discloses an anti-reversion rubber composition. The rubber composition employs 100 parts of natural rubber as a reference substance, and also comprises 30-35 parts of carbon black, 6-9 parts of white carbon black, 4 parts of organosilicon mixture TESPT, 5 parts of zinc oxide, 2 parts of stearic acid and 1-2 parts of a fire retardant. The anti-reversion capability of a tyre shoulder wedge is improved, and the stability of mechanical properties such as tensile stress, hardness and the like of the rubber composition under the over-cure condition are guaranteed.

Owner:QINGDAO SHUAIWANG OIL CHEM

Rubber material

ActiveCN109485932AImprove high temperature thermal oxygen aging resistanceExtend the service life of high temperature fatigue resistancePolyesterRubber material

The invention discloses a rubber material. The rubber material comprises 70 parts by weight of natural rubber, 30 parts by weight of polyurethane rubber (E6008), 0.5-1.5 parts by weight of sulfur, 1-2.5 parts by weight of a vulcanizing agent, 5-10 parts by weight of an anti-aging agent, 4-10 parts by weight of zinc oxide, 4-8 parts by weight of white carbon black, 10-30 parts by weight of carbon black and 4-8 parts by weight of a softening agent. According to the rubber material, the natural rubber and the polyurethane rubber (E6008) are used together, and polyester and polyether are blended in an isoprene rubber molecular chain and serve as a flexible chain section of the rubber.

Owner:建新赵氏科技股份有限公司

Rubber material with high aging resistance and preparation method thereof

The invention discloses a high-aging-resistance rubber material and a preparation method thereof. The rubber material is characterized by mainly comprising natural rubber and modified chlorosulfonated polyethylene rubber, wherein the modified chlorosulfonated polyethylene rubber accounts for 0.1-5 wt% of the total amount of the natural rubber and modified chlorosulfonated polyethylene rubber. By fully utilizing the characteristic of heat oxidation aging resistance of the chlorosulfonated polyethylene rubber and the characteristic that sulfur can be adopted for vulcanization after modification, after the MCSM-120 is doped into the natural rubber, a vulcanization crosslinked network structure can be generated between the two rubber molecules, and the chlorosulfonated polyethylene rubber molecular chain is connected into the natural rubber molecular chain, thereby improving the stability of the natural rubber vulcanization crosslinked bond structure under high-temperature conditions, and enhancing the high temperature resistance, heat oxidation aging resistance, ozone resistance and weather resistance of the rubber shock absorber and nti-reversion property of the natural rubber.

Owner:建新赵氏科技股份有限公司

Raw material for preparing high-temperature-resistant high-fatigue-resistance natural rubber

InactiveCN112080046AImprove fatigue resistanceImprove heat aging resistanceMicrocrystalline waxVulcanization

The invention relates to the technical field of rubber, in particular to a high-temperature-resistant high-fatigue-resistance natural rubber preparation raw material. The rubber is prepared from, by mass, 100 parts of smoke sheet rubber, 3-8 parts of zinc oxide, 1-2 parts of stearic acid, 1-3 parts of anti-aging agent RD, 1-2 parts of anti-aging agent 4010NA, 1-2 parts of anti-aging agent 4020, 2-5 parts of microcrystalline wax 9332F, 3-5 parts of silane coupling agent Si-669 / G, 0.5-1.5 parts of PAPI, 20-40 parts of carbon black N330, 30-60 parts of carbon blackN660, 10-30 parts of barium sulfate, 5-20 parts of aromatic oil Tudalen 84, 2-3 parts of sulphur, 1-2 parts of accelerant CZ, 0.5-1 parts of IDH, and 2-4 parts of Perkalink 900. By reasonably adjusting a formula system, the fatiguelife, the temperature resistance and the vulcanization reversion resistance of the natural rubber can be remarkably improved.

Owner:北威(重庆)科技股份有限公司

Composition for forming seam allowance wear-resistant rubber and seam allowance wear-resistant rubber

The invention provides a composition for forming a seam allowance wear-resistant adhesive and the seam allowance wear-resistant adhesive. The composition for forming the seam allowance wear-resistant rubber comprises natural rubber, butadiene rubber, composite rubber, a vulcanizing activator, an accelerant and a vulcanizing agent, and the composite rubber is a mixture of 1, 2-syndiotactic polybutadiene and high cis-1, 4-polybutadiene; the vulcanizing active agent comprises unsaturated carboxylic acid zinc salt. By adding the composite rubber, the modulus and hardness of the seam allowance wear-resistant rubber can be improved, and the wear resistance of the seam allowance wear-resistant rubber is improved; meanwhile, the using amount of filler can be greatly reduced, and heat generation is reduced. The addition of the unsaturated carboxylic acid zinc salt can increase the crosslinking density of each rubber material, and further improve the tensile strength, modulus, deformation recovery capability and anti-reversion performance, thereby inhibiting the compression set of the subsequently prepared seam allowance wear-resistant rubber at high temperature, and being beneficial to inhibiting the deformation of a tire bead part due to stress when being applied to a radial tire, and the service life of the tire bead wear-resistant rubber is prolonged. Meanwhile, the high-temperature-resistant performance is relatively good.

Owner:SAILUN GRP CO LTD +1

Method for preparing multi-functional rubber additives by recycling alkali reduction processing drainage liquid

ActiveCN104829879BFast plasticizing speedImprove anti-reversion performanceActivated carbon filtrationChloride

Owner:江苏爱特恩高分子材料有限公司

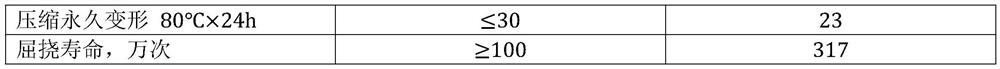

Rubber material and preparation method thereof

InactiveCN108250500AImprove high temperature thermal oxygen aging resistanceImprove anti-reversion performanceRubber materialVulcanization

The invention discloses a rubber material. The rubber material comprises the following raw materials: 100 parts by weight of natural rubber, 0.5-1.5 parts by weight of sulfur, 0.5-1.5 parts by weightof PDM, 1-2.5 parts by weight of a vulcanization auxiliary agent, 5-10 parts by weight of an anti-aging agent, 4-10 parts by weight of zinc oxide, 4-8 parts by weight of white carbon black, 10-30 parts by weight of carbon black, and 4-8 parts by weight of a softener. The invention also provides a preparation method of the above rubber material. The rubber material provided by the invention has high-temperature resistance, heat resistance and aging resistance, and the rubber preparing process is simple and easy to implement.

Owner:JIANXIN ZHAOS GRP CORP

Novel carbon black dispersing agent for rubber and preparation method thereof

ActiveCN103304881BIncreased process safetyImprove mechanical propertiesPigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsRubber materialPolymer science

The invention relates to a preparation method of a novel carbon black dispersing agent for rubber. The novel carbon black dispersing agent comprises the following raw materials in parts by weight: 10-30 parts of polyethylene waxes or oxidized polyethlene waxes, 10-20 parts of zinc stearate, 10-30 parts of stearic acid, 10-30 parts of polyethylene glycol and 30-80 parts of pentaerythritol stearate. The novel carbon black dispersing agent disclosed by the invention can enhance the processing safety property, physical and mechanical property and vulcanizing rate of a rubber material, has multiple functions of dispersion, lubrication and physical plasticizing, is used for the mixing process of natural rubber and synthetic rubber, and can enhance the dispersibility of a filler and other powdery auxiliary agents in the rubber material, reduce the viscosity of the rubber material and enhance the flowability and extrusion rate of the rubber material, thereby reducing the energy consumption of tire or product processing, increasing the mixing efficiency, facilitating the demoulding of a vulcanized product and keeping the mould clean; and the novel carbon black dispersing agent disclosed by the invention can enhance the vulcanization reversion resistance and heat resistance of vulcanized rubber after being applied to the natural rubber.

Owner:SHANDONG YANGGU HUATAI CHEM

a rubber material

ActiveCN109485932BImprove aging performanceExtend the service life of high temperature fatigue resistanceRubber materialPolyester

The invention discloses a rubber material. The raw materials include: 70 parts by weight of natural rubber, 30 parts by weight of polyurethane rubber (E6008), 0.5 to 1.5 parts by weight of sulfur, 1 to 2.5 parts by weight of vulcanization aid, and 5 to 5 parts by weight of anti-aging agent. 10 parts by weight, 4 to 10 parts by weight of zinc oxide, 4 to 8 parts by weight of white carbon black, 10 to 30 parts by weight of carbon black, and 4 to 8 parts by weight of softener; Rubber (E6008) is used together, a rubber material in which polyester and polyether are mixed into the molecular chain of isoprene rubber as a flexible segment of rubber.

Owner:建新赵氏科技股份有限公司

Anti-reversion shoulder pad rubber composition

ActiveCN102675697BImprove anti-reversion performanceExtended service lifeSpecial tyresVulcanizationStearic acid

The invention relates to the technical field of rubber, particularly an anti-reversion shoulder pad rubber composition which is characterized by comprising the following components in parts by weight: 100 parts of natural rubber, 25-40 parts of carbon black, 5-10 parts of silica white, 3-5 parts of organosilicon mixture TESPT, 3-6 parts of zinc oxide, 1.5-2.5 parts of stearic acid, 1-2 parts of tackifying resin, 1-2.5 parts of anti-aging agent 4020, 0.5-1.5 parts of anti-aging agent RD, 1-2.5 parts of insoluble sulfur, 0.2-5-2 parts of accelerator NS, 0.2 part of vulcanization retardant CTP, 0.5-2.5 parts of hexamethylene-1,6-dithiosulfate disodium and 2 parts of crystal water. The invention enhances the anti-reversion capacity of the tire shoulder pad, ensures the stability of stress at definite elongation, hardness and other mechanical properties of rubber under the condition of overvulcanization, lowers the tire shoulder generated heat, and prolongs the service life of the tire.

Owner:TRIANGLE TIRE

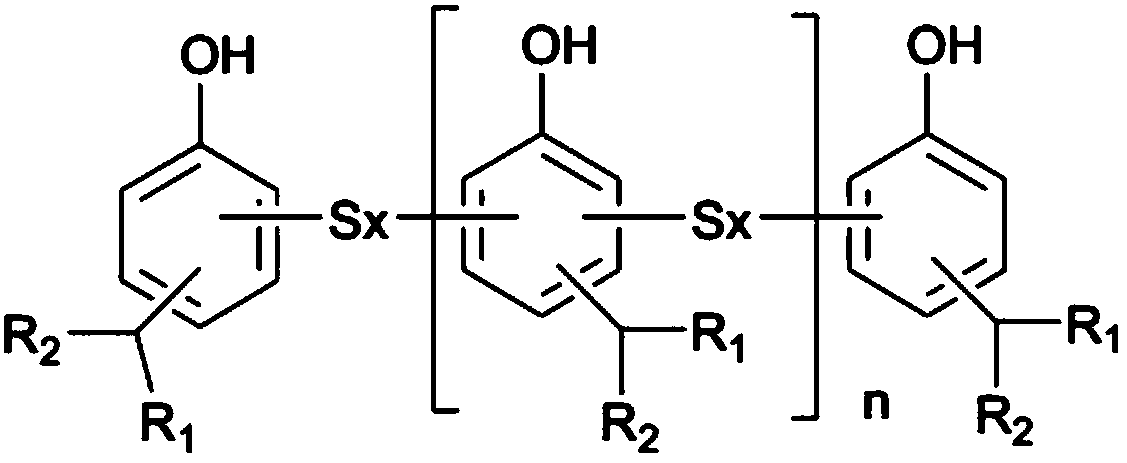

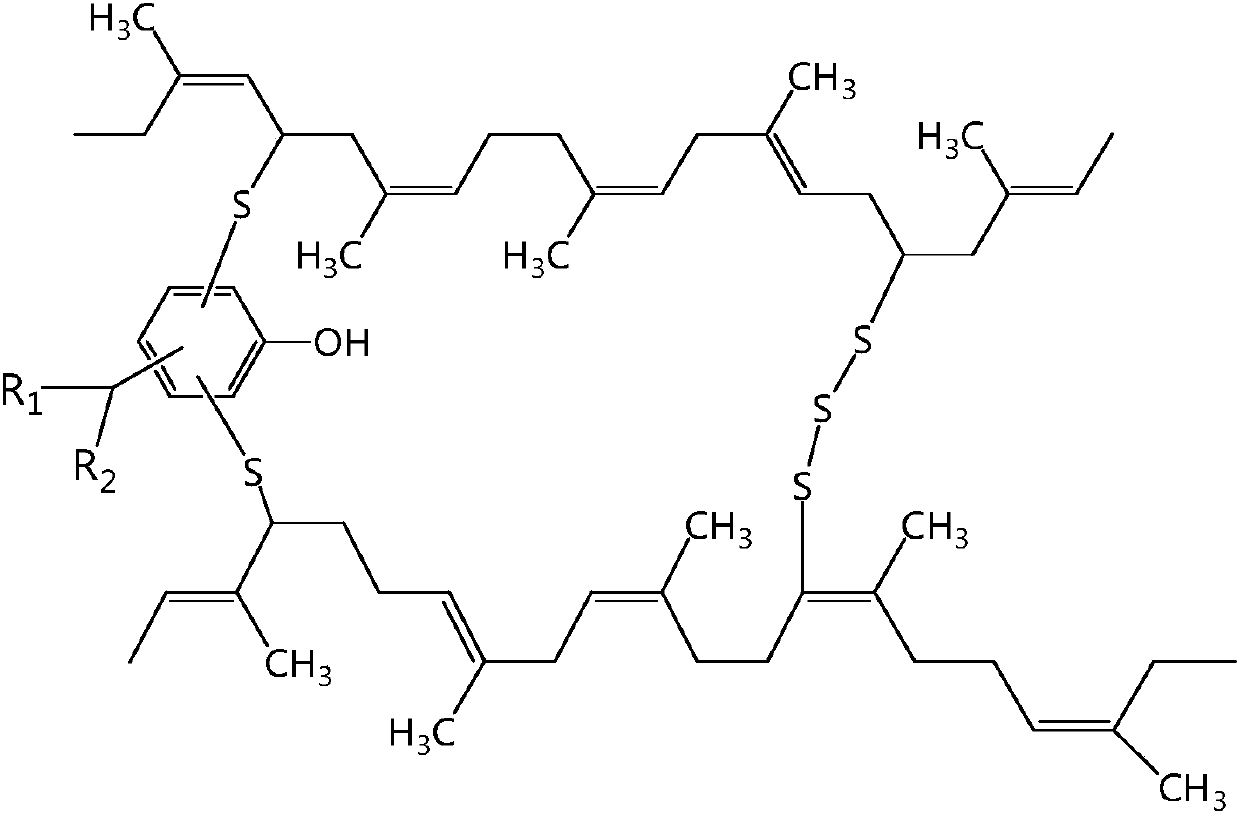

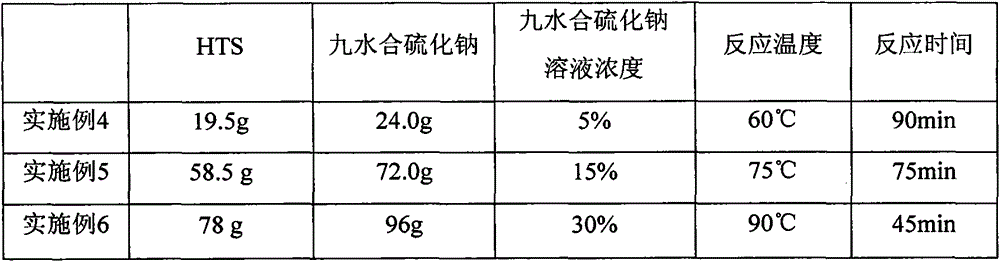

A kind of polymer containing polysulfide structure and preparation method thereof

ActiveCN103788372BImprove anti-reversion performanceEffective cross-linking reactionCross-linkRubber material

The invention provides a polymer containing an ether polysulfide structure and a safe and efficient preparation method thereof. According to the preparation method of the polymer containing the ether polysulfide structure, organic thiosulfate and sodium sulfide serve as raw materials and carry out homogeneous reaction in an aqueous solution or a mixed solvent of a water-soluble organic solvent and water so as to obtain a polymer containing an ether polysulfide structure, wherein a molecular structure of the polymer comprises a plurality of alkyl sulfide chain segments. The polymer containing the ether polysulfide structure can be used as a sulfurizing reagent and added in a rubber material; the alkyl sulfide in the polymer participates in a sulfuration reaction process of the rubber and can effectively carry out cross-linking reaction with the rubber material to form stable monosulphur bonds or disulphur bonds; and meanwhile, flexible alkyl chains are insertd into macromolecules of the rubber, so that anti-reversion performance of the rubber material is improved.

Owner:BEIJING RED AVENUE INNOVA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com